- Setting and adjusting the pressure switch

- To regulate or not - how to determine?

- If pressure is not built up or held

- Not enough pump power

- Air got into the pipe

- Water is leaking from the system

- Not enough mains voltage

- How to change the membrane?

- Possible breakdowns and ways to eliminate them

- Borehole pump connection diagram

- Dry running protective relay

- Hydraulic accumulator (expansion tank)

- Pressure switch

- Additional elements of the water supply system

- Expert answer

- Training

- Features of adjustment "from scratch" and errors in the settings

- Installation of a pumping station

- What breakdowns of the pumping station can occur and methods for their elimination

- Causes of failures in the operation of the pumping station

- Setting

Setting and adjusting the pressure switch

The settings do not always help to solve the problem with the operation of the pumping station. Before touching the springs, it is necessary to find out if the contacts are “sticking” due to adverse operating conditions - high humidity, condensation, overheating. First, check the contacts, if necessary, clean them with sandpaper and reconnect. All work is carried out with a de-energized device. At the same time, the tank is checked for integrity and the presence of the required volume of air inside, and the filters are cleaned. If there is no experience with such equipment, it is better to invite the master.

The settings do not always help to solve the problem with the operation of the pumping station. Before touching the springs, it is necessary to find out if the contacts are “sticking” due to adverse operating conditions - high humidity, condensation, overheating. First, check the contacts, if necessary, clean them with sandpaper and reconnect. All work is carried out with a de-energized device. At the same time, the tank is checked for integrity and the presence of the required volume of air inside, and the filters are cleaned. If there is no experience with such equipment, it is better to invite the master.

If the matter is really in the settings that have gone astray, before starting work, it is necessary to prepare a wrench that will turn the spring. It is necessary to turn on the unit and record the indicators of the upper and lower thresholds in order to more accurately determine which indicator needs to be changed and which one should be left the same.

Actions are performed in the following sequence:

- The station is de-energized.

- The water from the accumulator tank is drained and the cover of the pressure switch is opened.

- The inclusion indicator is regulated by a big spring. It is usually set to 2–2.2 atmospheres. The nut is tightened clockwise until the value is set to the desired number.

- The difference is adjusted by a small spring. If it is necessary to decrease the value, turn the nut counterclockwise; if it is necessary to increase, then turn it clockwise.

The difference between the indicators should optimally be 1 bar so that there is no change in pressure in the house.

To regulate or not - how to determine?

In the case when the equipment is purchased assembled, it is necessary to make sure that the pressure in the pumping station is within the allowable range.

The factory default settings are:

The factory default settings are:

- inclusions - 1.5-1.8 atm.;

- shutdown - 2.5-3 atm.

Next, it remains to check whether such parameters suit the family.

They also change the system parameters if they begin to feel discomfort while using the water supply. A consumer who is comfortable with medium pressure for washing dishes and taking a shower will choose a low threshold for turning on the engine.

When a person actively uses a hydromassage device, wants the bathroom and washing machine to fill with water as quickly as possible, he needs intensive work of the station with frequent turning on of the motor.

If the pump turns on when the tap is opened and turns off only when it is closed, this indicates that there is no additional voltage in the system

If pressure is not built up or held

When the pump is turned on, it starts to work without stopping, as it cannot “catch up” with the pressure in the system to the set maximum level. This happens quite often and for various reasons, many of which are easily fixed by hand.

