- Tips for choosing

- Instructions for use

- Criterias of choice

- Manufacturer

- What are

- Maximum pipe diameter

- Varieties of scissors for cutting polypropylene pipes

- Kinds

- precision

- Roller

- Ratchet

- Rechargeable

- Guillotine

- Types of scissors

- Selection Tips

- The nuances of the work

- Design features of pipe cutters

- Guillotine

- Ratchet

- Roller

- Scissors for cutting polypropylene pipes: types

- Advantages of working with polypropylene

- Features of cutting polypropylene pipes

- Types of scissors for cutting polypropylene pipes

- Polymer pipe cutters: instructions for use

- How to use a pipe cutter with rollers

- The nuances of using scissors for PP pipes

- Other requirements of instructions

Tips for choosing

Before choosing and purchasing such a device, you need to ensure that the quality is fully consistent with the proposed price.

If you plan to use the device for minor plumbing repairs, then buying expensive scissors is not advisable. However, do not forget that the cheapest options for scissors are very poor quality. Often their blades are not coated with a special substance, and they also do not have sufficient sharpness.

The so-called precision scissors have always been famous for their versatility and low price.Such devices have always been reliable and quite convenient to use.

The price of scissors for threading PP pipes depends on the size of their diameter. The vast majority of devices are designed to use the physical strength of the worker. When performing large amounts of work, chronic fatigue can occur.

If the device is intended for serial repair work, it is advisable to use automatic pipe cutters. Guillotine variant designed for pipes large diameter.

However, not all buyers know the types of pipes to be cut. Let's look at them in more detail below.

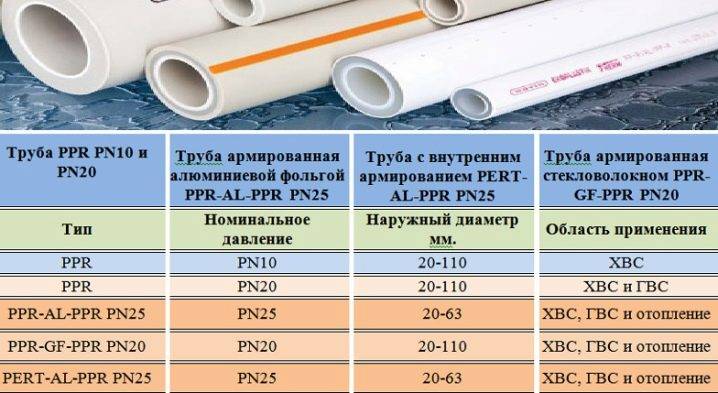

- Pipes that are used to create a warm floor, as well as for cold water systems, are marked with the label "PN 10". The maximum temperature that these pipes can withstand is 45 degrees.

- Pipes designed to bring cold water to the building are marked "PN 16". Such parts create wiring that can easily cope with increased pressure.

- Products designed for both cold and hot water are designated "PN 20". The highest temperature that these pipes can transfer reaches 80 degrees.

- There are pipes equipped with aluminum foil, with a maximum tolerated temperature of 95 degrees. They are marked as "PN 25". These products are used in the creation of central heating and hot water systems.

However, in addition to pipes, a fairly large number of additional propylene parts can be found on the market. And also there are products of the combined type. This option has brass inserts and is called "American". With the help of such a part, you can make the transition from a plastic pipe to metal elements of the plumbing system.

Instructions for use

How to use hand scissors:

Measure pipe sections and make appropriate marks.

Place the pipe section into the fixture, positioning it so that the blade is positioned over the mark. You can pre-make a small incision on your own.

With a smooth but strong movement, press the handle of the pipe cutter

The pipe must be placed exactly perpendicular, it is important to ensure that there is no accidental change in position.

After cutting, the ends of the pipe are processed, if necessary.

Thus, the selection of a pipe cutting tool requires time and advance preparation, and must be light in weight. It is required first of all to find out the diameter and length of the pipeline.

To determine the manufacturer, use the rating of well-known companies, their products will function efficiently. Also, before starting the procedure, it is recommended to familiarize yourself with the video lesson, how to cut a pipe straight.

Watch the video

Criterias of choice

To facilitate the selection of scissors, it is recommended to take into account important criteria that determine the functionality of the tool.

Manufacturer

There are different brands of scissors on the market.

