- Making a granulator with your own hands

- Homemade dryer for sawdust

- How to organize the production of pellets with your own hands

- What will be required

- Flat matrix round shape

- Powerful rollers with toothed working surfaces

- Device body

- electric motor

- Strong supporting frame

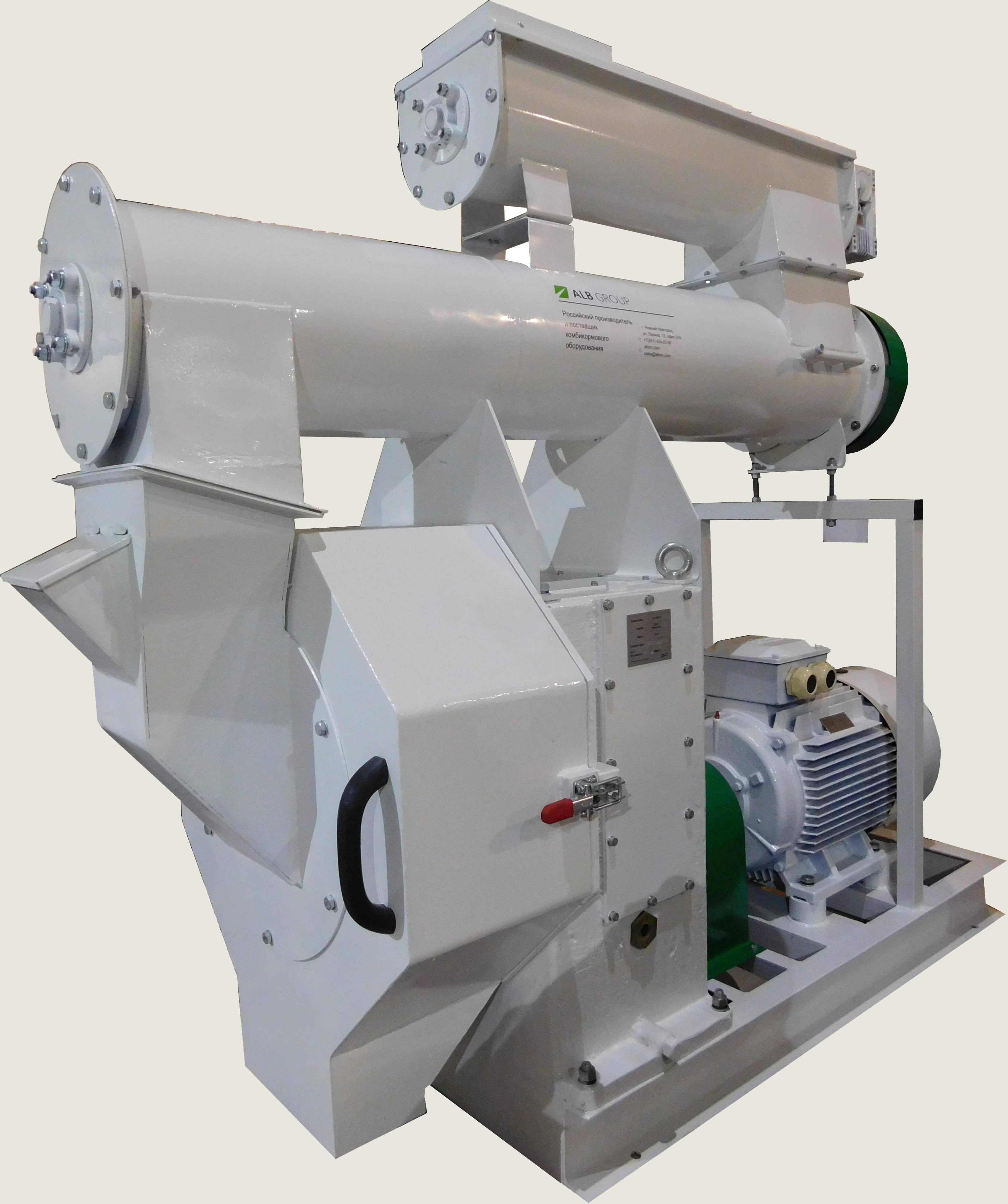

- Equipment for the production of pellets

- Homemade crusher

- sawdust dryer

- How to make a pellet mill with your own hands

- What is better - firewood or fuel briquettes?

