- Purpose of check valve ^

- The order and nuances of installation

- Check valve for water for a pump: price and manufacturers

- Materials, markings, dimensions

- What is indicated in the label

- Dimensions of check valves for water

- How to check

- Materials and accessories for installation

- Connection of a pumping station

- Water supply from a well for permanent residence

- Connecting the pumping station to the water supply

- Well connection

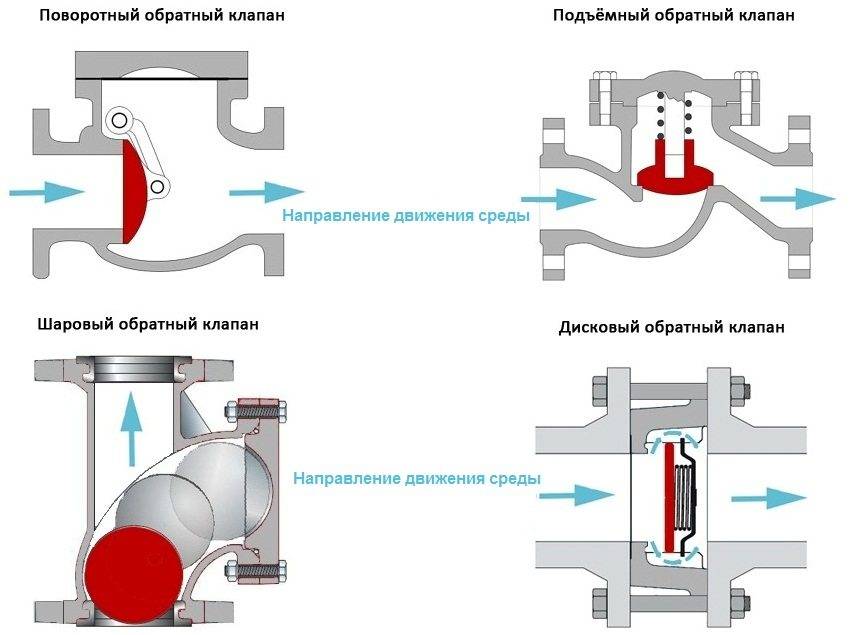

- The principle of operation and types of check valves

- Wafer Butterfly Valves - Spring and Butterfly

- Check lift valve

- Check ball valve

- Non-return rotary or reed valve

- A distinctive characteristic of the design and purpose of the check type valve

- Trick with a water station in the house

- Types of devices by type of attachment

- 2 Why do I need a check valve for a submersible pump?

- 2.1 Valve installation

- 2.2 Nuances of installation

- 2.3 Homemade valve

- Conclusions and useful video on the topic

Purpose of check valve ^

The task of the check valve is to let the water flow to the pump and prevent it from returning. Valves of this type are direct acting devices.

This means that it does not require any external control or power source to operate. The check valve opens and closes under the influence of the movement of fluid through it.

When the pump is running, the valve opens and passes water through the pipeline, and in the event of a shutdown of the unit, it closes and does not pass it in the opposite direction.

In this case, the pressure in the line before the check valve drops to zero, and after it it remains.

The order and nuances of installation

Before installing the shut-off element after the pump, it should be borne in mind that the power of the device will decrease due to overcoming the resistance of the spring or shutter. But on the other hand, the pump does not have to build up pressure in the system all the time, it is created once and subsequently only maintained. Thus, the operation of the unit becomes more rational.

If the device is installed on an already installed water supply system, the installation site is selected between the pump and the pumping station. It is necessary to make a break in the pipeline, install a valve on one of its edges and connect it with a drive to the other edge. In sewer pipes, the device is installed to prevent the reverse flow of waste water and waste. In this way, liquid leakage through the toilet bowl can be avoided when the public sewer is clogged. Installation is carried out on a horizontal or vertical cut into an existing or new sewerage system, in places where there are pipes of the required diameter. The diameter of the shut-off valve here can be from 50 to 100 mm. The connection is made using an adapter from cast iron to plastic. To tap into a cast iron pipe, you will need an angle grinder.

There are parallel motion systems where a pump is used along with the natural flow of water. In this case, the installation of a valve is necessary.

To install the locking element on the water supply and heating system, you need tools for tapping into the pipe: a grinder for metal pipes, and a regular hacksaw is suitable for plastic ones. On metal pipes for connection, it is necessary to make a thread using a thread cutting tool. A check valve is installed using an adjustable and gas wrench. After that, the pipe to which the device is screwed is connected to its other part by a drive using the desired key. To connect plastic pipes, special adapters are used.

If you are a little versed in plumbing and have free time, installing the unit yourself is not difficult. Non-specialists in this matter can always entrust the work to an experienced master.

Check valve for water for a pump: price and manufacturers

When choosing a check valve for water for a pump, the price and place of production is of fundamental importance. Everyone strives to acquire a quality product that can last a long time. Giving preference to well-known trademarks, there is no doubt: in the manufacture of a particular model, the declared materials were used, and the technology was strictly observed.

Model made in Italy

The cost of the product depends not only on the manufacturer, but also on the nominal diameter of the product and design features:

| polypropylene | ||

| VALTEC (Italy) | 20 25 32 | 128 160 274 |

| Piping systems AQUA-S | 20 25 32 | 110 136 204 |

| Spring coupling | ||

| VALTEC (Italy) | 15 20 25 | 191 263 390 |

| Danfoss CO (Denmark) | 15 20 25 | 561 735 962 |

| Tesofi (France) | 15 20 25 | 282 423 563 |

| ITAP (Italy) | 15 20 25 | 366 462 673 |

| Combined spring with drainage and air vent | ||

| VALTEC (Italy) | 15 20 25 | 652 1009 1516 |

| Spring coupling with brass spool | ||

| VALTEC (Italy) | 15 20 25 | 198 228 498 |

Materials, markings, dimensions

The check valve for water is made of stainless steel, brass, large sizes of cast iron. For household networks, they usually take brass - not too expensive and durable. Stainless steel is certainly better, but it is usually not the body that fails, but the locking element. That's his choice and should be approached carefully.

