- Why are all indicators flashing

- Broken electronic board

- Self drain broken

- Wrong installation

- Overload

- Pump problems

- Heating element failed

- Broken engine

- Why does the error appear, what does it mean?

- Where to look and how to fix the problem?

- How to reset the error?

- How does it all work?

- Causes and signs of failure

- Why does the board break

- Meaning of indicators and codes

- Error codes indesit w 105 tx

- Common manifestation of error

- Frequent failures of Indesit brand washers

- Errors related to the ECU board

- Meaning of the code

- How and under what circumstances does it manifest itself

- Finding and eliminating causes

- How to eliminate?

- Other Causes of Program Crash and Flashing Lights

Why are all indicators flashing

An automatic washing machine is a complex electromechanical device. Washing in it is carried out by circulating water with detergent and mixing the contents of the drum. Monitoring and control of operating modes is carried out by several sensors and an electronic unit, which, in case of deviation from the permissible parameters, turns off the device. But not every emergency stop means a breakdown. Consider the main reasons why the lights flash in the Indesit washing machine, and washing is not carried out.

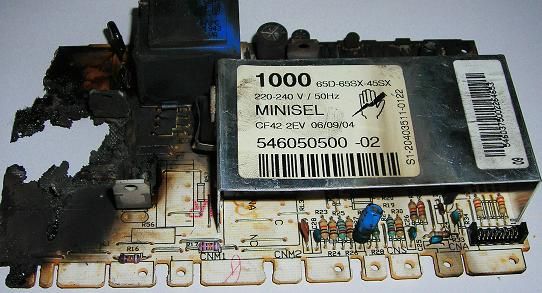

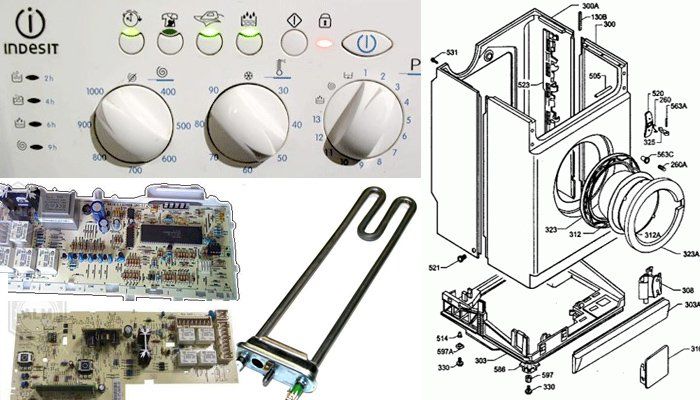

Broken electronic board

One of the reasons for stopping the washing machine is a breakdown of the electronics.There are many parts in the control unit that can burn out or work incorrectly. This leads to the cessation of the transmission of electrical impulses and the failure of automation. To carry out the repair of such a node, you must have certain knowledge.

Causes of malfunctions of the electronic board:

- poor quality parts;

- damage to tracks that transmit electrical signals;

- moisture ingress;

- voltage drops;

- violation of the quality of contacts;

- disconnection from the mains during washing.

Self drain broken

In this case, the machine drains water slowly or does it constantly. If the user has already installed the program, then the electronics will turn it off and show a fault code or all indicators will blink.

The main causes of the malfunction:

- flexible drain hose kinked;

- the outlet strainer is clogged with dirt;

- drain valve malfunction;

- breakdown of the drain pump;

- program crash.

Wrong installation

The washing machine is connected by hoses to the water supply and sewerage. Incorrect connection of them may cause spontaneous removal of water or inflow. The instructions for each device indicate the permissible parameters for the location of these elements.

Pay attention to the horizontal position of the machine. Neglect of this requirement leads to increased noise during operation and premature failure.

Overload

Each washing machine is designed for a certain amount of laundry. Underload or overload adversely affect the operation of the device. Modern devices equipped with imbalance sensors react to incorrect loading by stopping, and an error code is displayed.

In machines without such protection, overloading will not stop washing, but there will be increased noise, vibration, increased wear on the support bearings and shock absorbers.

Pump problems

The self-diagnosis system signals if there are problems with the drain pump: the program is reset, an error code is displayed. You can guess about the breakdown if you listen to the operation of the pump. If it makes a lot of noise or there is no sound, then repair is required.

Simple faults are easily corrected by a user familiar with the tools. It is possible that the pump is clogged, in order to clean it, you will have to remove it and inspect it. If there is no blockage, and power is supplied to the contacts, replacement is required.

Heating element failed

Water, to improve the quality of washing, is heated. A tubular electric heater (TEN) is responsible for this. This element can also fail. Burnout or insulation failure is detected by the diagnostic system, which includes flashing indicators.

Checking the heating element is simple - you just need to get to it and measure the resistance by disconnecting the wires. If the device shows zero - inside the circuit, an infinitely large value - open. Insulation breakdown is determined by checking the conductivity between the case and the heater contacts.

