- Features of calculating the air exchange in the room

- Drawing up an office ventilation project

- 11.2 Solution

- Calculation of the air exchange rate

- A little about air exchange

- Process description

- Energy Saving Recommendations

- Recommendations for installation with a heat exchanger

- Features and schemes

- Conclusion

- CALCULATION.

- Air exchange rates for production premises

- Calculation methods for premises of a residential building

- Conclusions and useful video on the topic

Features of calculating the air exchange in the room

Before arranging the ventilation system in the room, it is necessary to determine exactly how the air exchange process will take place. So, in most cases, a direct release of air through the wall to the outside is provided. This happens due to an axial fan or a system of branched air ducts, using a special ventilation pipe or a centrifugal volute.

Based on the obtained values, the equipment in the room is selected.

Also of no small importance is the ratio of the overall dimensions of the entire system to its specific amount of material passed through, and air losses per linear meter of the system. With an air exchange system of 1000 m3 / h, the most optimal dimension "D" will be an air duct system of 200 - 250 mm

With an air exchange system of 1000 m3 / h, the most optimal size "D" will be an air duct system of 200 - 250 mm.

As a result, using a large-diameter air duct, a sufficiently low resistance index and minimal equipment performance losses are formed.

Drawing up an office ventilation project

Taking into account the fact that ventilation is a complex engineering system designed to provide a constant supply of clean and fresh air, remove harmful compounds and create comfortable conditions, the need for a project is beyond doubt.

Ensuring adequate air exchange in an office space is a serious task, requiring detailed planning, drawing up a detailed estimate and taking into account many nuances.

Ensuring adequate air exchange in an office space is a serious task, requiring detailed planning, drawing up a detailed estimate and taking into account many nuances.

It should be borne in mind that each ventilation system has its own characteristics. Therefore, a project is being developed exclusively for a specific room, adjusted for all its features.

Takes into account:

- The number of personnel in the room at any one time.

- Requirements for temperature and / or humidity standards, cleanliness from dust and other harmful substances.

- Architectural features - the height of the room, the presence of beams and other utilities.

It is easy to guess that it is almost impossible to take into account all the nuances listed above without drawing up a preliminary project.

That is why, before starting work, a detailed draft of the ventilation system is drawn up.

The slightest deviation from the project is fraught with a gross violation of the ventilation system - that is why it makes sense to involve only specialized specialists in the work

The slightest deviation from the project is fraught with a gross violation of the ventilation system - that is why it makes sense to involve only specialized specialists in the work

Attempts to install a ventilation system without first creating a project almost always resulted in adverse consequences.

11.2 Solution

Below is a detailed calculation

air flow in the convective flow rising above the stove.

The calculation results for the rest of the kitchen equipment are summarized in Table 5.

11.2.1 Hydraulic diameter

surfaces of kitchen equipment we calculate by the formula ():

11.2.2 Share of convective heat release

kitchen equipment is determined by the formula ():

Qto \u003d 14.5 200 0.5 0.6 \u003d 870 W.

11.2.3 Air flow in the convective flow over

kitchen equipment at the level of local suction is determined by the formula ():

Lki = 0.005 8701/3 (1.1 + 1.7 0.747)5/3 1 = 0.201 m3/s

Exhaust air flow

local suction, determined by the formula ():

Lo = (0.201 3 + 0.056 2 + 0.203 2) (1.25/0.8) = 1.750 m3/s or 6300 m3/h.

Room air exchange rate

hot shop 6300/(6 8 3) = 44 1/h exceeds 20 1/h. In accordance with ,

general exchange hood is not required, therefore, Lin = 0 m3/h.

Air consumption from

adjacent rooms, taken in the amount of 60% of the volumetric air flow,

removed by local suction, and is Lc = 3780 m3/h.

mass air flow,

supplied to the premises of the hot shop, is determined by the formula ():

GP = Loρ - LWithpWith \u003d 6300 1.165 - 3780 1.185 \u003d 2861 kg / h or 0.795 kg / s,

where ρ = 1.165 kg/m3 at tabout

= 30 °С;

pWith = 1.185 kg/m3 at tc = 25 °С.

