Criterias of choice

To facilitate the selection of scissors, it is recommended to take into account important criteria that determine the functionality of the tool.

Manufacturer

There are different brands of scissors on the market.

When considering a model, it is worth paying attention not only to the price, but also to the convenience of managing the tool. Better products are offered by well-known manufacturers:

- Kraftool;

- VALTEC;

- TUNDRA,

- LOM;

- Tim;

- Sibrtech;

- GIANT;

- BISON.

Their products meet the standard requirements for tools. In addition, only high-quality materials are used for the manufacture of pipe cutters.

What are

There are different types of pipe cutters. They differ in structural elements and the principle of operation.

Telescopic. The design consists of rollers, carriages and guides. Thanks to this solution, the tool can be adjusted to a wide range of diameters.The cutter is adjustable, often it is equipped with a built-in deburring tool.

This type is suitable for cutting corrugated pipes made of stainless steel. The ability to adapt to the maximum range of diameters gives the pipe cutter universal qualities.

Ratchet Pipe Cutter 28-67mm

With ratchet. Due to the design features, the snack of the pipe billet is carried out by repeatedly pressing the handle. After the cut is completed, the blade returns to its original position, which is provided by a special gear rack. When using this tool, such consequences as crushing and deflection of the edges of the workpieces, loss of their original shape are possible. A calibrator is used for alignment. Manual editing is also carried out.

Desktop (floor) pipe cutter. In the design of such pipe cutters, shaped cutters are provided. The tool is used for simultaneous cutting and chamfering. In appearance, this is a desktop or floor-mounted machine. It works from the mains or batteries. The kit includes different sponges for fixing the workpiece. The cut is performed by rotating the working part of the device around the pipe.

This tool is available in two versions:

- detachable design - opening of the clip is provided due to two halves;

- one-piece models - the material to be cut is inserted inside a solid clip.

The purpose of the pipe cutter is not limited to plastic pipes. It is also used for pipe materials made of ferrous and non-ferrous metals.

Roller pipe cutter STAYER MASTER (2340-28) 3 – 28 mm red

Roller. This device provides a cut of firmly fixed pipes.Thanks to the movable cutting elements, it is possible to work on the operated pipeline. In this case, the gap between communications and walls / floor can be only 30 mm.

In the process of rotation of the pipe cutter, the clip is gradually drawn in. At this time, the rollers pass over the surface of the pipe material, deepening into its walls. The cutting off of the part is carried out in several revolutions.

Models with one roller are capable of cutting pipes with a diameter of up to 50 mm. With the help of a design consisting of 4 rollers, it becomes possible to work with a large diameter (up to 100 mm). Among the shortcomings of this type, the quality of the cut stands out - burrs may remain in the places where the rollers pass.

Pipe cutter chain for thin-walled pipes (20-75 mm)

Chain. The purpose of this type is cutting pipes made of brittle material. These include: concrete, cast iron and ceramic products. The principle of their work is similar to roller pipe cutters.

The basis of the design is the chain. Cutting rollers are located on its connecting links. Thanks to this solution, the insert into the part is carried out along the entire perimeter. In this case, the pressure is distributed evenly along the entire entry line of the cutting edge.

Rotation around the pipe is performed by controlling special levers. The device is also equipped with a clamping mechanism, which smoothly reduces the diameter of the ring formed in the process of immersion into the pipe wall by the chain.

Maximum pipe diameter

When choosing pipe shears, attention should be paid to the working diameter range. The maximum value corresponds to the parameters of the largest pipe that can be cut with the tool

The indicators of the models presented on the market (of all types) are from 3 to 350 mm.Using a hand tool, you can work with pipes with a diameter of up to 70 mm.

Other plastic pipe cutting tools

They are used occasionally when there is no pipe cutter at hand:

- Bulgarian - for cutting pipes, you will need a cutting disc for alloy. The main point when working with an angle grinder is a clear regulation of the effort; you can’t press very hard on the tool.

- An electric jigsaw is a more successful method in the absence of special scissors.

There is a great opportunity to get an oblique cut, therefore, for greater accuracy during operation, the pipe must be rotated several times.

