- Beretta CIAO 24 CSI

- Gas boiler Beretta. Malfunctions and their elimination (including models City csi 24, ciao csi 24, Fabula and others)

- How to run self-diagnosis

- Does not start (does not ignite) causes and solutions

- How to check Beretta gas boiler sensors

- Pump does not start

- How to flush the heat exchanger

- Error A01 Boiler Beretta

- Error A02 Boiler Beretta

- Error A03 Boiler Beretta

- Error A04 Boiler Beretta

- Most Common Error Codes and Troubleshooting

- 01

- 02

- 03

- 04

- 06

- 10

- 11

- 20

- 27

- 28

- Beretta Ciao

- Error code A01 - Flame error

- ADJ Error Code - Minimum and Maximum Power Electronic Settings Error

- Other malfunctions

- How to flush the heat exchanger

- Beretta City

- Blinking of the light bulb with a frequency of 1 time per half second

- The green light blinks quickly, with a frequency of 1 time per 0.1 seconds

- The green lamp is on continuously

- Red diode is on continuously

- Red light blinking

- The green light and the red LED flash at the same time.

- Yellow indicator is on

- Conclusions and useful video on the topic

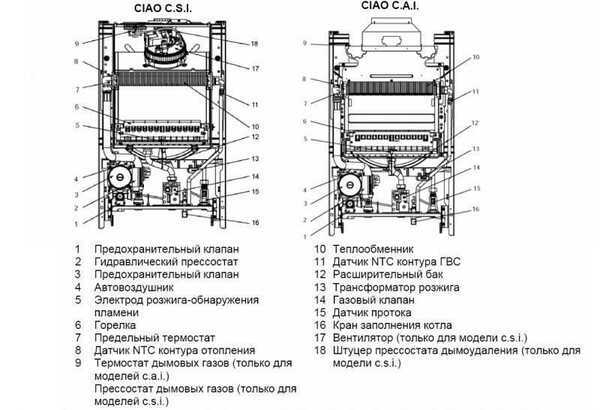

Beretta CIAO 24 CSI

The Beretta brand is owned by one of the leaders in the European heat engineering industry - the Italian company Riello, whose age is approaching its 100th anniversary.

Beretta boilers are manufactured using modern technologies and fully comply with European requirements for safety, economy and efficiency. Model CIAO 24 CSI is manufactured in accordance with the most promising technical developments and is able to meet the needs of a modern residential building.

The units are wall-mounted, have a compact and visually attractive case, which allows them to be installed directly in the kitchen and not to allocate a separate room for the boiler room.

NOTE!

The successful combination of price and quality of the Beretta CIAO 24 CSI model is highly appreciated by specialists and users, which confirms the steady demand and demand.

Gas boiler Beretta. Malfunctions and their elimination (including models City csi 24, ciao csi 24, Fabula and others)

It is worth familiarizing yourself with the main malfunctions of the Beretta unit, recommendations and repair instructions.

How to run self-diagnosis

The self-diagnosis system consists of a number of sensors located on irreplaceable parts and assemblies of the device. They do not need to be started, they function continuously from the moment of start until the suspension of the beretta gas boiler.

Heating unit self-diagnostics cannot be activated as a separate option. If the user wants to stop the operation of the heater, he will not succeed. Switching off the sensors is perceived by the boiler as an error, which leads to blocking of the structure.

Thanks to the self-diagnosis function built-in by the manufacturer, the equipment does not break down and notifies the user about the localization of a defect or a malfunction of the unit.

Does not start (does not ignite) causes and solutions

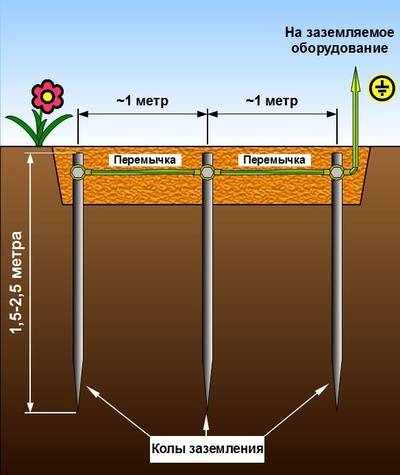

First, they check whether the boiler is plugged into the outlet or conduct a test, automatic ignition, the machine may have been knocked out. If it does not bring results, the casing is removed from the boiler and its internal state is analyzed, as well as the presence of a short circuit. You will probably smell or leak.

