- Conducting outdoor plumbing

- Summer water supply from polypropylene pipes

- Types and characteristics

- PVC sewerage

- Polypropylene (PP)

- corrugated polyethylene

- Asbestos-cement

- Concrete

- metal

- Cast iron sewer

- Ceramic products

- Problems of using plastic pipes

- Disadvantages of PVC pipes

- Advantages of plastic pipes for heating

- Advantages and disadvantages

- Installation of plastic sewer pipes

- Design work and diagramming

- Pipe laying

- Pipe connection

- Advantages of propylene pipes

- Pipeline installation method

- Features of using plastic pipes

- Disadvantages of plastic pipes

- Criterias of choice

- Is it worth it to use metal-plastic pipes for plumbing

- Scope of application

- Advantages of pipes made of metal-plastic

- Disadvantages of metal-plastic pipes

- Mounting

- What to consider when installing such pipes

- How can such pipes be installed?

- Advantages and disadvantages

- Installation of water supply from polypropylene pipes

- Conclusions and recommendations

- Types of XLPE pipes

Conducting outdoor plumbing

Polypropylene pipes for heaving soils are the best option: bury them to the freezing depth and you can forget about them. From the collector it is necessary to mark the markup so as not to make unnecessary connections and bends.

Summer water supply from polypropylene pipes

For summer water supply, it is quite possible to use pipes without reinforcement: they will withstand pressure, and if they turn yellow in a few years, then this is not significant on the site. Pipes are connected by soldering in the same way as with internal plumbing. The only difficulty can be connected to the central water supply, since it is necessary to drain the water from the main in a certain area.

Despite some shortcomings, a polypropylene pipeline undoubtedly has one of the main advantages over steel pipes: it does not require repair. And the second advantage, in addition to those listed above, is an environmentally friendly pipe material. Water from pipes will not rust, will not form any impurities, and this is the most important argument in favor of these pipes, since it directly affects human health.

Types and characteristics

For laying sewer systems, manufacturers offer finished pipes, tees, corner products, adapters, crosses. The materials used in production determine several varieties of products. These can be polymer, metal or ceramic components.

PVC sewerage

PVC pipes have a smooth surface, sufficient strength for internal and deep sewerage, are not afraid of ultraviolet radiation, can last more than 50 years and are inexpensive. The classification of types of PVC sewer pipes is based on strength indicators:

- SN2 - lungs.

- SN4 - medium.

- SN8 - heavy.

Regarding the application, there are restrictions due to poor resistance to low and high temperatures exceeding +40 degrees Celsius.The material becomes brittle and elastic, which leads to cracks and deformations. During combustion, toxic substances are released.

Polypropylene (PP)

Compared to PVC sewerage pipes plastic polypropylene pipes are inferior in strength, therefore they are used only for laying inside the building without external mechanical load. The permissible drain temperature is +80 degrees Celsius. The smooth surface contributes to the free flow of the medium, which is important for the circulation of drinking water. Inside the dwelling, it is better to lay noise-absorbing products (for example, under the rehau or politek brand).

corrugated polyethylene

Structurally, HDPE pipes are represented by a solid corrugation and a built-in smooth-walled channel. This design provides increased rigidity of products, which is important for deep laying (up to 16 m.). According to the technical characteristics, the material is similar to the plastic counterpart. It is used more often for the construction of engineering communications for the transportation of hot waste.

Asbestos-cement

Asbestos in the composition of the cement mortar plays a reinforcing role. Products belong to the most budget option for a sewerage device. Contact with water has a positive effect on the strengthening of the walls. Pipes have a low coefficient of thermal expansion and do not corrode. The characteristics are relevant for pressure systems and outdoor laying.

Concrete

For the manufacture of pipes, as a rule, M350 concrete is used. It is characterized by water absorption up to 3%, 200 cycles of freezing and thawing and high compressive and tensile strength. The material does not rot, does not burn, does not corrode, is resistant to chemical environment and low temperatures.It is used in the industrial, hydrotechnical and urban planning sectors with a low degree of aggressiveness.

metal

Such products are represented by steel-rolled products with a galvanized anti-corrosion coating. The material has high strength, long service life, withstands temperature extremes in a wide range and is relatively inexpensive. However, it is rarely used in the private sector due to its heavy weight. More often, a sewer pipeline of this nature is laid at industrial enterprises of the chemical and oil refining type.