11.2.4 If the hot shop and

trading floor directly communicate with each other, room ventilation

hot shop and trading floor are solved jointly.

When calculating ventilation

the temperature in the hot shop is assumed to be 5 °C higher than the outside temperature (parameters A []),

but not more than 27 °C; for the sales area is higher by 3 °С, but not more than 25 °С.

Heat dissipation in the halls should

take 116 watts per visitor (including 30 watts of latent heat from food).

Minimum amount of outdoor

air per visitor is taken 40 m3/h in the halls for

non-smokers and 100 m3/h in smoking rooms; for hot rooms

workshops - 100 m3 / h per worker [].

Calculation of ventilation separately

worthwhile catering should be performed for the summer,

transitional (tbunk = 10 °C) and winter periods - in order to

identification of the heat balance, taking into account heat losses and the need for regulation

performance of ventilation systems.

Supply air temperature in

the winter period is taken from 16 ° C to 18 ° C.

As a result of calculations, determine:

- the flow rate of air removed

local suction, which in this calculation example amounted to 6300 m3/h;

- mass air flow,

supplied to compensate for the exhaust air according to the calculation (see 11.2.3) is equal to

6300·1,165 = 7340

kg/h

Number removed by local

air suction compensates for:

- flow from the trading floor to

up to 60%; in this example we take LWith = 6300 0.6 = 3780 m3/h or GWith = 3780 1.185 = 4479 kg/h (1.244 kg/s);

- supplying the rest of the air

separate supply unit Gpr = 7340 - 4479 = 2861 kg/h

(0.795 kg/s).

Distribution of the amount of flow

and supply air is specified to compensate for apparent heat release in the room

hot shop, W, which come from the equipment Qabout, lighting Qocw of people Ql.

the value Qabout define similarly Qto sensible heat release from

installed capacity of equipment () in

the amount of 50% and the coefficient of simultaneity Toabout = 0,6 ():

Qabout \u003d (14.5 200 3 + 5 35 2 + 9 330 2) × 0.5 0.6 \u003d 4500 W;

Ql (7 people) \u003d 7 100 \u003d 700 W;

Qocw \u003d 48 20 \u003d 960 W.

Total heat inputs in

hot shop room:

ΣQexplicit = 6160 W.

It is believed that the convective part

heat release from kitchen equipment is captured by local exhausts, and

radiant - enters the room. Due to the lack of more accurate data

sensible heat emissions of kitchen equipment are divided into convective and radiant in

proportions 1:1.

Next, we calculate the temperature

hot shop in the summer, based on the air supply by the supply unit with

temperature tn = 22.6 °С. To do this, we compose the energy equation

room balance:

Qexplicit = GetcWithR(tkitchen — tn) + GccR(tkitchen — tWith);

Here Getc, Gc

- respectively, the mass flow rate of air supplied by a separate supply

installation, and overflow air, kg/s;

WithR — specific heat capacity of air, equal to 1005 J/(kg °C).

From here

which is less than 27 °С and by 26.4 - 22.6 = 3.8 °С < 5

°C above the outdoor temperature. Calculation completed.

When the temperature exceeds tkitchen

permissible value, it is necessary to increase the air flow supplied by a separate

supply unit, and accordingly reduce the consumption of overflow air. AT

If this is not enough, cool the air supplied by a separate

supply unit, to maintain the set air temperature in the room.

Mass air balance:

7340 = 4479 + 2861 kg/h.