Then they check the sensors and cables, their presence in the field. Next, inspect the fuses on the board. If they burn out, they are replaced with new ones. Next, you need to check the varistor, which serves to protect the unit from power surges. On impact, it will explode. If this is the problem, the varistor is soldered.

Read more: Why does a gas boiler go out? Main reasons

Common reasons why the boiler does not light up and turn on are:

- Temporary voltage drops. This may cause the fan to stop working. In view of what air does not go into the system, and the flame goes out.

- Incorrect connection of zero and phase.

- There was frost on the chimney. Carbon monoxide does not have time to overcome it, so the system blocks the start.

How to check Beretta gas boiler sensors

All sensors are located in the self-diagnosis system. They perform control functions and are the subject of observation. In the event of a breakdown, short circuit, cable breakage, an error code will appear on the screen.

Sensors are checked automatically, the user does not need to do anything. Most of them react to temperature changes or indicators going beyond the limits. The elements have a simple design, when replacing there will be no difficulties and it will take little time.

It is not recommended to replace it yourself, this work should be performed by a specialist from the service center.

Pump does not start

If the user detects a failure of the circulation pump, you must immediately suspend the operation of the boiler and call the wizard. There are many reasons for failure, ranging from simple problems with the power grid, ending with mechanical problems.

To establish a defect, you need to test and analyze the condition of the pump electric motor. Also, the problem can be identified by checking the condition of the moving parts of the pump. It is recommended to see if there are any difficulties in the rotation or movement of parts, check for breakage or wear of parts of the Beretta gas boiler.

Based on the results of assessing the condition of the parts, the ignition unit and examining the functioning of the gas boiler device, a decision is made on the need to repair or replace the heat pump. If the repair work will help restore the structure to its previous performance, then a complete restoration of the pump is carried out. With the worst forecast - it is subject to replacement.

How to flush the heat exchanger

Beretta appliances are equipped with heat exchangers.

If they are separate, then washing will give a good result. Bithermic devices are difficult to clean due to their design features. You can choose from two flush options:

- Mechanical means disconnecting the exchanger from the device. Such washing is not particularly effective, since it is difficult to mechanically treat the surfaces inside.

- The chemical method eliminates the dismantling of the exchanger. Washing is carried out by a special device. The method is quite effective, it can remove scale and extend the life of the device. To clean gas boilers, reagents are used that act on deposits and remove it from the internal cavity of the tubes.

Error A01 Boiler Beretta

In boilers, error A01 (or A01 in Russian) takes error indicates problems in the ignition system (lack of flame, malfunctions in the control board). This may be due to the following reasons:

- 1. The flame detection electrode is dirty. You can clean the electrode from the carbon deposits that have appeared on your own.

- 2. Lack of gas supply. Violation of the supply in the main gas pipeline or the gas valve is simply closed (open).

- 3. Violation of the gas valve. Only a qualified technician can adjust the valve operation.

- 4. The reliability of the connecting contacts on the ignition unit is broken. Corrects itself. Disconnect, clean, connect.

- 5. Failure of the relay included in the control system for the functioning of the ignition unit, gas valve, fan. This problem is eliminated exclusively by a specialist. The reason may be both in the relay itself and in the electronic board.

Error A02 Boiler Beretta

If the boiler displays error A02 (A03), then in this case there are problems with violation of the temperature regime. Usually occurs in the event of a sharp drop in pressure in the coolant circulation system. The reasons may be the following:

- 1. Malfunction of the circulation pump. Pump operation may be impaired due to contamination. After several inclusions, it can work in normal mode. It is not recommended to disassemble it yourself. This should be done by a specialist. Only he will determine the cause of the malfunction and repair the pump or replace it.

- 2. Faulty temperature sensor. This malfunction is eliminated only by replacing the part.

- 3. Violation of the integrity of electrical connections by the sensor.It is necessary to check the integrity of the wiring insulation and check the reliability of the contacts.

