- What is an instantaneous electric water heater?

- How it works

- Operating principle

- TOP 5 best warm cable manufacturers

- Heating

- The nuances of installation work

- Video description

- Briefly about the main

- Laying methods - hidden and open system

- How to defrost a pipe indoors

- Use of electric convectors

- Mounting

- Ways of laying the heating element

- Internal heater installation

- External installation of pipe heating

What is an instantaneous electric water heater?

An instantaneous water heater is a compact device that allows you to heat water immediately before it enters the faucet, without accumulation in the tank. The most popular heaters powered by electricity due to the ease of installation and control.

This device has its own features of operation, which you should pay attention to before buying. The main drawback of the device is the ultra-high power consumption for heating water, and even the most modern models do not reduce this figure.

- A flow heater is usually installed in the following cases:

- when hot water is needed all the time, for example, in public catering establishments in places for visitors, shopping centers;

- if there is no time to wait for heating, for example, in a country house or in the country;

- in cases of extremely cheap or even free electricity;

- in conditions of lack of space for a full-fledged storage heater.

It is worth remembering that, despite the durable materials and ease of operation, a flow-through water heater will in any case last less than a unit with a tank, and there is no question of saving at all.

How it works

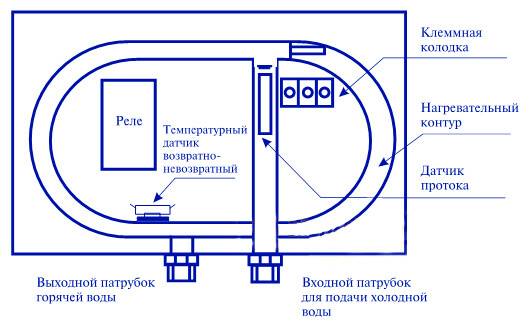

The flow model differs from the storage boiler in that there is no tank for accumulating hot water in the design. Cold water is directly supplied to the heating elements and comes out already heated through a mixer or faucet.

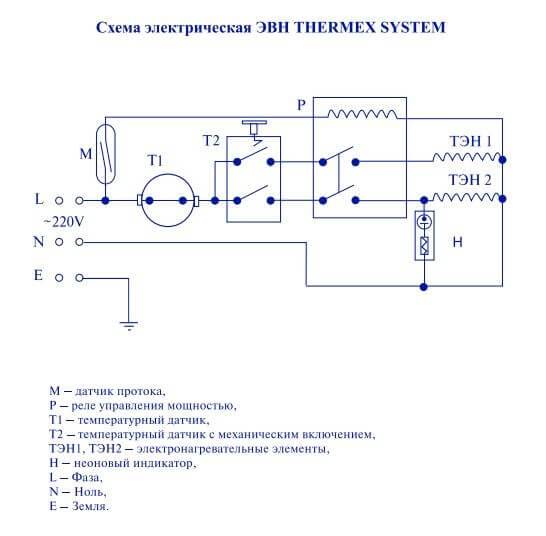

Consider the example of a Termex instantaneous water heater device:

As you can see, the electrical circuit of the heater is quite simple. All structural elements can be easily found and purchased if the device fails.

Now let's move on to the second, no less important issue - consider how a tankless water heater works.

Operating principle

So, using the example of the Termex heater provided above, we will consider its principle of operation.

Connection to the mains is carried out with a three-core cable, where L is a phase, N is zero, and PE or E is ground. Further, power is supplied to the flow sensor, which is triggered and closes the contacts if the water pressure is sufficient for operation. If there is no water or the pressure is very weak, the heating will not turn on, for safety reasons.

In turn, when the flow sensor is triggered, the power control relay is turned on, which is responsible for turning on the heating elements. Temperature sensors, which are located further in the electrical circuit, are designed to turn off the heating elements in case of overheating.

In this case, the temperature sensor T2 is turned on after the heating elements have cooled down in manual mode. Well, the last element of the design is a neon indicator that displays the process of heating water.

That's the whole principle of operation of a flowing electric water heater. If suddenly the device fails, use this diagram to find the faulty element.

In other models, there may be a modified scheme of operation, for example, there will be a thermostat, as in the image below.

When cold water is supplied, this membrane is displaced, thereby pushing the activation lever through a special rod. If the pressure is weak, the displacement will not occur and the heating will not turn on.

