- Features of installing a locking device

- How is the vacuum valve arranged?

- Types of valves and principle of operation

- Swivel

- Lift valve for sewerage

- ball valve

- Wafer type

- What is a check valve for sewerage 110 mm and a different size

- Types of dry shutters

- When is the only solution to install a vacuum valve?

- Advantages and disadvantages of the sewer element

- How does a vacuum valve work and how is it arranged?

- Types of back-locking devices

- Device and features of work

- Types of check valves and the principle of their operation

- Swivel (petal)

- Lift check valve for sewerage

- Ball check valve

- Wafer type

- Materials, markings, dimensions

- What is indicated in the label

- Dimensions of check valves for water

- How to check

- Which valve to buy?

Features of installing a locking device

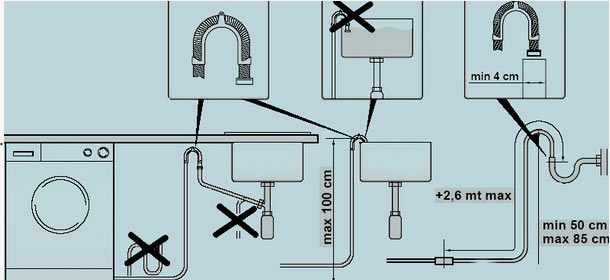

The best option for installing a shut-off valve is to repair an apartment or build a house. It is at this stage that it is easiest to design its location and calculate the required pipe length. In this case, the locking device will be mounted during the assembly of the entire sewer system.

Plastic check valves for arranging internal sewer networks are produced with shaped elements that facilitate installation and decorate the places of passage through building structures

Plastic check valves for arranging internal sewer networks are produced with shaped elements that facilitate installation and decorate the places of passage through building structures

Most often it happens that no one plans to do repairs, but the valve must be installed. Then you should choose this device, based on the realities of your sewer system. If the shut-off valve has already been selected and purchased, you can deal with the issue of its installation.

There are 2 options:

- do everything yourself;

- call a plumber.

Depending on the material of the pipes in the apartment / house, the installation methods and the list of works required for this will differ. The price of the issue will also differ - for cast-iron fittings, removing a part for installing a shut-off valve in this place is much more expensive than a similar amount of work with plastic materials.

When the option with the invitation of the master is chosen, then only funds will be required to pay for his services. It is also advisable to control the work and check the quality of the installation so that there are no problems later. It is best to contact a plumber serving the house / assigned to a certain territory.

The non-return valve is connected to the plastic sewer pipeline using a connecting element designed to exceed the standard pressure in the network. He does not allow leaks.

The non-return valve is connected to the plastic sewer pipeline using a connecting element designed to exceed the standard pressure in the network. He does not allow leaks.

If you decide to do everything on your own, then you need, first, to look at the installation theory or read a brief instruction on installing a check valve on the sewer system.

Firstly, you will need to check the purchased device in action before installing it. To do this, you can use, for example, a jet of water from a tap.After testing the performance of the valve and making sure that it passes water in only one direction, you can proceed to the next step.

The second step is to measure the length of the reverse device and mark the place of its installation, taking into account these dimensions.

It is important here that there is free access to the valve - periodically it will be necessary to carry out an audit

When everything is marked out, it is necessary to remove / cut off a section of the pipe, in place of which a locking device will be put. When installing, you must use an o-ring and sealant or fum tape to ensure a secure connection and prevent leakage.

To connect a check valve at the point of change in the direction of the sewer branch, elbows with seals are used. They allow you to create an optimal bending angle and ensure a reliable connection.

To connect a check valve at the point of change in the direction of the sewer branch, elbows with seals are used. They allow you to create an optimal bending angle and ensure a reliable connection.

Similarly, you have to do with the rest of the shut-off valves, if you plan to install separate shut-off devices for each plumbing fixture.

You should correctly position the valve using the instructions that came with the device, or you can look at the red arrow indicating the direction of movement of sewage.

When all the joints of the sewer pipe with the shut-off valve are securely insulated, you should check the work carried out in action by opening the tap or draining the water in the drain tank. If nothing leaks at the installation site, then everything is done with high quality and you don’t have to worry.

The option with separate blocking devices on each plumbing fixture is more convenient - this way the apartment will be more reliably protected in the event of a sewer blockage

When installing a shut-off valve in a common sewer pipe in a country house / cottage, you should also ensure free access to it, even if it is located outside. The outer part of the sewer, together with the device and other fittings, should be provided with a heating cable or a thermal insulation system.

How is the vacuum valve arranged?

