- Classification of modern pipe cutters

- Kinds

- Detachable and non-detachable

- Disc and incisive (roller)

- For steel, stainless pipes and more

- Manufacturers

- Hydraulic and pneumatic pipe cutters

- How not to cut polypropylene pipes

- Popular models of scissors for cutting plastic

- VALTEC products

- Scissors Rothenberger Rocut 42 TC 52000 0-42mm

- Pipe cutter KRAFTOOL

- Scissors REMS ROS P 42P

- GROSS scissors

- BADA pipe cutters

- Pipe cutter Exact PipeCut P400

- Inforce scissors

- Henco cutters

- REHAU products

- Preparation and cutting of steel pipes

- Cutting of pipes of small diameters

- Cutting steel pipes of large diameter

- Classification of pipe cutters by type of drive

- Model Exact Pipecut 220e

- Disc electric tool

- Price and manufacturers

- Tools

- Classification

Classification of modern pipe cutters

Tools designed for cutting pipes, first of all, differ from each other in terms of power and ability to work with materials of different densities.

Universal pipe cutters can easily withstand high loads and easily cope with thick-walled steel and cast iron pipes with a diameter of up to 12 mm. This class also includes progressive devices equipped with a clamp latch. Thanks to it, the tool becomes stronger and easily cuts a pipe with a diameter of up to 324 mm.

With a manual pipe cutter with a clamp latch, you can cut a steel pipe at home for laying a water or sewer system

The second group includes equipment designed to work with pipe products made of thinner materials: brass, copper and stainless steel. The same tool is usually used to cut plastic and metal-plastic pipes, especially when it is required to maintain the most accurate dimensions and obtain an ideal straight cut at the output.

So that there are no traces of screws on the copper, you do not need to clamp the pipe fragment strongly. It is better to slightly loosen the fixation and carefully make the cut

The third category includes aggregates for processing brittle, prone to crumbling material. They are used for cutting ceramic, concrete and asbestos-cement pipes. The tool provides a neat and smooth cut line and does not knock pieces out of the edge.

A high-quality pipe cutter allows you to clearly and accurately make not only a straight, but also an oblique cut on a ceramic pipe

For personal purposes, equipment with a mechanical lever drive is more suitable for performing one-time repair and installation work. Electric tools of this class are mainly used for regular mass work (services for laying sewers, gas and water pipes, etc.).

Contact with a cutting electrical unit requires certain skills and professional abilities, so it is rarely used in everyday life.

Kinds

Electric pipe cutters can be classified according to the following criteria:

- housing design (it can be detachable and one-piece);

- cutting can be done with a disk tool or cutters (rollers), that is, according to the method of carrying out a technological operation;

- what pipe materials the device processes and their standard sizes.

