- Rules for installing a check valve on water

- Product dimensions

- Types of check valves

- The valve is wafer, spring disk and two-leaf.

- Check valve rotary or petal

- reverse ball

- Reverse lifting

- Production material

- Water back pressure valve device

- Types of check valves and their principle of operation

- water check valve price for pump

- What is a check valve for water, its purpose and scope

- Valve classifications

- Station connection options

- Tips for Choosing a Water Check Valve

- What material should the valve be made of?

- Nuances of choice

- Installation nuances

- Expert advice

- What is a check valve and what is it for?

- Check valve types

- ball

- Swivel

- lifting

- Wafer

Rules for installing a check valve on water

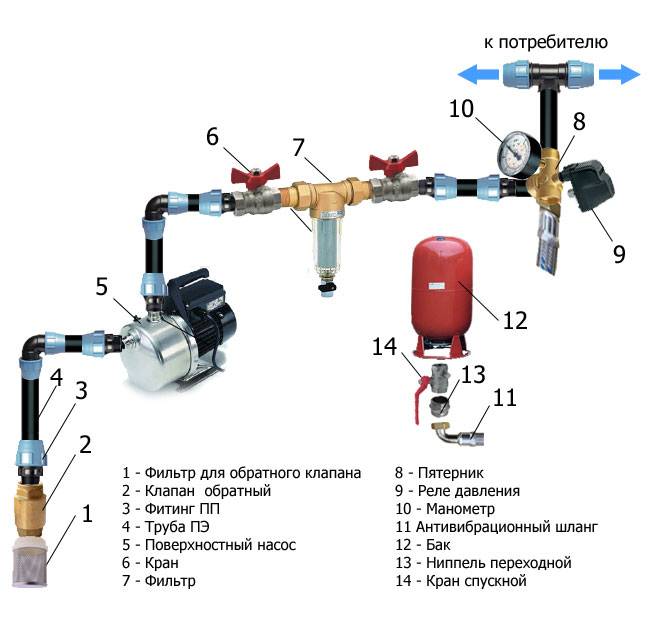

Protective fittings are used in autonomous water supply systems, in-house water supply networks in apartment buildings, with separate centralized supply of cold and hot water. Check valves are installed on the suction line of surface and deep pumps, in front of water meters, boilers, and storage water heaters.

Spring-loaded water back pressure valves have no rubbing surfaces, so they can be installed in any position (vertically, horizontally or obliquely).The arrow on the body of the product indicates the direction of movement of the medium, its vector must coincide with the mounting position of the protective fittings.

The instrument needs regular maintenance. Install a check valve in a place accessible for cleaning, revision, repair or replacement.

There is an arrow on the valve body that indicates the direction of water flow.

Product dimensions

The dimensions of the valves depend on the type of plumbing equipment installed in the apartment or country house. Here are the main running varieties:

-

Valve with a size of 1 inch. Is in high demand.

-

1/2 inch water valve. Not so popular due to weak bandwidth.

-

Check valve 3/4 inch. Quality product for small diameter pipes.

When choosing a product, you need to focus on 2 main characteristics: pressure and nominal diameter. The first is abbreviated RU (PN) - working pressure. If the valve is marked with the symbols RU-20 or PN-20, then it can work effectively at a pressure of no more than 20 bar. The second parameter is called DN (DN) - conditional pass.

Marking DU-22 or DN-22 indicates that the nominal diameter of the device is approximately 22 mm.