Cast iron sewer

Cast iron is an alloy of iron and carbon. The material is characterized by higher strength, pressure endurance and corrosion resistance compared to steel. It also has a service life of over 80 years.

For laying sewers, a negative fact is the rough inner surface, which makes it difficult to transport wastewater and contributes to the formation of plaque. In the private sector, cast iron is rarely used due to its significant weight, high cost and the need to additionally resort to sealing agents. More often, such pipes are used for the internal construction of risers and sewers in multi-storey buildings.

Ceramic products

The production of ceramic pipes is based on the processing of clay. The raw material has water resistance, resistance to aggressive environment in terms of temperature, chemicals, corrosion. Among the advantages, an unlimited service life is also noted. However, brittleness complicates installation work, the installation of fittings and limits the installation in places of increased mechanical stress.The use of ceramic pipes is relevant for sewerage in industrial areas, at strategic sites.

Problems of using plastic pipes

Many people still refuse to change old cast iron for polypropylene, and for good reason. Of course, the advantages of PVC pipes are more than enough. This is cheapness, and ease of installation, and many other advantages.

As for the shortcomings, the main ones are:

Linear expansion - this problem of plastic pipes is easy to encounter on large highways, more than 5-10 meters in length. If PVC pipes go outside, then even fasteners that are often placed, every 50 cm, are unlikely to save them from inevitable elongation.

When heated, plastic pipes lead to the sides due to this problem. In general, the linear expansion is approximately 3 mm per 1 meter of PVC pipe (much depends on the diameter). Therefore, installers know such an expression as "pipes float." A partial solution to this problem is to hide plastic pipes in strobes, however, there are also disadvantages here, which you will learn about below.

The importance of temperature conditions - plastic pipes are more demanding on temperature conditions. In the cold, the plastic can simply burst, and overheating, if the PVC pipe is not designed for a certain temperature regime, can cause the destruction of its outer layer

So, for example, at a temperature of -5 degrees, polypropylene pipes begin to collapse, so they are of little use for outdoor plumbing. In the cold, PVC pipes crack and delaminate.

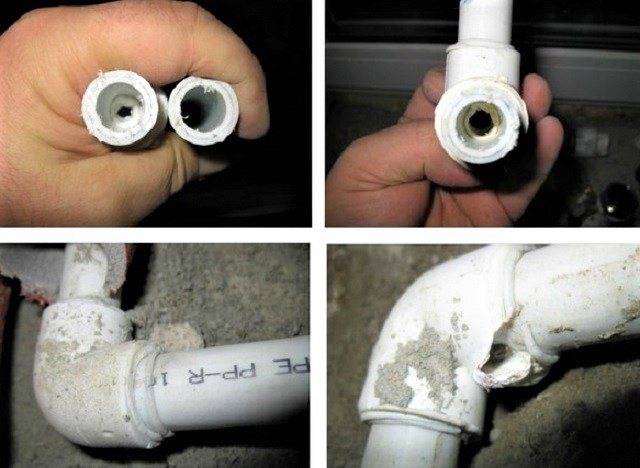

Installation problems - welding (soldering) and a lot of joints are used to connect plastic pipes.A large number of joints is also not entirely good (I don’t understand how some “wizards” manage to install a warm floor from PVC pipes). As for installation problems, experience with plastic pipes is needed here. Otherwise, there will be leaks, a strong narrowing of the internal passage due to overheating, burst fittings, and much more.

Disadvantages of PVC pipes

From all of the above, the main disadvantages of plastic pipes can be distinguished:

- The complexity of installation (you need to have work experience);

- The exactingness of pipes to certain temperature conditions;

- Strong linear expansion of pipes due to heating;

- A large number of joints that may someday leak;

- The service life of PVC pipes is 50 years (this is according to the manufacturers). However, as practice shows, the aging of a plastic pipe begins to occur after 10-15 years. Still, in this regard, PVC pipes can hardly compete with the same steel pipes or cast iron.

