- No draft in the chimney: 6 reasons for reverse draft and how to improve it yourself

- Why is there no draft in the chimney

- Pipe cleaning

- What affects traction

- Causes of reverse thrust

- Backdraft detection

- Folk ways of determining

- professional methods

- Visual ways

- The principle of operation of the stabilizer

- Why is it smoking

- Reverse thrust elimination

- Stabilizers

- Gate manipulations

- Using a draft regulator (stabilizer)

- Ventilation system

- Choice of devices for regulation

- Deflectors

- Photo gallery: types of deflectors

- Rotary devices

- Draft regulators

- Effective ways to increase chimney draft

- Measurement methods

- Causes of malfunctions

- Ways to increase traction

- What does the index depend on?

- Useful information about chimney draft

- House moments

- External factors

- Features of the design of the chimney

- Causes of reverse draft in the chimney

- More difficult situations

No draft in the chimney: 6 reasons for reverse draft and how to improve it yourself

The unpleasant smell of burning, smoke in the room, poor burning of firewood - all these are the consequences of reverse draft in the chimney. This is a problem faced by many owners of fireplaces, stoves, solid fuel boilers and other wood-fired heating appliances.

Later in the article, we will look at the main causes of poor draft in the chimney, as well as provide simple recommendations for eliminating this problem.

Why is there no draft in the chimney

Chimney clogged with soot

Perhaps this is the most common and main reason for the deterioration of traction.

When wood is burned, soot is formed. It is particles of combustion products that stick together and settle on the inner walls of the chimney, which leads to a narrowing of its diameter. As a result, the movement of air becomes difficult.

Therefore, the soot must be removed regularly. So you will not only improve traction, but also increase the efficiency and fire safety of the heater. To make the walls of the chimney less polluted with soot, you can use fuel wood briquettes, which contain less moisture and other harmful impurities.

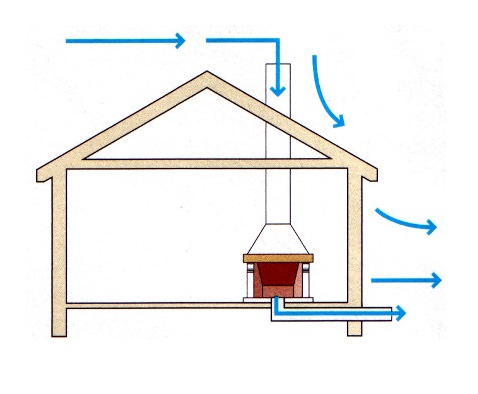

Insufficient air supply

When burning firewood, it is necessary that the air moves “from bottom to top”. That is, from the room to the chimney and to the street. To do this, in the room where the heater is installed, air flow - draft must be provided.

If all the windows are closed, if the ventilation is malfunctioning, then the smoke begins to move in the opposite direction - from the chimney to the room. That is, there is a backlash.

The easiest way to solve this problem is to create the right air movement in the room. For example, open a window before lighting a fire and close it 10-15 minutes after the flame flares up.

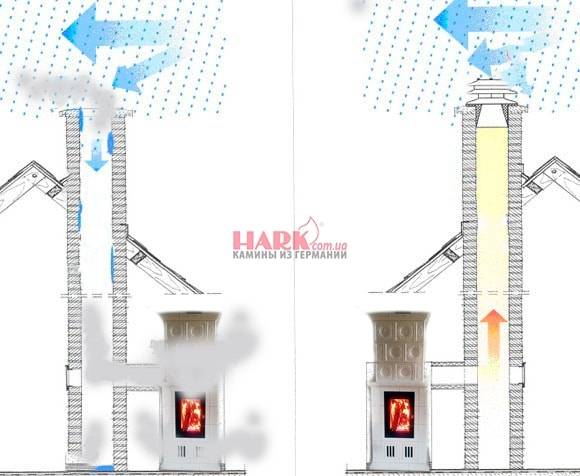

Cold outdoor air pressure

The draft in the chimney may deteriorate due to a decrease in the outside temperature. Since cold air is heavier than warm air, it sinks down and “presses” inside the pipe.This problem is especially often manifested in the presence of the previous two - the lack of air flow and a clogged chimney. It enhances their influence.

Therefore, the solution is: insulating the chimney, removing soot and creating an air flow.

The presence of a visor on the chimney

Often a hood is installed on chimneys, which can prevent smoke from escaping from the chimney. As a result, an air "plug" of smoke is formed and traction deteriorates.

In such cases, the visor should be replaced with a higher one or removed.

Incorrect chimney design

Backdraft can occur as a result of improper chimney design: narrow diameter, too high a height, a large number of bends or narrowings.

To eliminate problems of this kind, you will have to rebuild the chimney, which will entail a significant investment of time, effort and money.

brick collapse

Due to the constant heating-cooling process of a brick chimney, it can collapse. Bricks will fall off, fall down and clog the chimney.

To avoid such a situation, the chimney must be insulated. This will also solve the cold air pressure problem.

So, how to increase the draft in the chimney? Here are a few simple steps that do not require much time and money:

- Clean the chimney of soot. This is the first thing to do. You can do it yourself, with minimal time, effort and money.

- Ensure air flow. Open a window for 5-10 minutes before starting a fire. This will create the correct movement of air in the room "bottom-up". The window can be closed after the fire flares up.

- Insulate the chimney if it is not insulated. This will reduce the influence of cold air and also extend the life of the chimney.

As a rule, these simple actions are enough to increase the draft of the chimney. If the problem is related to the design features of the chimney channel, then more serious resources will be required to solve it.