Types of check valves

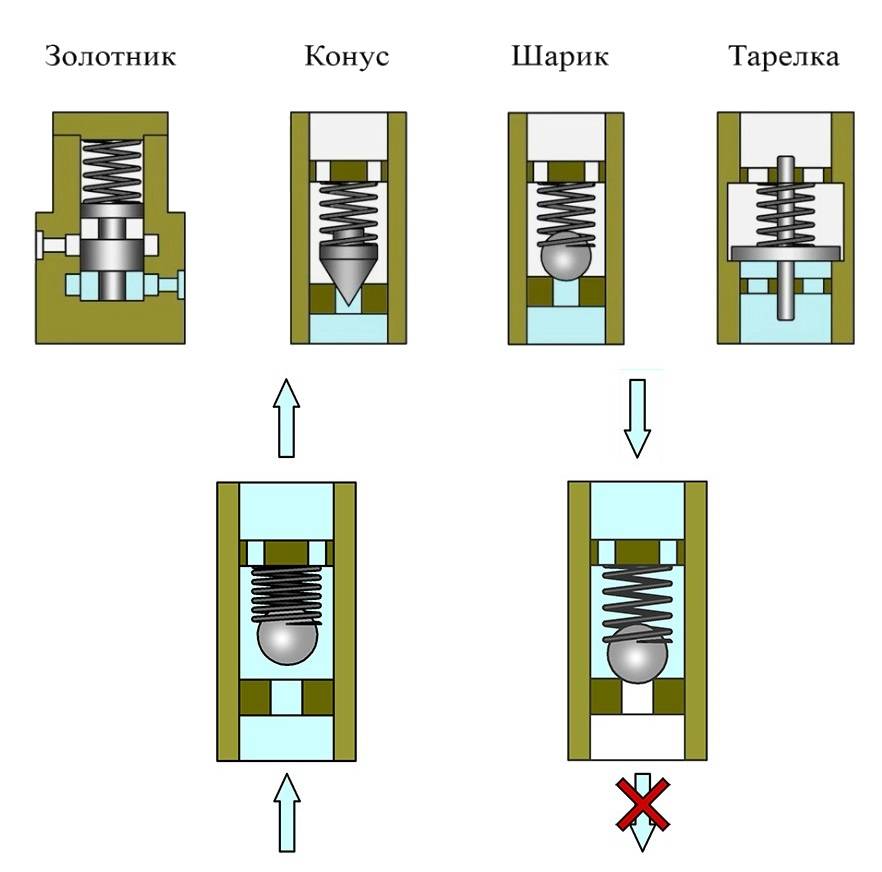

According to the internal structure and purpose, check valves for water are divided into the following types:

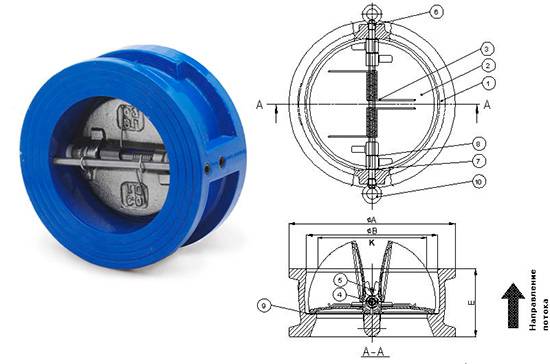

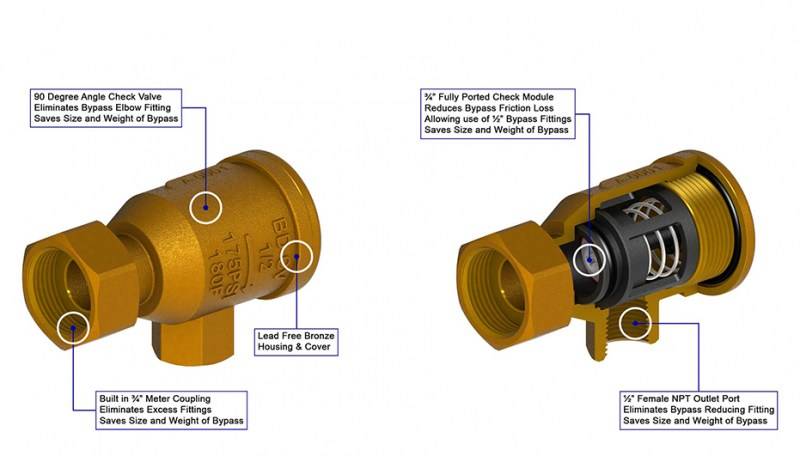

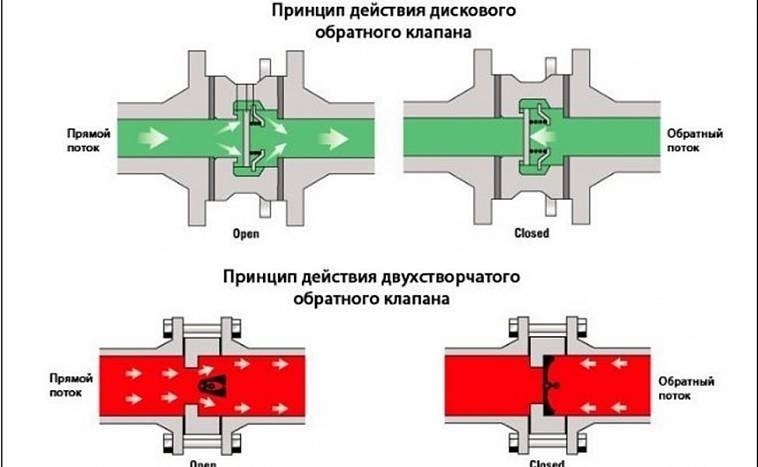

The valve is wafer, spring disk and two-leaf.

The most compact design of all types.

The most compact design of all types.

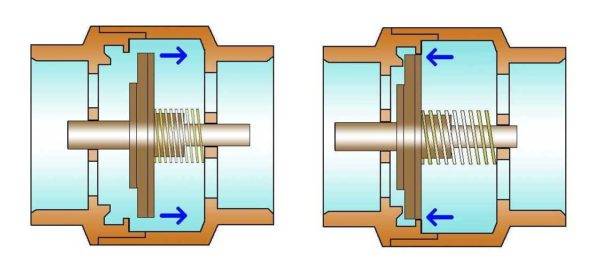

For a spring disc valve, the shutter is a disk (plate) with a clamping element - a spring.

In working condition, the disc is squeezed out under water pressure, providing a free flow.

When the pressure drops, the spring presses the disc against the seat, blocking the flow hole.

Check valve size range 15 mm - 200 mm.

In complex hydraulic systems, when the pump stops, water hammer can occur, which can cause damage to the system.

In such systems, butterfly valves are used: in large and complex systems, with shock absorbers to mitigate water hammer.

