- Water source

- Well types

- Pump selection

- Well equipment

- Device

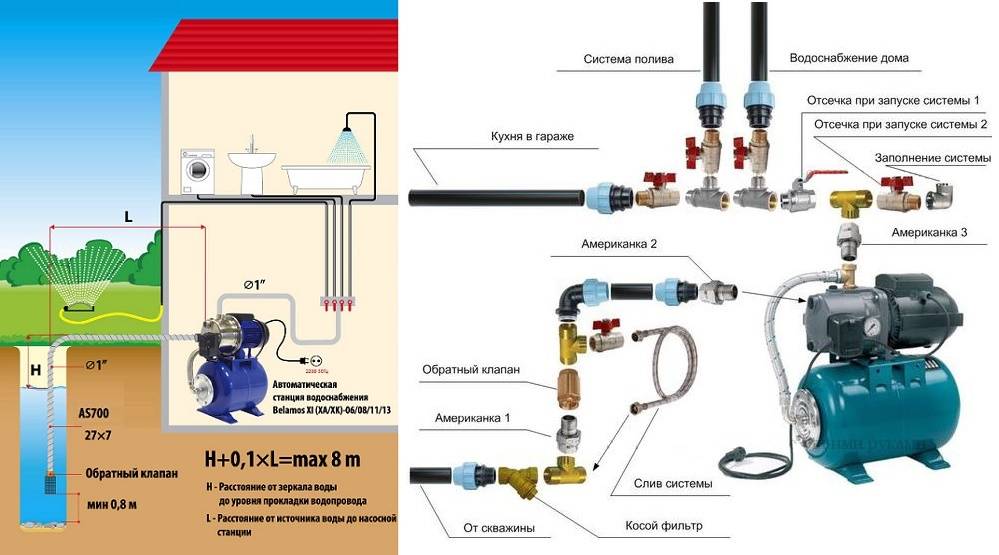

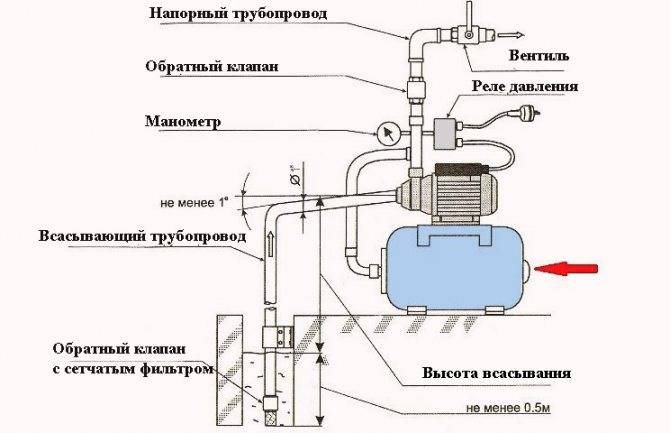

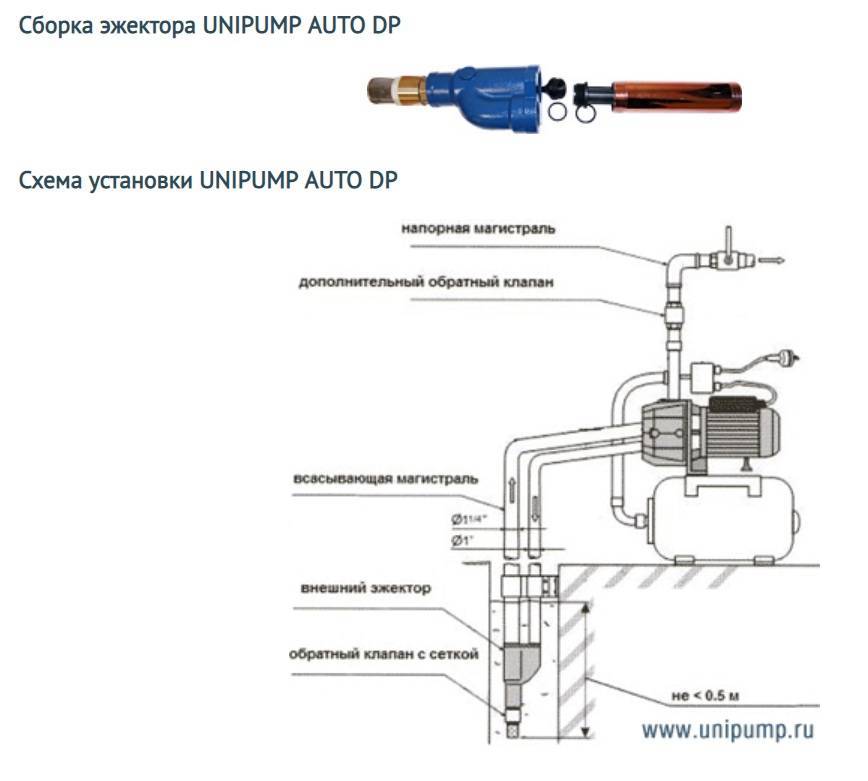

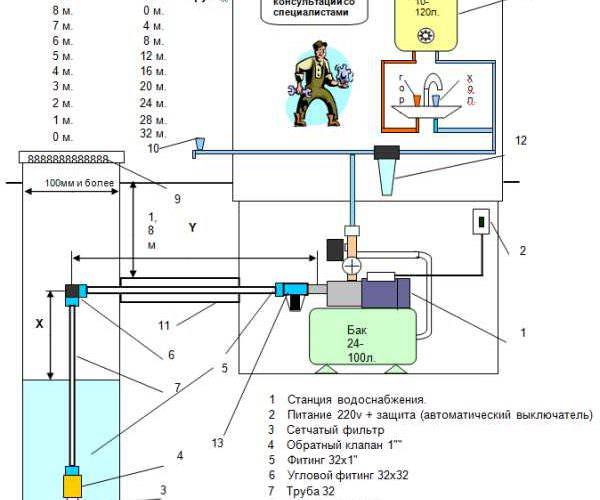

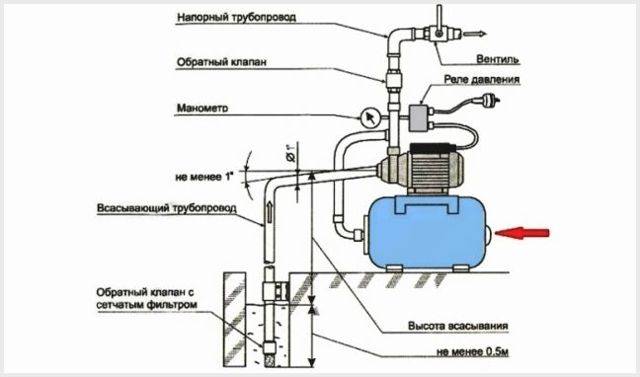

- 3 Installation at a pumping station - site selection

- Overview of popular models

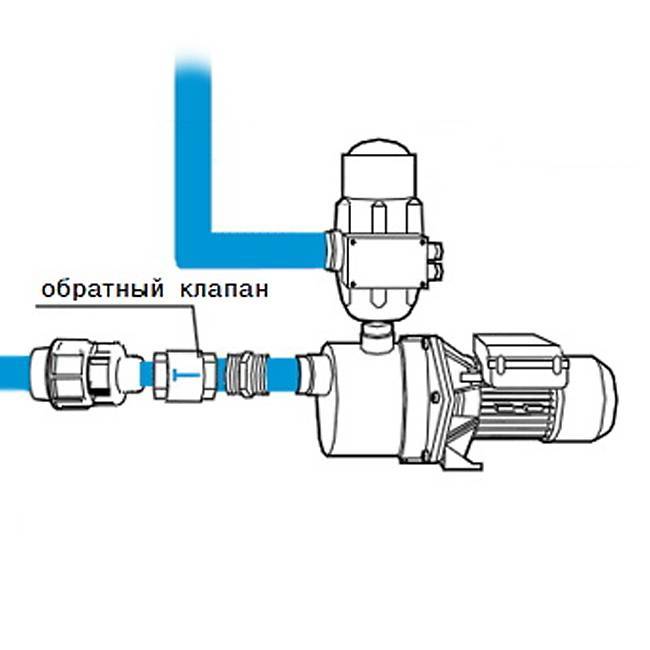

- Station connection options

- Types of pipe check valves

- Classification # 1 - by type of locking element

- Classification # 2 - by type of attachment

- Classification # 3 - by material of manufacture

- Do-it-yourself installation of an autonomous water supply

- Design

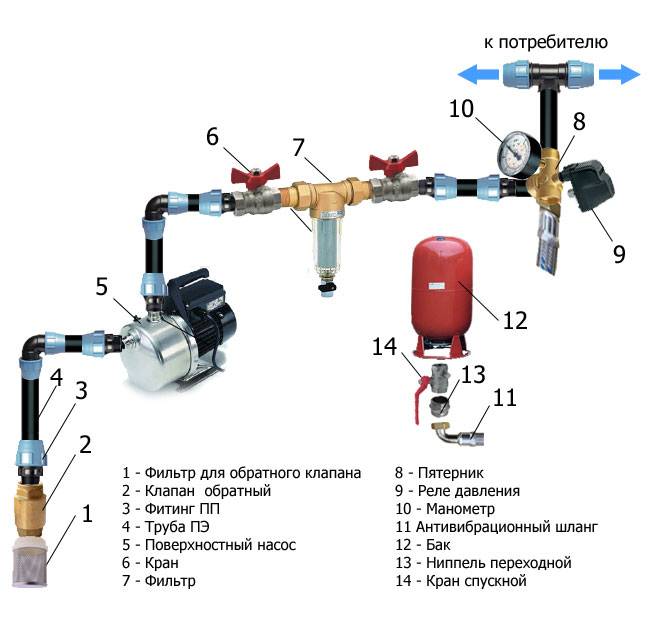

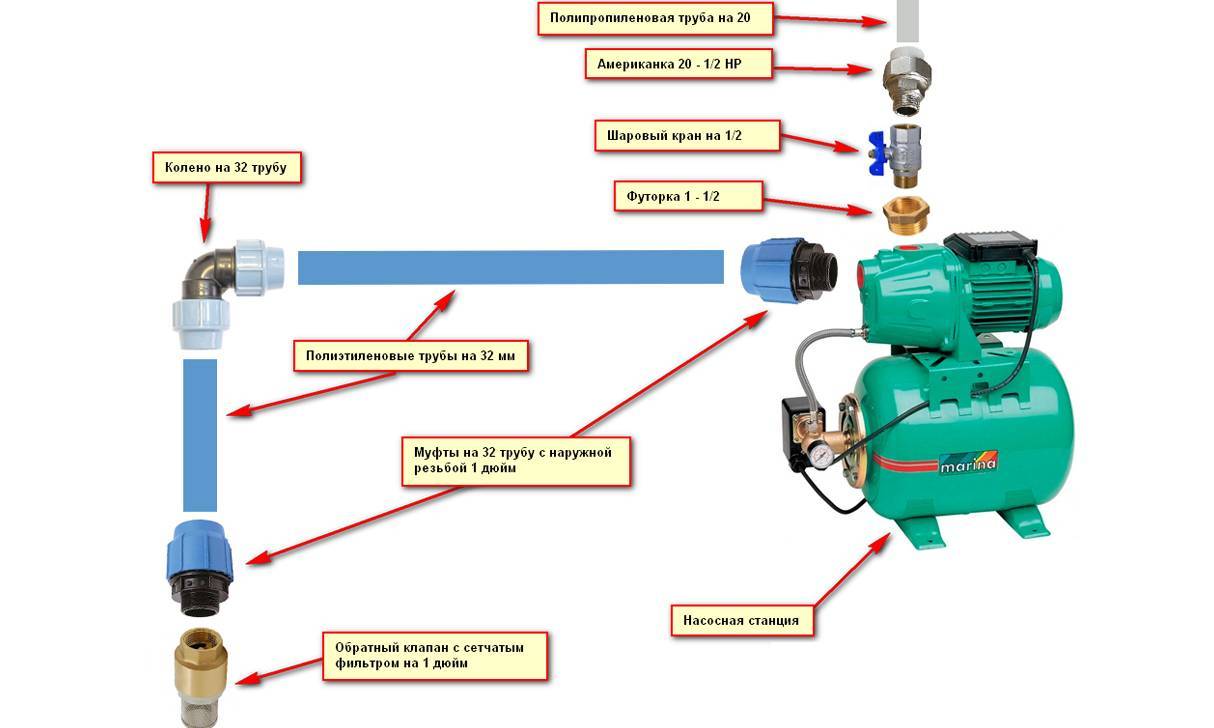

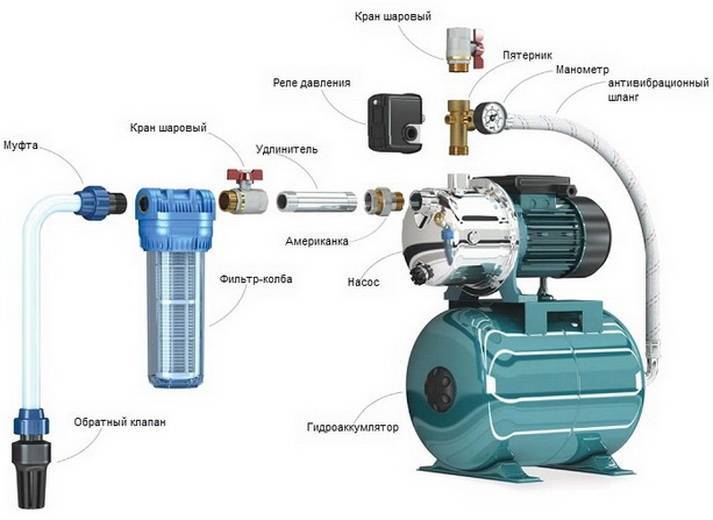

- Equipment switching sequence

- Bottom check valve

- Design and principle of operation

Water source

Well types

