- Some installation features

- Installation: recommendations and diagrams, the main stages of the installation of the chimney

- General requirements

- Installation steps

- Video description

- Connecting a ceramic chimney

- Video description

- Mounting Features:

- Advantages and disadvantages of coaxial chimneys

- Types of chimney systems for gas boilers

- brick chimney

- Requirements for coaxial chimneys of gas boilers

- Stainless steel sandwich chimney

- Stainless steel chimney elements

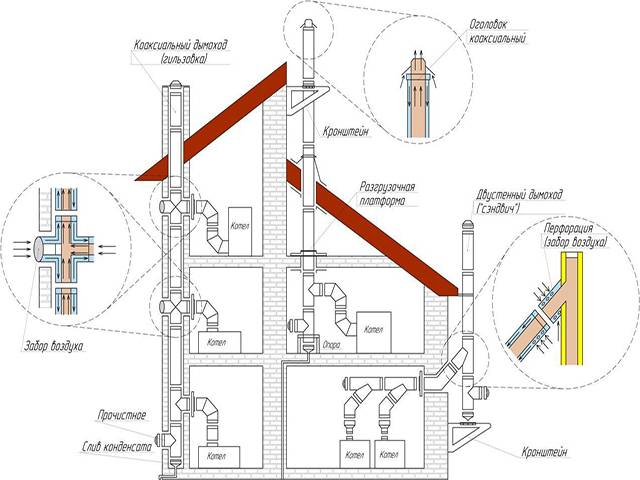

- The installation of a chimney can be considered using the example of a double-circuit design

Some installation features

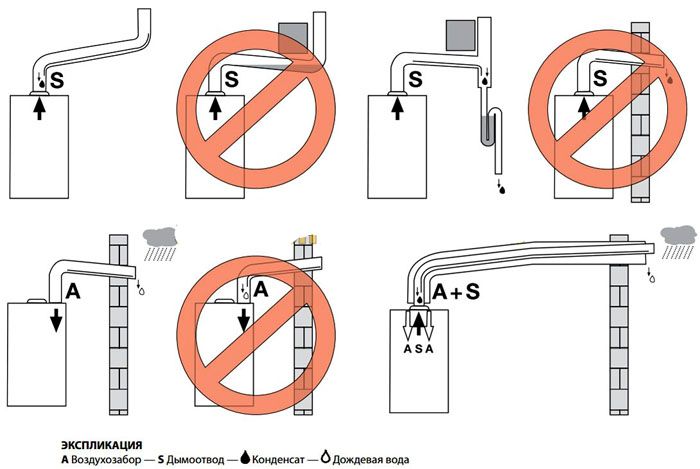

For each boiler, the direction of the channel that discharges the combustion products is determined individually. Horizontal systems can only be used for devices with forced ventilation.

Errors in calculations and installation can lead to freezing of the system and freezing of condensate at the outlet. In such conditions, the boiler will not be able to work.

But even in this case, the maximum length of such a section should not be more than 3 m. It happens that the manufacturer sets other standards for their boilers, so you should familiarize yourself with the technical documentation of the device.

Vertical type structures for private houses are used only if there are reasons preventing the chimney from being led through the wall.

These can be windows close to the outlet pipe, a narrow street on which the building stands, and the like. In some cases, if it is very necessary, an inclined installation of a coaxial chimney is allowed.