In them, the locking disc is folded in half under the action of the flow of water. The reverse flow returns the disc to its original state, pressing it to the seat. Size range 50mm - 700mm, even larger than spring loaded disc valves.

The main advantages of wafer type check valves are their smaller size and lighter weight. In their design there are no flanges for fastening to the pipeline.

Due to this, the weight is reduced by 5 times, and the overall length by 6-8 times compared with standard check valves of this bore diameter.

Advantages: ease of installation, operation, the ability to install, in addition to horizontal sections of the pipeline, also on inclined and vertical ones.

The disadvantage is that complete dismantling is required when repairing the valve.

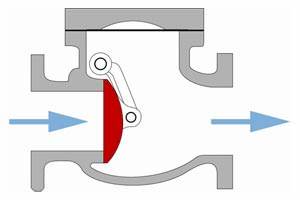

Check valve rotary or petal

In this design, the locking element is a spool - "slam".

In this design, the locking element is a spool - "slam".

The axis of rotation of the "flap" is above the through hole. Under the action of pressure, the "clap" leans back and does not prevent the passage of water.

When the pressure drops below the permissible value, the spool falls and slams the through passage.

In check valves of large diameter, a strong blow of the spool against the seat occurs, which leads to a rapid failure of the structure.

During further operation, this provokes the occurrence of water hammer when the check valve is activated.

Therefore, rotary check valves are divided into two groups:

- Simple - valves with a diameter of up to 400 mm. They are used in systems where impact phenomena cannot seriously affect the operation of the hydraulic system and the valve itself.

- Impactless - valves with devices that ensure a smooth and soft landing of the spool on the seat.

The advantage of rotary valves is the ability to operate in large systems and low sensitivity to environmental pollution.

A similar valve is installed in the NASA wind tunnel, which measures 7 meters in diameter.

The disadvantage is the need to use a damper in large diameter valves.

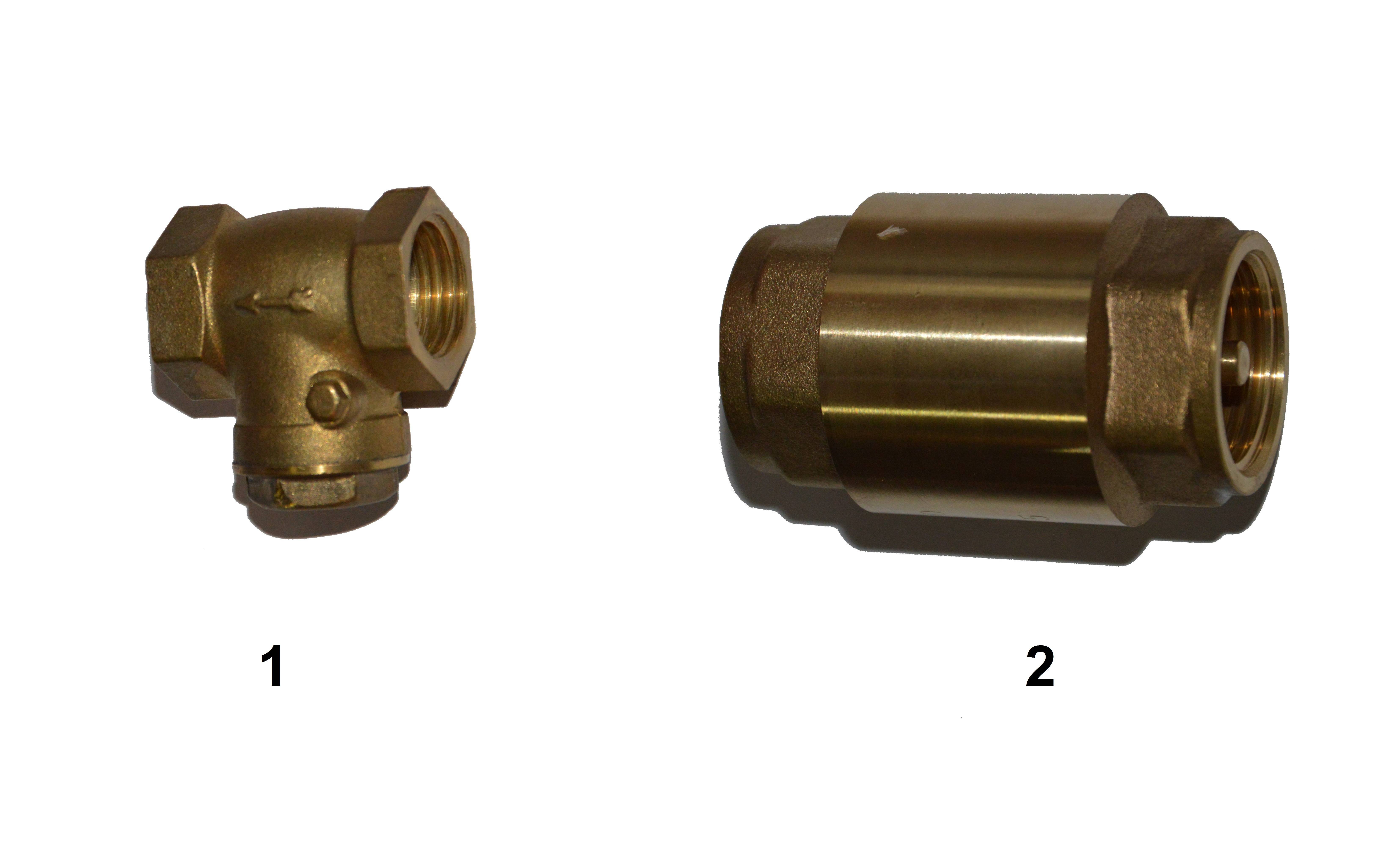

reverse ball

The principle of operation of the check ball valve is similar to that of the wafer spring disc valve.