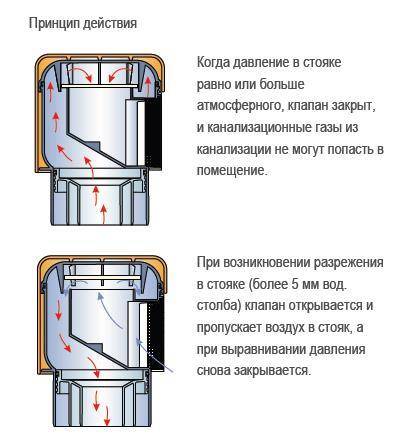

Already from the purpose of this device it is clear that it must remain closed at excess pressure in the sewer pipe or when it is equal to atmospheric pressure. But if a vacuum occurs in the pipe, the valve mechanism must ensure the opening of the passage for air to enter from the outside.

The principle is easily implemented with the "attraction" of ordinary gravitational forces. The diagram below shows the device of one of the models of aerators. Despite the possible difference in the design of valves from different manufacturers, the principle remains practically the same.

An example of a device and a demonstration of the principle of operation of a vacuum valve for sewers.

The entire valve mechanism is assembled in a polymer housing (item 1). By itself, the device implies only a horizontal arrangement, therefore, in its lower part, one or another device is necessarily provided for a tight connection with a sewer pipe. In the example shown, this is an elastic cuff (pos. 2) for inserting the aerator into a socket or even just into a cut pipe. There may be a connecting node in the form of a standard socket of sewer pipes or other options. But always this installation is simple, reliable and understandable.

Air can enter the aerator through the intake grille or slotted holes (item 3).They are located on the bottom or side of the valve "head", but outside air will almost always push against the valve diaphragm from below.

This is very easy to explain. The valve damper (pos. 5) is located in the seat allotted to it (pos. 4) and fits snugly to its edges with an elastic cuff (membrane), not letting air from the pipe into the room. And the fit is provided by the banal gravity of this damper. That is, even if the atmospheric pressure and the pressure established in the pipe (riser) are equal, the valve will be closed. Some more excess pressure in the pipe can contribute to this, since gas formation almost never stops in the sewer. That is, the flap will thereby be pressed even more against the saddle (in the diagram, this is the left fragment).

But if for one reason or another even a slight vacuum is created in the pipe, atmospheric pressure will overcome gravity and lift the damper above the saddle. As the saying goes, “nature abhors a vacuum,” and outside air will rush into the pipe, equalizing the pressure and preventing the siphons from breaking.

To prevent the damper from warping, it may have special guides (pos. 6). However, many models do without them - centering is done due to the cylindrical shape of the valve assembly.

Aerator for 110 mm pipe - model with two valve heads. One of them was dismantled to demonstrate its simple device.

Out of pure curiosity, you can “disassemble” a few more vacuum valves of various models. But we still won't find any fundamental differences there.

Differences in the design of various models of valves are unprincipled.

By the way, since the device is being considered, you can immediately draw the attention of readers to the “Achilles heel” of any valve. This, of course, is the membrane itself, or rather, that area of it, which is pressed against the valve seat by gravity.

And here we are not talking about wear (if it is, it is very invisible), but about other obstacles that can place the sash in a hermetic fit:

- Over time, dust can accumulate on the valve seat or on the membrane itself, which can turn into hard lumps of dirt that prevent the leaf from fitting snugly. Often, the owners are informed about this by the “aroma” of sewerage that has appeared in the premises. The first thing to do with such a “bell” is to check the cleanliness of the membrane and its fit, to carefully clean the assembly from contamination.

- The second conclusion is that the vacuum valve must be installed only in a heated room at home. Otherwise, with the onset of cold weather, drops of condensate may freeze on the seat or on the membrane, and the valve mechanism will not fit. And in general, too large temperature drops do not benefit the rubber membrane - it begins to “tan” in the cold, losing the necessary elasticity.

Otherwise, the mechanism is utterly simple, and it is difficult to come up with any circumstances that would lead to a breakdown of the vacuum valve.

Types of valves and principle of operation

There are several varieties of sewer check valves for 110 and 50 millimeters, which differ in scope. Accordingly, all types of mechanisms have a different design and principle of operation of one element.

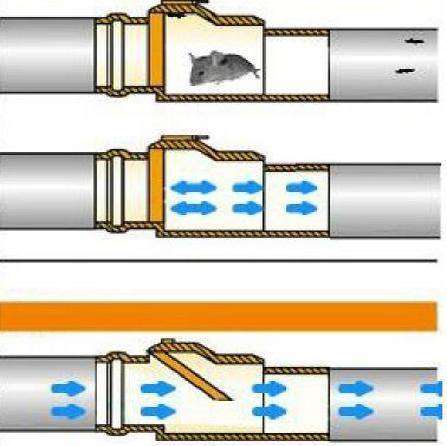

When waste liquids come up, the damper automatically rises, after which it returns to its original position again. It is according to the mechanism of operation of the damper that models of sewer check valves are classified.