Detachable and non-detachable

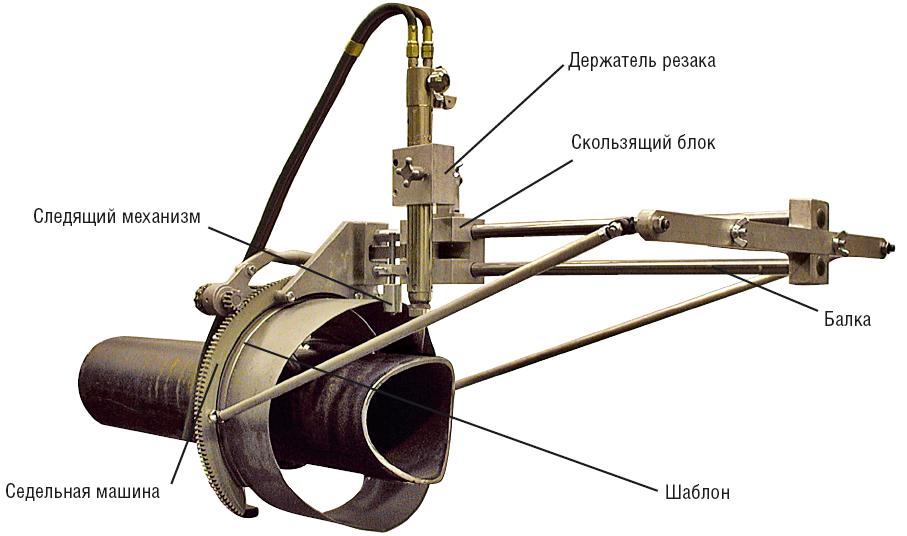

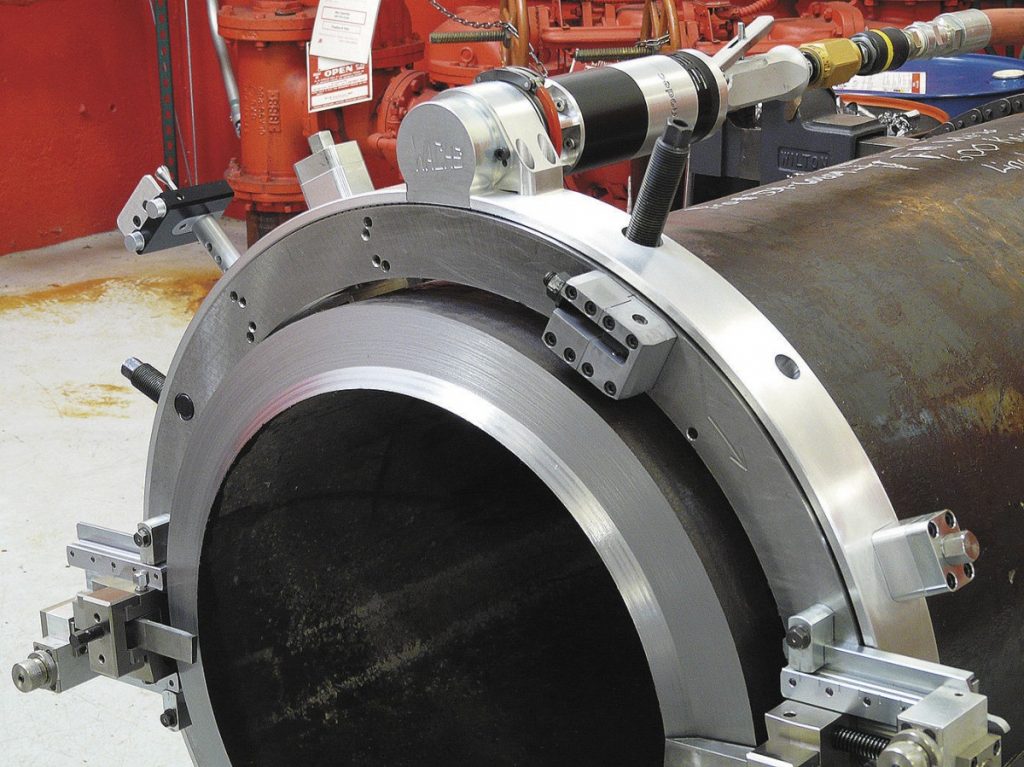

Detachable pipe cutters are used in work on already installed pipelines. The design allows you to cut the pipe in any desired place, as the body is divided into two halves. It is possible to cut large diameter pipes. Cutting pipes with a large diameter is performed with chamfers for welding, so both halves are equipped with supports for chamfering cutters.

Electric split pipe cutter Exact PipeCutting System 360. Photo by Svarbi-68

One-piece work where there is access to the end of the pipe. They cannot be used when cutting large diameter pipes.

Disc and incisive (roller)

In disk electric pipe cutters, the role of the cutting tool is performed by a cutting wheel. It does not have a special sharpening and therefore, after cutting, a small flash remains.

Cutting devices are equipped with special calipers with tool holders. Usually these are split pipe cutters for processing large diameter pipes. The cutting edge of such pipes should have chamfers, the end surface should be in the same plane as much as possible, and the diameter should be made according to the class size.

Disc pipe cutter RIDGID 258 with drive. Photo VseInstrumenty.ru

Calipers, depending on the operation performed, are equipped with cutting, chamfering, boring or trimming cutters. If the pipe cutter has two supports and both are equipped with cut-off cutters, the pipe will be processed twice as fast.

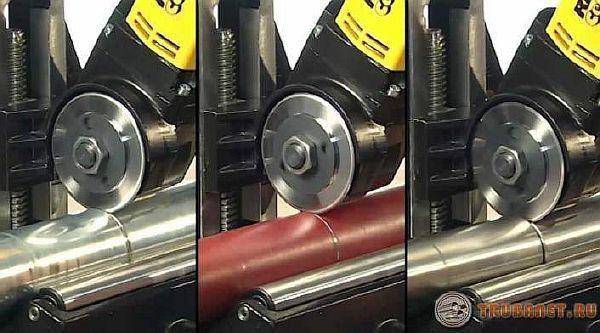

For pipes of small diameters with a small wall thickness, rollers can be used as cutting tools. The cutting process in this embodiment occurs without chip removal.