No draft in the chimney: 6 reasons for reverse draft and how to improve it yourself What to do if there is no draft in the chimney? The article discusses the main causes of poor traction, as well as tips for improving it.

Pipe cleaning

Work should begin with cleaning the chimney. All doors in the oven and flue ducts must be tightly closed and fixed. When a large amount of soot falls from a height of 3-4 m, dust may be released into the house. For cleaning, a special ruff is used, in the absence of a ready-made one, you can do it yourself. The device will require a strong rope or cable. At one end, a load weighing 2-3 kg and a pair of old hard washcloths should be fixed. You can use a fluffy coil of wire, a stiff cord, or something similar. The fastening must be strong, parts that come off and stuck in the pipe can cause a lot of problems.

With a ruff, you need to climb onto the roof, lower it into the pipe, stretch it up and down several times, rotating and swinging to the sides if possible. Similar work must be done to understand why the fireplace smokes. If the function stabilizes after cleaning, the problem is solved. Otherwise, you need to look further.

What affects traction

The size of the chimney is affected by many factors. The most important among them are the height and section of the chimney channel. These two parameters are always interconnected and depend on the characteristics of the stove or fireplace. Their calculation requires exceptional vigilance, because in the event of an error, traction will be poor.And this will lead either to the reverse movement of carbon monoxide, or to excessive burning of firewood.

Today there are entire tables that will allow do the right sizing smoke channels. For example, in order to create draft in a fireplace of the proper strength, it is necessary to make sure that the exhaust channel has a cross section that is less than 1/10 of the area of the furnace inlet. It seems that if you increase the cross section of the exhaust channel, then the thrust should increase. However, on the contrary, it will decrease, because the smoke will come out more slowly. Because of this, it will cool and accumulate in the outlet pipe. What's not good. Therefore, experts make a lengthy calculation to determine the correct cross section.

Causes of reverse thrust

Firstly, the design of the chimney itself may be the cause of the back draft. Too high a pipe always has more traction, while a low one often lacks it. A little over 5 meters is considered the most suitable length, then problems with traction will occur very rarely and will definitely not be associated with the height of the pipe. In addition, the cross-sectional area of the chimney must correspond to the furnace.

With very small cross-sectional dimensions and at the same time with a powerful furnace, a large volume of combustion products simply will not find a normal exit, there will be no sufficient thrust. Also, too large a chimney can cause all the heat to go outside. In no case should pipes of different diameters be installed at the chimney in different sections. Otherwise, soot will form and traction problems will occur.

A big obstacle to the movement of smoke is the uneven surface of the pipe.Numerous deposits reduce the diameter of the pipe, and the furnace becomes more and more difficult to melt each time. Certain difficulties are created by the corners with the turns of the chimney. With the constant accumulation of soot in them, obstacles will be created.

