- How to connect a membrane tank: diagram. Instrument setup

- Functions, purpose, types

- Purpose

- Kinds

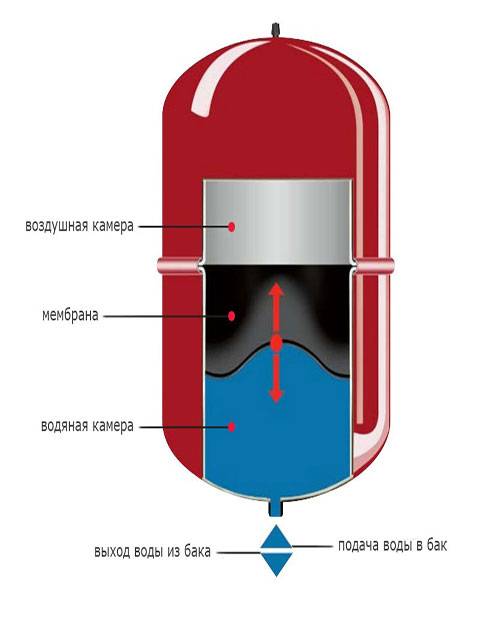

- Principle of operation

- Large volume tanks

- Technical advice

- Malfunctions in the operation of the expansion tank and how to eliminate them

- Frequent malfunctions and measures for their elimination

- Volume calculation

- What will cause the insufficient volume of the expansion tank

- What is an expansion tank for?

- Expansion tank open

- Closed expansion mat

- What is it for

- Rules for constructing closed contours

- Installation rules

- Conclusion

How to connect a membrane tank: diagram. Instrument setup

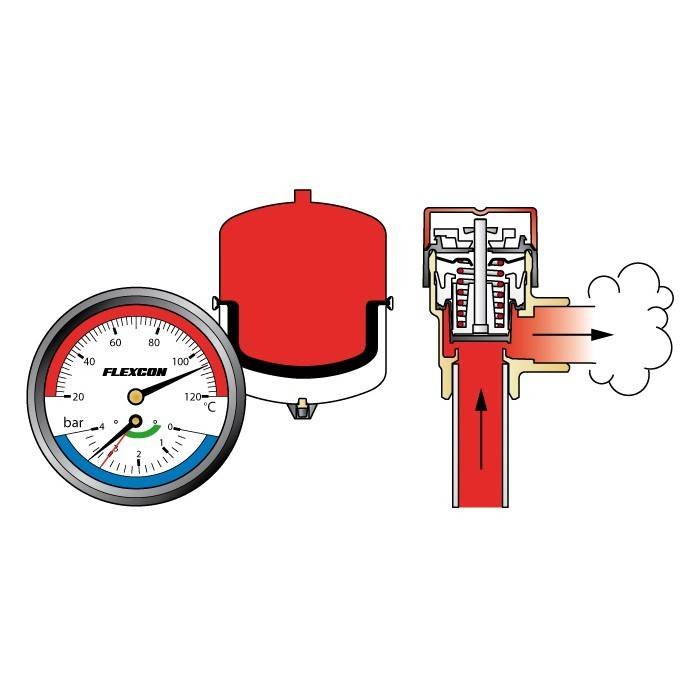

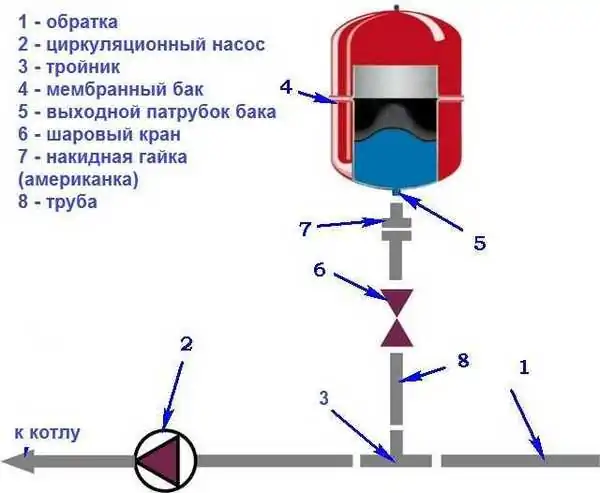

After carrying out installation work on inserting the tank into the general network, it is configured. In this case, the main task is to achieve the desired pressure corresponding to the heating system. This setting applies to closed tanks and is carried out as follows:

- after installing the expander, the system is filled with water;

- they bleed air from radiators and pipes, for this they use Mayevsky valves and taps;

- measure the pressure (manometer) in the air compartment of the tank and in the rest of the system;

- according to the rules, the pressure in the tank should be 0.2 bar lower than in the rest of the circuit, this difference is achieved by bleeding and pumping up the pressure in the chamber with a compressor.