It should be noted that all of the above problems, to one degree or another, are affected by the quality of polypropylene pipes.

If the pipes are of poor quality, then all of the above problems appear, which lead to an early replacement of the pipeline.

Advantages of plastic pipes for heating

When a heating system is arranged, then everything needs to be thought through to the smallest detail. In addition, it is necessary to consider the consequences of using materials in conditions of external influences. If you think in general about plastic pipes for heating, then here you can highlight some positive characteristics:

- Corrosion resistant.The material has properties that do not allow it to enter into any reactions. It can be concluded that plastic is in no way destroyed by moisture. In addition, it will not rot or rust. The characteristic is considered when pipes are selected, as well as for heating. Due to this property, the service life can reach even 50 years.

- This is an environmentally friendly material, the properties of which have been proven for a long time.

- You can find a low coefficient of thermal conductivity. The liquid in the pipes will not cool very quickly, as in other cases. This characteristic can help determine the quality of the pipes, because the purpose is the application for heating.

- Such material for pipes perfectly interacts with differences in temperature data and pressure. This is ideal for installation in ordinary rooms of residential premises. You can be absolutely calm that the material will not deteriorate and there will be no other troubles.

- Pipes will not make unnecessary noise during the flow of water. The inside of the component will be smooth, and there is no limescale.

- The components are lightweight and therefore do not require a lot of effort during movement. They are connected using fittings, which facilitates the process of installing pipes. At the same time, the need for seams is completely eliminated.

- A huge advantage is that the components have seams that will not deteriorate over time like other materials.

- Price because plastic is considered an economic component.

As you can see, there are many benefits. That is why now we also need to consider visible shortcomings, because plastic pipes still have them.

Advantages and disadvantages

Of the many advantages, the most important is the long service life of more than fifty years, which is more than three times the service life of metal pipes.

Plastic products do not change their properties upon contact with moisture, therefore they are not subject to corrosive formations. For their production do not use harmful and toxic substances. The usefulness of these pipes is that they can be made from waste used pipes.

Plastic has low thermal conductivity, so heat loss will be minimal. Such pipes weigh little, which will greatly simplify and reduce the cost of transporting a large number of large pipes. They are easy to install and transport. The cost of such products is quite acceptable and starts from twenty to eight hundred rubles.

Plastic has low thermal conductivity, so heat loss will be minimal. Such pipes weigh little, which will greatly simplify and reduce the cost of transporting a large number of large pipes. They are easy to install and transport. The cost of such products is quite acceptable and starts from twenty to eight hundred rubles.

The smoothness of the inner surface resists various deposits and growths. This is a guarantee that after the time has elapsed, the volume of the pipeline will not decrease, and bacteria will not multiply.

The main disadvantage of these products is not stability when working at high temperatures. However, many advanced types of plastics are now being produced that can be used in heating and hot water systems. The inconvenience can also be caused by the fact that, depending on the type of plastic, a different type of fastening is required (using fittings, different melting temperatures).

Also, when laying water pipes from plastic, one must not forget that certain types of plastics are characterized by destruction due to ultraviolet radiation. Insulation will be required to save the pipeline.

Installation of plastic sewer pipes

For the device of the system, plastic sewer pipes of different diameters are used, which is selected depending on the load in this area. So, for example, a pipe with a diameter of 50 mm is used inside buildings, as a rule, when distributing wastewater, a diameter of 110 mm is more suitable for transporting waste from toilets, and a pipe with a diameter of 300 mm is used in the construction of sewers in apartment buildings or industrial facilities, that is, there where it will bear the greatest load.

Required diameters of plastic sewer pipes

Design work and diagramming

The initial stage of sewerage construction is the preparation of a project, according to which sewer plastic fittings and pipes are purchased in the required quantity, observing all the required dimensions

You can draw up a project based on an existing system; before dismantling it, you need to carefully examine it, noting all the features and paying special attention to the shortcomings so as not to repeat them in a new structure

If possible, you should save the entire route of laying pipes, this is done in order to avoid making new holes in walls and ceilings. If the old scheme is preserved, it will also be easier to select the diameter and measure the pipes.

