- How to install such a chimney

- Why you need to insulate the chimney

- Benefits of an insulated chimney

- Sandwich setup diagrams

- How to insulate an iron chimney pipe

- How to secure the joint of the chimney with a wooden floor?

- Heating errors

- Chimney pipe insulation with basalt wool

- Basic rules for high-quality thermal insulation

- Insulation of a ceramic or asbestos chimney

- Ways to insulate a steel chimney

- Brick pipe insulation technology

- Elements of modular systems

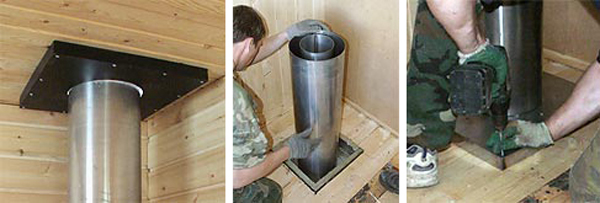

- The main stages of installation of a sandwich chimney

- We connect all the elements of the structure

- Let's secure the floors

- We bring the pipe to the roof

- Conclusion

How to install such a chimney

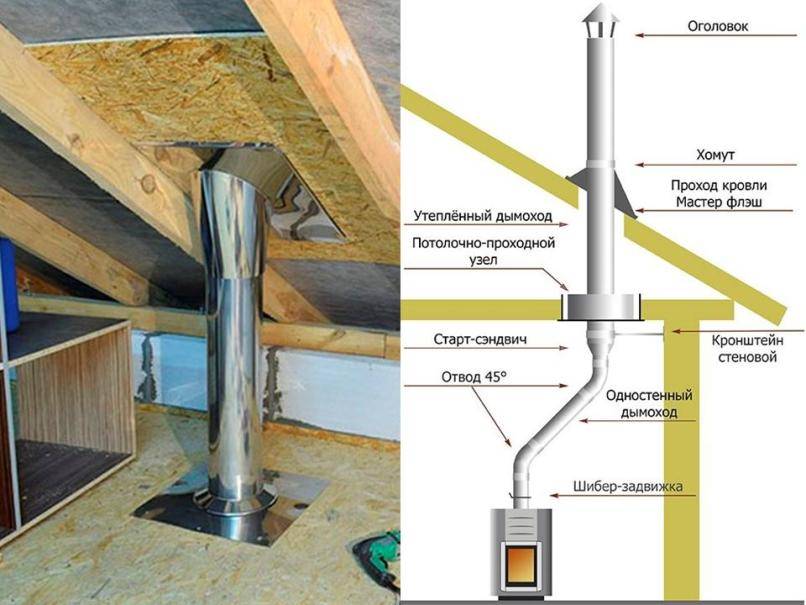

When installing a chimney from a sandwich pipe, there is no need to build a special concrete foundation, as for a brick or ceramic chimney, since light weight is one of the undoubted advantages of this metal structure. However, do not consider the task too simple. There are a number of rules and nuances that should be understood and considered at the stage of choosing equipment.

For example, it does not hurt to draw a plan diagram of a future design, indicating all dimensions on it.

Experienced stove-makers, who know exactly how to properly assemble a sandwich chimney, are especially urged to pay attention to such points as passing the chimney through the roof, through ceilings, etc. For example, the chimney is often mounted even before finishing and roofing work is completed.

In this case, the boiler or fireplace insert is installed on the subfloor. In this case, it is necessary to take into account the height of the "pie" of the floor, taking into account the installation of the floor covering and put the heating equipment, for example, on pieces of bricks, so that the structure exactly matches the hole for the exit of combustion products.

Start installing a sandwich chimney with your own hands from the outlet pipe of the heat-generating equipment. The first element of the chimney is a piece of pipe without insulation. If you start the installation immediately with a full-fledged sandwich pipe, the insulation will burn, sinter into stone and damage the chimney. Improper installation can result in damage to the heating equipment and even a fire. So, this element is inserted into the socket, and then the joint is isolated with a plug. After that, the structural elements are sequentially connected to each other, fixing the connection points with crimp clamps.

A common mistake when installing a sandwich chimney is the absence of a pipe without insulation immediately above the outlet pipe of the heating equipment. As a result, the insulation simply sinters into stone.

If there is a possibility of a significant increase in pressure in the chimney, the joints are additionally closed with sealing sleeves. Often, when installing steel chimneys, special high-temperature sealants are used to coat the joints. The tighter the chimney, the better the draft.

Despite the excellent thermal insulation properties of sandwich pipes, in places where the chimney passes through the ceiling, there is still a certain danger of heating and igniting the materials surrounding the pipe. To ensure the required level of fire safety, it is recommended to lay an additional layer of thermal insulation in such places.

Another important requirement of SNiP in this area: the distance from the chimney pipe to the wall should not be less than 25 cm. The design should include a sufficient number of elements equipped with inspection hatches to allow visual inspection of the chimney's internal walls

If it is necessary to make horizontal segments (the length of each should not exceed 100 cm), tees should be installed in such areas, which will effectively remove moisture formed during the condensation of water vapor.

We also invite you to watch a video clip with useful tips from an "experienced" master.

Why you need to insulate the chimney

During operation, a large amount of combustion products and hot air are transported through the smoke channel. All this reduces the service life of the chimney by accelerating the processes of corrosion and oxidation of the inner walls of the outlet channel.