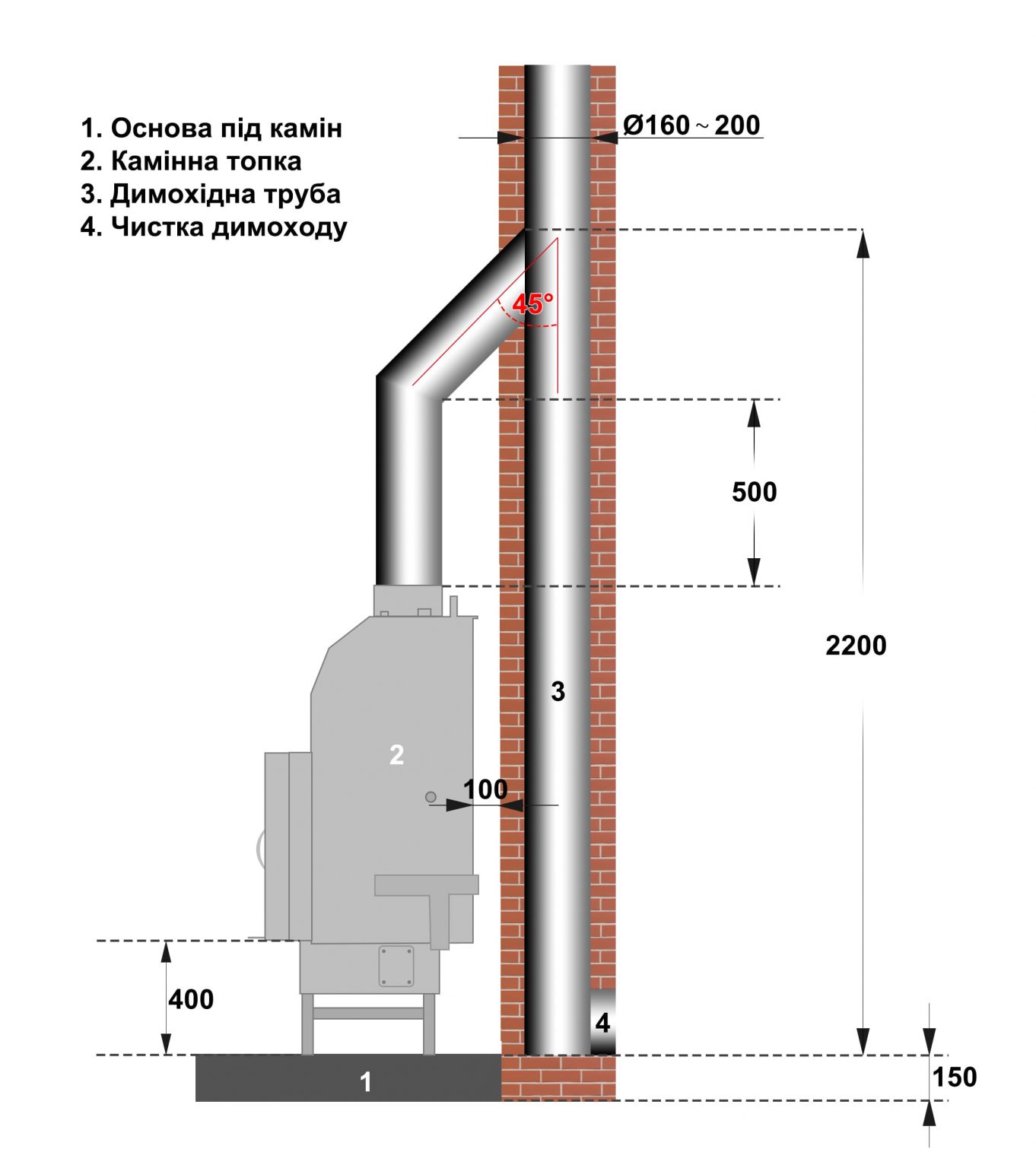

To prevent this, when designing a chimney, standard norms should be followed: the outlet should be at an angle of 45 °, and the turn should be 90 °. Equally important is the shape of the smoke hole. The round shape is considered the most suitable for good traction, while the square and rectangular shapes can create problems. At these corners, additional turbulence is formed, which to a certain extent interferes with the overall flow and, therefore, reduces thrust. Most often, poor draft is observed in metal chimneys. Their problem is that they quickly heat up, but also cool down rapidly, and cold air always sinks down. Therefore, brick chimneys are better in this regard.

Backdraft can occur due to a violation of ventilation or its complete absence. It is necessary to check if there are drafts in the room. Intense air currents in the baths often appear due to the presence of stairs to the second floor. Therefore, you need to monitor the air flow and never open the windows on the site if it is located much higher than the level of the firebox.

Ventilation should also be given special attention in cases where there is a geyser. It draws air from the combustion room

After some time, there will still be a serious lack of oxygen and rarefaction of the air will be felt.Periodically, air currents will penetrate through the chimney, the column will start to go out, and the room will begin to smoke.

There are also external factors that affect the formation of reverse thrust. Smoke can enter the room due to high humidity outside or strong winds. It also happens when it is noticeably warmer outside than inside the house, so there is a pressure difference. If this is the reason, then you can feel the unpleasant smell of burning. In this case, you need to open the window and ventilate well, in addition, the temperatures will even out a little. It is extremely rare that the cause of the traction violation is the wind, which causes turbulence above the roof. In addition to this, the heading may also be directed incorrectly in relation to the roof ridge.

And finally, the location of the chimney plays an important role. In the inner part of the bath, it has a good effect not only on the heating capacity of the system, but also makes it possible to maintain good traction even in severe frosts. And an external chimney running along an outside wall takes longer to warm up and often condenses.

Backdraft detection

To indicate the movement of air flow in the opposite direction, there is a special definition - overturning thrust. This means that the flow of gases from the burning fuel does not move outside, but into the room.

Before starting any heating unit, it is necessary to determine the force and direction of thrust when the ventilation devices are not activated.

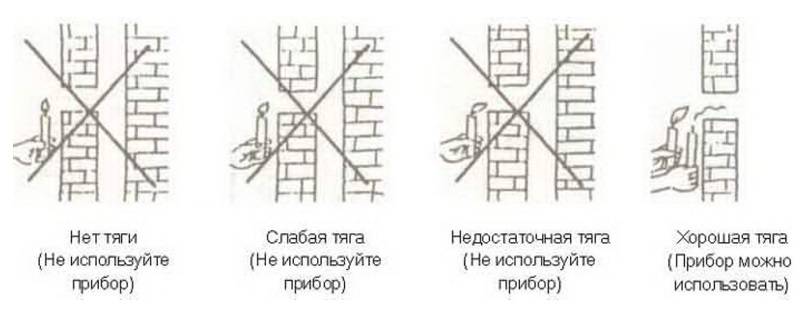

Folk ways of determining

Among the popular ways to determine the reverse thrust in the chimney, the following can be noted:

- If there is a glass door in the firebox (most often such a structural element is available for fireplaces), then through the glass it is clearly visible how quickly it is smoked. It is enough to slightly open the door and a stream of smoke will immediately fill the room.

- It is necessary to attach a sheet of thin paper to the opening of an open firebox and see in which direction it deviates. Exactly the same procedure can be performed with a smoking cigarette instead of a paper sheet.

professional methods

There is a special measuring equipment, which makes it possible to measure the draft in the chimney with high accuracy, in pressure units. Optimal performance is within 10-20 Pa.

Measurements are carried out by a two-way method:

- at the top of the chimney;

- at the base of the chimney.

It is worth noting that owners of private houses do not often use this method, they prefer folk ones more.

Vane anemometer

The anemometer does not provide objective information when the wind speed is lower than 1 m/s.

Visual ways

If the ratio of combustion and thrust processes is normal, then:

- the color of the flame is yellow, with golden fire;

- smoke is formed and immediately disappears into the chimney channel - without jerks, smoothly, but at the same time quite energetically.

In the case when the normal thrust is too high, this is considered not a very good phenomenon, since the fuel will burn out very quickly. You will understand that the draft is increased by the white color of the flame and the hum of the chimney.