Error A03 Boiler Beretta

The boiler display shows error a03, problems with the removal of combustion products. This may be due to:

- 1. Clogging of the channel for the removal of combustion products. This situation rarely occurs, there are practically no residues of gas combustion. But the cause may be the appearance of ice at the outlet of the pipeline system, due to freezing of condensate. Strong wind can also cause difficulty in the removal of combustion products, which entails the operation of the thermostat, shutdown and blocking of the boiler.

- 2. Lack of air supply, in case of forced smoke removal. The main problem is the failure of the fan. Replacement required.

Error A04 Boiler Beretta

On the display of the Beretta boiler, error a04 indicates the absence of optimal pressure in the heat exchange system. The error is similar to error a02. The only difference is that this code primarily indicates problems within the system of the boiler itself. The appearance of such an error on the display may be the following:

- 1. Blockage of the heat exchanger circuit inside the boiler. Long-term operation with hard water leads to the formation of scale on the internal surfaces of the heat exchanger. The addition of chemicals to the circulating heating system contributes to its removal.

- 2. Manifested leak. Sometimes the master will be able to repair the heat exchanger on the spot (solder). Otherwise, you will have to replace.

- 3. Violation of the tightness of the circuit of the heat supply system. Such problems can be eliminated independently, using a tool and sealing materials.

- 4. Malfunction of the circulation pump. The pump needs to be replaced.

- 5. Poor contact of the electrical wiring with the pressure sensor. Eliminated independently (clean and connect).

- 6. Damage to the pressure sensor. Replacement required.

In the instructions attached to all models of BERETTA boilers, most of the errors of the BERETTA boilers are indicated with a description of possible problem situations that arise during operation. In addition, the display shows the operating parameters of the boilers. For example, by comparing the error code of the city's boiler and the parameters of the operating functions, the master is able to identify the problematic block, assembly on the spot or eliminate the cause that does not require complex repair work. Troubleshooting related to the described errors should be handled by qualified craftsmen. Only a master with practical experience in servicing gas boilers of various brands and models can comprehensively diagnose and determine the specific cause of errors on the display.

| Boiler repair Navien | Baxi boiler errors |

| Installation of the heating system in the house | Gas boiler errors |

| Gas boilers with installation | Replacement of heating radiators |

By contacting us, you agree to the terms of the "User Agreement" - the Offer Agreement!

Remember - we are ALWAYS there!!!

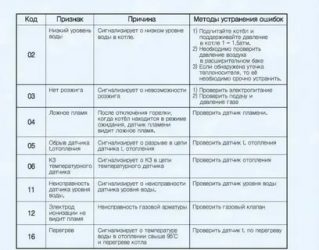

Most Common Error Codes and Troubleshooting

Let's try to figure out what the error codes mean gas boiler Immergaz. The most common error 01, it consists in blocking the ignition. Let's consider each error in more detail.

01

Ignition lock. The boiler is designed so that the inclusion occurs automatically. If after ten seconds the burner has not been ignited, a lockout is performed. To remove it, click on reset.

If the boiler turns on after a long period of inactivity, it will be necessary to remove the blockage, since air has accumulated in the gas line. If the unit turns on quite often, seek qualified help from a specialist.

02

Error 02 - the safety thermostat is activated, overheating has occurred, the flame control is faulty. If during the normal operation of the device the temperature begins to rise, the protective function is activated. Wait until the temperature drops to the required level, then press the reset key. If this problem occurs frequently, seek help from a specialist.

03

Error 03 is displayed when the smoke thermostat is activated. That is, a fan malfunction, to solve the problem, remove the case. Then open the chamber, it contains an engine that draws air from the combustion chamber. Open it by unscrewing the screws, clean its blades from accumulated dirt, this can be done with a brush. Treat the bearings with grease and install everything back.

04

Error 04 - high resistance of electromechanical contacts. The contact is blocked, the cause may be the failure of the protective thermostat or the sensor of the minimum allowable water pressure. Turn off the device, and after a couple of minutes, try restarting, or try closing the limit thermostat contact.

Water pressure sensor

If this does not work, close the minimum pressure contacts. Test the contact at the smoke exhaust pressure switch in the same way, after turning on the fan. If you find where the breakdown is, replace the element.If this does not work, you need a repair performed by a qualified specialist and diagnostics of the board.