TOP 5 best warm cable manufacturers

The leading manufacturers of heating cables are:

- The Swedish company Thermo Industri AB is engaged in the production of cables for heating domestic and main pipelines. For the manufacture of systems, automatic equipment is used, which improves product quality and reduces the cost of products. The manufacturer offers thermal regulators and additional devices that ensure reliable operation of pipe heaters.

- Eltrace products are produced by a company with French roots. The company specializes in the production of heating elements with automatic temperature control. For domestic use, a series of Tubes-heat products is offered. The Traceco range is suitable for mounting on industrial pipelines. But the use of products in the private sector is also allowed.

- Thermon products are manufactured by an American company. The equipment is characterized by ease of installation and low power consumption. The company offers products with self-regulating temperature.

- The Danish company Devi offers resistance-type heaters, as well as self-regulating equipment. The company has been specializing in the production of heating elements for over 50 years. The products are of high quality and easy installation.

- The Russian manufacturer Teplolux (SST) produces heating elements for pipes and floors. Products are distinguished by a reduced price with high quality workmanship.

If the site uses non-standard piping. Then the owner will need to independently create a heating circuit or contact the company. When arranging an electric heating circuit, one should remember about safety and provide for the installation of protective elements that eliminate the risk of electric shock.

Heating cable review and test, don't miss the video:

How to connect the heating cable to the network:

Helpful2Useless

Heating

When planning a winter water supply system, you need to keep in mind that insulation only helps to reduce heat loss, but cannot heat. And if at some point the frosts turn out to be stronger, the pipe will still freeze. Particularly problematic in this sense is the section of the pipe outlet from the underground sewer to the house, even if it is heated. All the same, the ground near the foundation is often cold, and it is in this area that problems most often arise.

If you don't want to freeze your plumbing, heat your pipes. To do this, use a heating cable or heating plates - depending on the diameter of the pipes and the required heating power. Cables can be laid lengthwise or wound in a spiral.

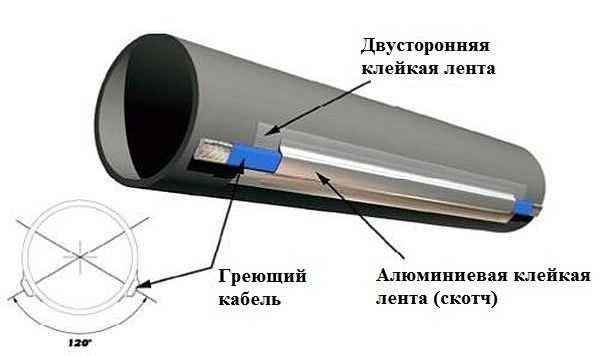

Way of fixing the heating cable to the water pipe (the cable must not lie on the ground)

The heating cable is good for everyone, but it's not uncommon for us to have power outages for several days. What will happen to the pipeline then? Water will freeze and can burst pipes. And repair work in the midst of winter is not the most pleasant experience. Therefore, several methods are combined - and the heating cable is laid, and insulation is placed on it. This method is also optimal from the point of view of minimizing costs: under thermal insulation, the heating cable will consume a minimum of electricity.

Another way to attach the heating cable. To make electricity bills smaller, you also need to install a heat-insulating shell on top or fix rolled thermal insulation

The development of a scheme for laying a water supply system in a country house is described here.

The nuances of installation work

When the wire is securely fastened inside or out, it is important to take care to insulate the end of the conductor. Experts recommend using heat shrink tubing

This product will perfectly protect the cores from moisture, which will reduce the risk of short circuits and repair work. We must not forget that it is required to connect the heating part with the "cold" one.

Wire connection

Tips and advice from experienced craftsmen:

- If you use two methods of laying the wire inside and outside the pipe at once, you can increase the rate of water heating by several times, but this will require additional installation costs.

- Heating water pipes with a self-regulating heating cable will allow you to ignore warm sections and direct current to cold places. It is allowed to cut, so there will be no problems in installation even in hard-to-reach places. The length of the cable does not affect heat dissipation.

- Resistive wire is half the price, but its service life is much lower.If a conventional two-core cable was installed, but it is worth preparing for the fact that after 5-6 years it will have to be replaced.

- The braid on the wire serves to ground it. You can skip this stage of work, but it is better to familiarize yourself with the methods of grounding.

Video description

How to make grounding plumbing shown in the video:

Most often, a linear cable laying method is chosen for self-assembly.