When considering a model, it is worth paying attention not only to the price, but also to the convenience of managing the tool. Better products are offered by well-known manufacturers:

- Kraftool;

- VALTEC;

- TUNDRA,

- LOM;

- Tim;

- Sibrtech;

- GIANT;

- BISON.

Their products meet the standard requirements for tools. In addition, only high-quality materials are used for the manufacture of pipe cutters.

What are

There are different types of pipe cutters. They differ in structural elements and the principle of operation.

Telescopic. The design consists of rollers, carriages and guides. Thanks to this solution, the tool can be adjusted to a wide range of diameters. The cutter is adjustable, often it is equipped with a built-in deburring tool.

This type suitable for cutting corrugated pipes made of stainless steel. The ability to adapt to the maximum range of diameters gives the pipe cutter universal qualities.

Ratchet Pipe Cutter 28-67mm

Ratchet Pipe Cutter 28-67mm

With ratchet. Due to the design features, the snack of the pipe billet is carried out by repeatedly pressing the handle. After the cut is completed, the blade returns to its original position, which is provided by a special gear rack. When using this tool, such consequences as crushing and deflection of the edges of the workpieces, loss of their original shape are possible. A calibrator is used for alignment. Manual editing is also carried out.

Desktop (floor) pipe cutter. In the design of such pipe cutters, shaped cutters are provided. The tool is used for simultaneous cutting and chamfering. In appearance, this is a desktop or floor-mounted machine. It works from the mains or batteries. The kit includes different sponges for fixing the workpiece. The cut is performed by rotating the working part of the device around the pipe.

This tool is available in two versions:

- detachable design - opening of the clip is provided due to two halves;

- one-piece models - the material to be cut is inserted inside a solid clip.

The purpose of the pipe cutter is not limited to plastic pipes. It is also used for pipe materials made of ferrous and non-ferrous metals.

Roller pipe cutter STAYER MASTER (2340-28) 3 – 28 mm red

Roller pipe cutter STAYER MASTER (2340-28) 3 – 28 mm red

Roller. This device provides a cut of firmly fixed pipes. Thanks to the movable cutting elements, it is possible to work on the operated pipeline. In this case, the gap between communications and walls / floor can be only 30 mm.

In the process of rotation of the pipe cutter, the clip is gradually drawn in. At this time, the rollers pass over the surface of the pipe material, deepening into its walls. The cutting off of the part is carried out in several revolutions.

Models with one roller are capable of cutting pipes with a diameter of up to 50 mm. With the help of a design consisting of 4 rollers, it becomes possible to work with a large diameter (up to 100 mm). Among the shortcomings of this type, the quality of the cut stands out - burrs may remain in the places where the rollers pass.

Pipe cutter chain for thin-walled pipes (20-75 mm)

Pipe cutter chain for thin-walled pipes (20-75 mm)

Chain. The purpose of this type is cutting pipes from brittle material. These include: concrete, cast iron and ceramic products. The principle of their work is similar to roller pipe cutters.

The basis of the design is the chain. Cutting rollers are located on its connecting links. Thanks to this solution, the insert into the part is carried out along the entire perimeter. In this case, the pressure is distributed evenly along the entire entry line of the cutting edge.

Rotation around the pipe is performed by controlling special levers. The device is also equipped with a clamping mechanism, which smoothly reduces the diameter of the ring formed in the process of immersion into the pipe wall by the chain.

Maximum pipe diameter

When choosing pipe shears, attention should be paid to the working diameter range.The maximum value corresponds to the parameters of the largest pipe that can be cut with the tool

The indicators of the models presented on the market (of all types) are from 3 to 350 mm. Using a hand tool, you can work with pipes with a diameter of up to 70 mm.

Varieties of scissors for cutting polypropylene pipes

PP pipes are sold in the form of even sections up to 12 meters, as well as in bays. Naturally, in the process of laying pipes, quite often there is a need for cutting and welding them.

Even though the polymer structure is quite soft, it is not easy to damage it. Cutting polypropylene pipes can be called a difficult process, especially considering that the cut must be extremely even. Otherwise, at the stage of pipe joining, it will be necessary to spend a lot of unforeseen time on aligning the joints. Since the pipeline is laid end-to-end, any, even the smallest deviation, will cause a poor result. Poor tightness, which is no secret to anyone, will cause the pipeline to burst.