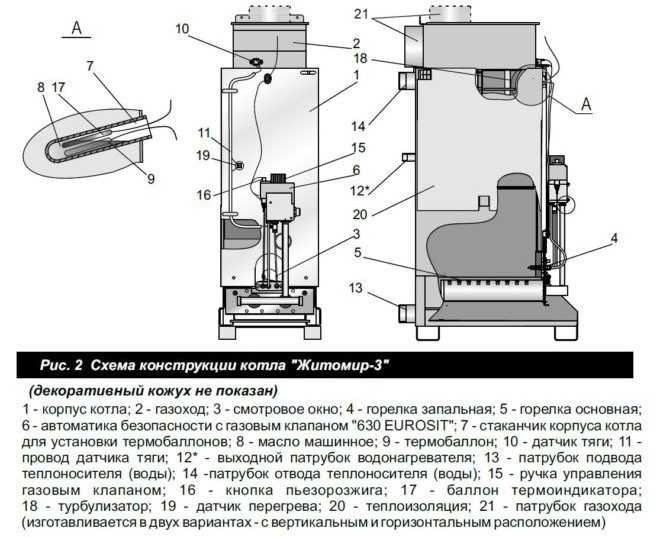

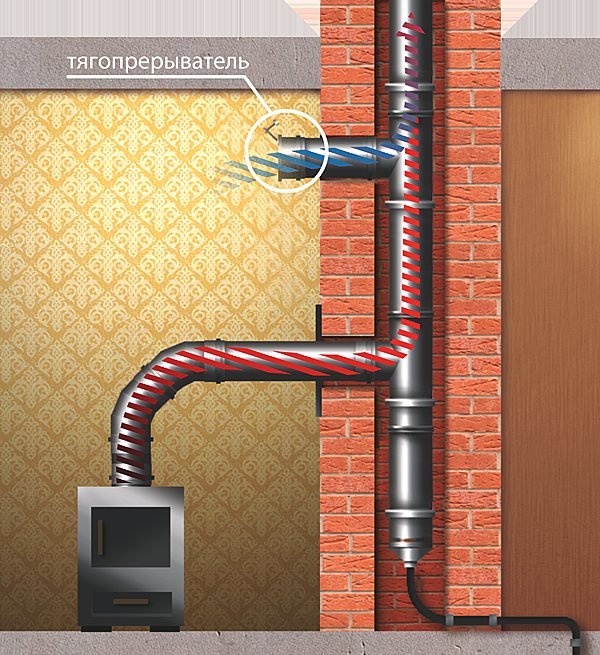

The principle of operation of the stabilizer

If the draft force in the system begins to exceed its optimal values, then a valve opens in the regulator, which lowers the pressure and thermal lifting force due to the air coming from the room and mixing with the flue gases.The valve will remain open until the temperature drops and reaches the optimum level. Further, the valve will automatically close, the chimney system will continue its proper functioning.

This method of maintaining traction in the normal range is simple and effective. Fuel in the furnace or boiler will be burned evenly, and spent sparingly.

Installing a chimney draft stabilizer provides the following benefits:

- improving the safety of operation of the chimney system;

- reducing the amount of harmful substances emitted into the atmosphere;

- better circulation of air flows when the valve is kept ajar;

- the possibility of functioning both on forced and natural draft;

- uniform combustion of fuel in the boiler, which makes it impossible to overheat the chimney;

- protection against strong gusts of wind;

- the absence of a smell of burning in the room;

- increase in service life of the channel for an output of a smoke;

- prevention of heat loss;

- possibility of installation in modern low-temperature boilers;

- ensuring fuel economy by 15-20%.

Why is it smoking

Smoke in the bath is not only unpleasant. It is also very dangerous. Any schoolchild knows: in the process of combustion, carbon monoxide is formed - a strong toxic substance. So you need to carefully ensure that in the room where you like to have a good time, only steam and heat remain, and not smoke at all.

So, for what reason does the stove smoke in the bath and what to do about it?

- The simplest reason (it may arise if you did not design and install the bath and stove equipment) is that the stove does not “pull” due to the too small inner diameter of the chimney. If this indicator is less than 120 mm. - change the pipe.

- This reason is more difficult to eliminate (and most likely, you will not be able to master the process yourself), but you still have to do something: if a metal sauna stove smokes at the first fire, it is highly likely that you incorrectly installed the unit or made errors in the design

- However, don't panic! Perhaps the point is not in the design of the furnace, but in the pipe, and then it will be relatively easy to correct the situation.

Reverse thrust elimination

In some cases, when the reverse draft is in the chimney, elimination can be done by hand.

- This applies to cleaning the chimney from soot and removing foreign objects. You will need a ruff and a weight with a cable.

- If there is a lack of air, you need to open the window for 10 minutes to ventilate.

- Chimneys in the outer wall or remote need to be insulated.

- Sometimes in wet weather or after a long break in the operation of the heater, it is enough to burn a piece of newspaper in the firebox to resume traction.