Calculation of the air exchange rate

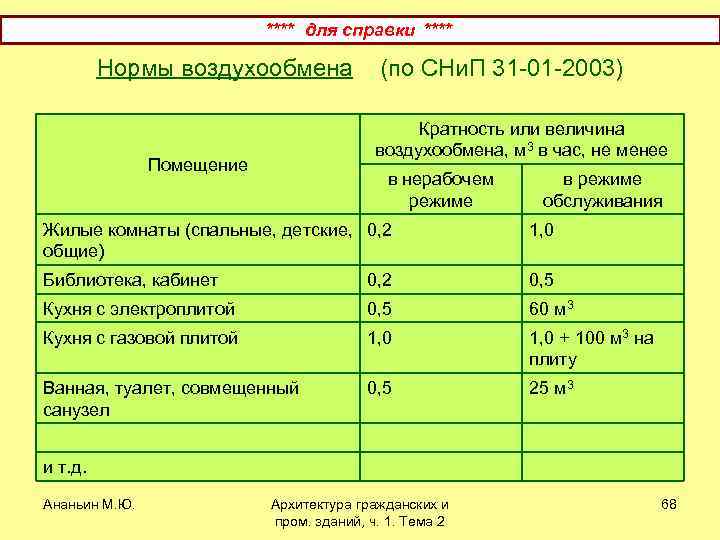

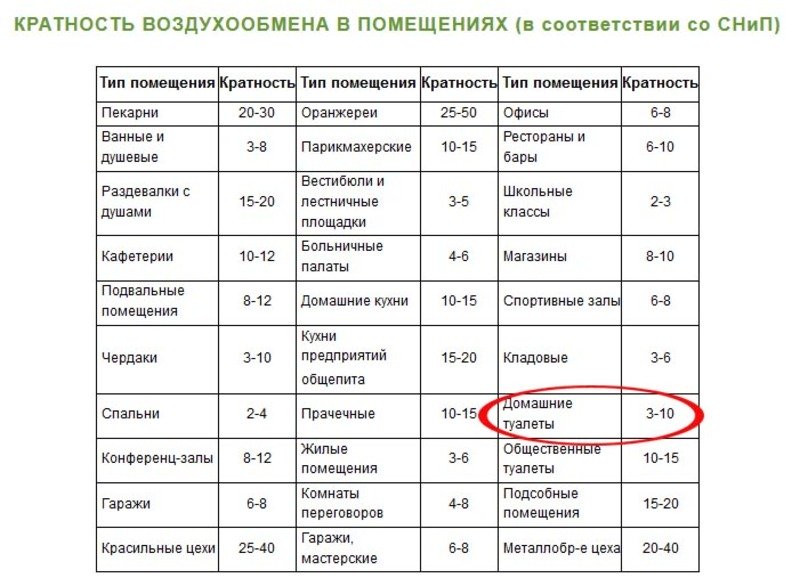

When determining the air exchange rate for each specific room, designers take into account the normative indicators fixed in sanitary and hygienic standards, GOSTs and building rules SNIP, for example SNiP 2.08.01-89. Without taking into account the content of harmful impurities in the air, the number of replacements for rooms of a certain volume and purpose will be calculated according to the values of the standard multiplicity indicators. The volume of the building is determined by the formula (1):

where a is the length of the room;

b is the width of the room;

h is the height of the room.

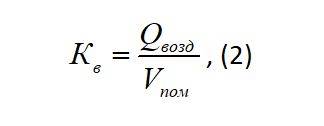

Knowing the volume of the room and the amount of oxygen supplied for 1 hour, it is possible to calculate the Kv ratio using formula (2):

Calculation of the air exchange rate

Calculation of the air exchange rate

where Kv is the air exchange rate;

Qair - the supply of clean air entering the room for 1 hour.

Most often, formula (2) is not used to calculate the number of cycles of complete replacement of air masses. This is due to the presence of tables of air exchange rates for all standard structures for various purposes. With such a formulation of the problem, for a room with a given volume with a known value of the air exchange coefficient, it is necessary to select equipment or select a technology that ensures the supply of the required amount of oxygen per unit time. In this case, the volume of clean air that must be supplied to ensure the complete replacement of oxygen in the room in accordance with the requirements of SNiP can be determined by formula (3):

According to the above formulas, the unit of measurement of the air exchange rate is the number of complete oxygen replacement cycles in the room per hour or 1/h.