The diagram shows the locations of the riser, sewer units and other key places.

Measuring the length of the pipe on the ground

Pipe laying

The laying of sewerage from plastic pipes begins from its highest point. As you lay, you should not forget about the need for a slope and observe its value.

This is especially important if the sewer is a non-pressure type and the water flows down into the riser by gravity.

It facilitates the task of using the level, with its help it is easiest to control and observe the angle of inclination. It is also necessary to ensure the minimum distance between the fasteners, since if it is exceeded, the plastic pipe may bend under its own weight.

Proper location of sewer plastic pipes

Pipe connection

Before proceeding with the installation of the system, you should consider how the sewer plastic pipes will be connected. There are two options for docking and sealing: with glue or welding.

- Adhesive connection. Before applying the adhesive, cut the pipes to the desired length, remove burrs with sandpaper and degrease both the surface of the pipe itself and the fittings that will be used for connection. The glue is applied in a thicker layer on the pipe, thin - on the connecting elements. When inserting the pipe into the fitting, it is recommended to turn it slightly to distribute the adhesive more evenly.

- Connection by welding. Before connecting sewer plastic pipes in this way, their surface is thoroughly cleaned of contaminants, the palnik is heated to the required temperature level and the fittings are prepared. Before soldering, both pipes and fittings also need to be degreased; after this procedure, they are put on the nozzles of the soldering iron, where, after heating for the required time, the fitting is inserted into the pipe. The quality of the resulting connection is checked: it should not have burrs and excess plastic.

Pipe welding

Upon completion of the installation of pipes, gaps between pipes and walls or ceilings should be sealed.As a rule, mounting foam is used for this.

The process of installing sewer pipes does not require high qualifications, but if there is even the slightest doubt about whether it will be possible to do all the work efficiently, you should turn to professionals.

Plastic pipes are by far the best material for sewerage, their installation and connections are not highly laborious and complex, but certain rules and requirements must be observed.

Advantages of propylene pipes

Propylene pipes have an absolutely smooth inner surface and this saves the water supply system from fatty, corrosive and other deposits.

This is especially important in cold water supply, since various kinds of additives are used in hot water and they prevent foreign substances from depositing on the pipe walls;

The service life of polypropylene pipes is expected to be about 100 years (their production has recently begun, so it is impossible to say more precisely);

The pressure that pipes made of this material can withstand reaches 20 atmospheres, although in multi-storey buildings, when pumps are running, more than 10 atmospheres are not created;

Maximum temperature with hot water supply it is 95 degrees, and polypropylene pipes can withstand it for a long time without changing shape;

Polypropylene is a wear-resistant material, so their inner surface is not subject to erosion by sand, limestone, slag, particles that are present in water;

Pipes are not electrically conductive. This means that no stray currents are transmitted to them;

Easy installation

Instant connection of pipes by heating and melting two mating elements.

Important. One of the important qualities is their low cost compared to metal and metal-plastic pipes.

Pipeline installation method

PP pipes are connected by soldering: both parts are heated and connected to each other. Heating is done with a special soldering iron. The installation of PP pipes requires certain professional skills, since if the part is overexposed or underexposed when heated, the passage hole may decrease or the parts will not connect well and will leak. In addition, the process of connecting fittings and adapters is longer than with MP.

MP pipes are also connected using fittings, but they only need to be crimped with press tongs. During the connection process, it is difficult to damage something, so even a beginner can handle the installation. If you plan to mount the pipeline yourself and have never done this before, then we recommend that you install the MP. If there is no desire (or opportunity) to buy pliers, you can get by with collet connections - however, like any threaded ones, they will have to be tightened periodically.

Features of using plastic pipes

Improvements in production processes are ongoing and this also applies to plastic pipes, which are commonly used for laying sewer systems. The development of such technologies is happening more than rapidly. Based on a considerable and comprehensive list of advantages of using polymer products, experts prefer this particular material, which makes it easy to design and implement systems of various shapes and levels of complexity.There are no analogues of this material at the moment. It is more durable and harder than ordinary polyethylene or the same plastic. Over time, it will not wear out or crack. And these are just some of its benefits.