For plastic plumbing systems, check valves are made from the same material. They are polypropylene, plastic (for HDPE and PVD). The latter can be welded / glued or threaded. You can, of course, solder adapters to brass, put a brass valve, then again an adapter from brass to PPR or plastic. But such a node is more expensive. And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are non-return valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it's hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to work. Plastic wears out faster, but it does not wedge. In this regard, it is more reliable. No wonder some manufacturers of pumping stations put check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to "poison" and it is changed.

What is indicated in the label

A few words about the marking of the check valve. It states:

- Type of

- Conditional pass

- Nominal pressure

-

GOST according to which it is made. For Russia, this is GOST 27477-87, but not only domestic products are on the market.

Conditional pass is designated as DU or DN.When choosing this parameter, it is necessary to focus on other fittings or the diameter of the pipeline. They must match. For example, you will install a water check valve after a submersible pump, and a filter to it. All three components must have the same nominal size. For example, all should be written DN 32 or DN 32.

A few words about conditional pressure. This is the pressure in the system at which the valves remain operational. You need to take it exactly no less than your working pressure. In the case of apartments - no less than a test one. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. The pressure for your home can be obtained from the management company or plumbers.

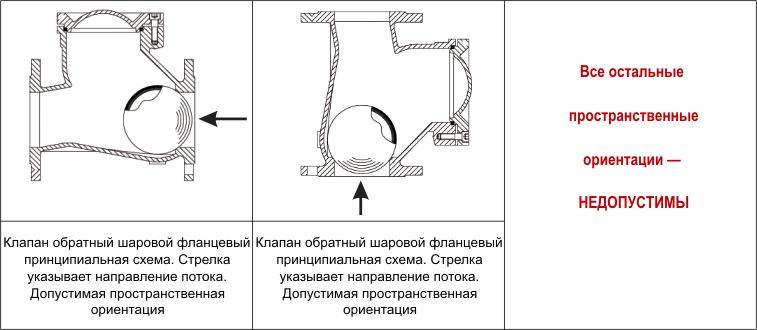

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it indicates in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. Therefore, they are popular.

The opening pressure characterizes the “sensitivity” of the valve. For private networks, it rarely matters. Unless on the supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation

Do not forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of the check valve for water is calculated according to the nominal bore and they are released for everything - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are of the same size as all other shutoff valves: taps, valves, spurs, etc. Another "size" can be attributed conditional pressure. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Then there are the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And yet, please note that for different companies with the same conditional passage, the external dimensions of the device may differ. Length is clear

Here the chamber in which the locking plate is located can be larger or smaller. The chamber diameters also differ. But the difference in the area of the connecting thread can only be due to the wall thickness. For private houses, this is not so scary. Here the maximum working pressure is 4-6 atm. And for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. Air must not pass. Generally. No way. Also try pressing the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a non-return valve: blow into it and check for smoothness