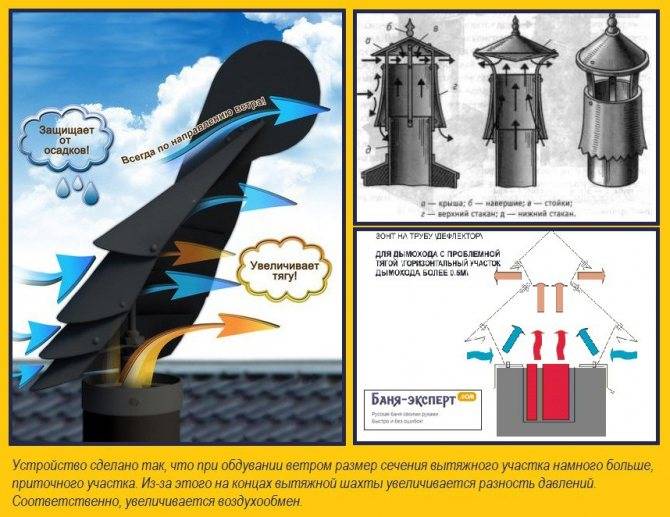

A good means of eliminating the possibility of reverse thrust is the use of various devices. These can be gate valves, deflectors (pictured), chimney weathercocks, smoke fans.

The deflector is always available for sale. The price ranges from 550 to 3800 rubles. The manufacturer provides instructions for use.

Safe and efficient operation of heating units is possible if there is draft in the chimney. At the first sign of back draft formation, it is necessary to check the chimney and ventilation ducts. The entry of combustion products into the home is fraught with health risks and can threaten people's lives.

Stabilizers

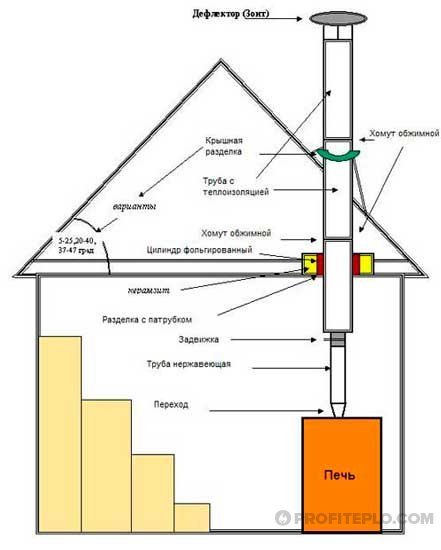

During the existence of heating, many devices have been invented that improve the flow of gases in the chimney (see photo):

rotary turbines - consists of a nozzle and a housing mounted on the chimney head. Under the influence of wind, the nozzle rotates and creates an increase in the flow of exhaust gases due to the created rarefaction;

electric smoke exhauster, or smoke fan. With forced draft, you don’t have to worry about tipping over - this is an almost ideal smoke outflow regulator, however, maintenance of the device on the roof is quite difficult, and the installation of such a design should be calculated even at the drawing stage;

all kinds of caps are also able to slightly improve the outflow;

chimney weathercocks, often mounted on wood-burning stoves.

Gate manipulations

Shiber - a damper that affects the strength and direction of thrust. Usually, during the construction of a stove or fireplace, two gates are installed. One is in the chimney, the second is in the stove or in its door. "Play" with the position of these flaps, often this increases traction, and the problem is solved by itself.

Using a draft regulator (stabilizer)

This is a special device that creates air currents in the chimney and controls their strength. It stabilizes draft and, among other things, contributes to fuel economy, and also prevents combustion products from entering the room.

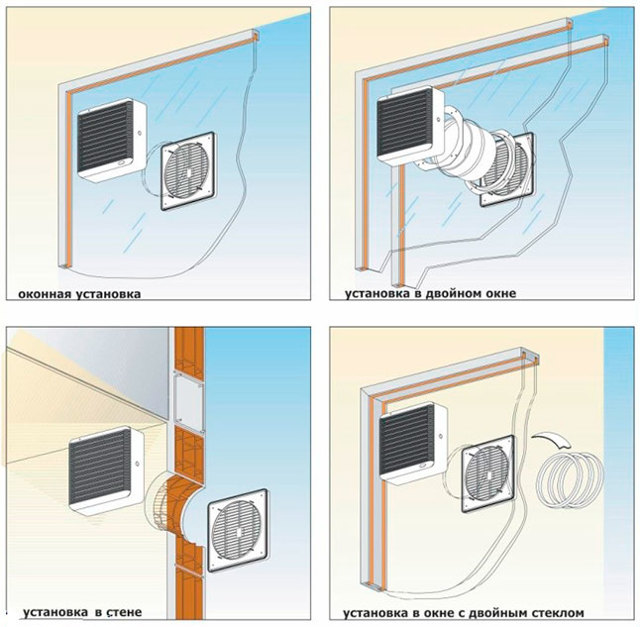

Ventilation system

Often a situation arises when everything is fine with the chimney, but there is still a reverse draft in the chimney, what to do then? What is the reason? Most likely, the matter is in the ventilation system, which works according to certain natural patterns.

The density of warm air flows is significantly lower than the cold masses, so warm air rushes up.If at this time the doors or windows are open in the room, then the air masses will go exactly into the open openings, and not into the chimney of the heater. Therefore, you need to ensure that when you turn on the device, all doors and windows to the street are closed.

Also, the internal architecture of the structure has a huge impact on traction. If there are many doors or windows in the building, there is a passage to a balcony or stairs to another level, then a draft will certainly occur. Therefore, it is impossible to keep open windows and doors located above the level of the combustion chamber.

It often happens that all openings are locked, but when the heating device is kindled, the low-pressure zones attract fresh air flows from the chimney, and as a result, the thrust is overturned. You can solve the problem by creating the necessary air circulation.

For this you need:

- install in-wall supply valves;

- equip windows with supply valves;

- install a forced ventilation device in the window glass;

- slightly open the door, window or window.