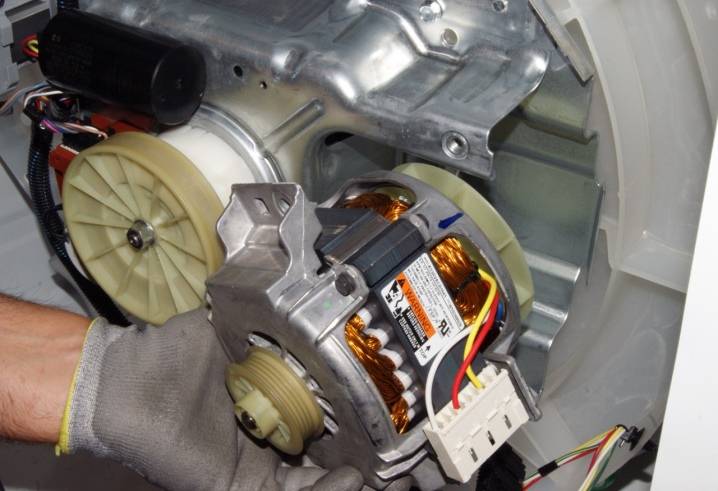

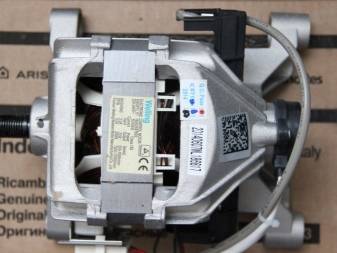

Broken engine

Without an engine, no washing in an automatic washing machine is possible. If a malfunction occurs, the diagnostic system will notify you of this.

Trained users can independently check the reliability of the connection, the condition of the brushes, or replace the entire motor. In order not to get confused during assembly, photograph each stage of dismantling, then the reverse process will be facilitated.

Why does the error appear, what does it mean?

If the Indesit washing machine has stopped draining water, then error f05 may appear on the screen. This means a malfunction in the drain system. What can go wrong? Option two:

- drain pump (most likely failure);

- water level sensor (pressostat).

If the water sensor malfunctions, the following happens: the pump pumps water out of the tank, the drain process is completed, but the pressure switch does not generate a signal that there is no water in the machine. As a result, the program hangs and an error appears on the display.

Where to look and how to fix the problem?

The first thing we do when error f05 appears is to eliminate all kinds of blockages throughout the entire drain path. To check the drain filter, at the bottom of the Indesit washing machine we find a small door or panel and open it. Behind it you will see a cover, which must be carefully turned counterclockwise and pulled out by pulling it towards you. Do not forget to place a large rag before unscrewing, which will absorb the rest of the waste water flowing from the tank.

The filter must be inspected and rinsed well with tap water. If it turned out to be relatively clean, and no blockages were found, we proceed to cleaning the drain hose that goes from the machine to the sewer branch. For this you need:

- prepare a bucket for waste water;

- loosen the clamp holding the drain hose on the sewer branch;

- lower the hose into a bucket to drain the remaining water;

- take out the drain filter;

- unscrew the bolt that holds the pump to the housing;

- now the Indesit machine needs to be put on its side;

- from the bottom we take out the pump;

- loosen the clamp on the hose;

- take the hose out of the body;

- we wash the hose;

- assemble the machine in reverse order.

You can immediately check for blockages in the drain pipe by disconnecting it from the pump and tank. We rinse it under water and install it in place. If the drain system also turned out to be without any major blockages, then do not rush to assemble the machine, but immediately inspect the pump. It also needs to be disassembled and cleaned, and possibly replaced with a new one. Detailed instructions for this work are described in the article on how to clean the drain pump.

After checking the drain system and pump, it is necessary to run the machine in test mode to check the troubleshooting. If error F 05 appears again, then you need to look for a water level sensor. Pressure switch in Indesit washing machine located under the top cover of the washing machine, it can be removed easily, you just need to unscrew the two bolts on the back of the case. On the side wall you will see a round piece, from which two wires and one small hose go.

Do not rush to immediately change it to a new one, you must first check the pressure switch for operability. The fact is that the wire contacts or the hose through which pressure is supplied from the tank to the pressure switch may be damaged. After checking all the details and the pressure switch itself, we assemble the machine and start the test mode.

So, error f05 is an error associated with the drain system of the Indesit washing machine, including the pump and pressure switch. A careful and phased inspection of all components in most cases will help you deal with the problem yourself. Happy repair!

