- How are they classified

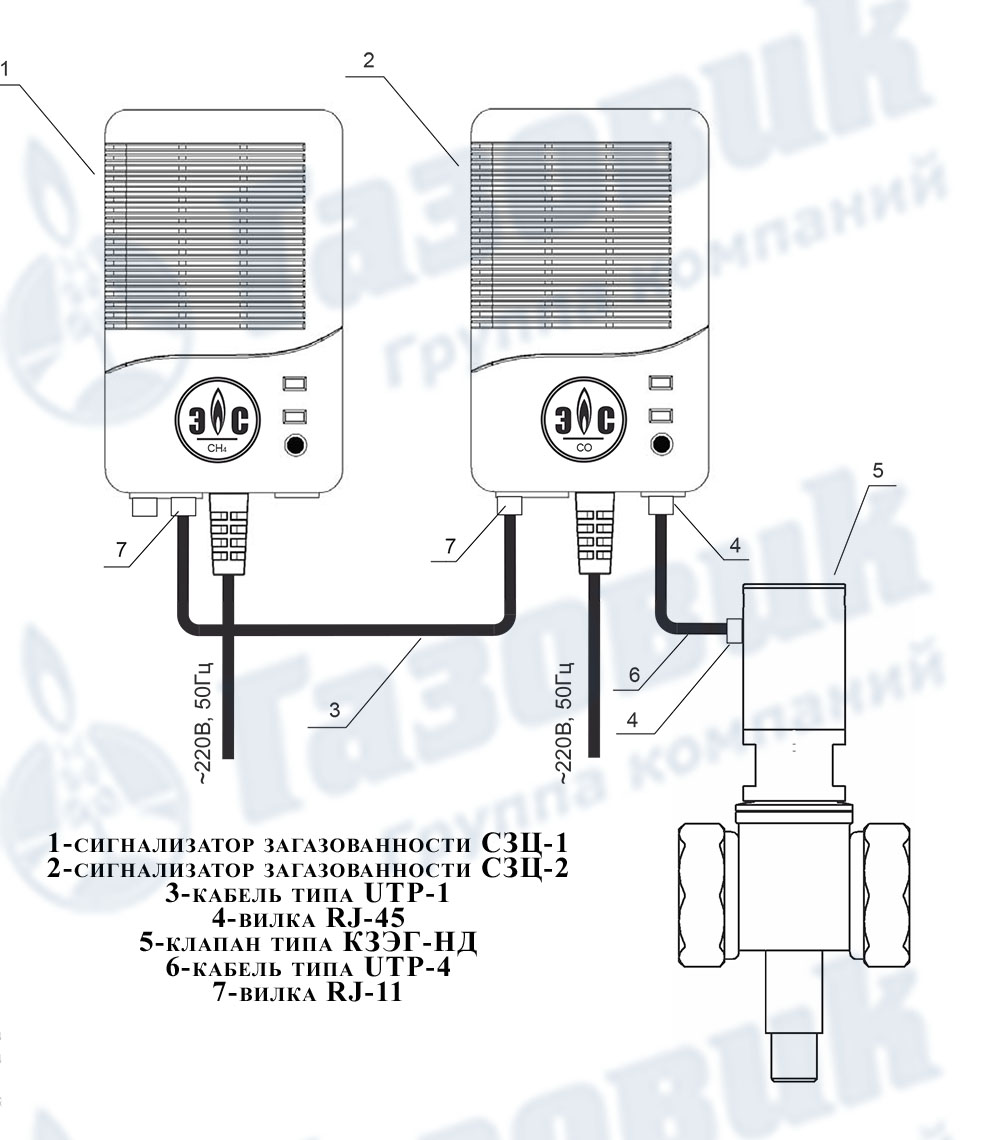

- Valve equipped sensors

- Gas analyzer with GSM response unit

- The system of automatic control and protection against gas pollution and gas leakage in a house, apartment

- Dangerous properties of gas fuel:

- Gas alarm - gas leak sensor, is it necessary to install

- Gas detector for LPG

- Installation, installation of a gas alarm

- Household natural gas detector

- Purpose and principle of operation of the gas contamination detector

- Tula residents are forced to install gas leak analyzers

- How are they classified

- Valve equipped sensors

- Gas analyzer with GSM response unit

- Device types

- How to protect yourself from scammers

- Yaroslavl residents are fooled by sellers of gas leakage control devices

- What are

- Gas workers explain: combustible gas detectors are not required to be installed

How are they classified

These devices are divided, depending on the type of gas for which they are designed. Given the differences in the physical and chemical characteristics of various substances, it is impossible to create a universal device. In addition to natural, sensors are available that can detect carbon dioxide and carbon monoxide.

Depending on the method of detecting a gas leak, the following types of sensors are distinguished:

- With a semiconductor sensitive element - a silicon wafer coated on the surface with metal oxide. The gas is absorbed by the oxide film, changing its internal resistance. Such devices are widely used in everyday life, due to the simplicity of design and low cost. They are not intended for work in the conditions of an industrial enterprise, since they are distinguished by low accuracy of operation, the complexity of recovery after switching on and the need for constant monitoring of the good condition;

- Catalytic - the principle of operation provides that after combustion, the gas decomposes into carbon dioxide and water. The design of the sensitive element is a small ball with a coil placed inside. For its winding, platinum wire is used, with a pre-applied substrate of aluminum oxide. A rhodium catalyst is used as the outer shell. Upon contact with gas, thanks to the catalyst, the surface of the sensing element ignites, reducing the resistance of the platinum winding. used in production;

- Infrared - use the properties of gas to be absorbed in the infrared spectrum. The device is quite compact and easy to use. The principle of operation is based on comparing the speed of passage of a light beam through two media, followed by a comparison of characteristics.

