- 10 Unusual Uses for Cable Ties

- hang curtains

- tie plants

- Lock the locks on the bag

- Close cupboard and cabinet doors

- Hang more clothes in the closet

- Make a key ring

- Make a smartphone stand

- Make a glass handle

- Blow soap bubbles

- Classification of cable ties

- Types of ties according to the material of manufacture

- Plastic bandages

- Metal ties

- Types of bandages according to the possibility of their reusable use

- Other types of bandages

- Work order

- Cable ties - types, types, characteristics and recommendations for choosing modern plastic ties

- What are cable ties

- Varieties of cable ties

- Areas of use

- Semi-dry screed

- Varieties of cable ties

- heat resistant

- mounting hole

- Anchor

- Powerful

- double lock

- Dowel

- Dowel platform

- ball grip

- split lock

- Venues

- Factors that reduce the service life of the CS

- Technology: important features

10 Unusual Uses for Cable Ties

31.05.2018

31.05.2018

It is believed that the champion of usefulness in the house is duct tape. Can you use it to hang curtains or blow soap bubbles? We don't think. But we know how to do it using clamps. Today we have prepared 10 life hacks for using cable ties. These tricks will come in handy at home, in the garden or on a trip.

hang curtains

Accidentally pulled the curtain in the bathroom and broke a couple of hooks? They can easily be replaced with cable ties. Simply slide the tie through the hole in the canvas and select the required loop size. Ready.

Another situation: you found out that relatives are coming to visit you. We need to quickly make the apartment more beautiful and comfortable. You decide to hang a new curtain, but when you take the fabric out of the package, you find that there are no hooks in the kit. No problem. Nylon ties and in this case will come to the rescue.

tie plants

Forget about the ropes that were entangled with indoor flowers. Fasten the stems with clamps. It will take less time, because you do not have to knit knots.

Use the same tying method in the country - install vertical supports and attach cucumbers, tomatoes, bush branches to them.

Lock the locks on the bag

Are you going on vacation? Nylon straps keep your belongings secure while you travel

It doesn't matter if you check in your luggage at the airport or just go on crowded excursions with a backpack, the locks will not unfasten. Your gadgets, money and other things will be intact

Close cupboard and cabinet doors

When a child begins to crawl and then walk, parents rush to block all cupboards available to him, especially kitchen cabinets, where knives, forks, and cereals lie. Move the necessary items higher, and hide everything unnecessary in a locker and put a collar on the furniture handles. Now the child will not open the door.

Also use clamps when transporting furniture.

Hang more clothes in the closet

If you have so many clothes that you can’t hang additional hangers on the crossbar, place them on top of each other. Here again, clamps come in handy. Place a coupler on one hanger, and hang the other on this loop. Arrange clothes in 2-3 rows or more.

Make a key ring

Your key fob is broken and now the keys are hanging in your pocket? Until you find a suitable ring, a screed will help fix the situation. It will securely fix the keys, and you will not lose any of them.

Make a smartphone stand

Only 2 plastic clamps will replace the phone stand. You can even adjust the angle of the gadget. Now in the country, on the train or at the dinner table, it will be convenient to watch movies and news releases.

Make a glass handle

On a hike, there may not be mugs with a handle nearby. And here you are pouring hot tea into a glass. It is absolutely impossible to drink at the same time: no matter how you take it, it burns your fingers. With the help of clamps, you can easily turn a glass into a mug.

Use this method when traveling. After all, you will not always have a mug or a cup holder with you.

Blow soap bubbles

Cable ties allow not only to do something useful and simplify your life, but also to entertain the child. Dilute the soap solution, then make a small loop out of the clamp and blow bubbles.

The same device will help if you bought a bottle and accidentally broke the inflation stick.

We considered 10 options for non-standard use of clamps. And now a bonus life hack: how convenient it is to store clamps of various colors. Just gather them into bundles and secure with zip ties.

Here are some nylon ties we used in our hacks.