For steel, stainless pipes and more

Electric pipe cutters have the versatility to process pipes of any material

Here it is important to select the necessary cutting tool with the required sharpening angle and select the desired cutting speed.

The electric drive will create the conditions for quick work, regardless of what material the pipe is made of: ferrous metal, non-ferrous, stainless steel or plastic. The seller usually completes the pipe cutter with various cutting tools for a specific type of pipe.

Reference. Other types of pipe cutters are analyzed in detail in a separate article.

Manufacturers

Many European and American companies are engaged in the production of electric pipe cutters. Russian manufacturers are also gaining their share of this domestic market.

- "Rothenberger" (Germany). The German concern has been present on the market for more than 70 years. The factories of this company are located in many European countries (Germany, France, Sweden, Spain and others). On the territory of Russia, the company's products are promoted by official dealers, for example, such as InterTechDealer. A distinctive feature of Rothenberger electric pipe cutters is high quality and comfort in work. Popular models: Rothenberger Rocut UKS 160/335; Rothenberger Pipecut Turbo 250/400.

- "Exact" (Germany). Products of the German company Exact GmbH & Co. KG has been on the market for over 50 years. The market is conquered by strict rules of technological production, application of computer innovations in production and control. Popular models of electric pipe cutters: Exact Pipecut 200; Exact Pipecut 280E; Exact Pipecut 220E System and others.

Electric pipe cutter RIDGID 258 XL. Photo VseInstrumenty.ru

- "Ridgid" (USA).The world famous American company for the production of hand and power tools was formed in 1923. The company began operating on the Russian market in 1996. The company has its own research base and many tools are created for the first time by its employees. Some Models:

- machine for cutting copper and stainless pipes Ridgid 122;

- electric pipe cutter Ridgid 258;

- electric pipe cutter Ridgid 258 - XL.

- TechnoMashHolding (Russia). The Russian company has recently appeared on the construction tool market with its own developments: electric pipe cutters PTM 14-60; PTM 57-114; PTM 57-108.

Here is a small part of the companies dealing with power tools for pipe processing.

Hydraulic and pneumatic pipe cutters

As mentioned above, the cut can be made by hydraulic and pneumatic mechanism.

Pneumatic pipe cutters for their work use air that is forced into the piston under pressure. Such pipe cutters are used for cutting pipes with a cross section of up to 130 cm. The cut itself is performed with cutters that can be provided for different materials, which allows cutting both metal and plastic pipes.

The disadvantages of this device include high weight, which often reaches 60 kg. It is not possible to work with such a heavy tool in a trench or at a height.

How not to cut polypropylene pipes

To make the edges of straight tubular products even, cutting is not recommended:

- hacksaw for wood or metal;

- electric jigsaw even at low speed;

- an electric drill with a disk nozzle from the side of the inner surface of the pipe.

If you use such devices, the edges will turn out to be torn. They will have to be carefully cleaned and leveled before soldering to create a reliable connection.

Hacksaw cutting

The grinder is also not suitable for cutting polypropylene. The reason for this is the high rotation speed of the disk element. Because of this, the material heats up and begins to melt.

It is also impossible to use cutting devices for rolled metal. They will tear polypropylene, as their knives are not designed to work with polymeric materials.