Any scheme for supplying water to a house from a well is built on the basis of a key component - the water source itself.

To date, all wells, depending on the characteristics of the substrate, are conditionally divided into three groups:

- Sandy - the simplest and cheapest in the arrangement. The disadvantage is a relatively short service life (up to ten years), and fairly rapid siltation. Suitable for garden installation.

- Clayey ones require a little more responsibility when drilling a well, but otherwise they have the same advantages and disadvantages as sandy ones. Should be used regularly, since after about a year without operation, it will be very difficult and expensive to restore a silted well.

- Limestone (artesian) wells are considered to be the best.The scheme for drilling a well for water in limestone involves deepening to a level of 50 to 150 meters. This provides a margin of reliability and durability of the water source, and in addition - improves the quality of natural filtration.

Main varieties

When choosing the type of well, one should not pay all attention to such a parameter as price. The fact is that the arrangement of an autonomous water supply is a very expensive task in itself, and it is better to invest in this project once (by choosing high-quality equipment and inviting professional craftsmen) than to reap the dubious “fruits of savings” in a few years in the form of impressive bills for repairs and source recovery

Pump selection

The next step in building a water supply system is the selection of pumping equipment.

Here the instruction recommends paying attention to such points:

- As a rule, high-performance models are not required for small cottages. Knowing that approximately 0.5-0.6 m3 of water is needed to operate one tap for an hour, a pump is usually installed that can provide an inflow of 2.5-3.5 m3 / h.