The locking element in it is a ball with a spring pressing it to the seat. Ball check valves are used in systems with pipes of small diameter, most often in plumbing.

The check ball valve loses to the spring disc valve in dimensions.

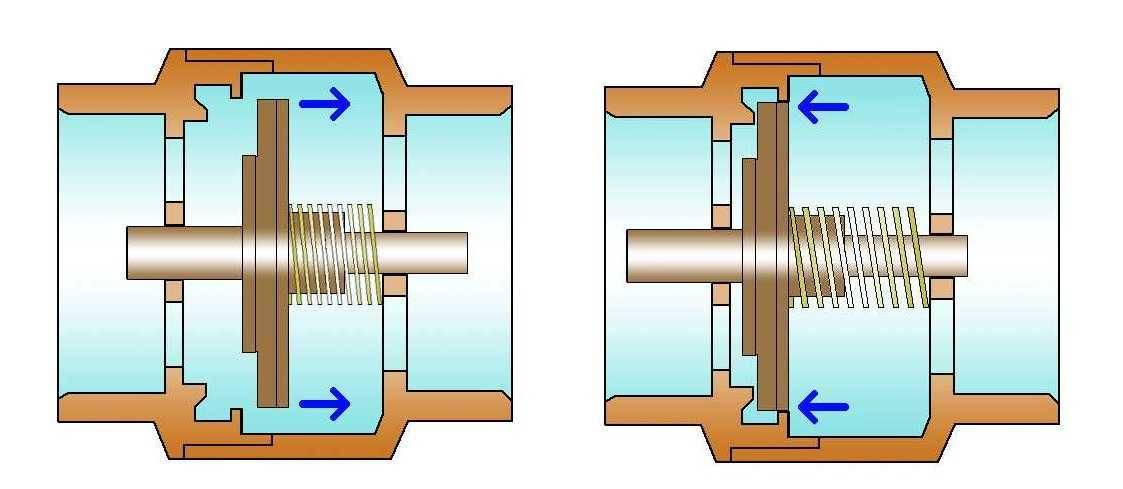

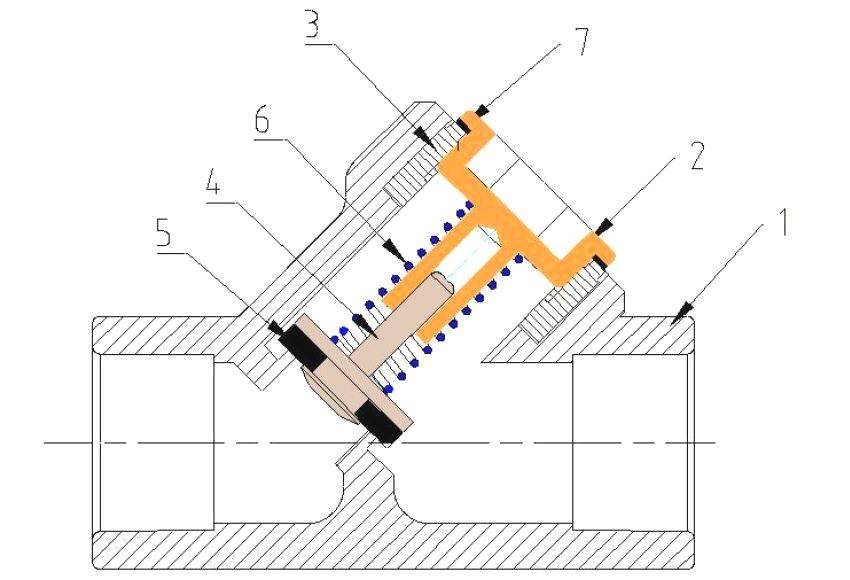

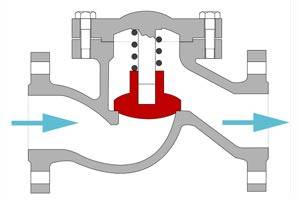

Reverse lifting

In the lift check valve, the shut-off element is the lift spool.

In the lift check valve, the shut-off element is the lift spool.

Under the action of water pressure, the spool rises, passing the flow.

When the pressure drops, the spool drops onto the seat, preventing the flow from flowing back.

Such valves are installed only on horizontal sections of pipelines. A prerequisite is the vertical position of the valve axis.

The advantage of a check lift valve is that it can be repaired without dismantling the entire valve.