Among the most common problems that lead to damage to the chimney are:

-

the presence of moisture - in the pipe of the smoke channel there is increased pressure and constant humidity. Due to the temperature difference inside and outside the chimney, moisture partially condenses on the walls of the channel, which ultimately adversely affects the operational state of the metal;

- chemical environment - during the combustion of solid or liquid fuel, a large amount of aggressive substances dangerous to human health is formed. With the correct operation of the chimney, all the formed substances are brought out under the influence of natural draft. When the draft level decreases or when the chimney is not functioning, substances accumulate on the walls of the chimney, which leads to a slow but progressive destruction of the chimney pipe.

Insulation of the chimney using modern heat-insulating materials reduces the risk of damage and reduces the rate of corrosion processes. For example, the insulation of steel chimneys extends the life of the product by 2 or more times.

Benefits of an insulated chimney

Timely thermal insulation of the chimney reduces the risk of exposure to factors that lead to the formation of damage in metal, brick or ceramics. With the right thickness of the insulation, the problem with condensate is solved almost completely - the dew point shifts to the pipe section located above the roof level. This significantly increases the resource of the smoke channel and the life of the flue system as a whole.

Insulation of the chimney increases its service life several times

Other benefits of an insulated chimney include:

- Reduction of deposits - thermal insulation materials help to reduce the temperature difference between the combustion products and the surface of the chimney. This reduces the amount of substances deposited on the inner surface of the chimney.

- Energy saving - in the process of operation, an insulated chimney takes less energy received from fuel combustion.This reduces the consumption of fuel and energy spent on maintaining a constant temperature in the combustion chamber.

- Strength and stability - thermal insulation, mounted around the chimney, plays the role of a frame and increases the strength and stability of the structure. This is especially noticeable when installing thin-walled metal chimneys.

Modern heaters increase the frost resistance of the smoke exhaust system. If the insulation technology is followed, it is possible to reduce or completely eliminate the effect of high temperature in the area where the pipe exits through the roof.