Using the natural type of air exchange, it is possible to achieve 3-4 times the replacement of air in the room within 1 hour. If it is necessary to increase the intensity of air exchange, it is recommended to resort to the use of mechanical systems that provide forced supply of fresh or elimination of contaminated oxygen.

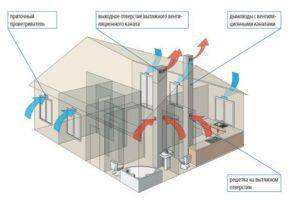

A little about air exchange

As you know, in residential buildings, ventilation systems are designed with a natural impulse.

Places for removing air from the premises are the kitchen, bath, toilet, that is, the most polluted premises of the apartment. Fresh air enters through cracks, windows, doors.

Over time, materials and window designs have improved. Current designs are completely hermetic, which does not allow for the necessary air exchange and satisfy the minimum air exchange rate.

Such problems are solved by installing various air supply systems. These are supply valves in the wall, as well as supply valves in the windows.

2. Calculation of air exchange

Air exchange is the amount of air required to completely or partially replace polluted air in a room. Air exchange is measured in cubic meters per hour.

How is air exchange calculated? In general, air exchange is determined by the type of air pollutants found in a given room.

The main calculations of air exchange are calculation for sanitary standards, calculation for a normalized multiplicity, calculation for compensation of local exhausts. There is also air exchange for the assimilation of apparent and total heat, for the removal of moisture, for the dilution of harmful substances in the air. Each of these criteria has its own method for calculating air exchange.

Before starting the calculation of air exchange, you need to know the following data:

- the amount of harmful emissions into the room (heat, moisture, gases, vapors) per hour;

- the amount of harmful substances per cubic meter of indoor air.

Process description

Air circulation with natural ventilation

Air circulation with natural ventilation

For an effective estimated characteristic of air exchange in an industrial building, the value - "kV" is used. This indicator of air exchange is the ratio of the total volume of air that comes "L" (m3 \ h) to the indicator of the total volume of cleaned space in the room "Vn", (m3). The calculation is carried out for the accepted time period.

If during the design, all calculations and the project itself are organized correctly, according to standards, then the air exchange rate for industrial premises will range from 1 to 10 units.

In addition to the calculation formulas and the theoretical basis, in order to determine the required indicator, experts advise conducting studies of natural conditions at similar operating enterprises, where there are actual data on the release of toxic fumes, gases, etc.

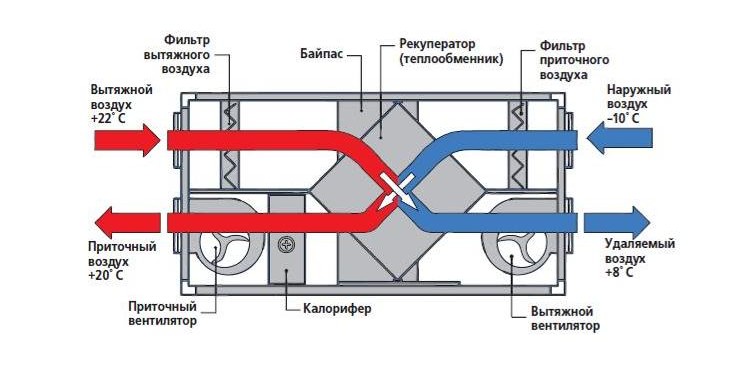

Energy Saving Recommendations

Ventilation systems are one of the main consumers of electrical and thermal energy, so the introduction of energy saving measures allows to reduce the cost of products. The most effective measures include the use of air recovery systems, air recirculation and electric motors with no "dead zones".

The principle of recuperation is based on the transfer of heat from the displaced air to a heat exchanger, which reduces heating costs.The most widespread recuperators are plate and rotary type, as well as installations with an intermediate coolant. The efficiency of this equipment reaches 60-85%.