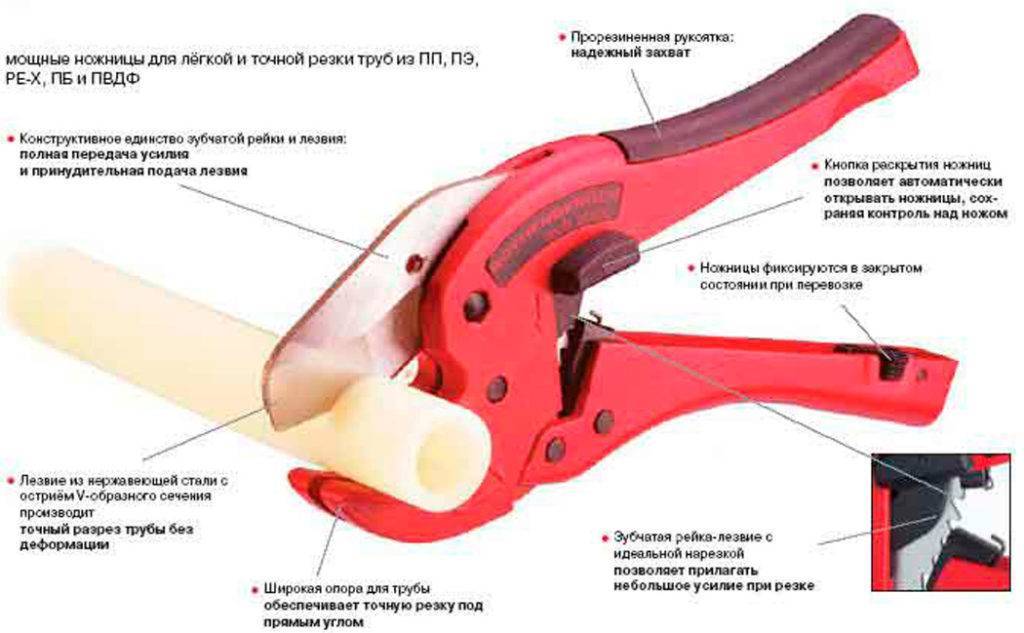

Popular models of scissors for cutting plastic

The construction tool market offers a wide range of products. What models and give preference to manufacturers we will tell further.

VALTEC products

Among the winners are scissors for polypropylene pipes with a diameter of 40 mm. The manufacturer guarantees high-quality cutting for 2 years or 5000 cuts. Tool weight 406 gr. Used for reinforced pipes, layer thickness up to 0.6 mm. Can cut pipes from any plastic, including metal-plastic products. Scissors have a ratchet mechanism and a spring breeding system.

Scissors Rothenberger Rocut 42 TC 52000 0-42mm

The Rothenberger Rocut 42 TC shears are suitable for cutting all types of reinforced polypropylene pipelines. Designed for diameters 42 mm and smaller. Equipped with high power cutting mechanism. The operation is carried out using a rack and pinion and a knife. The presence of a latch prevents the scissors from opening during storage. The pipe cutter is expensive and requires periodic blade replacement.

Pipe cutter KRAFTOOL

Pipe cutter KRAFTOOL

Pipe cutter KRAFTOOL

The most popular model is Kraftool EXPERT 23385-z01. Designed for cutting pipes with a diameter of 5 to 42 mm from copper, brass, aluminum and other non-ferrous metals.

The cutting force is adjusted by a screw, during the cutting process, chips are removed.

The case is aluminum, cutters are made of stainless steel.

Scissors REMS ROS P 42P

Shears for propylene pipes and all types of plastic of the German model REMS ROS P 42P are used for cutting diameters from 1 mm to 42 mm. It turns out a high-quality cut, while chips and burrs are removed. They use a ratchet mechanism that allows you to cut products with thick walls, without applying significant effort. The only drawback is their high cost.

GROSS scissors

PVC pipe shears of the GROSS 78424 brand are also used for cutting products with a diameter of up to 42 mm, skirting boards, various profiles and designs. They have a straight knife with one cutting edge made of tool steel. The lower support part is semi-circular for easy placement of round parts. The working movement is carried out using a ratchet mechanism. Weight 450 gr.