Based on the principle of operation, the sensors are divided into:

- Wired connection - they use a standard 220 V electrical network. They are characterized by low price and ease of maintenance, but additionally consume electrical energy and require stable network parameters;

- Wireless - work from autonomous energy sources, which greatly expands the possibilities of application. Disadvantages - high price and increased consumption of electrical energy.

The consumer selects the sensor based on the technical characteristics of the device and the characteristics of the room.

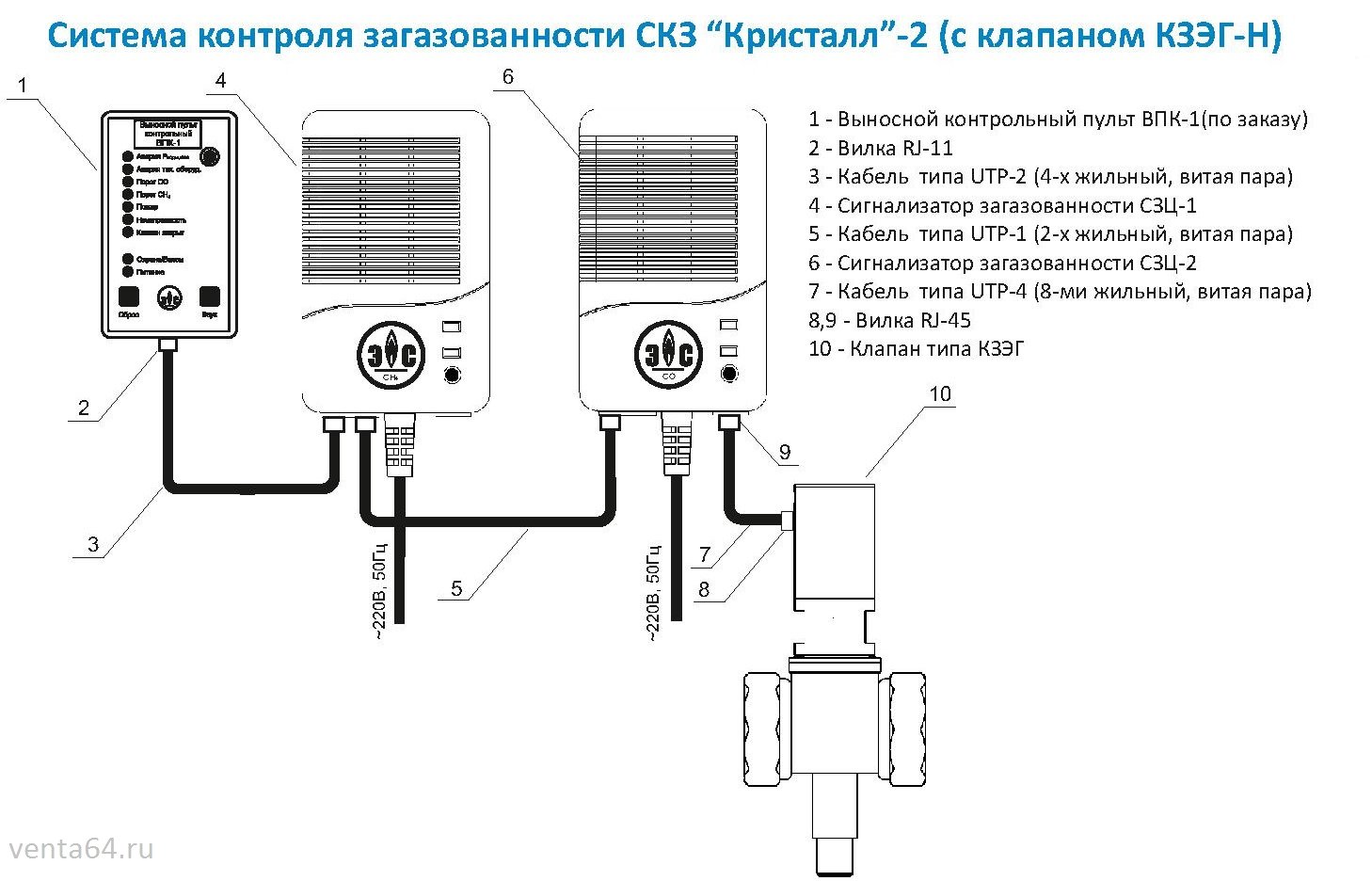

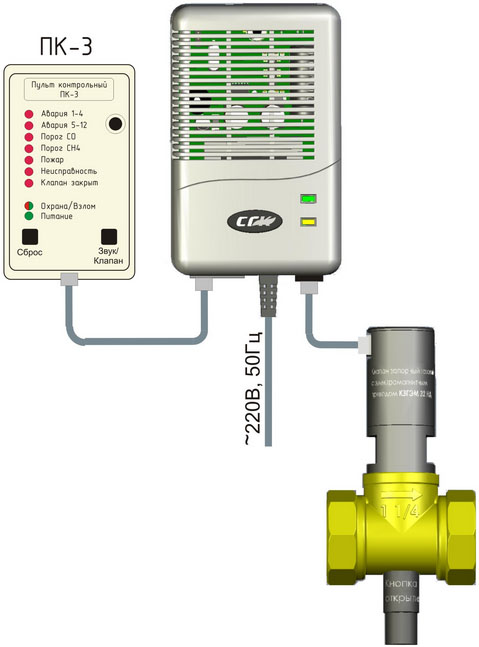

Valve equipped sensors

The use of such analyzers makes it possible to automatically shut off the gas supply in the event of a leak. After operation, the electrical circuit closes, with a signal to turn on the valve drive, which turns off the line.

The sensor crashes into the gas pipe in front of the equipment. The installation of these devices requires the involvement of qualified specialists so that the tie-in to the line is performed correctly, followed by a complete check of the system.

The advantages of these sensors are in a long service life - the shut-off valve wears out slightly. There is no need to connect the mains, because after the operation, the shut-off valves are opened manually.

Gas analyzer with GSM response unit

The device is equipped with an additional module that communicates wirelessly with the alarm. If the sensitive element is triggered, the owner is notified by phone and will be able to quickly respond to the received signal. A multifunctional device that allows you to connect the sensor to the fire system and other security services at the same time.

The system of automatic control and protection against gas pollution and gas leakage in a house, apartment

Dangerous properties of gas fuel:

- the ability of gas to form flammable and explosive mixtures with air;

- suffocating power of the gas.

The components of gas fuel do not have a strong toxicological effect on the human body, but at concentrations that reduce the volume fraction of oxygen in the inhaled air to less than 16%, they cause suffocation.

During the combustion of gas, reactions occur in which harmful substances are formed, as well as products of incomplete combustion.

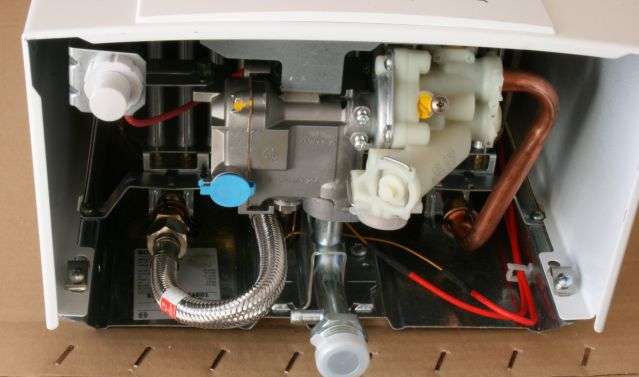

Carbon monoxide (carbon monoxide, CO) - is formed as a result of incomplete combustion of fuel. A gas boiler or water heater can become a source of carbon monoxide if there is a malfunction in the combustion air supply and flue gas removal path (insufficient draft in the chimney).

Carbon monoxide has a highly directed mechanism of action on the human body up to death. In addition, the gas is colorless, tasteless and odorless, which increases the risk of poisoning. Signs of poisoning: headache and dizziness; there is tinnitus, shortness of breath, palpitations, flickering before the eyes, redness of the face, general weakness, nausea, sometimes vomiting; in severe cases, convulsions, loss of consciousness, coma. Air concentrations greater than 0.1% result in death within one hour. Experiments on young rats have shown that a concentration of CO in the air of 0.02% slows down their growth and reduces activity compared to the control group.

Gas alarm - gas leak sensor, is it necessary to install

Since 2016, building regulations (clause 6.5.7 of SP 60.13330.2016) require the installation of gas alarms for methane and carbon monoxide in the premises of new residential buildings and apartments in which gas boilers, water heaters, stoves and other gas equipment are located.

For buildings that have already been built, this requirement can be seen as a very useful recommendation.

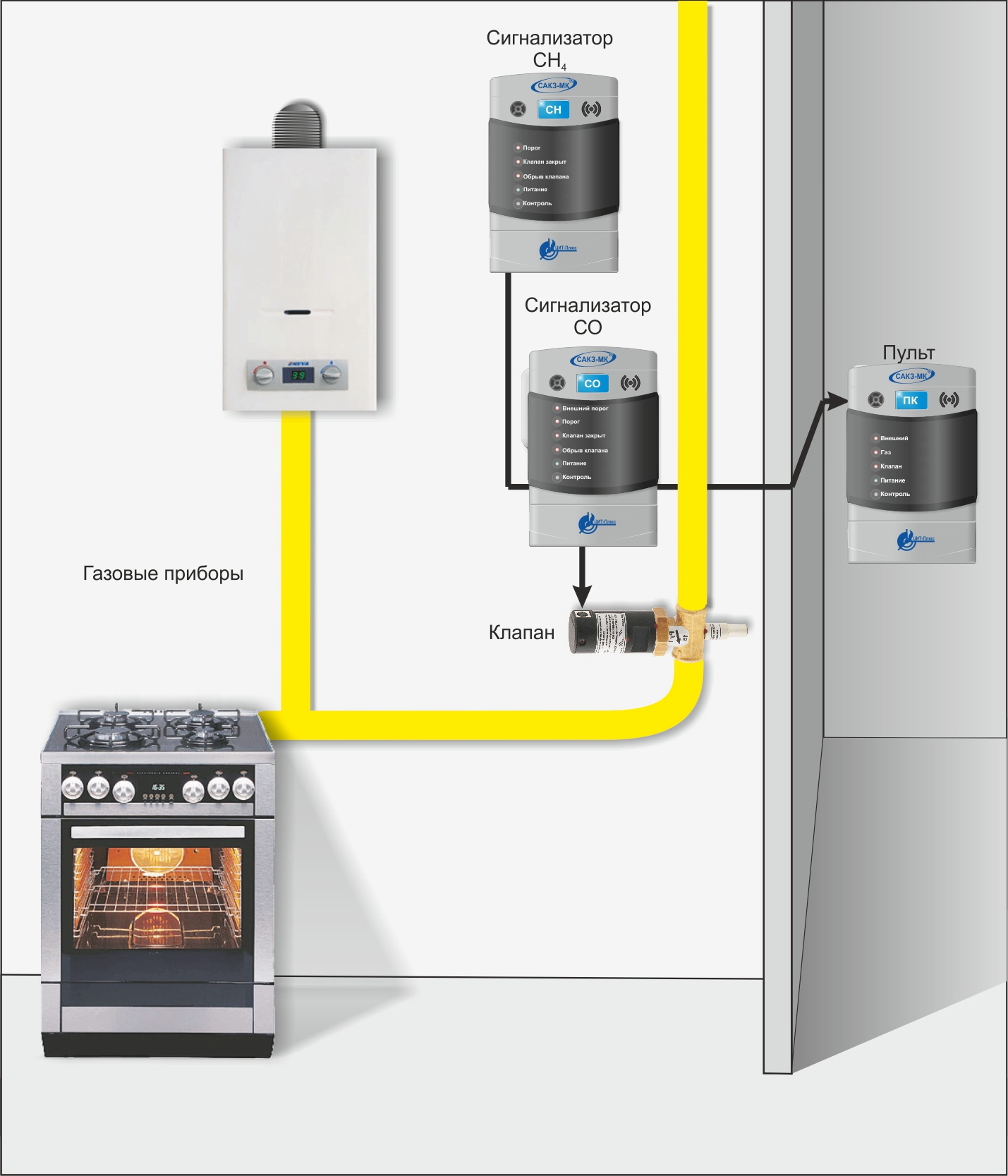

The methane gas detector serves as a sensor for the leakage of domestic natural gas from gas equipment. The carbon monoxide alarm is triggered in case of malfunctions in the chimney system and the ingress of flue gases into the room.

Gas sensors should be triggered when the gas concentration in the room reaches 10% of natural gas LEL and CO content in the air is more than 20 mg/m3.

Gas alarms must control a quick-acting shut-off (cut-off) valve installed at the gas inlet to the room and shutting off the gas supply by a signal from the gas contamination sensor.

The signaling device must be equipped with a built-in system for emitting a light and sound signal when triggered, and / or include an autonomous signaling unit - a detector.

The installation of signaling devices allows you to timely notice a gas leak and disturbances in the operation of the smoke exhaust path of the boiler, to prevent a fire, explosion, and poisoning of people in the house.

NKPRP and VKPRP - this is the lower (upper) concentration limit of flame propagation - the minimum (maximum) concentration of a combustible substance (gas, vapors of a combustible liquid) in a homogeneous mixture with an oxidizing agent (air, etc.) at which flame propagation through the mixture is possible at any distance from source of ignition (open external flame, spark discharge).

If the concentration of a combustible substance in the mixture is less than the lower limit of flame propagation, such a mixture cannot burn and explode, since the heat released near the ignition source is not enough to heat the mixture to the ignition temperature.

If the concentration of a combustible substance in the mixture is between the lower and upper limits of flame propagation, the ignited mixture ignites and burns both near the ignition source and when it is removed. This mixture is explosive.

If the concentration of a combustible substance in the mixture exceeds the upper limit of flame propagation, then the amount of oxidizing agent in the mixture is insufficient for complete combustion of the combustible substance.

The range of concentration values between NKPRP and VKPRP in the "combustible gas - oxidizer" system, corresponding to the ability of the mixture to ignite, forms an ignitable region.

Gas detector for LPG

The building regulations do not contain mandatory requirements for the installation of gas alarms in rooms when using liquefied gas. But liquefied gas alarms are commercially available and installing them will undoubtedly reduce the risks for you and your loved ones.