What is strongly discouraged from cutting pipes:

- Band saw - its blade moves very slowly and if it is not sharp enough, there is a high possibility of damage to the inner diameter of the pipe, which leads to chips and cracks.

- Circular machine. Since plastic pipes are flexible, pushing them into the machine often causes the pipe to move and strike, which is unsafe for the person making the cut.

Polypropylene pipes go on sale in the form of bays or straight segments, the length of which reaches 12 meters.

It is clear that during installation it often becomes necessary to cut them with scissors for cutting polypropylene pipes, since such huge segments for creating plumbing and heating systems do not fit. A pipe of suitable length is cut off and then welding takes place.

Types of scissors for cutting:

- precision. They cut pipes with a diameter of 3 to 42 mm. They have a ratchet mechanism and a blade with a gear rack, so the cut passes without much effort.

Comfortable and easy to use when working with one hand, but if the cutting is intense, the hand will quickly get tired;

- roller. In this tool, the pipe will rotate on guide rollers, and the other blade of the scissors, under pressure, feeds the cutting roller to the cut point. There is one huge advantage here - an impeccably even cut, but the cutting speed will be low;

- rechargeable. These scissors are equipped with an electric motor.

Cutting polypropylene pipes with such equipment is a pleasure, since the cutting speed is quite high - from 4 to 7 seconds. But there is also a drawback - a limited range of pipe cutting. Such equipment can only cut pipes up to 42 mm.

Guillotine pipe cutter

1. This PP pipe cutter can cut pipes with a diameter of 63mm to 350mm. It has Teflon-coated blades that cut at a ninety-degree angle, leaving a clean, burr-free cut. The blades are simply changed or sharpened.

2. This method of cutting has one great advantage.

It is not necessary to process the surface of the pipe before welding after cutting, because the cut comes out smooth and even, there are no deformations.

3. Guillotine cutting process. A guillotine blade mounted on wheels swings around a pipe fixed in a sector from 30 to 60 degrees. After the incision, the blade, under the action of a rotating screw handle, goes into the pipe to the depth of the entire diameter and cuts it completely.

Which tool is better to choose?

When choosing the type of pipe cutter for polypropylene pipes, you need to build on how intensively you will use it.

If it is needed at one time, then both roller scissors and precision ones are suitable for this. And if it is necessary to cut pipes often, then battery shears are best suited for these purposes. You will also need a guillotine pipe cutter for this, especially if you are dealing with pipes of a huge diameter.

But all scissors suffer from the same flaw; when cutting, the blade can go a little to the side. On small diameters, this is not such a terrible phenomenon, but when working with pipes of huge diameters, such a cut needs additional processing. That is why for pipes with large diameters it is better to take a guillotine pipe cutter.

Varieties of cutter designs

The standard version includes a ratchet mechanism. In one part, the cutting part is located directly, and in the opposite part, there is a special round recess for planting the workpiece. How does this type of plastic pipe cutter work? The operation is performed by bringing the two handles together until a complete cut-off is realized. A slightly different principle of operation is incorporated in telescopic models. Their device is provided with a bracket-shaped body and a cutting roller, which, in the process of passing over the surface, performs spot cutting.

Kinds

There are different scissors for plastic pipes, differing in design, principle of operation and area of use. Models used for domestic purposes for home renovations are usually manually operated and have an affordable cost. Models designed for cutting pipes for water supply and heating operate on an electric drive.

precision

Their design is simple, the master uses only one hand to work, which facilitates the procedure. The main task of such a tool is to cut polypropylene and plastic pipes with a diameter of 2.5 mm to 42 mm. However, special models are also sold that are suitable for pipes with a diameter of up to 70 mm.

The knife is made of alloy steel, which gives additional strength, and its sharp sharpening guarantees a perfect cut. A ratchet tool is best suited for domestic purposes.

Plastic pipe shears are also used for reinforced and metal-plastic pipe products. The main difference is in the cutting material used. The tool, designed for polypropylene pipes, has a steel variety with fine teeth that provide the tightest possible grip.

When choosing precision equipment, focus on the following points:

- the sharpness of the cutter and the possibility of replacing it if it is planned to use it for a long period;

- comfort during work: softness of movement (it can quickly rub the palm under mechanical load) and ease of placement (should not slip).