The implementation of one of the proposed measures will lead to a decrease in atmospheric pressure in the room and, accordingly, the disappearance of reverse thrust.

If a gas column is used as a heating device, then there are some nuances:

- the combustion chamber draws air flows from the room;

- oxygen deficiency begins to be felt in a fairly short time;

- air from the chimney will begin to flow back, which will lead to the extinction of the flame and smoke.

In this case, it is worth carefully checking the efficiency of the ventilation system.

Choice of devices for regulation

Consider some of the characteristic features and methods of using devices for controlling and adjusting thrust.

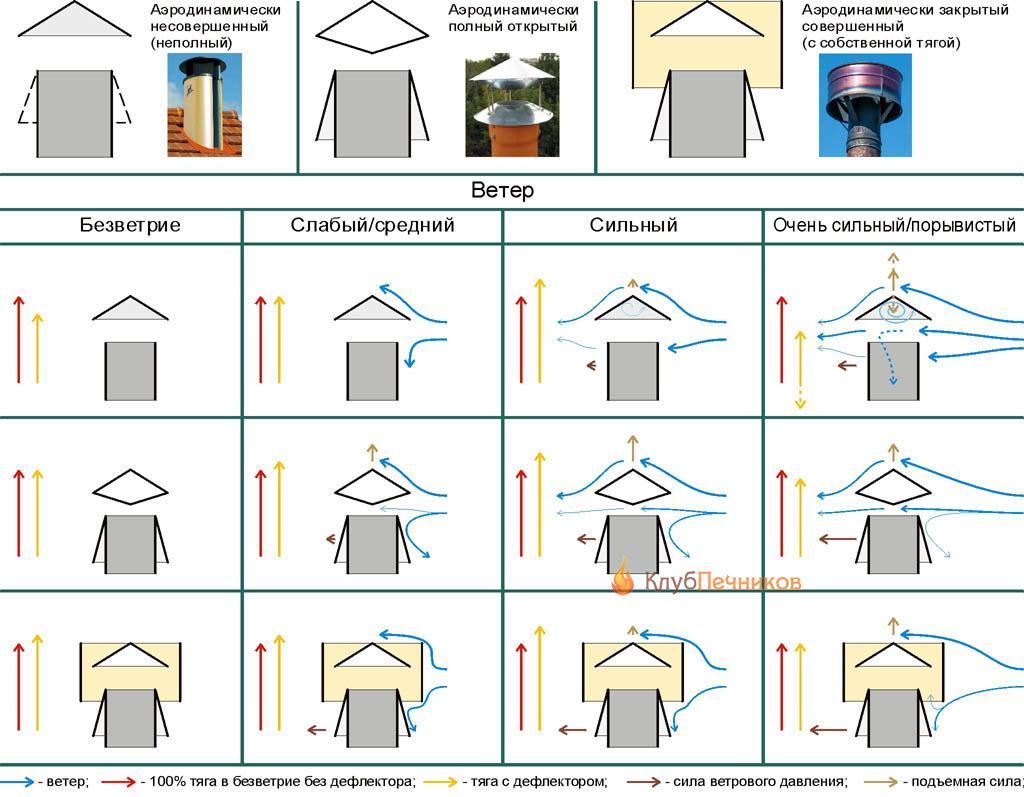

Deflectors

Such structures are installed on the chimney (in its very upper part) to create obstacles to air flows. The intensity of the wind force drops noticeably when it encounters such devices placed on a pipe. The smoke comes out through the channel "to the will" due to the ingress of weak air currents into the pipe. These flows "hook" the exhaust gases and "push" them out.

Deflectors eliminate the possibility of clogging the pipe, and also tastefully made, significantly improve the appearance of the entire building.

There are several types of deflectors:

- TsAGI;

- round Volpert;

- Grigorovich;

- in the form of a plate;

- in the form of the letter H;

- rotating;

- vane.

Almost all of these devices are made of stainless steel, in rare situations - of copper. Using brackets, clamps, bolts, sealing tape, the deflector is attached to the chimney pipe. Some devices are also equipped with additional functions: to extinguish sparks (to eliminate a possible roof fire), to control the temperature of the outgoing air (in this case, the sensor is triggered if hot air does not come out and there is a possibility of reverse draft).

The disadvantages of using deflectors are their minimal efficiency in calm weather.

Photo gallery: types of deflectors

The most common device for improving traction

Such a device can be purchased in specialized stores.

The choice of device depends on the design features of the pipes and your preferences.

Rotary devices

Turbines installed at the top of the chimney use the energy potential of the wind.Air currents set in motion a rotary nozzle (it always moves in the same direction), and thus the air is rarefied near the chimney. The ingress of any foreign objects and precipitation into the chimney with a rotary pipe is completely excluded.

Rotary pipes have a big disadvantage, similar to the operation of the deflector. Their use on a calm day is ineffective.

If you do not have great abilities, buying such devices is not a problem.

Draft regulators

Such devices are a real find for residents of country houses, lovers of baths and fireplace gatherings. These devices are attached to the chimney of the boiler. They are equipped with a metal plate with a load that balances it on one side. When the draft is good, the metal plate does not prevent the free access of air to the chimney. With weak or reverse thrust, the metal plate serves as a kind of stupor.

The range limits for thrust are set by the consumer himself, the usual parameters are 10–35 Pa.

The device works completely autonomously, it does not require the supply of electric current.