Swivel

This type of sewer valves has a spring-loaded membrane (it is called a plate because of its round shape). In the case when the wastewater moves in the right direction, the plate turns and goes up without interfering with the movement of liquids.

However, with the opposite direction of the drains, the spring-loaded membrane is tightly pressed against the outer rim, as a result of which the working area of the pipeline is blocked.

Some models additionally have a built-in additional damper, which is controlled manually. A similar locking mechanism can be adjusted using a special button located on the device.

Thus, the pipeline has first an expanding and then a narrowing section, which is a possible place for the formation of a blockage in the sewer system. The solution to this problem is the placement of the cover mechanism at the top of the housing. Having removed it, it is possible to quickly and easily remove the blockage that has appeared.

Lift valve for sewerage

The name of this type of device is based on the mechanism of operation of the damper. When the wastewater moves in the right direction, the damper is at the top.

Principle of operation: the liquid exerts pressure on the membrane, which blocks the movement of drains, the internal spring is compressed, as a result of which the damper rises. If the sewage does not move, then the spring is in its normal state, and the path to the drains is blocked.

Due to the non-linear body shape, when the liquid moves in the opposite direction, the valve cannot be opened, which ensures complete safety against flooding.

This type of check valve for 110 or 50 mm sewerage is more reliable than a rotary (petal) model, but there is a drawback.

The peculiarities of the form are the reason for the need for regular cleaning of the system, because. it gets dirty from time to time. To perform this procedure, you will need to unscrew the bolts (4 pcs.), Then thoroughly clean or, if necessary, replace the working mechanism. If the owner has the opportunity to perform regular cleaning, then it is better to purchase just such a variant of the check valve.

ball valve

In this type of device, the locking element is a small ball. The upper part of the body is designed in such a way that during the flow of sewage, the ball enters a separate hole and allows the flow to move.

When there is no liquid, the working area of the pipe is blocked, as a result of which the flow is not able to pass in the wrong direction. However, such models have a drawback - in contrast to the rotary and lifting mechanism in this design, the valve-ball does not completely adjoin the rim of the device.

As a result of leakage, a small flow of sewage water may occur. Of course, the likelihood of serious flooding, as if the sewer check valve was completely absent, is minimal.

Wafer type

The main advantage of this type of locking mechanism is its small size, which makes installation possible even in the absence of free space behind plumbing fixtures.Externally, the device looks like a miniature cylinder with a special butterfly valve.

This element can consist of 2 components, which are fixed at the central rod, or in appearance resemble a small plate, which is fixed to the body using a spring mechanism.

It is advisable to install such an option only if other varieties cannot be installed. Even taking into account the small size, it is still desirable to give preference to other types of device. A 50 mm wafer check valve is rarely installed on the sewer, because. belongs to the category of equipment for water supply. For sewer systems, its efficiency is quite low.

Another disadvantage of this design is the inability to quickly clean the device. Due to the nature of the shape, it will be necessary to completely disassemble the connection in order to clean the valve.