If, as a result of calculations, the pressure in the system should be 1.3 bar, then in the air compartment of the tank it must be lowered to a value of 1 bar. This is necessary so that sufficient pressure is exerted on the rubber “pear” from the side of the water, and when the coolant cools down, air is not drawn in. After such a system setup, the boiler is turned on, now the pressure in the expander will increase smoothly, regardless of whether the liquid cools or heats up.

Photo 3. Scheme of connecting a membrane tank to a closed heating system. All parts of the structure are marked with numbers.

Functions, purpose, types

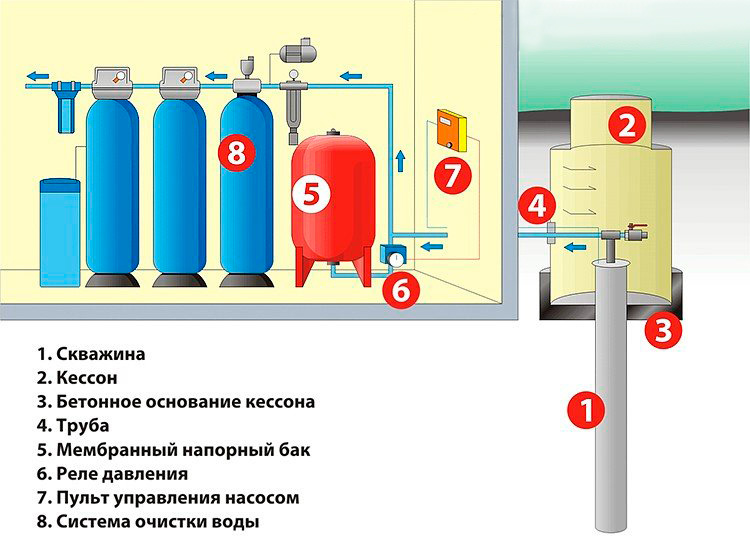

Place of installation - in pit or house

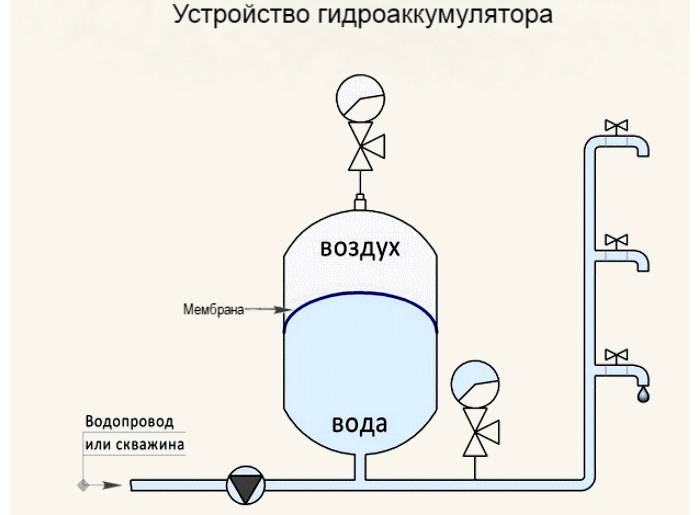

In the water supply system of a private house without a hydraulic accumulator, the pump turns on whenever water flows somewhere. These frequent inclusions lead to wear of the equipment. And not only the pump, but the entire system as a whole. After all, every time there is an abrupt increase in pressure, and this is a water hammer. To reduce the amount of pump activation and smooth out water hammer, a hydraulic accumulator is used. The same device is called an expansion or membrane tank, hydraulic tank.