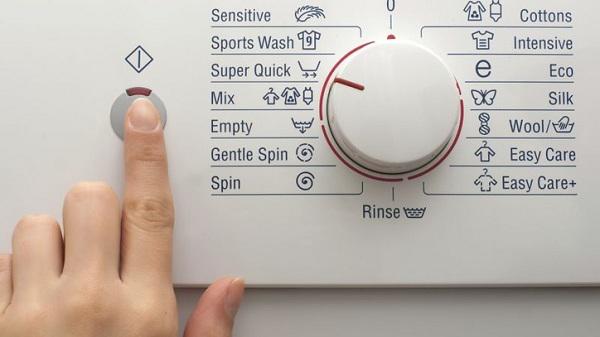

How to reset the error?

The need to reset the program in the Indesit unit often arises. Users sometimes simply make mistakes when choosing buttons, often want to place a forgotten item of clothing for washing at the last moment, and sometimes they suddenly find that they have loaded a jacket into the tank with documents in their pocket

In all these cases, it is important to interrupt the work cycle and reset the running mode of the machine.

The most common method of resetting a program is to reboot the system. However, this method is used if the unit does not respond to commands and freezes. In other cases, we do not recommend such an emergency method, since the control board, and the entire electronics of the machine as a whole, will be under attack. Therefore, we do not recommend taking risks, but using a safe reset of the work cycle:

- press the "start" button for 35 seconds;

- wait until all the lights on the device panel turn green and then turn off;

- check if washing is stopped.

If the mode is reset correctly, then the unit "falls silent", and its lamps on the panel begin to flicker, and then go out. If after the indicated operations there is no flickering and silence, then this means that the machine is faulty - the system shows an error. With this outcome, a reboot is indispensable. The reboot is done as follows:

- set the programmer to the 1st position;

- by pressing the stop / start button, holding it for 5-6 seconds;

- disconnect the unit from the power source by unplugging the power cord from the socket;

- Reconnect the power supply and run a test wash.

If the device does not respond to the turn of the programmer and the “start” button, then you will have to act more decisively - immediately unplug the cord from the outlet. But it is safer to carry out preliminary manipulations 2-3 times. Not forgetting at the same time that when the unit is suddenly disconnected from the network, we risk damaging both the control board and the electronics of the machine as a whole.

Reloading is used in the most extreme cases.If the forced stop of the cycle is caused by the need to urgently remove a document or other thing that accidentally got there from the drum, you should stop the process as soon as possible, open the hatch and remove the water

It is important to understand that soapy water, heated to 45-90 degrees, soon oxidizes the elements of microcircuits in electronic devices and destroys microchips on cards. In order to remove an object from a drum filled with water, the following operations should be performed:

- pause the cycle according to the previously shown scheme (hold down the “start” button until the LEDs on the panel blink);

- set the programmer in a neutral position;

- set the “drain only” or “drain without spin” mode;

- press the start button.

With correctly performed operations, the unit immediately stops the cycle, drains the water, and removes the blockage of the hatch. If the device does not drain the water, then you have to act forcibly - unscrew the garbage filter located at the bottom of the case behind the technical hatch (it is unscrewed counterclockwise). Do not forget to place a suitable container under it and cover the place with rags, as up to 10 liters of water can leak out of the device.

Washing powder dissolved in water is an active aggressive environment that negatively affects the elements and parts of the unit. In some cases, their independent replacement is possible. But if the breakdown is complex or the device is still under warranty, we strongly recommend that you take it to the official warranty workshop, where they will perform a free professional repair of the machine.

The fix for error F03 is presented in the following video.

How does it all work?

Despite the forced nature of the operation, it will not harm the system of the machine at all.Firstly, the program is developed and configured by the manufacturer using special technologies. Secondly, such an “examination” is much safer and more informative than depressurizing the machine with subsequent disassembly and inspection. Thirdly, the service test works faster and more accurately narrows down the range of possible faults. Turning on the diagnostic program with your own hands is simple.

- Set the gear selector to the first position and press the "Start" button.

- We switch to the second position, and then turn off the machine from the mains.

- We return the programmer to the first program and start the washer.

- We move the selector to the third mode and turn off the power again.

- Turn the knob one and press "Start".

- Select "Drain" and run the test program.

For some time, the machine will check the nodes of the machine, after which it will display the breakdown code on the screen. You will need to decipher the combination using the factory instructions or the Internet and clarify the localization of the failure that has occurred. If there is no display on the equipment, the system will inform about the error by flashing the LEDs on the dashboard.

The faulty part is searched as follows. When you turn on the test program, a quick wash is started on an empty tank, during which the system checks each piece of equipment for the quality of work. First, the filling valve is examined, then the integrity of the tank and the accuracy of the response of the pressure switch to filling the drum. After that, the ability of the heating element to heat the water to a given temperature and the engine speed are evaluated. The washing machine will definitely test the drain, as well as the spin cycle at maximum speed. As soon as problems are detected, the control board will fix the error and report it to the user.