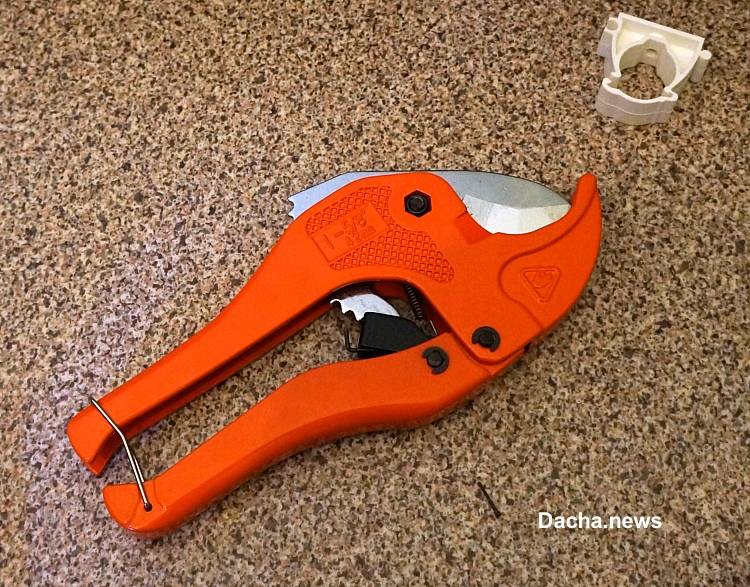

Roller

The simplest types are a hook, on the inside of which there are movable rollers. In the process of cutting, the plastic pipe is slowly rotated along these rollers, as a result of which an incision occurs. The spring and the force applied by the hand ensure the approach and retraction of the cutter.

Unlike precision, roller scissors involve two hands, because. it is necessary to hold not only them, but also the valve that extends the knife.This device makes a neat cut and does not compress the pipe as much as other types.

The main difficulty in the cutting process: the need to hold in a perpendicular position. If this requirement is violated, the result will be a malfunction of the knife.

