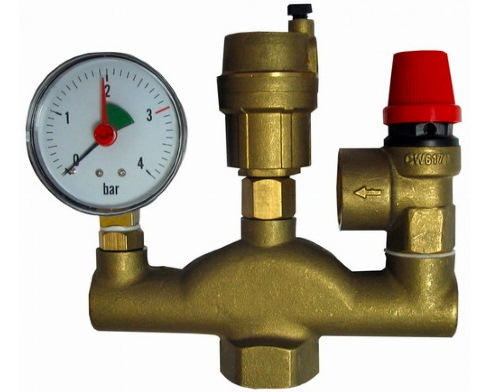

- Air valve recommendations

- What is a water check valve

- How does a water check valve work?

- What is forced circulation?

- Selection Tips

- How to install the valve correctly

- Options for working connection diagrams

- Materials, markings, dimensions

- What is indicated in the label

- Dimensions of check valves for water

- How to check

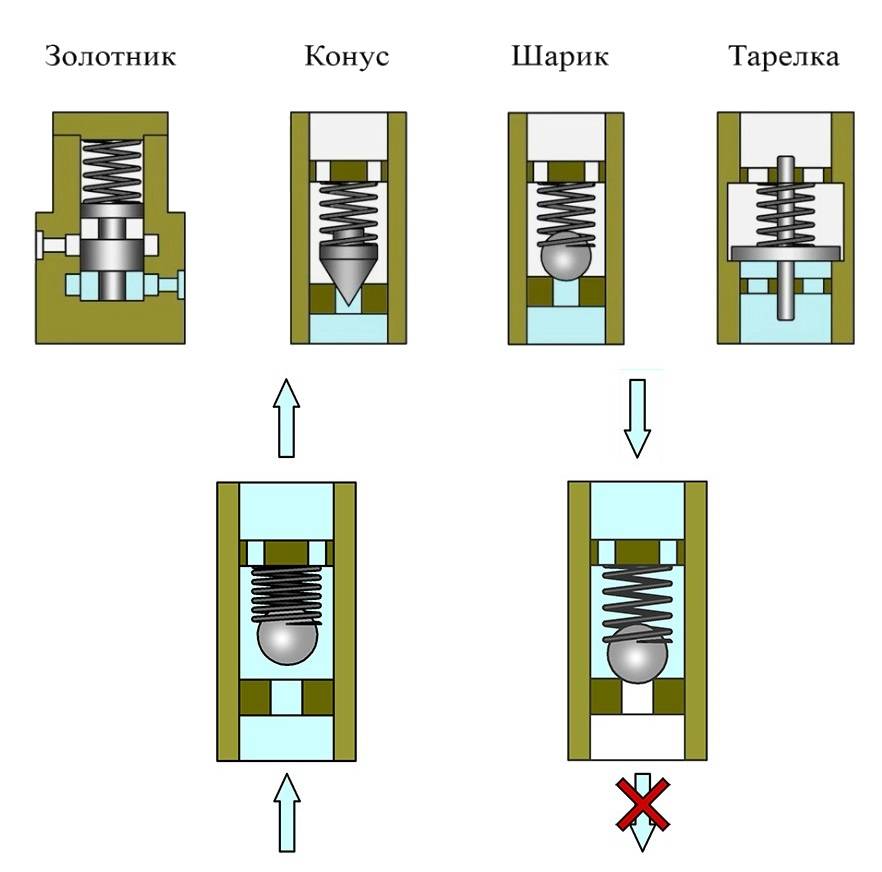

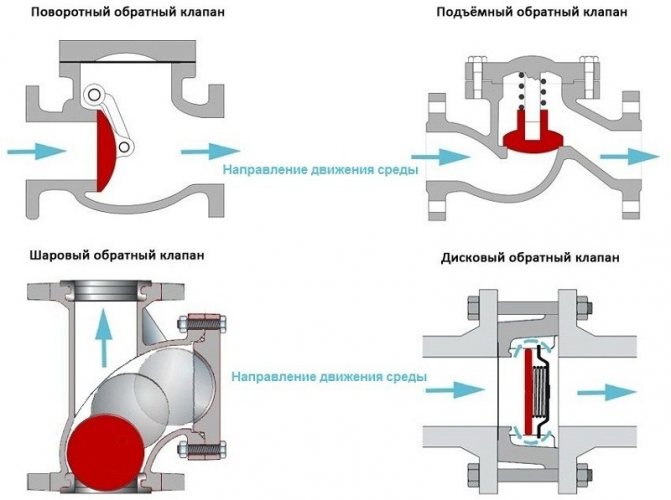

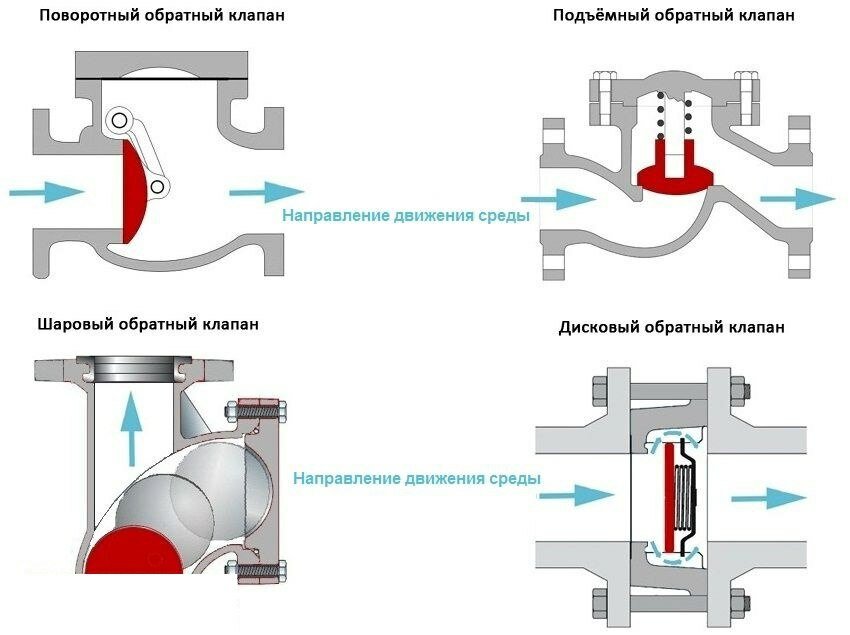

- Types of locking elements

- Reed valves

- Poppet valves

- ball valves

Air valve recommendations

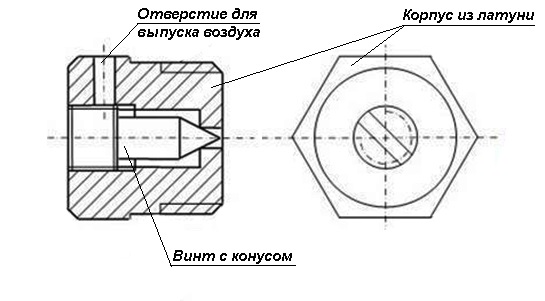

Theoretically, in all necessary places, you can put an automatic valve to release air. But in practice, the scope of automata is limited for many reasons. For example, the Mayevsky crane device is simpler and has no moving parts, so it is more reliable. The manual faucet is a cylindrical body made of tap brass with an external thread. A through hole is made inside the body, the passage in which is blocked by a screw with a conical end.

A round calibrated channel departs from the main hole located in the center. When the screw is loosened, a message appears between these two channels, due to which the air leaves the system.During operation, the screw is completely tightened, and in order to relieve gases from the system, it is enough to unscrew it a couple of turns with a screwdriver or even by hand.

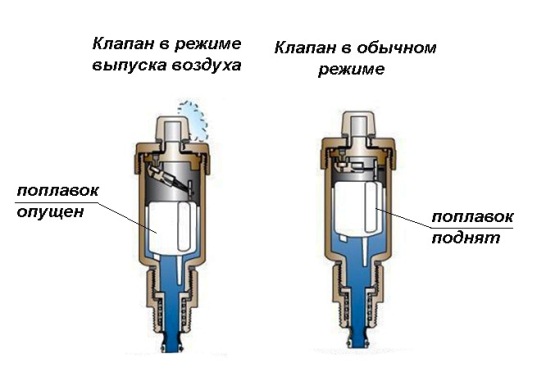

In turn, the automatic air valve is a hollow cylinder, inside of which there is a plastic float. The operating position of the device is vertical, the inner chamber is filled with coolant flowing through the lower opening under the influence of pressure in the system. The float is mechanically attached to the needle outlet valve by means of a lever. The gases coming from the pipelines gradually displace the water from the chamber and the float begins to sink. As soon as the liquid is completely expelled, the lever will open the valve and all the air will quickly leave the chamber. The latter will immediately be filled with coolant again.