Features include:

- in terms of ecology, this material will always be on the side of the best choice, like any other products and devices made of plastic. It is not subject to combustion, which means that there will be no destruction of the ozone layer;

- unlike the same pipes made of cast iron, they are not subject to corrosion;

- can be used for outdoor and hidden systems;

- amazing durability (about 45 years), when compared with metal counterparts;

- the quality of the material will not change depending on the temperature and weather conditions. They will perfectly cope with the tasks set, both under the condition of low and high temperatures. The stability index applies not only to the shell of pipes, but also to their internal matter. This made it possible to slow down the natural process of their destruction as much as possible;

- all polymeric materials have the ability to interact with various electrochemical reactions. Those. the material will not become a conductor for electric current, which makes it possible to use such material for laying sewer systems near electrical cables and other electrical appliances. They are completely safe;

- stable and extremely reliable, largely due to the fact that they are practically not affected by alkaline substances and acids. This also applies to various deposits that may be hidden in limestone rocks.Due to the many shortcomings of other similar materials, they quickly become unusable due to rapid aging.

Disadvantages of plastic pipes

Any material has its advantages and disadvantages, which should be carefully considered when choosing the material you need for installing the heating system. Compared with a fairly large number of advantages of using plastic in heating pipes, the disadvantages of this type of pipe installation are not decisive:

- Some types of plastic pipes are destroyed by ultraviolet sunlight. But in the case of choosing pipes for the heating system, this drawback is completely unimportant.

- Plastic pipes have a rather small temperature range, usually no more than 95 ° C, but given that such pipes will be installed in a residential area, too high temperatures are not required there.

Thus, the use of such materials for the heating system in a residential area is a very practical and profitable investment of your money. You can buy plastic pipes for heating at an affordable price from a representative office. After that, it remains only to carry out the installation of pipes without unnecessary expenditure of time and effort, and in the future you will feel confident about the safety and strength of your heating system.

plastic pipes for heating

Criterias of choice

Get it right to understand metal-plastic or polypropylene pipes for water supply are more suitable, given the following nuances:

Now you can understand how metal-plastic pipes differ from polypropylene pipes. It cannot be said that one type is unequivocally better than the other.It's just that each of them has its own purpose, it is necessary to select it for a specific situation.

Over time, construction technologies improve, so better and more reliable products appear. Now polypropylene pipes are suitable for transporting drinking liquids, all thanks to new technologies. When choosing the optimal solution for the installation of the pipeline, you should approach the task responsibly. This will significantly increase the life of the system.