Ratchet

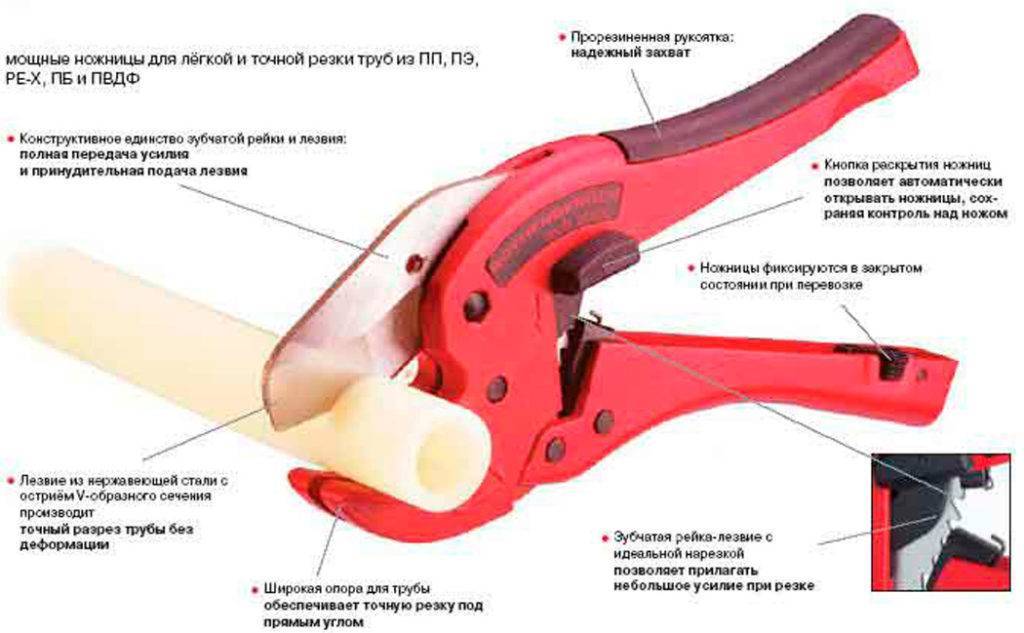

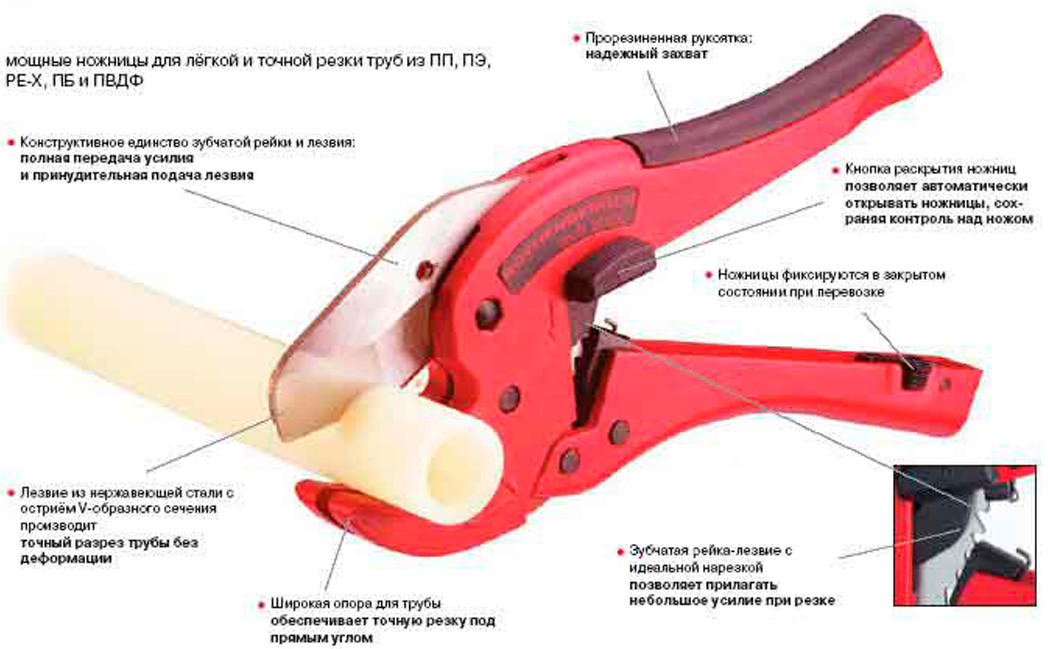

This type is an improved and, accordingly, more expensive version of roller shears. The ratchet mechanism provides the possibility of more convenient use and the absence of the need to apply tangible pressure. This is largely achieved due to the presence of a cutting rail and stop.

The support in the tool is wide, it is necessary for reliable fixation of the knee. This eliminates the need to ensure that the pipe cutter is level and perpendicular.

Accordingly, the presence of a stop reduces the likelihood of accidental change of position, damage and getting an uneven cut. The blade of the plastic pipe cutter is very sharp, which allows it to glide as smoothly as possible.

Rechargeable

The battery powered tool is an improved version of the handheld device. The master performing the procedure does not need to make efforts, because. the blade and fixing elements start to run on battery power.

The pipe cutter with an electric motor is able to carry out the most uniform cut and has a high speed of work. Due to the high cutting speed, this device is considered professional equipment and is used by workers for laying long lines for water supply or heating.

Their operation is simple: the area of the pipe to be cut is placed in a special clamp, then the motor is activated, after which the work is done.

Guillotine

As a professional equipment, in addition to a battery pipe cutter, scissors - guillotines are also used. They do not require any effort and guarantee fast and even cutting of pipes, therefore they are used for laying long networks. Suitable for large pipes with a diameter of 60 mm to 360 mm.

Check out the video

Also, for comparison, it is worth noting separately that guillotines are often used in production. A pipe is fixed in them, a blade is directed at it from above (it is sharply sharpened and Teflon coated on it for better performance). Such machines may have an electric or mechanical motor that starts the cutting part.

Mounting

The installation of an internal sewerage system and an external highway is in many ways similar. The difference is in the materials used. For internal sewer systems, collectors painted in gray are used. The outer ones are orange. This is due to the difference in external loads:

- Products located indoors are affected by their own weight and, periodically, by the load from the flowing liquid. Thermal heating up to 60–90°C is added, with a parallel chemical attack from the effluent components.