- Choice of pellet production as a business

- Raw materials for production

- Types of fuel briquettes

- What raw materials are pellets made from?

- Processing of sawdust, cake, husks, seed peel

- Making pellets from wood, hay and straw

- Wood pellet manufacturing technology

Making a granulator with your own hands

The algorithm of actions for the manufacture of such equipment is as follows:

- We make a matrix. If you do it yourself, you will need a disk blank with a thickness of 20 mm or more, if it is smaller, then the matrix will quickly deform. But the diameter can be different, the performance of the equipment depends on it. For example, if the diameter is 50 mm, and the engine is about 30 kW, then it will be possible to get up to 350 kilograms of pellets within an hour. And if the volumes are expected to be smaller, then a matrix up to 30 cm in diameter will suffice.In the center of the disc, you need to drill a hole along the diameter of the gearbox shaft, then a groove is made for a hard fit. And the holes for pressing and exiting the granules should be in the shape of a cone.

- Rollers or gears for rollers must be selected in such a way that the width matches the working area of \u200b\u200bthe matrix. Put a gear on the shaft, then it is fixed with a coupling perpendicular to the axis of the gearbox output shaft.

- Depending on the size of the matrix, it is necessary to weld the cylindrical body of the equipment based on sheet metal or pipe. The housing includes two parts: the raw material is loaded into the upper part, and then, after passing through the system of rollers and the matrix, the finished granules pass into the lower part of the housing, then they are poured into the container along the tray. And the matrix should move freely inside the upper part of the case with a minimum gap. A hole is made at the bottom of the body for the exit of pellets, a tray based on sheet material or pipes is welded to it.

- The gearbox output shaft must be placed at the bottom of the structure housing by means of bearings and a coupling.

- To make it convenient to clean and maintain the body, the top and bottom of the body must be detachable and bolted using welded lugs. A matrix and rollers are placed in the body.

- The granulator is placed on a frame based on a channel or angle and is rigidly fixed on it. Then the electric motor is attached and its output shaft is attached to the gearbox.

- From the outside, the frame and other parts are painted with paint for metal. Next, the engine is connected and a test run is performed.

With a granulator equipped with a flat-type matrix for the production of pellets, it is possible to solve the problem of heating a room up to 150 square meters.Ready-made pellets can be used for burning in a fireplace or stove, as well as for solid fuel boilers. The problem of recycling waste from agricultural activities and woodworking will also be solved.

Homemade dryer for sawdust

In order for home-made wood pellets not to crumble at the exit from the granulator matrix, the raw material must have a minimum moisture content. In industrial production, this is done through drying chambers, and at home, special drum-type dryers can be made based on old barrels.

In order for home-made wood pellets not to crumble at the exit from the granulator matrix, the raw material must have a minimum moisture content. In industrial production, this is done through drying chambers, and at home, special drum-type dryers can be made based on old barrels.

It is necessary to weld several iron barrels together and install them on the frame, taking into account a slight slope to one side. Inside, blades are welded to the walls for grinding raw materials. Inside, on one side of the drum, hot air is supplied using an electric or gas heat gun. The drum is rotated by an electric motor through a gearbox or a reduction belt drive.

Not in all cases there is a need to organize the production of pellets based on sawdust at home.

Not in all cases there is a need to organize the production of pellets based on sawdust at home.

This is justified if the equipment is completely self-made with minimal costs for components and spare parts, or if you have a small granulator, the performance of which is sufficient to produce pellets for domestic use and even sale. So you can recoup the cost of the purchased equipment.

It is not so easy to make a granulator and other equipment for the production of pellets on your own, but if you have the time, skills and patience, then it is quite possible. But to purchase an industrial granulator for sawdust for heating purposes a private country house, from an economic point of view, is completely unreasonable.