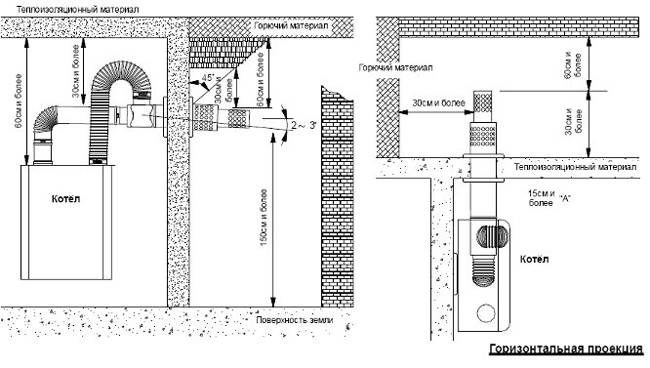

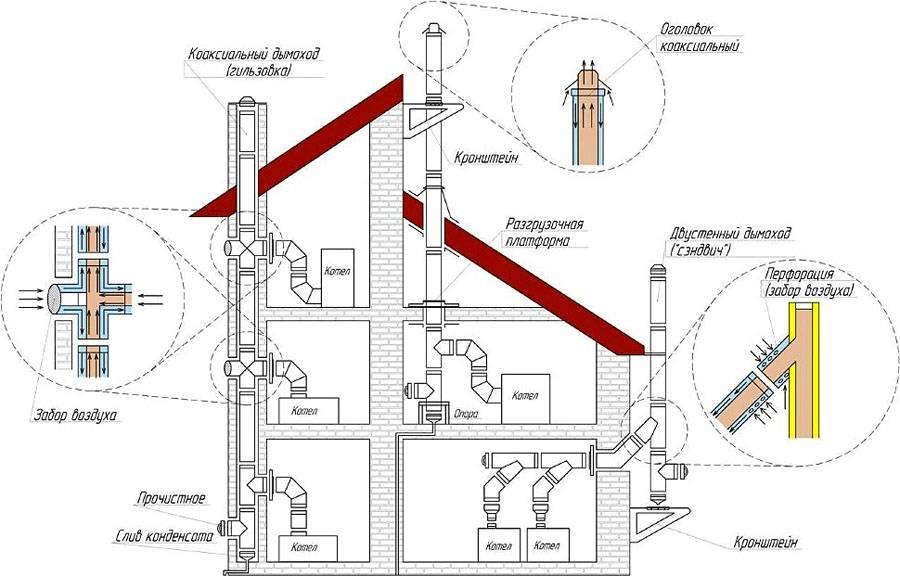

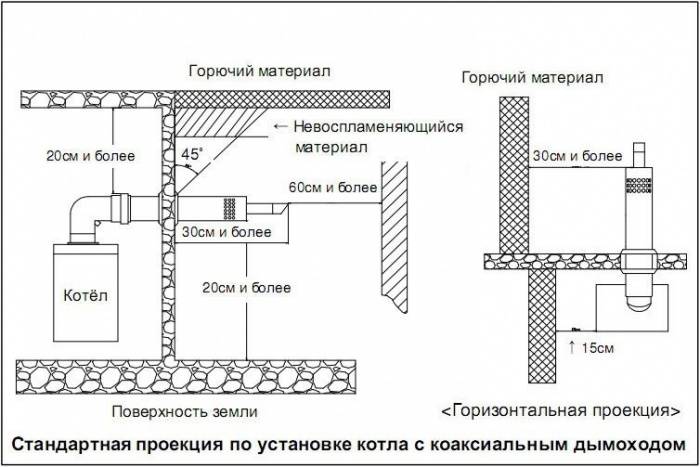

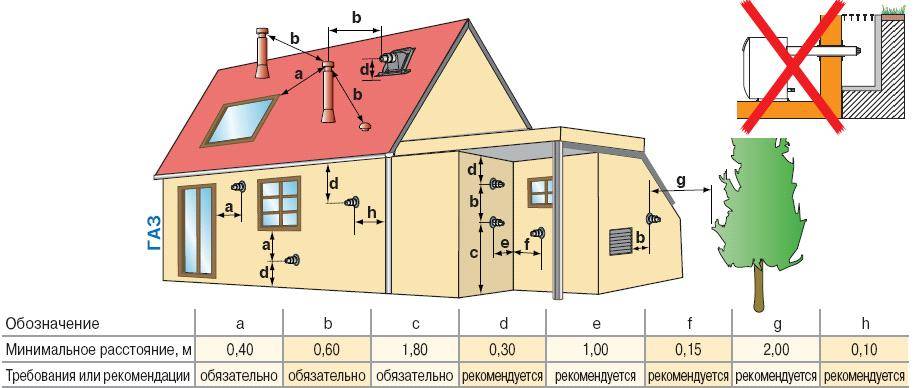

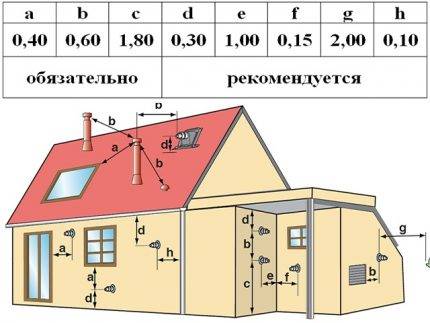

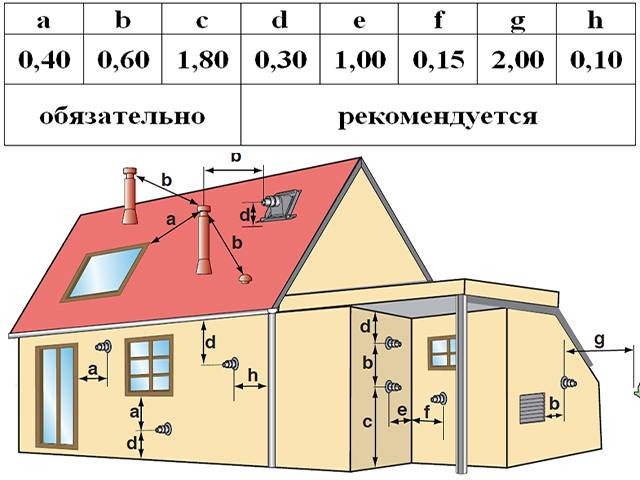

The options for the passage of a coaxial chimney through building structures and the distances between the chimney and the elements of the house are given on the basis of many years of operating practice.

The options for the passage of a coaxial chimney through building structures and the distances between the chimney and the elements of the house are given on the basis of many years of operating practice.