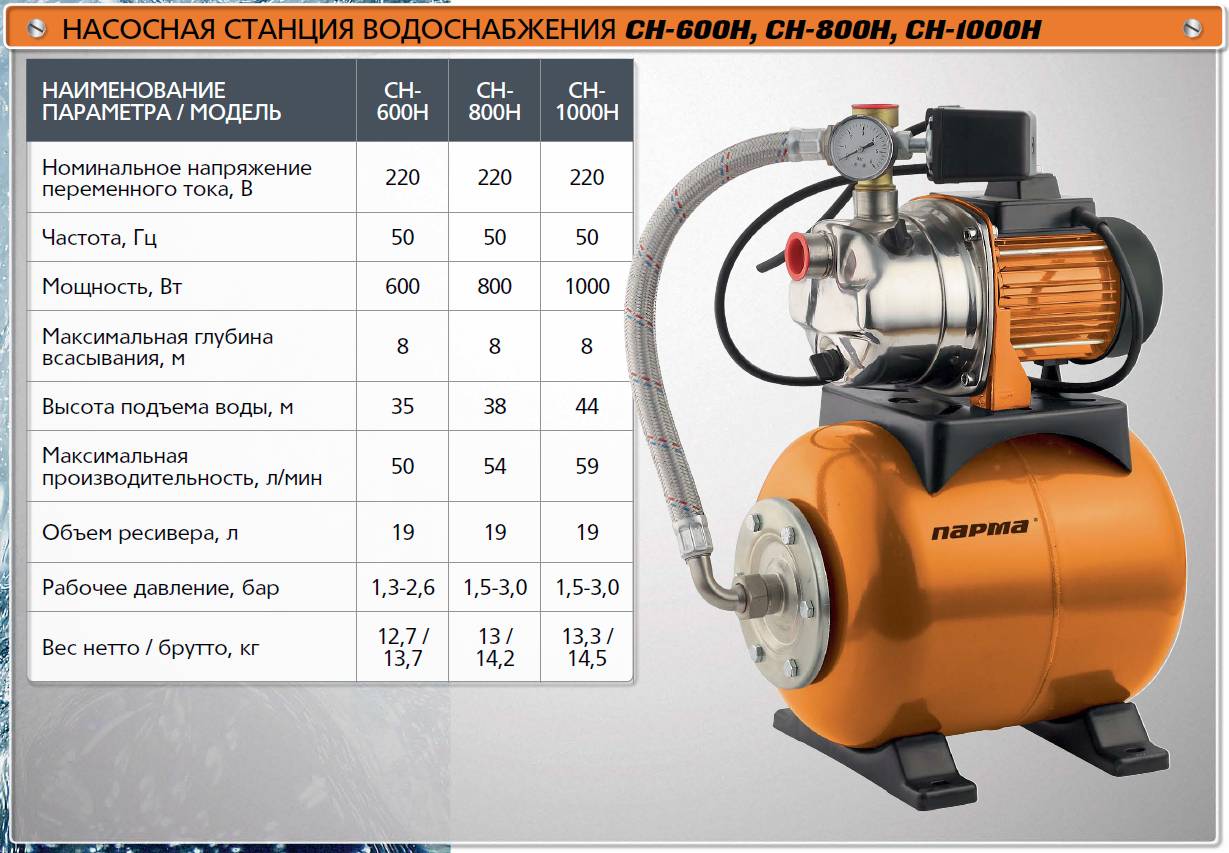

Not enough pump power

One of the main reasons why the pumping station does not pump up pressure is the discrepancy between the characteristics of the pump and the specified operating conditions, which include:

- Required volume of water supply;

- The height of the supply to the level of the location of the water folding devices;

- Pipeline diameter and length, etc.

In other words, the power of the device may simply not be enough to raise water to a given height, to overcome resistance in pipes in horizontal sections. This means that you initially did not take into account all the initial data and purchased a low-power station.

The situation can be corrected only by purchasing a new pump or by reducing the maximum set pressure to the level that it can provide.

Leaks on the case, as in this photo, indicate the wear of the seals

Air got into the pipe

This happens with surface type pumping stations.

Air can get into the suction pipe:

- In case of violation of the tightness of the connection of the pipe with the pump;

- When the pipe itself is depressurized (the appearance of cracks and fistulas);

The most common cause of pipe rupture is freezing of water in them.

With a strong decrease in the water level in the source, when the check valve is above this level.

Everything is clear here, it is unlikely that you need instructions for troubleshooting these problems.

Water is leaking from the system

- From a faucet left open or torn off;

- Through a faulty toilet drain;

- Through a break in the pressure or suction pipeline;

- Through poor-quality pipe connections with each other and equipment.

If the damage has touched that part of the pipeline that is laid underground or under the floor, you may not understand for a long time why the pressure in the pumping station drops.

Serious leaks do not allow the pumping station to reach the set pressure, it works continuously, making up for losses. It must be stopped forcibly in order to examine all the nodes and elements of the water supply for leaks.

Leakage can occur through any of the specified connections

They are also the reason that the accumulated pressure is not retained by the station in the absence of water flow through the distribution devices. And first of all, you should check the operation of the check valve, since it will not be possible to pump up pressure in the pumping station if it does not completely close and releases water back into the well.

This may be due to valve wear, a weakened spring, or solid particles that have entered the valve preventing it from closing.

Not enough mains voltage

The voltage in the mains in the event of such problems must be measured first. Its fall is a fairly common cause of failures in the operation of pumps and pumping stations, as well as any other electrical equipment.

If this is a common occurrence in your area, there is only one way out - you need to install a voltage stabilizer. His, frankly, a considerable price scares many owners of private houses. But financial losses can be much higher if complex household appliances and a pumping station that provides you with drinking water fail.

How to change the membrane?

Of course, the first rule is to empty the containers (if any) next to the accumulator and block all inlets and outlets for water in the accumulator, after “bleeding” the pressure to zero.

Then you need to press the spool at the back and release air from the rear compartment of the tank.

Nipple for pumping air.

Then the fun begins: you need to unscrew the 6 bolts that secure the flange to the accumulator. As a rule, access to one or more nuts is blocked by a pressure gauge and pressure switch. You can slightly turn the splitter by hand, which is attached directly to the tank flange, without unscrewing it entirely (otherwise you will have to rewind the FUM tape on the thread.

Usually, in the factory configuration of hydraulic accumulators, the flange is made of galvanized iron and quickly begins to corrode. In this case, it is better to change the flange to a plastic one (these are often sold in hardware stores) in order to forget about it once and for all.

So, substituting the containers, we take out the old "pear" and empty it. If a gap is visible on it, then it is also worth draining the water that has got into the metal tank itself.

This is a new membrane.

And this is the membrane after 2 years of operation. From the personal photo archive of the author

We install a new membrane, put the flange and inflate about 2 atmospheres at the back (or a bar, these are very similar values). Happy using!

Typically, the membrane in a new accumulator lasts 3-4 years, each replacement one is 1.5-2 times less.

plumbinghouse water supplyhydraulic accumulatorbulb accumulatorpump stationpressure drop in the accumulator

Possible breakdowns and ways to eliminate them

A turretless, or pumping station, can stop holding pressure. This can happen for various reasons, finding out which you can fix them yourself. Most often, the turretless remains working, but cannot gain pressure.

The pumping station may be equipped with a surface pump, which may stop working for other reasons. The water pressure is weak or absent due to a violation of the tightness of the pipeline or air entering the pump. Another reason for the lack of water is a clogged filter.

Parts for the pumping station can be found in the specialist shop

Troubleshooting methods:

To prevent damage due to lack of water in the suction pipe, check that the suction pipe and the pump are filled with water before starting the system directly.

If the water disappears later, special attention should be paid to the serviceability of the check valve.

To check the tightness of the connections, you need to dry them and carefully examine them.

If the cause is the pump impeller, you can try turning it while starting the unit.

If the motor makes an uncharacteristic sound when turned on, the problem may be a defective capacitor. The impeller and pump housing may wear out, most likely requiring replacement of old parts with new ones. Turretless may stop working properly due to low mains voltage. Before checking the voltage, it is necessary to disconnect the unit from the mains.

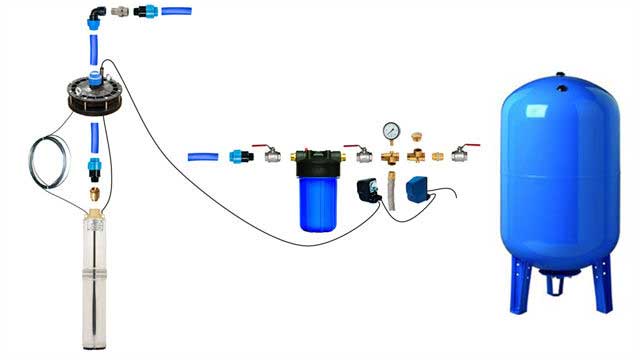

Borehole pump connection diagram

To determine why the pump does not turn off, consider its typical connection diagram. This will help identify the node or unit in which to look for the cause of the malfunction.

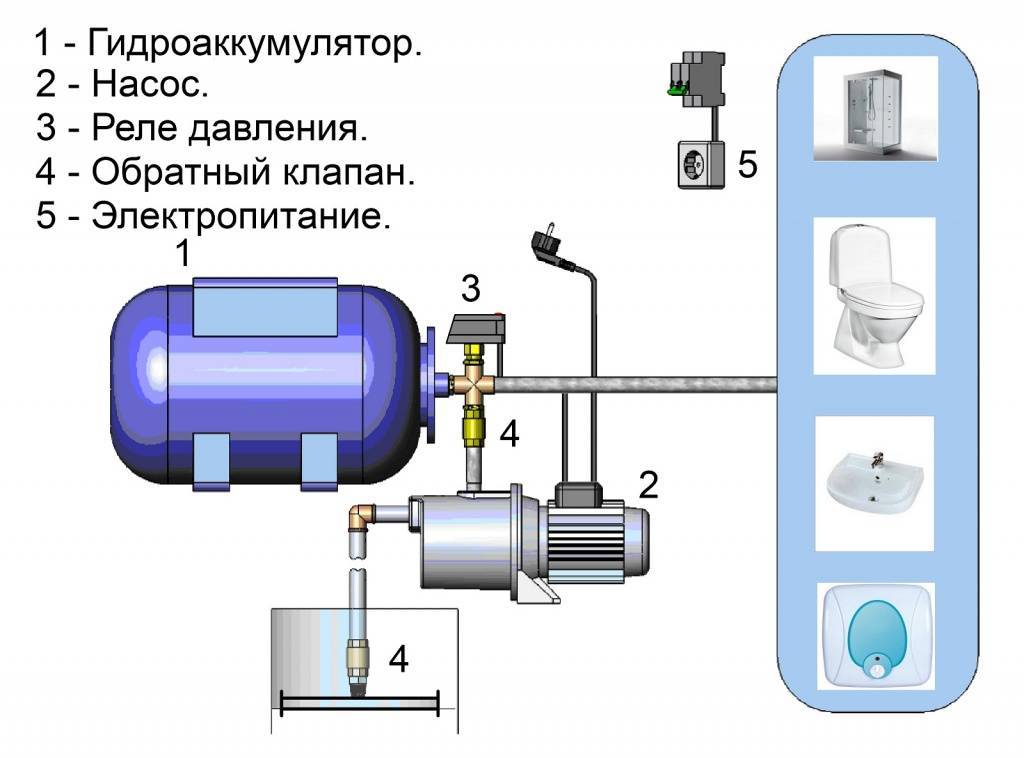

Rice. 1 Scheme for connecting a borehole pump for supplying water to a house

The main components of the connection scheme for a borehole pump for water supply in the house are the following nodes.

Dry running protective relay

The relay monitors the pressure in the plumbing system - as soon as it becomes less than a certain value, the membrane inside stops pressing the contacts and they open. Submersible pumps are disconnected from power when the pressure in the water supply system decreases from 0.1 to 0.6 atm. (can be adjusted). This situation occurs when there is no water in the system or its very small amount (clogging of the filter, lowering the water level).

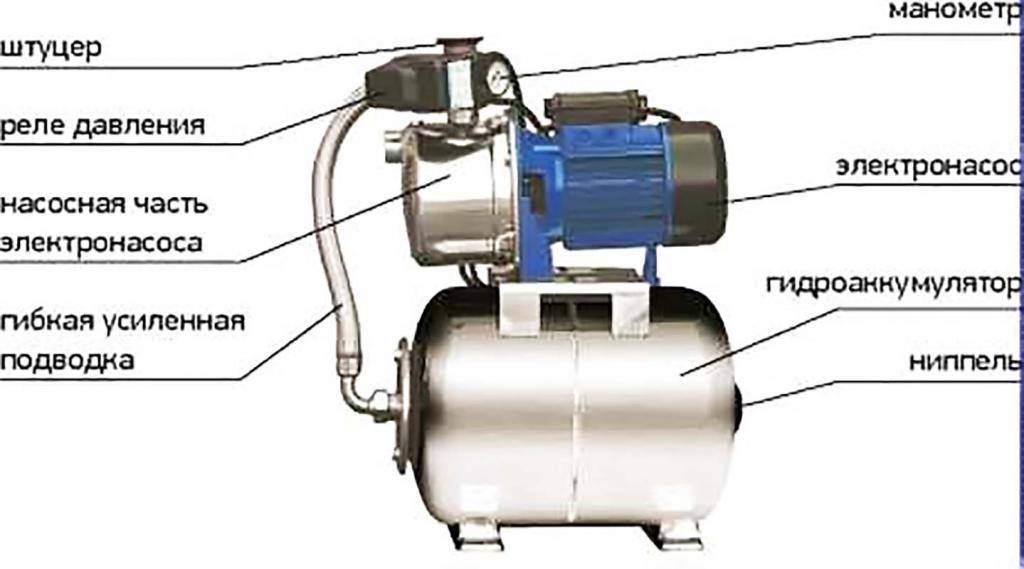

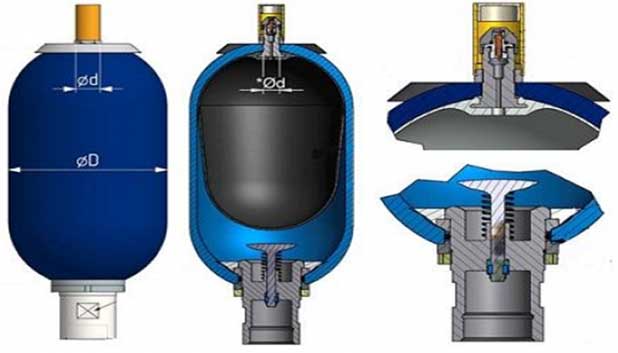

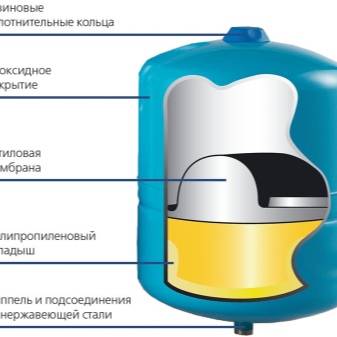

Hydraulic accumulator (expansion tank)

Fig. 2 Appearance and arrangement of the accumulator

The most important part of any water supply system, makes it possible to maintain a constant pressure in it. The device is assembled as a tank with a rubber membrane inside, during normal operation the tank is filled with water and the membrane is stretched. With a short-term loss of water, pressure drops, the membrane contracts and pushes the liquid out of the storage tank into the system, maintaining a constant pressure in it. If there was no storage tank, then for any short-term pressure changes, the pressure switch would trip, this would give impulse switching on and off of the power source, forcing the pump to turn off or turn on, respectively, leading to its premature failure.

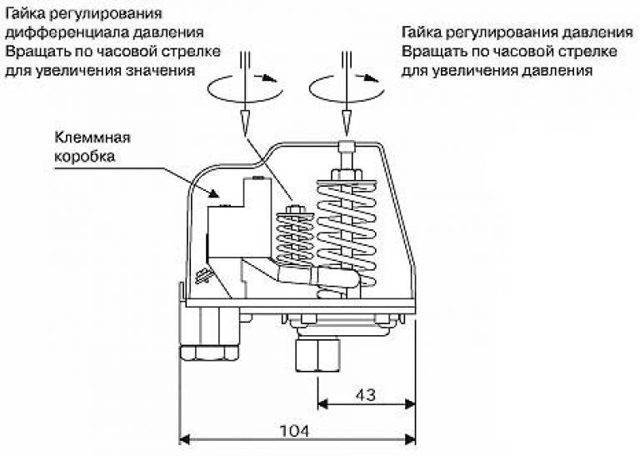

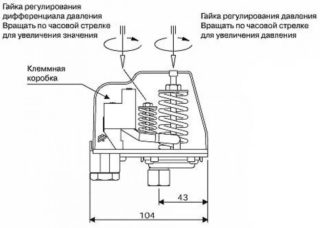

Pressure switch

Rice. 3 Pressure switch

The relay is the main element in the borehole water supply system, which provides automatic control of water intake. In case of insufficient pressure in the water supply, the relay contacts are closed, the electric pump is supplied with power, and water is drawn. When the use of water is suspended, the accumulator is filled and the pressure in the water supply rises - the membrane inside the relay presses on the contacts and they open, forcing the pump to turn off. Single-chamber low pressure switches are used to work in water intake systems using pumps with a power of up to 3 kW., Their response threshold is 1.2 - 1.6 atm., Adjustable with two clamping screws (one determines the upper limit, the second determines the response range).

Additional elements of the water supply system

head. A very convenient device, it is installed on top of the pipe if the pump is working in a well. A pipe with a pump and a suspension system is passed through it, it protects the well from foreign objects. If the well was drilled at the bottom of the well, the head can be used for rod systems to install the pump at a given depth.

Pressure gauge. It is built into all water supply systems using borehole pumps, it allows not only to monitor the pressure, but also serves to set the threshold for the operation of protective relays.

Check valve. The membrane, which is installed immediately at the outlet of the submersible pump before connecting to the water supply, prevents the reverse flow of fluid from the system into the well.

Filter.Flow-through fine filter with replaceable cartridges when using domestic water, the filter is an indispensable element

Additionally, the downhole pump connection system may consist of elements responsible for the safety of the pump motor: float or electronic water level sensors, flow sensors that respond to the speed of water movement in the pipes.

Expert answer

Hello, Sergey Viktorovich.

In order to avoid problems with cold water performance, pumping stations (systems that consist of several pumps, and not a unit with a hydraulic accumulator familiar to owners of country houses) designed to equip apartment buildings should be equipped with several types of automatic control and protection devices. As a rule, they solve problems:

-

maintaining the set pressure when the flow rate changes;

-

monitoring the voltage in the network and restarting the system after a power outage;

-

switching between individual units in case of failure of one of them, as well as in order to ensure the same wear of all equipment in the system;

-

automatic redistribution of load when the flow rate changes;

-

automatic diagnostics of equipment malfunctions (with sound and visual notification).

In systems with cascade control, flow control is carried out by turning on one or another number of pumps connected in parallel. As a rule, the more units are included in the pumping station, the softer, more efficient and more economical it works.

Another way to control performance is frequency regulation, which consists in changing the speed of rotation of the impellers of pumps by means of an electronic frequency converter. Due to this, it becomes possible to smoothly adjust the performance, it is possible to eliminate water hammer and increase the reliability and durability of the equipment.

And, finally, the most "advanced" method combines the combination of cascade and frequency regulation. Such automated pumping stations have all the advantages of the first two and can reduce electricity consumption by half.

Unfortunately, you did not provide accurate information about your engineering system, so we will try to give some recommendations. Perhaps one of them will be useful for your case.

-

When using a modern frequency-cascade system, it is necessary to check the correct operation of the PLC (programmable logic controller) and the serviceability of the state sensors of the units and pressure. After identifying the “weak link”, the problem will be solved by repairing or replacing the faulty node.

-

If the pumping station operates according to a simplified scheme, then it is possible to increase productivity and achieve pressure stability by connecting one or two additional units.

-

Perhaps the problems arose due to the long operation of the equipment without maintenance or repair? The fact of wear of parts and the associated decrease in productivity should not be overlooked.

As for the installation of a hydraulic accumulator, this method is not practiced in apartment buildings. Judge for yourself: when calculating the expansion tank, one apartment should have at least 50 liters of water tank volume.The cost of a hydraulic accumulator designed for 1000 liters or more is prohibitive, so it will be much easier to repair or upgrade the existing pumping system.

Training

The relay should only be adjusted after checking the air pressure in the accumulator. To do this, you should better understand how this very hydraulic accumulator (hydraulic tank) works. It is a hermetically sealed container. The main working part of the container is a rubber pear into which water is drawn. The other part is the metal case of the accumulator. The space between the body and the pear is filled with pressurized air.

The pear in which water accumulates is connected to the water supply system. Due to the air in the hydraulic tank, the pear with water is compressed, which allows you to maintain the pressure in the system at a certain level. Thus, when a tap with water is opened, it moves through the pipeline under pressure, while the pump does not turn on.

Before checking the air pressure in the hydraulic tank, it is necessary to disconnect the pumping station from the network, and drain all the water from the hydraulic accumulator tank. Next, open the side cover on the tank, find the nipple and use a bicycle or car pump with a pressure gauge to measure the pressure. Well, if its value is about 1.5 atmospheres.

In the event that the result obtained is of a lower value, then the pressure is raised to the desired value using the same pump. It is worth recalling that the air in the tank must always be under pressure.

When using a pumping station, it is important to periodically check the air pressure in the hydraulic tank (about once a month or at least every three months), and if necessary, pump it up.These manipulations will allow the accumulator membrane to work longer.

But also, the tank should not be empty for too long without water, as this can lead to drying out of the walls.

After adjusting the pressure in the accumulator, it happens that the pumping station stops working in normal mode. This means that the pressure switch should be adjusted directly.

Features of adjustment "from scratch" and errors in the settings

Set up the pressure switch of the pumping station DIY from scratch much more difficult. This procedure is required when the equipment is assembled from parts, and not bought in a store. In such a situation, several parameters must be considered:

- air pressure in the accumulator;

- relay capabilities - its operating range;

- line length and pump operation parameters.

The absence of air in the tank will cause the membrane to immediately fill with water and gradually stretch until it bursts. The maximum shutdown pressure must be the sum of the water and air pressures in the tank. For example, the relay is set to 3 bar. Of these, 2 bars are for water, 1 for air.

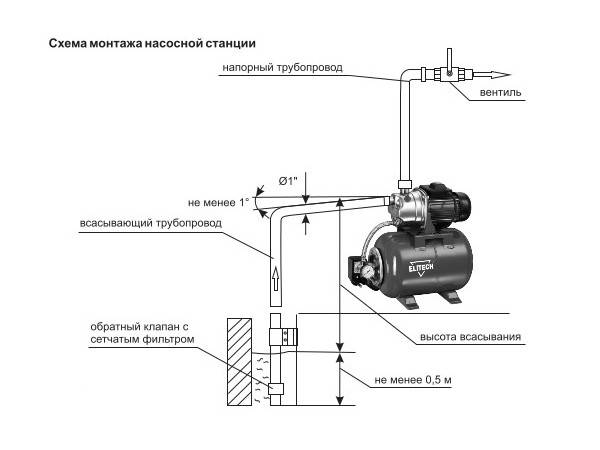

Installation of a pumping station

Installation of equipment in the water supply network

The photo shows the installation of a pumping station in a water supply system

In doing so, attention is drawn to:

- Plastic pipes or hoses are not bent or twisted.

- All pipe connections were well sealed. Air leakage in this case can have a negative impact on the operation of the equipment.

- Quick couplings provided convenience when servicing the pumping station.

- The suction pipe was with a check valve, at the end with a mesh and a main filter placed in front of the pumping station, and protecting it from small mechanical particles.