The disadvantage is high sensitivity to environmental pollution.

Valves are divided into four groups according to the method of attachment.

- Weld fastening. The check valve is attached to the pipeline by welding. It is used when working in aggressive environments.

- Flange mount. The check valve is connected to the pipeline through sealed flanges.

- Coupling fastening. The check valve is attached to the pipeline through a threaded coupling. It is applied in systems of small diameter.

- Wafer mount. The check valve does not have its own mounting assembly. Clamped between pipeline flanges. It is applied on sites with restriction on dimensions.

Production material

Plastic Plumbing Check Valve

Plastic Plumbing Check Valve

The market for plumbing fittings offers a fairly wide selection of check valves in terms of the material from which they are made. The main requirement is high strength and corrosion resistance:

- cast iron;

- stainless steel;

- bronze;

- brass;

- plastic.

The ideal option is stainless steel. But products from it are expensive. Cast iron models are the most bulky. In household networks, they are practically not used. The most popular are brass. These valves do not corrode under the influence of water, the price is acceptable. Plastic also does not corrode, but experts recommend installing them on pressure pipes with low pressure.

Locking devices are made of stainless steel, plastic or aluminum. In spring-type valves, the most vulnerable node is the spring. It most often fails, therefore, a stainless steel part is installed in almost all devices.

Today, many manufacturers are trying to reduce the cost of their products in order to make them competitive. Therefore, you can find combined models on the market. For example, a brass valve with a stainless steel or plastic shut-off device.All stop valves are tested and tested for tightness of the structure, which is confirmed by certificates, so the combined modifications comply with the standards and requirements of GOST.

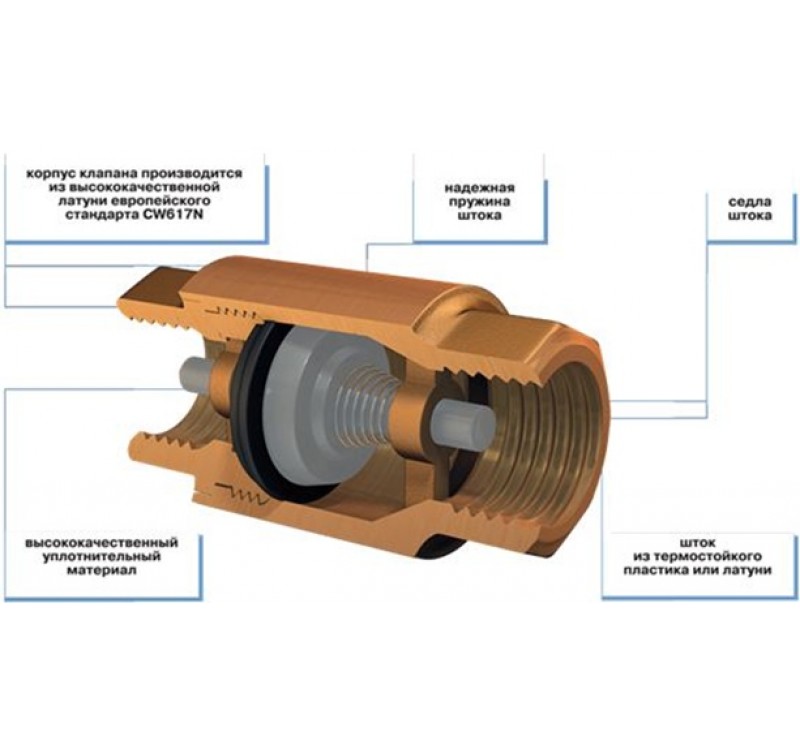

Water back pressure valve device

The material for stamping elements of the prefabricated body is brass. The alloy is resistant to aggressive substances (oxygen, mineral salts, sulfur, manganese, iron compounds, organics, etc.), which are dissolved or suspended in water. The outer surface of the product is electroplated (nickel plated).

The spool parts are made of a copper-zinc alloy or a high-strength polymer. The material of the sealing gasket between the locking discs is rubber or silicone. The spring is made from a special grade of stainless steel.

Types of check valves and their principle of operation

Check valves are divided into several types:

- Disk

- Two-bladed

- Ball

- Lifting

- Petal

Disc valve has the smallest dimensions. The locking disk under water pressure opens the working channel for the passage of water. When the pressure drops, the spring returns the locking disc to its original position, thereby preventing the backflow of water.

Double vane valve has much larger dimensions and is used in complex plumbing systems. An example of such a system is the plumbing system of a private house with water supplied by a pump. In such systems, when the pump fails, there is a possibility of a backflow of large forces. The principle of operation of such an element is quite simple: when sufficient pressure occurs, the obturator part of the valve folds in half.The reverse flow of water folds the locking element back.

ball valve the locking element of its design has a ball that rises to the open position under the influence of the water flow and, when the pressure decreases, returns to the opposite position, blocking the working channel. This type of valve is used in plumbing systems with different pipeline diameters.

check valve lifting type in the design it has a locking cup (lifting spool). With sufficient pressure in the water supply system, the cup rises, passing the water flow. If the flow pressure is reduced, the cup returns to the first position, shutting off the water flow. This type of valves can only be mounted in a horizontal position.