Effective ways to increase chimney draft

The design of a chimney is complex and responsible, the efficiency and safety of using a heater depends on the correct implementation of it. Not a single heat generator is able to function normally without a pipe that removes smoke from the room. Smoke is a mixture of gases containing residual products of combustion of fuel. The appearance of smoke inside the heated room is a sure sign of an incorrect calculation of the chimney system, which entails the risk of fire and carbon monoxide poisoning.This article will tell you what reverse draft in a chimney is and how to prevent it from occurring.

Measurement methods

If you doubt that the draft of the chimney channel of the stove, fireplace or heating boiler is sufficient, you need to check it. The easiest way to dispel doubts is to check with your own hands using an anemometer. If the device shows a thrust of 10-20 Pa, then it is considered normal. The problem of this method is the low measurement accuracy of inexpensive anemometers, if the thrust is less than 1 Pa, then they will show that it does not exist. More accurate professional instruments are expensive, stove-makers use them.

If you do not have an anemometer, use one of the popular methods for determining the chimney draft force:

- By smoke. The most obvious sign that there is no draft is the presence of even a small amount of smoke inside the room, a large amount of smoke indicates a high risk of fire and carbon monoxide poisoning.

Note! The draft inside the chimney duct is created due to the difference in pressure outside and inside the building. In a heated room, the temperature is higher than outside, so there is more pressure

Heated air, propped up from below by colder air, is squeezed out into a zone with lower pressure, that is, into the atmosphere. If you take measurements in summer, when the temperature difference between inside and outside is minimal, you will get a lower result than in winter.

Causes of malfunctions

After making sure that there is not a sufficient level of draft inside the chimney system, it is necessary to determine and eliminate the possible cause of this defect. Experienced craftsmen say that the most common causes of failures in the operation of smoke ducts are:

- Design error. The choice of the chimney pipe should be based on the volume of the furnace.If the diameter is less than the calculated parameter, a weak one will not allow smoke to leave their premises.

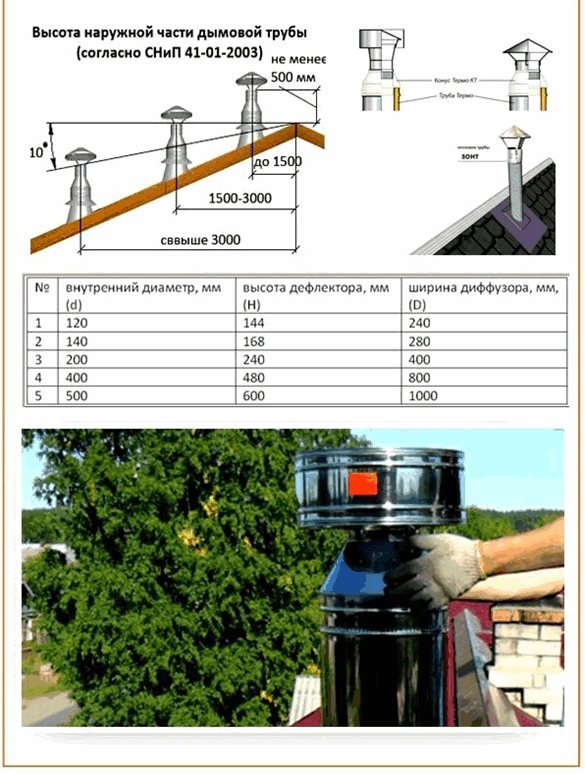

- Insufficient pipe length. A pipe length of less than 5 m does not provide a significant difference between the pressure inside and outside, which creates a weak draft.

- Incorrect location of the chimney tube. Furnace masters advise laying the chimney vertically, as narrow turns trap smoke inside the chimney, reducing draft.

- Long horizontal sections. If, when laying a chimney, it is not possible to avoid horizontal sections, then make sure that their length is no more than 100 cm. Otherwise, she will need an amplifier.

The first step in detecting problems in the chimney system is to eliminate the most obvious causes of insufficient draft. When inspecting, make sure that the connections of all pipe segments are tight, that there are no soot blockages. Check that no moisture has entered the flue ducts and that the atmospheric pressure is correct.

Ways to increase traction

If the traction force is in the chimney channel of the heater, it is not always easy to eliminate this defect. Experienced stove-makers use the following methods, ways to increase it:

- The first thing to do if you suspect insufficient draft in the chimney is to clean the pipe. To do this, call a chimney sweep or remove soot deposits from the inner surface of the chimney with your own hands using a metal stove brush.

- A significant increase in the power of the chimney can be achieved by increasing the height of the chimney above the roof surface by extending it with several additional segments. In the same way, the chimney is removed from the area of \u200b\u200bwind backwater from the ridge or a higher building.

If it was not possible to find a solution to the problem of the lack of draft inside the chimney channel on your own, seek advice from an experienced stove-maker who will tell you what to do and correct the defect in the most rational way.

Effective ways to increase chimney draft Effective ways to increase chimney draft. Common causes of reduced draft in the chimney and methods and devices for their elimination.

What does the index depend on?

On average, the thrust rate in a sauna stove is 10 Pascal. It is measured behind the smoke outlet, where the rate of smoke evacuation is clearly visible. In addition, here you can determine the correspondence between the dimensions of the furnace and the diametrical value of the chimney.

The traction force of the smoke and gas pipe is affected by:

- Chimney length. The minimum height is five meters. This size is sufficient to provide natural vacuum. The smoke begins to rise freely. The dependence of draft on the length of the chimney channel is proportional. Improve traction by increasing the height of the pipe.

- The temperature of the exiting smoke or gas. With increased heating, the gaseous products of combustion move upward at a faster rate. The traction increases.

