- Operating recommendations - how to turn on the gas boiler correctly

- Power outages

- Reasons for private switching on and off of a gas boiler

- Boiler automation - the wick goes out after the button is released

- The main reasons: why the gas boiler goes out

- Types of gas boilers

- Why is the pressure rising?

- How to repair boiler codes?

- Boiler overheat error

- Low system pressure

- There is no gas boiler draft

- The boiler does not ignite the flame when ignited

- The boiler is kindled, but the flame immediately goes out

- The panel gives incorrect errors

- Why does the device go out

- Pump not working well

- Malfunctions of heating boilers

- Built-in pump failure

- Clogged heat exchanger

- Availability of automation

- Other causes and remedies

- Two-pipe and one-pipe heating system: errors and their elimination

- Boiler problems

- Is the boiler always at fault?

- Breakdowns of gas boiler units

- Heat loss does not match the boiler output

- Features of ignition of gas heating boilers

Operating recommendations - how to turn on the gas boiler correctly

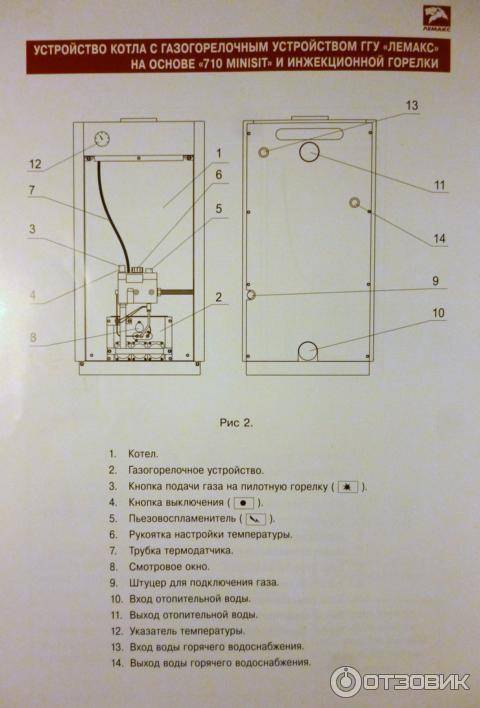

Before you fire up the Lemax boiler, you need to make sure that there is water inside it and other elements of the heating system. Next, they check the level of traction and choose the most optimal algorithm of actions.Its formation is influenced by the power of the equipment and the presence of automatic units. The Lemax boiler belongs to the category of non-volatile, therefore the task of how to light the Lemax gas boiler is solved using a conventional piezo ignition. Some models have a special draft sensor, which ensures the safety of the device.

To connect a similar boiler to the heating system, special skills are not required. In addition, during operation, special care is not required, and small malfunctions can be eliminated with your own hands. In order to avoid surprises during launch, it is imperative to check all your actions with the manual on how to ignite the Lemax gas boiler.

The list of actions on how to turn on the Lemax boiler with automation:

- Open the gas cock.

- Set the control knob to the ignition position.

- Press the knob all the way down for 10 - 60 seconds until the burner lights up.

- Carry out the temperature setting.

Power outages

It happens that the voltage in the electrical network drops below the permissible level. At the same time, the boiler immediately goes out, since modern automation can detect low voltage. When the power supply is restored, the same automation will turn on the burner, so that most of these failures can go unnoticed. However, this mode of operation is harmful to electronics, so it can fail over time. So if suddenly the gas does not light up when voltage appears in the network, perhaps something has happened to the automation. To avoid this scenario, it is better to buy a voltage stabilizer.

Reasons for private switching on and off of a gas boiler

It may happen that you just installed a new gas heating boiler at home, just set it up and put it into operation, and then it starts turning on and off every five minutes. In fact, he should regulate his work on his own, but turning off and on on his own too often indicates that something is wrong here. In addition, this behavior of the heating equipment adversely affects the length of the operating period, as the working parts wear out and the boiler fails.