When buying scissors for polypropylene pipes, each person wants to choose both a high-quality and inexpensive product. In this case, it should be understood that if you have plans for a simple repair, during which you will lay only a few segments of the pipeline, there will be enough scissors at the lowest price. They will be equipped with a blade made of cheap steel grades, therefore, in comparison with more expensive counterparts, their quality will be much lower, respectively, they will become dull faster.But is it worth it to overpay if you are going to use the tool for cutting polypropylene pipes several times?

If you plan to engage in the installation of plastic pipes very often, then in this case you simply cannot do without a high-quality tool (in more detail: “What tool is needed for polypropylene pipes and how to use it during installation”).

On sale you can find several varieties of scissors for propylene pipes.

There are precision scissors for polymer pipes, which are equipped with a ratchet. They have a simple design and are easy to use. Along with sufficient reliability, their price is at an average level and, as a rule, does not exceed $20. Additionally, the price can be influenced by the sections with which a particular product model allows you to work. Usually, with sections up to 42 mm, scissors will be cheaper. But if you plan to cut 63-75 mm pipes, you will have to pay a good extra for such a model.

You can purchase automatic scissors that are shaped like a gun. We can say that they are somewhat similar to the previous version. And even despite the fact that this kind of knife for plastic pipes costs much more, they are often bought by home craftsmen, since such a tool allows you to cut pipes of any section. Automatic scissors are ideal in places where pipes are located close to the wall. When cutting a pipe with this tool in a hard-to-reach place, you will need to apply less force with a brush.

Roller type pipe cutters. They are also easy to use. In inexpensive models, the movement of the knife for cutting plastic pipes is carried out by a threaded drive.The pipe is fed by rollers placed on a C-shaped arc, which in turn is mounted opposite the blade. For more expensive models, the mechanism is made according to the ratchet type.

Electric pipe cutter. The name implies that the tool is equipped with an electric drive - it has an advanced design of manual elements for cutting pipes. The only difference is that in this case the scissors do not work from the force applied by the operator's muscles, but from the electric motor. In order for the knife for cutting polypropylene pipes to do its job, you need to fix the pipe in the mechanism of the unit, and press the "Start" button. Now we wait until the blades cut the pipe - the result is an even cut. It does not require a lot of effort.

The disadvantage of an electric pipe cutter is that the device is not capable of operating pipes with a cross section of more than 42 mm, because the fasteners present do not allow this due to their size.

Kinds

There are different scissors for plastic pipes, differing in design, principle of operation and area of use. Models used for domestic purposes for home renovations are usually manually operated and have an affordable cost. Models designed for cutting pipes for water supply and heating operate on an electric drive.

There are different scissors for plastic pipes, differing in design, principle of operation and area of use. Models used for domestic purposes for home renovations are usually manually operated and have an affordable cost. Models designed for cutting pipes for water supply and heating operate on an electric drive.

precision

Their design is simple, the master uses only one hand to work, which facilitates the procedure. The main task of such a tool is to cut polypropylene and plastic pipes with a diameter of 2.5 mm to 42 mm. However, special models are also sold that are suitable for pipes with a diameter of up to 70 mm.

The knife is made of alloy steel, which gives additional strength, and its sharp sharpening guarantees a perfect cut. A ratchet tool is best suited for domestic purposes.

Plastic pipe shears are also used for reinforced and metal-plastic pipe products. The main difference is in the cutting material used. The tool, designed for polypropylene pipes, has a steel variety with fine teeth that provide the tightest possible grip.

Plastic pipe shears are also used for reinforced and metal-plastic pipe products. The main difference is in the cutting material used. The tool, designed for polypropylene pipes, has a steel variety with fine teeth that provide the tightest possible grip.

When choosing precision equipment, focus on the following points:

- the sharpness of the cutter and the possibility of replacing it if it is planned to use it for a long period;

- comfort during work: softness of movement (it can quickly rub the palm under mechanical load) and ease of placement (should not slip).

Roller

The simplest types are a hook, on the inside of which there are movable rollers. In the process of cutting, the plastic pipe is slowly rotated along these rollers, as a result of which an incision occurs. The spring and the force applied by the hand ensure the approach and retraction of the cutter.

The simplest types are a hook, on the inside of which there are movable rollers. In the process of cutting, the plastic pipe is slowly rotated along these rollers, as a result of which an incision occurs. The spring and the force applied by the hand ensure the approach and retraction of the cutter.