Clamp yellow, 2.5 × 100 mm

More

Clamp red, 3.6 × 300 mm

More

Collar blue, 3.6 × 200 mm

More

Clamp green, 2.5 × 150 mm

Find out more Think of other interesting uses for zip ties. Connect children to the process, fantasize and make life better.

Classification of cable ties

Bandages differ in width, length, material of manufacture, type of locking systems.

The wider the clamp, the more reliable it is, but also more expensive. The longer the product, the thicker the wire harness can be assembled.

Types of ties according to the material of manufacture

Depending on the material, the following types of products are distinguished: plastic and metal.

Plastic bandages

Two types are produced: polyamide, or nylon, and polyethylene.

Advantages of polyethylene clamps:

- operating temperature range – from -40 to 80°С;

- cheaper than nylon counterparts;

- more flexible, so it is more convenient to work with them.

Disadvantages of polyethylene clamps:

- their lock connections are less reliable than those of nylon;

- the plasticity of the material is not only an advantage, but also a disadvantage of the product, because this property in some cases can make installation difficult (the tail of the fastener is more difficult to push into the lock).

Attention! An ordinary plastic clamp can only be used indoors, as exposure to ultraviolet radiation quickly destroys the material. For outdoor wires, a special type with the addition of carbon powder is used.

This additive makes plastic less sensitive to ultraviolet radiation.

For outdoor wires, a special type is used with the addition of carbon powder. This additive makes the plastic less sensitive to ultraviolet radiation.

Metal ties

Made from stainless steel plate.Some types are available with an additional PVC coating to concomitantly protect the plate from aggressive environmental influences.

Advantages of metal type:

- the most tear-resistant;

- operating temperature range – from -80 to +500°С;

- do not support combustion;

- can be used both indoors and outdoors;

- resistance to moisture, chemicals, ultraviolet, vibration, radiation, etc.

Types of bandages according to the possibility of their reusable use

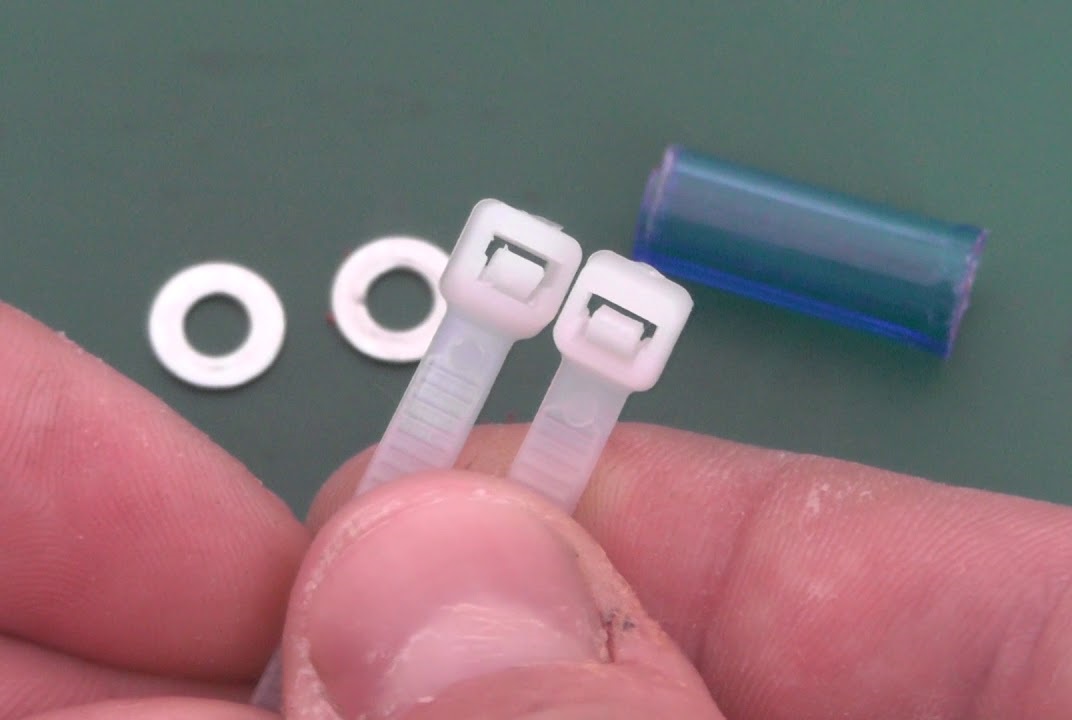

The collar is a disposable bandage with one-way travel, complete with one-piece locks. However, there are also universal options on the market with a reusable fastener.