The level of heat transfer directly depends on which pipes are installed in the room

For plastic pipes, this indicator will not be high, which means that when installing a heating cable for plumbing, it will be necessary to wrap the pipes with aluminum foil.

Before attaching the cable to the outside of the metal pipe, it is important to make sure that there is no rust. If it is, cleaning and treatment with a special antiseptic is required.

If this is neglected, then in the future there is a risk of damage to the insulation.

If fastening is carried out from the outside, then the distance between the insulating bundles should not be more than 30 cm. If you take a wider step, then after a while the fasteners will disperse.

In practice, some craftsmen stretch two wires at once to increase the heating rate. It is important that there is a small distance between the cables.

For fastening to plastic, it is better to use special clamps.

Fastening with clamps and thermal insulation in the section

- If it is decided to twist the wire in a spiral, then initially the pipe is wrapped with metallized tape.

- To fix the insulation, it is better to use special ties. They can be purchased at any hardware store.

- It is necessary to completely isolate the temperature sensor from the electrical cable in order to eliminate the risk of short circuit and fire.This requires not only maintaining the distance between these devices, but also making the insulating gasket a special material.

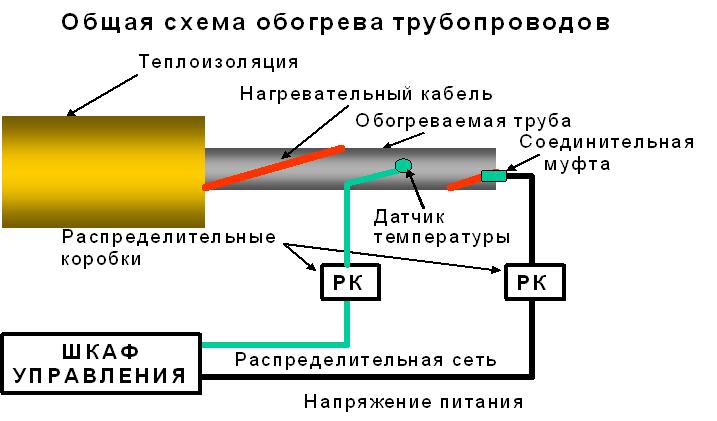

- Heating pipelines with a heating cable using a thermostat will provide constant temperature support. This device is best mounted next to the electrical panel or directly in it. It will not be superfluous to install an RCD.

wire with thermostat

Briefly about the main

First of all, it is important to choose the right cable for heating pipelines.

There are self-regulating and resistive types of cable that are used for plumbing

When choosing a cable, pay attention to the number of cores, type of section, heat resistance, length, presence of braid and other characteristics.

For plumbing, a two-core or zone wire is usually used.

Of the ways to install the wire, it is better to give preference to the outer one. Fasten the cable inside the pipe only if it is not possible to mount it from the outside. In general, internal and external installation technologies practically do not differ from each other, but the second method minimizes the risk of blockages, and also increases the life of the wiring.

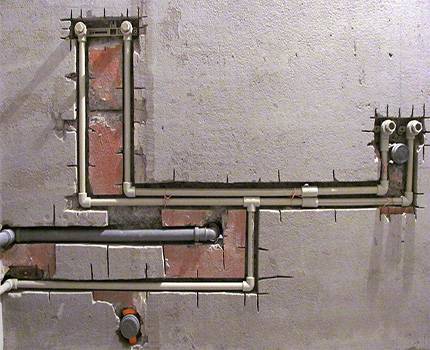

Laying methods - hidden and open system

Pipes in the water supply system can be laid in a closed and open way. The choice of one of the methods does not affect either the quality of the connections or the functionality of the entire system and depends only on personal preferences.

It would seem that it is not difficult to decide and the closed method is preferable as more aesthetic and allows you to save up to 10 cm of usable space. Why is an open pipeline still used in the installation of a water supply system? Let's try to give an answer.

Image gallery

Photo from

Non-reinforced versions of PP pipes are used in the laying of cold water lines, reinforced ones are used in the DHW device. Plumbing is assembled using fittings

As before, steel water and gas pipes are used in the organization of water supply systems. Steel water pipes are connected by welding, the disadvantages include a tendency to rust, the need for external painting

The advantages of flexibility, resistance to temperatures and aggressive environments are pipes made of copper and stainless steel. Connected by soldering and crimping, serve about 50 years, but are expensive

Plumbing from metal-plastic pipes

Polypropylene water supply system

Water supply device with VGP pipes

Copper and stainless steel plumbing

Hidden wiring allows you to hide pipes and not spoil the aesthetic perception of the interior of a house or apartment. They hide it behind a decorative wall, for example, made of drywall, or ditch the walls and lead the pipes into the formed niches, sealing them with facing material or plaster along the grid.