- Chimney warm-up time. The less time spent, the faster the thrust reaches the norm.

- Roughness of the inner walls of the chimney. The higher, the worse the traction. It is desirable to provide a smooth surface.

- Cross section and shape of the chimney channel. The best option is a circle, oval, rectangle. More intricate designs lead to reduced thrust.

- The ratio of the combustion device with the diameter of the pipe at the outlet of the chimney.If the height of the chimney exceeds the maximum values, the cross section must be reduced by 10%. You can use an adapter for this.

Chimney height

Useful information about chimney draft

All residents of country or private city houses are familiar with the concept of chimney draft. Do they know the meaning of this term?

If we move a little away from dry scientific terminology, then draft can be defined as a natural phenomenon in which air moves from one area to another, namely, from an air zone with high pressure to a zone with low pressure. All this happens with the help of a ventilation device - a special channel in the chimney.

Using this process of aerodynamics, mankind began to use fireplaces, stoves, boilers, heating their homes with the help of various types of fuel - coal, firewood, peat, etc.

Furanflex produces material for the restoration of chimneys of stoves and fireplaces. The material can be used to repair chimneys of any type and complexity of execution. Fast installation and quality installation. Warranty from 10 to 30 years.

With good draft, the stove quickly flares up and the room is filled with pleasant warmth.

From a properly designed and built chimney and, accordingly, from good draft depends:

- the quality of space heating;

- reduction of fuel costs;

- safety of being in buildings with their own heating.

House moments

A number of factors indoors can significantly affect the presence / absence of traction and its strength:

- The material from which the building is built.

- Average room temperature.

- The maximum amount of air space in the dwelling.

- The number of people permanently inside the dwelling.

- The presence of internal sources that additionally consume oxygen (heaters, heaters, stoves, etc.).

- The regularity of fresh air intake (ventilation, ventilation).

External factors

There are other factors that determine the draft of the chimney, and they are located outside the heated room. We are talking about the temperature of the external environment, atmospheric pressure, humidity, wind direction. Such a phenomenon as temperature changes during the day can also affect traction - due to the movement of cold and warm layers of air.

Difficulties with traction appear for various reasons, some can simply be overlooked. For example, problems with air escaping through a chimney can occur if the chimney is located well below the ridge of a building or tall nearby trees.

Features of the design of the chimney

The draft may be different depending on the design characteristics of the chimney:

- height;

- the presence of insulation;

- tightness;

- location (internal/external);

- length;

- presence / absence of irregularities or roughness, etc.

It is necessary and possible to control the traction in the room using the "levers" of the first and third factors (intra-house and design). Natural changes, of course, do not depend on man.

Keeping the draft in the chimney under control is a prerequisite for safe and comfortable living in your own premises. If the draft is very weak, then it is almost impossible to light the stove and heat the home.

With reverse thrust, the gases resulting from combustion are “thrown” into the living space, and not into the air through the pipe. This is very dangerous for human health and life!

It is impossible not to notice such atypical smoke behavior

With a very strong draft, all the heat is rapidly drawn out through the chimney channels without having time to warm the heated room to the desired temperature.

Causes of reverse draft in the chimney

Reversing the direction of air flow in the chimney is called "draft reversal".

This can happen for various reasons: a sharp gust of wind or the presence of tall trees in the immediate vicinity of the heating object. However, the main prerequisites for such an incident are miscalculations in the design:

- Insufficient height of the pipe or its protrusion above the roof ridge.

- Mistake in choosing the section of the chimney. Insufficient pipe diameter does not allow all combustion products to pass through the pipe in a timely manner. Traction deteriorates and it overturns. Too large a chimney will carry a large amount of heat to the outside.

- It is unacceptable to use pipes of different diameters in the same chimney. A large amount of soot settles at the joints, reducing its permeability.

- Soot-contaminated pipe walls slow down the movement of furnace gases, which causes a decrease in traction. Cleaning of the inner surface of the chimney is carried out mechanically using brushes of various designs. Chemical cleaning methods are also used, in which a special composition is placed in the furnace and its vapors clean the chimney channel.

- Violations in the design of corner transitions and horizontal sections.

- Thrust overturning is possible with insufficient ventilation of the room or its complete absence. It is impossible to keep windows or vents open at a level significantly higher than the location of the thermal unit during the heating of the furnace.

Particular attention should be paid to the ventilation of the room when using gas boilers and water heaters. When the draft is overturned, they can go out, and the gas will flow into the room. Modern appliances have automatic gas shutoff, but is it necessary to depend on it?

Modern appliances have automatic gas shutoff, but is it necessary to depend on it?

More difficult situations

Dealing with the complex causes of oven backflow is much more difficult.

It is possible to fix an incorrectly designed chimney, but only by rebuilding it completely, so it is very important to entrust the design to specialists. It is best that the chimney or pipe is installed strictly vertically.

Along a vertical straight pipe, without encountering obstacles on the way, the smoke will dynamically go up and go into the atmosphere. Bends, corners, sloping or horizontal sections in the chimney will make it difficult, slow down the outflow. In addition, soot will accumulate much faster in the corners, and this will also contribute to the fact that traction may one day disappear.

The material from which the chimney is made is very important. It is best to use ceramics and bricks. The height of the pipe is also important, which cannot be less than 5 meters. Its inner surface must be smooth.

Today, there are various devices that can eliminate reverse thrust. These include:

- deflectors for the chimney;

- fans;

- chimney exhausters;

- rotary turbines;

- chimney weathervanes.