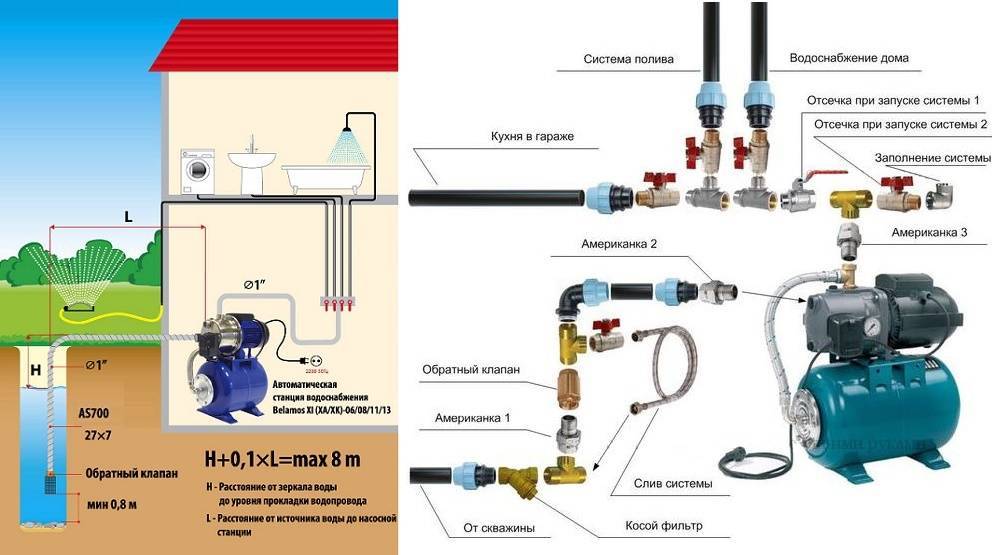

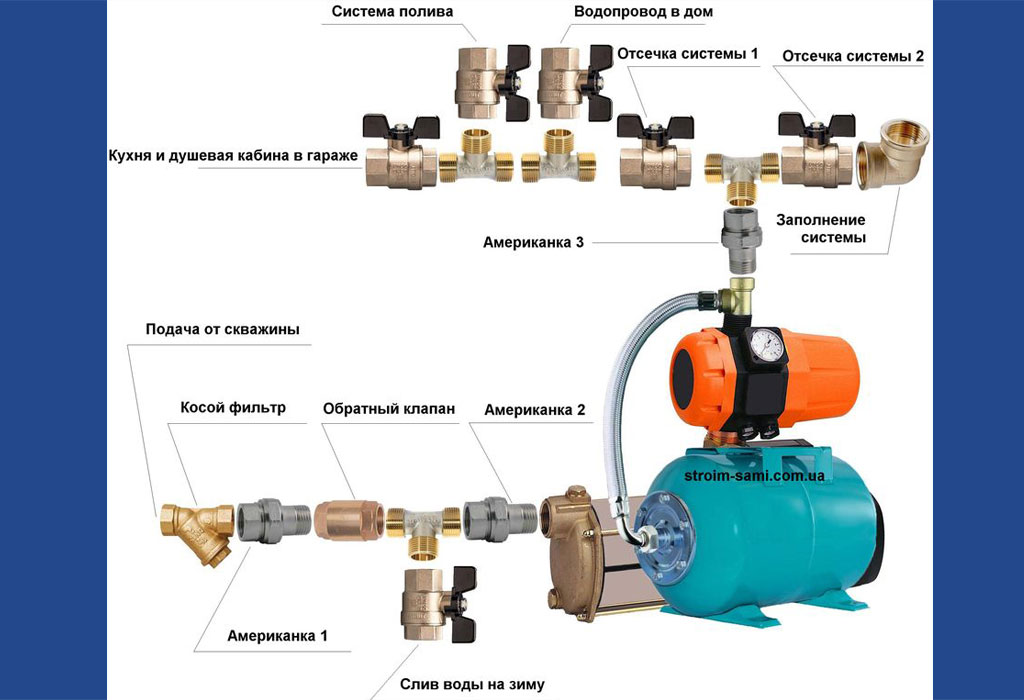

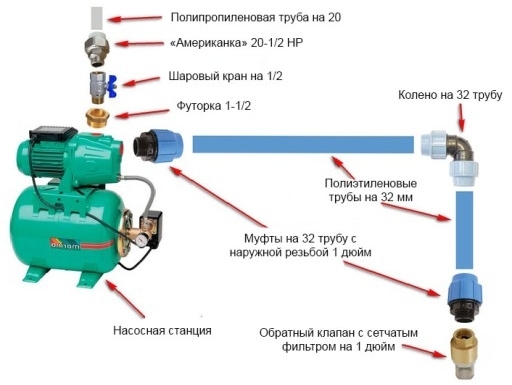

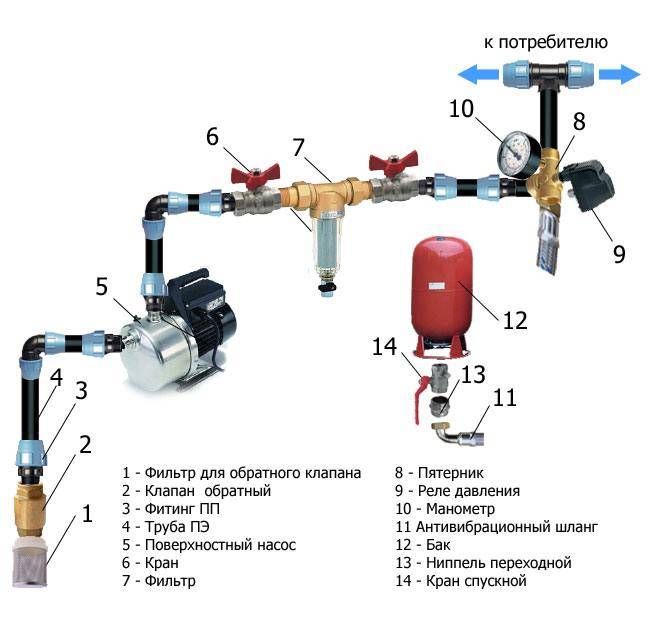

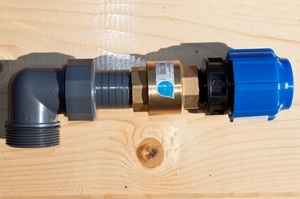

Materials and accessories for installation

The steel mains of the central water supply, which supply dirty and rusty water to our homes, are forever a thing of the past.For the water supply of a private house from a well or a well, use modern HDPE polyethylene pipes of the PE-100 brand with a wall thickness of 3 mm, which are easy to lay and bring into the house with your own hands. In the vast majority of cases, a diameter of 32 mm is enough for external wiring.

To supply water according to the first scheme (with immersion of the pumping unit) from the well, you will need:

- head or downhole adapter;

- suspension cable with a diameter of 3 mm;

- the pump itself, equipped with a check valve;

- hydraulic accumulator with a capacity of 25-100 l;

- pressure switch type RDM-5 and "dry" running;

- coarse filter and mud collector;

- manometer;

- ball valves, fittings;

- electrical cable and circuit breakers rated 16 A.

If the scheme with a pumping station is more suitable for you, then you do not need to buy a relay and a hydraulic accumulator separately, since they are included in the installation kit. How to correctly calculate the minimum volume of the storage tank and the pump power, see the video:

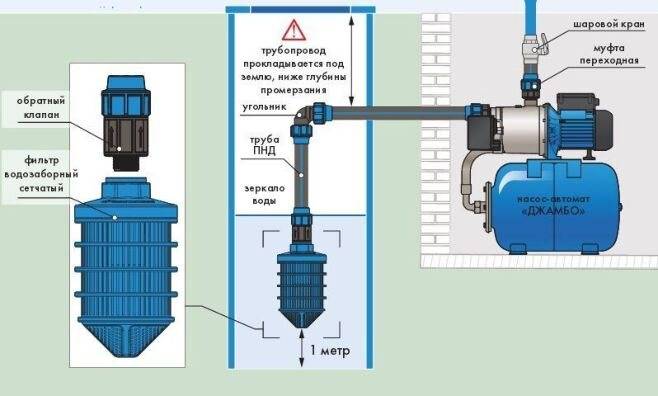

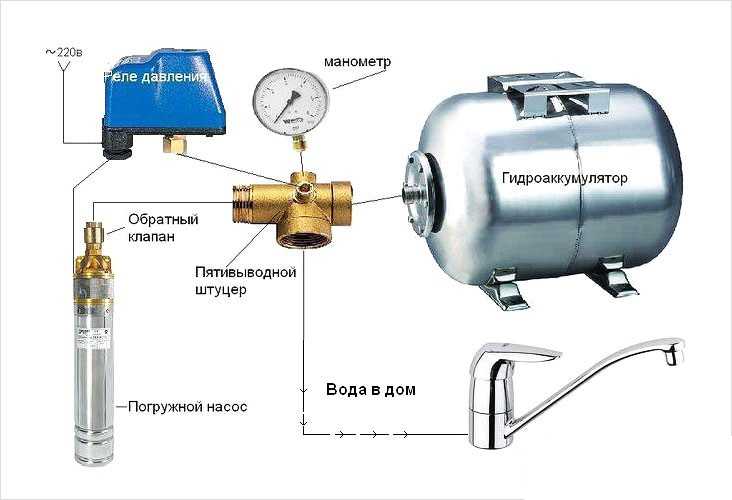

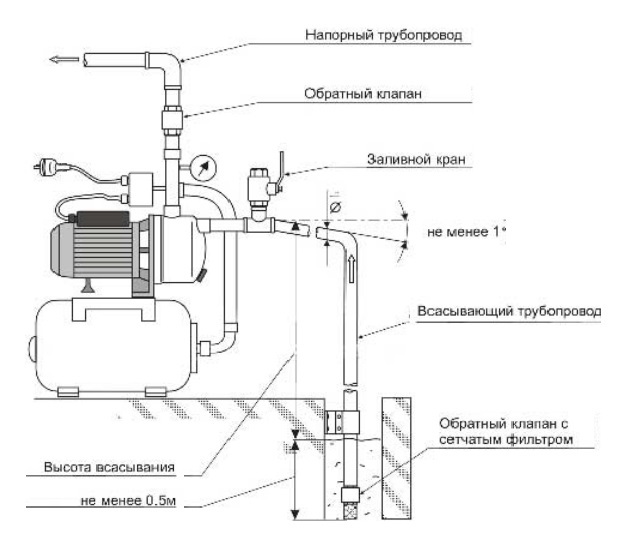

Connection of a pumping station

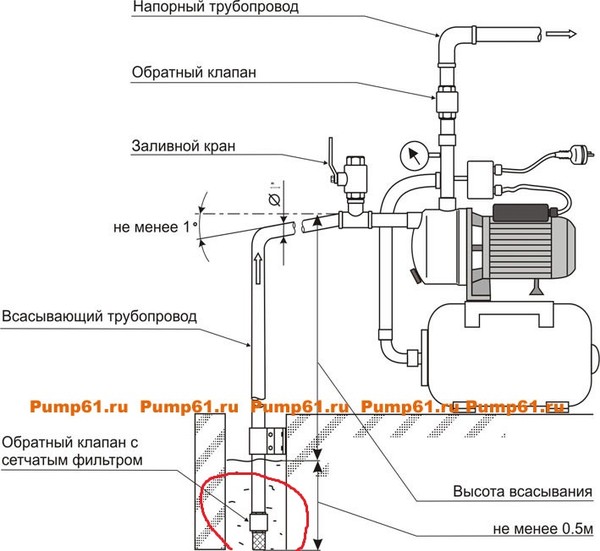

Choosing equipment and a place for installation is half the battle. You also need to correctly connect everything into a system - a water source, a station and consumers. The exact connection diagram of the pumping station depends on the chosen location. But anyway there is:

- Suction pipeline that descends into a well or well. He goes to the pumping station.

- The station itself.

- The pipeline going to consumers.

All this is true, only the strapping schemes will change depending on the circumstances. Let's consider the most common cases.

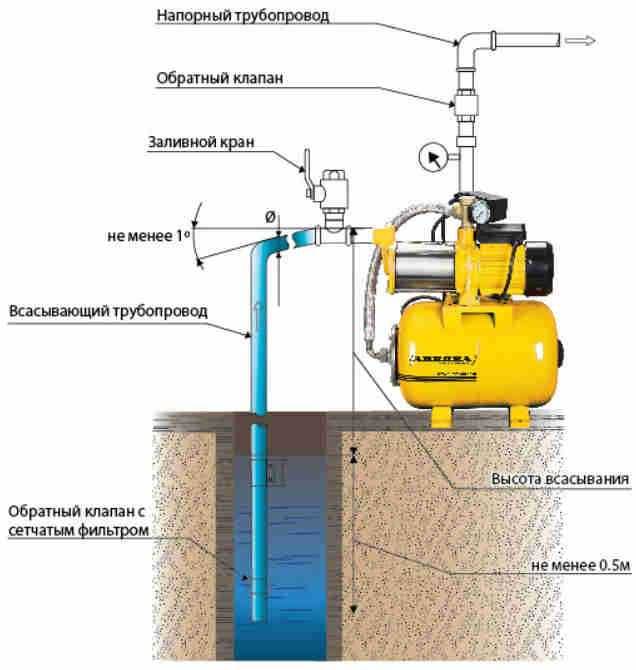

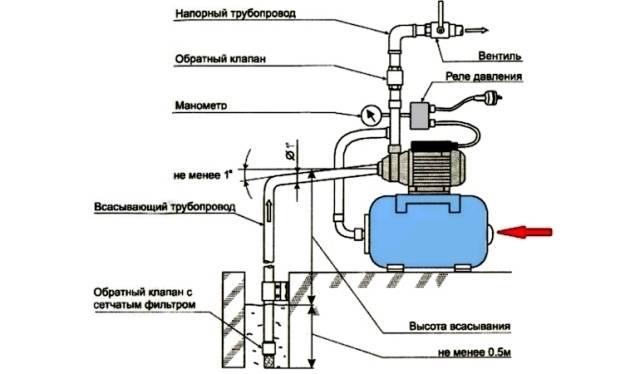

Water supply from a well for permanent residence

If the station is placed in a house or in a caisson somewhere on the way to the house, the connection scheme is the same.A filter (most often a regular mesh) is installed on the supply pipeline lowered into a well or well, a check valve is placed after it, then a pipe already goes. Why the filter - it is clear - to protect against mechanical impurities. A check valve is needed so that when the pump is turned off, water under its own weight does not flow back. Then the pump will turn on less often (it will last longer).

