- Rules for operation and timely maintenance

- Methods for self-diagnosis of faults

- Diagnostics

- Elimination of some problems in the operation of the boiler

- Error 01e

- 02e

- 03e

- 05e

- 10th

- 11th

- Noise and hum

- No hot water

- Classification of malfunctions of gas boilers

- A series of gas boilers Daewoo

- How is the heating system

- Problems in the operation of Kiturami boilers

- Error 2E (the first three indicators flash)

- Series and models

- Is it worth it to do the repair yourself?

- What can be repaired with your own hands

- The principle of operation of the smoke exhauster of a gas boiler

- When the boiler is turned on, the valve drips

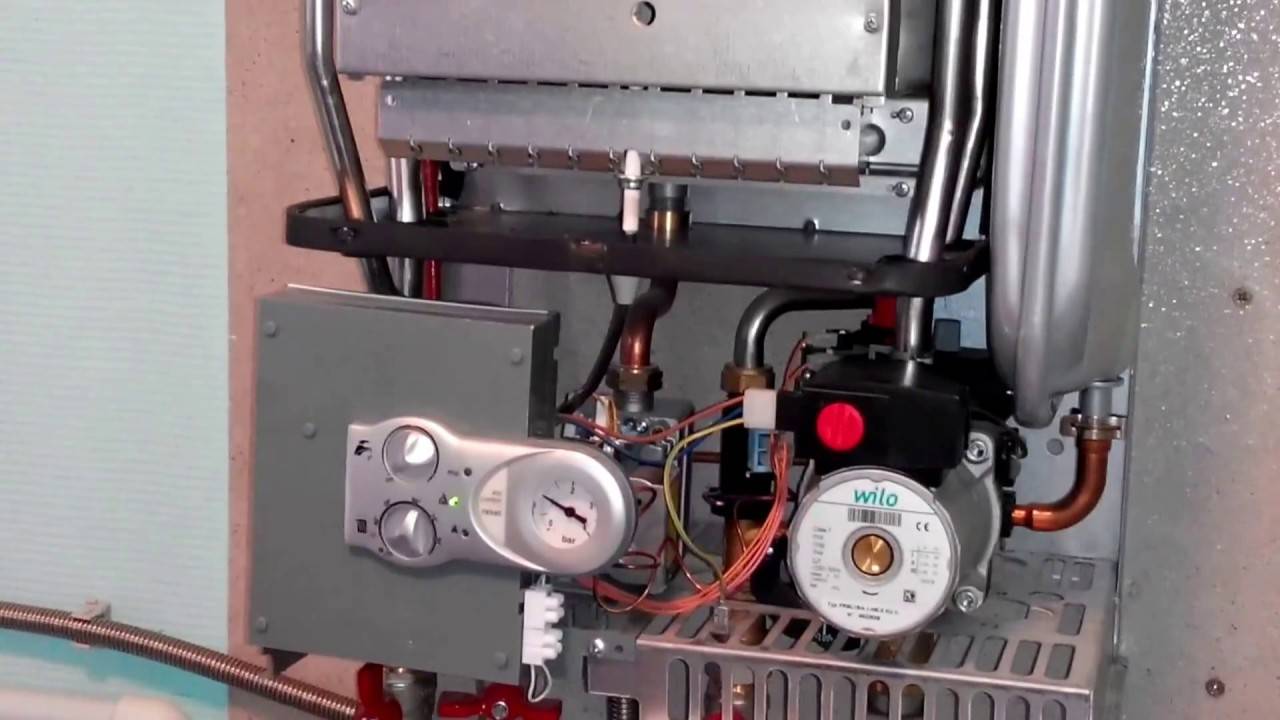

- Pump not working well

- Proper installation is a guarantee of long-term operation

- The main reasons for the unstable operation of the boiler

- Preventive measures

Rules for operation and timely maintenance

Experts recommend that the owners of Navien boilers, on the eve of operation, get acquainted not only with the device and technological parameters, but also with the matrix of self-diagnosis system codes, which the manufacturer is obliged to provide in the technical documentation.

Tips and tricks for servicing Navien boilers:

The tuning algorithm for the thermal performance of the boiler directly depends on the model of the burner.Units with digital control according to the set thermal mode include a thermostat operating in a unit with a room temperature sensor.

The setting is automatic, the thermometer monitors the indoor temperature

After some time, when it falls below a certain limit, the thermostat sends a signal to turn on the burner or, using a control valve, increases the gas fuel consumption.

As a rule, the thermostat controls the temperature in one room, but in the case when shut-off and control devices are installed in front of each radiator, the temperature can be controlled in all rooms.

The burner device can be regulated by turning the gas valve, which is especially important for atmospheric-type devices with open combustion chambers.

The mode change is made in the menu on the remote control.

Algorithm for setting the operating mode of the boiler unit through the service menu:

- Open the valves on the heating devices.

- Set the desired value on the heating thermostat in the room.

- The burner will stop when the temperature rises by 5 C from the set mode.

- Press "Mode" on the LCD. If "0" appears on the screen, enter the number "35" using the "+" and "-" keys.

- When presented on the screen "d. 0", dial the line number using "+" and "-". The setting will acquire automatic negotiation.

- Return to the service menu using "Mode".

- Carry out control of the flame in the combustion chamber and the rise in temperature.

At the same time, the radiators do not have time to heat up, and the functional units of the boiler quickly fail.In addition, in this mode, an excessive consumption of gas occurs, due to which the energy efficiency of the boiler and the overall efficiency of the thermal system decrease.

Suppress cyclicity with 2 options:

- Reduce the torch of the burner.

- They increase the load in the heating system by including an additional load in the form of installing radiators or an external tank for indirect heating of hot water.

The manufacturer of boilers Navien studied all possible variations of the unit's failure and issued factory instructions for the repair and adjustment of equipment. State of the art diagnostic system identify errors in work device and offer the user ways to troubleshoot.

The system is individual and depends on the model of the unit and the installation option - mounted or floor, as well as on the modification of the control unit.

She is a tried and true assistant even for an inexperienced user who is little versed in technology. It is thanks to error diagnostic programs that today it is possible to quickly overcome the emergency and restore the temperature regime in the house.