How to organize the production of pellets with your own hands

The rather high cost of fuel pellets makes the question of how to make pellets on your own very relevant for owners of private houses and summer cottages who want to use this type of fuel. It should be said right away that it is possible to make a home-made granulator for making pellets. However, before embarking on the implementation of such a project, it is necessary to carefully assess your capabilities. The manufacture of such equipment, during the operation of which significant loads are created, requires not only sufficiently serious technical training and the availability of appropriate skills, but also the use of turning, milling, welding equipment, as well as locksmith tools. All this presupposes the presence of high qualifications and sufficient experience in carrying out work of this nature.

Homemade granulator device

The most important condition for the expediency of independent production of fuel pellets is the availability of affordable raw materials, which must meet certain requirements in terms of their quality characteristics. If you purchase raw materials for self-production of pellets, which will have to be pre-treated, the cost of the finished product may turn out to be such that it will simply be unprofitable to use it for home heating.

When making pellets with your own hands, you should also take into account the fact that not all wood raw materials are suitable for production. Coniferous wood waste is optimal in terms of obtaining high-quality fuel pellets, which are distinguished by a dense and stable structure.

Drawing of the housing and matrix drive

What will be required

In order to make pellets at home, as mentioned above, you will need a machine for the production of such fuel pellets. Consider the main elements of its design.

Flat matrix round shape

It can be purchased ready-made or made independently, using a sheet of metal for this purpose. The thickness of such a sheet must be at least 20 mm. The holes in the matrix, in which the fuel pellets will be formed, must have a conical shape. When purchasing or manufacturing independently a matrix for a machine for the production of fuel pellets, you should keep in mind: the larger the diameter of such a structural element, the higher the productivity of the equipment.

The size of the granules depends on the diameter of the holes in the matrix

Operating principle flat die granulator

Powerful rollers with toothed working surfaces

These elements, interacting with the surface of the matrix, push loose wood mass through its holes, forming dense granules. Such rollers, mounted on a horizontal shaft through rolling bearings, are driven by a rotating vertical shaft. The degree of pressure of the toothed rollers to the surface of the matrix is regulated by a screw mechanism.

Toothed rollers and matrix

Device body

It is made from a pipe of the appropriate diameter or from a metal sheet rolled into a cylinder. The inner diameter of the housing must ensure free rotation of the matrix installed in it.

Matrix with rollers inside the body

electric motor

The shaft of the electric motor is connected to a vertical rod that rotates the matrix.

V-belt transmission

Strong supporting frame

For the manufacture of the frame, profile rolled products are usually used.

Homemade plant for the production of fuel pellets

Equipment for the production of pellets

The main role in the technological process is played by the machine for the production of pellets, which is also the most difficult to manufacture. It will not work to completely make a granulator with your own hands, since metalworking machines are needed for the manufacture of the matrix and rollers - turning, milling, drilling and grinding. So there are 2 options: buy a ready-made pair of matrix - rollers or order it from the masters.

The matrix pair for the pellet press should be made of high-carbon steel St45 or St50, and even better alloyed with manganese HVG or 65G. Moreover, after processing, the parts must necessarily undergo a hardening process in order to achieve a hardness of 58-60 units. To make a matrix for a granulator, it is necessary to withstand all the dimensions indicated in the diagram:

On the roller shaft, you can use simpler steel - St3, 10 or 20, and you do not need to harden it. But the working parts of the rolls must be made from the above grades, followed by hardening, and then put them on the shaft through the bearings, as shown in the photo below.

Now about what you can assemble the body and drive for a homemade pellet granulator from. The matrix pair must be placed inside a cylindrical body, which is made of sheet metal or a pipe with an internal diameter of 200 mm. The drive shaft is inserted into the hole of the matrix and fixed with a key, and below you need to make a platform for finished pellets.The assembly scheme of the pellet granulator is shown in detail in the video:

Watch this video on YouTube

To rotate the shaft, you need to take an electric motor with a power of at least 5 kW, and the drive can be assembled from an old car gearbox from the Volga or Moskvich with part of the rear axle. On the side where the cardan shaft should be connected to the gearbox, a pulley is installed, rotated by a belt drive from the electric motor. Both units are attached to the same frame, as described in the video:

Watch this video on YouTube

Note. In this design of the do-it-yourself pellet press, the shaft rotates the matrix, and the rollers remain stationary. The pulleys must be selected so that the speed of its rotation is no more than 250 rpm.