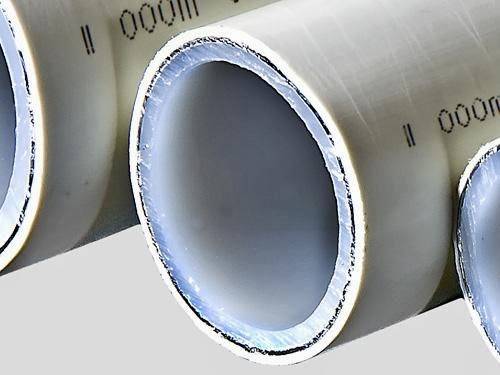

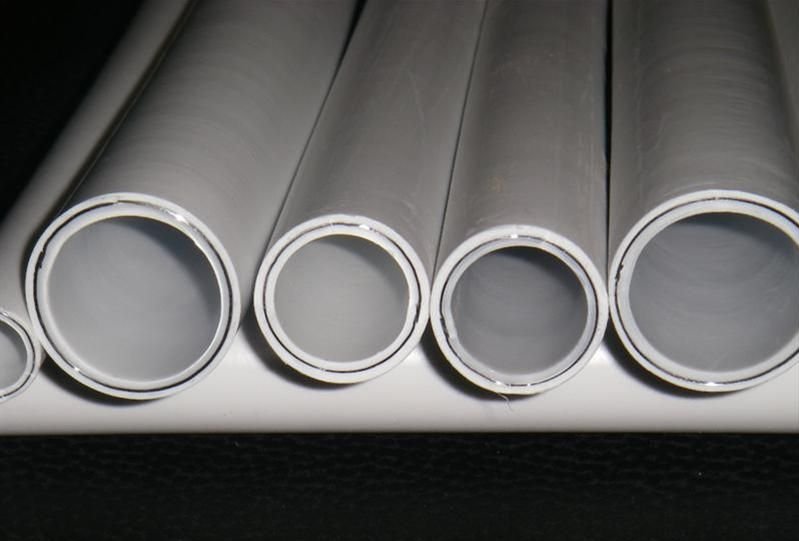

Is it worth it to use metal-plastic pipes for plumbing

The metal-plastic water pipe is a multilayer structure, the main of which are two polyethylene (outer and inner) layers and one aluminum layer. The layers are connected to each other with a special glue. Today, metal-plastic water pipes are produced with an outer diameter of 16 to 63 mm, the most popular sizes for internal wiring are 16, 20 and 26 mm. If it is necessary to arrange external wiring for large objects, the most common diameters are 32 and 40 mm.

The metal-plastic pipe consists of 3 layers connected by an adhesive composition

In apartment buildings, it is recommended to use metal-plastic pipes with a diameter 16 and 20 mm. From pipes of a larger diameter, the main wiring is performed, and from pipes of a smaller diameter, branches to household appliances (faucet, washing machine, toilet bowl, etc.) are made.

Scope of application

After the approval of the changes by the Ministry of Construction of the Russian Federation to SNiP 2.04.01-85, metal-plastic pipes began to be used everywhere in civil and industrial construction.They are successfully used in the organization of hot and cold water supply of multi-apartment and private houses, heating, in the reconstruction of plumbing systems, in the installation of watering systems, for supplying compressed air, in installations for taking water from wells and wells, for transportation of various liquids, including chemically aggressive ones. Especially relevant installation of systems from metal-plastic pipes where it is impossible (prohibited) to use welding.

Advantages of pipes made of metal-plastic

Compared with polymer pipes, all metal-plastic pipes for water supply have a number of advantages, namely:

- low coefficient of linear expansion;

- high ability to keep the original shape;

- exceptional tightness.

Most models of metal-plastic pipes have an inner composite layer with nanosized silver particles. This improves the hygienic qualities of the pipe, since silver ions destroy harmful bacteria and prevent the deposition of various suspensions on the pipe walls. Therefore, metal-plastic pipes serve flawlessly and for a long time.

Compared with pipes made of steel, cast iron and copper, metal-plastic pipes also have a number of advantages:

- they have a lower cost;

- low operating costs (do not require maintenance and repair);

- their installation is carried out much faster (about 5 times);

- they silently convey the flow of liquid;

- they are much lighter, do not carry a significant load on building structures;

- more aesthetic;

- they are the tightest.

elastic metal-plastic pipes withstand sub-zero temperatures, and also successfully cope with the transportation of hot (up to +90) water.They withstand water hammer and have low thermal conductivity.

With high-quality installation and careful operation, systems made of metal-plastic pipes can serve up to 50 years without the need for repair.

Disadvantages of metal-plastic pipes

With many indisputable advantages, metal-plastic pipes, like any other material, have their drawbacks. First of all, they are most susceptible to mechanical damage, especially for open communications. Even metal-plastic pipes for hot water are less resistant to high temperatures and water hammer, compared to the same metal ones.

Metal-plastic accumulates static voltage, so these pipes cannot be used for grounding.

When laying outside, metal-plastic pipes are at risk of mechanical damage, they are easy to damage even with a chopper or a shovel

Mounting units of the pipeline system made of metal-plastic during operation at low temperatures are subject to destruction.

Aging and weakening of the initial qualities of metal-plastic pipes are observed during their long-term intensive operation, especially if they are exposed to direct solar radiation or are operated at low temperatures.

Mounting

For large-sized pipes, fasteners with increased strength are needed, which can be difficult given the size of the products. The connection of plastic pipes can be carried out by detachable and one-piece methods.

For large-sized pipes, fasteners with increased strength are needed, which can be difficult given the size of the products. The connection of plastic pipes can be carried out by detachable and one-piece methods.

The detachable method makes it possible to dismantle the connecting elements. With the second connection, this is not possible.