- The highest points of water withdrawal should also be taken into account. In some cases, to provide the necessary pressure on the upper floors, the installation of an additional pump is required, since the downhole water-lifting device cannot cope.

Small diameter pump for lifting water from great depths

Almost all models of borehole pumps are characterized by a fairly high level of energy consumption.

Taking into account this fact, it is worth taking care of the power stabilizer in advance. And if the electricity in your village is often cut off, then the generator will not be superfluous

Well equipment

The equipment process itself is usually carried out by the same company that did the drilling.

However, you should also study it - at least in order to ensure quality control of the execution of work operations:

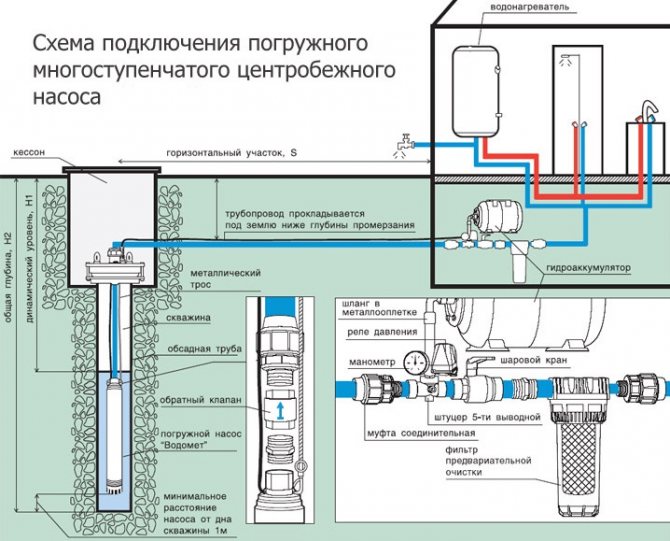

- We lower the selected pump to the design depth and hang it on a cable or a strong cord.

- Through the neck of the well with the head installed (a special sealing part), we bring out the water supply hose and the cable that provides power to the pump.

Head mounted

- Some experts advise connecting the hose to the cable. This is quite convenient, but you need to remember that in no case should the hose be pinched at the connection points!

- Also, a lifting device is mounted near the neck - a manual or electric winch. You can do without it only at very shallow depths, because the deeper, the stronger will be felt not only the weight of the pump itself, but also the weight of the hose with the power cable, and the weight of the cable.

Photo of the main pit

This is the view of the scheme of the well device for water. However, this is not even half the battle: we need to assemble an entire system on this base.

Device

Not all pipes on the building materials market are suitable for creating an autonomous water supply system. Therefore, when choosing them, first of all, you need to look at the markings. Water pipes have approximately the following designations - PPR-All-PN20, where

- "PPR" is an abbreviation, an abbreviated name for the material of the product, in the example it is polypropylene.

- "All" - an inner aluminum layer that protects the pipe structure from deformation.

- "PN20" is the wall thickness, it determines the maximum working pressure of the system, measured in MPa.

The choice of pipe diameter is based not so much on the diameter of the threaded inlet on the pump and the automated pressure control system, but on the expected volume of water consumption. For small private houses and cottages, pipes 25 mm in diameter are used as standard.

When selecting a pump, the following points should be considered:

If water from a well is used, a vibration unit cannot be used, it will damage the casing and filter element. Only a centrifugal pump is suitable.

The quality of the water from the well must meet the requirements of the pump. With a well “on the sand”, grains of sand will come across in the water, which will quickly lead to a breakdown of the unit

In this case, it is important to choose the right filter.

Dry run automatic. When choosing a pump, if the choice fell on a model without built-in protection against "dry running", you must additionally purchase automation for the appropriate purpose

Otherwise, in the absence of water that performs a cooling function for the motor, the pump will overheat and become unusable.

The next step is drilling a well. Due to the complexity and high labor intensity, this stage is best performed with the help of a specialized team with the necessary drilling equipment. Depending on the depth of water and the specifics of the soil, various types of drilling are used:

- auger;

- rotary;

- core.

The well is drilled until the aquifer is reached. Further, the process continues until a water-resistant rock is found. After that, a casing pipe with a filter at the end is inserted into the opening. It should be made of stainless steel and have a small cell. The cavity between the pipe and the bottom of the well is filled with fine gravel. The next step is to flush the well.Most often, this procedure is performed using a hand pump or submersible, lowered into the casing. Without this, the action of clean water can not be expected.

The caisson serves as protection for both the well and the equipment lowered into it. The life of the water supply system, as well as the convenience in servicing units immersed in the well, directly depend on its presence.

The caisson, depending on the material used, may be as follows:

- metal;

- cast from concrete;

- lined with concrete rings with a diameter of at least 1 meter;

- finished plastic.

The cast caisson has the most optimal qualities, the creation of which can take into account all the existing specifics of the well. Plastic caisson has low strength and needs to be reinforced. The metal look is subject to corrosion processes. Concrete rings are not very spacious and maintenance or repair work in such a caisson is very difficult. The depth of this structure is determined by the level of soil freezing in winter and the type of pumping equipment used.