Homemade crusher

It is good when it is possible to get good small wood waste from some production for pellet pressing. If there are small branches or slabs in this waste, then additional equipment is needed to crush them - a crusher. There are many home-made structures, but most of them cut wood into chips that are too large, from which it is impossible to make pellets at home.

Your attention is invited to a simple chipper wood waste, made from 3 dozen circular saw blades for a circular machine with carbide soldering. All saws are mounted on one shaft in such a way that between the teeth of each subsequent one they slightly shift relative to the previous one. A pulley and 2 bearings along the edges are placed on the same shaft, after which the entire structure is fixed on a frame made of corners or pipes.

As you understand, the performance of the unit is low, but such a wood waste chipper will allow you to get sawdust suitable for the production of pellets. If you have a circular saw on your farm, then the chopper can be adapted to its frame, as shown in the photo:

sawdust dryer

In order for hand-made wood pellets not to crumble at the exit from the granulator matrix, it is necessary to ensure the minimum moisture content of the raw material. In industry, this takes place in various drying chambers. At home, craftsmen adapted to assemble drum-type sawdust dryers, since their design is the simplest, as shown in the diagram:

Several iron barrels, welded together, are mounted on a frame with a slight inclination to one side. From the inside, blades are welded to the walls of the barrels to mix the raw materials. On the one hand, hot air is supplied inside such an impromptu drum by a gas or electric heat gun. The drum is rotated by an electric motor through a gearbox or a reduction belt drive.

For reference. When pellets are made from fresh woodworking waste, the biggest energy consumption is in the drying process. For home production, they may be too large, negating all the benefits of this venture.

How to make a pellet mill with your own hands

Do-it-yourself pellet granulators are made by many craftsmen without problems. But it is not assembled from consumable waste material. The matrix, rollers and other structural elements will either have to be ordered for manufacture, or ready-made.

Just at the very beginning you need to choose the type of machine design.That is, it is either a movable matrix and fixed rollers, or vice versa: the matrix is static, the rolls are moving. Both options require an engineering approach. And here it is impossible to say which of the proposals is easier and cheaper. But both options work effectively.

In addition to the above parts, you will need an electric motor, a gearbox, two pulleys of different diameters and a V-belt.

The type of gearbox is selected taking into account the plane in which the driven shaft will be located: horizontally or vertically. If vertical, then the electric motor and gearbox are assembled on the frame in sequential order. That is one after the other. At the same time, their shafts are located in the same direction. And these two elements are connected vertically and directly without intermediate parts. In this case, without pulleys and a belt.

The same design can be used by mounting the motor and gearbox horizontally. But in this case, it is necessary to choose the latter with two shafts coming out of it, located perpendicular to each other.

The third option is using intermediate parts. Here, the motor and gearbox are mounted on the frame next to each other vertically. The transmission of rotation is carried out by means of a belt and pulleys. The latter can be replaced with asterisks, that is, create a chain drive. This option is convenient because if you correctly calculate the gear ratio of the intermediate elements, you can not install the gearbox.

Attention! The optimal gear ratio is "6". Not less .. The rear axle from the car is suitable as a gearbox

The larger the latter, the more powerful the device for transmitting revolutions from the electric motor

The rear axle from the car is suitable as a gearbox.The larger the latter, the more powerful the device for transmitting revolutions from the electric motor.

Now about the matrix and rollers. Don't make them by hand. You will have to contact the turner. Or purchase ready-made parts. The thicker the matrix, the stronger it will withstand heavy loads and last longer. It is expensive, plus - a lot of weight.

The rollers must be wide enough to fit on the surface of the matrix, moving freely along it. For them, a cross member is selected, which is connected to the gearbox shaft. It must be strong, because the main loads fall on it.