- Parts located outside the building are subject to:

- pressure from the mass of covering soil;

- impact from the weight of passing traffic;

- experiencing efforts from buildings located above;

- exposed to external temperature changes, from negative to positive.

Hence, the installation of internal sewage is carried out with a predominance of polymeric materials:

- PVC (polyvinyl chloride). More precisely, unplasticized PVC (PVC-U).

- HDPE (low pressure polyethylene).

- PPR (polypropylene).

The most demanded PVC products. Installation of internal collectors is carried out by joining the narrowed part of the pipe and the expanded part (bell). Additional elements are used - fittings (reducing couplings, tees, elbows with an angle of 45 ° and 90 °, bends).

Installation of sewer pipes is carried out with the obligatory observance of the angles of inclination:

- For a collector Ø 50mm, the slope will be 2-3 cm per linear meter of length.

- For a product Ø 100mm, - about 1-2 cm per 1 meter.

During installation or repair work, there is a need to saw a plastic part. Polymers do not differ in high hardness and strength, compared with metal products. Therefore, they are processed by most plumbing and mechanical tools. It is possible to cut a plastic pipe by:

- hacksaws for metal or with a small hardened tooth;

- triangular file;

- jigsaw (for diameters not exceeding 50mm);

- circular or reciprocating saw;

- grinder and other tools.

Installation of sewerage systems is carried out according to the rules based on the requirements of SP 30.13330.2012. In addition to observing the slopes, it is necessary to correctly distribute the attachment points and connections. If technically possible, it is recommended to carry out hidden wiring.

Installation of sewer pipes indoors begins:

- from drawing up a work plan;

- making a sketch or drawing;

- determining the required dimensions of the collector;

- procurement of the necessary material;

- preparing a tool with which you can cut a plastic part.

At the end of the installation phase, the internal sewerage device is checked visually. Further, it is necessary to spill the system with water in order to identify possible product defects or leaks.

How to cut polypropylene pipes

The material is a high density thermoplastic polymer. At the same time, plastic is characterized by softness and pliability for processing with a metal blade and an abrasive cloth. Therefore, cutting polypropylene can be carried out at home, regardless of the diameter and thickness of the pipes.

To adjust the dimensions of polymer products made of heat-resistant plastic, you can use almost any tool with a durable sharpened metal blade. It can be a hacksaw, a jigsaw, a grinder, a drill attachment or a puncher in the form of a cutting disc.

Cutting plastic products with a hacksaw

Cutting plastic products with a hacksaw

It is necessary to shorten the polypropylene pipe so that the cut angle is as smooth and even as possible. If it bends, then it will not work to connect the elements of the highway, you will have to straighten it. The edges of the rough execution are ground and the angle is corrected. To exclude forced correction of work, craftsmen use a special tool for cutting polymer products.

The main advantage of narrowly focused equipment is an even cut, acceptable for soldering quality. A toothed saw blade or an unsharpened edge of a disc for metal leaves behind burrs, often deforming the edge of a polymer blank.As a result, the connection of such pipes will be of poor quality or it will take noticeably more time to work than it could be with the use of a special pipe cutter.

Design features of pipe cutters

Manufacturers manufacture manual mechanical and electric cutters for precise cutting of polypropylene products.

Cordless cutter for polypropylene pipes

When choosing a tool, consider:

- Scope of upcoming work.

- Blade quality. It must be made of alloy steel.

- Minimum and maximum diameter of pipes to be cut.

Cutting equipment is usually built with a metal body. Preference for aluminum models. Devices with a steel case are heavy.

Therefore, they are less convenient to use. Moreover, when cutting PP pipes, you do not need to exert great effort. Aluminum cases perfectly maintain the created loadings.

Models are available in which the cutting parts can be changed. For large volumes of work, this tool is used. In the absence of the possibility of changing the blade, you will have to buy a new device. This nuance is not taken into account for one-time work.

Guillotine

This type of tool features a simple design and the ability to accurately cut straight pipe parts. Manual and electrically driven guillotine models are available. In the design of the equipment there is a blade, which is strictly perpendicularly lowered onto the pipe.

Most hand tools are capable of cutting products with a diameter of up to 70 mm. A tool is also produced that allows you to work with parts with a cross section of 100-150 mm.