For clarity, consider an example. If the depth of soil freezing is 1.2 meters, then the depth of the pipelines leading to the house is approximately 1.5 meters. Given that the location of the well head relative to the bottom of the caisson is from 20 to 30 cm, it is necessary to pour concrete about 100 mm thick with about 200 mm crushed stone. Thus, we can calculate the depth of the pit for the caisson: 1.5 + 0.3 + 0.3 = 2.1 meters. If a pumping station or automation is used, the caisson cannot be less than 2.4 meters deep.When arranging it, it is worth remembering that the upper part of the caisson should rise above ground level by at least 0.3 meters. In addition, a natural ventilation system is needed to prevent the accumulation of condensate in summer and frost in winter.

3 Installation at a pumping station - site selection

The spring of the mechanism is not elastic enough, otherwise it would completely block the water flow. This feature contributes to the accumulation of various mud deposits on the walls. Clogs over time cause malfunctions in the entire system. Therefore, the correct installation of non-return valves is very important.

The installation of check valves used for pumping stations is quite simple. It is more difficult to choose the right place and model. It depends on the type of pump with which it will work. You can buy a unit with a built-in locking device. Manufacturers place them on the input and output highways. In any case, before buying, you should ask if the design has shut-off valves. If this is provided, then it is not necessary to install it yet: it is not only superfluous, but also harmful. The pressure in the system increases, the throughput decreases.

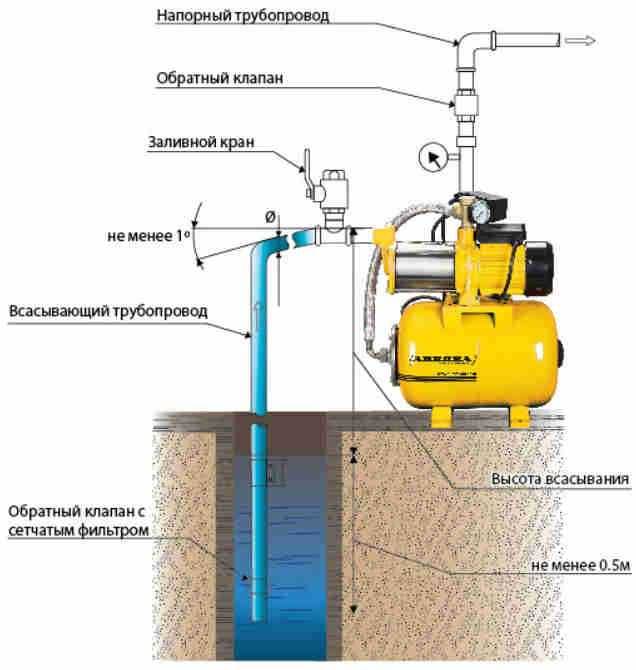

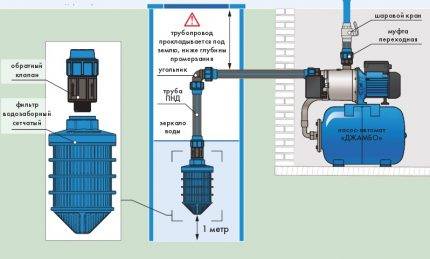

If a submersible vacuum pump is used in a well or well, a check valve is mounted in front of the accumulator. The best designs are those with a ball or lift-type spool. For pumping stations located on the surface, a bottom valve is mandatory, which is attached to the end of the pipe immersed in water. The second is pipeline, which is installed in front of the tank. Some manufacturers specify a specific model, but as a rule, devices of any type are suitable.

Assembly option

The determining factor when choosing a model is the diameter of the pipes (the required suction size is at least 1 inch), throughput, and operating pressure. Installed depending on the design, using the existing threads or fittings. It is necessary to ensure very high tightness - the slightest air leak leads to inoperability. Apply sealing FUM tape. Be sure to place the arrow indicating the direction of the water flow so that the device opens when the liquid is pumped.

Reverse setting do-it-yourself valves is performed in the following sequence:

1. Choose a model and check its performance. To do this, it is enough to blow with your mouth from both sides: in one case, the shutter opens, in the other it does not let air through.

2. Determine the correct installation direction. It is indicated by an arrow on the body.

3. Screw the valve onto the thread, after winding up the FUM tape. The pumping station has a built-in adapter, for the suction pipe it should be purchased.

4. Tighten the mount with a gas wrench

It is important not to overdo it - there are products that are not very strong.

In some cases, the system is arranged in such a way that it provides for the emptying of the distributing line or the operation of the pump in reverse mode. Then it is impossible to install a valve after the accumulator - it will block the outflow of water. The location in relation to the valve is determined by the station start-up technology. There are models whose operation starts with the tap closed. Then the locking device is mounted after it.

Mounting location - immersion pipe

The bottom valve is recommended to be installed together with a filter that purifies the water from sand, protecting the internal parts from premature wear. It is better to immediately buy a device with a grid. For some models, it is removed, which allows you to replace if necessary. Check valves with a spring and a lifting locking element are the least contaminated. The easiest pipe fitting to install, which uses a wafer connection. In a private house, mainly inexpensive devices with a coupling mount are used.

Overview of popular models

There are two types of pressure switches: mechanical and electronic, the latter are much more expensive and rarely used. A wide range of devices from domestic and foreign manufacturers is presented on the market, facilitating the choice of the required model.

RDM-5 Dzhileks (15 USD) is the most popular high-quality model from a domestic manufacturer.

Characteristics

- range: 1.0 - 4.6 atm.;

- minimum difference: 1 atm.;

- operating current: maximum 10 A.;

- protection class: IP 44;

- factory settings: 1.4 atm. and 2.8 atm.

Genebre 3781 1/4″ ($10) is a Spanish-made budget model.

Characteristics

- case material: plastic;

- pressure: top 10 atm.;

- connection: threaded 1.4 inches;

- weight: 0.4 kg.

Italtecnica PM / 5-3W (13 USD) is an inexpensive device from an Italian manufacturer with a built-in pressure gauge.

Characteristics

- maximum current: 12A;

- working pressure: maximum 5 atm.;

- lower: adjustment range 1 - 2.5 atm.;

- upper: range 1.8 - 4.5 atm.

The pressure switch is the most important element in the water intake system, which provides automatic individual water supply to the house.It is located next to the accumulator, the operating mode is set by means of adjusting screws inside the housing.

When organizing autonomous water supply in a private house, pumping equipment is used to raise water. In order for the water supply to be stable, it is necessary to select it correctly, since each type has its own technical characteristics and features.

For efficient and trouble-free operation of the pump and the entire water supply system, it is necessary to purchase and install an automation kit for the pump, taking into account the characteristics of the well or well, the water level and its expected flow rate.

The vibration pump is chosen when the amount of water spent per day does not exceed 1 cubic meter. It is inexpensive, does not create problems during operation and maintenance, and its repair is simple. But if water is consumed from 1 to 4 cubic meters or water is located at a distance of 50 m, it is better to purchase a centrifugal model.

Usually the kit includes:

- operating relay, which is responsible for supplying and blocking voltage to the pump at the time of emptying or filling the system; the device can be immediately configured at the factory, and self-configuration for specific conditions is also allowed:

- a collector that supplies and distributes water to all points of consumption;

- pressure gauge for measuring pressure.

Manufacturers offer ready-made pumping stations adapted to specific requirements, but a self-assembled system will work most efficiently. The system is also equipped with a sensor that blocks its operation during dry running: it disconnects the engine from power.

The safety of the equipment operation is ensured by overload protection sensors and the integrity of the main pipeline, as well as a power regulator.

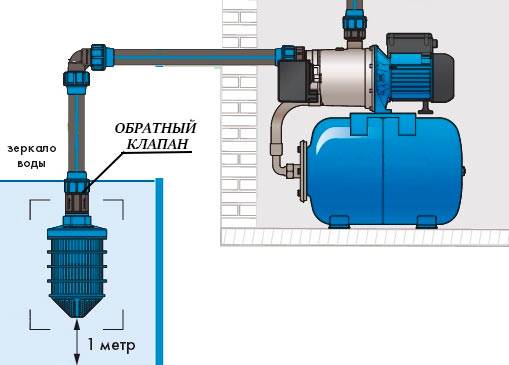

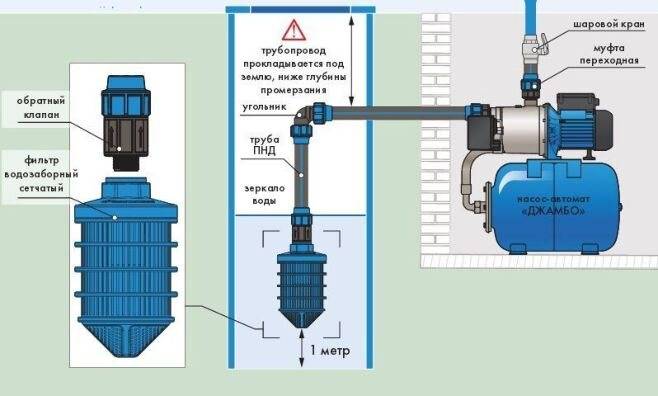

Station connection options

There are two ways to connect the pumping station to the pipeline:

- Through borehole adapter. This is a device that is a kind of adapter between the water intake pipe in the source shaft and the water pipes outside. Thanks to the borehole adapter, it is possible to draw the line out of the hydraulic structure immediately below the freezing point of the soil and at the same time save on the construction of the caisson.

- Through the head. In this case, you will have to take care of high-quality insulation of the upper part of the source. Otherwise, ice will form here in sub-zero temperatures. The system will stop working or break in one of the places.

Types of pipe check valves

Depending on the installation conditions and the characteristics of the plumbing system, valves are installed that differ in design, size, material and method of attachment. Some are designed for pipes of small diameter and domestic use, others for centralized water supply.

Consider the main classifications of check valves for water.

Classification # 1 - by type of locking element

The part of the valve inside the body, which is responsible for closing the section, can be of various configurations.

According to the locking element, the following types of devices are distinguished:

- Lifting, in which the shutter device moves up / down depending on the presence or absence of water pressure in the pipe. A spring is responsible for the dynamics, and a spool acts as a shutter.

- Swivel, also equipped with a spool - a flap or "petal".When the pump is turned on, it leans back and clears the way for the liquid, when turned off, it slams shut, blocking the cross section.

- Double-leaf, blocking the path to the flow of water with two connecting leaves.

The movement of the locking element occurs in parallel, perpendicular to the axis or at an angle, so manufacturers recommend installing some devices only on horizontal pipes, others on vertical ones.

For domestic use, it is advisable to purchase spring valves, which are distinguished by a simple design and ease of installation. If you decide to independently equip the pumping system with check valves, we recommend just such a model.

A sample of a spring valve installed in the boiler piping and preventing water hammer. A pumping station is connected to the system, pumping water from the well

A sample of a spring valve installed in the boiler piping and preventing water hammer. A pumping station is connected to the system, pumping water from the well

The design of the spring valve consists of the following elements:

- brass body (steel, polymer), consisting of two parts - a base and a cover with a seat;

- disc element with a rubber seal that abuts against the seat;

- a rod that performs the functions of centering and holder;

- spring to return the locking element to its initial state.

Valves such as rotary valves are almost never used in domestic water supply, but they are often used for industrial pipelines, the diameter of which reaches 0.5 and even 1.5 m.

Classification # 2 - by type of attachment

The tie-in into the pipe is produced in various ways, which are selected depending on the pipe material and installation conditions.

Four types of valves are recognized as the most acceptable:

- flanged;

- interflange;

- coupling;

- welded.

In systems associated with pumping stations, it is advisable to use a coupling type with a spring mechanism and simple installation. But in more “serious” networks, for example, for equipment for supplying water to an apartment building, all of the above types are successfully used.

Classification # 3 - by material of manufacture

Valve bodies are made from materials that reliably protect the internal mechanism, do not deform from the effects of the external environment and liquid flowing through the pipes.

The check valve on the pipe is:

- steel;

- cast iron;

- bronze;

- brass;

- plastic.

Products installed near centrifugal pumps in the heating system must be metal, since plastic is not intended for hot water.

A sample of brass OK, universal in application. It is installed on both metal and plastic pipes. The product does not rust bends, does not change technical characteristics over time

A sample of brass OK, universal in application. It is installed on both metal and plastic pipes. The product does not rust bends, does not change technical characteristics over time

Cast iron valves are characterized by high weight and roughness of the material. But they are not used for equipping autonomous home networks, but are installed only for industrial operation on large-diameter pipes.

Plastic devices are light and inexpensive, their installation is very fast. But they cannot be applied to serious water supply systems at home.

Polymer products are suitable for polypropylene pipes in networks with low water pressure - for example, for watering a garden or pumping water into a bath

Polymer products are suitable for polypropylene pipes in networks with low water pressure - for example, for watering a garden or pumping water into a bath

The internal parts - the seat, valves, stem - valves are made of polymers, stainless steel or aluminum. They are durable and corrosion resistant. The active element, the spring, is made of special spring steel, which has an extended service life.

In valves installed on centralized highways and industrial facilities that can withstand heavy loads, plastic or rubber seals are used to tightly fit the valve to the seat.

Do-it-yourself installation of an autonomous water supply

If you choose a well or well with a depth of more than 20 meters, then the first option is inexpensive, but the water is not always drinkable. You will need to install filters that need periodic maintenance. The second option is better, although more expensive. Having drilled the soil to artesian water, you can enjoy its purity. But the difficulty is not in making a decision, but in installing the pipeline.

Design

This is the first step, but the most important. In addition to the graphic scheme of autonomous water supply, calculations will have to be made. The need for cold and hot water is taken into account. This depends on the diameter of the pipes. Equipment is selected based on power (performance). This is the volume of liquid pumped per hour.

We must not forget that water must be raised to the surface, transferred through the pipeline and created in the system the pressure that must be for the operation of the gas column. A check valve in the system is needed so that it does not empty when the pumping equipment is not functioning. You will need a tap to relieve pressure and drain water.

Wherever a private house is located, the route is laid below the level of soil freezing. Crushed stone for drainage is laid at the bottom of the trench. At the same time, a slope towards the well or well should be maintained in case it is necessary to bleed the system by gravity. Pipes can be:

- Metallic.They are subject to corrosion, overgrow inside, but are suitable for systems of any type, including heating.

- Plastic. Not suitable for transferring hot water. They are cheap, do not rust, last a long time.

- Metal-plastic. The best option for any system. Resistant to corrosion, withstand temperatures up to 95 degrees Celsius.

If we are talking about do-it-yourself installation, you need to take into account that plastic and metal-plastic will require special equipment and adapters. The iron track can be mounted with hand tools. True, you will need a welding machine, a grinder and a threading tool. If the assembly is difficult, you can contact the experts.