The internal moving parts of the automatic air bleeder are gradually covered with scale, and the working openings are silted up. As a result, the mechanism seizes, and the gases exit slowly, water begins to flow through the needle assembly. Such an air release valve is easier to replace than to repair. Hence the conclusion: air vents are installed only in those places where you can’t do without them. They are selected for:

- boiler safety groups, where the coolant temperature is the highest;

- the highest points of vertical risers, where all gases rise;

- distribution manifold of underfloor heating, where air accumulates from all heating circuits;

- loops of U-shaped expansion joints made of polymer pipes turned upwards.

When choosing a device, you should pay attention to 2 parameters: maximum operating temperature and pressure.If we are talking about a heating scheme for a private house up to 2 floors high, then in principle any automatic air release valve will do. The minimum parameters of air vents offered on the market are as follows: operating temperature up to 110 ºС, pressure range in which the device operates effectively - from 0.5 to 7 bar

The minimum parameters of air vents offered on the market are as follows: operating temperature up to 110 ºС, pressure range in which the device operates effectively is from 0.5 to 7 bar.

In high-rise cottages, circulation pumps can develop higher pressure, so when choosing, you need to focus on their performance. As for the temperature, in the networks of private dwellings it rarely exceeds 95 ºС.

Advice. Practitioners recommend purchasing air vents with an exhaust pipe pointing upwards. According to reviews, a device with a side exit begins to leak much more often. In addition, during installation, it is necessary to strictly observe the vertical position of the housing.