Scheme of installing a pumping station in a house

The pipe is brought out through the wall of the well at a depth just below the freezing level of the soil. Then it goes into the trench at the same depth. When laying a trench, it must be made straight - the fewer turns, the lower the pressure drop, which means that water can be pumped from a greater depth.

To be sure, you can insulate the pipeline (lay sheets of polystyrene foam on top, and then fill it with sand, and then with soil).

Passage option not through the foundation - heating and serious insulation are required

At the entrance to the house, the supply pipe passes through the foundation (the place of passage should also be insulated), in the house it can already rise to the installation site of the pumping station.

This method of installing a pumping station is good because if everything is done correctly, the system works without problems. The inconvenience is that it is necessary to dig trenches, as well as bring the pipeline out / in through the walls, and also in the fact that it is difficult to localize damage when a leak occurs. To minimize the chances of a leak, take proven quality pipes, lay a whole piece without joints. If there is a connection, it is desirable to make a manhole.

Detailed scheme of piping a pumping station when connected to a well or well

There is also a way to reduce the volume of earthworks: lay the pipeline higher, but insulate it well and additionally use a heating cable. This may be the only way out if the site has a high level of groundwater.

There is another important point - the well cover must be insulated, as well as the rings on the outside to the freezing depth. It's just that the section of the pipeline from the water mirror to the outlet to the wall should not freeze. For this, insulation measures are required.

Connecting the pumping station to the water supply

Often a pumping station is installed to increase the pressure in the water supply system with centralized water supply. In this case, a water pipe is connected to the station inlet (also through a filter and a check valve), and the outlet goes to consumers.

Scheme of connecting the pumping station to the water supply

It is advisable to put a shut-off valve (ball) at the inlet so that if necessary you can turn off your system (for repairs, for example). The second shut-off valve - in front of the pumping station - is needed to repair the pipeline or the equipment itself. Then it also makes sense to install a ball valve at the outlet - in order to cut off consumers if necessary and not drain water from the pipes.