There are several reasons why the heating boiler often turns on. If you do not have enough experience, you should call a specialist for help, since blue fuel does not tolerate a careless attitude. So, the main factors provoking frequent switching off and on of gas heating equipment:

- Boiler selected incorrectly. Its power is designed for large rooms, and it was installed to heat a small room.

- Errors when installing the circulation pump.

- Temperature range set incorrectly.

- The absence of a thermostat in the room, the boiler operation is regulated only by the temperature of the coolant.

The problem is not complex, but in some cases the solution is to replace the heater.

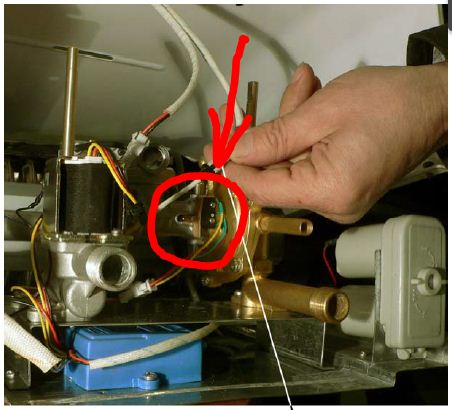

Problems with ignition piezo in a gas boiler

Boiler automation - the wick goes out after the button is released

There is also a decrease in gas pressure in the inlet pipeline. Sometimes there is a lack of voltage on the control board. Remind us what service work needs to be done in case of conversion from methane to propane? First, you need to change the nozzles of the main burner of the GGU. Then change the supply voltage of the modulator.

And at the end, adjust the parameter of the highest and lowest pressure. What is the principle of operation of the protection valve in the heating system? This component, which is adjusted to the required pressure, protects the heating system. It is forbidden to use the safety valve to drain the heating water. Often the pressure of the heating system rises. In the expansion tank, the pressure is reduced to 2.

Can water from the heating circuit leak from the DHW system? The increase in pressure in the heating system is formed by the following main factors. Expansion tank pressure not adjusted.

The feed faucet is leaking.

The main reasons: why the gas boiler goes out

Launching is hard. The igniter ignites, but the main burner does not fire. Please tell me what is the reason? Apparently, the ignition unit malfunction. You will need to do a technical inspection of the unit and clean the ignition mechanism. Can anyone help clarify the situation with the chimney? Soon three days, as there is a return draft, due to which the smoke passes directly into the room. I made the chimney myself.

It is a steel pipe. Perhaps there is a mismatch in the calculations. The main reason is the incorrectly manufactured design of the chimney. Soot pollution often occurs, which significantly reduces its efficiency.

In addition, it is necessary to check the exhaust openings in the living quarters. Heating system control. Transfer to another type of gas.

Control devices and protection devices. There was a problem after starting.It doesn’t want to turn on, it worked for two years, now the whole display lights up as when the boiler is turned on, when the self-diagnosis mode is in progress, then it clicks, turns off for miles and seconds and turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1. Tell me, what could be? In operation, the Baxi main four boiler turns off with an error E35 parasitic flame. Tell me what to do?

The first season is in operation. We installed and connected the Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit? Bosch boiler 24 kW, single-circuit with built-in three-way valve. Does not see the boiler sensor, gives an error.

Tell me how to make it not give an error and work normally both for heating and for the boiler?

Question: the Lemax boiler is floor-standing, with two buttons, red and white. It stopped starting automatically, the wick is on, and it starts when you set the gas regulator to zero, and then you raise the temperature and the boiler lights up, please tell me good people what could be the problem, otherwise we freeze at night. Answer: the rod wedges in the middle part of the automation. Question: my Lemax ksgd boiler with a GTU 24d burner goes out when the wind is on the igniter. Answer: it is necessary to increase the gas supply to the pilot burner, most likely when the main burner is turned on, the flame on the pilot burner decreases, which leads to the activation of the automatic protection.

If you turn off the DHW flow sensor, then maybe it will be possible to reprogram it into a single-circuit device through the L3 menu? They installed the Arderia esr 2 boiler. If my coolant pressure drops a little over the course of a couple of divisions, can there be a malfunction of the three-way valve? No leaks from the radiators?