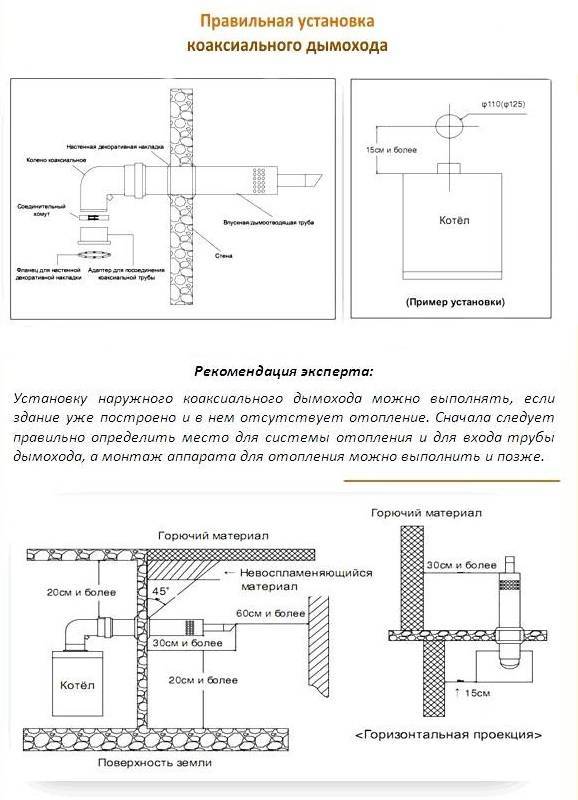

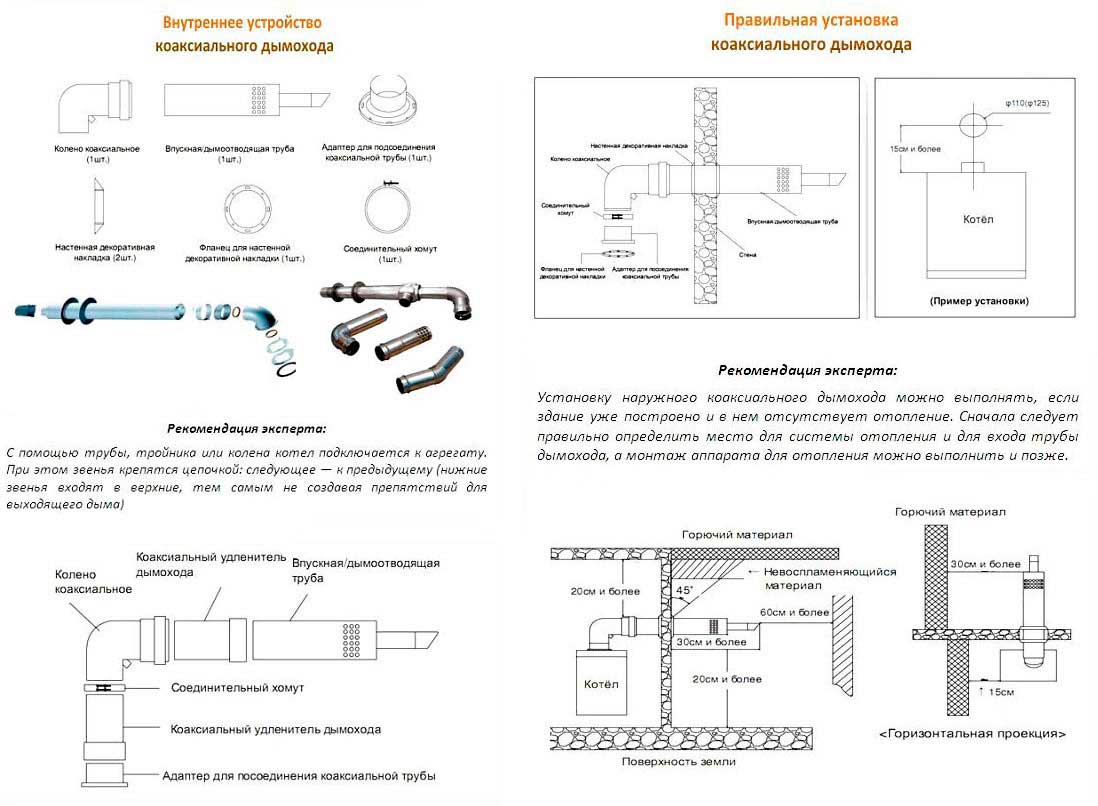

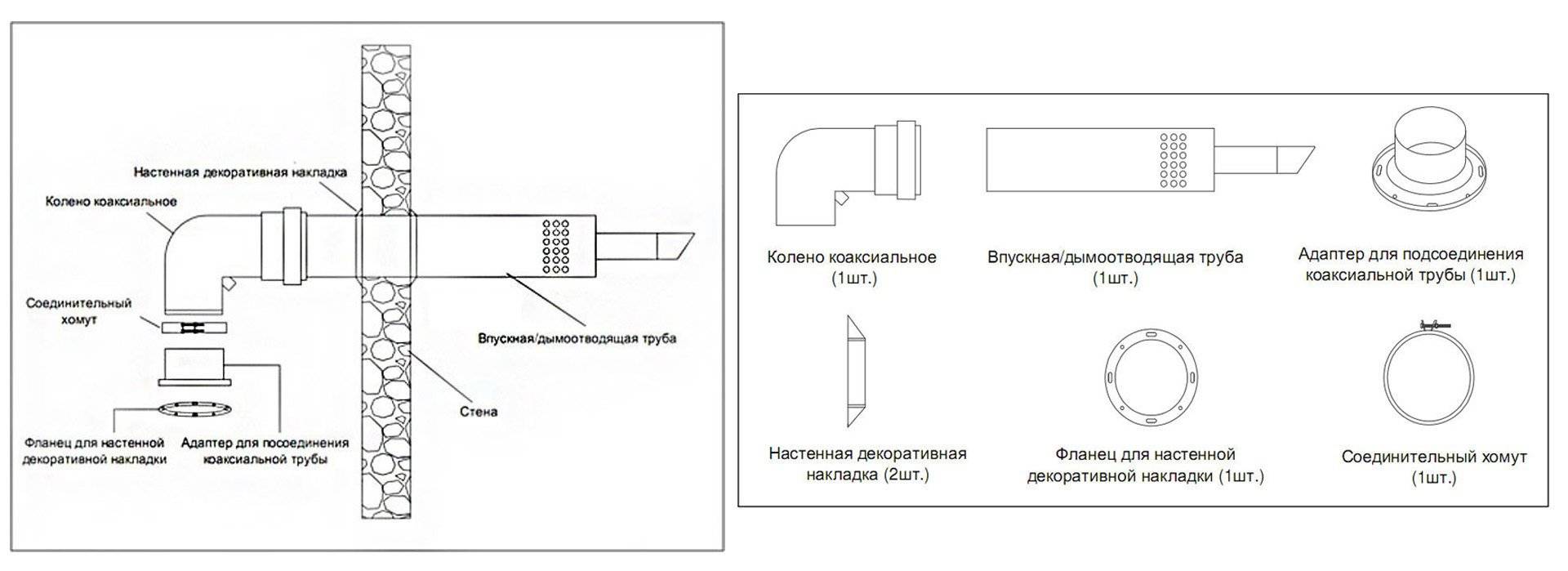

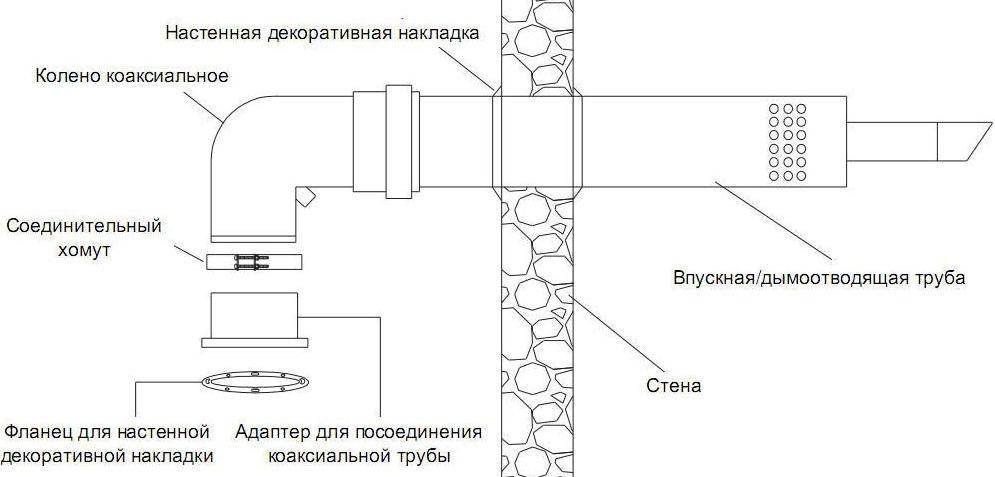

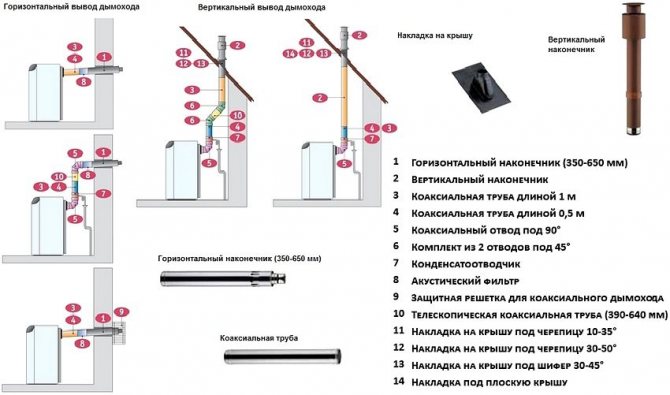

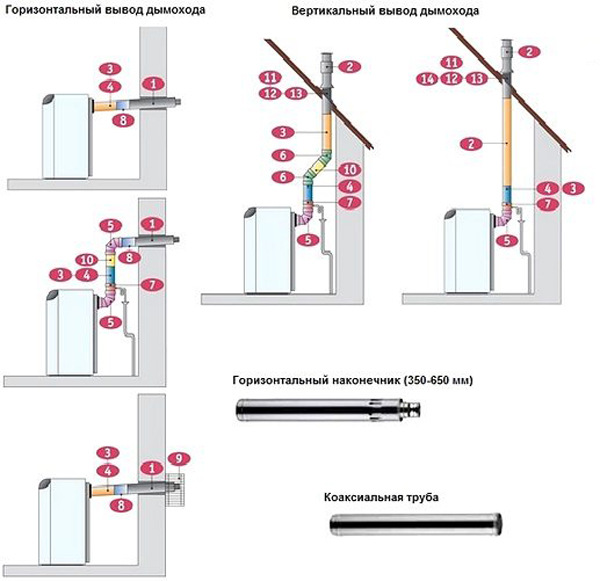

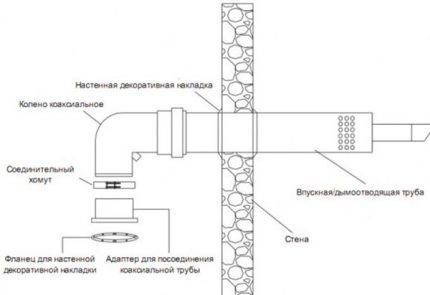

The system is connected to the heater using a tee, elbow or pipe. In this case, the diameters of the outlet channel and the boiler outlet must be the same.

During the installation process, all subsequent parts are fixed in the previous ones so that there are no obstacles that could interfere with the movement of combustion products. The number and type of elements for assembly directly depend on the location of the outlet pipe.

If it is on the side, it is supposed to arrange a horizontal system, if on top - vertical. The latter option is easier to install.

In the process of arranging a coaxial chimney, transitional nodes are necessarily used with rigid fastening of the junction areas of two elements using clamps. Some "craftsmen" prefer to use home-made options.

The figure shows a diagram of the arrangement of the passage of a horizontal coaxial chimney through the wall

The figure shows a diagram of the arrangement of the passage of a horizontal coaxial chimney through the wall

These can be hand-made adapters, windings from tape or seals from sealant. Such things are unacceptable in use, because they are extremely unreliable. A system assembled using such elements is considered unsafe to operate.

In addition, the following rules are observed during the installation process:

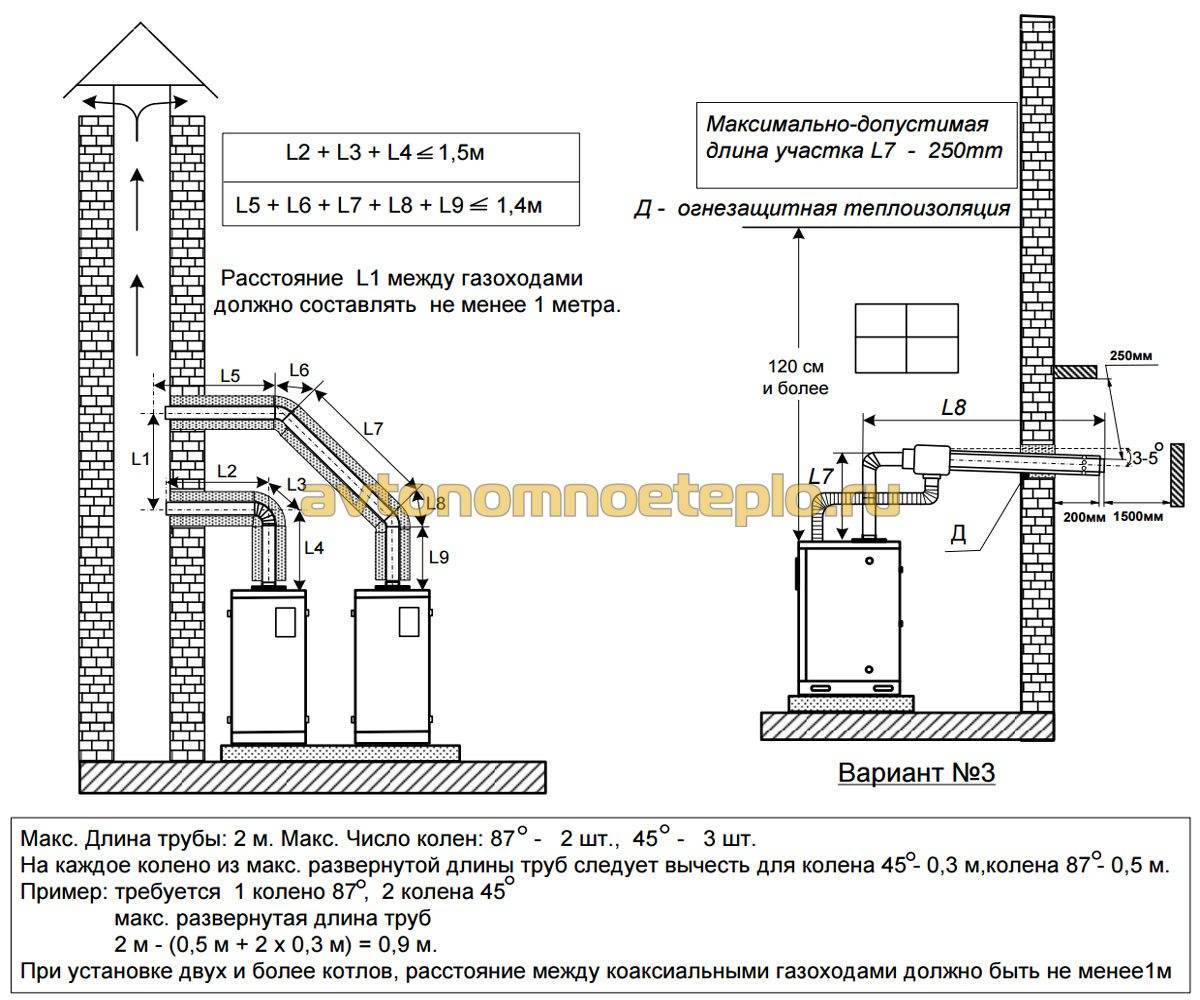

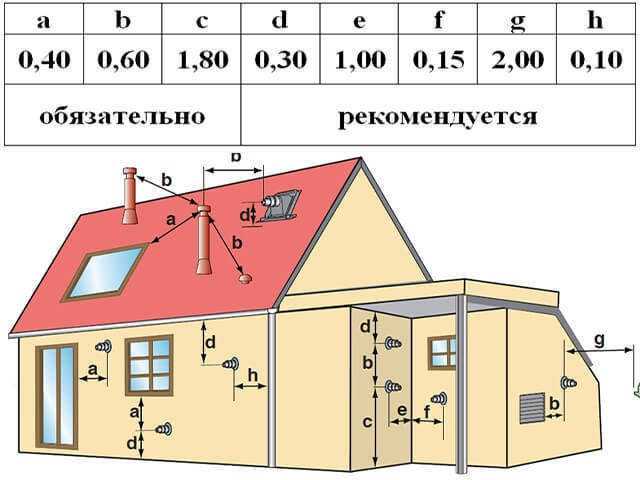

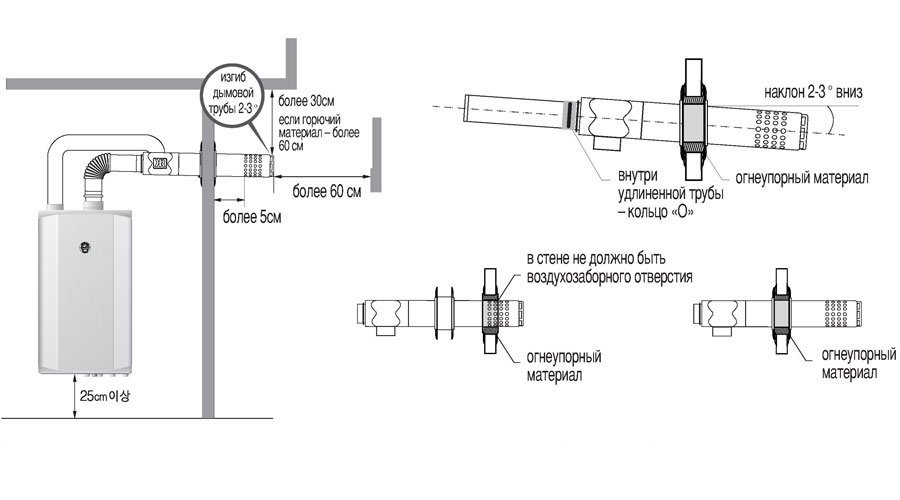

- The section of the horizontal chimney that goes out must be inclined 3° downwards. At the horizontal section of the chimney included in the common section, the slope is performed in the opposite direction, that is, it decreases towards the boiler. This is necessary for the unimpeded drainage of condensate.

- Throughout the chimney channel there should not be more than two folds.

- Inspection hatches, adapters and a condensate discharge device must be easily accessible for periodic inspection.

- The chimney cannot be led below ground level. In this case, the distance from the outlet of the coaxial chimney to the neighboring building must be more than 8 m. If a deflector is installed on the pipe, this distance is reduced to 2 m for a blank wall and 5 m for a wall with window openings.

- If a horizontal chimney is installed in a place where winds prevail, the direction of which is opposite to the direction of smoke extraction, a sheet metal barrier must be installed at the outlet of the chimney. The distance between it and the outlet must be at least 0.4 m.

- On coaxial chimneys rising above ground level less than 1.8 m, a deflector grille must be installed. It will work as a protection against hot smoke.