Manual air vents for heating systems (Mayevsky taps) are most often used for mounting on radiators. Moreover, many manufacturers of sectional and panel appliances complete their products with gas removal valves. In this case, there are 3 types of air vents according to the method of unscrewing the screw:

- traditional, with slots for a screwdriver;

- with a stem in the form of a tetrahedron or another shape for a special key;

- with handle for manual unscrewing without any tools.

Advice. The third type of product should not be purchased for a home where preschool children live. Accidental opening of a faucet by them can lead to serious burns from the hot coolant.

What is a water check valve

Check valve is one of the types of valves. The essence of his work is to block the movement of the flow in the opposite direction. Its second task is to prevent pressure drop.

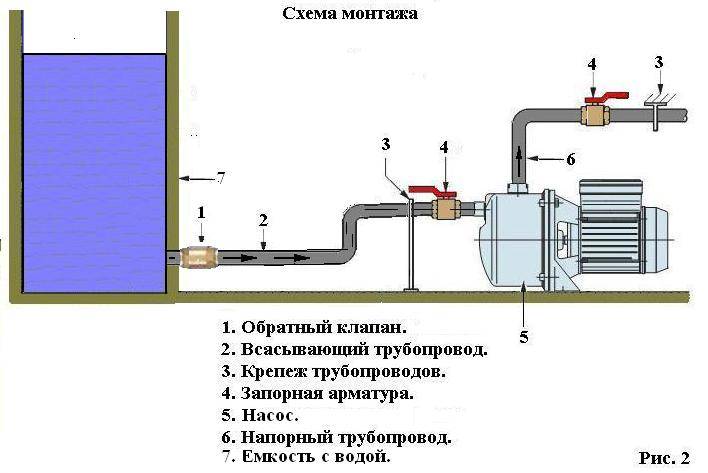

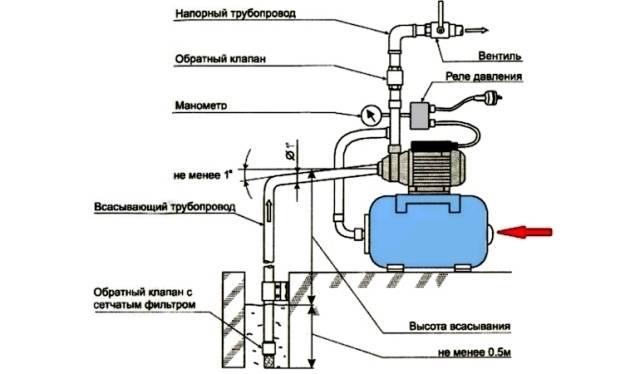

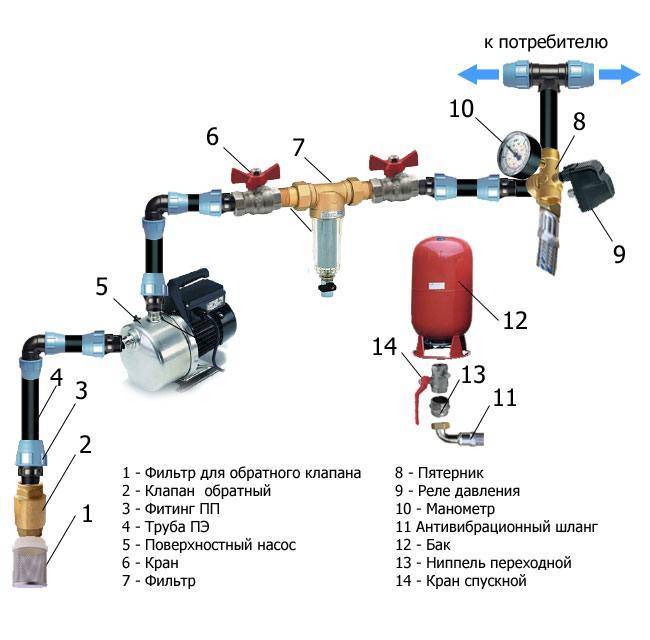

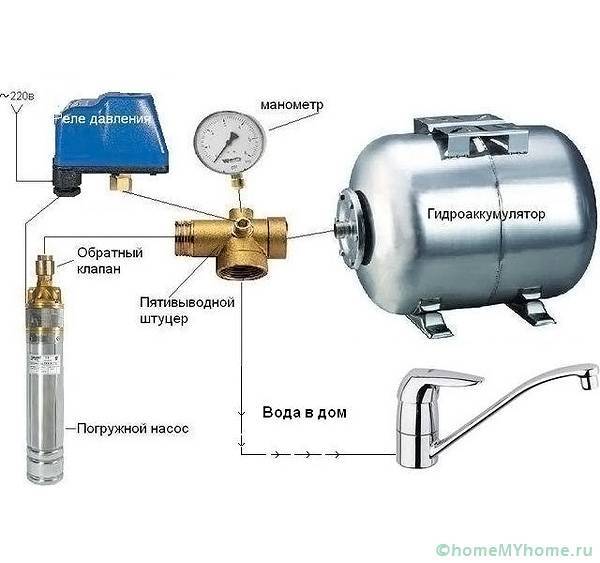

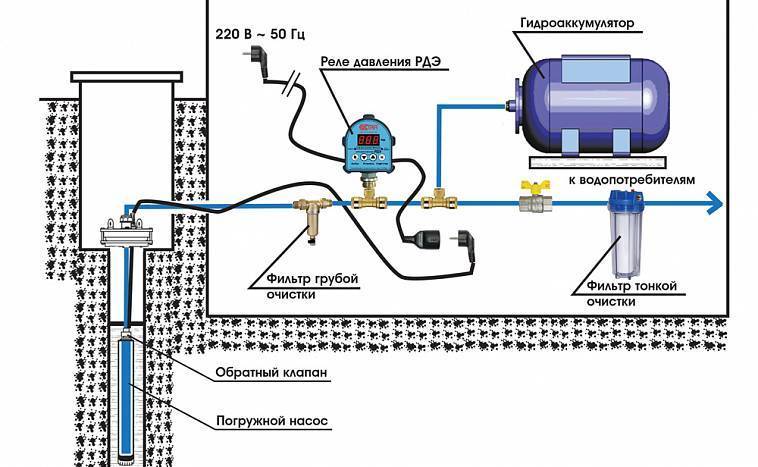

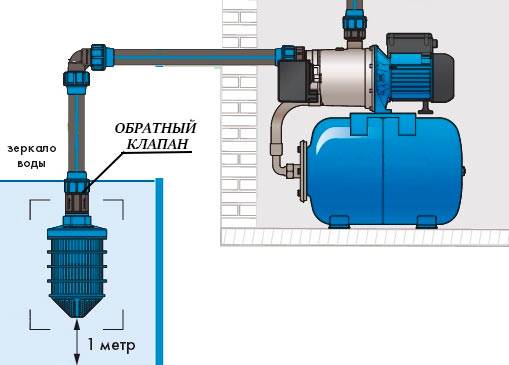

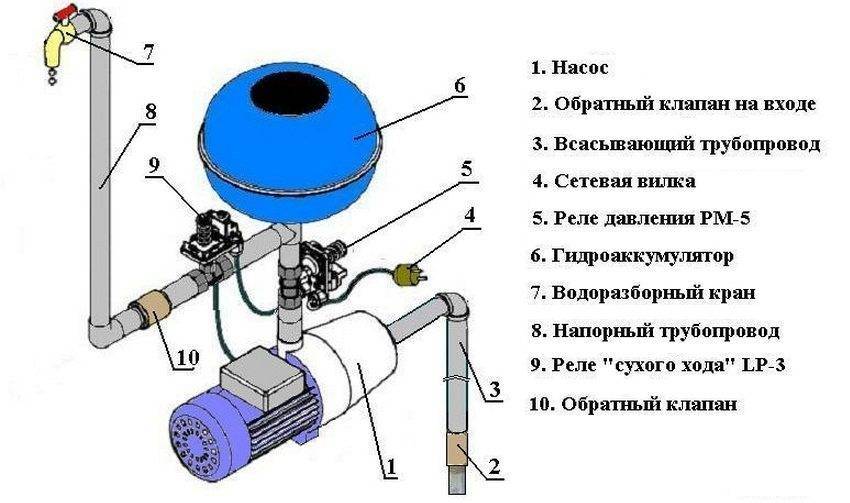

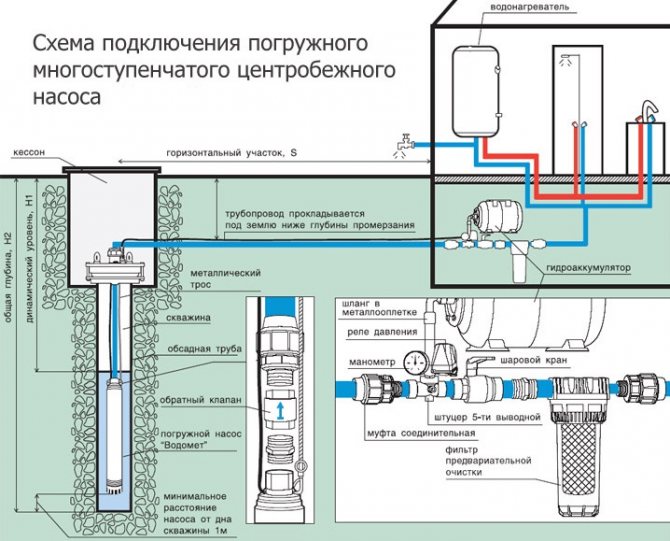

With regard to the water supply, it blocks the reverse movement of water. In private water supply systems (from wells or wells), the check valve is set so that after the pump is turned off, it retains water in the suction pipe. If the system is made on the basis of a pumping station, then most likely it contains a check valve. But this must be seen in the passport.

Illustration of the principle of operation of a shut-off valve

In apartments or with central water supply in the house, it is placed in front of the meter. But here his task is different - to prevent the possibility of "rewinding" testimony. The presence or absence of a check valve in this case does not affect performance. But its installation is a prerequisite for the operational organization. The seal is placed so as not to exclude unauthorized analysis of water.

Where else can a check valve for water be required? In the heating system. Not centralized, but private. It may contain circuits in which, under certain conditions, a reverse flow may occur. A non-return valve is also installed on such circuits. In the boiler piping, in the presence of a hygienic shower. These devices can also reverse flow. So a shut-off valve is needed.