One-piece. This method is used for high pressure pipelines.The connection is made by butt welding using an electronic clutch. This connection is completely sealed and durable.

Connection process by welding: The pipes are fixed and their ends are heated on the stove. Then the pipes are connected, butt joints are aligned.

The heating plate melts the plastic from the inside, which guarantees high-quality fastening.

Sectional. This method is used, as a rule, in the device of the drain system. When carrying out connecting work, flanges, rubber rings, sockets, union nuts are used. When installing non-pressure sewer systems, it would be advisable to use the socket and flange method.

What to consider when installing such pipes

installation of polypropylene pipes

The most relevant use of such pipes will be if there are no sudden temperature changes during the operation of the heating system. Thus, polypropylene pipes are an ideal option for those facilities that use a heating boiler equipped with a maximum temperature limitation system.

How can such pipes be installed?

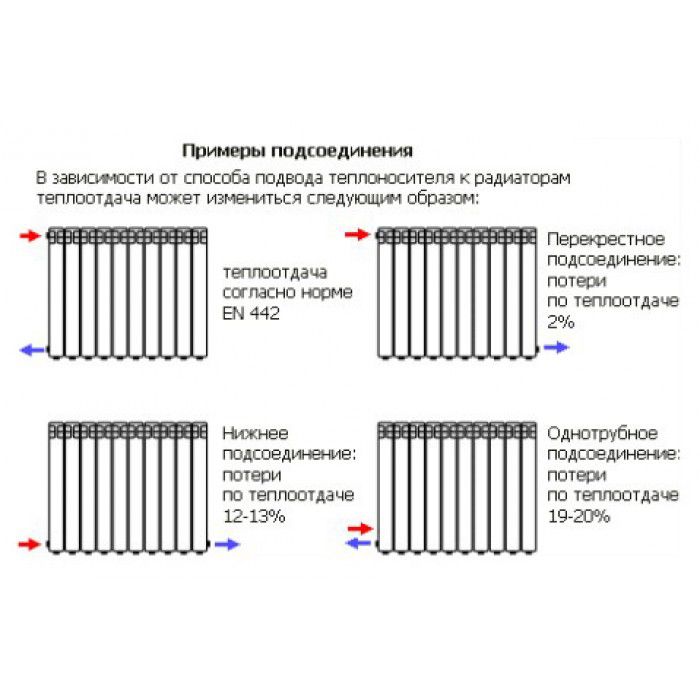

To date, specialists use only a few basic autonomous heating schemes, however, systems with lower and upper spills are the most widely used among all existing systems. In particular, due to the use of polypropylene pipes with such a system installation scheme, you can achieve certain advantages.

- The complete absence of the need for additional purchase and installation of a specialized circulation pump when using systems with a top spill, since the basic principle underlying the operation of such systems is a completely gravity-flowing water circulation, which is especially relevant for those facilities that may have frequent interruptions in the central power supply system.

- The contour of the system with a bottom spill is formed using a metal-plastic or plastic pipeline, with the help of which it becomes possible to make absolutely any connections and bends, which is especially relevant for those who want to minimize the presence of pipes in the interior or live in a room with various unusual features in construction.

It is worth noting the fact that today it is systems with a bottom spill that are more widely used, and in particular this is due to the advantages that this method of installation has.

- Sufficiently high efficiency of the system.

- The use of a specialized pump allows you to minimize the diameter of the polypropylene pipe for heating.

- The ability to make the pipeline system completely invisible to others by hiding it in the floor and wall coverings.

Special attention should be paid to the fact that in order to increase the efficiency of such a system, the manufacture of circuits is often carried out from rather expensive copper pipes, which are characterized by extremely high heat transfer and corrosion resistance.

In order to choose the best pipes for your conditions, it is important to consider such a factor as the marking of polypropylene pipes for heating

In order to choose the best pipes for your conditions, it is important to consider such a factor as the marking of polypropylene pipes for heating.

Advantages and disadvantages

The popularity of plastic pipes is determined by:

- Durability. Despite their low weight, plastic pipes for heating can withstand heavy loads and are quite elastic.

- Corrosion resistant.

- High thermal conductivity and sound insulation.