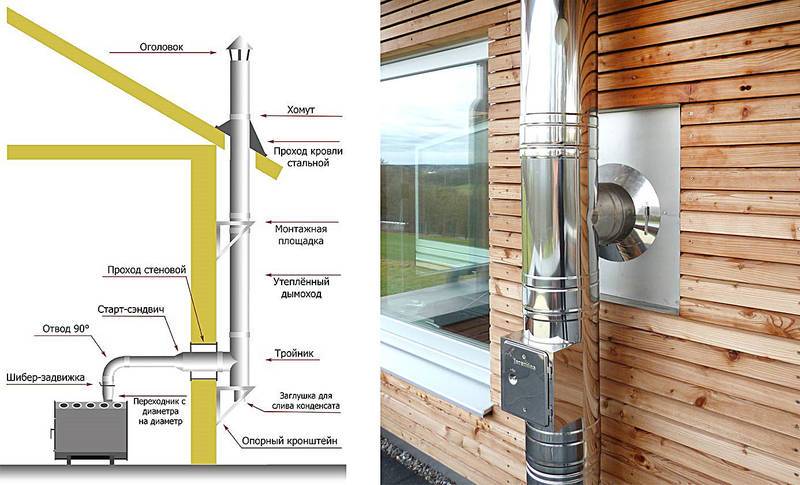

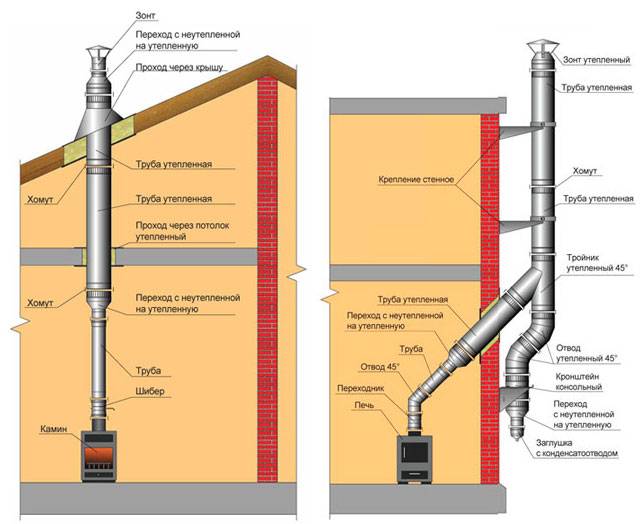

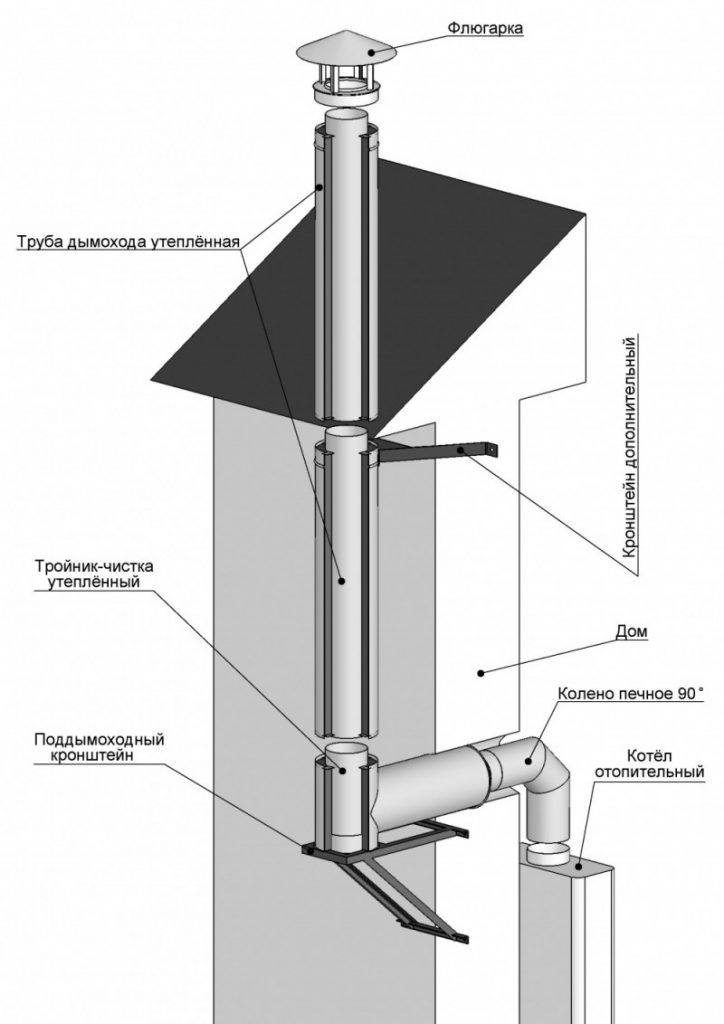

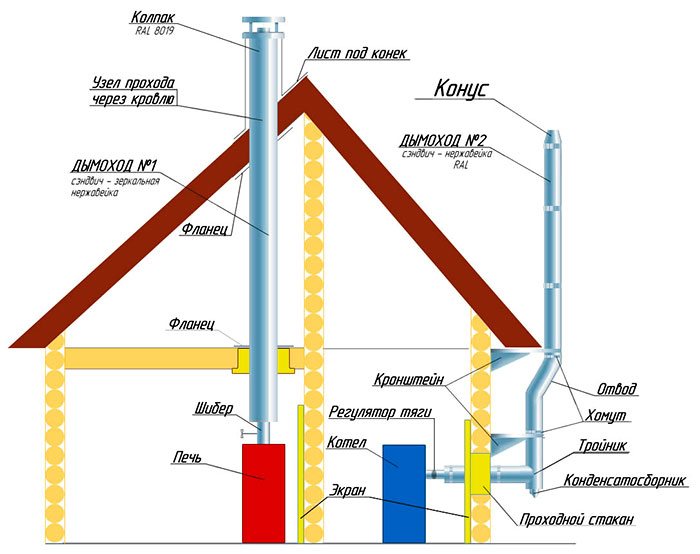

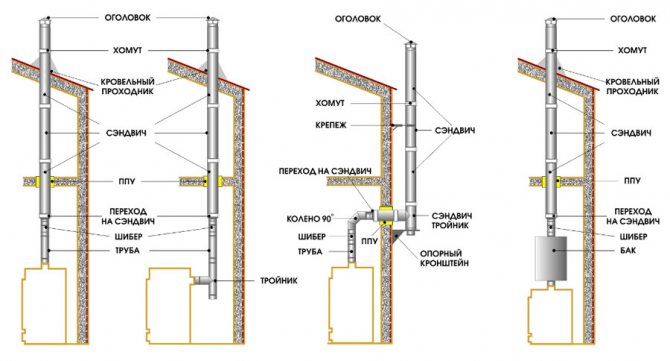

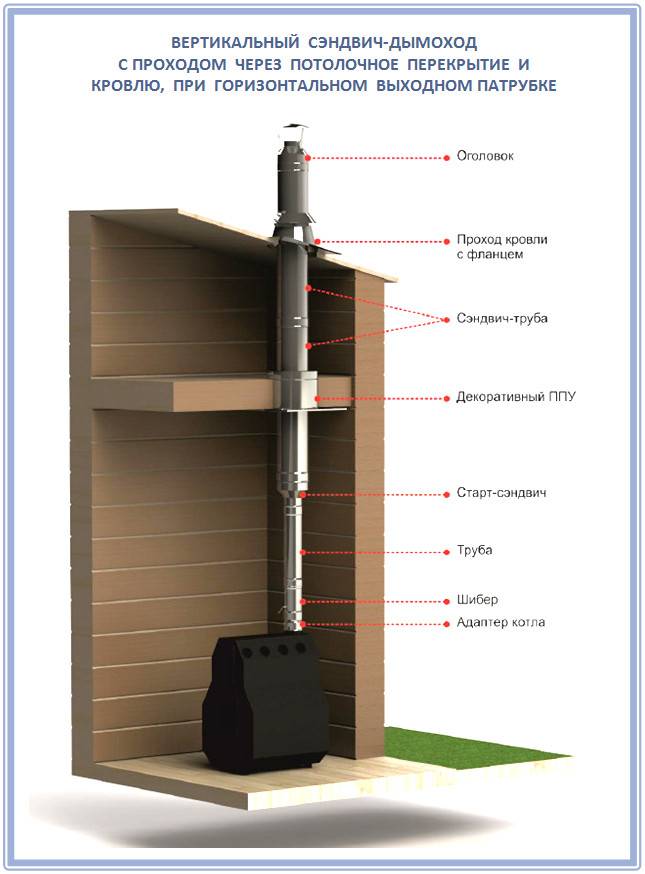

Sandwich setup diagrams

There are 3 ways to make a chimney from modular sandwich pipes:

- The vertical part is located on the street, attached to the outer wall of the building. The horizontal chimney crosses the outer fence, enters the house and is connected to the boiler (furnace) nozzle.