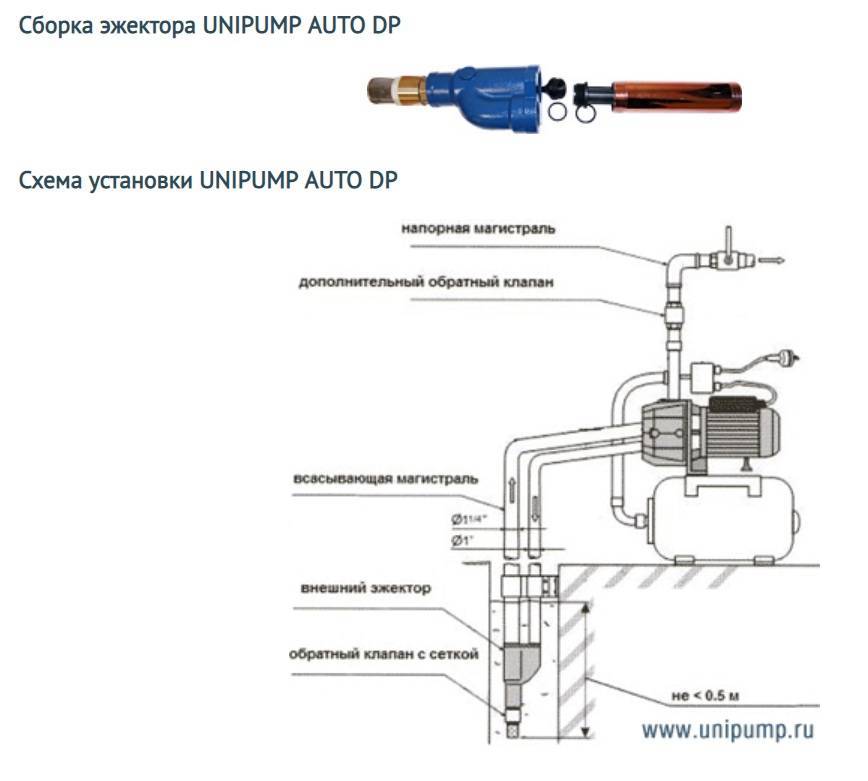

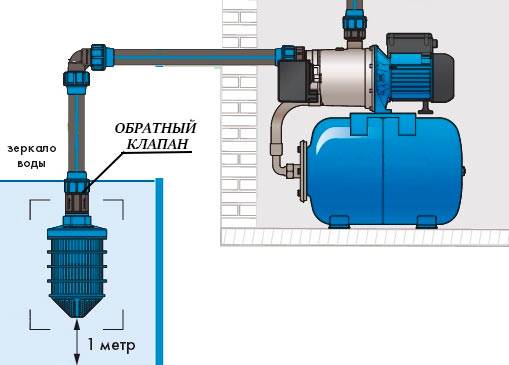

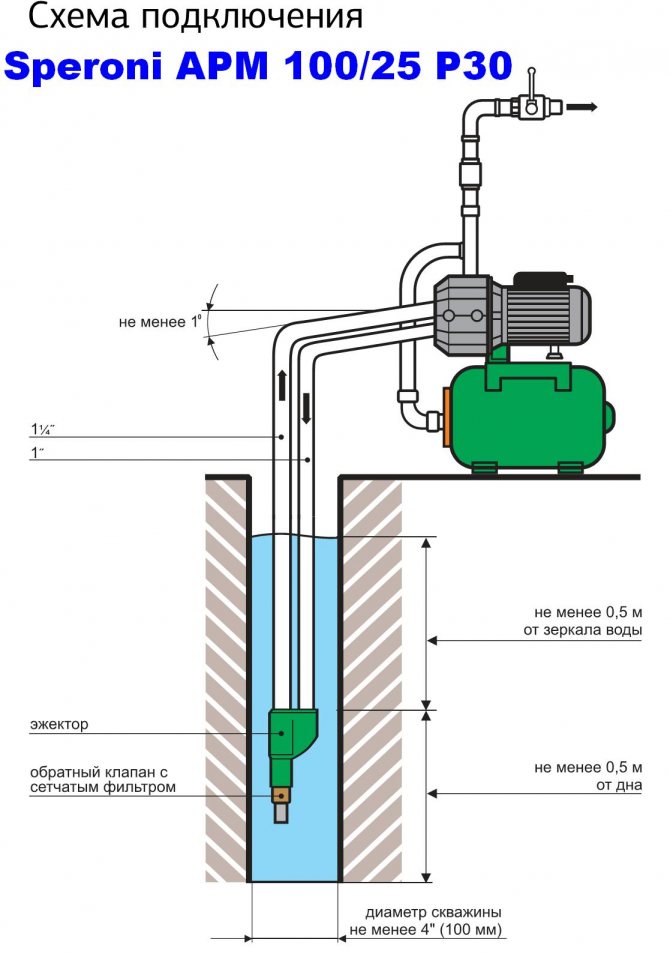

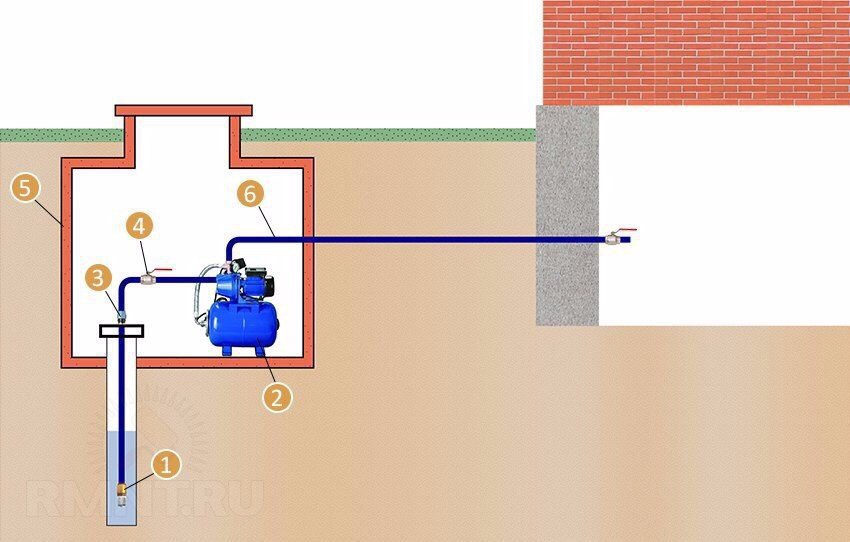

Well connection

If the suction depth of the pumping station for the well is sufficient, the connection is no different. Unless the pipeline exits at the point where the casing pipe ends. A caisson pit is usually arranged here, and a pumping station can be installed right there.

Pumping station installation: well connection diagram

As in all previous schemes, a filter and a check valve are installed at the end of the pipe. At the entrance, you can put a filler tap through a tee. You will need it for the first start.

The main difference between this installation method is that the pipeline to the house actually runs along the surface or is buried to a shallow depth (not everyone has a pit below the freezing depth). If the pumping station is installed in the country, it's okay, the equipment is usually removed for the winter. But if the water supply is planned to be used in winter, it must be heated (with a heating cable) and insulated. Otherwise it won't work.

The principle of operation and types of check valves

In water supply systems, the check valve plays an important role. It provides a continuous supply of water and maintains its pressure.

Most often, the design is installed in front of the pumping station or on the pump itself. The installation location depends on the features and characteristics of the system.

The principle of operation of the device is that the spool, plate or other constipation in it prevents the movement of water back to the pump and at the same time maintains the necessary pressure in the water supply.

There are several types of check valves for the pump, which differ in purpose and internal design.

Wafer Butterfly Valves - Spring and Butterfly

Among all types of valves, the spring design is the most compact. The shutter in it is a plate (disk) equipped with a spring. The dimensions of such a device can be from 15 to 200 millimeters.

In the event of a decrease in pressure in the pipeline, the spring presses the plate against the seat, thereby blocking the flow hole. After the pressure is restored, the spring is wrung out and the water is provided with a free flow.

In complex and large hydraulic systems, double-leaf structures with shock absorbers are used. They soften water hammer when the pump stops, which can cause damage to the system.

The principle of their operation is that under the action of the medium flow, the locking plate folds in half. The reverse flow presses the plate against the seat, returning it to its original position. The dimensions of the structure can be from 50 to 700 millimeters.

Benefits of Wafer Type Check Valves:

- Light weight and small size. There are no flanges in the design, due to which its length is 6–8 times less, and the weight is 5 times less than standard check valves of identical bore diameter.

- The ability to install not only on horizontal, but also on vertical and inclined sections of the water supply.

- Ease of operation and installation.

The disadvantage of the wafer device is that its repair requires complete dismantling.

Check lift valve

In such designs, the lifting spool plays the role of a shutter. If the water pressure in the pipeline is low, then the spool falls on the saddle, thereby blocking the return path for the medium. At high pressure, the valve rises, passing water.

Lifting structures are used only on horizontal sections of pipelines, while the spool axis must be vertical.

Reverse lifting structures are divided according to the method of attachment:

-

Devices with wafer fastening do not have their own fastening unit, therefore they are installed between pipe flanges. Used in restricted areas.

-

Union-mounted instruments are mounted in small-diameter systems using a threaded socket.

-

Flange-mounted structures are equipped with special flanges with seals, with which they are installed in the water supply system.

-

Weld-on devices are mounted by welding and are used in aggressive environments.