Plastic disposable cable ties

Unlike disposable fasteners, they have two eyes, which allows them to be connected in a chain to create a collar of the desired length. In addition, such a chain, if necessary, can be quickly disassembled. These straps are used not only for electrical work, but also in everyday life for binding bulky objects. With their help, it is convenient to shorten the wires, winding the excess part, while fixing it with a universal clamp. Thanks to this, the specialist’s workplace will be neat, and an extra piece of cable will not get under your feet.

Using a universal cable tie to shorten the wire

The category of reusable options also includes a collar with a Velcro lock. Products of this type are easy to use, securely fasten the conductors, and allow you to quickly add new cables to the bundle. Made from nylon or polyethylene. They are difficult to transfer cables in a bundle. In the construction market, you can purchase reusable bandages of different colors.

Also, a Velcro collar is used as a reusable bandage. Such a fixative is applicable to plastic products. When using them, you can quickly and reliably both connect and disconnect bundles of wires.

If a disposable tie is used, then, if necessary, disconnect the cables, it is simply cut with a knife.

Other types of bandages

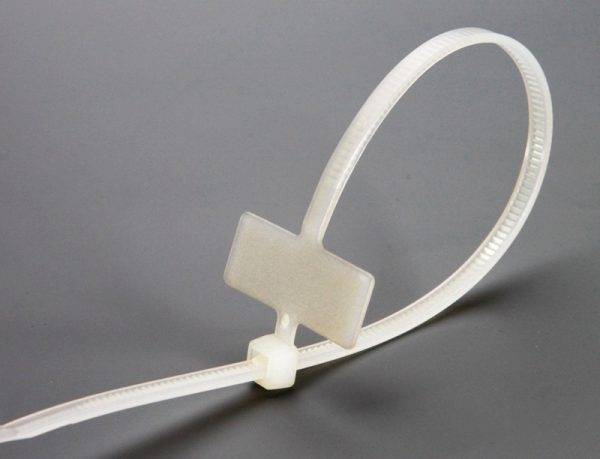

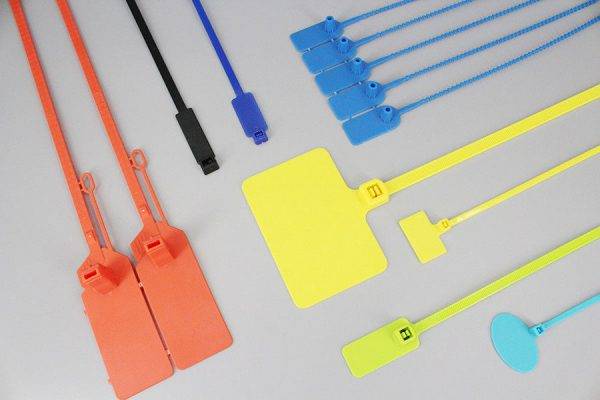

The industry produces clamps designed not only for tying wires into a bundle, but also for marking the bundles themselves. Marking can be done with different colored plastic bands.

Multicolored cable ties

Metal and plastic views can be additionally equipped with a small area on which text can be applied with a permanent marker, or information can be pasted using self-adhesive materials that have been previously printed with text. The platform itself is made in the form of a wrapper or a flag.

Bandages with areas for marking bundles

Work order

- Preparatory stage. The first step is to prepare the floor surface. To do this, it is cleaned of dust, as well as chemical and organic contaminants. A thorough inspection is carried out to identify and remove loose parts of the old concrete. Next, the floor is primed in 1 or 2 layers.

- Installation of beacons. With the help of a hydraulic level or a building laser, the zero point of the future subfloor is determined, marks are made on the walls of the room and beacons are installed on it.