Share your opinion - leave a comment

Causes and signs of failure

The electronic module is a complex part, and the microprocessor in its composition is the most expensive part. Before attempting to repair or replace the control unit, it is necessary to accurately determine the breakdown.

Why does the board break

Causes of the error code:

- Factory marriage is typical for both cheap and expensive Indesit models.

- Long operation in the conditions of the increased humidity. It has been proven that moisture is the most common cause of module failure, because it leads to a short circuit.

- Power surges in the network.

- Frequent disconnection of the washing machine from the mains during the washing process.

The Indesit washing machine gives an F09 error if there is a problem with the control board. What external signs may indicate this breakdown:

- The control unit freezes in spin mode, the system does not respond to button presses, and does not show error F 09 on the display.

- The readings of the temperature sensor and the actual water temperature do not converge. An electric heater (heater) overheats or, conversely, does not heat the water at all.

- The indicator lights flash randomly, the machine does not respond to your actions.

- Suspicious change in the speed of rotation of the drum, not provided by the program.

- Inadequate behavior of the program: the wash is running - there is no set of water, or it immediately drains. The system hung. After the reboot, the error is cleared, and work proceeds as normal.

- All programs work, but in reality nothing happens, the wash does not start.

- With any choice of program, the wash takes too long, the water does not drain, the system freezes.

- Immediately after turning on the program hangs and turns off.

These are just possible signs of a module malfunction.How to fix everything and remove the error?

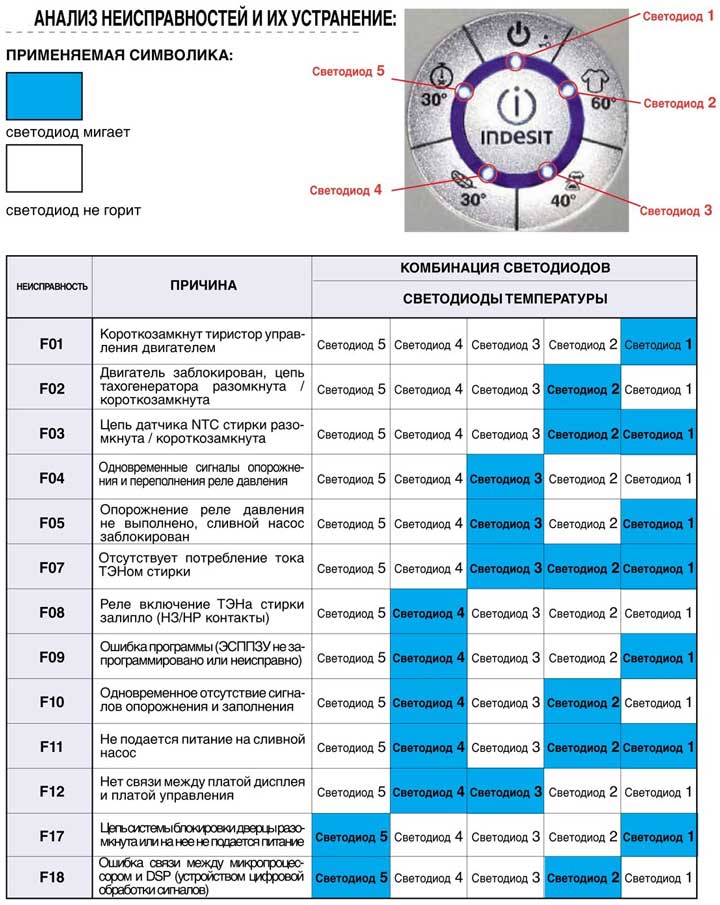

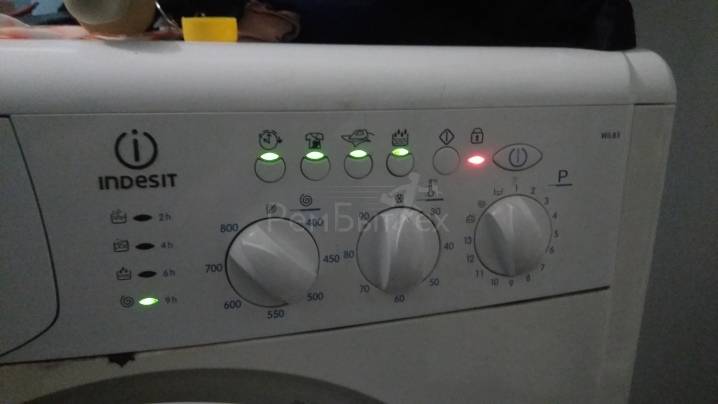

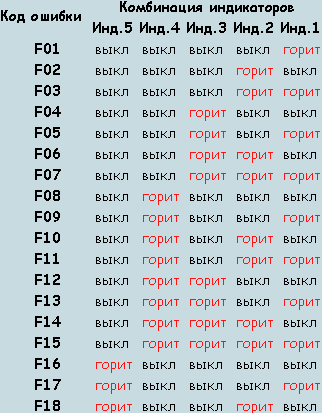

Meaning of indicators and codes

A serviceable machine systematically executes a set of commands, announcing the current stage with indicators, alternating the usual hum with small stops. Failure immediately makes itself felt by beeping, uncharacteristic sound, flashing, or the absence of any action at all. And most importantly, the smart mechanism immediately gives the owner a code of the malfunction that has occurred, according to which repairs can be quickly made.