This range is quite enough to complete the installation of plumbing and heating in an apartment or cottage. Industrial models allow you to cut larger diameter pipes.

The guillotine pipe cutter consists of the following main parts:

- sharp blade usually Teflon coated;

- clamp for tubular element, opening from the bottom;

- handle with a stem that allows you to create a smoothly increasing pressure.

The guillotine tool is not designed for fast work. The reason for this is the stem, which after each cut has to be unscrewed in the opposite direction.

Ratchet

Such devices are structurally similar to scissors. The devices have two handles and one blade. The design also includes a semicircular stop to accommodate the pipe being cut.

Polypropylene pipe shears

The ratchet mechanism is a ratchet. It moves the knife smoothly with minimal effort. With the help of such a tool, pipes with a diameter of 15 to 30 mm are usually cut. If the blade is dull, the polypropylene product will wrinkle.

With a sharp pressure on the ratchet mechanism, deformation of the walls of the pipe parts can occur. Therefore, you need to work with the tool as carefully as possible. Also, keep the pipe cutter strictly perpendicular to the axis.

Even a slight deviation to the side will result in an oblique cut. In this case, the butt has to be sharpened. If it is also jammed, then a calibrator is additionally used to straighten it.

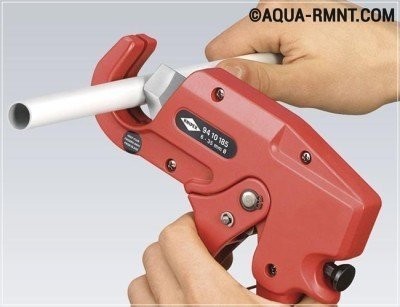

Ratchet pipe cutters are also made in pistol version. Such models allow you to get a more even cut with even less effort.

In their design there is a spring that returns the knife to its original position.Pistol ratchet pipe cutters are suitable for cutting thick hard wall pipe parts.

Roller

The devices are made in the form of a hook, inside which there is one or more movable wheels. The cut pipe is placed precisely on the rollers.

Roller pipe cutter for polypropylene pipes

The design also has a sharp wheel. It is used to cut details. The cutting roller is placed on a telescopic extension. It slides out of the handle.

The section of the pipeline part is carried out by turning the roller device around the clamped workpiece. The number of turns depends on the wall thickness. In this case, the cutter is tightened each time by turning the screw mechanism.

Roller tool will perform fast cutting of polypropylene pipes. Most importantly, accurately position the cutter on the marked cutting line.

During cutting, the roller must not be strongly pressed against the polymer surface. Otherwise, microcracks form in the material. Because of them, strength characteristics decrease, which leads to the formation of chips.

You need to cut off a part of a straight part smoothly. These rules must be strictly observed when working with thick-walled pipes of large diameter.

Four main types of instrument

All manufactured equipment for cutting polypropylene pipes can be divided into several groups.

Precision scissors equipped with a ratchet mechanism are designed for cutting products with a diameter of 3 to 42 mm. This type of cutting tool has a steel blade with a toothed rack, which makes it easy to cut the pipe.These scissors can be safely operated with one hand, but with large volumes of cutting, muscle fatigue occurs. When buying a tool, a one-year warranty is given, which is valid in case of purposeful use of scissors for its intended purpose.

Roller pipe cutter is more convenient to use. Despite the simplicity of its design, the master manages to get a perfectly even cut. This cuts pipes at a 90 degree angle. Deviation from the right angle during the cutting process can lead to deformation of the cut line, as well as breakage of the scissors. Roller pipe cutters can be telescopic. A tool equipped with a ratchet mechanism is more similar to ordinary scissors. On one side of this pipe cutter there is a c-shaped notch into which the pipe is placed. On the other hand, there is a cutting blade that cuts off the pipe after simply closing the handles.

Roller pipe cutter makes it easier to cut polypropylene pipes

- The cordless pipe cutter provides a high cutting speed, allowing you to spend no more than 7 seconds per operation. The equipment drives a small electric motor.

- A guillotine pipe cutter cuts pipes of large diameter, ranging from 63 to 350 millimeters.

In the photo - cutting polypropylene pipes with a cordless pipe cutter