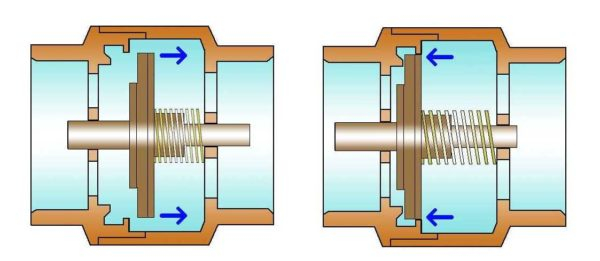

How does a water check valve work?

The principle of operation of the check valve is schematically shown in the figure:

The principle of operation of the check valve is schematically shown in the figure:

It is built on elementary physical and hydrodynamic laws. After the water stops flowing into the pipes, the spring tightens the shutter, completely closing it.As soon as pressure arises and begins to put pressure on the valve, the spring weakens and opens the way for the water flow. After the pump has switched off and the pressure has dropped, the valve is released again. The resistance of the spring increases under the action of the pressure itself, which prevents the valve from opening.

The sewer safety mechanism has a slightly different design and mode of operation. It consists of a body, a springy lever and a rounded plate with a gasket. When water begins to drain into the sink, the constipation opens. At the moment when the pressure has dropped, the lever closes it and prevents the sewage from flowing back into the bathroom.

What is forced circulation?

The natural circulation of the coolant occurs according to physical laws: heated water or antifreeze rises to the top of the system and, gradually cooling down, goes down, returning to the boiler. For successful circulation, it is necessary to strictly maintain the angle of inclination of the direct and return pipes. With a small length of the system in a one-story house, this is not difficult to do, and the height difference will be small.

For large houses, as well as multi-storey buildings. such a system is most often unsuitable - it may form air locks, disruption of circulation and, as a result, overheating of the coolant in the boiler. This situation is dangerous and may cause damage to system components.

Therefore, a circulation pump is installed in the return pipe, immediately before entering the boiler heat exchanger, which creates the necessary pressure and water circulation rate in the system.At the same time, the heated coolant is diverted to the heating devices in a timely manner, the boiler operates normally, and the microclimate in the house remains stable.

Scheme: elements of the heating system

- the system works stably in buildings of any length and number of storeys;

- it is possible to use pipes of a smaller diameter than with natural circulation, which saves the cost of their purchase;

- it is allowed to place pipes without a slope and lay them hidden in the floor;

- warm water floors can be connected to the forced heating system;

- stable temperature conditions extend the life of fittings, pipes and radiators;

- It is possible to regulate the heating for each room.

Disadvantages of a forced circulation system:

- calculation and installation of the pump is required, its connection to the mains, which makes the system volatile;

- The pump makes noise during operation.

The disadvantages are successfully solved by the correct placement of the equipment: the pump is placed in a separate boiler room next to the heating boiler and a backup power source is installed - a battery or generator.

Selection Tips

An ignorant homeowner who decides to look through the catalog of any well-known company in search of a three-way valve may be confused by the number and variety of products on offer. To help you choose the right valve from a wide range, we will give you some recommendations and start with a list of brands whose catalogs are generally worth checking out. Here is a list of well-known companies whose products are trustworthy:

- Danfoss (Denmark);

- Herz Armaturen (Austria);

- Honeywell (USA);

- Icma (Italy);

- Esbe (Sweden);

- Caleffi (Italy).

Now the main block of recommendations:

- To protect the solid fuel boiler from condensate, you can choose 2 types of three-way valves - with a fixed setting and a thermal head with a remote sensor. The second option will cost 20-30% more and is not always justified, since changing the return temperature is unnecessary here. Purchase a regulator with an internal thermostat set to 50 or 55°C.

- To control the heating of individual branches and circuits of underfloor heating, a 3-way valve with an external sensor and a thermostatic head is definitely needed. The sensor flask is installed on the manifold or pipeline whose temperature is to be controlled.

- Ball (they are also rotary) regulators are paired with an electric drive or set manually. If you do not want to complicate the circuit and depend on electricity, choose a product that is suitable for its characteristics among saddle valves powered by thermal heads.

- The most common case material is brass or bronze. Stainless elements are more expensive, and cast iron is afraid of temperature shock and has a decent mass.

- In the schemes, both mixing and dividing three-way valves are used with equal success. But if you are not a specialist in the field of heating and assemble the system with your own hands, then it is better to take a mixer valve. It is easier to deal with it and put it correctly, which the expert will tell in detail in his video:

How to install the valve correctly

The easiest way is to install a check valve in a coupling version. It is suitable for embedding in heating and water supply systems both in apartments and in private houses.

To protect metering devices and other network segments from the occurrence of water hammer, you must perform 3 simple steps:

-

Choose a location. In apartments, a water return valve is usually inserted to the meter or in front of the heating boiler.

-

Take the fittings of the required diameter and wrap the sealant on the thread: tape, thread or linen.

-

Fix the device with fittings, open the water tap and check the connection for leaks.

Let's give some advice:

-

In the circuit of the working water supply system, the valve is installed in front of the pumping station. To do this, a place is chosen on the pipe where a break is made, and connected with a locking device.