Methods for self-diagnosis of faults

Often the user is in a situation where he is not sure what exactly has broken in the gas boiler. In such cases, there is no need to rush to remove and repair something. This is risky and dangerous. Before work, it is necessary to diagnose the equipment and identify the exact causes of malfunctions.

If the boiler smokes, then usually the cause of this phenomenon is the consumption of low-quality gas or lack of air. You can check the cause of the malfunction yourself

Modern gas boilers are equipped with various sensors that reflect a number of important functional indicators of the unit. They track changes in temperature, pressure and other parameters.In the event of a malfunction, modern models of boilers provide for automatic shutdown of the device.

The source of the breakdown is identified by the consequences caused by it. For example, visually you can see burning, smudges, sparks. By smell, you can feel a gas leak or a short circuit. By the changed sound of the gas boiler, it becomes clear that the unit has failed.

The instructions that came with the purchase of the device describe the most common malfunctions in the boiler model being purchased and how to detect, diagnose, and eliminate them. It also indicates what a specific error code means and flashing lights on the dashboard.

So the light can flash in different modes: fast or slow. Or burn all the time. The color of the light bulb can be red, green or yellow.

The manufacturer's instructions indicate all possible error codes that may appear on the display. It also explains how to troubleshoot.

Do not throw away the instructions from the device, as it may be useful to the gasman called by you to fix the breakdown. It indicates the characteristic features of the gas boiler model, the dimensions and location of components and parts.

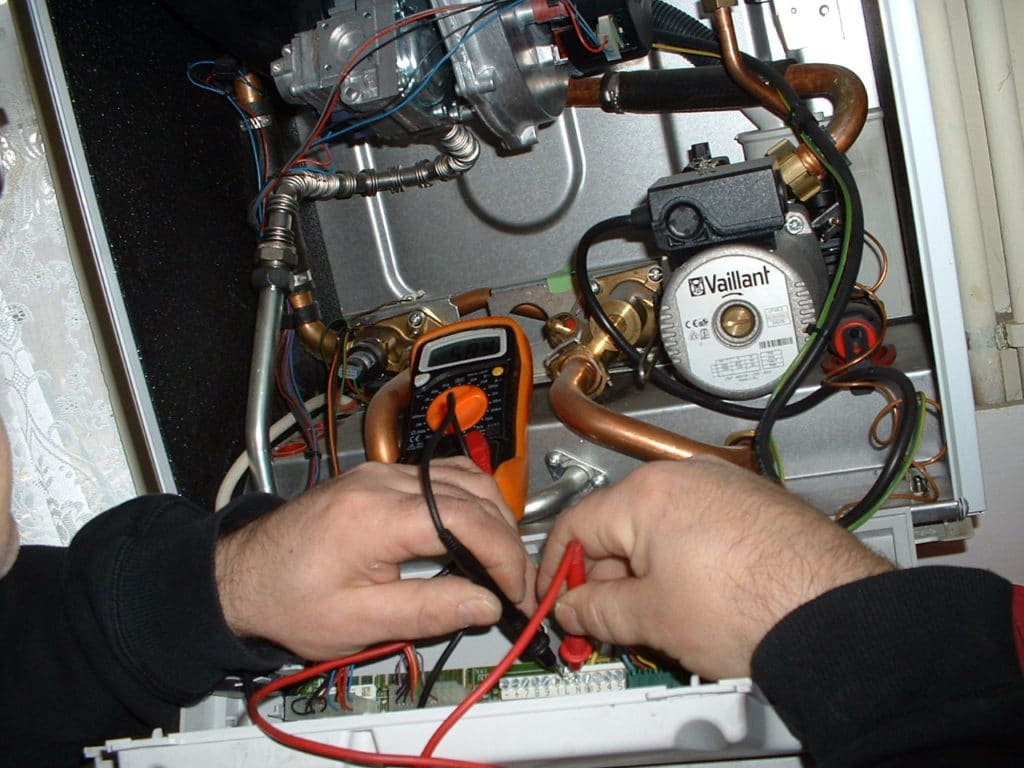

Diagnostics

Competent implementation of repair involves compliance with a certain sequence of actions:

- Troubleshooting. There are obvious and implicit breakdowns. With a boiler that has ceased to function, everything is clear, but there may be defects that are difficult to notice immediately or do not greatly affect the operation of the boiler room.

- Diagnostics: search for the causes that led to the breakdown. This may be a clogged filter, a violation of the integrity of the wires, the failure of individual nodes.

- Elimination of causes.First you need to determine whether it will be possible to repair the boiler on your own, in some cases you can save a lot by performing simple manipulations, and sometimes there is a risk of exacerbating the situation if the wrong actions are taken.

Reference! Do not disassemble and repair the boiler when the warranty period of its operation has not yet expired. If the equipment cannot be repaired on its own, the repairmen will refuse to fix the defects free of charge.

Unstable operation of the burner, which often fades. To maintain the combustion process, the presence of oxygen is necessary, its deficiency (during the operation of the boiler) can be easily detected if, for example, the windows in the boiler room are opened. Stabilization of combustion indicates the need to improve ventilation in the working room.

You may need to install air inlets or a door with a vent.

Insufficient gas flow in the line is determined when the hose is disconnected from the boiler. When the valve is open, hissing should be heard and the smell of additives in the gas mixture should be felt.

The pressure may drop as a result of the clogging of the filter, to clean it, the mesh inside must be removed and rinsed. If a blockage occurs in the gas meter, you will have to call the gas service workers.

Overheating of the coolant can cause an emergency shutdown of the equipment. This often happens due to a malfunction of the pump that accelerates the working fluid around the house.

If air has entered the working chamber of the pump, then to remove it, you need to add coolant there.

Sometimes the rotor - an element of the pump - sticks and stops rotating, you can fix the problem by disassembling the housing, the rotor is scrolled by hand, removing debris in the chamber if possible.

And you should also check the expansion tank, which in modern models of boilers is built into the unit itself. The pressure in it is checked with a standard automobile pressure gauge, its value should be 0.2 atm less than the working pressure in the pipeline.

If necessary, air is pumped by a manual or electric pump.