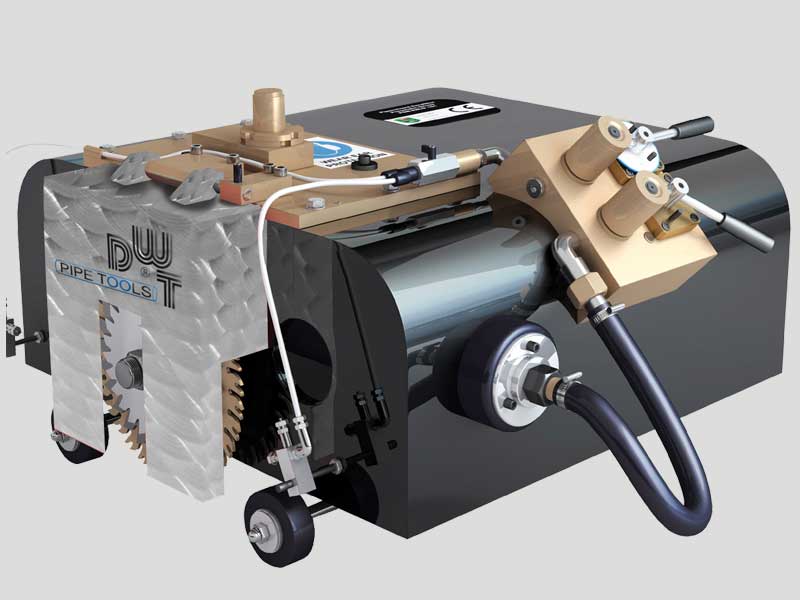

BADA pipe cutters

BADA pipe cutters are professional equipment for cutting polypropylene pipelines with a diameter of 63-1600mm. Blades can be positioned at different angles, which is important when installing backbone systems. The most commonly used band saws are SJC 315; SYH 500; SJC 1600. These are fixed type units. Power is supplied from a 380 V network.

Pipe cutter Exact PipeCut P400

Exact PipeCut

Exact PipeCut

Small-sized pipe cutting machine for pipes with a diameter of 400 mm from a Finnish manufacturer.

An additional operation is chamfering at an angle of 4-15 degrees.

Complete with two supports, powered by 220 V, weighs 6 kg. Can be used for domestic purposes.

Inforce scissors

This is a Russian brand, production is in China.It is used for diameters not exceeding 42 mm when laying domestic water supply. The material of the body is aluminum, the cutting edges are made of hard steel, they are sharply sharpened to eliminate the formation of burrs. The mechanism is ratchet, there is a locking bracket. Product weight 250 gr.

Henco cutters

Henco produces guillotine cutters for multilayer pipes. This is not the main product of the company, but its quality has not suffered. Scissors are produced for sizes 14-20, 25-40 mm with replaceable knives. The variant with non-replaceable knives is designed for diameters 14-20 mm. Used for domestic purposes and by professionals.

REHAU products

Under the REHAU brand, they produce a tool for preparing polymer pipes for installation. For cutting a small diameter (15-40 mm), scissors are used. To work with diameters of 63-125 mm, use a disc pipe cutter. Scissors are also suitable for cutting HDPE pipes. High quality products, cutting parts are made of tool steel, equipped with a comfortable handle. There is a latch for storage in the non-working position.

REHAU guillotine cutter

REHAU guillotine cutter

Preparation and cutting of steel pipes

Before proceeding with cutting, the pipe material must be properly prepared:

- Moisten the intended separation area with oil. This will reduce the temperature of the metal during operation, clean the outer perimeter and partially remove scale.

- Using a clamp, fix the pipe in the holder, focusing on the cut line previously marked with a marker.

- Using the rod, move the cutting head around the perimeter of the part. Gradually increase the feed to achieve the desired cut.

- If the knives have the required strength and a good level of sharpening, the cut-off point will be smooth and will not require further processing.

In models designed for cutting pipes of small diameter (no more than 30 mm), the stem is combined with the handle. When it is set in motion, the cutting itself occurs.

Cutting of pipes of small diameters

For cutting steel pipe material of small diameter, the part to be processed is clearly fixed with a pipe cutter clamping mechanism. The handle of the tool is turned clockwise so that the cutting element comes into contact with the metal surface.

Then they make another turn of the handle, making sure that the beginning and end of the incision line are in contact, creating a clear closed circle without interruptions and other violations.

A manual roller pipe cutter is the most convenient and practical option for domestic processing of small diameter steel pipes. Its use does not require specific skills and professional knowledge.

If these parameters are met, the tool handle is shifted another half turn, pulling the cutting element closer to the pipe. When the cutters are clearly in the metal, the scroll is slightly accelerated and the handle is rotated until clipping occurs.