If the device breaks down, it can be repaired without dismantling the entire structure. The disadvantages of the non-return lift valve include their high sensitivity to water pollution.

Check ball valve

The locking element in the design is a ball equipped with a spring that presses it against the seat. The principle of operation of the ball device is identical to the operation of the wafer spring device, however, it loses in dimensions.

Check ball valves are most often used in plumbing in pipes with a small diameter.

Non-return rotary or reed valve

The role of the locking element in this design is played by a spool, which is called a "slam". Its axis is located above the through hole, therefore, under the pressure of water, the “clap” leans back and the water passes unhindered. In the event of a decrease in pressure in the water supply, the spool falls, blocking the channel.

The role of the locking element in this design is played by a spool, which is called a "slam". Its axis is located above the through hole, therefore, under the pressure of water, the “clap” leans back and the water passes unhindered. In the event of a decrease in pressure in the water supply, the spool falls, blocking the channel.

In large diameter rotary devices, the spool hits the seat, which can lead to a quick failure of the structure. Therefore, reed valves are divided into two groups:

-

Non-impact designs are equipped with special devices that soften the landing of the "clap" on the saddle.

-

Simple valves are installed in those systems where impact phenomena do not affect the operation of the structure and the system itself.

Butterfly check valves for pumps are insensitive to contamination and can be installed in larger diameter systems.

The disadvantage of such a large diameter design is the mandatory use of a damper.

A distinctive characteristic of the design and purpose of the check type valve

The device is small in size, but without it it is not possible to maintain water pressure in the system. It belongs to that plumbing fitting, which is intended to prevent a change in the direction of fluid flow. You can meet pneumatic water-pressure installations, in the models of which a check valve is incorporated. In most cases, it is completed with a suction hose. But most products are supplied without this part, you have to buy it separately. The working principle is similar to the ventilation valve known to many: it allows flow in one direction and blocks it in another.

There are many, many types of check valves. For domestic use, apply:

- 1. Spring coupling. They consist of 2 parts, united by a thread and a rubber gasket installed between them.

- 2. Similar, but with a brass spool having a spherical shape. They are distinguished by high throughput.

- 3. Combined spring, including an air vent, through which air is bled. Thanks to similar devices, system maintenance becomes easier.

- 4. Spring loaded with polypropylene body. Put on a water meter assembly of the same material.

Place of installation: supply line, entry into an independent system directly behind the pump or in front of it. Depending on accommodation check valves are bottom and pipelines. The former protect against the return flow of water raised from the source when the equipment is turned off. The latter protect the pressure drop in the system.If there is no valve at the beginning of the suction pipe, then when the pump stops, the water flows back, air locks appear in the line. When starting “dry”, the seals become unusable, after which the wet electric motor burns out.

Pumping station with bottom valve

Modern pumps are protected from such formidable consequences, and older models are not protected from this. But all the same, after each stop of the station, it will be necessary to fill in water - this is how it works. Installation of shut-off valves on the intake pipe is mandatory. Actually, this simple device is needed that works mechanically, due to the fact that no electronics is able to overcome the force of earth's gravity, under the influence of which the liquid flows from the pipes, if there is no check valve.

Shut-off valves play a slightly different role. It is intended to largely protect not the pump, but the domestic water distribution system. Closing the flow, it does not allow to return to the membrane tank, maintaining the pressure. The installation of a pumping station without a check type valve at the distribution causes water hammer, the operation of the device in an emergency mode. Installing a shutter increases the reliability and effectiveness of the water wire, increases the working life of plumbing equipment, appliances that are used at home.

Trick with a water station in the house

The dimensions of check valves depend on the area of use:

- ordinary - used in almost all water supply systems;

- very small - placed in the middle of the water meter pipe segments;

- not very large - located at the output of the accounting device;

- large - made of cast iron, used in industrial systems.

The part is cast from brass: the metal is resistant to the influence of salts, minerals and acids, which are dissolved in water. The material for other elements is copper and zinc or specialized polymer compositions. All gaskets are rubber or silicone. Stainless steel devices are also sold. They stand out for their high price due to their strength and very high corrosion resistance. If it is possible to purchase such a part, you do not need to look at the cost - it serves faithfully. Brass has to be changed or repaired very often.

Device for pumping station

The area of use is not limited to a station with a pump. For domestic purposes, the check valve is used:

- on hot and cold water risers, if the living area is in a high-rise building;

- in heating devices - an electric water heater, electric or gas column;

- for local heating of a private house;

- they are equipped with sewage to eliminate dangerous situations.

Types of devices by type of attachment

Important features of locking devices include the method of fastening, which depends on the material and technology of connecting pipelines. According to the method of connection with the pipeline, check valves are divided into:

- coupling;

- fatty;

- flanged;

- interflange.

The first variety is connected to pipes through a threaded transition. The weld-on version is more suitable for use in pipelines through which aggressive media are pumped. Flanged devices are equipped with flanges with seals through which the connection is made. Concerning check valves with wafer fastening, they have special fixing pins.In this case, the latter option is available exclusively in a double-leaf or disc version.

In water supply systems, locking devices with a lifting-spring mechanism and a coupling connection are usually used. They are distinguished by ease of installation and dismantling, and their repair is most often limited to replacing the spring, which is the weakest element in all fittings.