The principle of recirculation is based on the reuse of air after it has been filtered. At the same time, part of the air from the outside is mixed in with it. This technology is used during the cold season in order to save heating costs. It is not used in hazardous industries, in the air environment of which there may be harmful substances of hazard classes 1, 2 and 3, pathogens, unpleasant odors, and where there is a high probability of emergency situations associated with a sharp increase in the concentration of flammable and explosive substances in the air. .

Given that most electric motors have a so-called "dead zone", their correct selection allows you to save energy. As a rule, "dead zones" appear during start-up, when the fan is running in idle mode, or when the mains resistance is much less than what is required for its correct operation. In order to avoid this phenomenon, motors with the possibility of smooth speed control and with no starting currents are used, which saves energy at start-up and during operation.

Recommendations for installation with a heat exchanger

Installation recommendations mainly refer to the rooms in which the heat exchanger should be installed. First of all, boiler rooms are used for this (if we are talking about private households). Also, recuperators are mounted in basements, attics and other technical rooms.

If this does not differ from the requirements of the technical documentation, then the unit can be installed in any unheated room, while the wiring of ventilation ducts, if possible, should be installed in rooms with heating.

Ventilation ducts passing through unheated premises (as well as outdoors) should be made insulated. Also, thermal insulation is necessary in places where exhaust ducts pass through the outer walls.

Considering the noise that the equipment can produce during operation, it is best to place it away from bedrooms and other living areas.

As for the placement of the heat exchanger in the apartment: the best place for it would be a balcony or some technical room.

In the absence of such an opportunity, free space in the dressing room can be allocated for the installation of the heat exchanger.

Be that as it may, the location of the installation largely depends on the design features of the ventilation system, on the location of the ventilation wiring and on the dimensions of the device.

The main mistakes in the installation of ventilation systems in the following video:

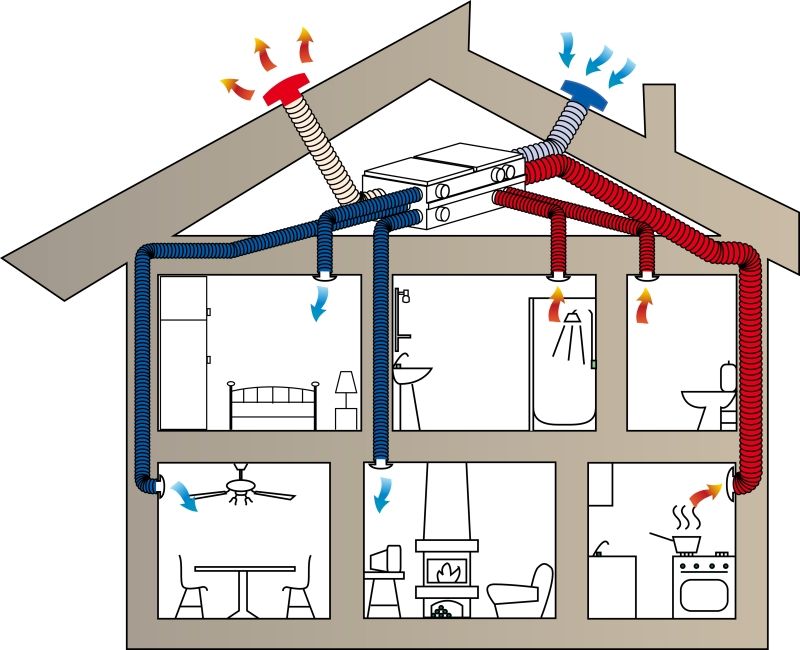

Features and schemes

Each type has its own characteristics that affect its choice for operation. There are several main points:

most of the frame houses have a pre-installed air exchange system;

Pipes for air exchange are mounted according to the project during the construction of the house

- each house uses its own scheme and layout of ventilation ducts;

- automation ensures full-fledged functioning only if there are good and serviceable sensors;

- the ventilation scheme and plan should be drawn up even when planning the house, but if this did not happen, then the plan is carried out before the arrangement of all premises;

- most often, metal pipes are not used in the ventilation system due to their heat loss and too high sound conductivity;

- for permanent residence, mechanical ventilation is used, which can fully provide a good microclimate and air exchange in the premises at any time of the year and at any temperature.