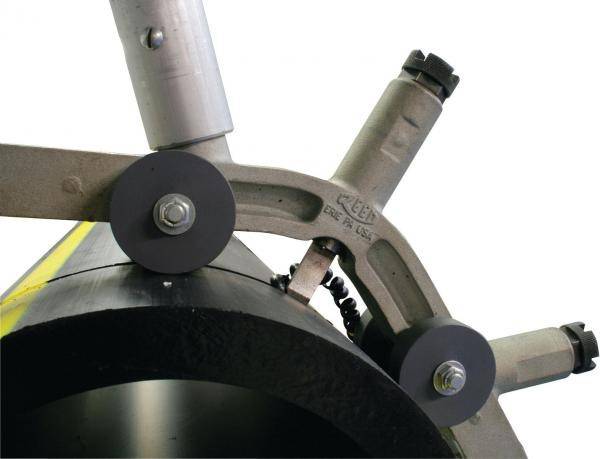

Cutting steel pipes of large diameter

In everyday life, cutting steel pipes of large diameter is practically not in demand. Basically, material of such dimensions is processed on an industrial scale. For this purpose, enterprises buy very powerful, expensive equipment.

The laser machine allows you to effortlessly and at high speed cut steel pipes of large diameter and large thickness.Through a computer control system, the operator can set the machine to a suitable program for making cuts of any complexity.

If, nevertheless, there is a sudden need for cutting large-diameter pipes, it is not necessary to purchase professional equipment.

You can use the usual grinder available in the arsenal of each owner, and by installing a cutting element for metal on it, make a quick, accurate and high-quality cut

But when working with this tool, you should not forget about safety precautions.

When cutting steel pipes of large diameter, it is not recommended to put a working element for wood or stone on the grinder. A discrepancy in the density of the cutters can provoke damage to the workpiece, and subsequently lead to breakage of the tool itself.

But nevertheless, the angle grinder is only suitable for one-time cutting and cutting work. For regular large-scale events, it makes sense to acquire a more durable and strong unit.

You can read more about the different types of pipe cutting equipment in this material.

Classification of pipe cutters by type of drive

Modern models of pipe cutters designed for cutting steel pipes of various diameters differ in the type of drive.

Hand tools are considered the simplest and do not require special skills to use. Usually they are simply fixed in the processing area, make a few turns and get a fragment with a clear cut. However, this option involves the use of significant physical effort and is not suitable for large-scale work.

A manual pipe cutter is very easy to use, but it will be quite difficult to use it for a long time without proper physical training.It is better to leave it as a one-time "assistant" to solve local repair and installation problems

Electrical units are made of more durable, wear-resistant materials, so they are suitable for active use, easily cope with intense loads and can cut steel pipes of any diameter, including large ones, with high quality.

Electric pipe cutters not only make a clear, even cut without burrs, but also process the end areas of the part

Pneumatic pipe cutters are professional equipment. They provide high precision processing and quickly make the necessary cut.

Cut pipes of any thickness (from thin-walled to 60 mm). They allow to carry out the necessary work in a small-sized room and have the function of boring the inner diameter of the pipe for subsequent welding.

They have high power and easily cope with the increased loads of industrial scale.

In everyday life, pneumatic pipe cutters are used extremely rarely, as they have significant weight and impressive dimensions. They usually come with a special trolley designed to move the unit around the working area.

Hydraulic pipe cutters do not require an electrical connection, and work using the principle of fluid pressure. Pumping through the pump, it acts on the piston and sets the unit in motion. When the water pressure is reduced, the cutting elements return to their original position.

Tools of this class are more powerful than hand tools, but they are inferior to electric devices in all respects.

The choice of the unit, first of all, depends on the amount of work that is planned to be performed.For a one-time use, a simple hand tool is enough, and for large-scale events (such as laying communications on a personal site), it is better to use an electric option.

If it is not possible to connect to the network, for domestic purposes you will have to consider buying or renting a hydraulic pipe cutter. In industry, it is most productive to use pneumatic machines for cutting steel pipes.

Model Exact Pipecut 220e

The Exact Pipecut 220e electric pipe cutter belongs to the universal power tools as it has an extensive cutting range.

The Exact Pipecut 220e pipe cutter does an excellent job with both plastic and steel pipe blanks.

The advantages of Exact Pipecut 220e pipe cutters are as follows:

- Maximum cutting accuracy.

- Quite a small weight.

- Area of use - 1.5-20 cm.

- The largest pipe wall thickness is 0.8 cm (steel) and 1.2 cm (plastic).

- Significant time savings.

- The edges of the pipe are obtained without burrs and can be immediately taken for joining.

- No hazardous dust or sparks are generated.