The pipeline should not be tightly adjacent to the surfaces - always leave a small gap for possible repairs. When installing a pipeline in a monolith, it is recommended to place them in a casing, inserting a pipe into a pipe.

The disadvantage of the method manifests itself when it becomes necessary to repair or replace the hidden elements of the system - the plaster or tiling has to be opened and then re-decorated.

In addition, in the event of damage and leaks, the problem may not be detected immediately and lead first to the loss of operational technical characteristics of structures, then to flooding of the premises.

To avoid such difficulties, when installing the wiring, only whole sections of the pipe are hidden, placing the docking fittings in open areas. In places of installation of shutoff valves, invisible doors are made. This gives access for maintenance to pipe connections, which are the weakest links in the system.

It should also be noted that pipes made of not all materials can be hidden under a layer of plaster - only products made of polypropylene, metal-plastic or copper are suitable for this.

Pipe laying in an open way is carried out after finishing is completed. The method involves the uncovered laying of pipes and water supply elements. It looks ugly, reduces the usable area of the room, but at the same time this method is very convenient for maintenance, repair and dismantling of elements.

Redevelopment and rearrangement of plumbing in the house with such a plumbing device will also not cause difficulties.

How to defrost a pipe indoors

The methods used to defrost utilities directly depend on where exactly the pipeline is located. So if it is mounted indoors, then you can get rid of ice jams using:

- hot water;

- building hair dryer;

- electricity.

Hot water is used to warm pipes in open sections of highways, while this method can be used to clean products, both metal and plastic. In this case, it is best when it is boiling water, since it is it that allows you to melt the ice the fastest. In addition, rags and rags are also used to speed up the process.

- To begin with, rags and rags are placed on the pipe.

- The place of the alleged congestion begins to be poured with boiling water or hot water.The process is lengthy, since the surface of the line will have to be constantly irrigated with new portions of hot water.

- The heating process stops only after water does not start flowing from the open taps.

- Complete removal of ice from the system can be completed in a few hours and during this time the valves should not be closed.

Rags and rags are needed here to increase the area of contact of the pipe with boiling water, as well as to extend its impact on it.

Rags and rags increase the area of contact of the pipe with boiling water, and also prolong its effect on it.

Frozen plumbing can also be warmed up with hot air by exposing it to open areas of the system. For this purpose, a heat gun or a powerful building hair dryer is usually used. At the same time, a temporary canopy from improvised materials is erected over the problem area. In the same case, when the homeowner does not have industrial equipment, he can use any device that generates warm air. So they can be a regular household hair dryer.

The third common way to defrost pipes is the use of electricity. It is considered one of the most effective and can be used to get rid of ice from both metal and plastic products.

At the same time, it should be noted separately that this method requires the adoption of certain precautionary measures.

Metal lines are heated in this way using a welding transformer.

- The output cables of the device must be connected to a suspicious area at a distance of at least half a meter from the blockage.

- Voltage is applied so that a current of 100 to 200 amperes passes through the metal.

- Usually, a few minutes of such exposure causes the ice to melt, thereby restoring the patency of the pipe.

As for plastic communications, they are heated using a two-core copper wire with a cross section of 2.5 - 3 mm:

- One of the cores is partially stripped and 5 turns are made around the cable.

- The second vein falls below the first and the same manipulations are performed on it. Trying to make a spiral winding at a distance of 3 millimeters from the first winding. The resulting device is the simplest homemade boiler.

- The finished product is inserted into the pipe and the current is turned on. Under the influence of the potential that has arisen between the coils, the water heats up, and the ice begins to melt.

This method is good because when using it, the system does not heat up and the plastic does not deteriorate.

Use of electric convectors

If, despite the fact that electricity cannot be called the most economical of all types of heating, you still decide to use this option, then convectors that can be installed both on walls and on the floor will be an excellent solution. In the latter case, the device can be moved from room to room, making it mobile. Among the additional advantages, absolute safety can be distinguished, since the devices have protection against overheating, and their case does not heat up so much, the temperature does not exceed 80 degrees.

Considering that convectors cannot be called the most economical, it is best to purchase devices with built-in thermostats to reduce electricity bills, which make the system the most economical during operation.In terms of functionality, such units are the most innovative, which is associated with the use of an additional control unit. But as for the price, the convector will cost about 3000-7000 rubles. for the heater. If we expect that one device is required for one room, then the cost of such a heating system will cost about 20,000 rubles. Economical electric heating convectors can meet expectations if the house is small enough, and you choose the device taking into account the presence of a thermostat in it.

Mounting

Ways of laying the heating element

The heating cable for heating pipes can be installed in several ways, depending on the installation requirements and the diameter of the water supply.

There are three of these methods:

- laying inside the pipe;

- installing it outside with the location along the pipe in a straight line with fixing with adhesive tape;

- external mounting around the pipe in a spiral.

When laying a heater inside a pipe, it must meet several requirements. Its insulation must not be toxic and must not release harmful substances when heated. The level of electrical protection must be at least IP 68. Its end must end in a tight coupling.

When laying outside the pipe, it must fit snugly against it, secured with adhesive tape, and polyurethane thermal insulation must be put on top of the pipe.

Scheme of the device of the resistive heating cable for pipes

Internal heater installation

The first method is the most difficult from a technical point of view. For this purpose, special types of heating cable with food-grade fluoroplastic outer insulation are used, which do not contain harmful substances and have an electrical protection level of at least IP 68.