The codes necessary for diagnostics for errors that have occurred according to the device of the Indesit washing machine are displayed:

- on the general display - when the model is equipped with a panel screen;

- by means of combined flashing of command lamps - on models without a display.

It is most convenient if the so-called washing machine has a display: the fault number immediately lights up on it. It is enough to notice it and proceed to reconcile the values, and then proceed to eliminate it.

Extended Indesit models always have a digital display on the panel. It will definitely display the breakdown number, even if before that the screen showed the execution of another function. If we are talking about models without a separate display, you need to linger on the next section and carefully study the LED flashing combinations that reveal the current error code.

In the working state, the indicators on the machine panel light up in accordance with the command being executed. In this case, as a rule, they do not flicker at a high frequency, but blink smoothly and / or shine constantly. Pointers that light up at random, simultaneously with others and begin to flicker quickly, notify of a breakdown.

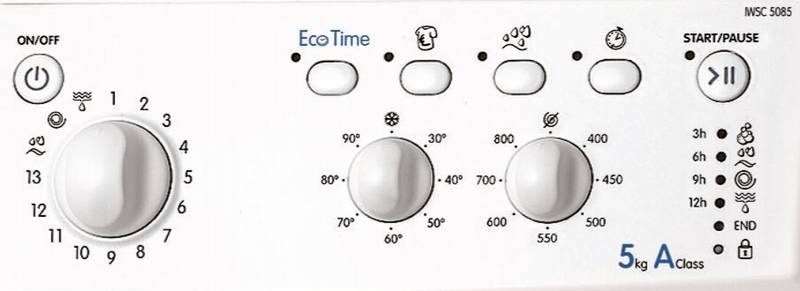

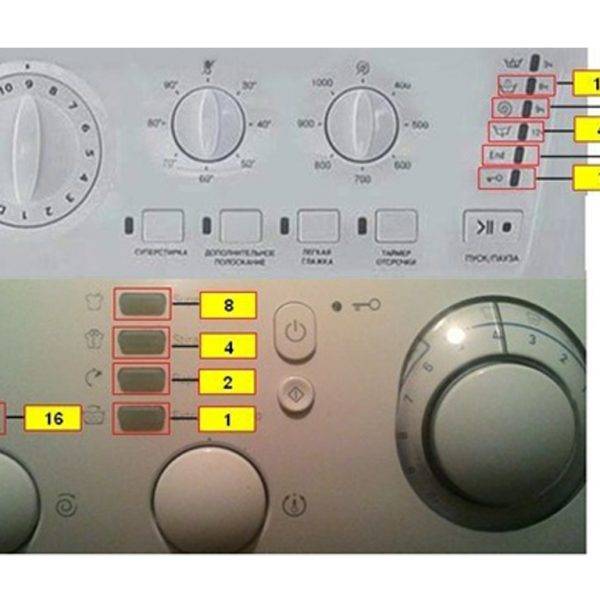

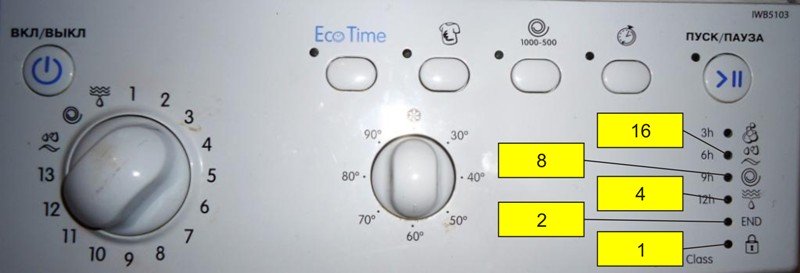

Notification occurs depending on the model range:

- Indesit IWDC, IWSB-IWSC, IWUB electronic-mechanical ruler and its analogues - the breakdown code is recognized by the burning LEDs of the working phases on the right (door block, rinsing, draining, spinning, etc.), the signal is also accompanied by the simultaneous flickering of the upper additional indicators and network indicator.

- The model range marked WIDL, WIL, WISL-WIUL, WITP - on the contrary, the type of failure indicates the burning of the upper line of lamps of additional functions along with the last diode of the left column (most often it is “Spin”), along the way quickly flashes the door block icon.

- Models of the WIU, WIUN, WISN series and their analogues - all bulbs, including the lock icon, participate in the error indication.

- The oldest prototypes of Indesit W, WI, WS, WT with only two light buttons for the unit and network - continuously and quickly flash exactly as many times as the number in the error number means.

It remains only to carefully look and determine which particular indicator lights are beeping, check the combinations with the list of fault codes and choose the right path for repair.

The indication panel of the functions of the latest Indesit models is located vertically on the right, and not horizontally at the top, like the rest, and the signals need to be read precisely on it. We will try to figure out how to unravel the meaning of the codes and correct the situation by performing feasible repairs.

Error codes indesit w 105 tx

The codes for the displayed malfunctions of the Indesit washing machines are presented in Table 1.

Table 1 - Errors, their names and possible causes

| Deciphering the information that appeared | Causes of a malfunction |

| F01 | Short circuit (short circuit) in the motor control circuit | 1) The triac is out of order, which is responsible for: turning on and off the electric motor; regulation of its speed. 2) Contact closure on the connector due to water ingress. |

| F02 | Lack of feedback from the tachogenerator | 1) Broken power wire to the motor. 2) Motor stator winding break. 3) Malfunction of the tachogenerator. 4) Lack of contact with the controller board. |

| F03 | Temperature sensor is defective | No change in water temperature. 1) The temperature sensor is defective. 2) The heating element is defective. 3) Lack of contact in the heating element relay. |

| F04 | Double signal on the pressure switch | The controller receives two signals about a high water level, at which the drain valve opens and about a lack of water, at which the water supply valve turns on. Malfunction of the sensor that controls the water level in the tank. |

| F05 | No empty tank signal | 1) Breakage of the drain pump. 2) Clogged drain line. 3) Malfunction of the sensor responsible for monitoring the water level in the tank. |

| F06 | Mismatch when choosing a washing program | 1) The preset code from the wash mode selection button does not match the controller parameter. |

| F07 | Insufficient water level to turn on the heating element | 1) No signal from the pressure switch about filling the tank. 2) The heating element is defective. 3) Contact sticking in the heating element. |

| F08 | Operating heating element while draining water | 1) Malfunction of the pressure switch. 2) Contact sticking in the heating element relay. |

| F09 | Error in the operation of non-volatile memory installed on the controller board "EEPRO M" | 1) Failure of the PROM - a rewritable programmable storage device (non-volatile memory). |

| F10 | No signals from the pressure switch | 1) Malfunction of the pressure switch.2) Lack of contact with the controller board. |

| F 11 | Drain pump not receiving power | 1) Winding break in the motor. 2) Malfunction inside the unit. |

| F 12 | No indication | 1) Display board defective. 2) Lack of contact between the controller board and the indication board. |

| F 13 | No signal from the temperature sensor for drying clothes (only for machines equipped with this function) | 1) Sensor failure. 2) Lack of contact. |

| F 14 | Lack of heating of the heating element in the drying mode | 1) Faulty heating element. 2) The supply chain is broken. |

| F 15 | Drying mode won't turn off | 1) Contact sticking in the heating element relay. 2) The chain of control is broken. |

| F 16 | Drum stop not in upper position (for machines with top loading) | The loading door of the drum must be at the top. 1) Lack of power. 2) Breakdown of the stop control system. |

| F 17 | Loading door not closed | 1) Lack of power on the door lock. 2) Breakage of the lock mechanism. |

| F 18 | Internal controller error | 1) There is no connection between the controller board and the executive control board. |

As can be seen from the table, for each information about the error, there are several reasons for its occurrence. And as a result, the warning light shows the direction in which to start troubleshooting, which significantly saves the time of service workers and reduces the time the washing machine is in repair.

Common manifestation of error

The car breaks down when you least expect it. The user, out of habit, puts the laundry in the drum and starts the washing cycle. However, contrary to regular work:

- washing does not start, instead, the lights on the control panel flash;

- the process starts, but after a certain time the machine “freezes”, stops functioning, and the LEDs on the panel are lit or flashing.

Interruption of the washing mode can happen at any of the stages: soaking, rinsing, spinning, draining water. A burning indication, coupled with a stopped operation of the washing machine, indicates a malfunction of the equipment. To find a solution to the problem, you need to understand what kind of failure the device notifies. Deciphering blinking indicators is not as difficult as it might seem at first glance. In this article we will try to describe all possible breakdown codes and their corresponding indication. To decrypt errors, you should:

- find out the type of your washing machine Indesit by the first letters in the model name;

- understand which combination of light bulbs glows;

- based on the description presented in the article, identify the alphanumeric designation of the error code indicated by the self-diagnosis system of the machine.

You can often find out the cause of the breakdown and repair the washing machine yourself. However, if it is difficult for you to decipher the code by flashing the lights, you can invite a qualified craftsman to help identify the problem and fix it.