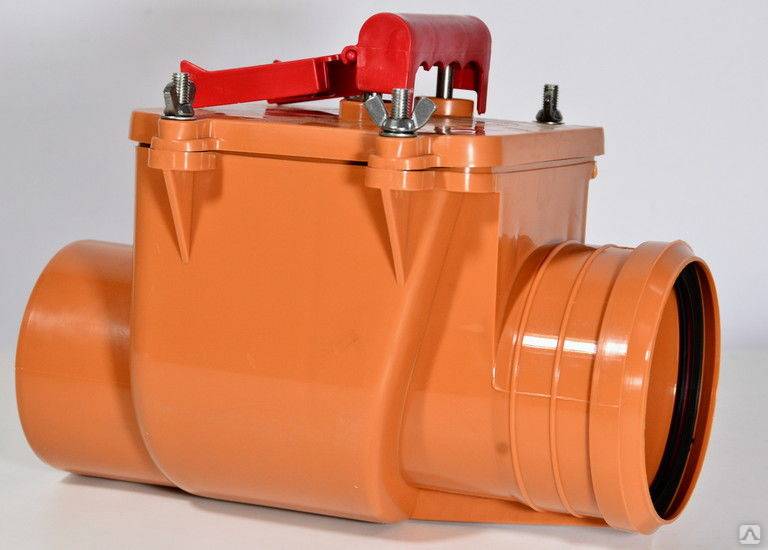

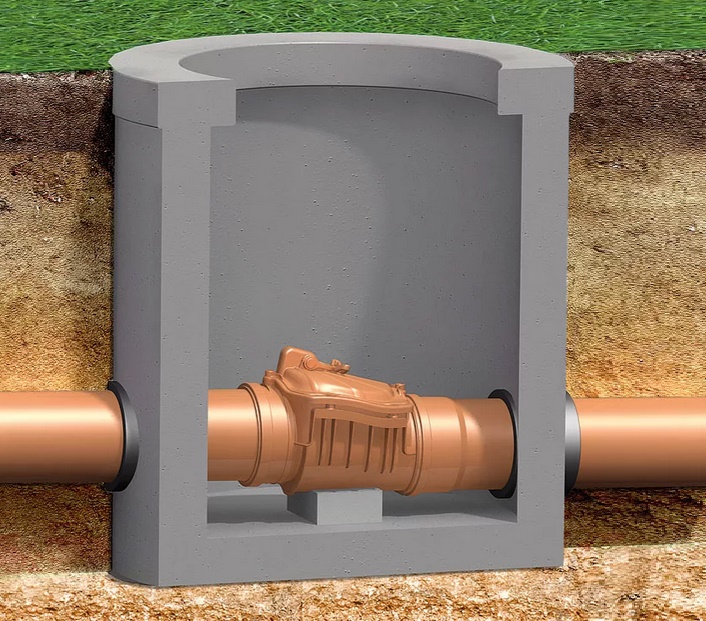

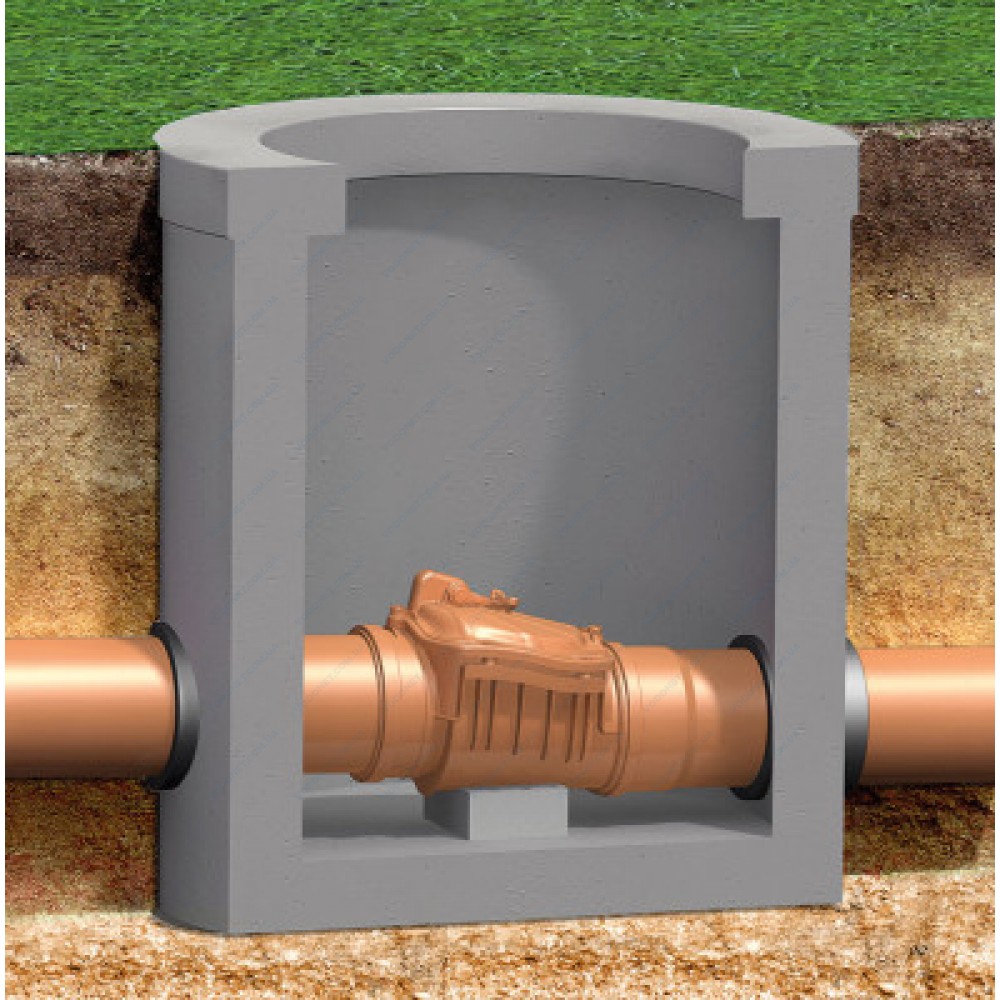

What is a check valve for sewerage 110 mm and a different size

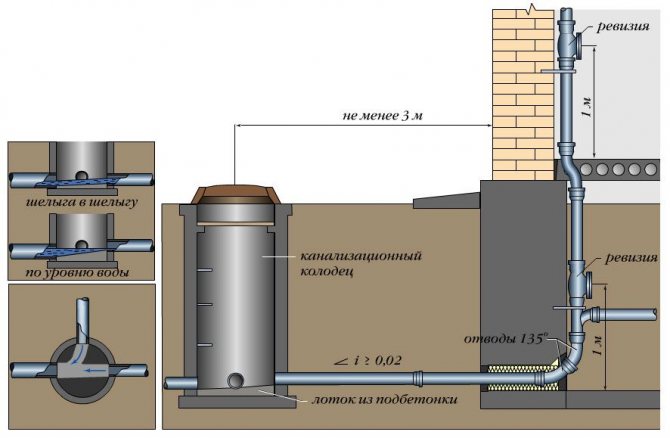

A check valve is a type of shutoff valve. It is installed in the lumen of the pipeline to block the reverse flow of liquid in case of system clogging. The device is mounted in the basement on a horizontal section of a common sewer at the pipe junction. It can also be installed at a 90º pipe bend.

For maximum safety, a 50 mm sewer check valve can also be installed on the outlets to plumbing fixtures on the first and second floors of an apartment building. Such an enhanced measure is justified by the fact that faecal water, during a reverse outflow, can only rise above the first floor.Further, the accumulated mass is able to independently push through the plug formed in the pipe.

A non-return valve can be installed at a 90º bend in the pipeline

For the private sector, the check valve is mounted before being released into the sewer well (for each house separately - on the inside of the foundation). Such a device is also intended for an autonomous system, where wastewater accumulates in a drain pit or in a septic tank. In this case, you should worry about how to fill the lid on the sewer with your own hands.

The check valve is characterized by simple structure, reliability, efficiency, durability, easy installation and convenient maintenance.

Types of dry shutters

Dry shutters, like any other devices, have varieties. Each of them has its own distinctive characteristics that affect performance. Consider the main models of this device:

Membrane. Such a device is the simplest and most common of all options. The working process takes place thanks to a spring-loaded membrane, which opens under the influence of a liquid flow and water freely enters the sewer system. When the flow is blocked, the membrane takes its original position, resulting in a reliable and tight barrier.

Float. This type of shutter is quite capable of being made at home. According to the design features, such a shutter is considered a combination of water and dry types. It includes a ladder with a vertical outlet, equipped with a float valve. When assembling such a device at home, tennis balls of a suitable diameter are used.

The principle of operation of such a device is quite simple: if the water seal is filled with water, then the float valve is in a floating position and does not interfere with the outflow of fluid into the sewer. When the water leaves the float valve lowers and seals the lumen of the tube.

The pendulum valve closes the flow thanks to a valve that moves under the action of water