For the arrangement of frame houses of a certain type, a ventilation system has already been thought out, which facilitates planning. This approach provides a complete ventilation system based on all the characteristics of the premises and the building as a whole.

The scheme also depends on the type of building. For example, for a two-story house, you can use a mixed type, which will be different on two floors.

Scheme of air inflow and outflow in a two-story house

Previously, the scheme should be drawn up depending on the wishes of the residents. Having forced ventilation in a seasonal home does not make sense. It is also worth considering that frame houses can be made of various materials, which facilitates the integration of ventilation of one type or another.

All schemes are drawn up according to the parameters of the premises and the design of the house. In addition, all channel outlets must have gratings, as well as bolts. From the side of the interior, special dampers are installed, which are necessary not only to regulate the flow, but also for the full conservation of the house during the absence of residents.

What is ventilation and how does it work in this video:

Conclusion

Ventilation in a frame house is necessary. For different options for buildings for use and residence, you can select your own ventilation systems. Each system has its own characteristics and characteristics that must be taken into account when arranging.Part of the frame houses during production already has a layout of ventilation ducts and everything for their installation.

CALCULATION.

We start the calculation from the warm period of the year TP, since the air exchange in this case is maximum.

Calculation sequence (see Figure 1):

1. On the J-d diagram we put (•) H - with the parameters of the outside air:

tH"A" = 22.3 °C; JH"A" = 49.4 kJ/kg

and determine the missing parameter - absolute humidity or moisture content dH"BUT".

Outside air point - (•) H will also be an inflow point - (•) P.

2. Draw a line of constant temperature of the internal air - isotherm tAT

tAT = tH"A" 3 = 25.5 °C.

3. Determine the thermal stress of the room:

where: V is the volume of the room, m3.

4. Based on the magnitude of the thermal stress of the room, we find the gradient of the temperature increase in height.

The air temperature gradient along the height of the premises of public and civil buildings.

| Thermal tension of the room QI /Vpom. | grad t, °C / m | |

|---|---|---|

| kJ / m3 | W/m3 | |

| Over 80 | Over 23 | 0,8 ÷ 1,5 |

| 40 ÷ 80 | 10 ÷ 23 | 0,3 ÷ 1,2 |

| Less than 40 | Less than 10 | 0 ÷ 0,5 |

and calculate the temperature of the air removed from the upper zone of the room

ty=tB + grad t(H-hp.z.), ºС

where: H is the height of the room, m; hr.z. — height of the working area, m.

On the J-d diagram we plot the isotherm of the outgoing air ty*.

Attention! When the air exchange rate is more than 5, ty=tB is taken. 5. Determine the numerical value of the heat-humidity ratio:

We determine the numerical value of the heat-humidity ratio:

5. Determine the numerical value of the heat-humidity ratio:

(we will take the numerical value of the heat-humidity ratio as 6,200).

On the J-d diagram, through point 0 on the temperature scale, we draw a line of heat-humidity ratio with a numerical value of 6,200 and draw a process beam through the point of outdoor air - (•) H parallel to the line of heat-humidity ratio.

The process beam will cross the isotherm lines of the internal and outgoing air at point B and at point U.

From point Y we draw a line of constant enthalpy and constant moisture content.

6. According to the formulas, we determine the air exchange by total heat

and moisture content

The obtained numerical values should coincide with an accuracy of ±5%.