Elimination of some problems in the operation of the boiler

Like any, even the most reliable technique, some problems may occur in Navien boilers, some of which the owner of the device can fix on their own.

First of all, it is important to recognize the cause of the breakdown. So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code

So that the owner can quickly find out about the problem and respond competently, the self-diagnosis system displays data with an error code.

Here are the Navien boiler trouble codes:

- 01e - the equipment has overheated.

- 02e - there is little water in the heating / the circuit of the flow sensor has broken.

- 03e - there is no signal about the flame: it may not really exist, or there may be problems with the corresponding sensor.

- 04e - false data about the presence of a flame / short circuit in the flame sensor.

- 05e - problems with the heating water t sensor.

- 06e - short circuit in the heating water sensor t.

- 07e - problems with the hot water supply t sensor.

- 08e - short circuit in the hot water supply t sensor.

- 09e - a problem with the fan.

- 10e - problem with smoke removal.

- 12th - the flame went out during work.

- 13e - short circuit in the heating flow sensor.

- 14e - no gas supply.

- 15e - a problem with the control board.

- 16th - the boiler is overheated.

- 17e - error with the DIP switch.

- 18e - the smoke removal sensor is overheated.

- 27e - a problem with the air pressure sensor (open or short circuit).

Error 01e

Overheating of the equipment can happen due to the fact that the ducts have narrowed as a result of blockage, or the circulation pump has broken.

What you can do yourself:

- Examine the impeller of the circulation pump for damage to the impeller.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Check the heating system for air. If there is, it needs to be bled.

02e

An error that there is little coolant can be generated by the boiler if there is air in the system, little water, the impeller of the circulation pump is damaged, the distribution valve is closed, or the flow sensor is broken.

What can be done:

- Bleed the air.

- Adjust pressure.

- Check if there is resistance in the pump coil, if there is a short circuit.

- Open distribution valve.

- Check the flow sensor - is there a short circuit in it, is there resistance.

- Open the sensor housing, clean the flag (moving mechanism with a magnet).

Most often, the problem is the presence of air in the hot water system.

03e

No flame signal. The reasons for this may be:

- Damage to the ionization sensor.

- No gas.

- No ignition.

- The faucet is closed.

- Faulty boiler grounding.

The blockage on the flame sensor must be cleaned. The gray coating on the electrode is cleaned off with fine sandpaper.

05e

What can be done:

- Check the resistance on the entire circuit from the controller to the sensor. Having found a malfunction, replace the sensor.

- Disconnect the controller and sensor connectors and reconnect.

10th

Smoke removal problems can occur due to fan failure, kinking, or improperly connecting sensor tubes to the fan. In addition, the chimney may be clogged, or there was simply a sharp and strong gust of wind.

What can be done:

- Repair the fan or replace it.

- Check the correct connection of the sensor tubes.

- Clean the chimney from blockages.

11th

A problem with the water filling sensor - this error is provided only for European-made boilers equipped with the appropriate sensors.

Noise and hum

It may happen that the error does not appear on the display, but an unnatural buzz or noise appears in the device. This happens when water hardly passes through the pipes due to scale, overheats and boils. The reason may be a bad coolant.

Coolant Navien

Troubleshooting procedure:

- You can fix the problem by disassembling the unit and cleaning the heat exchanger. If this fails, the part must be replaced.

- In addition, you need to check the taps - whether they are open to the maximum.

- Turn the water temperature down. It is possible that the boiler capacity is excessive for the pipeline to which it is connected.

No hot water

It happens that the heating boiler heats up as it should, but the water for hot water supply has stopped heating. This is a problem with the three way valve. Cleaning and repairs will not save - you need to change the part! The problem is not rare, the valves work normally for about 4 years.

So. Navien boilers are reliable and economical equipment. With proper operation and a competent approach to the difficulties that have arisen, problems can be eliminated even without the involvement of specialists from the service.

Classification of malfunctions of gas boilers

The first type includes signs intermittent.They are the most unpleasant, as they are very difficult to diagnose. Malfunctions of this type occur when a parameter is violated, for example, the voltage drops below an acceptable level. In this case, most of the gas boilers simply will not start. If any malfunction has already occurred, it will lead to other breakdowns. Therefore, such signs are called primary and secondary.

Malfunctions can be obvious, or obvious, and non-obvious. The first include such malfunctions that are easy to detect, for example, a defect in the heat exchanger. But there are also such malfunctions that only professionals can detect.

Gas boiler installation.

Breakdowns can occur suddenly, when nothing portends this type of trouble. It stops unexpectedly without any reason. Breakdowns can also be gradual, which are caused by the long life of the gas boiler, which gradually leads to "fatigue" of the equipment or the materials from which its parts are made.

The exact diagnosis of breakdowns can only be determined by a specialist, since he has not only professional knowledge, but also the appropriate equipment for diagnostics.

The heating system is a single organism. All its parts are interconnected. Failure of one component of the system will inevitably lead to a malfunction of the entire structure. All elements can be divided into those that are subject to repair, and those that cannot be repaired. If a part cannot be repaired, it is immediately replaced with another part after it has broken.