- The vertical smoke channel passes through the roof, descends into the boiler room and ends with a condensate collector. The heat generator is connected to it by a horizontal pipe.

- The shaft again crosses all roof structures, but is connected directly to the heater, without a pocket and horizontal sections.

Installation diagram of a wall-mounted chimney (left) and an internal channel passing through the roof (right)

The first option is suitable for finished houses of any type - frame, brick, log. Your task is to put the boiler against the outer wall, bring the sandwich to the street, then fix the main pipe. In terms of financial and labor costs, this is the most profitable way to install a chimney.

Installing a modular system according to the second scheme is much more difficult.In a one-story house, you will have to go through the ceiling and roof slope, arranging fire cuts. In a two-story house, the pipeline will get inside the room and make you think about decorative cladding. But you do not need to bypass the roof overhang and fix the end of the chimney with braces.

The latter option is suitable for sauna stoves and fireplace inserts. The former are very hot and practically do not condense, the latter are hidden behind a fire-resistant drywall finish. To organize the cooling of the sandwich channel, ventilation is provided in the space between the lining and the pipe. The photo above shows convection grates that remove heated air from under the casing of the fireplace insert.

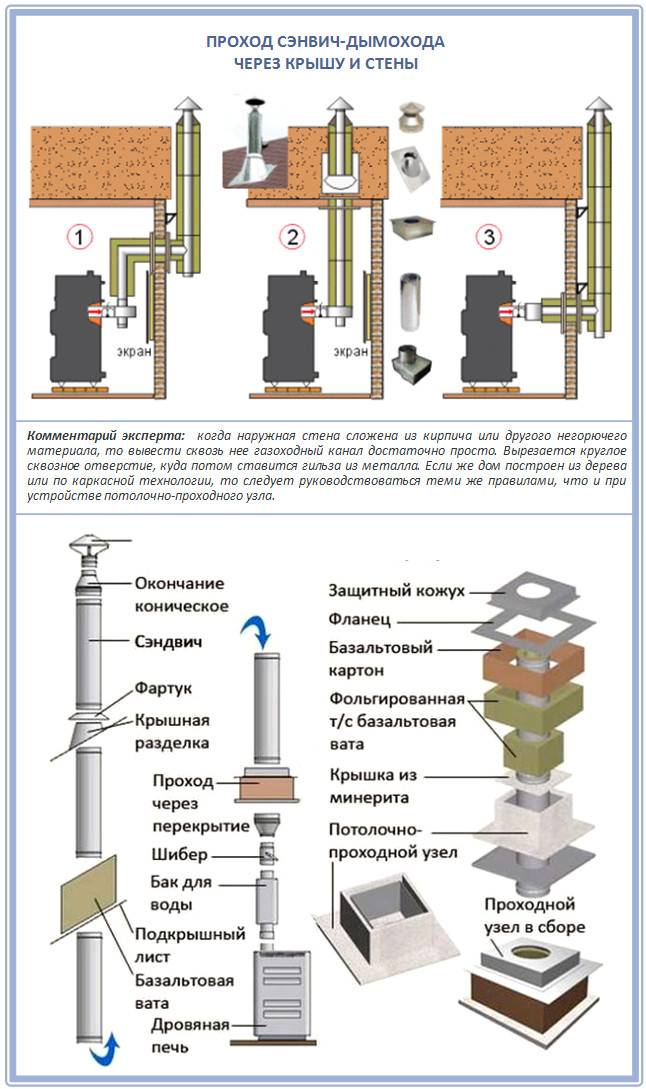

How to insulate an iron chimney pipe

To insulate a metal pipe on the street, they use basalt insulation and metal clamps - the rolled insulation must be wrapped around the pipe and secured with clamps after 30-40 cm. A tool that is useful for insulation:

- Hammer, pliers, screwdriver, clamp, and other metalwork tools;

- Roulette, metal ruler or square, building level, pencil or marker;

- Cutter or scissors to cut the insulation for chimney pipes to size;

- A device for riveting and rivets that connect the casing. Instead of rivets, short press washers can be used;

- Screwdriver or electric drill, drills Ø 3-4 mm for rivets;

- If the chimney is plastered, then you will need: a spatula and a bucket for mortar;

- For sealing cracks and joints - a construction gun and bituminous mastic.