Purpose

We found out one of the functions of hydraulic accumulators - to smooth out hydraulic shocks. But there are others:

It is not surprising that this device is present in most private water supply systems - there are many advantages from its use.

Kinds

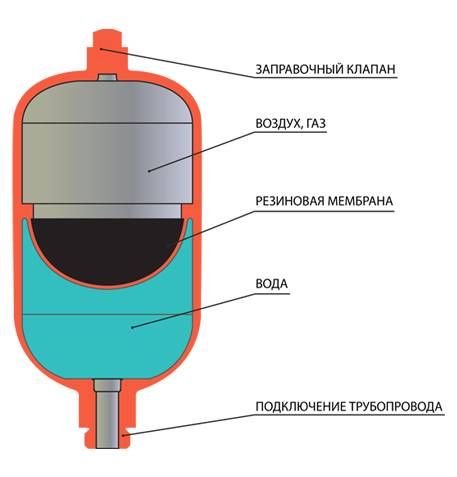

A hydraulic accumulator is a sheet metal tank divided into two parts by an elastic membrane. There are two types of membrane - diaphragm and balloon (pear).The diaphragm is attached across the tank, the balloon in the form of a pear is fixed at the inlet around the inlet pipe.

By appointment, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Hydraulic tanks for heating are painted red, tanks for plumbing are painted blue. Expansion tanks for heating are usually smaller and cheaper. This is due to the material of the membrane - for water supply it must be neutral, because the water in the pipeline is drinking.

According to the type of location, accumulators are horizontal and vertical. Vertical ones are equipped with legs, some models have plates for hanging on the wall. It is the models that are elongated upwards that are more often used when creating the plumbing systems of a private house on their own - they take up less space. The connection of this type of accumulator is standard - through a 1-inch outlet.

Horizontal models are usually completed with pumping stations with surface-type pumps. Then the pump is placed on top of the tank. It turns out compact.

Principle of operation

Radial membranes (in the form of a plate) are used mainly in gyroaccumulators for heating systems. For water supply, a rubber bulb is mainly installed inside. How does such a system work? As long as there is only air inside, the pressure inside is standard - the one set at the factory (1.5 atm) or which you set yourself. The pump turns on, starts pumping water into the tank, the pear begins to grow in size. Water gradually fills an increasing volume, more and more compressing the air that is between the tank wall and the membrane.When a certain pressure is reached (usually for one-story houses it is 2.8 - 3 atm), the pump turns off, the pressure in the system stabilizes. When you open a tap or other flow of water, it comes from the accumulator. It flows until the pressure in the tank drops below a certain level (usually about 1.6-1.8 atm). Then the pump turns on, the cycle repeats again.

If the flow rate is large and constant - you are taking a bath, for example - the pump pumps water in transit, without pumping it into the tank. The tank begins to fill after all the taps are closed.

The water pressure switch is responsible for turning the pump on and off at a certain pressure. In most accumulator piping schemes, this device is present - such a system works in the optimal mode. We will consider connecting the accumulator a little lower, but for now let's talk about the tank itself and its parameters.

Large volume tanks

The internal structure of accumulators with a volume of 100 liters and above is slightly different. The pear is different - it is attached to the body both above and below. With this structure, it becomes possible to deal with the air that is present in the water. To do this, there is an outlet in the upper part, into which a valve for automatic air release can be connected.

Technical advice

membrane tank installations

Before you start connecting the accumulator to the water supply system, you should:

- Carefully study the instructions supplied with the equipment.

- Carry out technical pressure calculations and compare with those indicated in the regulatory manual for operation.

- In order to carry out the installation with high quality, you need a wrench for detachable connections and plastic pipes, a wrench of the right size.

- Special brackets will be needed to mount large volume equipment.

Note! Measurements and calculations of the operated equipment should be carried out by a highly qualified specialist. The quality of the water supply system depends on the accuracy of the calculations and measurements performed. Many years of experience in using membrane tanks for water supply has shown that horizontal models are the best option.

If you have a submersible pump connected, purchase and install vertical accumulators

Many years of experience in using membrane tanks for water supply has shown that horizontal models are the best option. If you have a submersible pump connected, purchase and install vertical accumulators.