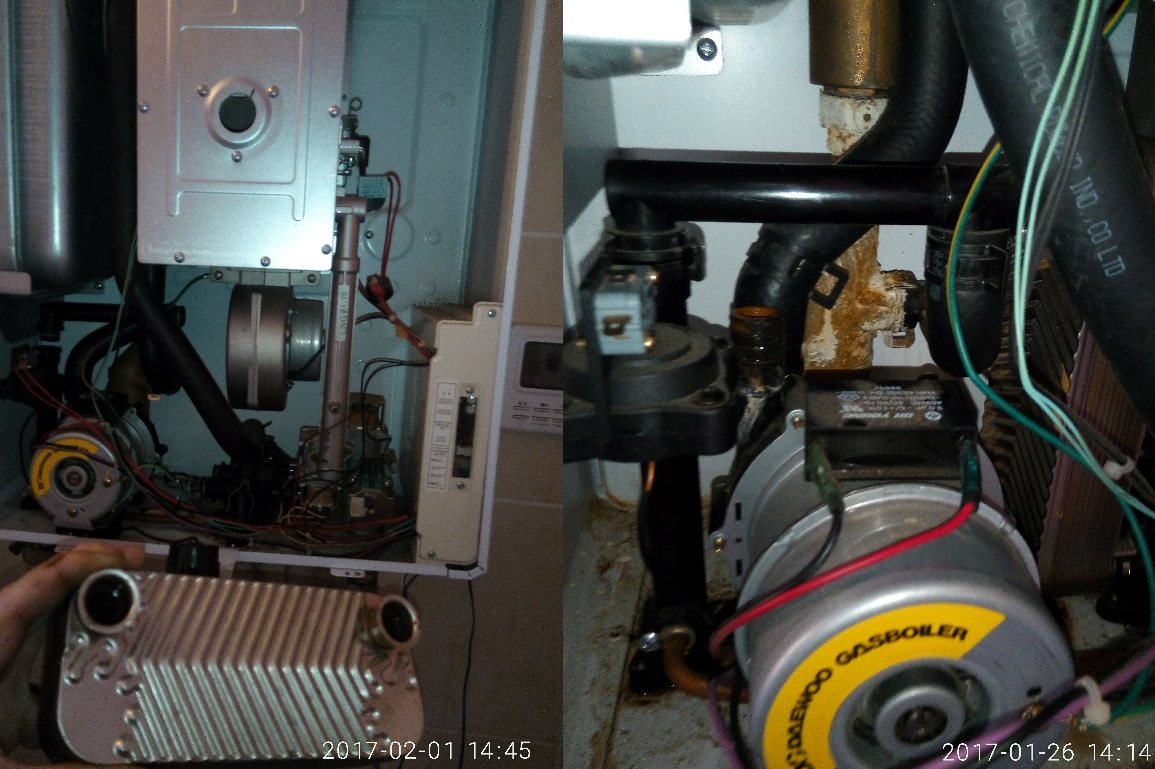

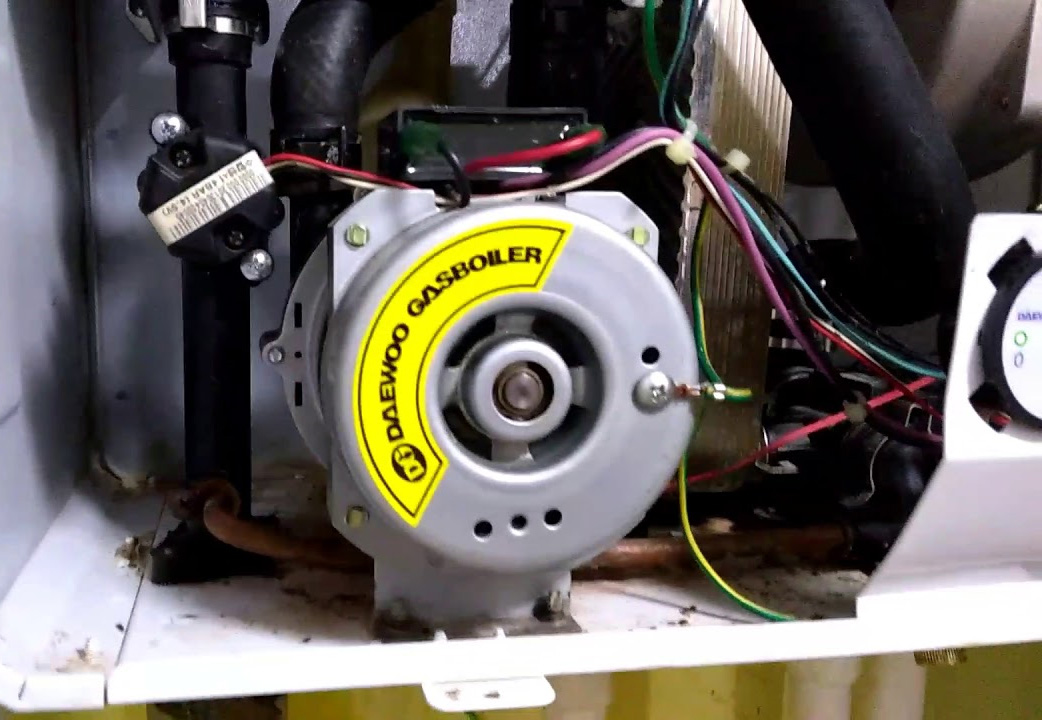

A series of gas boilers Daewoo

Daewoo is one of the most famous Korean conglomerates, which ceased to exist in 1999.Many divisions of the concern received independence or merged into the structure of other companies.

Now in South Korea there are two companies that were previously related to the corporation and produce gas boilers:

- Altoen Daewoo Co., Ltd (until 2017 - Daewoo Gasboiler Co., Ltd). Now production facilities are located in Dongtan.

- Daewoo Electronics Co., which produces gas equipment at the factories of KD Navien.

Components for the boilers of both companies are made in South Korea and Japan, and the assembly is carried out in an automated mode.

Altoen Daewoo Co., Ltd did not transfer production facilities to Chinese industrial clusters in order not to lose the possibility of constant quality control of products

The following lines of gas boilers from Altoen Daewoo Co. are presented in Russia. Ltd:

- DGB MCF. Boilers with an open combustion chamber.

- DGBMSC. Boilers with a closed combustion chamber.

- DGBMES. Boilers of condensing type with a closed combustion chamber. The models of this line have a weekly work programmer, an autonomous control panel, and the connection of the chimney is also simplified.

All models of the listed lines are wall-mounted, double-circuit, that is, they are designed for heating and hot water supply.

Models of the DGB series are equipped with an informative display that shows an error code if a malfunction occurs or the built-in automatic diagnostic system is triggered.

Daewoo Electronics Co. There are two lines of gas boilers: wall-mounted "DWB" and floor-standing - "KDB".They have their own characteristics, including error codes that differ from competitor models. However, these boilers in Russia are not widely used.

Therefore, the article will only provide error codes for gas boilers from Altoen Daewoo Co., Ltd.