Frequent failures of Indesit brand washers

Repair of Indesit washing machines is a common thing for employees of workshops and service centers

Experts say that Indesit washing machines are not the most reliable, they have many vulnerable nodes that you need to pay attention to first of all if the CMA does not work

We used the statistics of the world's leading service centers to come to a simple conclusion: Indesit washing machines are among the most broken brands.For the first 5 years of use, every third Indesit machine requires repair, unlike German or Korean-made equipment.

What is it connected with? In 8 out of 10 cases, the owners of CM Indesit contact service centers with such breakdowns:

- A tubular electric heating element (TEH) is one of the typical breakdowns for machines of this brand.

Why is this such a problem area for Indesit washing machines? Manufacturers decided not to cover the part with any protective compounds, they provided only stainless steel (whereas, for example, Samsung took care of the coating). In this regard, scale accumulates on the heating element 2 times faster. - Network filter. The failure of this element is a common cause of a malfunction of the Indesit washing machine. There are entire batches of machines in which a defective filter is installed. Usually they burn out after 3-4 years of operation.

The only plus is that in this case, repairing the Indesit washing machine with your own hands is a completely doable task. - Bearings. The breakdown of the Indesit automatic washing machine, caused by bearing wear, is a real scourge. The difficulty is not in replacing the bearings, but in disassembling the housing and getting to them. Therefore, problems with the Indesit washing machine associated with broken bearings are among the most difficult.

- Indesit washing machine control unit (electronic module, controller, board). Masters believe that this is the most “sore spot” of SMA, especially the lineup that rolled off the assembly line before 2012. Cars made from 2014 onwards have more reliable processors, but they often need to be repaired.

Repairing the control unit of the Indesit washing machine is almost impossible at home - you can only check the wiring and cables connecting the controller to other washing machine elements. But it is too difficult to repair or replace the block on your own, such work should be entrusted to a professional. - Electric motor sensor. If the engine itself can be attributed to more or less reliable parts, then problems often occur with the electrician connected to it. Vulnerable place - capacitors.

The problem is that they are not repaired, capacitors need to be changed in the event of a breakdown.

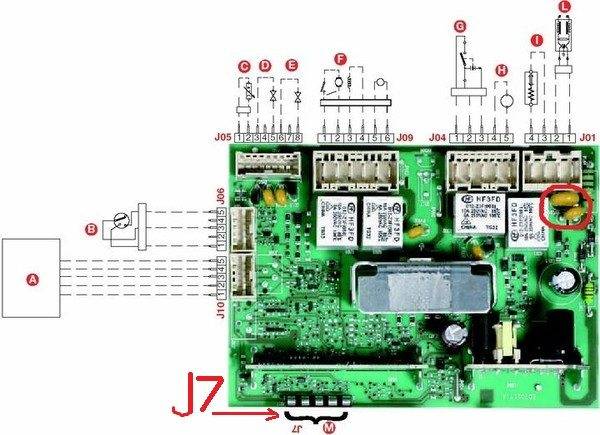

Errors related to the ECU board

The memory chips located on the control unit board contain all service algorithms and washing programs. If a failure occurs, the memory must be removed from the computer (soldered or removed from the microcircuit connectors) and reprogrammed with a special device - a programmer.

If the connection between the display module and the computer board is broken, this malfunction of the Indesit washing machine manifests itself in the absence of a reaction to the buttons and the impossibility of executing programs. If nothing has changed after disconnecting from the 220 V network and rebooting the ACM, the condition of the connectors and the reliability of the switching connections are checked. The most likely malfunction is in the display module board or computer.

Control and display module in some Indesit CM models

Control and display module in some Indesit CM models

Meaning of the code

According to the established tradition, we will start with a general decoding of the error code, in this case code F12, such a decoding can be found in the instruction manual for the Indesit washing machine. And then we will give a more detailed transcript, which will finally shed light on the problem.So, the general interpretation of the F12 error code can be represented as follows: "the control module has stopped interacting with the buttons and lights of the control panel."

In fact, in this case, the Indesit washing machine states that there is no connection between its two most important modules. However, the connection is not completely lost, since the module was able to convey information about the error to the user, which means that the electronic module retains some control over the control panel. Despite this, the F12 error is accompanied by the inability to use the control panel in any way, in rare cases even the on / off button does not work.

How and under what circumstances does it manifest itself

If the Indesit washing machine does not have a display, then the electronic module (bypassing the usual circuit) will connect some control panel lights, which, in fact, will indicate an error. We are talking about the burning indicators "Super Wash" and "Delay Wash". On some models of Indesit washing machines, only the speed indicator may flash.

If the Indesit washing machine does not have a display, then the electronic module (bypassing the usual circuit) will connect some control panel lights, which, in fact, will indicate an error. We are talking about the burning indicators "Super Wash" and "Delay Wash". On some models of Indesit washing machines, only the speed indicator may flash.