Pendulum dry. It is supplied with a valve, which necessarily has one attachment point. When a fluid stream hits the valve surface, it deviates from its axis and opens the fluid path. Return to the reverse position occurs under the influence of gravitational forces.

Locks with molecular memory. Such devices are considered high-tech and their cost is an order of magnitude higher than other models. Thanks to the molecular memory of the material, their elements always return to the desired position, sealing the structure.

When is the only solution to install a vacuum valve?

As a rule, pipes are used to connect the toilet to the central sewerage system, inside which gases are always present. In any case, a large amount of both cold and hot water is flushed into the sewer, while, according to the law of physics, hot steam rises.

To quickly solve such a problem, you need to immediately tighten the plug at the end of the riser. To eliminate unpleasant odors, you need to install special water seals. If there is no ventilation on the riser, then due to the powerful flow of water in the pipe, a vacuum is created when the toilet is drained. As a result of this phenomenon, the contents of the nearby water seal are taken. After some time, an unpleasant smell from the sewer may be felt in the room.To prevent such a nuisance, many experts recommend installing a vacuum valve at the highest point of the riser.

You can decide whether to install this element by paying attention to the following tips:

- Using a vacuum valve, you can effectively solve the problem of ventilation of the sewer riser in a low-rise building. If there is a simultaneous drain of several toilet bowls, then the device is unlikely to cope with its intended purpose;

- you cannot independently cut off the fan riser leading to the attic in a house with several floors in order to install a vacuum valve. In such situations, apartments located on the upper floors are unlikely to suffer from unpleasant odors, but on the lower floors there will be a clear sewer smell. One way or another, experts will identify the cause of the problem, which will have to be fixed at their own expense.

Advantages and disadvantages of the sewer element

The advantages of a vacuum valve include:

- no need to make a special hole in the roof to remove the riser pipe. The roofing remains intact, while the process of installing the sewerage system is greatly simplified;

- the sewer riser ends exactly inside the building, so the appearance of the house will not deteriorate due to the installation of numerous pipes to create ventilation, which are not cheap;

- there is no need to perform periodic maintenance and repair of the device.