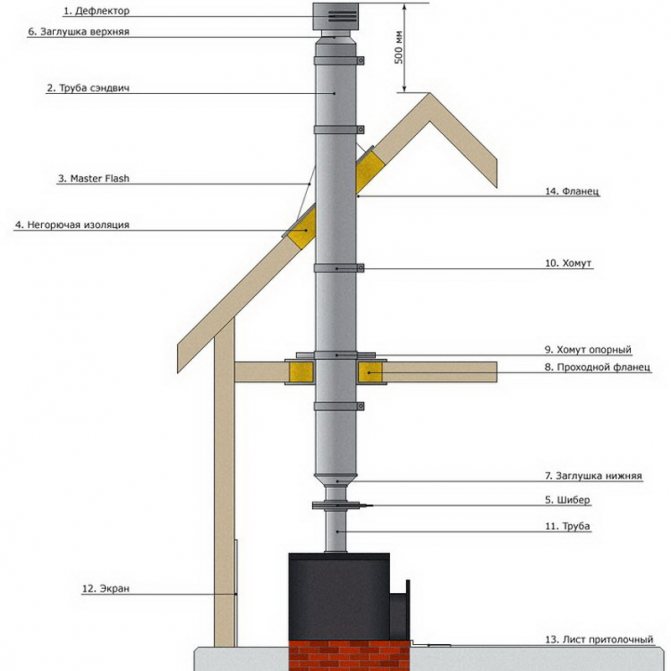

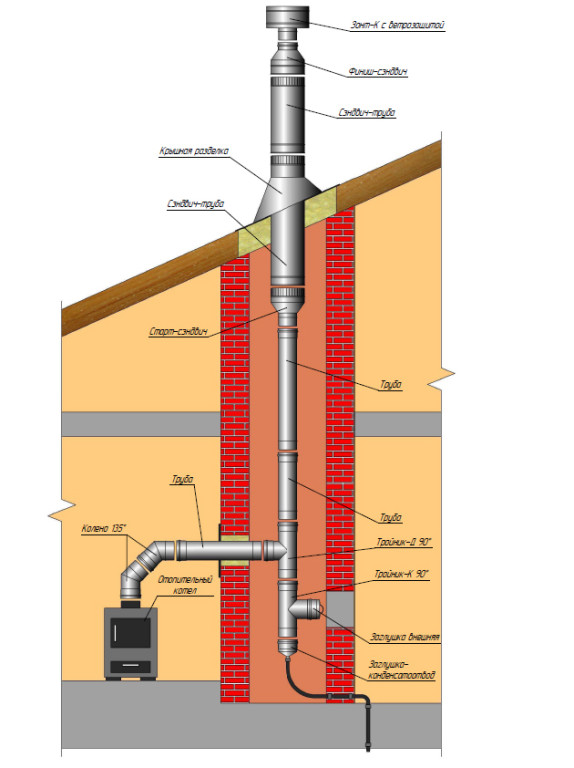

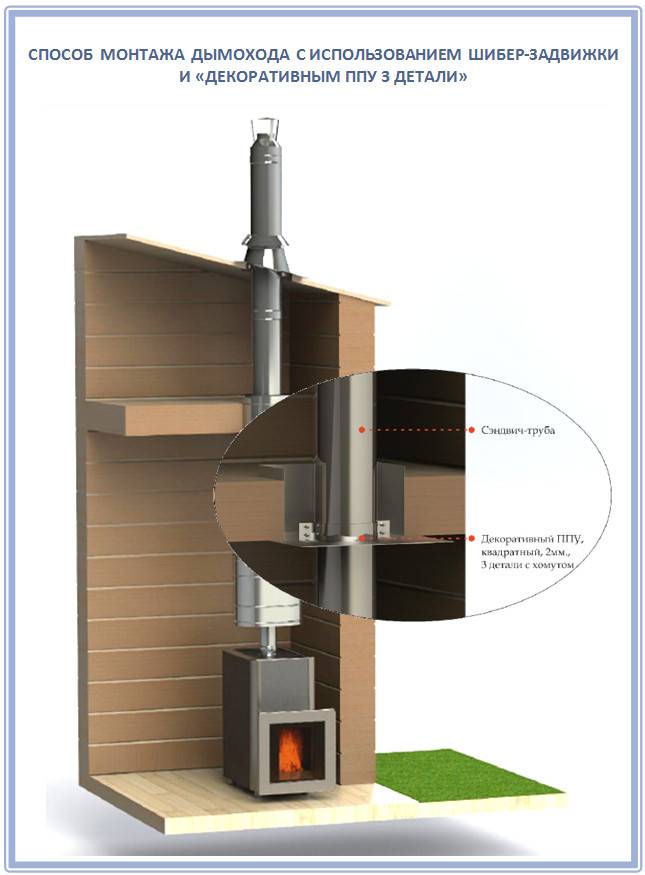

How to secure the joint of the chimney with a wooden floor?

And now we will touch on the most important point, the knowledge of which will help you avoid a completely unexpected fire.So, the higher the flue gas temperature, the stronger the sandwich pipe heats up, and all the structural elements around it are exposed to temperature

Therefore, it is extremely important to take care that the passage elements are reliably protected. And don't think it's that simple

So, the higher the flue gas temperature, the stronger the sandwich pipe heats up, and all the structural elements around it are exposed to temperature

Therefore, it is extremely important to take care that the passage elements are reliably protected. And don't think it's that simple

For example, a normal tree without special protection charred already at a temperature of 200 degrees. And dried wood can even catch fire at a temperature of 270 degrees Celsius! If you act on wooden logs for more than a day at a temperature of 170 degrees, they can also catch fire. Unfortunately, it is this moment, which many do not know about, that often causes fires, even if a high-quality sandwich pipe is installed.

Therefore, it is desirable to perform the overlap with good insulation of sufficient thickness so that there is practically no heat from the pipe to the wall and wooden elements. In addition, the more the wood floor itself accumulates heat from the sandwich, the worse the wood will perceive this heat each time. Of course, in an hour or two, the usual insulation in the PPU unit does not have time to warm up to a critical temperature, but the problem is that, speaking in the language of stove-makers, after heating, heat accumulates in wood and insulating materials, and gradually changes their chemical composition.