Unlike precision, roller scissors involve two hands, because. it is necessary to hold not only them, but also the valve that extends the knife. This device makes a neat cut and does not compress the pipe as much as other types.

The main difficulty in the cutting process: the need to hold in a perpendicular position. If this requirement is violated, the result will be a malfunction of the knife.

Ratchet

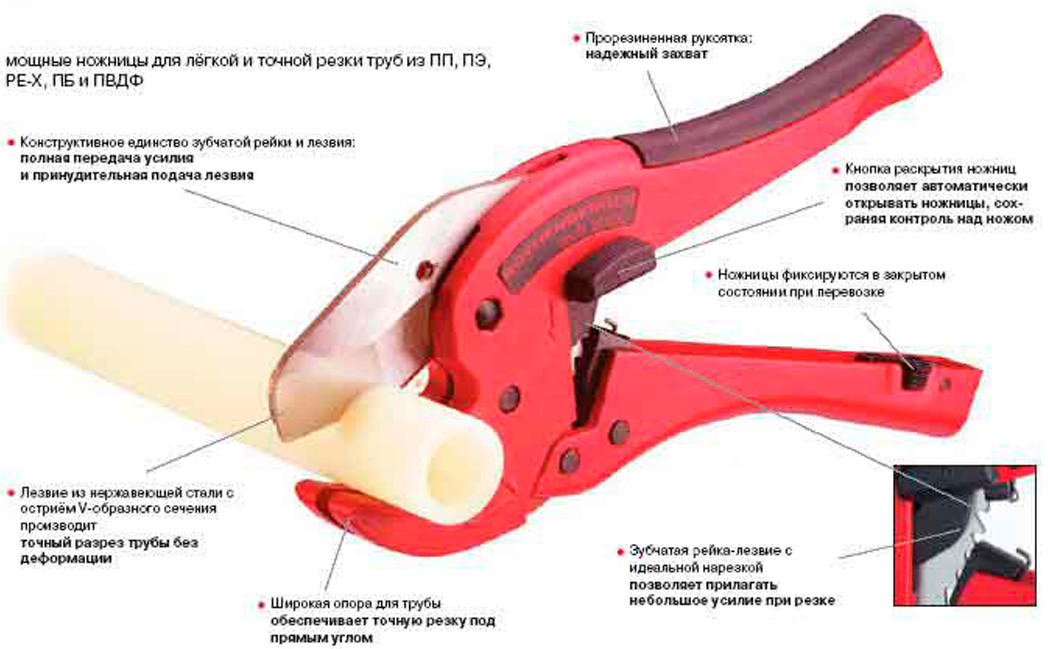

This type is an improved and, accordingly, more expensive version of roller shears. The ratchet mechanism provides the possibility of more convenient use and the absence of the need to apply tangible pressure. This is largely achieved due to the presence of a cutting rail and stop.

The support in the tool is wide, it is necessary for reliable fixation of the knee. This eliminates the need to ensure that the pipe cutter is level and perpendicular.

The support in the tool is wide, it is necessary for reliable fixation of the knee. This eliminates the need to ensure that the pipe cutter is level and perpendicular.

Accordingly, the presence of a stop reduces the likelihood of accidental change of position, damage and getting an uneven cut. The blade of the plastic pipe cutter is very sharp, which allows it to glide as smoothly as possible.

Rechargeable

The battery powered tool is an improved version of the handheld device. The master performing the procedure does not need to make efforts, because. the blade and fixing elements start to run on battery power.

The battery powered tool is an improved version of the handheld device. The master performing the procedure does not need to make efforts, because. the blade and fixing elements start to run on battery power.

The pipe cutter with an electric motor is able to carry out the most uniform cut and has a high speed of work. Due to the high cutting speed, this device is considered professional equipment and is used by workers for laying long lines for water supply or heating.

Their operation is simple: the area of the pipe to be cut is placed in a special clamp, then the motor is activated, after which the work is done.

Guillotine

As a professional equipment, in addition to a battery pipe cutter, scissors - guillotines are also used. They do not require any effort and guarantee fast and even cutting of pipes, therefore they are used for laying long networks.Suitable for large pipes with a diameter of 60 mm to 360 mm.

Check out the video

Also, for comparison, it is worth noting separately that guillotines are often used in production. A pipe is fixed in them, a blade is directed at it from above (it is sharply sharpened and Teflon coated on it for better performance). Such machines may have an electric or mechanical motor that starts the cutting part.