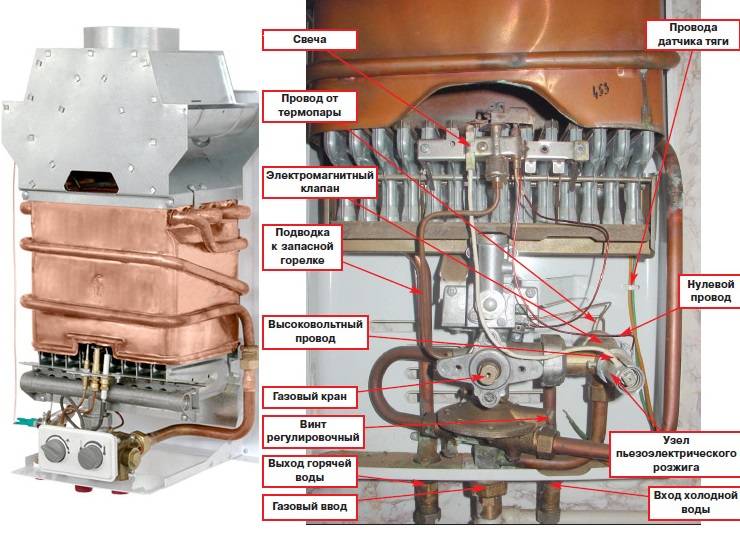

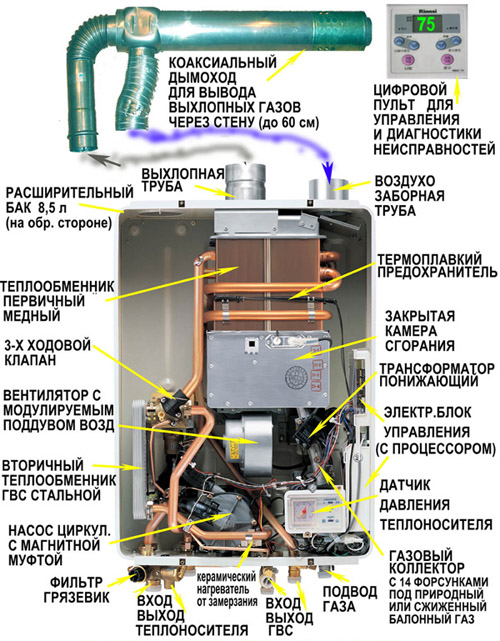

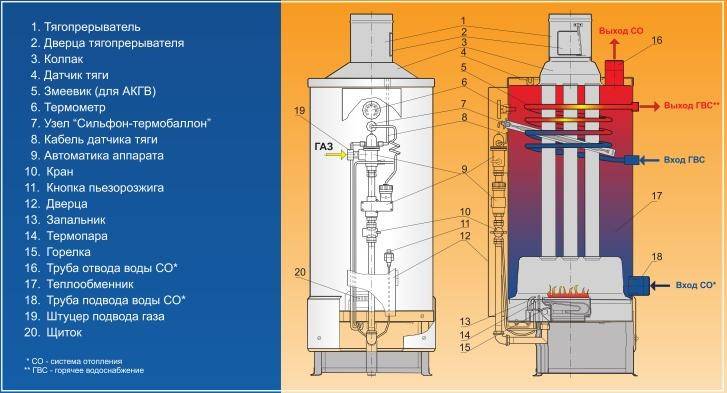

How is the heating system

As already mentioned, modern heating systems are technologically complex systems. And the user, before undertaking repairs on his own, must have an idea about their device.

Usually, the entire process of monitoring the operation of an installation that heats a house is carried out using built-in automatic equipment. All boiler systems interact in a complex, and it is worth familiarizing yourself with them in some detail

In the group that is responsible for safety, the main elements include the following devices:

- a sensor that is responsible for adjusting traction. It can withstand up to 750 C. With the help of such an element, it is possible to monitor the general condition of the chimney. If failures occur during normal operation, the temperature immediately begins to rise, and the sensor gives a signal. If it is not included in the kit, then it is additionally worth purchasing another sensor that shows the gas content in the room;

- an element such as a monostat helps protect a turbocharged gas installation from such a nuisance as insufficient removal of products that remain after combustion. This happens if the heat exchanger grate is heavily clogged or there are problems in the chimney;

- the "limit" thermostat is mounted in order to be able to control the temperature fluctuations of the coolant itself;

- using the electrode, the operation of the flame is controlled; if the water begins to boil, then the entire installation stops its work;

- pressure control inside the system is carried out through a blast valve. If the pressure rises above the maximum mark, then the excess coolant liquid is discharged in parts.

Problems in the operation of Kiturami boilers

Not all problems have their own code, so we will consider them separately.

The "Network" indicator is not lit - check the power in the socket and the fuse on the ignition transformer. If there is no voltage in the mains, call an electrician, if there is, call the service department.

The low water indicator on the control unit is on - there is no water in the device or the level is too low. Damage to the black wire of the boiler and the red cable of the sensor also lead to a malfunction.

The room temperature sensor works fine, but the radiators are cold - the circulation pump does not accelerate the coolant through the pipes or does it too weakly. Inspect the locking parts on the heating pipes. Check the pump itself.

The “Overheating” light came on - the heating system is not working properly. Check her out.

If the problem persists, do the following:

- Adjust the shut-off valves on the heating pipes.

- The mesh filter may need to be cleaned. Examine it.

- Check circulation pump, repair or replace if necessary.

The "Safety" diode is lit - gas enters the boiler burner in small quantities or does not enter at all. Inspect the valves and open them if necessary. The problem remains - call the gasmen.

Schematic representation of a room remote thermostat: 5 main modes are laid in it, including presence, absence, shower, sleep, water heating control

The pump is running too long. The water temperature indicator on the control unit is constantly on - the heating system is not working properly or there are air pockets in it. Release the air.

The boiler began to heat up longer - look for a problem with gas pressure and the condition of the filters.

The burner vibrates when turned on - the size of the chimney is not enough for the normal removal of gases.

The efficiency of the device in terms of hot water supply and heating has decreased - bad water or dirt from the heating system enters the boiler. The chemical treatment of the circuits and the heat exchanger will help.