Flap check valve. The locking element of this type of valve is the petals, which move apart under the influence of water pressure, ensuring the passage of fluid through the working channel. In the event of a reverse flow of liquid, the petals return to their original position.

water check valve price for pump

Prices for existing protective fittings depend on the brand of the manufacturer, throughput (diameter) and design modification of the valve. The cost of main fittings exceeds the prices of household devices by dozens of times.

Comparative table of prices of check valves for water from different manufacturers:

| Manufacturer | Diameter, mm | Price per piece, rubles |

| Check valve polypropylene | ||

| Piping systems AQUA-S | 20 25 32 | 110,00 136,00 204,00 |

| VALTEC (Italy) | 20 25 32 | 128,00 160,00 274,00 |

| Coupling spring check valve | ||

| VALTEC (Italy) | 15 20 25 | 191,00 263,00 390,00 |

| Danfoss CO (Denmark) | 15 20 25 | 561,00 735,00 962,00 |

| Tesofi (France) | 15 20 25 | 282,00 423,00 563,00 |

| ITAP (Italy) | 15 20 25 | 366,00 462,00 673,00 |

| Combined spring check valve with drain and air vent | ||

| VALTEC (Italy) | 15 20 25 | 652,00 1009,00 1516,00 |

| Check valve, spring coupled, with brass spool | ||

| VALTEC (Italy) | 15 20 25 | 228,00 198,00 498,00 |

Analyzing the information presented on the websites of official representatives and companies that produce protective fittings, we can conclude: check valves for water for pumps increase the level of reliability and quality of operation of autonomous water supply systems.

What is a check valve for water, its purpose and scope

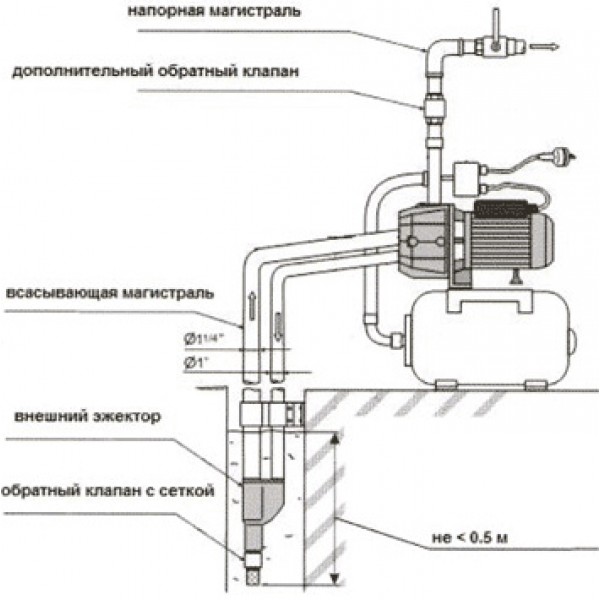

Check valve is one of the types of valves. The essence of his work is to block the movement of the flow in the opposite direction. Its second task is to prevent pressure drop.

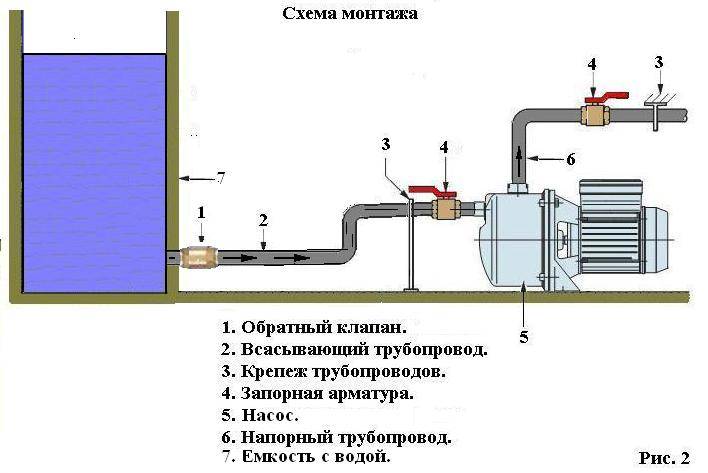

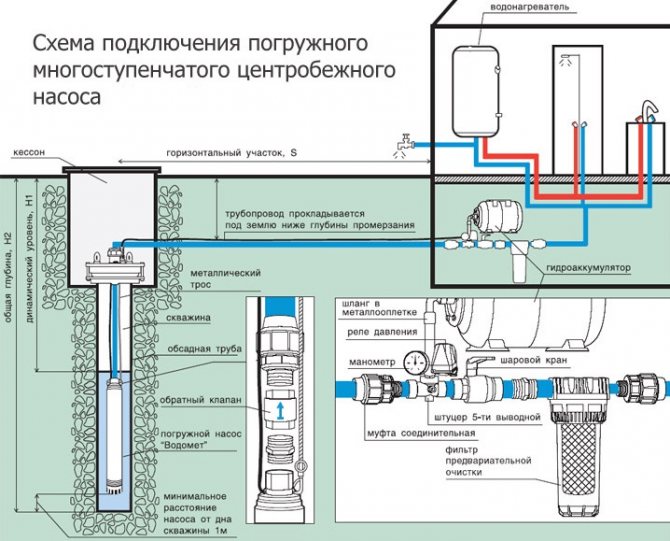

With regard to the water supply, it blocks the reverse movement of water. In private water supply systems (from wells or wells), the check valve is set so that after the pump is turned off, it retains water in the suction pipe. If the system is made on the basis of a pumping station, then most likely it contains a check valve. But this must be seen in the passport. Is the second necessary or not in this case? Depends on the length of the supply line, pipeline cross-section, pump performance and several other factors. But more often they put it on.