Malfunctions in the operation of the expansion tank and how to eliminate them

Standard maintenance of the tank consists of periodically inspecting its body (and painting over dents or corrosion spots if necessary), checking the pressure in the gas chamber every 2-3 months, monitoring the integrity of the membrane and replacing it if leaks are detected.

In the summer or during other long downtimes of the system, the water must be drained from the tank, the device, if possible, is stored in a dry place.

In general, high-quality devices rarely fail, but recently a lot of subclocks have appeared on the market. For example, at one of my facilities, in two years we have already changed tanks to new ones. So, buy tanks from a trusted manufacturer.

The exception is cases of sticking or wear of the built-in safety valve (if any), accidental breakage of the lid or mechanical damage to the tank body, wear of the membrane or rubber seals.

Signs of a malfunction or malfunction of the expansion tank in the heating circuits include:

• Sudden pressure surges in the system. In correctly configured and functioning heating circuits, the difference in pressure between the cold and the most heated coolant does not exceed 0.5-1 bar. In systems with failed or incorrectly configured tanks, on the contrary, pressure indicators are far from stable.

• The need to top up the coolant in the absence of other leaks.

• Water escaping rather than venting when the pneumatic valve spool is pressed briefly. This symptom clearly indicates damage and the need to replace the membrane or the expansion tank itself.

To check the operability of the tank, after excluding other problems (airing, pump malfunctions, clogging of network filters, blocking of the coolant with fittings), the device is disconnected from the system.

After that, the pressure of the tank chambers is checked using a pressure gauge and a car pump. The indicators are checked in the normal state and after draining the coolant, if necessary, the pressure in the tank rises to the desired value.

After that, all drain valves are closed, the car pump and pressure gauge are removed, the heating system is supplemented with a coolant and put into operation.

With stable pressure readings, the tank is simply left alone with slightly more frequent monitoring of system parameters.

If the swapping of the camera did not help, it is sequentially checked:

To replace the membrane (if there is such an option), the tanks are disconnected from the system, depressurized and untwisted.

As a rule, membrane flanges are placed on the same side as the connecting pipes; in some cases, rubber is held by additional fasteners that also need to be removed.

The membrane is taken out through a special hole, after which the tank is washed from dirt and corrosive deposits and dried.

The new membrane is inserted in the reverse order, its flange is twisted after assembling all additional fasteners.

The repaired tank is connected to the system, if necessary - with the adjustment of the initial and working pressure.

The visual signs of tank malfunctions in DHW systems are generally similar: in water heating modes, the pressure growth indicators are close to emergency, water is often discharged through the safety valve.

The procedure is also unchanged: if problems are detected, the presence and pressure of air in the external chamber of the tank and the integrity of the membrane are sequentially diagnosed.

Damaged membranes in DHW tanks are replaced to meet the need for higher pressure food grade rubber products.

Now you know the answer to the question of an expansion tank for closed-type heating installation pressure, principles of operation, malfunctions and ways to eliminate them.

Frequent malfunctions and measures for their elimination

The flame of the burner does not reach its maximum power during the operation of the boiler

This malfunction of the gas boiler may occur due to incorrect pressure settings in the heating system. Also, such a breakdown can also occur with a faulty gas valve modulator.Another reason for its occurrence is the breakdown of the diode bridge.

Remedy: it is necessary to adjust the system parameters using the boiler operating instructions.

Boiler starts but stops immediately

This malfunction of the gas boiler may occur due to low pressure in the gas pipeline.

Remedy: it is necessary to adjust the gas pressure downwards to 5 mbar.

Weak heating of the coolant in the heating system

Weak heating of the coolant in the heating system

Remedy: Perform a pressure test on the gas valve. It is highly likely that the min and max values have failed.

modulation not working

To eliminate the problem, the valve must be replaced.

Temperature sensor values become inaccurate

To fix this problem, replace the old sensor with a new one.

Weak heating in the hot water system

The cause of this malfunction may be the incomplete opening of the three-way valve. In some cases, its appearance is associated with a breakdown of such a valve. In order to accurately establish that the cause of the malfunction lies precisely in the valve, it is necessary to wait a while until the system cools down. Then the shut-off valves of the heating system will need to be closed. When this is done, the boiler should be switched on to hot water mode. A confirmation of a valve malfunction will be heating in the heating system.