-

As part of the sewer, the valve will help prevent the flow of waste and sewage in the opposite direction. Installation is carried out on pipes of suitable diameter using a tie-in. The valve diameter can be 50-100 mm. Cast iron or plastic connections are made with a special adapter.

-

In a single-circuit heating system, a valve is necessary to create coolant pressure due to heating, without using a pump. Installation is carried out similarly to the process of installing a valve on a water supply system.

Sometimes even reliable shut-off valves fail. If a breakdown occurs, you need to learn how to disassemble the check valve. This is not difficult. First you need to block the flow of working fluid and drain it from the system. Then you should unscrew the nuts, dismantle the flanges or fittings. The final stage is the removal of the locking unit and the replacement of failed parts. Assembly is carried out in reverse order.

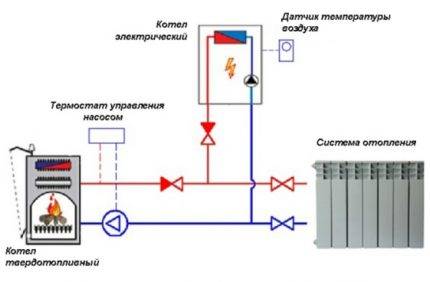

Options for working connection diagrams

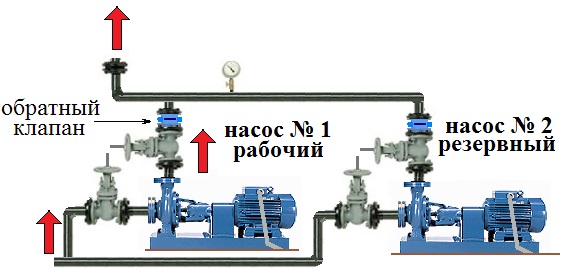

Heating systems are very diverse and the presence of a check valve is not necessary in all.Consider several cases when its installation is necessary. First of all, a check valve must be installed on each of the individual circuits in a closed circuit, provided that they are equipped with circulation pumps.

Some craftsmen strongly recommend installing a spring-type check valve in front of the inlet pipe of the only circulation pump in a single-circuit system. They motivate their advice by the fact that in this way pumping equipment can be protected from water hammer.

This is in no way true. Firstly, the installation of a check valve in a single-circuit system is hardly justified. Secondly, it is always installed after the circulation pump, otherwise the use of the device loses all meaning.

If two or more boilers are included in the heating circuit, the occurrence of parasitic flows is inevitable. Therefore, the connection of a non-return valve is mandatory.

If two or more boilers are included in the heating circuit, the occurrence of parasitic flows is inevitable. Therefore, the connection of a non-return valve is mandatory.

For multi-circuit systems, the presence of a reverse-acting shut-off device is vital. For example, when two boilers are used for heating, electric and solid fuel, or any others.

When one of the circulation pumps is turned off, the pressure in the pipeline will inevitably change and a so-called parasitic flow will appear, which will move in a small circle, which threatens trouble. Here it is impossible to do without shutoff valves.

A similar situation occurs when using an indirect heating boiler. Especially if the equipment has a separate pump, if there is no buffer tank, hydraulic arrow or distribution manifold.

Here, too, there is a high probability of a parasitic flow, to cut off which a check valve is needed, which is used specifically for arranging a branch with a boiler.

The use of shut-off valves is also mandatory in systems with a bypass. Such schemes are usually used when converting a scheme from gravitational fluid circulation to forced circulation.

In this case, the valve is placed on the bypass in parallel with the circulation pumping equipment. It is assumed that the main mode of operation will be forced. But when the pump is turned off due to a lack of electricity or a breakdown, the system will automatically switch to natural circulation.

When arranging bypass units for heating circuits, the use of check valves is considered mandatory. The figure shows one of the possible options for connecting the bypass

This will happen as follows: the pump stops supplying the coolant, the check valve actuator stops under pressure and closes.

Then the convection movement of the liquid along the main line resumes. This process will continue until the pump starts. In addition, experts suggest installing a check valve on the make-up pipeline. This is optional, but highly desirable, as it avoids emptying the heating system for a variety of reasons.

For example, the owner opened a valve on the make-up pipeline to increase the pressure in the system. If, due to an unpleasant coincidence, the water supply is cut off at this moment, the coolant will simply squeeze out the remnants of cold water and go into the pipeline. As a result, the heating system will remain without liquid, the pressure in it will drop sharply and the boiler will stop.