- Equipped with a speed controller allows you to get a constant torque.

- Works with all workpiece materials.

The scope of this tool is as follows:

- Housing construction.

- Shipyards.

- Installation of pipes in various industries.

- Installation and repair of water supply network.

- Heating, cooling and gas lines.

- Power plants.

- Repair measures of pipe rolling in the old building.

Disc electric tool

The electric disk pipe cutter is designed for cutting round pipe assortment from different materials.

The rigidity of the mounting base allows you to make a smooth cut without burr sticking, which is performed by a diamond disk during rotation.

Such disc mechanisms function as follows: a steel or any other pipe is placed on a pair of discs for support and rotates.

The telescopic support moves the cutting roller to the desired location on the part. Gradually deepening, the disk element cuts off part of the pipe.

The main feature of the disc electric options is cutting without chip removal. But, after mechanical sawing of a rotating steel pipe, a very slight flash remains at its end.

Such tools are widely used in the utility and gas industries. They are also often used in industry.

Price and manufacturers

The electric pipe cutter for steel pipes on the market is provided in a very large assortment, the price for them is quite different.

You can buy a device for twenty thousand rubles, or you can pay two hundred thousand for it. It is clear that the price of the electric option is higher when compared with the manual one, but in the first option, the functionality and ease of use are much higher.

Video

And if you purchase a device for steel blanks, then there will be no problems with cutting plastic either.

There are situations when, when a pipe is cut, it is not possible to make a complete revolution of the apparatus around the workpiece.

In this situation, you need to buy a device with several cutting rollers. The price of such a product will be fully justified by easy and high-quality work.

The price of quality equipment from a trusted manufacturer is never low. But, such tools are distinguished by a successful and lightweight design. It is very convenient to use them at work.

Video

Here you can also find reviews of people who have tested these proposals in the work. With this information, the choice is easier to make.

The largest manufacturers of pipe cutters are such European and American companies:

- Rothenberger;

- reed;

- Virax;

- Rems;

- Ridgid.

Products from these companies have established themselves as high quality and reliable.

Also, a large number of these companies have opened their representative offices or enterprises that represent their interests with us.

Video

- Reed Manufacturing Company (USA).

- General Wire Spring Company (USA).

- Rothenberger Werkzeuge AG (Germany).

- REMS-WERK Christian Foll und Sohne GmbH (Germany).

- Virax (France).

The sale of pipe cutters and spare parts is carried out by manufacturing plants. Official dealers on the Russian market also do this.

Realization takes place in specially equipped warehouses. And you can choose the right electric pipe cutter for steel or plastic pipes in convenient catalogs.

Tools

Today, on the market for such products, you can find various portable equipment for cutting and processing pipes. To choose the right fixture, you need to take into account the design features, whether it be a flameless cutting and trimming machine or a circular knife.

The best type of devices for cutting metal and plastic pipes and bevelling are cold or fireless machines. In addition to the function of the cutter, they provide for chamfering the inner and outer sides of the pipe walls, as well as boring the inner diameter.

In addition, a cutter is used. The disadvantage of such a machine is the greater noise during operation in comparison with the propane counterpart. In home workshops, pipe cutters and electric welding are usually used for cutting.

Classification

Cutters according to their purpose are divided into special and universal. Universal ones are ejector and non-ejector, it all depends on how combustible gas and oxygen are mixed in them.

According to the method of cutting products, gas cutters of any kind are as follows:

- for surface treatment of metal;

- spear;

- separating;

- oxygen-flux.

Gas burners are as follows:

- oxygen - these are ejector structures in which a burning jet is formed by means of oxygen.

- kerosene - works with kerosene and is used to process products up to 20 cm thick based on carbon steels.

- propane - this option is suitable for cutting cast iron pipes and other ferrous or non-ferrous metal products. A gas propane torch is considered the most reliable and safe, while providing high performance.

- acetylene - designed for cutting sheets and parts of large width, often used for oxy-fuel cutting, and must be equipped with a special valve that controls the power and speed of oxygen supply to the working area.

Universal torches with an ejector are the most popular. Such units help to use combustible gas under certain conditions, the pressure should be 0.03-1.5 kgf / square centimeter. The universal device can cut metal products in different directions, it is simple and easy to use, has small dimensions. With it, you can process metal with a thickness of 3-300 ml.