The disadvantages include:

- danger of failure under heavy load on the sewer system;

- the vacuum valve is quite expensive, this is due to the fact that the device is made by hand.

How does a vacuum valve work and how is it arranged?

If normal pressure is observed in the sewer pipeline, then this device will be closed. As a result of this phenomenon, protection against the ingress of unpleasant odors and harmful fumes into the room is provided. When pressure is released, such as when flushing a toilet, the vacuum valve opens automatically, allowing air into the system. In the process, pressure equalization is performed.

Such an element for sewage can be used to create local aeration. To do this, the valve is installed on the pipes of plumbing devices, the use of which involves a large flow of water.

In order for such a solution to be as effective as possible, you must follow the installation rules:

- the valve must be installed on the sewer riser above the point of supply of the plumbing device;

- installation must be carried out in a room that is well ventilated, it can be an attic, a toilet or a bathroom. In addition, access to the device for periodic technical inspection should be provided;

- the vacuum valve should only be installed on the vertical area of the pipe.

This sewer device is a simple fitting, so you can attach it using a seal.

The item package includes the following parts:

- a plastic case with a side hole;

- a rod that, if necessary, is able to open a side hole;

- so that the stem does not move up, a special rubber gasket is installed;

- the rod assembly is securely closed with a protective cover connected to the body.

On sale there are vacuum valves having a diameter of 50 and 110 mm.The first option can be installed in homes equipped with no more than two plumbing fixtures or in cases where a small water flow is provided.

Types of back-locking devices

At the installation site, all check valves designed for pumping equipment are divided into two categories:

- for mounting on the suction pipe of a surface pump or through an adapter to a submersible pump;

- for pipeline installation.

The former prevent the reverse movement of water and ensure that the system is constantly filled, the latter regulate the pressure in the water supply.

We recommend installing both types of check valves, as the functions of the devices are different. The valve on the suction hose additionally protects the pump from "dry running", prevents the occurrence of air pockets, that is, it is responsible for the health of the pump. Even if the equipment is initially equipped with the option of protection against "dry running", thanks to the check valve, you will not have to constantly fill in water.

Installing such a valve at the suction point is a must. But to stabilize the pressure in the system, a similar device is mounted in front of the pumping station or in front of the hydraulic tank, if it is located separately

Valves that are installed on the pipe in the house wiring prevent the liquid from returning to the outside - to the pump or well. They maintain the required water pressure and regulate the pressure. The main function of pipe models is considered to be the protection of pumping and plumbing equipment from sudden pressure surges and water hammer.

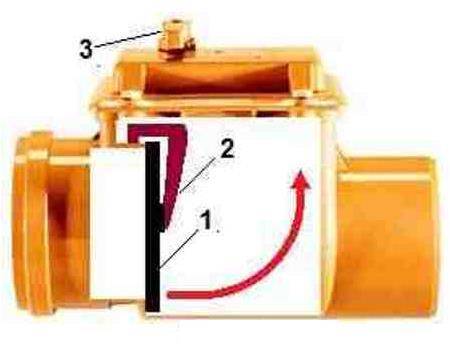

Device and features of work

A modern non-return valve has a solid body in the form of a hexagon, the inner part of which is divided into several separate compartments: a receiving compartment, a restrictor with a secure fixation of the shut-off unit and the function of a small inspection window, as well as an outlet compartment.

The receiving area is located directly in front of the locking mechanism that connects the inlet to the product with the sewer. A special limiter is necessary for the free movement of the drained liquid in only one direction.

If the water begins to move in the opposite direction, the device instantly closes. The outlet compartment is needed to quickly remove wastewater from the restrictor section, therefore it is considered a connecting element between the mechanism and the outgoing circuit.

The principle of operation of the check valve is based on shutting off the pipeline with the help of a shutter mechanism. This occurs when the free movement of effluents along the circuit completely stops.

The device equalizes the pressure in the system, and constipation, due to gravity, closes the pipeline and closes the valve.

The device is controlled mechanically or automatically. The nominal size of manufactured fixtures ranges from 50 to 300 mm. Due to the design features, the device can be mounted at a specific junction of two pipes in a horizontal or vertical plane. And also it is connected to the main riser or to each drain of plumbing mechanisms.

Types of check valves and the principle of their operation

The main task of the check (shut-off) valve is to block the flow going in the opposite direction. To do this, a movable barrier is placed in these mechanical devices.The basic principle of operation is that in a calm state, the mechanical damper is lowered down, blocking the lumen of the sewer pipe and preventing the reverse flow from passing. When drains appear, it rises (moves to the side), the drains leave, and it closes again. By the type of this barrier and the principle of its operation, this equipment differs.