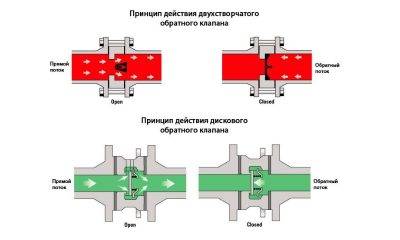

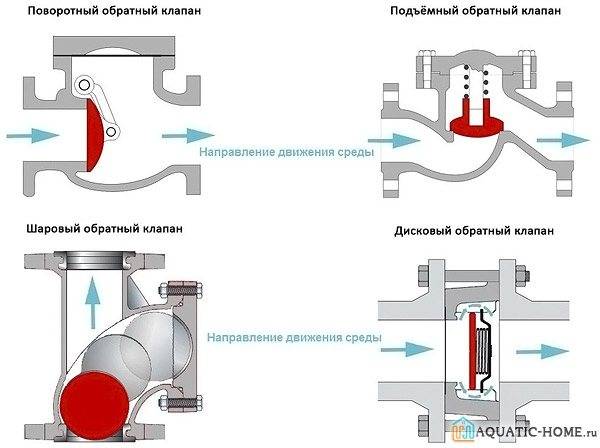

In the schemes described above, it is important to use the right valves. To cut off parasitic flows between adjacent circuits, it is advisable to install disk or petal devices

In this case, the hydraulic resistance will be less for the latter option, which must be taken into account when choosing.

In heating systems with natural circulation of the coolant, the use of spring check valves is impractical. Only paddle rotators can be installed here

For the arrangement of the bypass assembly, it is preferable to choose a ball valve. This is due to the fact that it gives almost zero resistance. A disc-type valve can be installed on the make-up pipeline. It should be a model designed for a fairly high working pressure.

Thus, the non-return valve may not be installed in all heating systems. It is necessarily used when arranging all types of bypasses for boilers and radiators, as well as at branching points of pipelines.

Materials, markings, dimensions

The check valve for water is made of stainless steel, brass, large sizes of cast iron. For household networks, they usually take brass - not too expensive and durable. Stainless steel is certainly better, but it is usually not the body that fails, but the locking element. That's his choice and should be approached carefully.

For plastic plumbing systems, check valves are made from the same material. They are polypropylene, plastic (for HDPE and PVD). The latter can be welded / glued or threaded. You can, of course, solder adapters to brass, put a brass valve, then again an adapter from brass to PPR or plastic. But such a node is more expensive.And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are non-return valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it's hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to work. Plastic wears out faster, but it does not wedge. In this regard, it is more reliable. No wonder some manufacturers of pumping stations put check valves with plastic discs. And as a rule, everything works for 5-8 years without failures. Then the check valve begins to "poison" and it is changed.

What is indicated in the label

A few words about the marking of the check valve. It states:

- Type of

- Conditional pass

- Nominal pressure

-

GOST according to which it is made. For Russia, this is GOST 27477-87, but not only domestic products are on the market.

Conditional pass is designated as DU or DN. When choosing this parameter, it is necessary to focus on other fittings or the diameter of the pipeline. They must match. For example, you will install a water check valve after a submersible pump, and a filter to it. All three components must have the same nominal size. For example, all should be written DN 32 or DN 32.

A few words about conditional pressure. This is the pressure in the system at which the valves remain operational. You need to take it exactly no less than your working pressure. In the case of apartments - no less than a test one. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. The pressure for your home can be obtained from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it indicates in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. Therefore, they are popular.

The opening pressure characterizes the “sensitivity” of the valve. For private networks, it rarely matters. Unless on the supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external. Choose based on ease of installation

Do not forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of the check valve for water is calculated according to the nominal bore and they are released for everything - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are of the same size as all other shutoff valves: taps, valves, spurs, etc. Another "size" can be attributed conditional pressure. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Then there are the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And yet, please note that for different companies with the same conditional passage, the external dimensions of the device may differ.Length is clear

Here the chamber in which the locking plate is located can be larger or smaller. The chamber diameters also differ. But the difference in the area of the connecting thread can only be due to the wall thickness. For private houses, this is not so scary. Here the maximum working pressure is 4-6 atm. And for high-rise buildings it can be critical.

How to check

The easiest way check valve check - blow into it in the direction that locks it. Air must not pass. Generally. No way. Also try pressing the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a non-return valve: blow into it and check for smoothness

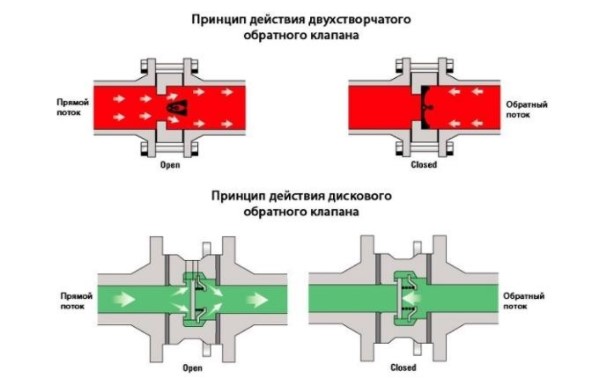

Types of locking elements

Any non-return valve (the obsolete name is non-return) performs a simple task - it does not allow the coolant flow to change direction, passing fluid in only one direction. In water heating circuits, this function is not always needed and is implemented as needed.

The following types of non-return valves are used in heating systems of private houses and apartments:

- petal;

- dish-shaped;

- ball.

Industrial models are installed in large boiler houses and production facilities

We will analyze the device and the principle of operation of each type of valve separately. In the future, this will help you understand which product is better to choose and install in a particular heating system.