- In order to increase the strength of a lightweight screed, a reinforcing mesh can be used.

- Preparation of a building mixture, which must be carried out in strict accordance with the required proportions.It should be remembered that in order to obtain a high-quality mixture, a large amount of water is not required, its content should not exceed 25% of the total volume of the solution. The resulting material must be used very quickly (for various types of mixture - from 0.5 to 1.5 hours)

- The solution is applied to the floor surface with a spatula, a rule or a vibrating screed is used to level it. Most of the materials used in the installation of a light screed have significant shrinkage. Therefore, when applying the building mixture on the floor surface, its layer thickness should be 1-1.5 cm higher than the installed beacons. The thickness of the lightweight screed should not be less than 3 cm.

- Within 2-14 days the screed dries up. All this time, its surface should be covered with polyethylene and regularly (every 12 hours) wetted with water.

Thus, the use of additional components in the solution is not associated with too significant financial costs, however, it can significantly reduce the mass of the concrete floor and, consequently, the load on the floors. In addition, this technology makes it possible to achieve an improvement in a number of technical characteristics of the screed and is quite simple to use it for self-repair of an apartment.

It should be remembered that a light screed is still inferior to traditional concrete in strength, therefore, in order to improve the performance of such a floor, it is necessary to apply a leveling layer of high-strength building mixture on its surface.

Cable ties - types, types, characteristics and recommendations for choosing modern plastic ties

When it comes to working with wires and cables, sooner or later we start thinking about their proper layout and labeling. Cable ties already familiar to everyone are best suited for such work.

About 30 years ago, it was enough to connect everything correctly, but now there are aesthetic requirements for the installation of cables, and therefore it must be both functional and neat. In our article, we will try to understand in detail the issue of screeds.

What are cable ties

Now it is difficult to imagine a person who has never in his life had to deal with cable ties. If you fall into this category, you can look online for pictures of cable ties, or just go to a hardware store and buy a pack of them.

Ties are a very versatile and convenient fastening element, despite the fact that the price tag of the ties is very low. Usually it starts from 30-40 rubles for 100 pieces. and can reach up to 500, depending on the type and application.

The cheapest ones you can find on store shelves are nylon cable ties. They invented this method of fixing cables, and not only, back in the middle of the last century.

We must thank Logan, an American engineer who created a fairly simple but very useful thing.

This happened against the backdrop of work with underwater trays and aircraft. Such large equipment requires a lot of electronics, just like wires - the total length in this case is considered not meters, but kilometers.

At that time, ordinary wax thread was used during installation. As you might imagine, it was quite inconvenient.I had to tie it in a knot, which means that with the slightest changes it had to be cut and a new one used, which again is difficult to fasten.

If on the scale of a computer system unit or a small room this is not such a problem, then when working with large equipment, people had to think about a possible alternative.

The first to appear were white cable ties and black counterparts. This is because these colors were the easiest to work with nylon. Now in the store you can find ties for every taste and color, which is especially good for marking wire bundles. Along with new colors, new varieties appeared.

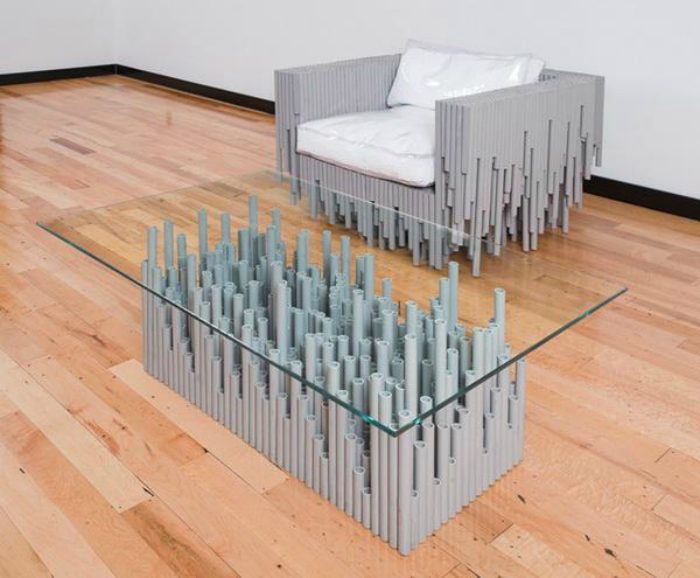

Varieties of cable ties

A lot has changed over the past 70 years, including the screed market. Now the variety lies not only in different colors or sizes, but also in the materials from which the screed is made. We are not yet talking about narrow areas of application, as is the case with pipe clamps, which also belong to screeds. The price of cable ties depends on all of the above.