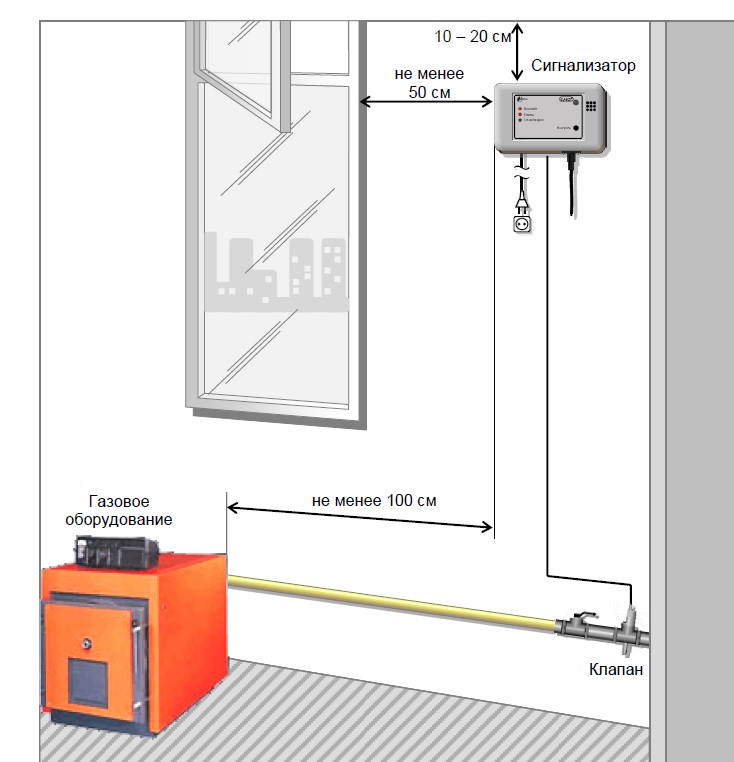

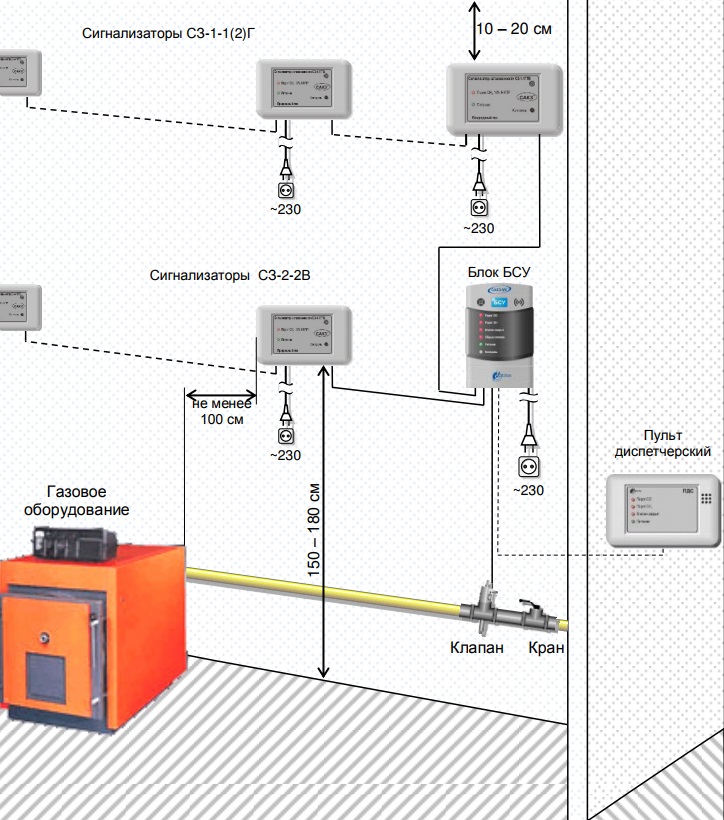

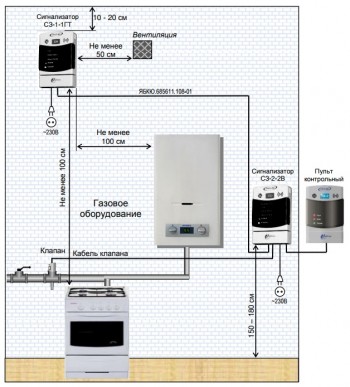

Installation, installation of a gas alarm

The installation of gas alarms in a house or apartment can be carried out by organizations and individual entrepreneurs admitted to these types of work.

Recommended locations for gas detectors in the kitchen

Recommended locations for gas detectors in the kitchen

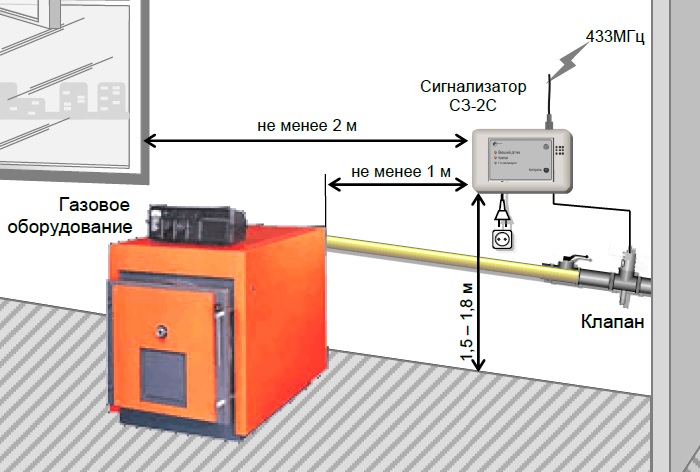

Gas alarms are installed on the wall of the room, near the gas equipment. Gas sensors should not be placed in blind areas where there is no air circulation, behind cabinets. For example, the device is recommended to be installed no closer than 1 m.from the corners of the room. In addition, it is forbidden to install devices in the immediate vicinity of supply and exhaust ventilation devices, from heat sources.