- Long service life.

On average, a well-installed pipeline serves more than fifty years without leaking or changing its characteristics. Particularly durable options can serve up to a hundred years.

Of course, plastic products also have disadvantages. These include:

- Fear of ultraviolet radiation. Ultraviolet is able to destroy polymer compounds, which disrupts the structure of pipes and leads to their fragility.

- Heat instability. When exposed to high temperatures, polypropylene pipes can ignite, which is unacceptable in conditions of increased fire hazard.

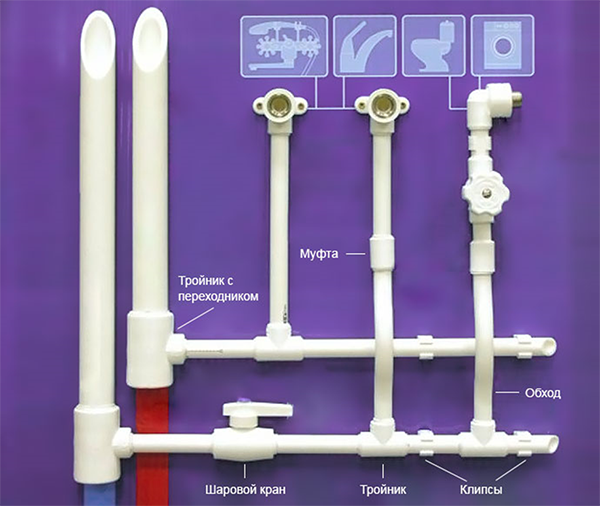

Installation of water supply from polypropylene pipes

Before starting the installation of the internal pipeline, it is necessary to make markings using a level and a plumb line. Then drill and install clips of a certain size for pipes, then proceed with the installation of pipes.

An important advantage of these pipes is their easy installation. For internal wiring, if the length of the pipeline is less than 10 meters, a pipe Ø 20 is sufficient. If a longer line is required, then pipes Ø 25 and Ø32 mm must be used.

On a note. Connect pipes from polypropylene is possible only with one soldering, or combined, using fittings that are pre-soldered to the pipes.

To make the installation, you need to have a soldering iron and nozzles of different diameters (you can rent it if the installation work is one-time). You will also need a tape measure, pencil, knife, special scissors for cutting pipes or a hacksaw.

Conclusions and recommendations

Even the best pipes can fully test all their merits only under one condition. They need to be chosen correctly for a particular case. To do this, it is best to take into account two main parameters: pressure fluctuations and dimensions.

You also need to take into account the inner diameter, which will vary depending on the method of use. It must be remembered that today it is a worthy alternative to all previous materials. That is why such pipes are now used everywhere and are widely used in many areas of human life. This is a practical and cost-effective investment in the purchase.

You can now buy such pipes even via the Internet. After that, it will be necessary to make only installation, which is almost always not complicated. That is why, this option is worth considering, but only after analyzing the pros and cons. In this case, you will protect yourself and will only guarantee that you can use such plastic pipes for a long time. Buy only the best and high quality, do not spare money for the purchase of components, and then you will be satisfied with using this option.

Types of XLPE pipes

For greater strength and an increase in the melting point of polyethylene elements, this material is processed under pressure. At the same time, domestic standards must be observed.As a result of such processing, peculiar bridges are formed between the molecules, which contribute to an additional bonding of molecules.

This process is called crosslinking, and the resulting polyethylene is called crosslinked. Pipes made of cross-linked polyethylene are not recommended to be connected using a welding iron. The best option for joining pipes made of such material is the “cold” connection method, namely, gluing elements using special types of fittings.

Cross-linked polyethylene is obtained as a result of a special processing of the material using one of the options:

- Peroxide method (PEXa).

- Silane method (PEXb). It should be borne in mind that organosilanides belong to the group of toxic substances.

- Radiation method (PEXc).

- Treatment with nitrogen compounds (PEXd).

Cross-linked polyethylene is especially popular in systems where the working medium is water. This includes heating and plumbing networks. Docking of pipe elements is carried out using compression fittings. In addition, cross-linked polyethylene is used in the installation of underfloor heating and in fire protection systems.