When the unit is ignited, "pops" are heard

Noise can appear for several reasons:

- Insufficient gas pressure;

- The changed distance from the gas supply to the igniter due to careless transportation of the Baksi boiler.

To eliminate this malfunction, you should adjust the gap. It should be set within 4–5 mm.

How to adjust the gap between the burner and the igniter

The temperature of the coolant in the circuit has dropped sharply

The main cause of this malfunction is clogged filters. They need to be removed and cleaned. In some cases, they may need to be replaced. The reason may be damage to the radiators or pipes. If these heating systems are frozen or clogged, then repair is necessary in this case. The area where the defect was found should be cleaned or replaced.

How to clean the primary heat exchanger with your own hands

The pipes of the device should be connected to the heating pipes of the Baxi boiler

Within a few hours on the device, we switch in manual mode the direction of the flushing liquid. When two hours have passed, the device must be turned off. Next, turn off the tap to drain the water. Then you need to remove the hoses. But before that, you need to make sure that the liquid is glassed back into the device. Next, we connect the boiler to the system. After that, it must be filled with coolant. After cleaning the boiler, its parts must be cleaned of scale. And this will eliminate the clogging of the system and its failure.

Do-it-yourself cleaning of the secondary heat exchanger (heating circuit)

Before installing the boiler, it is necessary to consult a specialist. You should also contact him if the boiler needs repair.Baksi gas equipment, like any other, has its own tensile strength, so at some point the boiler will need to be repaired.

Volume calculation

There is a very simple method for determining the volume of an expansion tank for heating: 10% of the volume of coolant in the system is calculated. You should have calculated it when developing the project. If these data are not available, you can determine the volume empirically - drain the coolant, and then fill in a new one, measuring it at the same time (put it through the meter). The second way is to calculate. Determine the volume of pipes in the system, add the volume of radiators. This will be the volume of the heating system. Here from this figure we find 10%.

Shape may vary

The second way to determine the volume of an expansion tank for heating is to calculate it using the formula. Here, too, the volume of the system will be required (indicated by the letter C), but other data will also be needed:

- the maximum pressure Pmax at which the system can operate (usually take the maximum pressure of the boiler);

- initial pressure Pmin - from which the system starts work (this is the pressure in the expansion tank, indicated in the passport);

- expansion coefficient of the coolant E (for water 0.04 or 0.05, for antifreezes indicated on the label, but usually in the range of 0.1-0.13);

Having all these values, we calculate the exact volume of the expansion tank for the heating system using the formula:

The formula for calculating the volume of an expansion tank for heating

The calculations are not very complicated, but is it worth messing with them? If the system is open type, the answer is unambiguous - no. The cost of the container does not depend very much on the volume, plus you can make it yourself.

Expansion tanks for closed-type heating are worth counting. Their price depends heavily on volume.But, in this case, it is still better to take it with a margin, since insufficient volume leads to rapid wear of the system or even to its failure.

If the boiler has an expansion tank, but its capacity is not enough for your system, put the second one. In total, they should give the required volume (the installation is no different).

What will cause the insufficient volume of the expansion tank

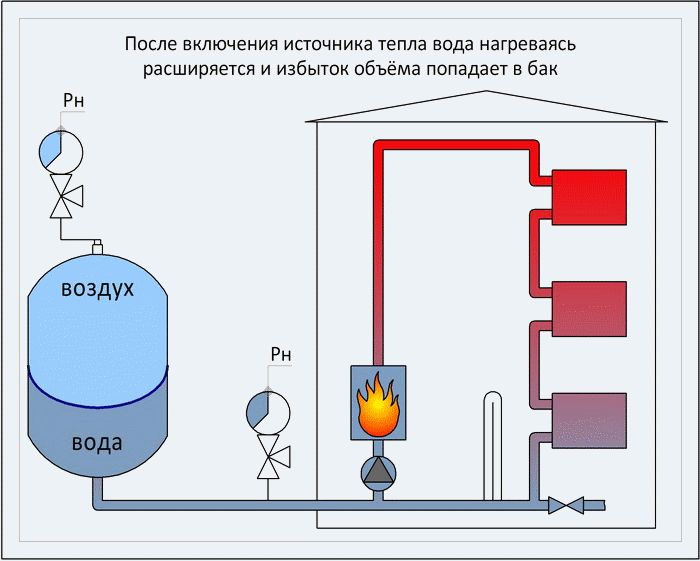

When heated, the coolant expands, its excess is in the expansion tank for heating. If all the excess does not fit, it is vented through the emergency pressure relief valve. That is, the coolant goes into the sewer.