Types of scissors

There are the following types of the presented tool, which can be:

- precision;

- roller;

- battery (automatic).

Precision scissors for cutting polypropylene pipes are equipped with a special ratchet mechanism and blades, which are equipped with a toothed plate.

They are used for dividing into segments of pipes with a diameter of 3-42 mm. This product is very comfortable and easy to handle.

Cutting is done without the application of strong physical effort. The disadvantage lies in the fact that when performing work, the blade quite often shifts to the side and the cut edge does not always turn out to be sufficiently even.

Roller pipe cutter can be telescopic and ratchet. Trimming of polypropylene pipes is carried out in the process of rolling rollers over them.

The advantage of this tool lies in the fact that it forms perfectly smooth cut edges, and the disadvantage is the relatively slow speed of work.

Scissors for cutting polypropylene pipes

In telescopic modifications of the device, the cutting edge can rotate around the pipe, due to which cutting is ensured.

Automatic (battery) scissors are equipped with a compact electric motor.

This ensures the shortest cut time - only 5-7 seconds. As you might guess, the leading advantage of such a tool lies in the high speed of the work performed.

And the disadvantage lies in the fact that such a pipe cutter can be used to cut pipes with a maximum diameter not exceeding 40 mm.

Selection Tips

When choosing such a tool, it is important to ensure that the proposed price is fully consistent with the quality. If the product will be periodically used for minor repairs, then it would be most rational to buy scissors with an insufficiently high price.

If the product will be periodically used for minor repairs, then it would be most rational to buy scissors with an insufficiently high price.

But it should also be taken into account that the cheapest analogues are characterized by a reduced quality of the materials used to make the blades.

Choosing automatic scissors, you can be sure that they will allow you to cut those pipes that have a large diameter.

Precision scissors are distinguished by their versatility, coupled with an affordable price. This product has a high degree of reliability and very high user-friendliness.

The price may fluctuate depending on the diameter of the pipes to be cut. Most tools for work use the muscle power of the operator, and with a large amount of work, chronic fatigue can appear.

In the case of serial work, it is recommended to use a battery pipe cutter, and a guillotine cutter is suitable for pipes with a large diameter.

The nuances of the work

For convenience, the blade of the tool is equipped with a special rail, with small teeth on it.

This allows you to apply a minimum amount of effort during the work. Scissors are designed in such a way that they can be held with only one hand, and the second will be free to perform other actions.

When installing the pipeline manually out of habit, you can quickly get tired - electric scissors for cutting metal-plastic pipes will come to the rescue.

When choosing a tool, it is best to give preference to well-known manufacturers - lower-priced Chinese counterparts can fail pretty soon.

This is how a polypropylene pipe is cut

If during the process of facing the pipe section was damaged, then it should be removed, otherwise, the docking with the fitting will not have the necessary tightness. Slicing is performed with an orientation to the following algorithm:

- With the help of a marker, the surface of the pipe is marked with a mark in the place where cutting will subsequently be performed.

- Above the mark is the base blade. In order to more conveniently fix the tool, you can initially make a shallow cut in the material.

- Without pressing hard on the handles, it is necessary to insert into the pipe with a high degree of accuracy and to trim, applying effort for this.

- When performing work, sharp brush movements should be avoided, otherwise the scissors may accidentally slip off the guide rail and the whole process will have to be started again.

- The base blade must be positioned accurately along the surface of the pipe.

Thus, using this tool and following the instructions, you can easily cut off the desired section of the metal-plastic pipe.

Design features of pipe cutters

Manufacturers manufacture manual mechanical and electric cutters for precise cutting of polypropylene products.

Cordless cutter for polypropylene pipes

Cordless cutter for polypropylene pipes

When choosing a tool, consider:

- Scope of upcoming work.

- Blade quality. It must be made of alloy steel.

- Minimum and maximum diameter of pipes to be cut.

Cutting equipment is usually built with a metal body. Preference for aluminum models. Devices with a steel case are heavy.

Therefore, they are less convenient to use. Moreover, when cutting PP pipes, you do not need to exert great effort. Aluminum cases perfectly maintain the created loadings.

Models are available in which the cutting parts can be changed. For large volumes of work, this tool is used. In the absence of the possibility of changing the blade, you will have to buy a new device. This nuance is not taken into account for one-time work.