The last element of the granulator is the body. The easiest option is a thick-walled pipe. Its inner diameter will be the outer diameter of the matrix. That is, it will be necessary to order from a turner with an indication of this size. The same goes for rollers.

Assemble granulators for sawdust with your own hands possible, given not the complexity of the design, but the cost of parts and assemblies. And if some can be found in a landfill, then such as a matrix, you will have to buy expensive. But in any case, it will cost less than the factory machine. True, no one will give a guarantee of reliability and quality here.

The principle of operation of the magnetic separator - how it works, what it consists of

Making a filter in a vacuum cleaner with your own hands

Sparking of the brushes of the electric motor of the vacuum cleaner - why does it happen

Reception of wood and trees - methods of processing and use

How Roll Crushers Work - Scope of Application

How to make a grass and branch chopper for a summer cottage with your own hands

What is better - firewood or fuel briquettes?

The bottom line is that this question cannot be answered unambiguously.

Fuel briquettes will benefit in terms of:

- warehouse characteristics,

- calorific value,

- time spent on direct application as intended by the buyer.

In terms of quality, everything depends on the quality of production.

As practice shows, unscrupulous manufacturers do not stay on the market for a long time. Therefore, if an advertisement for the sale of briquettes has been observed for more than a year, most likely, the quality is present. Another question is whether it is profitable to produce them in forest areas? It is beneficial if it is not sold where production is carried out. Only a marketing genius will be able to sell people what they can get for free.

Choice of pellet production as a business

First of all, it is necessary to assess the demand for the products that the new enterprise will produce, and decide in which region it is most expedient to open it. The main trend of world development is the increased interest in alternative and renewable energy sources, as well as a significant tightening of requirements for their environmental safety.

Pellets are a waste product of enterprises for various purposes:

- woodworking;

- sawmills;

- a number of food industries;

- agricultural

Often these products are called wood pellets or "euro firewood", but the production of pellets can be organized using waste from any of the above-mentioned industries.

The main areas of use of pellets are, first of all, energy:

- generation of heat and electricity;

- cogeneration at power plants and boiler houses;

- private households (boilers running on pellets, or combined, pellet - gas);

- products are widely demanded by manufacturers of such a product as cat litter.

Options for the use of pellets in auxiliary industries are possible. For example, for the operation of industrial steam generators, absorbents, etc.

The pellet production line, oriented to the domestic Russian market, is not particularly profitable today, since the volume of consumption is extremely small. The main consumers of the mentioned products are the states of Western Europe and China.

It is possible to organize pellet production, which differ significantly in composition due to the feedstock (pure sawdust, wood with a certain percentage of bark, straw, cake, etc.). The more impurities, the more significant the ash content of the finished product and, accordingly, the lower its quality, and hence the cost.

The most expensive and high-quality pellets are considered, in which the mentioned indicator does not exceed one and a half percent. It is this product that is most in demand for pellet boilers installed in private homes, as well as for the production of filler.

If the indicator of 1.5% in terms of ash content is exceeded (1.5 - 5.0)%, then pellets can only be used as fuel in large industrial installations.

It should be borne in mind that there are no uniform international standards for these products. Therefore, you should carefully read the requirements of the current regulations in the country where you plan to organize the supply of finished pellets. And it is with this in mind to select equipment for the production of pellets.

The diameter of the finished product can be set in the range of 5.0 - 10.0 mm, and its length, respectively, 6.0 - 75.0 mm. The requirements for the ash content of products differ (the highest grade in the USA ≤ 1.0%, in Europe ≤ 1.5%. The grade “standard” is ≤ 3.0%, respectively);

- commodity market;

- leading manufacturers already operating in this market (level of competition);

- availability of solvent demand (description of consumers of the mentioned products);

- analysis of existing prices, their dynamics and the capacity of the existing market;

- selection of technologies by which the production of pellets will be organized. Determining the suppliers of the equipment required for this.

The project can be implemented in any region of Russia.