Natural gas alarm (methane, CH4) are mounted in the upper zone, at a distance of no more than 30 - 40 cm from the ceiling, since this gas is lighter than air.

signaling devices for LPG (propane-butane), which is heavier than air, is installed below, at a height of about 30 cm from the floor.

For carbon monoxide, the detector is recommended to be installed in the working area of a person, at a height of 1.5 - 1.8 m from the floor. The density of this gas is approximately equal to the density of air. Carbon monoxide is heated from the boiler into the room. Therefore, the gas rises up to the ceiling, cools and is distributed throughout the entire volume of the room. A carbon monoxide detector may be installed near the ceiling, next to the same device for methane. Given this circumstance, some manufacturers produce a universal gas alarm that reacts immediately to both gases - methane and carbon monoxide.

The shut-off electromagnetic shut-off valve is installed on the gas pipe, in a place convenient for access to the manual cocking button.

The installation of a shut-off valve on the gas pipeline should include:

- in front of gas meters (if a disconnecting device at the input cannot be used to turn off the meter);

- in front of household gas appliances, stoves, water heaters, heating boilers;

- at the entrance of the gas pipeline to the room, when a gas meter with a disconnecting device is placed in it at a distance of more than 10 m from the place of entry.

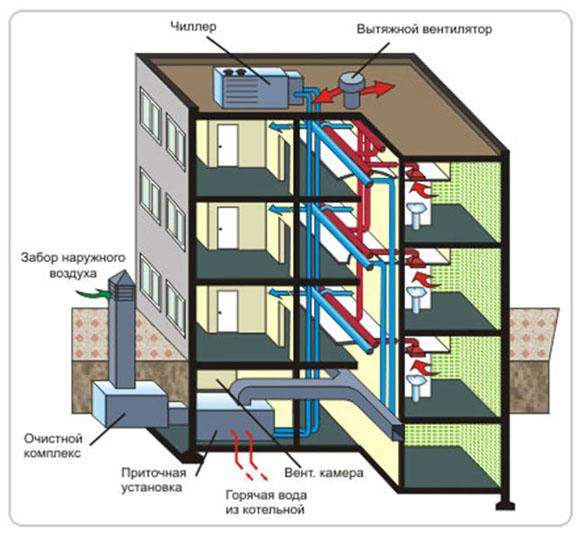

Some models of gas detectors, in addition to the shut-off valve on the gas pipeline, can control the activation of an additional light and sound detector or an electric fan in the ventilation duct.

Some models of gas detectors, in addition to the shut-off valve on the gas pipeline, can control the activation of an additional light and sound detector or an electric fan in the ventilation duct.

Household natural gas detector

The use of natural gas for domestic purposes is a very common phenomenon. But unfortunately, few people think about the risks that this explosive substance carries. Therefore, in order to protect yourself and your loved ones from the negative consequences of a gas leak, experts recommend installing household alarms. Read on to find out how to choose, install and operate this device correctly.