- The suction pipe was lowered with its end into the water at least 30 centimeters, from the lowest liquid level. Between the bottom of the tank and the end of the suction pipe, the distance must be at least 20 centimeters.

- A non-return valve installed on the outlet pipe of the device helps to prevent water hammer that may occur when the unit is turned on / off.

- The pumping station was well fixed in the required position.

- A large number of bends and taps in the equipment were not allowed.

- When suction from a depth of more than four meters or the existence of a horizontal section of the same length, a large pipe diameter is used, which greatly improves the operation of the equipment.

- From all points of the system, ensure the drainage of water, if it is possible to freeze in the cold season. In this case, it is necessary to install drain taps, non-return valves, which should not interfere with the drainage of water.

The pump must be securely fixed. For this:

- The device is placed on a flat area, closer to the water source.

- In the place where the pumping station is located, it is necessary to organize ventilation, which will make it possible to reduce humidity and lower the air temperature.

- There should be no less than 20 centimeters from any wall to the pumping station to provide access to it during maintenance.

- Pipes must be of the appropriate diameter.

- Holes are marked and drilled to fix the pumping station.

- The absence of mechanical stresses, pipe bends is controlled, fastening screws are screwed.

What breakdowns of the pumping station can occur and methods for their elimination

Connection diagram of equipment parts

The reasons breakdowns and methods for their elimination it is suggested to look at the table:

We install a peristaltic pump with our own hands

It is not so easy to make a peristaltic pump with your own hands. Domestic water supply systems mainly use classic centrifugal, vibration, screw pumps that can provide good pressure and lift water from great depths. But for its disinfection by adding a certain amount of reagents to the water, a perist pump is often used.

The pumping station works jerkily: what is the cause of the malfunction

Pumping station: how it works Equipment that never breaks down does not exist, and pumping stations - even if they are from the most famous manufacturers, are no exception. What is very pleasing is that the causes of malfunctions are often not in the pump itself, and problems are fixed quite easily. What are they expressed in, and for what reasons arise.

Water pressure regulator for a pumping station: installations for comfortable network operation

Pressure regulator for a pumping station Setting up a pressure regulator for a pumping station is one of the most important manipulations carried out when preparation of equipment for initial start-up. This device is a sensor, at the command of which the pump should be started and stopped.

Pumping station: which is better for production

Pumping station: which one is better Before talking about which pumping station is best for an enterprise, we note that most often production needs an installation that removes and transports wastewater.In this case, the pumps are selected and installed taking into account the specifics of the pumped liquid.

Industrial pumps: design features and characteristics

Industrial equipment: pumps for pumping water The technical characteristics of industrial units are not comparable with the power of household pumping equipment, and this is natural. The general classification includes at least seventy types and subspecies of pumps.

Causes of failures in the operation of the pumping station

Sometimes it happens that the pumping station "gets sick" with the so-called turretless. The disease is based on the continuous operation of the device without the required shutdown cycles, when the device pumps water without stopping. Therefore, in this material we will find out what to do if the pumping station does not turn off and why this happens.

Important: a water station operating in a continuous mode (pumping and pumping water) will definitely soon lead to the combustion of the pump itself. Therefore, it is necessary to detect the causes of such equipment failure as soon as possible and put the entire water supply system in order.

Setting

So, let's figure out how to adjust the water pressure in the pumping station. Having familiarized yourself with the design of the relay and the scheme of its operation, the way to configure it becomes quite obvious:

- By increasing or decreasing the compression of the large spring by turning the nut holding it, the user, respectively, increases or decreases both the pressure P1 and P2 by the same amount.

- When adjusting the compression of the small spring, the pressure P1 will remain unchanged, and P2 will change. In other words, the working pressure range depends on the tension of the small spring, and its lower limit is fixed.

The dry-running protection mechanism is also set to a certain water pressure, which is usually 0.4 atm. If it falls below this level, the protection will disconnect the contacts.

This parameter cannot be adjusted by the user.