To analyze the sales of products, it is necessary to obtain the most complete characteristics of the target market, which it is planned to enter with pellets.

Based on the analysis of the collected information, a marketing strategy is developed that the new plant or production complex will follow, and a business model of the future enterprise is selected, which will be the basis for the production of wood pellets.

Raw materials for production

Pellets are granulated fuel made from any waste. Traditional firewood is cheaper, as it can be sawn in the nearest forest if you have the appropriate permit. Then they will only have to split (or saw) and dry - you can use it. In the absence of relevant documents, self-cutting of forests is a crime.

Fuels such as pellets are made from plant and wood waste. This waste is carefully crushed, after which it is pressed.Granules appear at the output of the production equipment - this is the finished product. It remains to be packaged in bags and sent for sale. For domestic use, it must be sent for storage in a dry room - it cannot be stored outside.

The traditional raw material for the production of pellets is wood. Sawdust and wood waste are loaded into the equipment. In general, everything that is not suitable for direct use. In addition to wood, pellet production is carried out:

- From straw - a widespread material remaining after harvesting and processing crops.

- From sunflower waste - give a considerable amount of heat.

- Peat is an excellent natural material for the production of pellets and fuel briquettes.

- From tree bark - any parts of trees are used.

Such rubbish costs a penny, and in some cases it can be obtained for free. Although it has become increasingly difficult to get it lately, people and enterprises that produce pellets on their own equipment are actively buying it.

Types of fuel briquettes

Briquettes are divided into types depending on their shape. Basically, the following types can be found on the market:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from sawdust of natural wood with the addition of special components.

- Nestro. Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading tank, then fed for pressing by means of a screw. The mass is distributed by dispensers according to the forms under pressure.

- Pini kay. In shape, these are polyhedra with the number of faces from 4 to 6.In the production process, they are subjected to high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

The chemical composition and heat transfer of all these types of pressed sawdust is the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. The high density and slight hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

If you have the necessary raw materials to form briquettes, you can make them yourself.

What raw materials are pellets made from?

There are no particular restrictions on the use of raw material for the production of pellets. The main thing is that they must be of natural origin, plus - combustible.

But the raw material has its own requirements:

- Ash content. These are non-combustible residues that remain after burning fuel. For pellets, this figure should not exceed 3%.

- Humidity - 8-15%.

- The minimum amount of chemical components such as sulfur, chlorine, nitrogen, etc.

- The freshness of the material, because the old raw material loses its energy value.

- Possibility of granulation. Not all natural combustible materials have low strength. And the stronger the raw material, the weaker the pellets in terms of hardness. Because they are harder to press.

Processing of sawdust, cake, husks, seed peel

Unfortunately, the waste of the agro-industrial complex does not meet all the parameters. They have a high ash content, low energy value, plus a high content of chemical elements. The only plus that interrupts the shortcomings is the minimum price. This reduces the cost of pellets.

Granular fuel from agricultural plant waste has a fairly good energy value - up to 5 kW / kg. But they have an increased ash content compared to wood - 1.5-3%. Therefore, pellets from such raw materials belong to the third grade. Hence the low price.

Making pellets from wood, hay and straw

Pellets from wood without bark - the first grade. The ash content of such fuel does not exceed 0.5%, the thermal power is 5.4 kW / kg. This is the most expensive option.

Wood with bark belongs to the second grade. This also includes straw and hay pellets. Here the ash content is 1-1.5%, the combustion power is 5.2 kW/kg.

Wood pellet manufacturing technology

The manufacturing method is simple. Includes several technological operations:

- Sorting wood by size: into sawdust and shavings, as well as into chips, branches and slabs.

- Crushing of large elements.

- Crushing of small elements to obtain dimensions of length up to 4 mm, thickness up to 1.5 mm.

- Drying. At the exit, the humidity should not exceed 12%.

- Granulation. This is where the sawdust granulator comes into play.

- Secondary drying of the finished material.

During the pressing process, lignin is released from the wood. It is a natural polymer compound found in plant cells. It is he who binds the particles of wood together, that is, glues them together.