Regular nylon ties can be up to 1.5 cm wide. In this case, the maximum load rises to an impressive 110-115 kg.

As you understand, in the case of cable installation, this is difficult to meet under normal conditions. Such ties are designed either for installation in the industrial sector, or for work in other areas of everyday life.

Areas of use

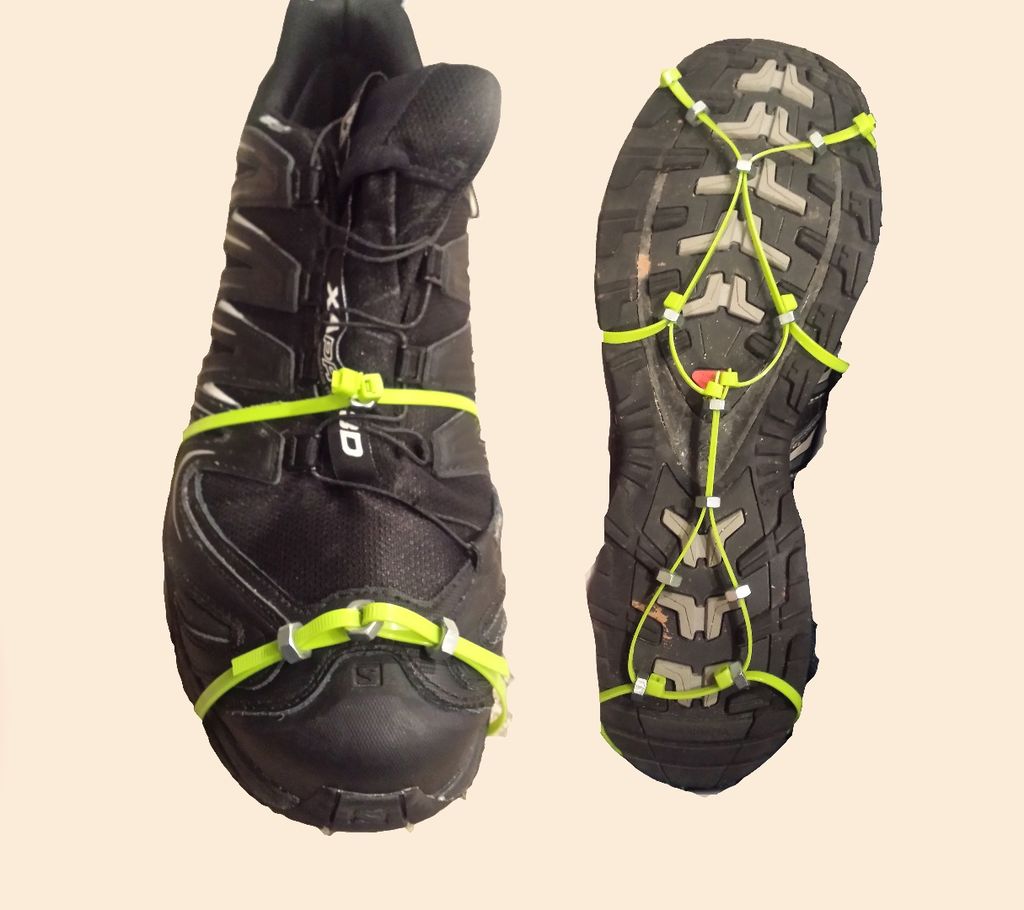

We have sorted out the dimensions of cable ties, and now let's talk about where they can be used. It is clear that the installation of wires and cables in the room and in technology is the most common way to use cable ties. But there are other options as well.