The principle of operation in a graphic image

Then, when the temperature drops, the volume of the coolant decreases. But since there is already less of it in the system than it was, the pressure in the system drops. If the lack of volume is insignificant, such a decrease may not be critical, but if it is too small, the boiler may not work. This equipment has a lower pressure limit at which it is operable. When the lower limit is reached, the equipment is blocked. If you are at home at this time, you can correct the situation by adding a coolant. If you are not present, the system may unfreeze. By the way, working at the limit also does not lead to anything good - the equipment quickly fails. Therefore, it is better to play it safe and take a slightly larger volume.

What is an expansion tank for?

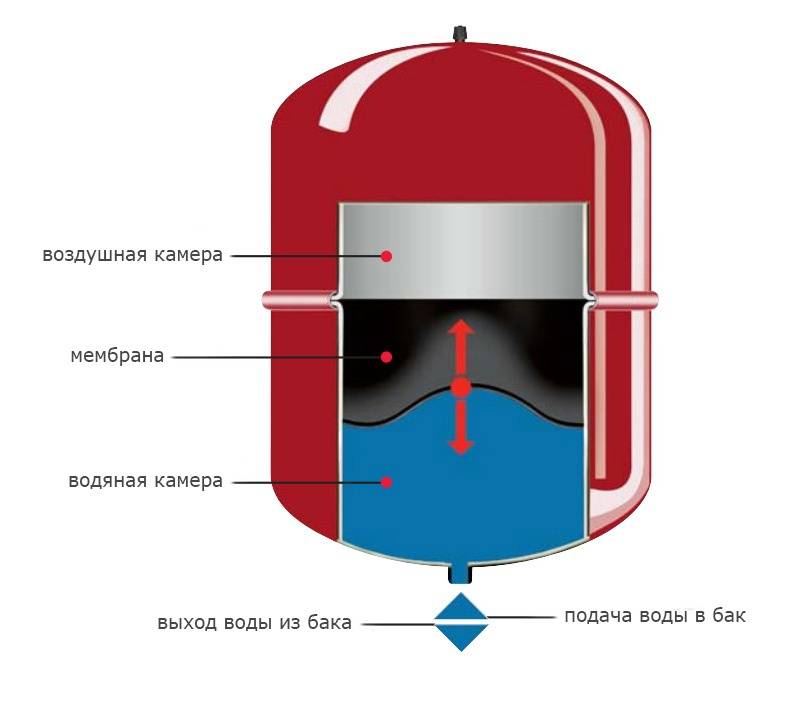

In the process of heating, water tends to expand - as the temperature rises, the volume of the liquid increases. Pressure begins to rise in the heating system circuit, which can have a devastating effect on gas equipment and pipe integrity.

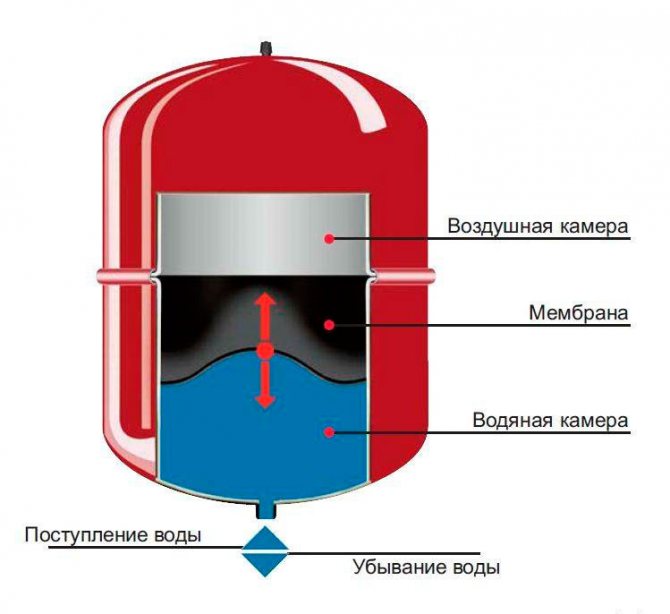

The expansion tank (expansomat) performs the function of an additional reservoir into which it squeezes out the excess water formed as a result of heating. When the liquid cools and the pressure stabilizes, it returns through the pipes back to the system.