7. We calculate the standard amount of air required for people in the room.

Minimum supply of outdoor air to the premises.

| Type of buildings | Premises | Supply systems | |||

|---|---|---|---|---|---|

| with natural ventilation | no natural ventilation | ||||

| Air supply | |||||

| Production | for 1 person, m3/h | for 1 person, m3/h | Air exchange rate, h-1 | % of total air exchange not less than | |

| 30*; 20** | 60 | ≥1 | — | Without recirculation or with recirculation at a ratio of 10 h-1 or more | |

| — | 60 90 120 | — | 20 15 10 | With recirculation at a multiplicity of less than 10 h-1 | |

| Public and administrative | According to the requirements of the relevant chapters of SNiPs | 60 20*** | — | — | — |

| Residential | 3 m3/h per 1 m2 | — | — | — |

Note. * With the volume of the room for 1 person. less than 20 m3

3

Air exchange rates for production premises

Since industrial buildings differ in a number of factors from buildings in which people live, the calculation of air exchange processes is carried out taking into account the following parameters:

- number of personnel;

- number of electrical appliances;

- climatic conditions;

- power of natural ventilation;

- purpose of the premises;

- heat generating factors;

- the presence of impurities of dust and harmful substances;

- chemical impact.

The norms of air exchange are enshrined in industry standards of the enterprise, safety regulations. SP 60.13330.2012 “SNiP 41-01-2003. Heating, ventilation and air conditioning. These rules are followed when designing. To comply with sanitation standards, an air inflow of approximately 30 m³ / hour per working person is required if the volume of the ventilated room is less than 20 cubic meters. In the absence of natural ventilation, the air inflow should be 60-65 m³.

Ventilation is carried out to ensure the well-being of employees, reduce fatigue and allows you to get rid of a large amount of accumulated carbon dioxide and toxic fumes. There are no special requirements for the ventilation of production. However, in the conditions of large areas of production workshops, the function of ventilation is performed by a continuously switched on air circulation system.

Calculation methods for premises of a residential building

The supply of the required amount of air in residential premises, depending on the type of room, can be provided through autonomous air valves in the walls with adjustable opening parameters, vents, doors, transoms and windows

Specialists draw the attention of designers to the fact that when calculating the indicators of complete air replacement in living rooms, it is necessary to take into account a number of parameters, including:

- purpose of the premises;

- the number of people permanently in the building;

- temperature and humidity in the room;

- the number of operating electrical appliances and the rate of heat they emit;

- the type of natural ventilation and the indicators of the multiplicity of oxygen replacement provided by it within 1 hour.

To create comfortable conditions in accordance with the norms of SP 54.13330.2016, the amount of air exchange should be:

- With a room area per person of less than 20 m² for a children's room in the apartment, bedrooms, living rooms and common areas, the air supply should be 3 m³ / h per 1 m² of each room.

- With a total area per person exceeding 20 m², the air exchange rate should be 30 m³ / h per 1 person.

- For a kitchen equipped with an electric stove, the minimum oxygen supply cannot be less than 60 m³/h.

- If a gas stove is used in the kitchen, the minimum value of the air exchange rate increases to 80-100 m³ / h.

- The standard air exchange rate for vestibules, stairwells and corridors is 3 m³/h.

- The air exchange parameters increase slightly with increasing humidity and temperature in the room and amount to 7 m³ / h for drying, ironing and laundry rooms.

- When organizing a bathroom and a toilet in a living room, located separately from each other, the air exchange rate should be at least 25 m³ / h, with a combined location of the bathroom and the bathroom, this figure increases to 50 units.

Taking into account the fact that during cooking, in addition to steam, a number of volatile compounds containing oil and burning are formed, when organization of the air exchange system in the kitchen, it is necessary to exclude the ingress of these substances into the space of living rooms. To do this, the air of the kitchen room is removed outside by creating a draft in the ventilation duct, at least 5 m high and using a special exhaust hood.This type of organization of rotation of air masses ensures the elimination of excess heat. However, in order to avoid the ingress of exhaust air into the apartments located on the upper floors, during the construction of the structure, an air lock is installed to ensure a change in the direction of the air flow.

Conclusions and useful video on the topic

About the calculation of the air exchange rate:

Few of the owners of city apartments or houses are concerned about the compliance of air exchange in housing with the requirements. More often, engineers, builders and installers are interested in standards when designing or installing ventilation systems.

But we recommend that you familiarize yourself with the existing standards - focusing on the proven values, you can create the most favorable and comfortable microclimate in your home.

If you have questions or can share valuable tips on the topic of the article, please leave your comments in the block below.