For example, you decide to use a mesh as a fence.It should be attached to the racks, but the method of attachment is up to you to choose.

Usually, nails were used for this if the fence posts were made of wood, or wire if the posts were made of steel. It will be easier to use screeds for outdoor work - installation is easier, and dismantling too. Why outdoors?

The thing is that the screeds also differ in conditions, for which they are intended. Outdoor screeds are more expensive because additional polymers were used in their creation, thanks to which the screeds can be easily exposed to heat, rain and frost.

You can use the most ordinary ties outside without any problems, they will just dry out relatively quickly and lose their elasticity. As a result, they will simply break.

Mounting a fence is just one of a huge number of options, the variety of which is limited only by your imagination and ingenuity.

After all, you can connect several small ties to secure one large bundle or cable. As you can see, screeds are a fairly flexible mounting tool.

Semi-dry screed

A semi-dry screed is mounted using a cement-sand mixture with fiber, plasticizers or other additives as a filler. Expanded clay may be present in such aggregate. Distinctive characteristics of this screed are the absence of a rough coating and the use of a specially prepared backfill. After installation, the screed must be completely dry and hardened. Since the finish coating is mounted on it.

This type of screed involves the use of a small amount of liquid necessary for the hydration process.Such a batch is not poured, but laid out on the previous layer. Such a screed withstands large vibration and dynamic loads, provides the necessary sound insulation. An additional layer of insulation allows you to increase heat savings. This screed is practically not subject to shrinkage, cracking or deformation.

In some situations, only a wet screed can be used, with heavy loads, vibrations, and other indoor conditions. At the same time, its alternative options are quite acceptable for city apartments, as they provide high-quality sound and noise insulation, and are quickly and easily mounted.

Varieties of cable ties

According to their purpose and operating conditions, CSs are divided into the following types.

heat resistant

Heat-resistant products made of polyamide are used where the ambient temperature can reach +1200C. Screeds with increased heating for a long time retain their performance.

mounting hole

The cable, covered with a tape with a mounting hole, is attached to the enclosing structures of buildings and structures with a screw, screw or dowel, depending on the surface material.

Anchor

The tape lock is equipped with a hook - an anchor. With this detail, the screed is hooked to the metal profile no more than 2 mm thick.

Anchor tie

Anchor tie

Powerful

The clamping strip is made of stainless steel. There are no teeth on the tape. Fixation in the lock is carried out due to the friction force of the metal parts of the screed.

double lock

COP is made of high density nylon. Products have a high bearing capacity. The double lock is strong and resistant to adverse weather conditions.

Dowel

A hollow protrusion with a relief surface is made on the tape - a dowel.It is inserted into the mounting hole of a concrete or brick structure. Then a plastic rod is driven into the dowel.

Dowel platform

The fastening consists of a locking tape with a platform and a screw rod. After installing the dowel, a platform is screwed onto it. Then they cover the cable with a tape threaded through the openings of the site. The strip is pulled through the locking ring.

KS with a platform for the dowel

KS with a platform for the dowel

ball grip

These are reusable products. The screed strip is a periodic profile in the form of balls. The lock ring has a narrow slot. The balls are threaded into the hole and the thin part is shifted into the slot. To remove the fastening ring from the cable, perform the steps in reverse order.

split lock

A lever lock is installed on the lock ring. By pressing on it, the strip is released from capture. Ties with such a lock are used to fix cables of large diameter.

Tape with detachable lock

Tape with detachable lock

Venues

Products have mounting holes and openings for the tie-down band. The platforms are fixed with dowels to the walls along the wiring line. After that, it remains to pass the wire ties through the openings and tighten them.

Factors that reduce the service life of the CS

- Temperatures of +850C and above destroy nylon. In the cold, the screed becomes brittle and breaks easily;

- Polymer clamps in conditions of high humidity absorb moisture and lose their bearing capacity;

- Ultraviolet does not destroy only the black polymer. Multi-colored screeds are not installed on the street;

- COPs do not tolerate constant vibration of various equipment. Over time, the screeds are destroyed;

- When the calculated load is exceeded, the tie bands are torn;

- The aggressive environment of acidic or alkaline vapors adversely affects the plastic and leads to the complete destruction of the screed.