All structural elements must fit snugly against each other. Each subsequent part must go inside the previous one at a distance equal to at least half the diameter of the channel section.

To circle the structure around any obstacle, specially designed knees are used. The angle of their inclination may be different. If the system is removed through the roof, all fire safety requirements must be observed.

The arrangement of the passage of a coaxial chimney through the roof or through the wall must be carried out in strict compliance with all fire safety requirements

For this purpose, special insulating pipes and non-combustible insulating materials are used. There must be an air gap between the pipe and the ceiling.

A protective cover is used to avoid contact between the smoke channel and fragments of the roofing cake. The exit of the structure through the roof is carefully sealed. The joints are covered with a special apron.

Installation: recommendations and diagrams, the main stages of the installation of the chimney

The installation of the chimney is divided into several stages - this is the preparatory work, the installation itself, then the connection, start-up and, if necessary, debugging of the entire system.

General requirements

When combining several heat generating installations, a separate chimney is created for each of them. In exceptional cases, a tie-in to a common chimney is allowed, but the difference in height must be respected at least one meter.

First, the parameters of the chimney are designed and calculated, which are based on the recommendations of the manufacturers of gas boilers.

When summarizing the calculated result, the inner section of the pipe cannot be less than the diameter of the boiler outlet pipe. And according to the check according to NPB-98 (fire safety standards), the initial speed of the natural gas flow should be 6-10 m / s. And besides, the cross section of such a channel must correspond to the overall performance of the unit (8 cm2 per 1 kW of power).

Installation steps

Chimneys for gas boilers are mounted outside (add-on system) and inside the building. The simplest is the installation of the outer pipe.

Installation of an external chimney

Installing a chimney at a wall-mounted boiler is done as follows:

- A hole is cut in the wall. Then a piece of pipe is inserted into it.

- A vertical riser is assembled.

- The joints are sealed with a refractory mixture.

- Fixed with wall brackets.

- An umbrella is attached to the top to protect it from rain.

- An anti-corrosion coating is applied if the pipe is made of metal.

Proper installation of the chimney guarantees its impermeability, good draft, and prevents soot from accumulating. Installation performed by specialists will significantly reduce the cost of maintaining this system.

In the case of arranging an opening for a pipe in the roof of a house, special boxes with aprons are used. In this case, the design as a whole is influenced by such factors as:

- The material from which the pipe is made.

- Exterior design of the chimney.

- Type of roofing.

The main factor influencing the choice of design is the temperature of the gas that passes through the pipe. At the same time, according to the standards, the distance between the chimney pipe and combustible materials must be at least 150 mm. The most advanced is the assembly system by segments, where all elements are assembled by cold forming.

Video description

How the chimney pipe is installed, see the following video:

Connecting a ceramic chimney

Ceramic chimneys themselves are almost eternal, but since this is a rather fragile material, you need to clearly imagine how the connection (docking) of the metal part of the chimney and the ceramic one is correctly performed.

Docking can only be done in two ways:

By smoke - a metal pipe is inserted into a ceramic

It is important to remember here that the outer diameter of the metal pipe should be smaller than that of the ceramic one. Since the thermal expansion of the metal is much greater than that of ceramics, otherwise the steel pipe, when heated, will simply break the ceramic one.

For condensate - a metal pipe is put on a ceramic one.

For both methods, specialists use special adapters, which, on the one hand, are equipped with a gasket for contact with a metal pipe, and on the other, which contacts directly with the chimney, are wrapped with a ceramic cord.

Docking should be carried out through a single-wall pipe - it has a higher heat transfer coefficient. This means that the smoke will have time to cool down a little before it reaches the adapter, which ultimately extends the life of all materials.

Video description

Read more about connecting to a ceramic chimney in the following video:

VDPO shows great requirements for chimneys for gas boilers, because of this, it must be installed by specialized teams. Since competent installation guarantees not only long-term operation of the device, but also makes living conditions in a private house safe.

Mounting Features:

- The chimney channel should not have more than two folds.

- For horizontal chimneys, the outlet to the outside must be inclined downwards by 3° to allow the condensate to drain off. If the horizontal section enters the common chimney, the slope must be carried out in the opposite direction (declining towards the boiler).

Frozen condensate at the outlet of the coaxial chimney.

- The installation of a gas boiler with a closed combustion chamber does not require any windows or shutters in the room.

- Installation must be carried out in such a way that during the subsequent maintenance work, the relative position of the boiler and the chimney cannot change.

- The adapter, areas for inspection and cleaning, the condensate drain must be accessible for periodic inspection.

- It is not allowed to lead the chimney below ground level.

- The distance from the pipe to the wall of the neighboring building must exceed 8 meters. When installing a deflector, the distance can be reduced to 2 meters (for a blank wall) or 5 meters (for a wall with openings).

- If the outlet is less than 1.8 meters above the ground, a deflector grille is required to protect against hot smoke.

- In order not to impede the movement of the smoke flow, when installing the chimney, the previous section is inserted into each subsequent (direction from the boiler).

- If at the place of installation of a horizontal chimney, winds directed against the removal of smoke prevail, a tin barrier is installed at the outlet of the chimney. The distance from the outlet to the barrier must be at least 40 cm.

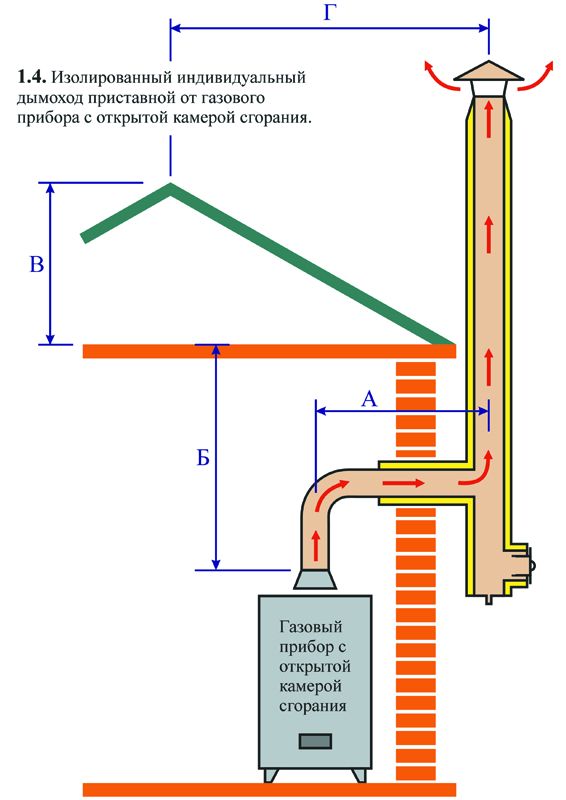

Options for the location of the coaxial chimney in a private house and the minimum distance between the axis of the pipe and the nearest objects, m.