Swivel (petal)

In sewer valves of this type, a spring-loaded round membrane (plate) is installed. If the flow moves in the “right” direction, it turns, rising up does not interfere with drains. If the movement starts in the other direction, the membrane (plate) is pressed against the rim inside the valve, tightly and hermetically blocking the pipe lumen. Some models have a manual shutter. This is the second membrane, which can be controlled using a button mounted on the body.

Due to the shape of the membrane, such shut-off valves are also called flap valves, and sometimes you can hear the term “slams” - this is because of the way they work - the membrane slams if there is no drain.

The figure shows how the check valve for sewerage works.

The device itself is larger than the pipe on which it is installed. So in the pipeline there is first an expansion, and then a narrowing of the lumen, and these are potential places for blockages to form. To be able to quickly eliminate blockages, a removable cover is made in the upper part of the check valve body. By removing it, the problem can be quickly eliminated.

Lift check valve for sewerage

This type of locking device for a sewer pipe is so named because when the drains pass in the “correct” direction, the locking element rises.Drains press on the plate blocking the passage, compressing the spring, which rises. There are no drains - the spring is unclenched, the passage is locked. When effluents come in from the "wrong" side, there is no way to open the passage. This is achieved by a non-linear hull shape.

Scheme of the device of the lifting sewer valve

The lift check valve is more reliable, but its design is such that it often clogs and requires periodic cleaning. Why do you need to remove the cover (unscrew four bolts), clean or replace the mechanism.

Ball check valve

Another option for a locking device in a check valve is a ball. In these devices, the internal structure of the case plays an important role. Its upper part is designed in such a way that when passing through the drains, the ball rolls into a special recess in the body, opening the passage.

The structure of the ball check valve for sewerage

When it is dry in the pipe, it blocks the section; when the flow passes in the opposite direction, it blocks the lumen of the pipe. The main drawback of this design is the leakage of drains during flooding - the ball and the side wall of the body do not always fit perfectly, which leads to the fact that some of the drains still seep through. But mass flooding and a geyser from the toilet will not be for sure.

Why you need an air valve in the sewer and how to install it, read here.

Wafer type

Many people like this type of check valves more because of their miniature size. This is a very small cylinder, inside of which a rotary damper is installed. It may consist of two parts that are attached to the central rod, or it may look like a small plate, attached to the housing wall in one place with the help of a spring.

Wafer Type Check Valve

Despite its compactness, it is better not to install this type of check valve on the sewer: this is plumbing equipment and it will not work well on the sewer. The second disadvantage is the impossibility of quick cleaning - the design is such that you can get to the valve only by disassembling the connection.

Materials, markings, dimensions

The check valve for water is made of stainless steel, brass, large sizes of cast iron. For household networks, they usually take brass - not too expensive and durable. Stainless steel is certainly better, but it is usually not the body that fails, but the locking element. That's his choice and should be approached carefully.

For plastic plumbing systems, check valves are made from the same material. They are polypropylene, plastic (for HDPE and PVD). The latter can be welded / glued or threaded. You can, of course, solder adapters to brass, put a brass valve, then again an adapter from brass to PPR or plastic. But such a node is more expensive. And the more connection points, the lower the reliability of the system.

For plastic and polypropylene systems there are non-return valves made of the same material

The material of the locking element is brass, stainless steel or plastic. Here, by the way, it's hard to say which is better. Steel and brass are more durable, but if a grain of sand gets between the edge of the disk and the body, the valve jams and it is not always possible to return it to work. Plastic wears out faster, but it does not wedge. In this regard, it is more reliable. No wonder some manufacturers of pumping stations put check valves with plastic discs. And as a rule, everything works for 5-8 years without failures.Then the check valve begins to "poison" and it is changed.

What is indicated in the label

A few words about the marking of the check valve. It states:

- Type of

- Conditional pass

- Nominal pressure

-

GOST according to which it is made. For Russia, this is GOST 27477-87, but not only domestic products are on the market.

Conditional pass is designated as DU or DN. When choosing this parameter, it is necessary to focus on other fittings or the diameter of the pipeline. They must match. For example, you will install a water check valve after a submersible pump, and a filter to it. All three components must have the same nominal size. For example, all should be written DN 32 or DN 32.

A few words about conditional pressure. This is the pressure in the system at which the valves remain operational. You need to take it exactly no less than your working pressure. In the case of apartments - no less than a test one. According to the standard, it exceeds the working one by 50%, and in real conditions it can be much higher. The pressure for your home can be obtained from the management company or plumbers.