Reed valves

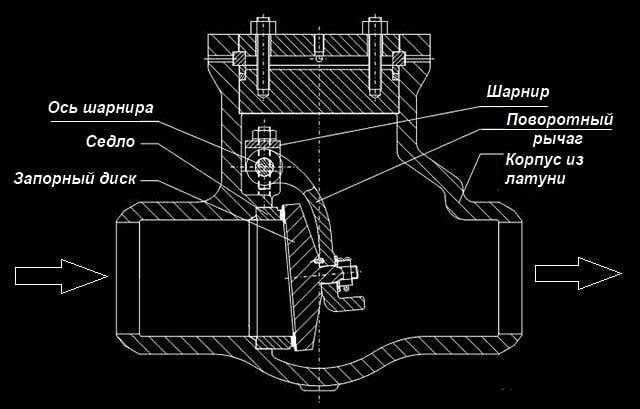

An element made of brass or stainless steel consists of the following parts:

- housing in the form of a tee with an unscrewing top plug (for maintenance);

- butterfly valve fixed on the axis by means of a rotary lever;

- a seat with a seal where the disc rests when closed.

The general arrangement of the leaf check valve is shown in the detail drawing. The principle of operation of the element is as follows: the coolant moving in the indicated direction deflects the locking disc and freely passes further along the pipe. When the direction of the water flow is reversed, the shutter automatically closes under the influence of gravity (or spring) and closes the passage.

Typical design with gravity lock

We list the important characteristics of petal check valves installed in the heating systems of private houses:

- diameter of the internal passage - from 15 to 50 mm (½-2 inches);

- maximum working pressure - 16 bar;

- low hydraulic resistance;

- on the side of the body there is a screw for disassembling and adjusting the axis of the shutter;

- gravity version without spring can only work normally in horizontal position.

A detailed design and principle of operation of the rotary valve is shown in the video:

Poppet valves

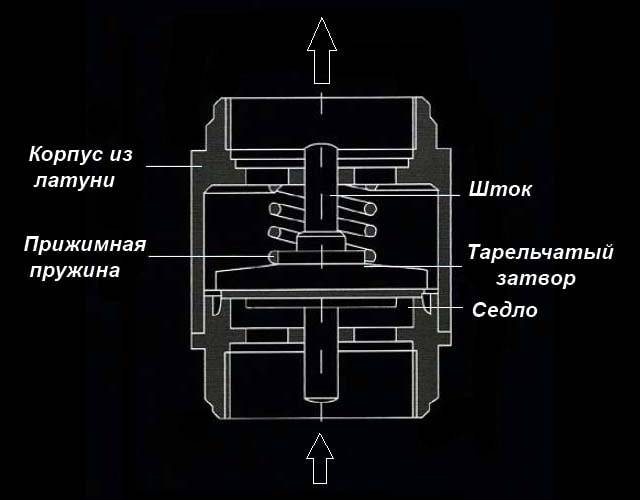

The principle of operation of the poppet check valve is clear from its design shown in the drawing:

- Inside the cylindrical brass body there is a platform with a round hole - a saddle.

- On the other side of the part, a partition is made with a hole in the center.

- A rod with a poppet-shaped valve at the end, equipped with a seal, is inserted into the opening of the partition.

- A spring is installed between the partition and the "plate", pressing the disc to the seat.

Water flowing in the right direction overcomes the spring force, opens the gate and moves on. In the opposite direction, the flow is impossible - the duct closes instantly. What properties of the check valve are important for heating systems:

- the ability to function at any orientation of the body in space;

- working pressure - not less than 10 bar, diameters DN15 - DN100 (internal);

- type of connection - coupling (internal pipe thread);

- spring constipation creates increased hydraulic resistance to fluid flow;

- the seal loses its tightness in the event of ingress of solid particles, such as sand.

In the engineering networks of private houses and apartments, valves with coupling connections are used

Disc locks are also used in water supply networks, for example, in conjunction with submersible pumps. The valve does not allow water from the pipelines to flow back into the well or well.

ball valves

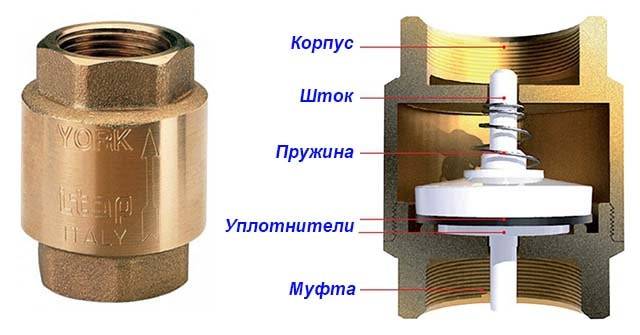

This is a check valve of the simplest design, operating according to the following principle:

- Inside the cylindrical brass case is placed a ball made of rubber, less often aluminum.

- The ball is not allowed to jump out by 2 partitions with holes made along the edges.

- The coolant flow presses the rubber ball against the partition with ribs. These protrusions form a gap where water flows freely.

- If the coolant moves in the opposite direction, the ball will press against the second jumper - the saddle. Since there are no ribs, the ball body will completely cover the bore.

The advantages of a ball check valve are low price, low hydraulic resistance and operation without any springs in any position, although vertical is preferable. The disadvantage is the loss of tightness when the pressure rises to 6-7 bar, which does not happen in individual heating networks.

For a closer look at the ball valve, watch the following video: