- Typical malfunctions of gas boilers

- The smell of gas

- Flame sensor failure

- Boiler overheating

- Boost fan malfunctions

- Chimney problems

- Boiler turns off

- Floor steel models Conord

- Typical problems with turbocharged models

- Reasons for stopping work

- The coolant in the heat exchanger does not heat up

- Low coolant pressure

- Traction violation

- What to do if the gas boiler does not turn on?

- What is a bimetallic plate

- Popular breakdowns and their elimination

- What devices use bimetal

- Gas boiler Conord specifications and features

- 1. When turned on, the boiler does not work at all

- Removing air pockets in the system

- The boiler blows out in strong winds what to do in this case

- Reasons for the attenuation of the boiler

- What to do when a malfunction occurs?

Typical malfunctions of gas boilers

Typical malfunctions of gas boilers

There are a number of typical problems, which in most cases can be dealt with on your own. Problems will also be listed, in the event of which you can only protect yourself before the arrival of a specialist.

The smell of gas

The smell of gas

If there is a distinct smell of gas or smoke in the room, immediately turn off the boiler and leave the room, opening it for ventilation.

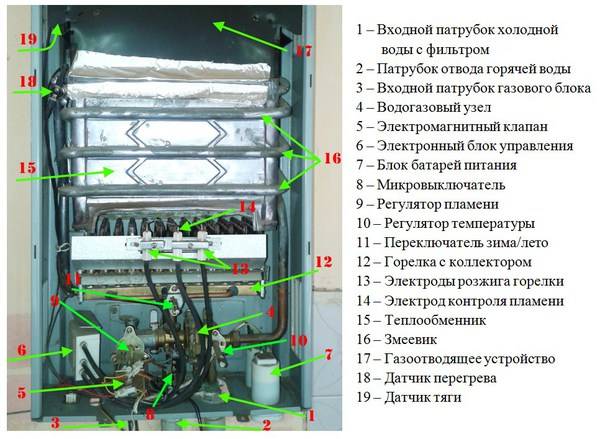

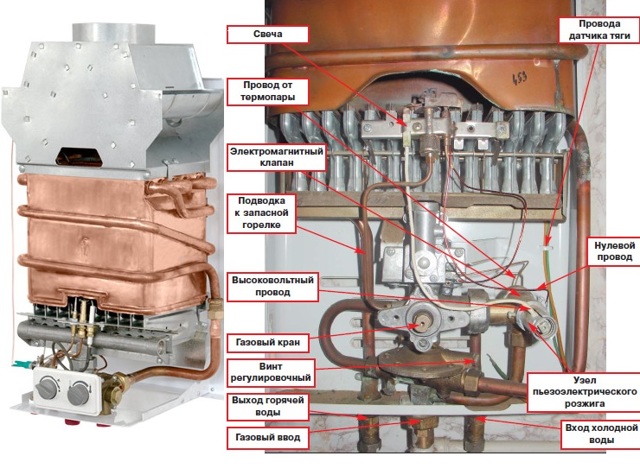

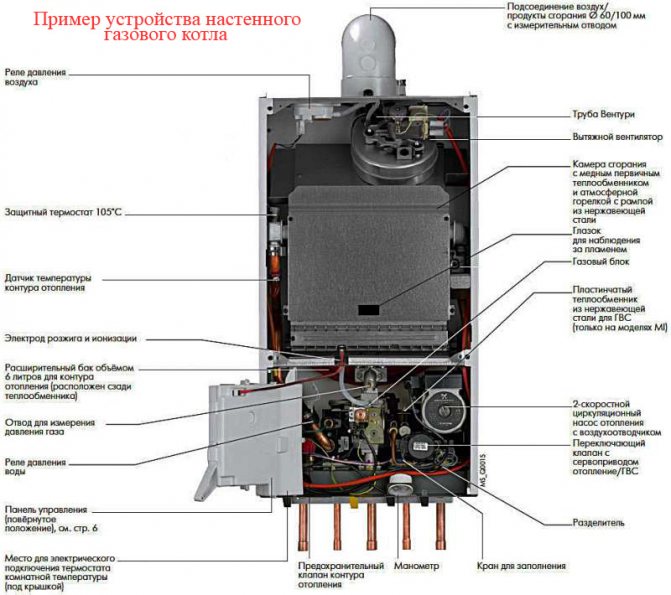

Scheme of functionality of a gas boiler

Flame sensor failure

If the combustion sensor or the gas supply pipe is broken, turn off the boiler, close all gas valves and allow the unit to cool completely.

After some time, return to the room to check it for the smell of gas. If everything is in order with the draft, try turning the boiler on again. If there is no traction, call a repairman immediately.

Boiler overheating

Overheating is one of the most common problems in modern gas boilers. The reason for this may be a malfunction of the automation equipment or a clogged heat exchanger.

You can clean the heat exchanger with your own hands. The most common materials for the manufacture of heat exchangers are copper and stainless steel. There are usually no problems with cleaning them, but still be extremely careful.

Primary heat exchanger for Beretta wall-mounted gas boiler

According to manufacturers' recommendations, heat exchangers should be cleaned of soot every few years (each manufacturer specifies a specific interval in the instructions for their equipment).

Primary heat exchanger (heating circuit) of the Rinnai SMF gas boiler

To clean the heat exchanger, simply remove it and clean it thoroughly with a wire brush. In the case of a copper heat exchanger, it is better to replace the brush with a metal sponge used for washing dishes.

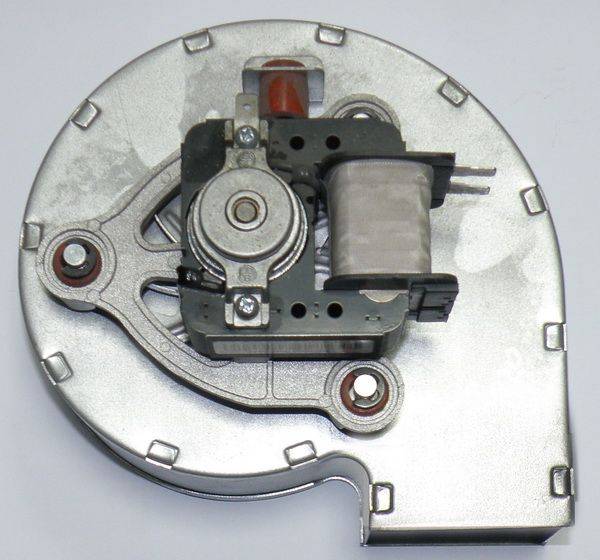

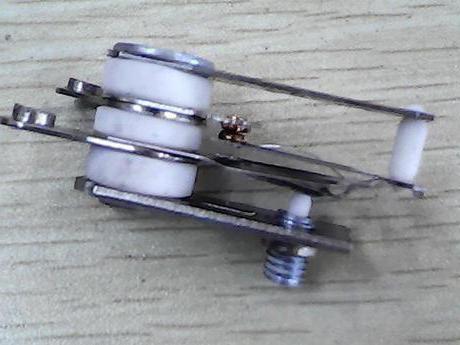

Boost fan malfunctions

The problematic place of fans are their bearings. If the fan of your boiler has stopped developing the set number of revolutions, try to eliminate the malfunction as soon as possible.

Fan (3311806000) for Daewoo gas boiler

To do this, remove the back of the fan, remove the stator and grease the bearings. Machine oil is fine for lubrication, but if possible, it is better to use a higher quality carbon compound with heat-resistant properties for this.

Fan RLA97 (Aa10020004) for Electrolux gas boiler

Also, an interturn short circuit can lead to problems with the fan. Only a specialist can cope with the elimination of this malfunction. Hand over the stator for repair to replace the winding, or immediately replace the faulty unit with a new device.

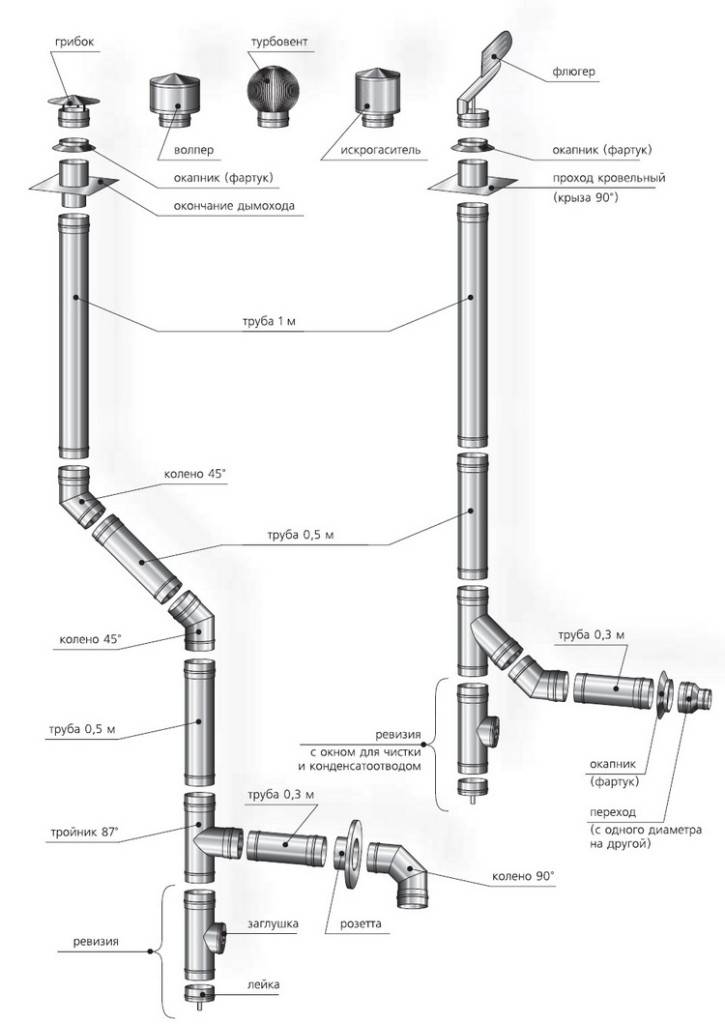

Chimney problems

Gas boiler chimney diagram

Often, excessive clogging of the coaxial chimney leads to the appearance of various malfunctions in the operation of a gas heating boiler.

Chimney

Remove the chimney and carefully clean all of its components from soot. So you will not only return the previous level of efficiency of the unit, but also significantly increase the efficiency of the boiler.

Boiler turns off

The boiler can spontaneously turn off for several reasons. This is usually due to a malfunction of the combustion sensor. This problem, in turn, most often leads to contamination of the gas pipe.

Draft sensor 87°C for Thermona boiler

Remove the nozzle, rinse it thoroughly with water, clean it with a cotton swab and blow out any remaining moisture. Return the pipe to its place and try to turn on the boiler. If it doesn't work, call the wizard.

Floor steel models Conord

We note right away that all boilers of this brand are produced in floor version. "Steel" refers to boilers whose heat exchanger is made of steel.It is easy to find such a device in a catalog or price list by marking, which begins with the letters "KS" (steel boiler).

For example, it is the steel heat exchanger that is installed in the boiler of the KSTs-G-16 brand.

Here the letter "C" denotes the cylindrical shape of the heat exchanger, "G" - the type of fuel (gas), and the number "16" - power in kilowatts.

The presence of the letter "B" in the marking (for example, KSTs-GV-20) means that the boiler is a 2-circuit one.

Boilers with a steel heat exchanger are lighter and heat up quickly. However, they are less reliable and not as durable as cast iron. A significant disadvantage of steel is its susceptibility to corrosion.

Typical problems with turbocharged models

The indicated difficulties also arise in turbocharged vehicles. And since this technique has an isolated combustion chamber and additional components, it is characterized by such difficulties:

- The hood or coaxial chimney is covered with ice.

- The integrated air blower has broken.

The culprits of the first problem are accumulated condensate and adhering snow.

You can avoid it by protecting the chimney from aggressive factors - a deflector is placed.

If ice plugs have already formed, they can be melted with a building hair dryer or a spray burner.

As a rule, condensate settles in pipes of convection modifications, for example Lemax PRIME-V10.

Traffic jams form here due to temperature differences in air flows coming from the street and heading outside. They block the path to the combustion chamber.

The solution lies in kindling the chimney with a portable burner. When the plug is removed, insulate the pipes.

If the boiler has a built-in blower, as in the Baksi ECO-4s 24 model, and it goes out during operation or the wick does not start immediately, pay attention to the sounds that appear. With stable functions, there are measured beeps

Excessive noise is a sign of a problem.

With stable functions, there are measured beeps. Excessive noise is a sign of a problem.

Turbocharging, as a rule, is not repaired, but quickly replaced.

If there are no sounds during the operation of the device, it means that the automatic mechanism prevents the opening of the protective valve, and the filter does not catch fire.

Call the experts to replace the turbo. Since this work is quite complex and associated with a certain risk.

Reasons for stopping work

There may be several reasons, let's consider each separately:

1. Long idle time of the boiler.

As a result, defrosting of the boiler may occur and it will become unusable. As a result, there is a sharp attenuation, the sounds of the wind blowing out the flame are heard from the combustion chamber.

Due to these factors, an alarm appears on the dashboard, indicating the need for urgent diagnostics of the device. Modern boilers are a rather complex and fully automated system.

Therefore, if one of the sensors signals a problem, the unit stops working.

It is not necessary to immediately change the boiler or install a new chimney, it is very important to understand the problem and find a way to solve it. 2

2

Chimney malfunction

If there are problems in the form of attenuation of the boiler, it is also important to check the serviceability and functioning of the chimney.The first reason may be the formation of ice on the walls of the chimney, which occurs through the deposition of hot steam, followed by the formation of condensate

After a certain period of time, the condensate freezes and becomes a thick layer of ice. After that, the draft decreases and the boiler dies out. The solution to this problem will also be its insulation in order to minimize the freezing of condensate.

3.Reverse thrust. As a rule, this kind of problem is observed with strong gusts of wind. The wind enters the chimney and blows out the boiler flame accordingly.

Please note: backdraft is quite dangerous, as some old-style boilers have outdated automatics that do not turn off the boiler, and it continues to accumulate combustion products inside the room. four

Insufficient chimney lift. If the height of the chimney is not enough to prevent air from entering the boiler with subsequent attenuation, a good solution for quick ignition would be to increase its length, at which the top of the chimney should extend beyond the roof ridge by about 50-60 cm

4. Insufficient chimney lift.

If the height of the chimney is not enough to prevent air from entering the boiler with subsequent attenuation, a good solution for quick ignition is to increase its length, at which the top of the chimney should extend beyond the roof ridge by about 50-60 cm.

5. Pipe burnout.

Insufficient draft is the result of a hole in the pipe into which wind enters, and therefore the chimney begins to function poorly.In this case, a complete replacement of the chimney is required.

6. Voltage surges.

This reason does not depend on external factors in any way and arises as a result of a drop in the voltage level. When the proper voltage level is restored in many boilers, the flame ignites again, in this regard, many owners do not even notice this problem. 7. Missing gas pressure. Very often, the problem of boiler extinction lies in the lack of sufficient gas pressure at the inlet to the boiler, at which the unit thumps and fades. The reason may be a malfunction of the network itself or internal reasons, namely:

7.1 Gas meter malfunction.

There are times when the boiler mechanism sticks, and it blocks the gas admission. To identify the source of the breakdown, it is necessary to check the operation of the counter mechanism, the readings of which should change.

7.2 Sealing fasteners broken.

A gas leak provokes a pressure drop, at which the system automatically operates and the gas apparatus goes out. You can identify this problem by the presence of a specific smell in the room.

Note:

you can conduct an independent diagnosis and identify the problem using a regular sponge with soapy foam - bubbles will appear at the leak points.

The coolant in the heat exchanger does not heat up

If the coolant is not heated either for heating or for supplying hot water, the reasons are as follows:

- The settings are set incorrectly. They need to be adjusted.

- The pump is blocked. You should try to reconfigure its indicators and put it into operation.

- A lot of scale has accumulated in the heat exchanger. It is recommended to descale the element using special tools or home methods.

- Thermal breaks. You need to change them for new ones.

In the event that the water is not heated only for hot water supply, the problem lies in the three-way valve, which just switches between heating and hot water.

Also, the causes of this breakdown are clogging in the coolant, leaks in the heat exchanger or connections.

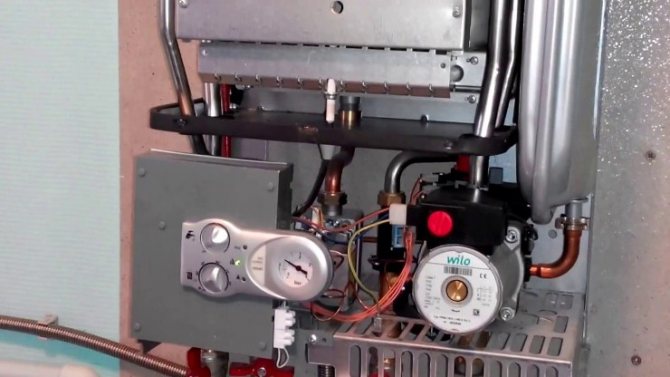

Low coolant pressure

On the front panel of each boiler there is a manometer indicating the pressure in the heating system. It has red zones for too low and too high readings. A pressure of 1.5 bar is considered normal for a cold boiler: at 1 bar the arrow is already in the red zone, and at 0.5 bar the boiler will turn off by error CE or CF until the pressure is restored.

If the boiler was installed recently - a few weeks ago, this situation is common, you just need to add clean water through a special tap. But do not rush to add water to a system that has been in operation for more than a year.

When heated, the water expands and the pressure rises - this is the norm. However, if it immediately jumps to 0.7 - 1.5 bar, this indicates a lack of air in the expansion tank.

If in such a situation, add water, heating up, it will increase the pressure too much and the safety valve will work, dumping excess coolant.

The built-in expansion tank differs from the external one: it is flat and located at the back of the boiler. Inlet connection - top, with threaded cap

In order to pump up the tank, you first need to relieve the pressure on the switched off boiler by draining some water. Then connect a pump or compressor to the fitting in the upper rear part of the tank and pump it up to 1.3 - 1.4 bar. After turning off the pump, add water, bringing the pressure in the cold system to 1.5 - 1.6.

If even when the boiler is heated, low pressure in the heating circuit persists, then it is really necessary to add water. Where to find the tube intended for this is indicated in the instructions for the device model, but we will only remind you of the need to fill this tube with water before opening the tap so that air does not enter the pump and batteries.

Be sure to check all taps, connections and radiators, as well as the inside of the boiler for leaks - the water that circulated in the system has gone somewhere.

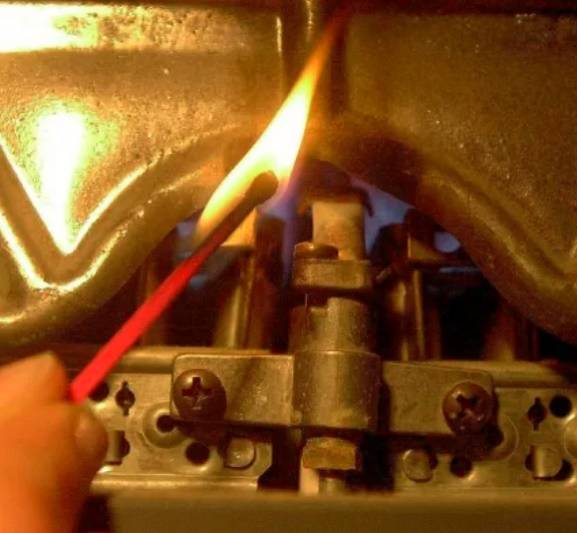

Traction violation

Checking for traction is the first thing the owner of a gas device should do. To do this, take a match and bring it lit to the window. If the flame leans towards the opening, everything is in order and the cause must be looked for elsewhere.

If the fire remains motionless, a list of the following actions is required.

- The window to the boiler room should be slightly opened to ensure the flow of fresh air.

- Next, disconnect the section of the chimney that is connected to the outlet of the heating equipment. After that, check if there is a draft in the pipe itself. If there is, you will need to clean it up.

- In the absence of thrust in the main channel, there is only one way out - to clean it. There is a special hatch hole created for cleaning. It is enough to open it and place a small mirror inside. If the outlet is not visible, you will have to start cleaning.

- Visually assess the condition of the pipe going outside. It may happen that birds have built a nest there. Another option is frosting the cut. In winter, condensation accumulates at the end of the pipe that goes outside. It quickly freezes on the walls, and the through hole narrows. All this leads to fading.

To normalize the work, there are several possible solutions:

- For gas wall-mounted boilers, the exhaust gas and air intake are located at one point of the coaxial pipe, and because of this, frost occurs. As solutions, they lengthen the inner pipe (through which the gas goes out to the street) relative to the outer one.

- Experts also recommend insulating the outer area of the chimney with 5 cm thick mineral wool to prevent the duct from becoming covered with ice.

To understand why the wick goes out in a gas boiler, you need to alternately check all described points in the article. Thus, you will surely identify the cause and troubleshoot. The main thing in this matter is to act carefully and without experience, try not to disassemble the main elements of the equipment - this is dangerous. If standard methods do not help, it is quite possible that the reason lies in more complex components. In this case, an experienced master should carry out their diagnostics and fix the breakdown.

What to do if the gas boiler does not turn on?

If the gas boiler does not turn on, the reasons may be as follows:

- The unit is not plugged in or the power has been turned off.

- A short circuit has occurred. Then you should remove the cover and inspect the wires and assemblies for such a problem. You should check the condition of the wires, sensors and fuses. If the fuse is blown, then it is replaced with a new one. If the element was changed not so long ago, and it burned out again, you need to call a specialist, as this indicates a serious breakdown.

- The varistor exploded due to a voltage drop.The presence of this problem will be indicated by a damaged varistor, which protects the gas boiler from power surges. Such a malfunction is eliminated by soldering the broken part.

- Clogged coarse filter. To adjust the work, the filter is removed and cleaned. At the same time, the taps are closed, and the boiler is disconnected from electricity.

- The reason is the pump, which does not pump the coolant for the following reasons: due to the accumulation of air, the rotor has jammed. If the cause is in the accumulated air, then you need to open the air duct and release all the oxygen. At the same time, the sound of escaping air should be heard. If the rotor has stopped, it is better to call a specialist who can start it.

- The room sensor is switched off. The reason may be an open circuit of the sensor in the unit's thermostat, a switched off room sensor or dead batteries in the electronic thermostat. The fact is that the security systems of the unit are combined into one chain, and if one of them breaks down, electricity is not supplied to the others.

What is a bimetallic plate

An element that has the property of deforming (bending) in one direction under the influence of elevated temperature is called a bimetallic plate. By the name, you can guess that the plate contains two metals. Each of them has its own value of the coefficient of thermal expansion. As a result, when such a plate is heated, one component of it expands by a certain amount, and the second by another.

This leads to a bend, the shape of which depends on the difference in temperature coefficients. The rate of deformation is directly proportional to the change in temperature. When the plate is cooled, it acquires its original position.The plate is a monolithic connection and can work indefinitely.

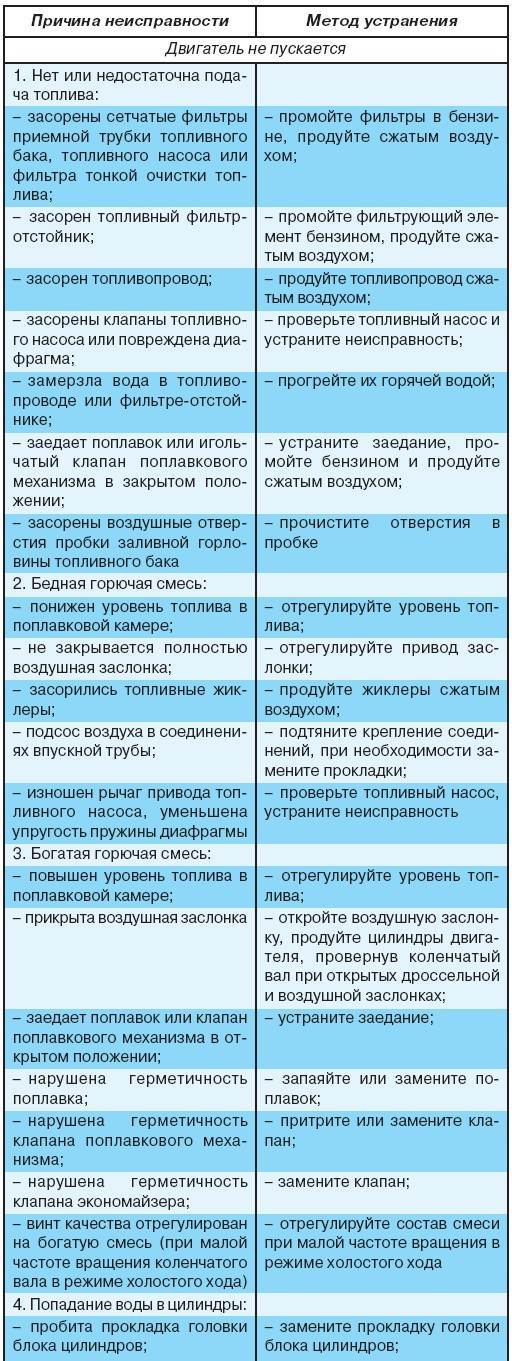

Popular breakdowns and their elimination

The lower the serial number of the error, the more often it occurs during the operation of the Beretta boiler.

Consider the most common errors and possible ways to fix them:

- A01. Blockage due to lack of flame. Several reasons are possible - problems with the gas supply in the main line, the gas supply valve to the boiler is closed, the burner nozzles are heavily clogged. Find out if there is gas in the line, clean the burner and nozzles.

- A02. Overheating of the heat exchanger indicates a lack of water. Check the operation of the circulation pump and the RH pressure, add fluid to the system.

- A03. High pressure in the chimney indicates blockage of the outlet with ice, frost, and soot accumulation. Possible weather factors - strong gusty winds.

- A 04. A drop in coolant pressure can be caused by a lack of liquid. Check the system for leaks, repair if found.

- A05. Malfunctions of the thermistor of the DHW line are eliminated by replacing the sensor.

- A06. A defective heating circuit thermistor must be replaced immediately.

- E33. It is necessary to swap the electrodes in the power plug. Beretta boilers are phase-dependent, do not work if the phase wire is connected incorrectly.

- E46. Exceeding the permissible temperature of the coolant indicates problems in the circulation of the liquid. The operating mode of the circulation pump should be checked.

- The bell symbol (bell, p) flashes. This is a signal from the chimney pressure sensor, indicating an obstruction to the exit of smoke, the formation of frost or frost at the outlet of the pipe.

IMPORTANT!

The Beretta boiler error is reset by pressing the off button and turning the boiler back on after 5-6 seconds.

What devices use bimetal

The scope of the bimetallic plate is unusually wide. Almost all devices where temperature control is required are equipped with bimetal thermostats. This is due to the constructive simplicity and reliability of such relay systems. In our usual technique, thermostats are:

- In household heating appliances: stoves, ironing systems, boilers, electric kettles, etc.

- Heating systems: electric convectors, gas and solid fuel boilers with electronics.

- In electropackets of automatic shutdown.

- In electronics in measuring instruments, as well as in pulse generators and time relays.

- in thermal engines.

In industrial technology, bimetallic plates are installed in thermal relays designed to protect powerful electrical devices from thermal overloads: transformers, electric motors, pumps, etc.

Gas boiler Conord specifications and features

The thickness of the steel sheets used to make the furnace of the Conord boiler is 3 mm. The material has a refractory powder coating, thanks to which the life of the boiler, as the manufacturer assures, is 15 years.

The efficiency of boilers of this brand is 90%.

Such a high rate was achieved due to the installation of turbulators in the fire tubes.

Branch pipes for connection to pipelines are located on the rear panel of the heat generator.

Their diameters are 50 mm or 2 inches (heating circuit connection) and 15 mm or ½ inch (DHW).

The smallest model provides heat generation in the amount of 8 kW. The oldest representative of the line has a capacity of 30 kW. Intermediate values: 10, 12, 16, 20 and 25 kW.

The diameter of the chimney depends on the power of the appliance. For boilers with a heat capacity of up to 12 kW inclusive, it is 115 mm, for more powerful ones - 150 mm.

Heat generators of this brand have built-in expansion tanks with a volume of 8.5 liters. The maximum allowable coolant pressure is 6 atm.

An important feature of the Conord boilers is the ability to operate at a gas pressure in the pipeline of only 0.6 kPa (usually the pressure in the distribution gas pipeline is maintained at 1.3 kPa)

1. When turned on, the boiler does not work at all

To eliminate this malfunction of a gas boiler, there can be several ways. The easiest is to check whether the boiler is plugged in or the machine has been knocked out. If this does not help, you need to remove the boiler casing and inspect its insides for a short circuit. Perhaps there is some smell or something has flowed. It is necessary to check whether all the wires and sensors are located in their places. If everything is in order, then you need to proceed to inspect the fuses on the electronic board. After making sure that the fuse has burned out, you just need to replace it with a new one. If the new fuse immediately burned out, then it is necessary to call the wizard, as this means some kind of serious breakdown, which is unlikely to be fixed on your own. A specialist must also be called in the case when all the fuses are normal, This indicates that the problem is not in them.

Pay attention to the varistor.It is designed to protect the boiler from power surges.

If there was any difference, then the varistor will be blown up and only a small part of it will remain. Because of this, the boiler may also not turn on. The solution to this boiler malfunction is simply to solder the varistor.

gas boiler varistor

Removing air pockets in the system

Better to start with batteries. To remove air jams, a Mayevsky crane is usually installed on them. We open it and wait for the water to run. Did you run? We close. Such manipulations must be done with each heater separately.

How to start the boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-feeding the system with liquid.

Now, the most difficult thing is that starting gas boilers requires venting air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny cap in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electric power and set the water heating regulators to the working position.

Releasing air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and a loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is airy, it will be so. We take a screwdriver and slowly unscrew the cover in the middle of the pump - as soon as water begins to seep out from under it, we twist it back.After two or three such manipulations, the air will come out completely, incomprehensible sounds will subside, the electric ignition will work and start working. We check the pressure again and, if necessary, add water to the system.

Basically, everything. While the system is warming up, you can do a detailed study of the instructions (if, of course, you have not already done so) and debug the system, which involves starting the boiler. Everything is simple here - the batteries closest to the boiler must be screwed on, and the distant ones should be run to the fullest. Such debugging is carried out by means of control valves installed on the pipe connecting the supply to the heating radiator.

The boiler blows out in strong winds what to do in this case

Mechanical heating boilers can go out due to the fact that they are blown out by strong winds. Any atmospheric phenomena - rain, high humidity, low atmospheric pressure, wind can affect traction, causing its excess or lack, and also cause reverse thrust. Outcome: the boiler went out. What to do in this case?

The solution to the problem lies in the following:

- You can install a special umbrella fungus on the edge of the pipe, which will cover the chimney from unwanted effects;

- And you can increase the pipe itself, if its length is not enough.

By the way, this is not the only problem that can arise with the chimney. In addition to blowing smoke, frost may form on the pipe. The reason for this phenomenon is condensation.

The fact is that moisture tends to accumulate and freeze over time, and then become so thick that it simply blocks the access of oxygen and the flame dies out, and the boiler turns off.

However, it happens that it is very difficult to knock down ice growths and then you have to defrost them.You can purchase a disposable burner with a small canister. To melt the ice, you need to light the burner and stick it into the cleaning hatch. When the pipe warms up, the boiler can be put into operation.

Reasons for the attenuation of the boiler

According to the safety rules in the gas industry, if the gas boiler goes out, then you can not start re-igniting it without finding out the reasons for the shutdown. Failure to comply with the requirement can lead to a fire and even an explosion of the boiler. Read also: maintenance of wall and floor gas boilers.

Troubleshooting should be entrusted to specialists. The main reasons may be the following.

- Low gas pressure at burner inlet. As a result, protection is triggered by this parameter.

- Igniter failure.

- Attenuation of the gas burner from insufficient draft at the exit of combustion products from the furnace. There are cases when the flame of the burner is blown out by the wind into the pipe.

- Lack of air for proper combustion of gas (low percentage of excess air in the combustion chamber).

- Gas leakage through leaks in the gas pipeline, its fittings and gas distribution devices. In this case, the sensors of the gas analyzers are triggered, and the device is turned off in the normal way.

- Interruptions in the power supply. Lack of electricity is the reason for closing the fuel supply valve to the burners and turning off the electrical auxiliary mechanisms of the boiler (pumps, fans).

- Power surges. This malfunction is similar to the previous paragraph, therefore, it often leads to the landing of the gas supply valve or the shutdown of mechanisms without which the boiler cannot work (fans, smoke exhausters, water pumps).

- Volatile units with a circulating heating system will turn off if the circulation pump breaks down and stops.

- Increasing the water pressure in the heating system in excess of the protection activation setting.

In this video you will learn what to do if the gas boiler goes out:

What to do when a malfunction occurs?

Gas consumers should understand that they are not entitled, but obliged, to repair their in-house or in-house equipment. And in a timely manner and with high quality.

And since the frequent shutdown of the boiler is potentially a malfunction, it is impossible to ignore the specified legal requirement. Since for this, according to Art. 9.23 of the Code of Administrative Offenses threatens with a fine.

Repair of any gas equipment is a responsible procedure, as it significantly affects safety. Therefore, you should not overestimate your capabilities or try to save money, risking the lives and health of people nearby, including relatives and friends.

The size, which is 1-2 thousand rubles. And, if suddenly the situation, through the fault of the user, becomes dangerous for the life and health of people or an accident occurs, then you will have to part with 10-30 thousand rubles (Article 9.23 of the Code of Administrative Offenses).

It is easier and more reliable to contact the gas company with which the contract has been signed. And all the risks will fall on their shoulders. As well as responsibility for the timeliness and quality of repairs. And for violations, the company will be held liable in accordance with Art. 9.23 of the Code of Administrative Offenses. Where does it say that penalties can reach an impressive 200 thousand rubles

It should also be remembered that one should not take responsibility for trying to eliminate the cause of the on / off on their own.Especially against the background of the fact that problems with equipment inoperability should be solved by specialists of companies with which the gas consumer has signed an agreement. And for ignoring such a rule, additional sanctions in the amount of 1-2 thousand rubles threaten - this is also spelled out in Art. 9.23 of the Code of Administrative Offenses.

Any repeated violation of the above norms will be the reason for punishment in the form of a fine, the amount of which will be 2-5 thousand. The basis for this is the corresponding norm in the above article of the Code of Administrative Offenses.