Error 2E (the first three indicators flash)

The logic of the error is that the flow temperature rises too fast, i.e. the coolant at the outlet of the heat exchanger heats up too quickly and to prevent emergency overheating, the operation of the boiler is blocked for two minutes. The main reason for this behavior of the boiler may be poor circulation of the coolant. The most common causes of poor circulation are:

-

malfunction of the circulation pump or insufficient performance

-

heat exchanger clogged with dirt or scale

-

air in the heating system

In this article, we examined the most common malfunctions of Buderus gas boilers. A complete list of errors is contained in the equipment manual. Modern gas engines are designed so that the elements are as accessible as possible for ease of service. Some errors can be corrected by the user himself, for example, make up the boiler or inspect the chimney for blockages.

Doing any self-diagnosis actions should be done only in case of urgent need in compliance with precautionary and safety measures. If you do not have an idea about the principles of operation and the device of a gas boiler, it is better to call a qualified specialist

The Buderus company posts informative videos in which the specialist talks, including about the boiler errors that occur.

Series and models

Daewoo produces the following series of gas boilers:

- Daewoo Gasboiler DGB. Consists of models DGB-100, 130, 160, 200, 250, 300 and 350. Their power is 10, 13, 16, 20, 25, 30 and 35 kW. Double-circuit atmospheric boilers capable of heating rooms from 100 to 350 m2. Equipped with a copper primary heat exchanger with high efficiency and long service life. The secondary heat exchanger is plate type, made of stainless steel.

- Daewoo MCF. Wall-mounted boilers with an open combustion chamber. Equipped with a separate heat exchanger, have the ability to work up to 3 days in emergency mode. The power of the boilers is in the range of 10.5-29 kW.

- Daewoo MSc. Double-circuit units with a closed burner. The extended model line consists of boilers with a capacity of 7-45 kW. Equipped with a separate heat exchanger. They can be controlled from a remote control, which has a range of up to 50 m. There is a weekly programmer, which makes it possible to plan the operation of the boiler with high accuracy.

- Daewoo MES. Series of condensing boilers. The power of the models ranges from 19.8 to 40.6 kW. For normal operation, it is necessary to provide the units with appropriate conditions, which is possible only in certain climatic conditions.

All boilers are made in accordance with the most efficient and advanced production methods, have a balanced set.

Daewoo consistently embodies the principle of simplicity, low cost and high quality products.

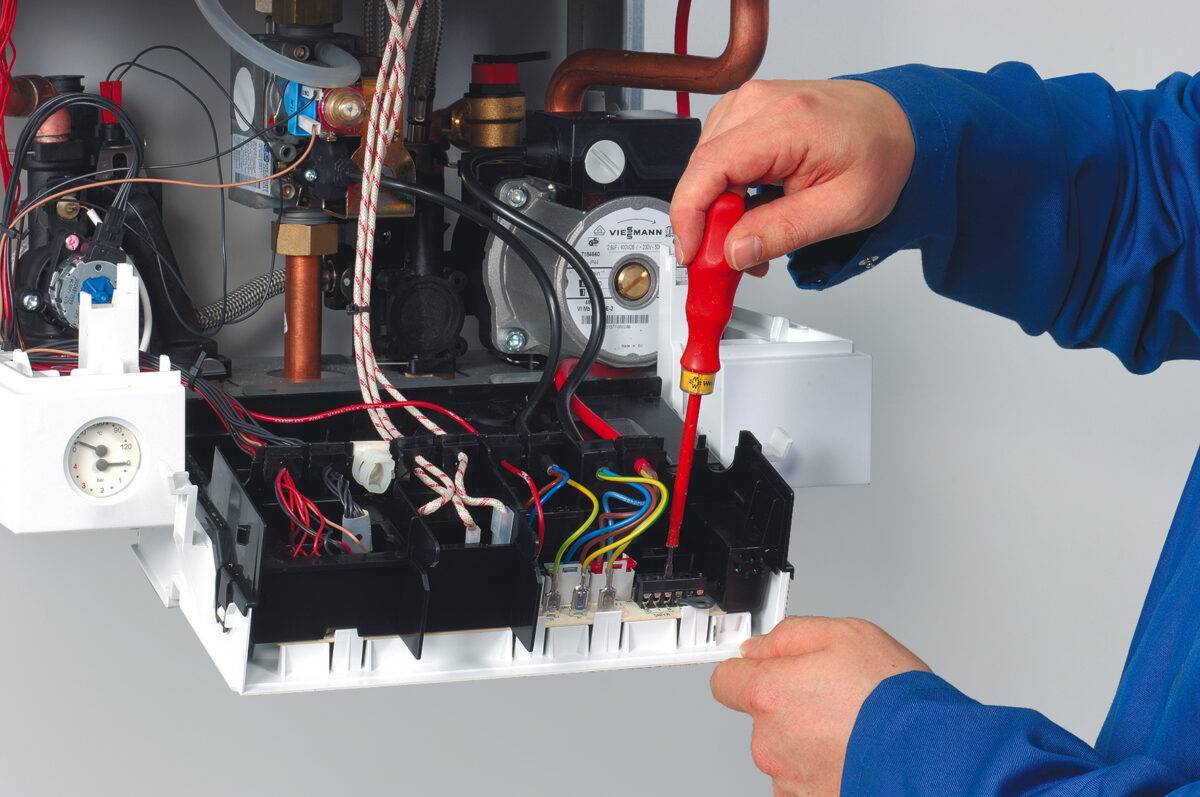

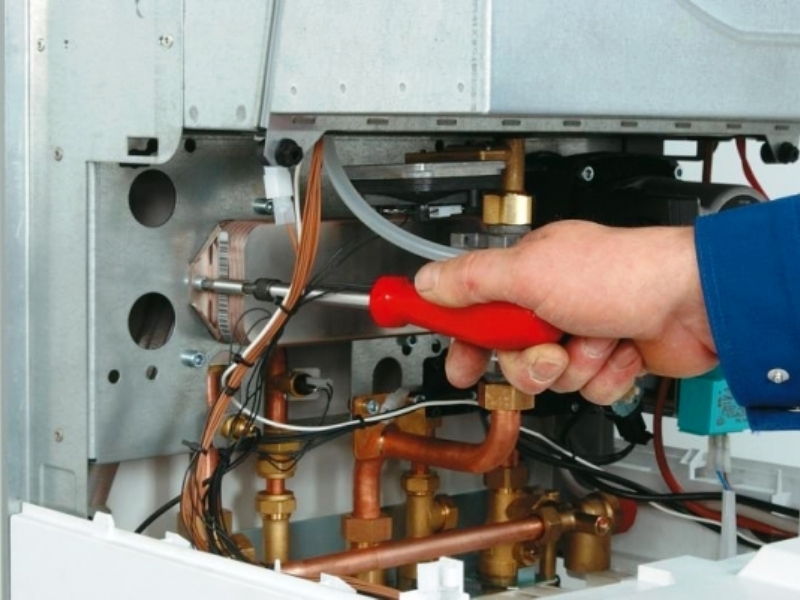

Is it worth it to do the repair yourself?