Guillotine

This type of tool features a simple design and the ability to accurately cut straight pipe parts. Manual and electrically driven guillotine models are available. In the design of the equipment there is a blade, which is strictly perpendicularly lowered onto the pipe.

Most hand tools are capable of cutting products with a diameter of up to 70 mm. A tool is also produced that allows you to work with parts with a cross section of 100-150 mm.

This range is quite enough to complete the installation of plumbing and heating in an apartment or cottage. Industrial models allow you to cut larger diameter pipes.

The guillotine pipe cutter consists of the following main parts:

- sharp blade usually Teflon coated;

- clamp for tubular element, opening from the bottom;

- handle with a stem that allows you to create a smoothly increasing pressure.

The guillotine tool is not designed for fast work. The reason for this is the stem, which after each cut has to be unscrewed in the opposite direction.

Ratchet

Such devices are structurally similar to scissors. The devices have two handles and one blade. The design also includes a semicircular stop to accommodate the pipe being cut.

Polypropylene pipe shears

Polypropylene pipe shears

The ratchet mechanism is a ratchet. It moves the knife smoothly with minimal effort. With the help of such a tool, pipes with a diameter of 15 to 30 mm are usually cut. If the blade is dull, the polypropylene product will wrinkle.

With a sharp pressure on the ratchet mechanism, deformation of the walls of the pipe parts can occur. Therefore, you need to work with the tool as carefully as possible. Also, keep the pipe cutter strictly perpendicular to the axis.

Even a slight deviation to the side will result in an oblique cut. In this case, the butt has to be sharpened. If it is also jammed, then a calibrator is additionally used to straighten it.

Ratchet pipe cutters are also made in pistol version. Such models allow you to get a more even cut with even less effort.

In their design there is a spring that returns the knife to its original position.Pistol ratchet pipe cutters are suitable for cutting thick hard wall pipe parts.

Roller

The devices are made in the form of a hook, inside which there is one or more movable wheels. The cut pipe is placed precisely on the rollers.

Roller pipe cutter for polypropylene pipes

Roller pipe cutter for polypropylene pipes

The design also has a sharp wheel. It is used to cut details. The cutting roller is placed on a telescopic extension. It slides out of the handle.

The section of the pipeline part is carried out by turning the roller device around the clamped workpiece. The number of turns depends on the wall thickness. In this case, the cutter is tightened each time by turning the screw mechanism.

Roller tool will perform fast cutting of polypropylene pipes. Most importantly, accurately position the cutter on the marked cutting line.

During cutting, the roller must not be strongly pressed against the polymer surface. Otherwise, microcracks form in the material. Because of them, strength characteristics decrease, which leads to the formation of chips.

You need to cut off a part of a straight part smoothly. These rules must be strictly observed when working with thick-walled pipes of large diameter.

Scissors for cutting polypropylene pipes: types

In most cases, pipes made of polypropylene go on sale in the form of straight sections, the length of which is not more than 12 m, or in the form of coils.

Quite often, they have to be cut to the desired length in order to carry out subsequent welding.

To obtain a segment of a certain size, a special tool is used - scissors for cutting polypropylene pipes.And further welding is carried out with a relatively inexpensive device powered by the mains.

Polypropylene pipes: internal reinforcement

Advantages of working with polypropylene

A significant advantage of polypropylene pipes is their ability to withstand sub-zero temperatures without bursting. This is especially true in country houses, where gas and electricity supply can sometimes disappear. That is why the owners of cottages and dachas prefer to use polypropylene pipes in plumbing systems.

In turn, the presence of scissors for cutting polypropylene pipes allows you to instantly correct problems that arise in the home pipeline. Simply cut out the damaged part of the pipe and replace it with a new one. In this case, all work will take no more than half an hour. But in the presence of metal pipes, the replacement of the pipeline section will be carried out for at least several hours.

In general, polypropylene communications are successfully used at temperatures up to sixty degrees. If there is a need to transport liquids up to ninety-five degrees, then reinforced pipes are used, equipped with a thin aluminum shell on the outside. It is this shell that prevents sagging and softening of products.

Before welding, the outer sheath on reinforced pipes must be cleaned. To do this, there is a special knife that removes the coating from aluminum exactly to the depth of welding.

Today, some enterprises have begun to produce products, the reinforcement of which is made from the inside. In this case, pre-cleaning is not required for welding.