Each chimney system must be supplied with detailed assembly and installation instructions. Before starting installation, you need to compare the requirements set out in the instructions with the requirements of the current regulatory documents, and be guided by the more stringent of them.

Options for the location of coaxial chimneys with a vertical outlet.

A coaxial chimney and a closed combustion chamber of a gas boiler make it possible to exclude the influence of the combustion process on the atmosphere inside the room, thereby increasing the comfort of people living in the house. Due to their positive qualities, pipe-in-pipe chimneys are gaining more and more adherents every year among those who plan to equip a house with an efficient and economical gas heating system.

Interior solution: decorative grilles for heating radiators

Optimal thermal insulation for heating pipes

Independent insulation of heating pipes on the street

Advantages and disadvantages of coaxial chimneys

Such systems for supplying air and removing combustion products have now gained the widest popularity. This is easily explained by the many advantages of such a scheme:

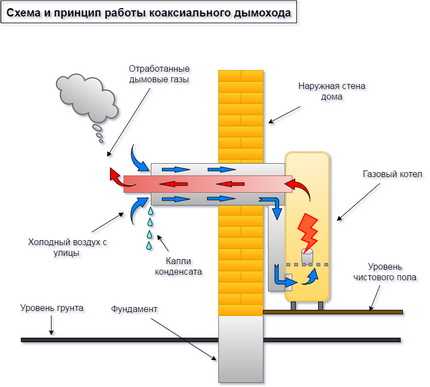

First of all, the advantage is that the air necessary for the combustion of "blue fuel" is taken not from the premises, but from the street. This circumstance greatly simplifies the organization of general ventilation - no additional inflow calculations are required, there is no need to resort to frequent ventilation or organizing other ways of air intake from the street

This is especially important for those cases when the boiler is installed in the "living area" of the house or in the apartment, for example, in the kitchen. In frosty weather, there will be no unnecessary influx of cold into the premises.

In principle, combustion products cannot enter the room - they are immediately discharged from the closed chamber to the street.

The air taken from the street receives a very noticeable heating from the inner pipe, through which the waste products flow in the opposite direction.

And this is important for uniform and complete combustion of gas, for maximum efficiency of the boiler. In addition, the complete combustion of the gas provides a minimum release of substances that can cause pollution to the atmosphere. And the products of combustion, on the contrary, are effectively cooled, which significantly increases the fire safety of the system. The likelihood of ignition of soot particles, which can accumulate in the pipe over time, is sharply reduced. And at the outlet, the gases no longer have a dangerous temperature.

The outer surface of the coaxial pipe does not heat up to too high temperatures. And this is a big “plus” in the sense that the requirements for organizing safe passage through walls (floors, roofs) are significantly reduced. No other type of chimney, including sandwich pipes, allows such "liberties".

Even through a wooden wall, you can lay a coaxial chimney without cutting out a huge window for this fireproof penetration.

- The installation of a coaxial flue gas exhaust system will not be associated with large-scale construction and installation work, as is usually the case with the installation of "classic" vertical chimneys.

- The installation itself is quite simple and intuitive. Any kit is always accompanied by detailed instructions. So in many cases it is quite possible to carry out installation work on your own.

- A wide range of sets of coaxial chimneys is on sale, and therefore it is possible to choose the right system for a boiler of a certain model. As a rule, it is purchased immediately along with heating equipment.And for any system in the assortment, the necessary additional parts are offered - tees, bends at 90 or 45 degrees, condensate collectors, inspection chambers, cuffs, clamps, fasteners, etc. That is, with the acquisition of problems does not arise.

The main disadvantage of coaxial chimneys is the abundant formation of condensate, which is inevitable at the border of pronouncedly hot and cold gas flows. And as a result - freezing of ice at the head in severe frosts. And this, in turn, is fraught with failure not only of the combustion products removal system itself, but even of the heating unit.

In severe frosts, despite the very hot exhaust, ice growths can form on the coaxial chimney pipe. This phenomenon must be fought so as not to "ditch" the entire system.

Often such a disadvantage is attributed to the fact that initially coaxial chimneys were developed for European countries with much more gentle climatic conditions than in Russia. In an effort to increase the efficiency of boilers, the designers tried to minimize the possible diameter of the inner pipe for exhaust gases, which led to a shift in the dew point inside the air duct and abundant freezing of the condensate that had fallen out.

Additional insulation of the outer section of the outer pipe of the coaxial chimney is a simple and effective means of combating its icing.

The second, but very conditional drawback, is the high cost of high-quality coaxial chimneys. But there is something to argue about here. Firstly, the price still does not look frightening against the background of the total cost of the heating system. And secondly, if we add considerable savings on construction and installation work, then it becomes ridiculous to talk about the cost.And this is without taking into account the other advantages of the coaxial system.

Types of chimney systems for gas boilers

To date, several types of chimneys are most often used for heating systems with a gas boiler. Any of them can be built independently, but you will need a diagram for assembly and expert advice. We will try to help you in this matter!

brick chimney

brick chimney

Brick pipes have been installed for a long time, even before the appearance of pipes from new materials. But even now, some homeowners have not abandoned their construction, although, to be honest, such a chimney is complex in design and time-consuming to install. In addition, the construction of a brick chimney takes a lot of time and is not cheap. It should also be noted that the brick version is inferior in terms of technical characteristics to more modern systems, since due to its shape and rough inner surface, it is often overgrown with soot, which slows down the removal of fuel combustion waste. You don't want to hire a chimney sweep in a couple of years, do you?