In a typical gas boiler, all structural elements are conditionally combined into three groups:

- burner;

- blocks that are responsible for security;

- a heat exchange unit equipped with a fan, a circulation pump, and many other elements.

During repairs, the main safety risk arises from a possible gas leak. The reason for this may be improper repair, dismantling or installation of equipment with fuel supply functions.

Because of this, it is better to have these structural parts repaired by a specialist. In addition, self-troubleshooting in the electronic equipment of the gas boiler is not allowed. The automatic system is quite specific, and if you do not have the appropriate qualifications, it is impossible to correctly restore this type of equipment in practice.

And yet, if you do not have enough experience, it is better to entrust the maintenance of heating boilers and the repair of gas water heaters to professionals.

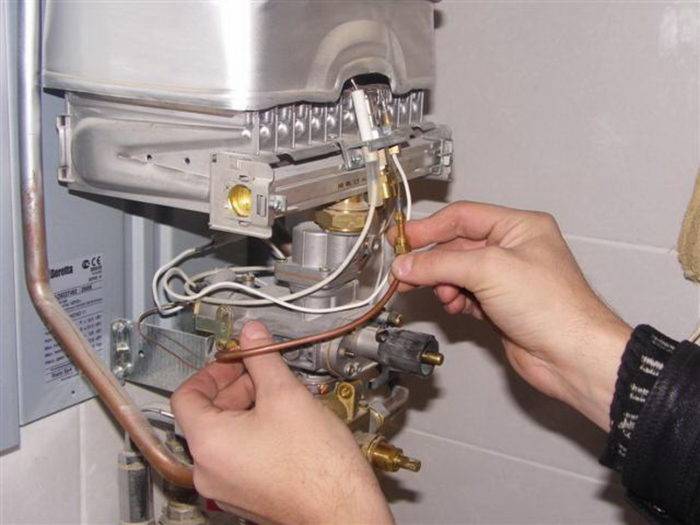

What can be repaired with your own hands

All other elements can be repaired independently, for example:

- The heat exchanger is flushed manually (for this, the unit is dismantled, after which it must be correctly put in place). You can perform these works without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is performed).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, it is possible to repair a gas boiler on your own only in cases where we are talking about mechanical damage or blockages that are easy to identify visually (or by smell).

The remaining breakdowns are considered more serious, so they are eliminated with the help of a specialist, and not with their own hands.

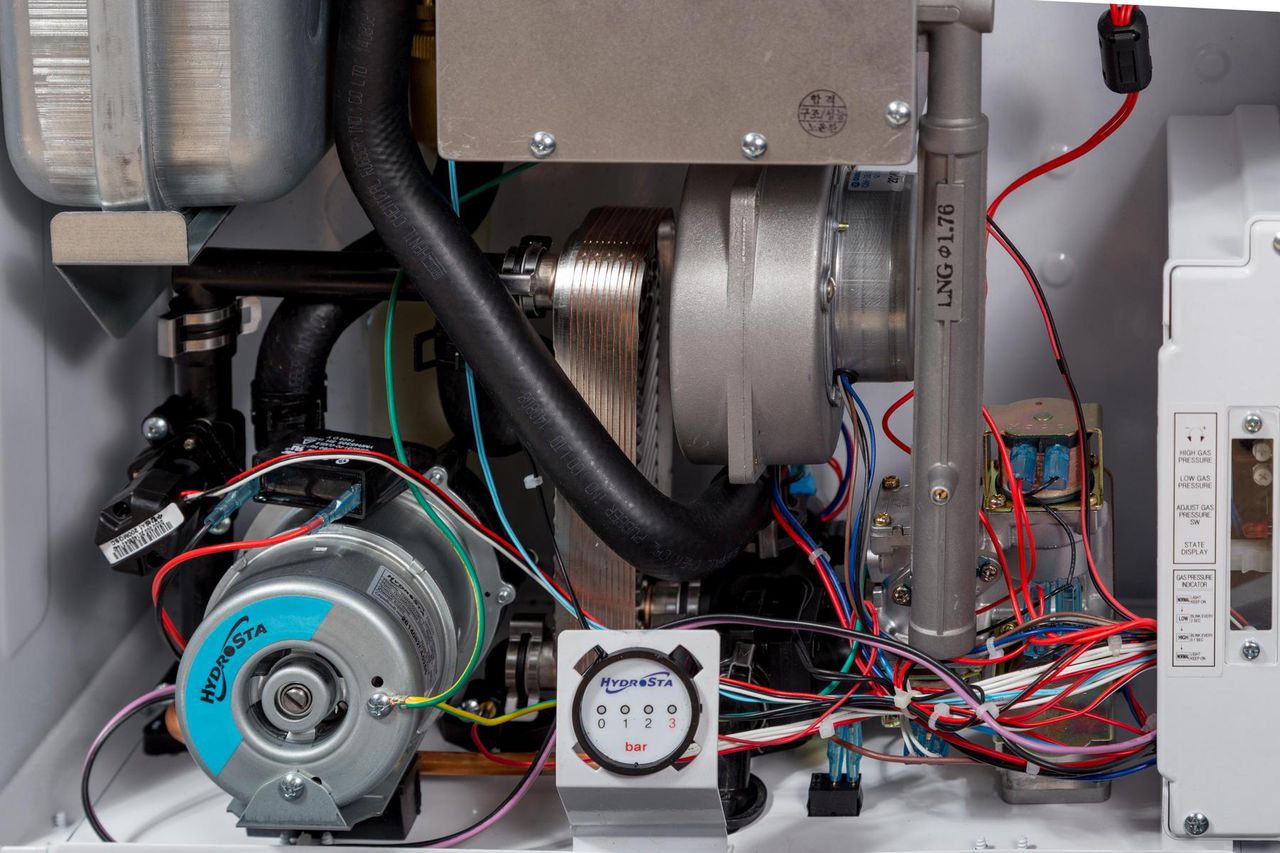

The principle of operation of the smoke exhauster of a gas boiler

The fan consists of nodes:

- An engine that rotates the impeller.