Features of cutting polypropylene pipes

- Cutting can be done with only one hand, without requiring its maximum tension.

- On the blade of scissors, as a rule, there is a gear rack. It is due to its presence that the work of cutting polypropylene pipes is quite simple.

If you need to get a high quality cut without damaging the pipe, you can not use cheap Chinese scissors. In addition, these products are able to withstand only a couple of cutting cycles. After that, they fall into disrepair.

Types of scissors for cutting polypropylene pipes

Precision scissors option

The following types of scissors work with polypropylene pipes:

- Precision. They are equipped with a ratchet mechanism and are designed to work with pipes whose diameter is from three to forty-two millimeters. The blade in these scissors is equipped with a gear rack, so you don’t need to make a lot of effort to cut. It is convenient that you can work with precision scissors with only one hand.

- Roller pipe cutter. These are specific scissors, in which the pipe moves on guide rollers, and at the same time, another blade feeds the cutting roller under pressure to the cut point. Of the advantages - the perfect cut quality. Among the shortcomings - low speed.

- Cordless pipe cutter. Equipped with an electric motor, due to which the speed of work is very high: one operation can be completed in 4-7 seconds.

Roller pipe cutter

Polymer pipe cutters: instructions for use

Of course, the scissors for cutting plastic pipes, depending on the design features, have their own instructions. Regardless of the type of tool and the conditions of work, it is recommended to follow the instructions exactly.This approach will protect the user from industrial accidents and help to maintain the life of the tool.

You should always remember: instructions are written with the aim of conveying to the user all the subtleties of working with the tool.

How to use a pipe cutter with rollers

The instruction for the user of a pipe cutter with rollers usually mentions the following sequence of actions:

- Use a marker to mark the cut line on the surface of the pipe.

- Unscrew the stop screw to the point where the pipe freely enters the mouth of the bracket.

- By turning the stop screw clockwise, press the disk mechanism against the pipe wall with a little force.

- Rotate the cutter around the pipe axis by 360º (you can repeat the operation).

Then repeat steps 3 and 4 until the pipe is completely cut.

The design of each cutting tool provides a high quality cut, provided that the operating instructions are followed exactly

It should be emphasized that it is unacceptable to press the cutter disc excessively against the pipe. Such an action can cause the effect of the appearance of microcracks at the point of cut, which will have a negative impact on the quality of work.

The nuances of using scissors for PP pipes

The instruction for cutting a pipe with hand shears mentions the following user actions:

- Mark the cut line on the pipe with a marker.

- Place the blade-base of the scissors on the marked line.

- Check through a special slot the accuracy of the installation of the blade.

- With a little effort, gently squeeze the handles of the tool.

Approximately according to the same scheme, cutting is performed using guillotine shears, with the only difference being that in this case the tool handles must be squeezed several times in order to achieve complete cutting.

Plus, the guillotine design has a cutter blade return mechanism.Therefore, before each new use, by pressing the return button, the cutter is reset to its original state. As a rule, maintenance should be performed after 450-500 cuts.

When using special scissors to work with plastic pipes, it is necessary to study the operating instructions and act in accordance with the instructions of the tool manufacturer

Maintenance consists in actions aimed at cleaning and lubricating all working parts of the mechanism. The body of the tool is carefully opened, cleaned and the rubbing parts are lubricated with machine oil. According to the instructions, the tool should be stored in the packaging in which it was purchased. It is forbidden to use a pipe cutter to work with pipes made of materials other than polymer.

If it's time to replace the knife on the guillotine, it must be dismantled, sharpened or replaced. The procedure for removing the blade is as follows:

- Set the knife to a position where the heads of the fastening screws are visible in the holes on the body.

- Loosen the fixing screws with a Phillips screwdriver.

- Remove the blade from the holder body.

Install a sharpened or new cutting element in the reverse order.

Other requirements of instructions

Relevant for persons using cutting tools for domestic purposes. Each instruction contains information warning that manual cutting of polypropylene pipes and using cutters is a full-fledged plumbing work.

In fact, work with pipe cutters of various types should be carried out only by qualified personnel (at least a plumber of 4-5 categories), trained and having the appropriate certificates.

Actions with the tool performed by unqualified persons, without permits and certificates, may result in an accident and damage to the tool. Therefore, in such cases, cutter manufacturers disclaim any liability and leave no chance for damages.