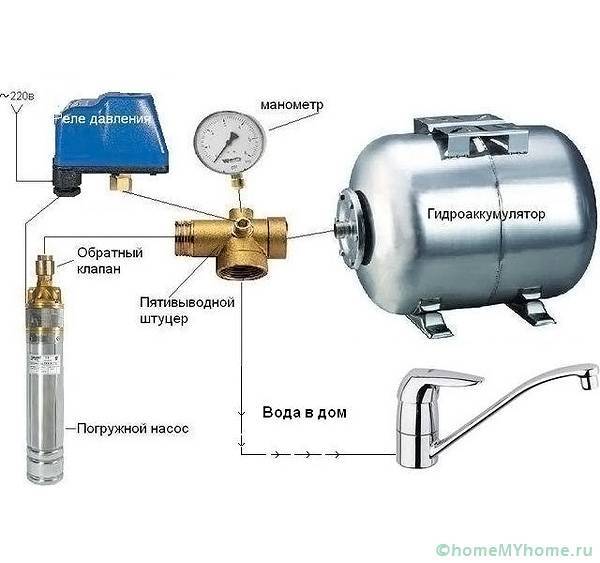

2 Why do I need a check valve for a submersible pump?

Check valves for pumps prevent water from flowing in pipes in the opposite direction or mixing water from taps with different temperatures. It all depends on where this valve is installed. Recently, reverse-flow valves made according to the API standard, which are designed for pressure levels from 10 to 170 bar, have become widespread. Lap welding dimensions for pipes according to the same standard - ANSI B16.11.

Valves for the pump are:

- with folding mechanisms;

- with lifting mechanisms.

Hinged mechanisms are distinguished by the fact that a hinged shutter is attached above the saddle, which opens under the pressure of the incoming water flow. The lift gate is operated by moving up and down a vertically mounted cylinder. When the shutter (flap) is pressed against the seat, the flow of water stops flowing in.

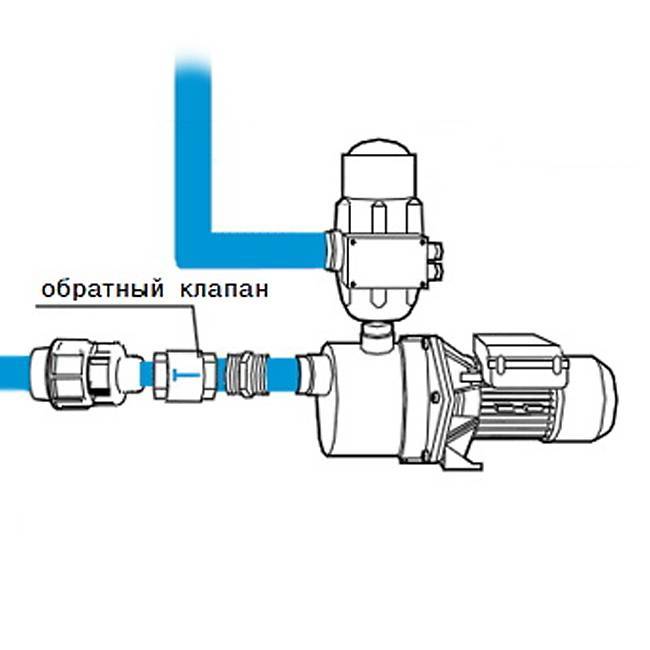

2.1 Valve installation

Very often on the forums you can find heated debates about one single question: “How much is it necessary to put a check valve on the pump?”.

Check valve location when installing a borehole pump

Submersible pumps with a non-return valve, if you have a well in your yard or an electric water pump installed near the well, then when you turn on the pressure unit, without waiting for the water to displace air from the pipes, immediately supply water to the tap. If, for example, you put shutoff valves on the pump for hot water, then you will not need to drain cold water from the pipe, waiting for the “warmth to go”.

2.2 Nuances of installation

In order not to carry out permanent repairs due to deposits of dirt and sediment on the membrane, and the spring, which in the end simply does not hold water, must be installed vertically.

Depending on the type of well or well, taking into account the characteristics of the pipeline, valves should be installed either from below or from above. The position on top is required when the well is drilled to a shallow depth (up to eight meters, which is typical for Abyssinians).

If you put a lock from below, then you can track the flow of water from the well when you already get into the aquifer only when using a hand or foot pump.

If you put a back-locking mechanism on downhole devices, then its direct purpose is to prevent water from constantly returning to the well. This will save time for water to enter the taps. Therefore, it is necessary to install shut-off valves at the outlet of the pressure apparatus.

With a shallow level of immersion of the pumping apparatus, and if the distance to the house is small, then you can limit yourself to installing one valve.If the distance figures are greater, then a pair of shut-off valves is installed - at the outlet of the pressure apparatus and at the entrance to the house or directly at the water intake point near the hydraulic accumulator and automatic control of the pressure apparatus.

If you have a pumping station, then you need to install shut-off valves either in the well directly at the inlet of the water-suction pipe, or directly in front of the inlet of the pressure station. Considering the features of the mechanism of back-stop valves, the second option is preferable.

And, for example, check valves for sewer pumps are needed so that water does not go back from the toilet. The installation of this locking mechanism is implied on a common sewer pipe. But, you can always improve your life and install back-stop valves on each drain separately.

2.3 Homemade valve

You do not need to be seven spans in the forehead or have plumbing skills and education in order to try to make it yourself instead of a purchased locking mechanism.

Ball check valve installation rules

To make your own back locking mechanism, you need to purchase the following parts:

- coupling with external threaded connection;

- tee with internal threaded connection;

- a spring freely entering the tee;

- the metal ball is 2-3 mm smaller than the inner diameter of the tee;

- threaded plug;

- fum tape.

Instead of a back lock body, we use a standard tee made of brass, steel, cast iron or plastic with female threads. Better take from brass. Then install the clutch. We insert the ball and spring into the brass case on the other side, install the plug.

Conclusions and useful video on the topic

Video #1All about the technology of installing a check valve for water:

Video #2 Overview of the backflow blocking valves:

Video #3 Which check valve option to prefer for the cottage water supply system:

The use of check valves simplifies the operation of pumping stations and reduces the risk of accidents in the water supply system

Don't skimp on this small but important item.

Manufacturers now offer a mass of options for this fitting of different sizes, the way the constipation is actuated and the type of fastening. For any water supply system and type of pump, it is easy to find the best solution.

We will be glad to know your opinion. Those who wish to clarify complex technical issues, share experience or point out a flaw in the material in the block below can leave comments.