Purpose and principle of operation of the gas contamination detector

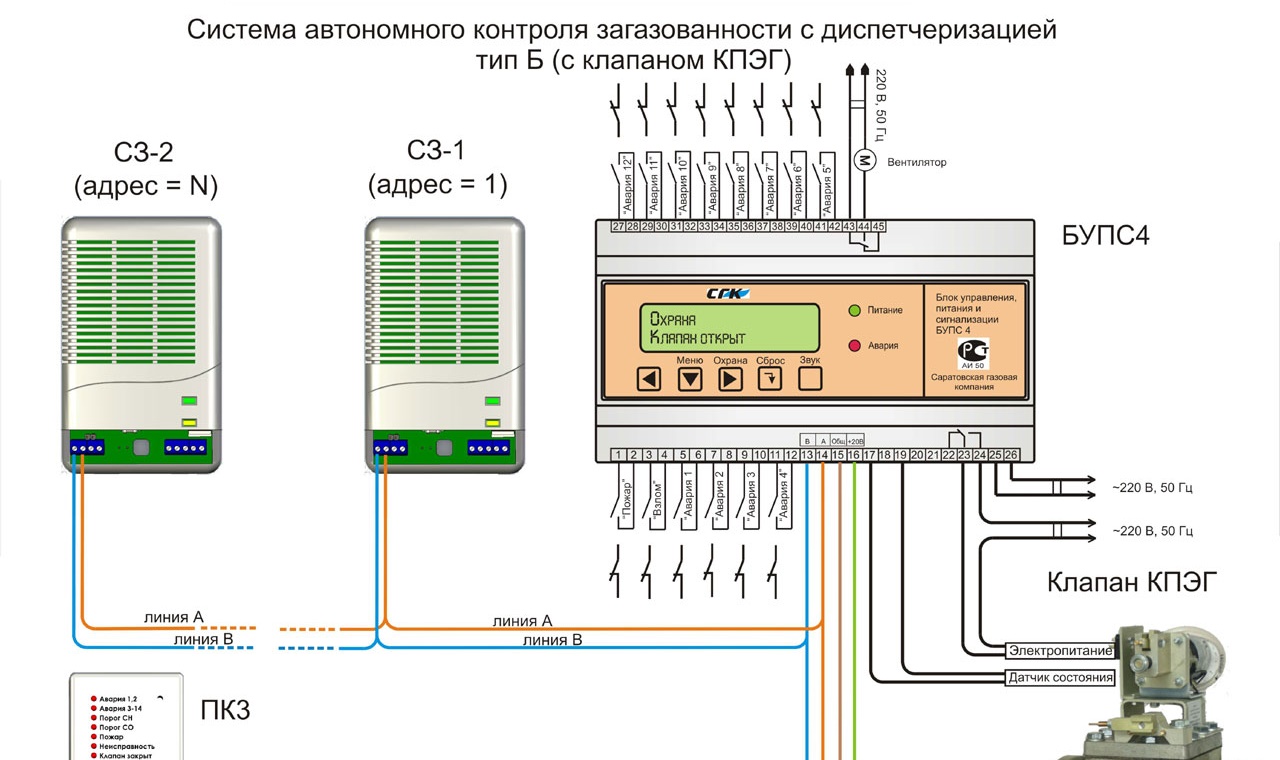

The gas contamination detector (SZ) is designed for continuous monitoring of the concentration of natural gas (methane) in the room, timely notification of exceeding the permissible threshold, as well as giving a signal to shut off the gas pipeline.

All SZs operate in automatic mode, have sound and light alarms, and are set to a certain response threshold in accordance with GOST. The signaling devices can be used both independently and together with a gas supply blocking device.

The principle of operation of the SZ is quite simple. When exposed to natural gas on a sensitive sensor, its electrical parameters change. The processor module then processes the sensor signal. In case of exceeding the specified parameters, it gives a command for light and sound notification, as well as a signal to block the gas pipeline with a locking mechanism.

Varieties of gas contamination devices

Household SZ are of two types:

- Single-component - control only the content of natural gas.

- Two-component - monitor the concentration of methane and carbon monoxide.

The second option is considered the most preferable, since in the event of a deterioration in chimney draft, an excess of the concentration of combustion products is possible. Although this cannot lead to ignition, it is also very dangerous for the lives of residents.

Devices are also sold in a monoblock version, where sensitive sensors are built into the housing and with remote sensors that allow remote control of the room. For example, you can install a sensor in a boiler room and monitor it from the living room.

The Basics of Installing a Natural Gas Alarm

Gas detectors are usually located in possible areas of gas accumulation. However, they should not be:

- more than 4 meters from the source of the likely leak;

- near windows, ventilation shafts;

- close to ovens and burners;

- directly exposed to dust, water vapor and ash.

The installation height of the SZ should be at least 0.5 meters from the ceiling, and the carbon monoxide alarm should be at least 0.3 meters.

Operation and maintenance household gas alarm

After installation of the SZ, the following routine inspections and checks are required to maintain the device in working order:

- monthly external inspection with cleaning from dust and dirt;

- check the response threshold once every six months;

- Once a year, the instrument is calibrated and verified.

For technical checks, it is recommended to contact the representatives of the gas service!

Given that the gas detector is a device to ensure the safety of residents, you should not neglect the advice of gas services and save on its installation. The spent several thousand rubles sometime, perhaps, will save people's lives from tragedy.

Tula residents are forced to install gas leak analyzers

- equipped with boilers and water heaters with a capacity of more than 60 kW;

- basements, ground floors and outbuildings - regardless of the performance of heat generating installations.

It will be necessary to install carbon dioxide level alarms even if gas-burning equipment with an open combustion chamber is installed in the room (in other words, when the air required for the operation of a gas boiler or gas column is not taken from outside, but from the same room in which it is installed). As you can see, the norms clearly spell out all cases of mandatory installation of control and alarm devices. If your case does not fall under any requirement of the Rules, feel free to write a request addressed to the head of the Gorgas, and then contact Rostekhnadzor with his answer and project documentation.

How are they classified

These devices are divided, depending on the type of gas for which they are designed. Given the differences in the physical and chemical characteristics of various substances, it is impossible to create a universal device. In addition to natural, sensors are available that can detect carbon dioxide and carbon monoxide.

Depending on the method of detecting a gas leak, the following types of sensors are distinguished:

- With a semiconductor sensitive element - a silicon wafer coated on the surface with metal oxide.The gas is absorbed by the oxide film, changing its internal resistance. Such devices are widely used in everyday life, due to the simplicity of design and low cost. They are not intended for work in the conditions of an industrial enterprise, since they are distinguished by low accuracy of operation, the complexity of recovery after switching on and the need for constant monitoring of the good condition;

- Catalytic - the principle of operation provides that after combustion, the gas decomposes into carbon dioxide and water. The design of the sensitive element is a small ball with a coil placed inside. For its winding, platinum wire is used, with a pre-applied substrate of aluminum oxide. A rhodium catalyst is used as the outer shell. Upon contact with gas, thanks to the catalyst, the surface of the sensing element ignites, reducing the resistance of the platinum winding. used in production;

- Infrared - use the properties of gas to be absorbed in the infrared spectrum. The device is quite compact and easy to use. The principle of operation is based on comparing the speed of passage of a light beam through two media, followed by a comparison of characteristics.

Based on the principle of operation, the sensors are divided into:

- Wired connection - they use a standard 220 V electrical network. They are characterized by low price and ease of maintenance, but additionally consume electrical energy and require stable network parameters;

- Wireless - work from autonomous energy sources, which greatly expands the possibilities of application. Disadvantages - high price and increased consumption of electrical energy.