The expansion tank performs the function of a protective buffer, it dampens the water hammer that is constantly formed in the heating system due to the frequent turning on and off of the pump, and also eliminates the possibility of air locks.

To reduce the likelihood of air locks and prevent damage to the gas boiler by water hammer, the expansion tank should be mounted in front of the heat generator, on the return

There are two different versions of damper tanks: open and closed types. They differ not only in design, but also in the way, as well as in the place of installation. Consider the features of each of these types in more detail.

Expansion tank open

An open tank is mounted at the top of the heating system. The containers are made of steel. Most often they have a rectangular or cylindrical shape.

Typically, such expansion tanks are installed in the attic or attic. Can be installed under the roof

Be sure to pay attention to the thermal insulation of the structure

In the structure of the open-type tank there are several outlets: for water inlet, cooled liquid outlet, control pipe inlet, as well as an outlet pipe for coolant outlet to the sewer. We wrote more about the device and types of an open tank in our other article.

Functions of an open type tank:

- controls the level of the coolant in the heating circuit;

- if the temperature in the system has decreased, it compensates for the volume of the coolant;

- when the pressure in the system changes, the tank acts as a buffer zone;

- excess coolant is removed from the system into the sewer;

- removes air from the circuit.

Despite the functionality of open expansion tanks, they are practically not used anymore. Since they have many disadvantages, for example, a large container size, a tendency to corrosion. They are installed in heating systems that operate only with natural water circulation.

Closed expansion mat

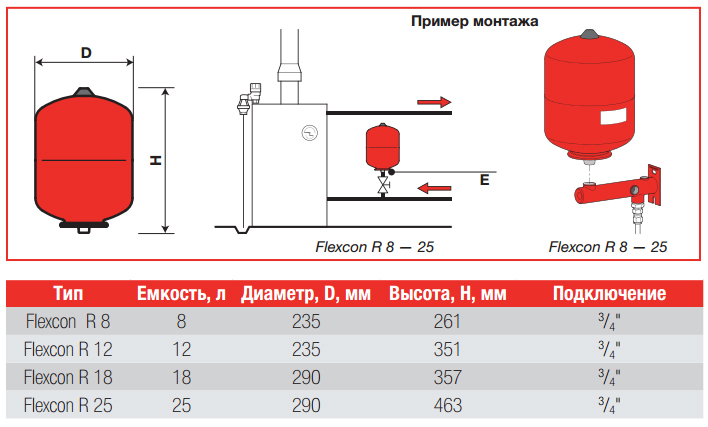

In closed circuit heating systems, a membrane-type expansion tank is usually mounted; it is optimally suited for any type of gas boiler and has many advantages.

Expanzomat is a hermetic container, which is divided in the middle by an elastic membrane. The first half will contain excess water, and the second half will contain ordinary air or nitrogen.

Closed heating expansion tanks are usually painted red. Inside the tank is a membrane, it is made of rubber. A necessary element to maintain pressure in the expansion tank

Compensation tanks with a membrane can be produced in the form of a hemisphere or in the form of a cylinder. Which is quite suitable for use in a heating system with a gas boiler. We recommend that you familiarize yourself with the features of the installation of closed-type tanks in more detail.

Advantages of membrane types of tanks:

- ease of self-installation;

- resistance to corrosion;

- work without regular topping up of the coolant;

- lack of contact of water with air;

- performance under high load conditions;

- tightness.

Gas attachments are usually equipped with an expansion tank. But not always the additional tank from the factory is set up correctly and can immediately start heating.

What is it for

The installation is most often used for water supply needs.