What else to pay attention to

Each product must come with a passport or description. It indicates the temperature of the working environment. Not all valves can work with hot water or in a heating system. In addition, it indicates in what position they can work. Some should only stand horizontally, others only vertically. There are also universal ones, for example, disk ones. Therefore, they are popular.

The opening pressure characterizes the “sensitivity” of the valve. For private networks, it rarely matters. Unless on the supply lines close to the critical length.

Also pay attention to the connecting thread - it can be internal or external.Choose based on ease of installation

Do not forget about the arrow that indicates the direction of water movement.

Dimensions of check valves for water

The size of the check valve for water is calculated according to the nominal bore and they are released for everything - even the smallest or largest pipeline diameters. The smallest is DN 10 (10 mm nominal bore), the largest is DN 400. They are of the same size as all other shutoff valves: taps, valves, spurs, etc. Another "size" can be attributed conditional pressure. The lowest is 0.25 MPa, the highest is 250 MPa.

Each company produces check valves for water in several sizes.

This does not mean that any of the valves will be in any variant. The most popular sizes are up to DN 40. Then there are the main ones, and they are usually purchased by enterprises. You won't find them in retail stores.

And yet, please note that for different companies with the same conditional passage, the external dimensions of the device may differ. Length is clear

Here the chamber in which the locking plate is located can be larger or smaller. The chamber diameters also differ. But the difference in the area of the connecting thread can only be due to the wall thickness. For private houses, this is not so scary. Here the maximum working pressure is 4-6 atm. And for high-rise buildings it can be critical.

How to check

The easiest way to test a check valve is to blow into it in the direction that is blocking it. Air must not pass. Generally. No way. Also try pressing the plate. The rod should move smoothly. No clicks, friction, distortions.

How to test a non-return valve: blow into it and check for smoothness

Which valve to buy?

The question is not easy in the sense that there are no obvious “favorites” or “promoted” models. But at the same time - there is a very serious variation in prices. And plus everything - there are no clear selection criteria, except, perhaps, the diameter of the pipe on which the valve is mounted, dimensions, if the place for its installation is limited, and the most convenient way to connect to the pipe.

At one point, the drain pipes from the shower and washbasin converge. To protect this unit from the failure of the siphon, it was decided to install an aerator on a 50 mm pipe

In this case, of course, the dimensions of the device are important.

Of course, it should be assumed that the more well-known manufacturers of plumbing products and the valve will offer the most durable and reliable. But you can find a lot of examples when the most uncomplicated and inexpensive aerators of domestic production serve for decades and continue to serve.

Therefore - just a brief overview of the models offered for sale and their prices, but without any recommendations in favor of a particular product.

| Illustration | Short description | Approximate cost, rub. |

|---|---|---|

| "MkAlpine HC 50-50" - products of the company from the British Isles. Polypropylene. Model for pipe ø50 mm. Fits in a standard bell. Throughput - 3 l / s. | 850 rub. | |

| Model "MkAlpine" for pipe DN110 mm. Polypropylene. | 2500 rub | |

| "HL900NECO" Austrian company "HUTTERER & LECHNER GmbH". Available in three versions - for pipes DN50, DN70 and DN110 mm. Polypropylene. Mesh on the side of the case. The capacity of the DN110 valve is 37 l/s. Thermally insulated housing walls. | For model DN110 - 2800 rubles. | |

| Air valve "Wavin Optima Mini vent" of the famous Dutch company.Compact models for installation on sewer pipes with a diameter of 30, 40 and 50 mm. Polyvinyl chloride. Throughput - 7.5 l / s. Installation - in a standard socket. | 3600 rub. | |

| The product of the Finnish company UPONOR is the HTL vacuum valve. It is made for 110 mm, it is completed with adapters for 50 and 70 mm. Polypropylene. | 4700 rub. | |

| Valve of the German brand "Ostendorf" of Russian production. Diameter - 110 mm. Polypropylene. | 1900 rub. | |

| Vacuum valve manufactured in Russia by Rosturplast. Diameter - 110 mm. | 190 rub. | |

| The valve of the Russian production of the Politron company. Polypropylene. Diameter - 110 mm. | 240 rub. |

Probably, this is already enough to understand how the prices for such products “dance”. Moreover, with approximately equal characteristics, material of manufacture, etc. So the author of this article in no way assumes the responsibility to recommend certain models - everything is too non-obvious.

True, they may ask a question - why do some DN110 aerators have one common head, and others have two small ones?

There is no particular secret here. It's just that the manufacturer produces models for both 50 mm and 110 mm pipes. And it is technologically easier for him to combine two smaller valve heads in one body to get an aerator for a larger diameter. And this does not affect the operation of the device itself. Unless you have to take care of two membranes. But if one fails, it will cost less to replace than one large one.