For example, with prolonged and constant accumulative heating, wood can catch fire already at a temperature of 130 degrees! But on the outside of the sandwich, it often reaches up to 200 degrees (from 75 to 200, as laboratory tests have shown). So this sad thing happens when the stove or fireplace was successfully heated for more than one year, everything was great, and then one day the owners drowned it only 2 hours longer and hotter than usual (to warm up on a particularly cold winter evening or heat a steam room for guests) , and the temperature in the sandwich crossed the critical temperature, and the same temperature of 130 degrees Celsius reached the wood of the ceiling, already dried over the years.

You also need to be careful if mineral wool is used as the PPU thermal insulation material. Over time, from exposure to high temperatures, it also changes its properties and even becomes more thermally conductive! This does not mean that the wool is one day at risk of catching fire, but the outer contour of the chimney in this place will already be much hotter than you originally expected. But this is a factor that was not initially taken into account!

That is why experienced stove-makers are advised not to make the floor insulation too dense (the denser it is, the more heat accumulates in itself). Moreover, the natural possibility of blowing air through the pipe is vital:

They often make a dangerous mistake, poorly calculating the distance between the rafters for the passage of a pipe, which does not correspond to the norm.

Please also note that an empty ceiling assembly, in which thermal insulation has not been installed at all, is also not the best option.

Also keep in mind that the material that envelops the inner arc of the chimney tends to settle slightly over time. As a result, the junction of the two walls is sometimes unprotected. And, if this joint burns out (and it is especially dangerous if it is also located inside the ceiling), then the fire that has arisen in such voids will be almost impossible to extinguish. Therefore, once a year or two, all the passage nodes of the sandwich chimney should be carefully examined.

Here is how the passage of a sandwich chimney through the ceiling is properly organized in the simplest version:

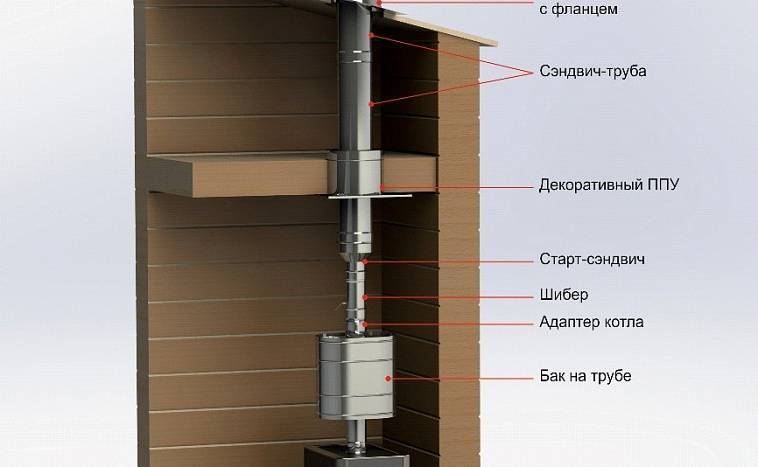

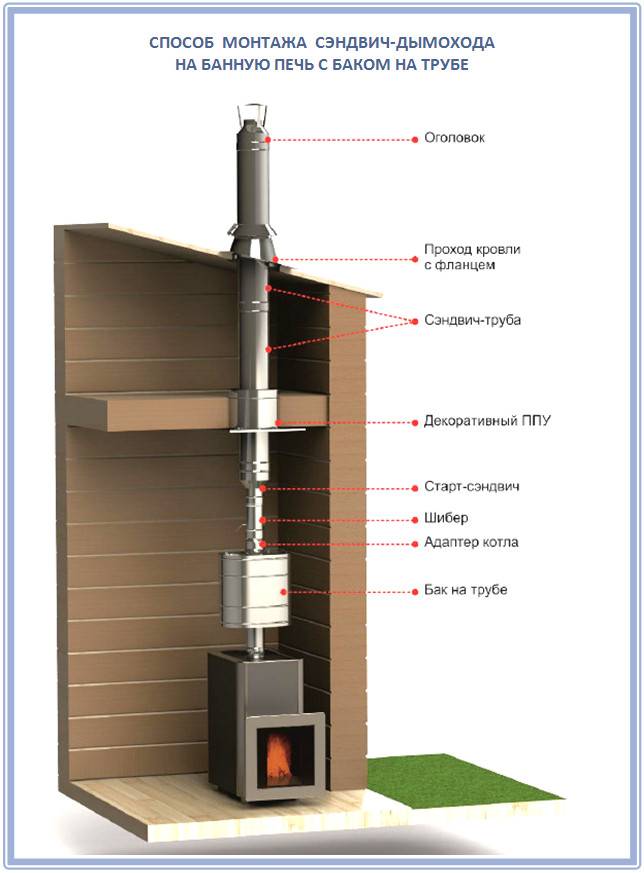

If you install a water tank on the chimney, then the whole installation should look like this:

Pay attention to how the passage of the sandwich pipe through the floor should be performed:

And finally, if it is not possible to put a stove or fireplace directly under the place where the sandwich pipe is removed, you will need a special tee:

Heating errors

The most common reasons for the inefficiency of protection are incorrect calculation of the thickness of the insulation, its insufficient sealing. The first sign of poor quality work is the appearance of condensate inside the chimney. In this case, it is better to immediately “redo what has been done”. But already try to provide all the conditions: both the necessary thickness of the heat insulator, and the tightness of the structure itself.