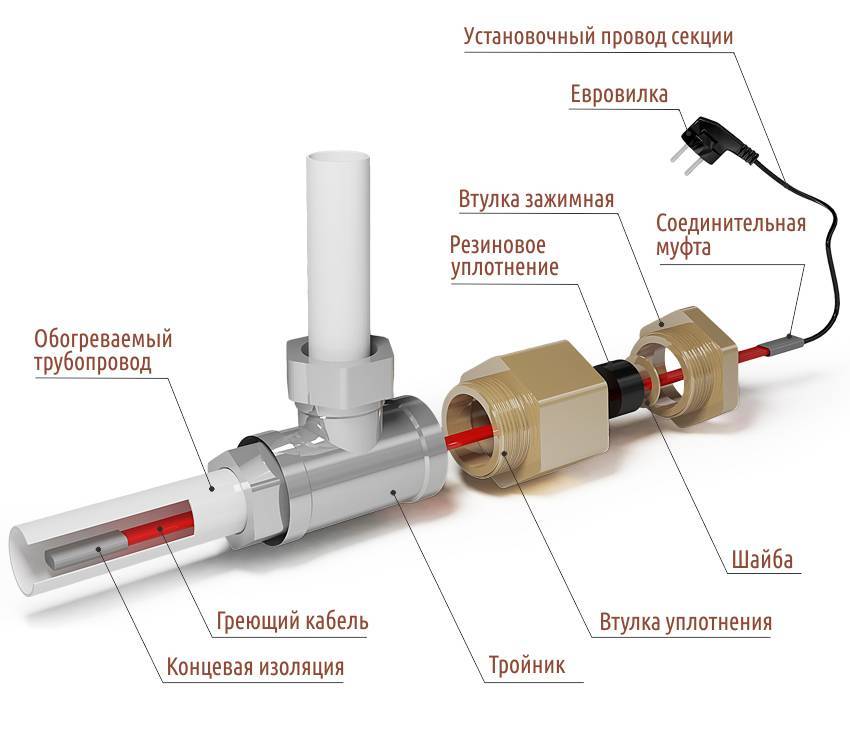

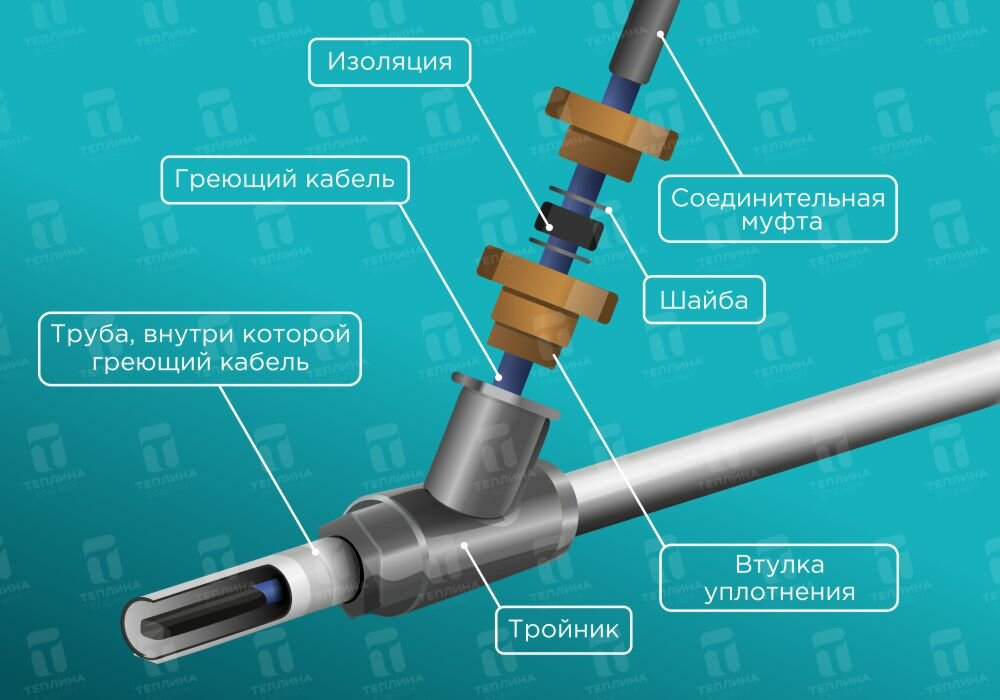

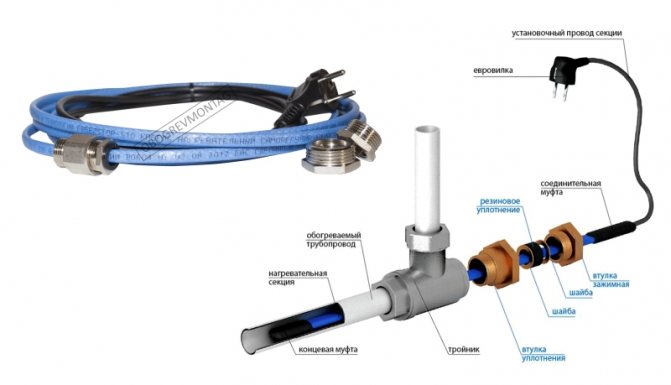

In this case, its end must be carefully sealed with a special sleeve. For this installation method, a special kit is produced, which consists of a 90 or 120 degree tee, an oil seal, as well as a standard kit for connecting to the electrical network with an end sleeve.

It is worth saying that in order to connect the heater and to install it inside the pipe, you must have basic knowledge of plumbing and electrical installation. And the sequence can be described as follows. In the presence of all components: an oil seal, a tee, as well as the necessary set of tools, we begin with the installation of a tee on the water supply system, which must be protected from freezing in winter.

The tee is installed on the pipe using a threaded connection with a seal with FUM tape or tow with paint. In the second outlet of the tee intended for the stuffing box, we insert the heating cable prepared for installation for plumbing with a washer put on it, a polyurethane stuffing box and a threaded stuffing box.

After installing it in the water supply, the gland is installed. In this case, it is necessary to ensure that the connecting sleeve between the heating and electric cables is outside the pipeline by about 5-10 cm from the stuffing box. It is better to purchase a kit for internal installation from cable suppliers, since all gland gaskets are made for its cross section. This will allow in the future during operation to protect yourself from water leaks from the stuffing box.

For internal pipes, special types of heating cable are used with food-grade fluoroplastic outer insulation, which does not contain harmful substances, has an electrical protection level of at least IP 68

External installation of pipe heating

Heating of external pipes with a cable

Installation of heating outside the water supply is much easier. It is laid along the pipe, fixed along the entire length with aluminum tape every 30 cm. If possible, it is attached to the bottom of the pipe so that the heating is optimal - from the bottom up.

The considered method refers to water pipes of small diameter, with large diameters it is selected more powerful and the laying is performed in a spiral around the pipe. Shut-off valves such as valves, taps, filters are wrapped with a cable in any form.

If it is self-adjusting, then the shape of the winding around the valves is not important for it, even a crosshair is allowed. Regardless of the type of installation - inside or outside, along the pipe or in a spiral - all water pipes must be insulated. There is a very convenient polyurethane shell for different diameters.

Since the protection of sewers from freezing is just as important as the protection of water pipes, sewer outlets are heated in the same way. The only difference is that the sewer pipes have a diameter of 150 mm or more and the heating system is mounted on them outside in a spiral.

Pipe cable heating: system components