Illustration of the principle of operation of a shut-off valve

In apartments or with central water supply in the house, it is placed in front of the meter. But here his task is different - to prevent the possibility of "rewinding" testimony. The presence or absence of a check valve in this case does not affect performance. But its installation is a prerequisite for the operational organization. The seal is placed so as not to exclude unauthorized analysis of water.

Where else can a check valve for water be required? In the heating system. Not centralized, but private. It may contain circuits in which, under certain conditions, a reverse flow may occur. A non-return valve is also installed on such circuits. In the boiler piping, in the presence of a hygienic shower. These devices can also reverse flow. So a shut-off valve is needed.

Valve classifications

There are three main features by which valves differ. These are the triggering system of the closing mechanism, the material of manufacture and the type of construction of the flap. The first classification has already been partly touched upon. It refers to the initial state in which the valve resides. In a permanent working position, it can be open (the most common configuration) and closed. This classification can also include valves that are installed on the horizontal contour of the pipeline and universal fittings with gates that allow the integration of devices also on vertical channels. There are types of check valves and depending on the material of manufacture. The body base can be made of bronze, steel alloys, brass, titanium and other metals

It is important that they are impact-resistant, heat-resistant and resistant to corrosion processes. And to ensure the tightness of the shutter, seals are used, which, in turn, can be made of plastic, rubber or based on hard surfacing. Types of products that differ in the type of flap itself should be considered separately

Types of products that differ in the type of flap itself should be considered separately.

Station connection options

There are two ways to connect the pumping station to the pipeline:

- Through borehole adapter.This is a device that is a kind of adapter between the water intake pipe in the source shaft and the water pipes outside. Thanks to the borehole adapter, it is possible to draw the line out of the hydraulic structure immediately below the freezing point of the soil and at the same time save on the construction of the caisson.

- Through the head. In this case, you will have to take care of high-quality insulation of the upper part of the source. Otherwise, ice will form here in sub-zero temperatures. The system will stop working or break in one of the places.

Tips for Choosing a Water Check Valve

For each hydraulic system, the check valve is selected in accordance with its operating conditions. In this case, the pressure in the pipeline, the method of fastening, installation dimensions, installation location, and pipe diameter should be taken into account.

For each hydraulic system, the check valve is selected in accordance with its operating conditions. In this case, the pressure in the pipeline, the method of fastening, installation dimensions, installation location, and pipe diameter should be taken into account.

For plumbing systems with small pipe diameters and purified water, a reverse ball device equipped with a coupling mount is suitable.

In metal-plastic pipes with minimal contamination, you can install a disc spring check valve.

In heating systems mounted from metal pipes, it is necessary to install a rotary reverse device. They are insensitive to environmental pollution, and in heating systems, water is heavily polluted from constant circulation.

The correct choice and installation of a non-return valve for water will save users of autonomous water supply, sewerage or heating from many problems, save money and bring considerable benefits.

What material should the valve be made of?

When choosing valves, it is important to know what material it was made of and what advantages each option has:

- Cast iron. Extremely rarely used in domestic systems.Mainly used in industrial plants. Such a seemingly strong alloy as cast iron is very prone to the formation of lime deposits in water, which can break and restrict water access.

- Brass. Ideal for domestic water systems. Brass does not corrode, does not accumulate lime deposits, and does not oxidize. The service life of parts made of this alloy is quite long.

- From stainless steel. Such parts have the highest cost among the rest. And this is not surprising - after all, stainless steel has incredible strength and resistance to corrosion. If possible, it is best to buy just such valves, because their service life is measured in years.

Carefully read on the packaging what other materials are used in the manufacture of the part. For example, a plastic spring may be hidden under the brass body. If you are on a tight budget, a brass pump station valve may be the best option. A fairly long service life and a reasonable price are the main advantages of such a part.

Nuances of choice

You can buy a valve for an aquarium (electromagnetic or non-return) in specialized stores that sell aquarium equipment.

The market is full of offers of this kind - now many people have an aquarium, both at home, as well as offices or offices. Moreover, there are both products of domestic production and foreign companies on sale.

You can select from the whole set:

- Aqua Szut;

- Tetra;

- Atman;

- Ferplast;

- O.D.E.;

- Camozzi (Italy);

- Eheim;

- Dennerle (Germany);

- Hagen (Canada).

Some of them are popular in many countries.

check valve for aquarium

For example, the solenoid valve for the Camozzi aquarium (Italy) is by far the most widely used among aquarium hobbyists, due to its quality and durability.

The price range of solenoid valves is quite large, but it all depends on what end product the buyer wants to receive.