The question of how to insulate an asbestos chimney pipe can be answered as briefly as possible: with something that has the right weight and does not burn. For metal channels, it is better to prudently buy ready-made elements that only need to be installed. You will have to spend quite a lot of time on brick walls.

For those who are interested in this topic, this informative video will be useful:

Chimney pipe insulation with basalt wool

The technology and mechanism for installing the casing is influenced by many factors, including the material from which the pipe is made, its diameter, and others.

Basic rules for high-quality thermal insulation

Compliance with the following standards is mandatory when lining the chimney with a heat insulator:

- for wooden coating, the layer of wool must be at least 50mm and not more than 100mm;

- in the passages through the tree, this layer should reach at least 5 cm;

- if mats of material are stacked in several layers, then their joints must be covered with upper layers;

- for heat insulators in a cylindrical form of release, when they are applied in several layers, each subsequent one must be laid with an offset of 180o;

- for boilers with liquid fuel or gas heating technology, it is advisable to use high-temperature cladding materials with a range of up to 300 °;

- a protective screen is a mandatory measure of isolation if materials without a foil layer were used during the work.

Insulation of a ceramic or asbestos chimney

For asbestos chimneys, the outer cladding procedure is carried out, and the material layers are fixed with special brackets. To simplify and speed up the work, you can use basalt cylinders, the thickness of which should not exceed 5 cm.

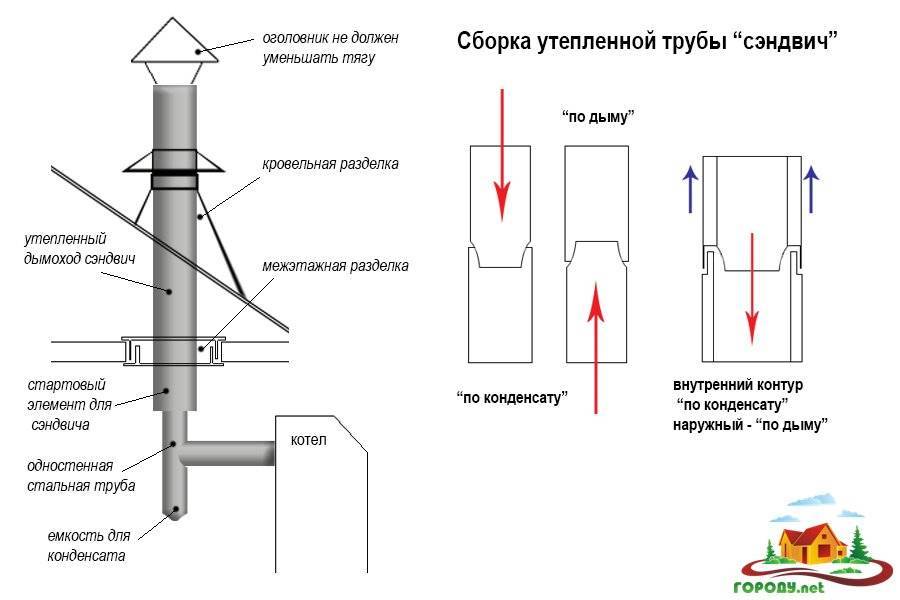

Ways to insulate a steel chimney

The mechanism of the procedure is almost completely similar to the method for a ceramic chimney, and is as follows:

- 2 pipes of different diameters are used: a large one for the outer surface, and a smaller one for interior decoration.

- One pipe is inserted into another.

- The resulting gap between the products is filled with the selected non-combustible insulation to isolate the chimney.

- If the material has a foil layer, it is not necessary to install a protective cover.

- The end structure must be additionally insulated.

The instruction itself is quite simple, but it can also be simplified using ready-made sandwich pipes, which replace the first 3 points of the manual. Such ready-made consumables for insulation have high heat resistance and help to achieve high insulating characteristics.

Brick pipe insulation technology

Warming a brick pipe is not an easy task.

To carry out the procedure, 2 methods are used:

- plastering;

- lining with mineral wool.

To plaster a pipe you need:

- a special reinforced mesh is installed on its outer surface;

- the first layer is applied directly to it in a small amount;

- after drying, a thicker mixture is made and laid on the grid in several layers;

- to achieve an aesthetic appearance after drying, the substance is overwritten, leveled, whitened or painted over with paint.

For the second method - sheathing - use basalt wool in rolls or mats:

- the required amount of material is cut depending on the size of the surface to be insulated.

- the resulting layers of material are attached to the chimney using thick adhesive tape.

- a protective casing made of bricks or slabs (optional) is mounted on top of the wool.

- to obtain the desired external characteristics, the surface can be plastered or painted.

Basalt wool - the best option for chimney insulation. It can be used for any premises: residential and industrial. It also has the characteristics necessary for these purposes - it is refractory, has resistance to moisture and vibrations, easy tolerance of high and low temperatures.