06

Error 06 - there was a breakdown of the NTC sensor in the hot water system. For identification and repair, you must contact the service center.

10

Error 10 - low pressure in the system. Error e10 occurs when the pressure drops in the system, when it is less than 0.9 bar. First, try restarting, if the error remains, you need to check the following.

The cause may be a heat exchanger leak, check it, if a leak is found, fix it. To eliminate it, use the recharge lever, it looks like a screw, turn it counterclockwise, by this action the water from the water supply will flow into the heating, follow the pressure values, when the number is 1.3, close the valve.

11

Error 11. Smoke pressure thermostat operation. When the chimney does not work well, the boiler is blocked, after half an hour it restarts if the draft has become sufficient. If more than three shutdowns occur in a row, the display will turn red with an error code.

Smoke pressure switch

Press restart to unlock the boiler. In the instructions, the manufacturer recommends contacting a service center, however, first you can check the chimney draft and clean it.

20

Error 20 occurs with a parasitic flame. This indicates a gas leak, or a failure of the flame control system. Restart, if the same thing happens when you turn it on again, you need to test the board in a service center.

27

Error 27. This error indicates insufficient circulation in the heating system.The boiler starts to overheat, the reasons for overheating may be the following: air in the heating pipes, the taps are closed. It is also possible that the circulation pump has been blocked, unblock it. The cause may be clogged filters, check and clean. Check the heat exchanger for deposits.

Removal of air from the heating system

28

Error 28 indicates a leak in the water supply circuit, that is, the device heats the heating circuit, and the temperature in the water supply also increases, at a time when it should be unchanged. Check all the faucets in the house for leaks, also check that the taps are closed.

Beretta Ciao

The Beretta Ciao boiler is equipped with a liquid crystal display, which shows not only the operating modes, but also possible breakdowns. There is no standby mode.

Error code A01 - Flame error

This DTC appears when there is no flame. The display shows two characters. Crossed out flame and call.

ADJ Error Code - Minimum and Maximum Power Electronic Settings Error

This DTC indicates problems in the minimum and maximum power electronic settings. Bell symbol on the display.

Activation of standby ignition 88 degrees. The bell symbol flashes. A breakdown associated with the blocking of the boiler by a signal from the smoke exhaust pressure switch. At the same time, the bell symbol blinks. Failure associated with stopping the device due to the hydraulic pressure switch. At the same time, the bell symbol blinks.

Operating mode, showing the presence of sensors, measuring the temperature outside. The thermometer icon lights up on the display.

Operating mode indicating that the unit is supplying domestic hot water. The display shows the value 60 degrees and the sign faucet.

Operating mode indicating that the device is working on the heating system. The display shows the temperature value of 80 degrees and the sign "radiator".

The mode in which the operation of the apparatus is aimed at counteracting the freezing of the system. A snowflake lights up on the display.

Boiler mode indicating that a flame is present. The flame sign is lit on the display.

If you are not 100% sure what exactly the problem is and that you can solve it, immediately contact the service center to diagnose and fix the problem.

Other malfunctions

Other damage may also occur. If you smell gas in the room where the boiler is located, turn off the boiler and all electrical devices. Open the window and call the emergency service. If you smell combustion products, the problem is most likely in traction. Inspect the chimney for blockages and its connections for leaks.

Delayed ignition may be caused by an incorrect setting of the gas valve. If the coolant does not heat up to the required temperature, the problem may be a clogged burner or incorrect settings on the control panel.

Gas fittings for Beretta boilers

When the required temperature is reached on the boiler screen, and the heating radiators are cold, this may indicate the following:

- The presence of air in the system. In this case, it is necessary to remove excess air from the heating pipes.

- No circulation. It is necessary to inspect the heating system and the serviceability of the circulation pump.

- Expansion tank broken.

How to flush the heat exchanger

Beretta boilers are equipped with either separate or bithermic (combined) heat exchangers.In the first case, flushing gives a greater effect, the second type of heat exchangers is difficult to flush due to design features.

There are two ways to flush:

- Mechanical. Requires disconnection of the heat exchanger from the boiler. The results of such washing are not particularly successful, since it is extremely difficult to clean the internal surfaces mechanically.

- Chemical. It does not require the dismantling of the heat exchanger, but is carried out using a special device. It has a sufficiently high efficiency, is able to eliminate scale and extend the life of the unit.

For flushing, special reagents are used that dissolve scale and remove it from the internal cavity of the heat exchanger tubes. The procedure should be done every 2-3 years, depending on the quality of the water. To perform work, you must invite a specialist from the service center.

Beretta City

The Beretta City boiler is equipped with lights, as well as a display that shows possible errors. Two light diodes installed on the central control panel are configured to notify of possible malfunctions.

Blinking of the light bulb with a frequency of 1 time per half second

This means that the Beretta boiler has stopped due to an accident. In this case, several variants of breakdowns are possible. The device stopped at the signal of the hydraulic pressure switch, the stop lasts no more than 10 minutes. Stop on signals from the smoke exhaust pressure switch. The stop lasts no more than 10 minutes. The unit is serviceable, and at the moment it is in an intermediate state before ignition. When this error code appears, the instrument is in standby mode. As soon as the conditions for full-fledged work are restored, the device starts up.If after the set time the operation is not restored, the temporary stop will become emergency. In this case, a red light bulb located on the same control panel will be added to the green LED.

The green light blinks quickly, with a frequency of 1 time per 0.1 seconds

S.A.R.A function input/output. (system of automatic installation of temperature in the room). The automatic control system is activated if the temperature controller responsible for the temperature in the heating system switches to auto mode. In this case, the boiler automatically sets the water temperature, focusing on the readings of the thermostat, which measures the temperature in the room. After the water reaches the set temperature, a countdown of 20 minutes occurs. If during this time the thermostat continues to send a signal that the temperature in the room is below the required one, the unit will automatically set the temperature of the water supplied for heating by 5 degrees more. After another 20 minutes, the device again compares the set temperature in the room and the signal coming from the thermostat. If the temperature is again insufficient, a new rise in water heating by 5 degrees follows. After the second increase in temperature, the system will automatically return to the user-defined settings. And so it will be repeated until the temperature in the room reaches the required value.

The green lamp is on continuously

The Beretta boiler is operating normally. The flame is present.

The red light always indicates that the instrument has stopped in an alarm. The different indications of this diode indicate the type of fault.

Red diode is on continuously

There is no flame.After the end of the transitional stage in the operation of the boiler, a signal came from the smoke exhaust pressure switch. Broken NTC sensor in the heating system. Due to an electronics failure, the unit stopped. After the end of the transitional stage in the operation of the unit, a signal came from the hydraulic pressure switch.

Red light blinking

This fault code appears when the limit thermostat is triggered. In order for the Beretta City boiler to be put back into operation, the mode switch must be moved to the desired positions. Next, you need to wait about 6 seconds, and then set the words to this mode of operation, which is required. If this does not help, then further repairs are carried out by service specialists.

The green light and the red LED flash at the same time.

This operation of the indicator lights indicates that the NTC sensor of the DHW circuit is defective. In this case, the unit will continue to work, but it will not be able to maintain a constant temperature of the water supplied for household needs. To eliminate the breakdown, you need to contact a specialized service center. If these two lights flash alternately, it means that the machine is currently in the setting mode.

Yellow indicator is on

If it lights up continuously, it means that the appliance is in the domestic water preheating mode.

Conclusions and useful video on the topic

To eliminate failures and errors during the operation of the Beretta gas boiler, it is necessary to understand the principle of its operation:

The video below will help to recognize the errors of Beretta boilers:

An example of determining and eliminating a Beretta gas boiler error:

p> If your Beretta gas boiler began to produce this or that error, it is not recommended to let things take their course and pull with repairs or adjustments. But before contacting the gas workers, it would be nice for the owner of the equipment to figure out what the equipment error is.

Knowing the cause of the identified failure will help the owner find the best solution to the problem when communicating with the authorized service master.

Do you want to talk about how you yourself determined the breakdown of a gas boiler of the Beretta brand by indication or code? Is there any useful information that may be useful to site visitors? Please leave comments in the block form below, ask questions, post photos on the topic of the article.