- Turbine that creates a vacuum in the combustion chamber.

- Blades for mixing supply air.

- Venturi tubes, which create a pressure drop for the efficient operation of the pressure switch.

Gas boiler fan device.

The turbine of the smoke exhauster is housed in a housing made of galvanized sheet or aluminium. The motor is attached to the body with mounting bolts, through vibration pads.

When 220 volts appears on the stator inductor, the armature begins to rotate the turbine and blades. The supply air is mixed and flue gases are removed through a coaxial pipe or a separate air duct and chimney.

The electrical power of the fan depends on the thermal power of the boiler, for domestic models, 35 - 80 watts.

When the boiler is turned on, the valve drips

The situation is simulated when the water heater is turned on without water intake.

The reason for the discharge of water will be a valve failure.

This is explained simply: with the initial heating of the liquid, its volume increases by 3%. This surplus is discharged into the sewer. But after the heating device simply keeps the water at a constant temperature.The valve must not drip.

The appearance of drops indicates a malfunction of the device or its clogging with debris particles.

The second, considered situation, paints a picture of the correct operation of the mechanism.

The water heater works with increased water intake (take a shower). The volume of hot water leaves, cold liquid enters in its place. The new supply begins to heat up - “new” excess water appears, which is continuously discharged into the sewer.

The third situation arises when the water intake is stretched over time. Water discharge does not have to be permanent. Drips from safety valve intermittently. This indicates the correct operation of the device.

For example, washing dishes. The water withdrawal process is extended. Water also should not drip constantly.

Pump not working well

Users of gas boilers sometimes face various problems in the operation of the pumping unit. Such equipment stops pumping water if the rotor fails or a significant amount of air has accumulated in the inside. To exclude such a breakdown, it is necessary to unscrew the nut from the unit and drain the water, after which the axis is forcibly scrolled with a flat screwdriver.

Pump in a gas boiler

Separate equipment requires compliance with installation rules. It is advisable to install the pump before the gas boiler, which will extend the life of the heating system. This rule is associated with the presence of a high temperature regime at the outlet of the boiler, which can cause damage to the device. Of course, the design characteristics of the circulation pump must also be taken into account, as well as the need to mount a filter or sump directly in front of the pump.

Proper installation is a guarantee of long-term operation

The process of installation and maintenance of gas equipment is regulated by:

- SNiP 2.04.08-87 (gas supply).

- SNiP II-35-76 (boiler plants).

- Government Decree No. 549 of 2008 (rules for the supply of gas to citizens of the Russian Federation).

Thus, installation, replacement and maintenance of boilers should be carried out only with the participation and control of the relevant authorities, since gas appliances are equipment of increased danger.

For unauthorized installation and replacement of boilers, a fine is provided. Utility services can even turn off the gas supply.

Installation of gas equipment, carried out with disregard for the basic rules, will lead, at best, to its inefficient operation, and at worst, to boiler failure.

The destruction of the case can occur if the device is strapped incorrectly, the power of which is higher than 50 kW (at low temperatures it can crack).

Installing a voltage stabilizer will solve the problem of breakdowns in the electrical part of the boiler equipment. In this case, the total power of the connected devices, starting currents, the value of which is approximately 3 times higher than the operating ones, should be taken into account (this is true for pumps that distribute the coolant throughout the house).

Prevention of boiler equipment will help ensure its uninterrupted operation during the season. It is recommended to carry it out twice a year: before the start of the heating season and after its completion.

Preventive work includes inspection of the boiler units, pipelines, lubrication of bearings, checking the tightness of the joints of pipes and hoses, cleaning the chimney.

The main reasons for the unstable operation of the boiler

Even the most modern technology breaks down from time to time.In such a situation, the owner needs to identify the cause of the malfunction and carry out a quality repair. It is impossible if you use cheap spare parts for heating boilers.

Most often, the equipment stops working for the following reasons:

- Violation of the rules of operation. Before using the device, users often do not even read the instructions for use. As a result, this leads to the fact that pretty soon the installation begins to demand attention. Often, the installation of the device is carried out independently, even if there is no experience in this matter. This is done to save money and not pay for the services of a specialist. To avoid malfunctions of the device, the best solution would be to invest in the services of a master who can properly install the boiler.

- Unstable voltage. In the private sector, this is one of the main reasons leading to equipment failure. It can occur due to severe wear of the electrical network. Also, the cause of jumping voltage indicators can also be intensive construction ongoing in adjacent areas, using several welding machines and the use of home-made heaters.

- Insufficient gas purification. When using a boiler operating on such an energy carrier, the contamination of the "blue" fuel can lead to disturbances in the operation of the installation. When the gas is dirty, it contains small solid fractions, as well as water droplets. This provokes a situation of incomplete combustion of fuel. As a result, deposits in the form of soot form in the boiler burner.

- Low water quality. If a boiler-based heating system uses water of poor quality as a heating medium, then over time the efficiency of the installation will decrease.In addition, this has a bad effect on the service life of the heat exchanger and the device as a whole.

Preventive measures

To prevent breakage of any parts of the boiler, special preventive measures are taken. Before the start of the heating season and after it, the unit must be serviced in a special way. If possible, it is disassembled and all components of the spare part are carefully inspected for damage. All malfunctions must be eliminated, broken parts replaced with new ones or repaired.

Due to the danger of gas boilers, you should not deal with problems on your own if there is no experience in repairing units. It is better to entrust the repair of the device to a master who, without errors, will identify broken parts and repair or replace them with new ones. During operation and maintenance, the manufacturer's instructions must be followed.