Elements of modular systems

To draw up a wiring diagram, purchase components and subsequent assembly, you need to understand what parts are used in a double-circuit chimney. We list the main elements, accompanied by photographs:

- straight sections of sandwich pipes 25, 50, 100 cm long;

- tees at 45, 90°;

- knees 90, 45, 30 and 15 degrees;

- transitions from a single-wall pipe to a double-circuit one - “start sandwich”;

- rotary gates (flaps);

- condensate collectors and various heads;

- ceiling passage units (abbreviated as PPU);

- support platforms, brackets;

- fastenings - crimp clamps, for stretch marks;

- pitched roof sealing elements called master flash or "kryza";

- end caps, skirts.

Two-layer pipes are connected to other fragments by the method of socket-profile joining. In a more accessible language, the connection is called "thorn-groove" or "dad-mother", as you like. In the manufacture of each shaped part (except for the end parts), a spike is provided on one side, and a groove on the other.

Scheme of installing a chimney along the outer wall of a country house

As an example, we propose to consider the assembly scheme of a wall-mounted chimney-sandwich starting from the boiler:

- We connect a single-walled pipe to the outlet of the heat generator through the coupling, then we mount the starting adapter on the sandwich.

- We connect a straight section of a double-circuit pipe facing the street to the transition. There she is inserted into the tee.

- Below the tee we have an inspection section, then a support platform and a condensate collector. The structure rests on a wall bracket.

- From the tee we rise in straight sections, every 2 meters we fasten to the wall with sliding brackets, we crimp the joints of the elements with clamps.

- At the end of the chimney we install a cone without an umbrella (for a gas boiler), a simple cap or a deflector.

When you need to bypass the roof overhang, we use 2 outlets at 30 or 45 degrees. We fasten the end of the chimney with stretch marks so that it does not sway with the wind, as was done above in the photo. Professional installation of a sandwich pipe for a steel furnace, look at the video:

The main stages of installation of a sandwich chimney

How to install a chimney quickly? The answer is simple: buy a sandwich pipe. This material is an ideal solution for a private house, especially if there is no much experience in construction. For the installation of this material, you do not even need an assistant, all the steps can be performed independently.

We connect all the elements of the structure

The sandwich pipe has one design feature - a ribbed coating on both sides. Such a device allows you to connect the elements to each other, simply by inserting different parts one into the other. To drain the condensate that will occur during operation, additional tees should be installed.

Serial connection of the chimney

All joints must be tightened with steel clamps with high quality and reliability. To connect the starter part to a boiler, fireplace or other heating device, you must purchase an appropriate adapter with two different diameters.

A simple method is used to connect internal products. They take out one inner pipe at a distance of 10 cm, connect it to the second one (using a steel clamp of a smaller diameter) and push it inside the outer pipe.For greater tightness, it is not enough to use only clamps, you will also need a special sealant designed to work at high temperatures.

Let's secure the floors

When installing a chimney made of sandwich pipes, or other material, through a wall, fire safety rules should be taken into account. If it is concrete or brick, then it will be enough to simply seal the joint with sealant. Much more difficult in wooden houses, where the contact of the chimney with a wooden wall will lead to a fire.

Closing the pipe passage

How to secure the junction of the drainage system with the ceiling:

- Use galvanized sheet, which should be fixed to the ceiling. A hole is cut in the middle of the sheet, and a chimney is inserted into it. Galvanized sheet does not heat up completely and does not transfer excessive heat to the wooden surface.

- Treat the distance from the pipe to the nearest wooden surface with a heater. Almost all modern heaters are heat-resistant - they do not ignite at high temperatures.

Instead of galvanized sheet, many builders use asbestos material. It also has increased resistance to high temperatures.

We bring the pipe to the roof

Installing a chimney from sandwich pipes and laying it through the roof is the most painstaking part of the work. Here you will need not only to apply physical force, but also to accurately and correctly calculate everything.

Protective structure for the chimney

The procedure for bringing the chimney to the roof:

- Make a hole in the roof. To make it neat, the place should be marked in advance with a construction marker. There is no need to rush, because a crooked hole will not add aesthetics to the entire structure.It is most convenient to cut the roof from its inner part.

- From the inside, a roof sheet is installed, securely fixed, and from the outside - roof cutting.

- It remains only to bring the outer part through the hole and securely process the edges with sealant.

Now you can once again check the quality of the construction, and as a final step, remove the entire protective film. You can safely melt the boiler or fireplace and look at all the joints and holes treated with sealant.

Conclusion

As you can see, finishing a chimney in a private house is quite within the power of a home master, there is something to choose from, there would be a desire. In the photo and video in this article, I picked up additional material on the arrangement and decoration of chimneys. If you still have questions after watching, write them in the comments, we'll talk.

The original design of the chimney.

November 21, 2020

If you want to express gratitude, add a clarification or objection, ask the author something - add a comment or say thanks!

- February 27, 2020

- February 21, 2020

- February 20, 2020

- February 16, 2020

- February 15, 2020

- February 13, 2020

Latest replies on the forum

- Cinder block walls How to sheathe cinder block walls

Question added: February 09, 2020 — 19:32

views

- Walls Hello. Tell me, can I put a decorative stone on a putty wall?

Question added: August 03, 2020 — 12:25

views

- Question about wall cladding in the bathroom Good afternoon. Having studied quite a lot of information, I could not come to an unequivocal conclusion. Maybe you can help me. Situation …

Question added: 20 May 2020 — 11:50

views

- Mysticism ... scary Dear forum users, I want to know if anyone had anything like that .. I must say right away that alcohol and nothing else that fogs my brain, I don’t ...

Question added: October 20, 2020 — 08:44

views

You may be interested