- Removing air pockets in the system

- The device and principle of operation of Bosch boilers

- Main characteristic

- Types of equipment

- New Deluxe Model

- What causes breakdowns

- Insufficient circulation, error 104. How I searched for the cause

- What can be repaired without gasmen?

- Gas boiler startup technology

- 1. When turned on, the boiler does not work at all

- Model overview

- Navien Atmo 24AN and others

- Deluxe 24K and other turbo modifications

- NCN 40KN and other condensing models

- LST 30 KG and other floor models

- Features of the operation of gas boilers "Beretta"

- Communication with peripheral devices (errors 4**)

- Error 502

- The main causes and malfunctions of gas boilers

- Other boiler malfunctions

Removing air pockets in the system

Better to start with batteries. To remove air jams, a Mayevsky crane is usually installed on them. We open it and wait for the water to run. Did you run? We close. Such manipulations must be done with each heater separately.

How to start the boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-feeding the system with liquid.

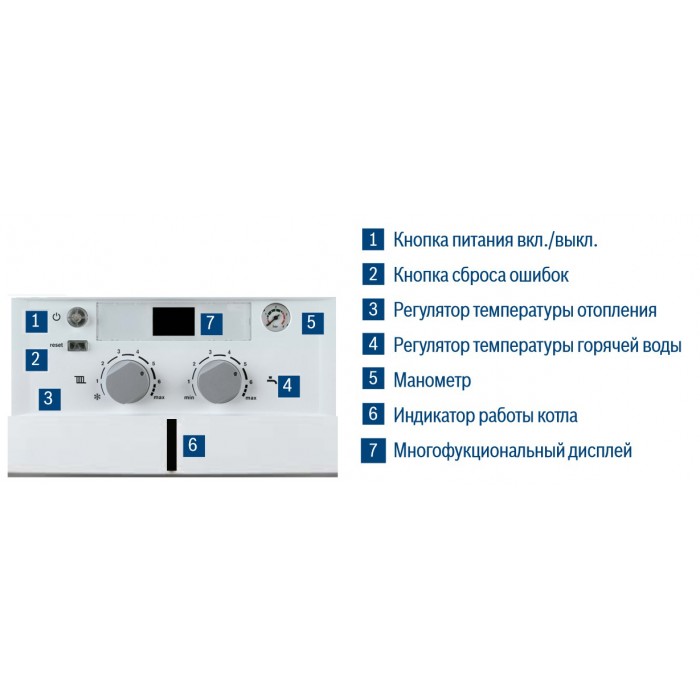

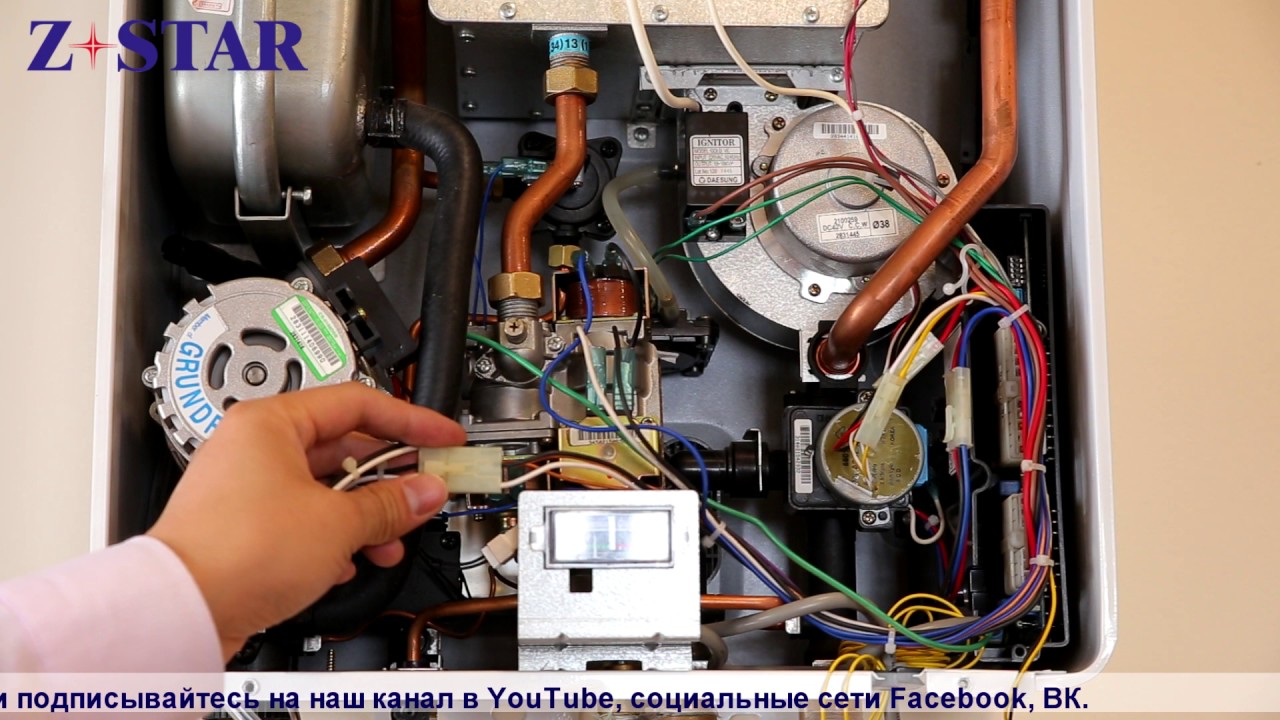

Now, the most difficult thing is that starting gas boilers requires venting air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny cap in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electric power and set the water heating regulators to the working position.

Releasing air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and a loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is airy, it will be so. We take a screwdriver and slowly unscrew the cover in the middle of the pump - as soon as water begins to seep out from under it, we twist it back. After two or three such manipulations, the air will come out completely, incomprehensible sounds will subside, the electric ignition will work and start working. We check the pressure again and, if necessary, add water to the system.

Basically, everything. While the system is warming up, you can do a detailed study of the instructions (if, of course, you have not already done so) and debug the system, which involves starting the boiler. Everything is simple here - the batteries closest to the boiler must be screwed on, and the distant ones should be run to the fullest. Such debugging is carried out by means of control valves installed on the pipe connecting the supply to the heating radiator.

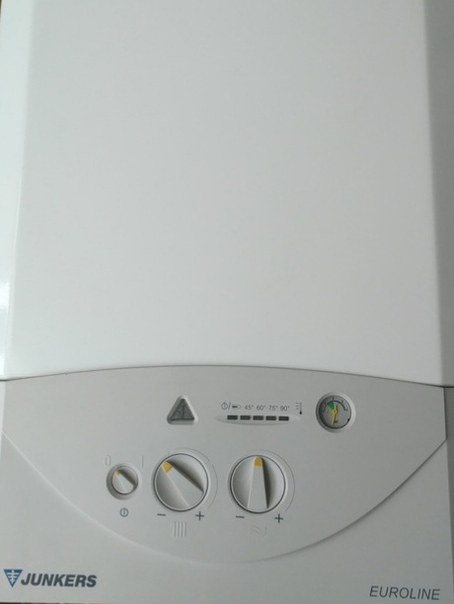

The device and principle of operation of Bosch boilers

The most popular models among the Bosch boiler line are double-circuit ones. They have two tasks: the first is heating the room to a predetermined temperature, the second is the provision of hot water for domestic needs.

Bosch devices, namely the Bosch Gas 4000 W and Junkers Bosch models, are equipped with two independent heat exchangers, which allows them to perfectly perform two tasks: heating water and providing heat in the room.

In each of the models, it is possible to choose the power of the device that suits you from 12 to 35 kW, when choosing, the area of \u200b\u200bthe room is taken into account. As for heating the liquid for household needs, the performance is about 8-13 liters per minute.

Advantages of a wall-mounted double-circuit boiler:

Flaws:

The first 20-40 seconds after you turn on the hot water faucet, cold water flows.

Let's take a closer look at how the device works, using the example of the Bosch Gas 4000 W ZWA 24 model. When the boiler is operating in heating mode, heat is transferred using a gas burner to the primary heat exchanger, which is a structure of copper tubes and plates.

In order for them not to deteriorate from exposure to high temperatures and water, their surface is covered with a protective layer. Its main task is to transfer the heat generated during the combustion of the flame to the heating system. The movement of water in the system is provided by the pump.

Also, the design provides a three-way valve, its task is to prevent water from entering the secondary heat exchanger. The secondary heat exchanger is necessary for domestic water heating. The heated liquid for the heating circuit leaves the device through the heating supply line, and the cooled liquid enters through the heating return line.

When the boiler is set to heat domestic hot water, the 3-way valve closes the heating circuit.The heated liquid flows from the primary heat exchanger to the secondary one, and then flows out of the device.

The advantage when using different heat exchangers is obvious. When heating, plain water is often used, and it usually contains impurities. When it is heated, impurities begin to form deposits that adversely affect the heat exchanger, reduce its throughput, prevent water from heating, and shorten its service life.

And when the liquid that flows through the primary heat exchanger is in a closed circuit, it does not change its chemical properties and minimizes negative consequences.

The fluid that flows through the secondary heat exchanger will form deposits over time, and over time, the heat exchanger will need to be replaced or cleaned. If the fault occurs during the winter period, your boiler will be able to operate uninterruptedly in heating mode using the primary radiator.

Main characteristic

Korean manufacturers have taken care of the convenience of consumers and have released an extensive range of heating systems. The equipment is highly reliable and affordable. Features of Navien gas boilers:

- The machine is equipped with an adjustment circuit that avoids problems caused by voltage fluctuations in the network. This function protects the system from breakdowns when the sensors are falsely started. This feature is very useful as the power grid voltage is not always stable.

- The heating system is able to stabilize its operation when the supply pressure is reduced to 4 bar.

- The device does not freeze even in the absence of gas supply. There is a pump for forced circulation of water.

- The system has a double heat exchanger designed to heat the coolant and water. Preheating can be programmed.

- Electronics is simple and convenient.

Navien gas boiler:

Types of equipment

Navien has a very wide range, including floor and wall equipment. The units can function normally even with an unstable supply of fuel and electricity. Models have a turbocharging function and are equipped with a frost protection system.

Outdoor equipment is ideal for country houses. It efficiently heats the room and provides it with hot water. The units are simple and compact. There is condensing equipment. Such devices significantly reduce the cost of heating the house.

Types of Navien boilers: The following Navien models are very popular: Ace (Ace), produced with different power levels, for example, 16 k or 20 k, Deluxe (Deluxe), Prime (Prime).

New Deluxe Model

Navien Delux is the latest heating system that has replaced the Ace. This model has a closed combustion chamber and a turbine for forced smoke removal. Equipment features:

- Increased frost protection. At a temperature of -6 degrees, the automatic burner turns on, and at -10 ° C, the circulation pump is activated, allowing the coolant to move continuously.

- Fan with adjustable speed. The speed of the turbine changes depending on the reading of the air pressure sensor.

- The heating system is made of stainless steel, which has a much longer life than other materials.

- Protection against the effects of voltage drops in the network and the ability to operate at low pressure of water and coolant.

Gas boiler Navien Deluxe: >All work is done using a separate remote control. It displays a temperature indicator and various information about the current status of the device, including error and malfunction codes.

There is also an air pressure sensor, which not only checks the draft, but also notifies about the reverse thrust and sends data for portion control to the control panel.

If there is excess pressure in the chimney, the gas will stop moving to the burner and the boiler will stop temporarily.

Navien error 02:

2 id="ot-chego-proishodyat-polomki">What causes breakdowns

The reasons that can disable Junkers gas boilers can be explained by external factors:

- intermittent power supply;

- low gas pressure in the system;

- clogged ventilation;

- in poor water quality in the tap.

Based on the severity and possible damage to the entire unit, a troubleshooting technology is selected. This can be both cosmetic repairs associated with coating water and gas pipes with paint or anti-corrosion compounds, preventive maintenance associated with scheduled cleaning or replacement of some component parts, as well as major troubleshooting measures that may be caused by a violation during installation or in the process operation.

Among the elements that are most prone to failure under the influence of external factors, we can distinguish:

- gas burner;

- electronic board;

- circulation pump.

Insufficient circulation, error 104. How I searched for the cause

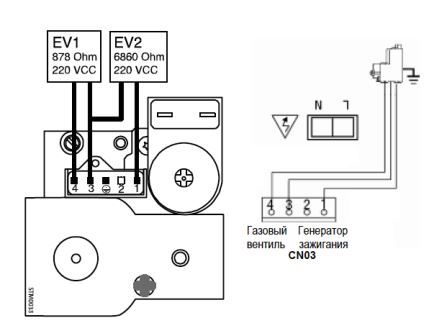

According to the manual, I determined that 104 is “Insufficient circulation” I argue: What can interfere with normal circulation? After all, a clogged filter in the heating system or slag that has accumulated in the primary heat exchanger can interfere with the desired flow of the coolant. Could it be the circulation pump? Has the pump gone? To check it, unscrew the bleed screw on it, this will allow you to see whether the shaft is rotating or not.

There is a slot on the shaft for a wide, flat screwdriver, I tried to turn the shaft with a screwdriver ... it didn’t jam, it rotates. I try to start the boiler and see if the shaft rotates. The cauldron plays its terrible sounds and again goes into defense. The shaft does not rotate. At the time of launch, I tried to turn it with a screwdriver .... I thought, but suddenly a “dead point” appeared ... .. no, the shaft did not rotate.

Decided to check the pump supply voltage. When the presence of 220 volts was detected on the chip, the conclusion was unequivocal .... Replacement pump. Eeeh, I think, again, unforeseen expenses.

However, the conclusion was hasty, when I was looking for wires coming from the board to the circulation pump motor, I noticed that there were more than two of them. For what? Started looking into it and here's what I found out

What can be repaired without gasmen?

There are several main causes of failures. This is the improper operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or poor-quality components.

When repairing yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

During the repair of gas equipment, the main danger is a possible gas leak.

Therefore, it is necessary to carefully carry out all manipulations for the installation and dismantling of components and parts of the device.

Particular attention should be paid to the replacement of components associated with the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for their elimination allows you to independently make simple repairs. It is worth remembering that serious repairs can only be done by gas workers, but there are procedures available for independent home craftsmen.

Boiler manufacturers strongly recommend calling gas service employees to fix problems associated with breakdowns in the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently set up, repair and restore the functions of specific automation in a gas boiler.

There are three main elements in the design of a typical gas boiler, these are:

- Gas burner closed / open type;

- Specific security blocks;

- Heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, chimney, boiler control devices, multi-level security systems.

Most often, users have problems of the following nature: the boiler emits an unpleasant smell of gas, does not turn on, turns off during operation, does not heat pipes or smokes

Most of these items cannot be changed and repaired by yourself. In the event of intervention in the design of the boiler, its owner loses the right to restore working capacity at the expense of the manufacturer during the warranty period. But what and how the masters from the organization with which the contract for the maintenance of the unit and the supply of gas is repaired must be known.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is produced in cases of weakening of traction by mechanical manipulations or with the use of chemicals.

- Checking the tightness of the water supply connections, gas supply lines, heating circuit branches.

- Installation of a voltage stabilizer.

Once again we warn that all actions for the implementation of which it is necessary to remove the casing from the boiler must be performed by a representative of the gas service.

However, if the warranty is not important for you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade aqueous solutions of citric acid (100g / 1l) or suitable household chemicals that can dissolve calcium deposits.

- Servicing the blower fan. Replace the fuse or the fan itself, check the electrical circuit connected to it, lubricate the bearings with technical fluid.

- Nozzle cleaning. Clogged nozzles cause a weak burner flame. They periodically need to be cleaned with a fine sandpaper and remove dirt with rags with household chemicals.

- System pressure regulation.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to make a visual inspection of it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the warranty from the manufacturer has already expired.

If you smell gas, you should immediately forget about your own intervention. It is necessary to shut off the gas supply, immediately produce salvo ventilation and call an emergency gang. The detailed rules for the operation of gas equipment are set out in the following article, the contents of which we strongly advise you to read.

Gas boiler startup technology

Scheme of installation of a gas boiler.

The first start-up of the equipment involves filling the system responsible for heating with water. The initial start-up should focus on setting up and checking not only the unit itself, but also the heating system, which serves as the basis. How correctly the launch will be made will determine how efficient the heating of the house has become.

Initially, the system should be filled with water. At the bottom of the equipment, where the pipelines are connected, you can find a valve. Its shape may vary between models, so it may look like a rotating pin, for example. The faucet should not be fully open. Otherwise, the pipes may form free air in the interior.

The gas boiler must have a pressure gauge that represents the pressure indicator. The equipment should be started by creating a pressure of approximately 2.5 atm.At the moment the arrow reaches the corresponding value, the pressure pump should be turned off, which is true if it is present. After that, you can close the tap and start bleeding air, which is done using automatic or manual crane Mayevsky, it is necessary to apply it on each of the heating devices. At that moment, when the water starts to flow, the tap can be closed. The boiler pressure gauge should show a pressure of 1.5 atm, this figure will have to catch up to 2 atm. This level will be the optimal pressure for a double-circuit boiler.

1. When turned on, the boiler does not work at all

To eliminate this malfunction of a gas boiler, there can be several ways. The easiest is to check whether the boiler is plugged in or the machine has been knocked out. If this does not help, you need to remove the boiler casing and inspect its insides for a short circuit. Perhaps there is some smell or something has flowed. It is necessary to check whether all the wires and sensors are located in their places. If everything is in order, then you need to proceed to inspect the fuses on the electronic board. After making sure that the fuse has burned out, you just need to replace it with a new one. If the new fuse immediately burned out, then it is necessary to call the wizard, as this means some kind of serious breakdown, which is unlikely to be fixed on your own. A specialist must also be called in the case when all the fuses are normal, This indicates that the problem is not in them.

Pay attention to the varistor. It is designed to protect the boiler from power surges.

If there was any difference, then the varistor will be blown up and only a small part of it will remain. Because of this, the boiler may also not turn on. The solution to this boiler malfunction is simply to solder the varistor.

gas boiler varistor

Model overview

Many users initially gave negative feedback about Korean boilers. Causes - leaks in the connections. They had to be eliminated by replacing the gaskets - you need to buy a rather expensive kit. The second flaw was associated with a belated start of the burner - the coolant had time to cool down more than necessary. But the company corrected the shortcomings, today there are practically no such accusations against Navien. The brand produces hanging heaters of three types:

- atmospheric;

- condensation;

- turbocharged.

The consumer can purchase a gas boiler:

- Single circuit or double circuit.

- Wall or floor. The latter are more bulky and require a separate room.

- With open or closed combustion chamber.

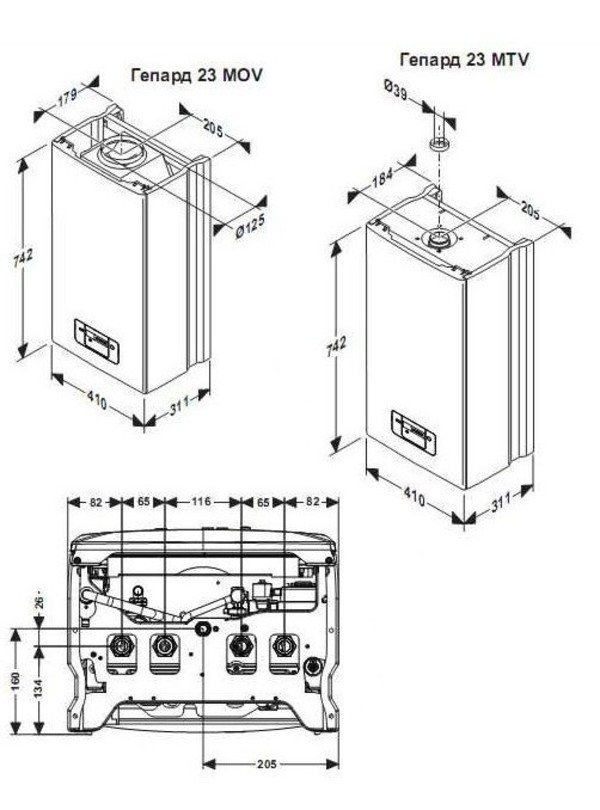

Navien Atmo 24AN and others

The atmospheric wall-mounted device Navien Atmo replaced the less successful modification of Ace. It can operate at extremely low fuel pressure - 8 mbar, and water - 0.6 bar. There are 4 models of different power in the series - 13, 16, 20, 24 kW. The heat exchanger for heating is made of copper. For hot water - stainless steel. Automatic control. There is a remote control. There is frost protection. Specifications:

- 24 kW.

- Water heating in the heating system - 80 ° C.

- The pressure in the circuit (maximum) - 3 bar.

- Efficiency - 86%.

- The maximum water temperature in hot water supply is 60 °C.

- Weight - 27 kg.

- Estimated cost 26-27 000 rubles.

- Heating area - 240 m².

Deluxe 24K and other turbo modifications

The line of turbocharged modifications is represented by three series of Deluxe (13-40 kW), Prime and Smart TOK (13-35 kW) at once. Navien Ice Turbo is an outdated model, it was replaced by Deluxe and Prime devices. Forced heaters have a closed firebox, and air is forced into it - by a fan.The performance of the fan is controlled by the controller. In order for air to enter the chamber, a coaxial chimney is organized. Due to forced injection, turbocharged modifications are characterized by increased efficiency.

There are no more differences between turbocharged and atmospheric versions. The equipment is completely similar - an expansion tank, a pump, an additional heat exchanger.

The Prime series, like the Deluxe Coaxial, has a closed firebox and all the usual elements of a turbocharged model. But Prime has an additional module - weather-dependent automation. Characteristics of the 2-circuit wall-mounted boiler Deluxe 24K:

- Efficiency - 90.5%.

- 24kW.

auto ignition.

- The maximum heating area is 20 m².

- Consumption of natural gas - 2.58 m3 / h.

- Dimensions (WxHxD) - 440x695x265 mm.

- Weight - 28 kg.

NCN 40KN and other condensing models

The principle of operation of the condensing heater is based on the use of both direct and latent heat released during gas combustion. This allows achieving high efficiency values - more than 100%. Condensing heaters are available in the Navien NCN and NCB models. Their heat exchangers are made of stainless steel. The package is similar to the turbocharged versions. The difference is that the functions of the controller are expanded. For example, he can program work for the next seven days. NCN is represented by 4 boilers 21-40 kW, NCB also 4 models 24-40 kW. Air is supplied forcibly - through a coaxial or separate chimney. For example, the characteristics of NCN 40KN:

- 40.5 kW.

- Two contours. Wall mounting.

- Closed furnace.

- Auto ignition.

- Weighs 38 kg.

- Efficiency 107.4%.

- The maximum heating of water in hot water supply is 65 °C.

LST 30 KG and other floor models

The brand introduces a line floor standing boilers from four series - LST, LFA, GA, GST with a capacity of 13-60, 13-40, 11-35 and 35-60 kW, respectively. Each of the presented samples is a universal outdoor apparatus capable of operating on both natural gas and diesel fuel. Floor versions, no less than wall-mounted ones, are saturated with automation. For example, the characteristics of LST 30 KG:

- 90% efficiency.

- Weight - 45 kg.

- 30 kW.

- Heated area - 300 m².

- Auto ignition.

- Volatile.

Features of the operation of gas boilers "Beretta"

The instruction manual for the Beretta geyser says that this is a complex self-regulating system, the main work of which is to convert gas into useful heat, heat the room and heat water. Proper operation with the device requires full adherence to the prescribed instructions that come with the boiler.

After installing floor or wall equipment, the engineer must check the first ignition before supplying gas, so that the communications correspond to the technical characteristics of the boiler, the smoke extraction system with air intake works correctly, the gas pipeline is tight, and the flow characteristics correspond to the gas pressure in the gas pipeline. Otherwise, the display will flash and give an error.

Subsequently, the operation according to the manual can be carried out by the user. To switch the boiler mode to heating in enhanced mode, you need to turn the switch button to the left in accordance with the picture, which indicates winter. To switch to the "summer" indicator, you need to turn the lever in the opposite direction.

Attention! Ignition must be carried out in a dry room at temperatures above 0 degrees. To turn it off for a long time, you should switch the button to the off mode, close the valve of the fuel supply pipeline and turn off the water in the DHW system

It is also recommended to drain the water from the system.

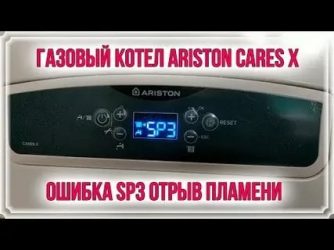

Communication with peripheral devices (errors 4**)

On the screen gas water heaters Ariston error codes for standard peripherals are displayed. This is done in order to explain the reaction of the boiler automation to an emergency situation. In this case, the consumer will be able to try to fix the equipment breakdown or conflict on their own.

Error No. 401. Communication problem between the bus and the data transfer device. It can be caused either by a malfunction of the device itself or by tire damage. Repair is possible only in the service center.

Error No. 402. GRRS/GSM modem malfunction. You need to check its connection or replace the device.

Error No. 403. SIM card problem. The contact has come off or the card itself is damaged.

Error #404. Communication failure between modem and motherboard. First of all, you need to check the contacts. If they are tightly connected, then the modem is faulty.

The GSM-module for controlling a gas boiler allows you to remotely control the heating modes of a building. However, in addition to the obvious pluses, there is also a minus - this is another node that can break

Error ## 405-406. Data bus (interface) problem. Usually the fault lies in loosely connected contacts. Rarely, the tire itself needs to be replaced.

Error No. 407. Break in the signal from the room temperature sensor. You need to check the connection (wire and contacts). If they are in good condition, then you need to replace the sensor itself.

Error 502

The electronics considers that the valve is closed and registers the presence of a flame. Possible causes and things to check:

- condition of the flame control electrode (it must be dry and securely connected to the ignition generator)

- carry out a gas valve test (qualified technician only)

- check the compliance of the power supply with the norms and the presence of grounding on the boiler elements

- visually inspect the board for damage (it is not uncommon for error 502 to appear after a thunderstorm)

If no checks have led to a result and all actuators are working, an in-depth diagnosis of the control board for damage is necessary. We repair gas boiler boards in Kostroma. Ariston equipment also has experience in successful repairs and the necessary components for the prompt replacement and restoration of boards, as well as stands (simulators of a real boiler) for testing.

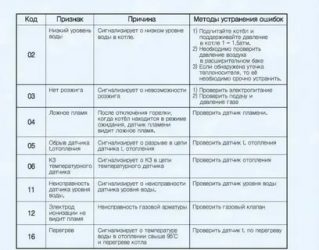

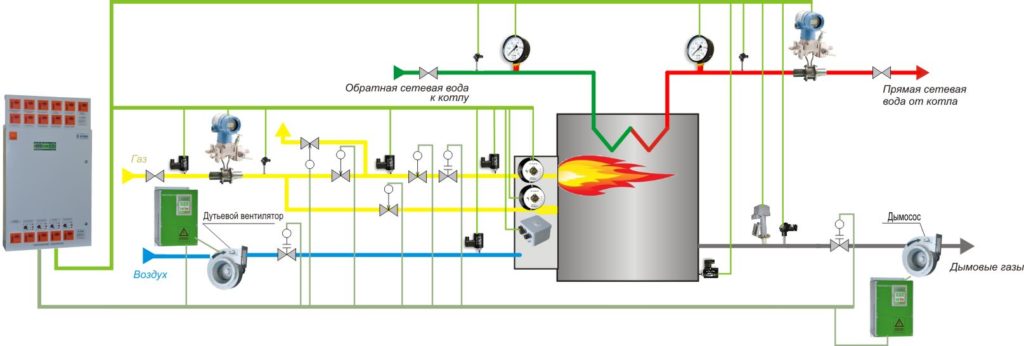

The main causes and malfunctions of gas boilers

The typical thermal scheme for various gas-fired boilers is almost the same, the main elements of the thermal scheme include a boiler with a furnace and heaters for hot water, one boiler for single-circuit boilers for heating systems and two for double-circuit ones. A burner and chimneys connected to a chimney are located along the gas path.

If the boilers operate with forced circulation of flue gases, as in closed furnaces, then an additional exhaust fan or fan is installed to supply air to the furnace and create a gas-air mixture. The gas pipe system and pipelines of direct and return water are tied with the boiler using shut-off and control valves, in addition, safety and control automation devices are installed in the circuit.All these elements must work reliably and in concert with each other, otherwise, the boiler will issue an error code.

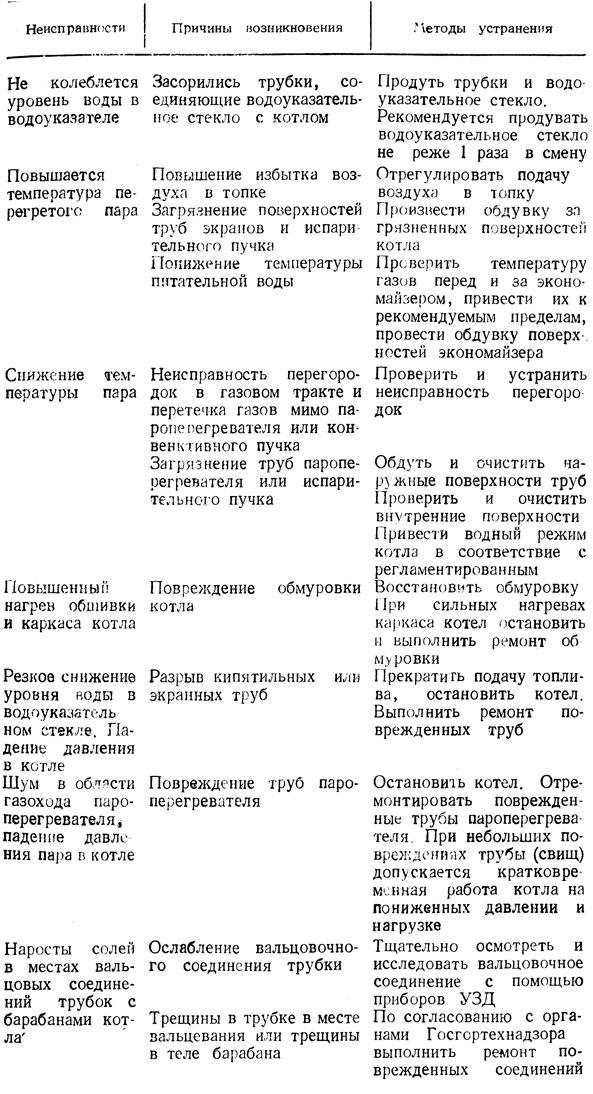

Other boiler malfunctions

In addition to code settings, problems that are not fixed on the display can also occur.

If you smell gas, it is necessary to turn off the burners not only on the Baltgaz boiler, but also on the gas stove and close the shut-off valves on the gas pipelines. Then call 04

The boiler does not turn on at all.

Possible reasons:

- There is no power supply. Check if the line is not de-energized and if current is being supplied. No - contact your electricity supplier to find out the reasons and timing of the shutdown.

- Also, the fuse in the board could have blown, and in this case, just install a new one.

- If the reason lies in the fact that water has got on the board, try to put it on natural drying for 48 hours until the moisture has completely evaporated.

- The boiler does not start even if there is a fault on the control board. Try restarting or replacing this item

If the actions did not bring any positive result, there is only one way out - contact the service center.

If you are unable to light the boiler, first of all, pay attention to whether you forgot to open the gas supply valve located on the pipeline leading to the boiler

The burner makes strange sounds like pops:

- Insufficient air supply occurs when the duct is clogged, improperly installed, or for other reasons.

- A spark jumps past the burner.

- The burner is clogged.

No hot water or insufficient pressure. Check the filter, heat exchanger and flow restrictor for blockages.

The device does not heat the room, but at the same time it functions in the DHW mode.The problem may be related to jumpers, a malfunction of the thermostat and temperature sensor, or simply incorrectly set temperature parameters.

Coolant inlet temperature is too low. Check the set temperature and temperature sensor.

Heating system pressure too low. Inspect the system for possible leaks, inspect the pressure gauge for correct operation, clean/replace the relief valve.