With the help of plastic ties, bundles of wires and cables are formed, which can be compactly placed both inside and outside buildings and structures. The low cost of products led to the fact that when laying electrical networks, they abandoned other expensive and inconvenient fasteners. Quick installation and dismantling of fixing fittings significantly save the cost of installation and repair of wire communications.

Technology: important features

When point beacons are installed for pouring the floor, a certain sequence of actions should be followed:

- The minimum height of the screwed-in self-tapping screws must not be less than the thickness of the solution. At the same time, their average step should be 50 cm.

- The distance from the nearest beacons to the wall is 30 mm.

- From one beacon (control point) to the second from above, a level is set, according to which the required height is set. Similarly, all other elements in the room are fixed.

- The pitch of the screws can be increased by using a two-meter level. True, and experience in pouring a self-leveling floor along beacons with such a distance should be available.

- The height of the screws between the extreme elements is adjusted by eye, to the level of a stretched cord or fishing line.

The floor beacon must not remain in the solution after curing. This applies to cases and the location of their upper points at the level of the solution. Subsequently, if necessary, grinding, they will create a bunch of problems.

After studying all the recommendations, everyone will know how to use beacons when pouring the floor.Their high-quality execution will result in a perfectly flat surface over the entire area in the room. The use of beacons for self-leveling floor is not a prerequisite for installation. But in the end, they contribute to obtaining a base adjusted to all parameters.

If there is no self-confidence, then such work should be entrusted to specialists. Payment for services will be more pleasant than the subsequent dismantling of the entire self-leveling floor structure.

As practice shows, even a self-leveling mixture must first be evenly distributed over the surface of the base. And the self-leveling effect will work only on a small area of \u200b\u200bthe mixture, that is, if you accidentally drop a solution, it will dissolve on its own in the total mass, unlike cement-sand mortars.

Since the self-leveling floors begin to dry out quickly enough, when pouring, you will not have time to measure the level, it has spread enough or you need to remove the excess solution a little more. It is for this reason that the use of beacons is recommended.

After installing the beacons, they proceed directly to pouring the floor, which means that the priming of the floor, the installation of waterproofing and other preparatory work of the base must be carried out in advance.

Determine the highest point of the floor, set at this point a benchmark with a central pin at a height of two millimeters. This will be the required height of the self-leveling floor. We wrote more about rappers in this article.

Perhaps it is worth dwelling separately on the method of finding the highest point of the base.

There are three main ways:

- The easiest, fastest and most accurate way is to use a laser level.It will help not only to quickly determine the highest point of the floor, but also help to cope with other benchmarks.

- Use a liquid level consisting of two glass vessels connected by a long silicone tube. The system is filled with water in such a way that there is water in the middle of the vessel. This method is longer and requires at least two people. The accuracy is comparable to a laser level.

- You can use the usual liquid level: the longer it is, the easier it will be to measure. The method is long and has a fairly large percentage of error.

All beacons for the self-leveling floor, exposed around the room, are adjusted by the central pin to the same height as the first one. A level will also help you with this task. Thus, you will get a plane along the lower level of the central pin, along which you want to fill the floor.

If some of the benchmarks show a pour height of more than five millimeters, then consider pouring part of the floor the first time and the entire floor the second time.

For example, the benchmark showed a height of nine millimeters at the far wall, and in the middle of the room the height reaches four millimeters.

In this case, you can fill half the room with the first layer.

After the mortar has been poured and it has been verified that it is at the required level, the benchmarks are removed so that the self-leveling compound can fill the places of their installation. Before pouring the second layer, it is recommended to check the height again over the entire area of the base.

Recommendation: Do not forget to remove the beacons before the solution dries. Otherwise, the remaining holes in the floor may cause water to penetrate into the base. Filling them with a solution after the floor has dried will not be able to create the same wear-resistant properties of the floor as a whole as a solid cast surface.