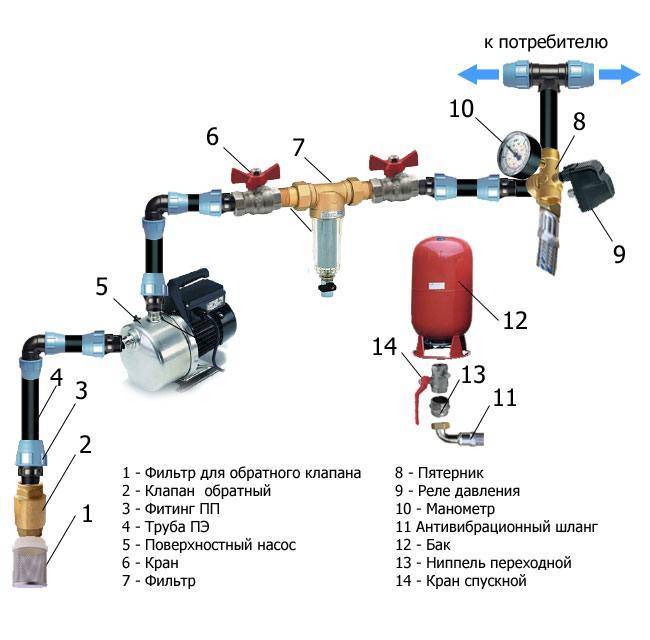

Equipment switching sequence

There are many publications that describe the water supply systems of a private house. The lion's share is devoted to the characteristics and performance parameters. But how to mount an autonomous water supply? All elements are connected in a certain sequence.

From the source to the consumer, water passes the following control points:

- Water is drawn into the system from a well or well.

- The mesh filter prevents pestle and soil from entering the system.

- The check valve prevents fluid from flowing back when the pump is turned off.

- The coarse filter captures solid suspended particles and sludge.

- The pumping station provides forced circulation of water if necessary.

- The block of instrumentation allows you to control the operating parameters of the water supply.

- The fine filter absorbs the remaining impurities, leaving the water clean, suitable for drinking.

The set of funds with which the autonomous water supply system of a private house is implemented may differ, but these differences are insignificant. The main feature is that pipes are laid first. And for this you need a ready-made pipeline project with the arrangement of all the necessary elements.

Bottom check valve

Bottom varieties of check valves are installed at the inlet of the water pumping line. They are used to equip surface pumping systems in order to protect against pressure drops.

The task of the bottom check valve is to keep water in the system and maintain the working pressure level (+)

The task of the bottom check valve is to keep water in the system and maintain the working pressure level (+)

According to the design specifics, bottom check valves are divided into:

- Spring. Their working locking mechanism consists of a spring and a disk, which, when the spring contracts under the pressure of water, moves along the body of the device and passes the flow.

- Sash. The main organ consists of one or two transverse flaps that open under the pressure of pumped water and return to their place when it stops.

According to the method of attachment to the end of the suction hose or pipe, bottom valves are divided into coupling and flange valves. In tandem with household pumping units, the coupling type is most often used.

Under water pressure, the spring of the device is compressed, and the locking disc attached to it opens the way for flow in only one direction

Under water pressure, the spring of the device is compressed, and the locking disc attached to it opens the way for flow in only one direction

Check valve couplings are easier to install, but require periodic monitoring of the condition, especially when working with a vibrating pump

Check valve couplings are easier to install, but require periodic monitoring of the condition, especially when working with a vibrating pump

The flap check valve is the easiest to operate repairable version of the device, the flap of which opens only in one direction under the pressure of pumped water (+)

A strainer is recommended before the bottom check valve. It must prevent the penetration of biological contaminants and solid particles with an abrasive effect into the pumping system.

The device must be installed according to the direction indicated by the arrow on the housing. The distance from the bottom of the water intake to the check valve should be at least 0.5 - 1.0 m, depending on the class of the unit and the manufacturer's recommendations. Between the water surface in the well or well and the valve there must be a water column of at least 0.3 m.

Pumping systems with a submersible pump are equipped with a check valve without a filter, because they are equipped with built-in cleaning devices to protect the functional "stuffing" from friction. The non-return valve in this case is installed in front of the supply pipe immediately after the pump unit. Used to prevent pressure drops in the network.

A non-return valve in a pumping system with a submersible pump is installed immediately after the unit at the inlet of the suction pipe

Design and principle of operation

Relay for pressure regulation has a simple collapsible design, thanks to which the user can independently adjust the operation of the accumulator, narrow or expand the parameters.

The internal parts are arranged in a durable plastic case that resembles an irregularly shaped box. It has a smooth surface and only 3 external working elements: two coupling clamps for electrical cables coming from the network and the pump, and a ¼, ½, 1 inch metal pipe for connecting to the system. The thread on the pipe can be both external and internal.

To remove the case of the device, it is necessary to arm yourself with a flat screwdriver and slowly and carefully unscrew the screw recessed into the plastic, located above the axis of the large spring

Inside there is a base to which the working elements are attached: large and small springs with adjusting nuts, contacts for connection, a membrane and a plate that changes its position depending on the increase / decrease in the pressure parameters in the system.

The contacts of two electrical circuits, which are closed when the pressure limits are reached, are located under the springs, which are fixed on a metal plate. When the pressure rises, the tank membrane deforms, the pressure inside the pear increases, the mass of water presses on the plate. That, in turn, begins to act on a large spring.

When compressed, the spring works and opens the contact that supplies voltage to the motor. As a result, the pumping station is turned off. With a decrease in pressure (usually in the range of 1.4 - 1.6 bar), the plate rises to its original position and the contacts close again - the motor starts to work and pump water.

When buying a new pumping station, it is recommended to test the equipment to make sure that all components are working. The performance test of the relay occurs in the sequence described below. An example is the Haitun PC-19 model.

Mechanical models do not have an indication and control panel, however, they can be equipped with a forced on button. It is necessary to make it function.