But no less relevant is the use of a hydraulic accumulator for heating systems (how to expel an air lock).

This mechanism serves to take on an excess volume of liquid substance and, thereby, reduce excess pressure in the line, and, if necessary, return water back to the system to maintain the optimal pressure of the working medium.

In fact, there are three goals, and they are all interconnected:

- The ability to accumulate the volume of liquid necessary for the normal operation of the heating system.

- By accumulating water, requisition excess pressure.

- Suppression of water hammer in the heating system (how to bleed air through the Mayevsky tap is written here). It is for this reason that even the smallest fixtures have a rather large thread.

Thanks to the design capabilities of the accumulator (expansion tank), it is possible, in automatic mode, to normalize the pressure of the coolant in case of a change in temperature indicators.

Read on this page what electrodes you need to buy for welding aluminum with an inverter.

Rules for constructing closed contours

For open-type hydraulic systems, the issue of pressure regulation is irrelevant: there simply are no adequate ways to do this.In turn, closed heating systems can be configured more flexibly, including in relation to the coolant pressure. However, first you need to provide the system with measuring instruments - pressure gauges, which are installed through three-way valves at the following points:

- in the collector of the security group;

- on branching and collecting collectors;

- directly next to the expansion tank;

- on mixing and consumable devices;

- at the outlet of circulation pumps;

- at the mud filter (to control clogging).

Not every position is absolutely mandatory, much depends on the power, complexity and degree of automation of the system. Quite often, the piping of the boiler room is arranged in such a way that the parts important from the point of view of control converge in one node, where the measuring device is installed. So, one pressure gauge at the pump inlet can also serve to monitor the condition of the filter.

Why do you need to monitor pressure at different points? The reason is simple: the pressure in the heating system is a collective term, which in itself can only indicate the tightness of the system. The concept of the worker includes static pressure, formed by the effect of gravity on the coolant, and dynamic pressure - oscillations that accompany the change in operating modes of the system and appear in areas with different hydraulic resistance. So, the pressure can change significantly when:

- heat carrier heating;

- circulation disorder;

- turning on the power supply;

- clogging of pipelines;

- the appearance of air pockets.

It is the installation of control pressure gauges at different points in the circuit that allows you to quickly and accurately determine the cause of failures and begin to eliminate them.However, before considering this issue, you should study: what devices exist to maintain the working pressure at the desired level.

Installation rules

When installing a hydraulic accumulator, you must strictly adhere to certain rules.

The first thing to do is to select a site in the heating network where the device will be mounted.

Experts strongly advise mounting the expansion tank in the return pipe through which chilled water circulates.

Important! The unit must be installed before the pumping equipment. In order to ensure maximum protection of the network from sudden pressure drops of the working fluid, a safety valve must be installed at the outlet of the heating device.

In order to ensure maximum protection of the network from sudden pressure drops of the working fluid, a safety valve must be installed at the outlet of the heating device.

The valve has the same purpose as the hydraulic accumulator, but it is able to withstand higher pressure drops.

The expansion tank normalizes the operation of the heating system with slight surges in water pressure.

Before proceeding with the installation, you need to select the installation location of the device. Do not forget that the device must be freely accessible, nothing should prevent you from getting to the air compartment control valve.

Shut-off and control valves cannot be installed between the expansion tank and the pump; they can significantly modify the hydraulic resistance.

In the room where the accumulator will be located, the air temperature must be at least 0 degrees. The surface of the device is not allowed to be exposed to mechanical loads.

The actuation of the reducer for removing air from the heating system of a private house must be carried out in accordance with the parameters of the heating system.

If you follow all the above recommendations, you will be able to install an expansion tank on your own, without outside help.

Why do we need a hydraulic accumulator in heating systems, how to install and configure it - we suggest watching it in the video.

Conclusion

The expansion tank is the most important additional element in any heating system. If for open systems with gravitational circulation it is enough to install a simple open tank at the top point, then for complex closed systems installation of industrial models is required.

These containers are hermetically sealed. During the production process, air is pumped into the housing to maintain the pressure necessary for the normal functioning of forced circulation systems. You can set the desired pressure indicators yourself using a pressure gauge and a conventional automobile compressor.