Sectional view of a ceramic chimney

Requirements for coaxial chimneys of gas boilers

The coaxial chimney differs significantly from all other designs in all respects.

Scheme of connecting a coaxial chimney.

It has a neat, compact look and a different shape than other chimneys - it does not rise to the roof, but is discharged through the wall.

... and coaxial

Despite its small size, the chimney has a high efficiency due to its structure and coating on the inner walls.

Condensation does not appear inside it, which is very important for the operation of gas-fired heating systems.

Stainless steel sandwich chimney

This model is the most popular and in demand in recent years, as it has a number of unconditional advantages over other options. They have a large number of different transitions, tees and other parts made at different angles, which allows you to assemble structures of any complexity.

Stainless steel sandwich chimney

Chimneys made of stainless steel consist of three layers. The middle one is heat-insulating, which is made of mineral wool. This insulation layer can have a different thickness - from five to ten centimeters. The choice of its thickness will depend on the location of the chimney and the average winter temperatures of the region where the building is located. It will depend on the correctly selected chimney pipe whether condensate will collect in it, and hence the correct operation of the entire system as a whole.

The stainless steel chimney has a perfectly flat inner surface, which allows you to easily remove the combustion products of the boiler. In addition, it has a mirrored outer surface, which contributes to the presentability of the overall appearance of the system.

Stainless steel chimney elements

A variety of parts of the chimney system

Whatever chimney (with the exception of a brick one) is installed, additional elements will be needed for it, which are selected according to a pre-designed system assembly scheme. These include the following details:

- The connecting pipes that connect the pipe to the boiler are adapters.

- Pipes of various lengths.

- Pass pipes.

- Revision tee, having a fitting at the bottom, with the help of which condensate is removed.

- Conical tip.

- Branches.

The installation of a chimney can be considered using the example of a double-circuit design

Chimneys for a gas boiler are being installed in the direction of the structure from the bottom up, that is, from the heating objects of the room towards the chimney. With this installation, the inner tube is put on the previous one, and the outer tube is inserted on the previous one.

All pipes are fastened to each other with clamps, and along the entire laying line, every 1.5–2 meters, brackets are installed to fix the pipe to a wall or other building element. A clamp is a special fastening element, with the help of which not only the parts are connected to each other, but also the tightness of the joints is ensured.

The laid sections of the structure in the horizontal direction up to 1 meter should not come into contact with elements that pass close to the communications. The working channels of the chimney are placed along the walls of buildings.

Be sure to install a bracket on the wall every 2 meters of the chimney, and the tee is attached using a support bracket. If it is necessary to fix the channel on a wooden wall, then the pipe is lined with non-combustible material, for example, asbestos.

When attaching to a concrete or brick wall, special aprons are used. Then we bring the end of the horizontal pipe through the wall and mount the tee necessary for the vertical pipe there. It is necessary to install the brackets on the wall after 2.5 m.

The next step is to mount, lift the vertical pipe and bring it out through the roof. The pipe is usually assembled on the ground and the mount for the brackets is prepared.The fully assembled volumetric pipe is difficult to install on the elbow.

To simplify, a hinge is used, which is made by welding pieces of sheet iron or cutting a pin. Typically, the vertical pipe is inserted into the tee pipe and secured with a pipe clamp. The hinge is attached to the knee in a similar way.

After raising the pipe in a vertical position, the pipe joints should be bolted where possible. Then you should unscrew the nuts of the bolts on which the hinge was fastened. Then we cut or knock out the bolts themselves.

Having selected the hinge, we attach the remaining bolts in the connection. After that, we stretch the remaining brackets. We first adjust the tension manually, then we fix the cable and adjust it with screws.

Necessary distances to be observed when the chimney is located outside

The installation is completed by checking the chimney draft. To do this, bring a burning piece of paper to the fireplace or stove. Draft is present when the flame is deflected towards the chimney.

The figure below shows the distances that must be observed in various options for the location of the chimney from the outside:

- when installed on a flat roof, the distance must not be less than 500 mm;

- if the pipe is removed from the roof ridge to a distance that is less than 1.5 meters, the height of the pipe must be at least 500 mm in relation to the ridge;

- if the chimney outlet installation is located at a distance of more than 3 meters from the roof ridge, then the height should not be more than the expected straight line.

The setting depends on the type of duct directions required for the combustion of the fuel. In the interior of the room, there are several types of directions for the chimney channel:

Support bracket for chimney

- direction with a rotation of 90 or 45 degrees;

- vertical direction;

- horizontal direction;

- direction with a slope (at an angle).

It is necessary to install support brackets for fixing the tees every 2 meters of the smoke channel, it is necessary to provide additional wall mounting. In no case, when installing a chimney, horizontal sections higher than 1 meter should not be created.

When installing chimneys, consider:

- the distance from metal and reinforced concrete beams to the inner surface of the chimney walls, which should not exceed 130 mm;

- the distance to many flammable structures is at least 380 mm;

- cuttings for non-combustible metals are made for the passage of smoke channels through the ceiling to the roof or through the wall;

- the distance from combustible structures to an uninsulated metal chimney must be at least 1 meter.

The connection of the chimney of a gas boiler is carried out on the basis of building codes and the manufacturer's instructions. The chimney requires cleaning up to four times a year (see How to Clean a Chimney).

In order to optimally calculate the height of the chimney, it is necessary to take into account the type of roof and the height of the building:

- the elevation of the chimney pipe must be at least 1 meter when installed on a flat roof and at least 0.5 meters above a non-flat one;

- the location of the chimney on the roof must be made at a distance of 1.5 meters from the ridge;

- the height of an ideal chimney has a height of at least 5 meters.