The consumer selects the sensor based on the technical characteristics of the device and the characteristics of the room.

Valve equipped sensors

The use of such analyzers makes it possible to automatically shut off the gas supply in the event of a leak. After operation, the electrical circuit closes, with a signal to turn on the valve drive, which turns off the line.

The sensor crashes into the gas pipe in front of the equipment. The installation of these devices requires the involvement of qualified specialists so that the tie-in to the line is performed correctly, followed by a complete check of the system.

The advantages of these sensors are in a long service life - the shut-off valve wears out slightly. There is no need to connect the mains, because after the operation, the shut-off valves are opened manually.

Gas analyzer with GSM response unit

The device is equipped with an additional module that communicates wirelessly with the alarm. If the sensitive element is triggered, the owner is notified by phone and will be able to quickly respond to the received signal. A multifunctional device that allows you to connect the sensor to the fire system and other security services at the same time.

Device types

By means of a gas contamination sensor, it is possible to register an excess of the content of one or another gaseous component in the air or its presence. The device includes a gas sensor (gas analyzer). It converts the measured concentration of a substance into an electrical signal (or another type of signal), which allows you to register and visualize this signal. The main characteristics of the gas sensor are:

- the degree of selectivity (selectivity) for a particular substance;

- the rate of reaction (response) to fluctuations in the concentration of a substance;

- limits for determining the concentration of a substance.

Recording devices are part of special systems - signaling devices, the general tasks of which include:

- Continuous automatic monitoring of the concentration of installed gases in the air;

- Receiving signals about a malfunction or an accident from an external device;

- An alarm is given when the gas content is detected above the norm.

- Emergency termination of the supply of the component.

Measuring tools that are part of the signaling devices differ in the principles of operation. The following types of devices are installed in industrial premises:

- Electrochemical - works on the basis of an electrochemical three-electrode sensor placed in a container with an electrolyte.

- Semiconductor - is a silicon substrate with a heating film deposited on it.

- Infrared (optical) - operates on the basis of the principle of absorption of infrared rays.

- Thermochemical - works on the basis of the principle of heat release during gas oxidation.

- Photoionization - operates on the basis of ionization of a gas molecule by ultraviolet radiation when passing through the sensor.

- The linear gas sensor measures the gas content and converts it into a linear analog signal that is output to the imaging device.

The optical gas contamination sensor is widely used along with semiconductor and electrochemical ones.

Gas detector sensor according to the type of execution can be:

- stationary - fixed motionless;

- portable - powered by a built-in battery.

The design of the room gas sensors is carried out in accordance with GOST 12.2.007-75 (last edition 10/18/2016) “Occupational safety standards system. Electrical products. General safety requirements”.

How to protect yourself from scammers

Recently, due to the large number of explosions and fires, cases of deception have become more frequent. Often, under the guise of employees of the gas service or the Ministry of Emergency Situations, fraudsters force residents to enter into appropriate contracts and install sensors at inflated prices, including fabulous installation and connection fees. Swindlers are especially active in relation to lonely old people.

To counter fraudulent schemes, you must adhere to the following recommendations:

- check the documents of visitors who want to install the sensor, apply directly to the authorities and the organization - the gas supplier, if unexpected visitors insist on the obligation to provide such services;

- purchase analyzers from trusted dealers, with verification of the relevant certificates, passport documentation for the equipment;

- preliminary study the technical characteristics of the systems, taking into account the features of operation, choosing the best option.

Gas metering sensors will protect housing from the danger of leakage, saving the property and life of not only the owners of housing, but also neighboring apartments and houses. A timely warning will allow homeowners to quickly respond to a malfunction by calling emergency service personnel and cutting off the gas supply.

Good afternoon. I am re-planning the gas supply with the transfer of the boiler in a private house.Forced to put a gas alarm sensor. Question: how reasonable is this requirement and what law regulates it?

Yaroslavl residents are fooled by sellers of gas leakage control devices

He also said that in some houses, usually new ones, there is a practice installation of a gas safety system individually for each apartment. It costs the owner up to 10 thousand rubles. Sergey Grinin, chairman of the Civil Security public organization, considered the idea of installing sensors “sensible”, but expressed concerns about its financing. “It may turn out the same as with water meters, when at first it was decided that they should be in every apartment, and then they forced the tenants to install these meters at their own expense,” suggests Grinin. Klychkov also said that the deputies are considering the issue of increasing the frequency of inspections of gas communications by the Moscow Housing Inspectorate.

The optimal timing in which they should occur is still being discussed.

What are

Now the market sells different gas leak detectors, they are divided according to the principle of operation, the type of sensitive element and the type of gas detected (carbon monoxide, carbon dioxide and natural). According to the principle of operation, it means that there are wired devices that connect to a 220-volt network, and there are wireless devices. Their functioning depends on the battery, which is very convenient when the electricity is turned off in the house.

The sensing element is of three types: semiconductor, catalytic and infrared. The most inexpensive ones are with a semiconductor element, they are most often bought by ordinary property owners.Catalytic analyzers are used in large enterprises in industry, their action is based on the combustion of gas and its decomposition into carbon dioxide and water. Infrared devices pass the gas through their beams and determine the excess concentration with extreme accuracy.

Gas workers explain: combustible gas detectors are not required to be installed