Error F12 in 99% of cases appears shortly after turning on the machine in the network. In this case, the user does not yet have time to select any washing program, and indeed to do anything with the control panel. The Indesit washing machine freezes immediately, in addition, the on / off button may fail and then you will have to turn off the machine by unplugging the power cord from the outlet.

Finding and eliminating causes

The malfunction that the F12 error generated can often be eliminated by restarting the Indesit washing machine. Moreover, the reboot must be done not anyhow, but according to the following scheme.

- We turn off the washing machine with the on / off button, if it is working.

- We disconnect the power cord of the Indesit machine from the power supply.

- We are waiting for 2-3 minutes.

- We turn on the machine in the mains and press the on / off button.

- If the error persists, repeat the above steps two more times.

If the malfunction has not been eliminated within 3 reboots of the machine, such actions should be stopped so as not to harm the control module even more. If the reboot does not help, it means that a serious breakdown of the control module has occurred, or the contacts connecting the module and the control panel lights have oxidized. With such a problem, there is little that you can do on your own. Unless you check the J11 connector, which, as you may have guessed, connects the display module to the control board.

If, after stripping the contacts of the J11 connector and the display module, the Indesit washing machine does not start working correctly, then the problem is in the control module. Perhaps the question will immediately come to your mind, is it worth doing the repair of electronic modules with your own hands? We will answer shortly - it is not worth it! Most often, this ends with the final breakdown of the washing machine and the user's forced appeal to a service center. Just keep in mind that in this case, repairs will cost 2-3 times more, since you will definitely have to change the parts of the “home assistant”, and this is completely different money.

So, the malfunction caused by the F12 error can only be eliminated if the control board is not damaged, but only the contacts are burnt or oxidized. If the module breaks down, definitely contact the master. Good luck!

How to eliminate?

Before proceeding with the elimination of the breakdown, it is necessary to check the voltage level in the network - it must correspond to 220V.If there are frequent power surges, then first connect the machine to the stabilizer, so you can not only diagnose the operation of the unit, but also extend the operating period of your equipment many times over, protect it from short circuits.

If after rebooting the error code continues to be displayed on the monitor, you need to start troubleshooting. First, make sure that the outlet and the power cord are intact. In order to make the necessary measurements, you need to arm yourself with a multimeter - with the help of this device, finding a breakdown will not be difficult. If the external monitoring of the machine did not give an idea of the cause of the breakdown, then it is necessary to proceed with the internal inspection. To do this, you will have to get to the engine by doing the following:

open a special service hatch - it is available in every Indesit CMA;

supporting the drive strap with one hand and scrolling the second pulley, remove this element from the small and large pulleys;

carefully disconnect the motor from its holders, for this you will need an 8 mm wrench;

disconnect all wires from the motor and remove the device from the CMA;

on the engine you will see a couple of plates - these are the carbon brushes, which also need to be unscrewed and carefully removed;

if during a visual inspection you notice that these bristles are worn out, you will have to change them for new ones.

After that, you need to assemble the machine back and run the wash in test mode. Most likely, after such a repair, you will hear a slight crackle - you should not be afraid of this, so the new brushes are rubbed. After several washing cycles, extraneous sounds will disappear.

If the problem is not in the carbon brushes, then you need to make sure the integrity and insulation of the wiring from the control unit to the motor. All contacts must be correct. In high humidity conditions, they can corrode. If rust is found, it is necessary to clean or completely replace parts.

The motor can fail if the winding burns out. Such a breakdown requires a rather expensive repair, the cost of which is comparable to buying a new motor, so most often users either change the entire engine or even purchase a new washing machine.

Any wiring work requires special skills and knowledge of safety, so in any case it is better to entrust this matter to a professional who has experience in such work. In such a situation, it is not enough to be able to handle a soldering iron; it is possible that you will have to reprogram new boards. Independent disassembly and repair of equipment makes sense only if you are repairing the unit in order to gain new skills. Remember, the motor is one of the most expensive parts of any SMA.

See below for information on how to repair electronics.

Other Causes of Program Crash and Flashing Lights

On the control panel, the LEDs can blink not only due to a breakdown, but also due to incorrectly set parameters. There are a number of washing modes that provide for the possibility of connecting additional functions:

- extra rinse,

- higher degree of water heating,

- ironing.

Instead of turning on, the indicator may flash if the selected program cycle does not provide a particular function.

The machine can issue a service error both at the initial stage of washing and during it.In cases where the weight of the load of laundry is not compatible with the number of revolutions or the maximum allowable amount of laundry provided for in the technical specifications, the spinning process may not start. In this case, the buttons indicating a failure in the “Rinse”, “Spin” mode and the door lock indicator will flash. At the moment, you need to restart the machine a second time, reducing the number of things.

After that, the execution of the specified program will stop. After a few seconds, the door will unlock, you will be able to make adjustments and start washing.