You can buy a Camozzi aquarium valve (Italy) for $5 or $255, but when buying, you should take into account all the influencing factors: the volume of the aquarium, the additional equipment that will be used, the number of "inhabitants", the number of plants.

By the way, in fact, the above parameters are key when choosing the right model. Going to the store, you must know them - otherwise you will not be able to choose the right option.

Buying a non-return valve for a Camozzi aquarium (Italy) is also not difficult, especially considering that its cost most often ranges from $ 1 for a “Chinese” to $ 10 for a quality “European” with a name.

It all depends on how much you will not regret paying for such a product. Good quality Camozzi models (Italy) will cost about $3-4.

Installation nuances

Now we will mention how to properly install such an important mechanism with your own hands.

First of all, it should be noted that it is indispensable only if the compressor in your aquarium is located below the water level (for example, in a bedside table, under the aquarium).

The process of installing Camozzi (Italy) looks something like this:

- The hose through which air enters is cut. You can do this anywhere.Preferably before the hose enters the aquarium itself.

- After checking the direction of work (there must be a mark on the body indicating exactly how it is required to carry out the installation with your own hands) of the valve - it is installed at the cut site.

Expert advice

If the purpose of the check valves is to protect the elements of the water supply, it is necessary to install mechanisms made of brass and other alloys that are resistant to corrosion. When it comes to heating that runs on a special coolant that excludes the appearance of rust, iron models can be used.

Experts recommend embedding shutter elements at a distance of 350 mm from the floor or more. This rule applies to any type of valve. When the system does not require the presence of a drain, the installation point should be the highest in relation to the level of drainage. And when it is planned to modernize the heating system, the valve cuts into the return circuit in front of the boiler with heat exchangers.

Before you install equipment in an apartment building, you need to consider the location of the water meter. The valve is installed after it. This is the case when separate water supply of apartments is provided. In any case, all connected appliances, including washing machine and dishwasher, will be safe. And it even makes sense to equip the sewer with a locking reverse mechanism to avoid flooding with sewage.

HelpfulUseless

What is a check valve and what is it for?

It is used in systems with a borehole pump. It is screwed directly into the pump, which is lowered to a certain depth.In the absence of a check valve, the water that is in the hose, as well as in the hydraulic accumulator of the boiler house, would simply be drained back into the well every time the pump was connected. The issue of installing a valve solves this problem, with a small cash investment. In addition, it allows you to maintain pressure in the circuit, which once again makes it possible not to turn on the pump (due to the operation of the accumulator).

The water back pressure valve is installed in the hot water supply systems of private houses. For example, with any hot water boiler at the inlet of the device. Here it serves to protect the liquid inside the tank, in case the central water supply is turned off, or there is no water in the accumulator.

Check valve types

Check valves can be divided by materials:

Check valves can be divided by materials:

- cast iron;

- brass;

- from various steels;

- plastic.

The latter are often preferred because of their low cost.

By design, there are four main types of valves:

- Ball.

- Rotary (petal or return).

- Lifting.

- Wafer type.

Consider their features.

ball

The spring-loaded ball is made of rubber or cast iron coated with rubber.

The spring-loaded ball is made of rubber or cast iron coated with rubber.

During the normal movement of the flow, the ball moves back and passes the liquid; during the return movement, it tightly blocks the outlet.

Suitable for outdoor sewage and where good flow is required.

It is advised to install fittings in the heating system that create minimal resistance, since the temperature in the house directly depends on the speed of water movement.

Swivel

The petal, blocking the inlet, is mounted on a hinge and, like an ordinary door, "swings open" from the movement of water.

It does not interfere with the passage of the flow, since it is placed open in the plugged side branch of the valve.

The disadvantage of the design is that when the water pressure drops and the petal closes, water hammer occurs.

This is not so bad if the valve diameter is not large, but in large structures, the impact can damage the mechanism itself or the devices that it is designed to protect.

For valves with large diameters, a non-impact butterfly valve design has been developed - with a soft stroke.

lifting

This design is with a curved fluid stroke. In the Perpendicular compartment there is a mechanism consisting of a spring and a spool, which, under the pressure of water, rises up and is pressed against the plugged part of the device.

For the normal operation of the reinforcement, it is important that it is placed on a horizontal section, and the plugged section is located strictly vertically.

The mechanism is susceptible to the quality of the liquid - dirty water can damage it over time.

Wafer

They, in turn, are divided into:

- Disk.

- Bivalves.

Disk. Its shutter is made in the form of a round plate, which in the usual position is pressed against the saddle by springs.

But the pressure created by the flow of water deflects the disk, and water enters through the pipe.

However, the turbulence created by this design makes it not suitable for all cases.

Bivalves. In the second case, the shutter consists of two halves attached to a rod in the center of the device. The flow of water folds them and passes through the pipe, with little or no resistance.

The advantage of the miniature design is that it can be installed vertically, horizontally, and at an angle.

Both types of wafer valves are easy to install by clamping them between the flanges and bolting them together.The scheme practically does not lengthen the pipeline, and the mechanism weighs 5-8 times less than other analogues of the same diameter.