The gas boiler Arderia 2 is in operation.

Types of gas boilers

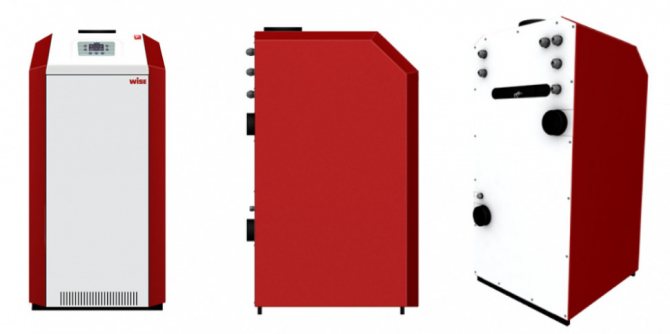

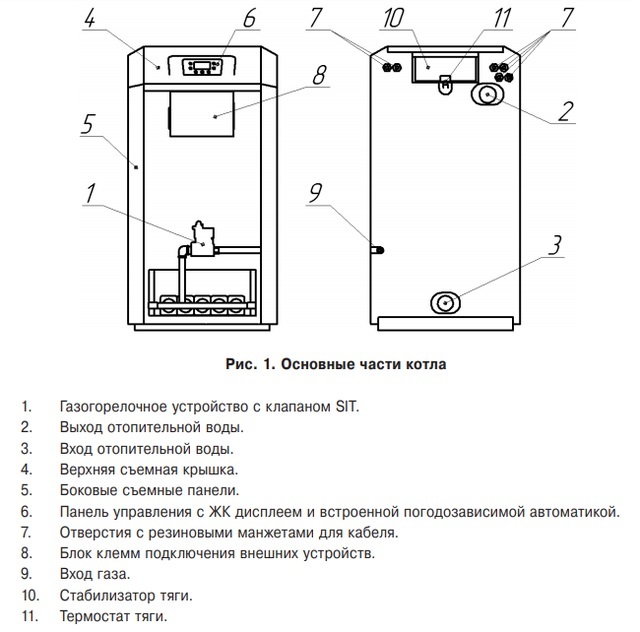

According to the type of installation, boilers are divided into wall-mounted and floor-mounted units.

Floor-standing gas boilers are characterized by greater power, which means the ability to heat large areas of premises, long service life due to the fact that heat exchangers for such heat generators are made of steel or cast iron. For floor boilers, a separate room is required - a furnace.

Floor standing gas boiler

Wall-mounted boilers are more compact and have less weight, which allows them to be installed on the walls of rooms. This type of heat generators is characterized by limited power, shorter service life, increased requirements for the quality of cleaning of the coolant and heated water. Gas boiler malfunctions can be different depending on the type of installation.

Wall mounted gas boiler

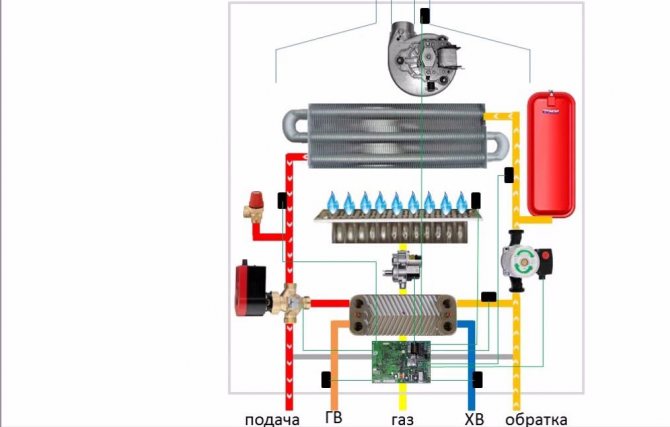

By design, boilers are divided into single-circuit, used only for space heating, and double-circuit, intended, in addition to heating, for heating hot water.

According to the type of removal of combustion products, heat generators are equipped with systems with natural or forced draft. In the first case, the units are connected to a traditional chimney, which is led to the roof of the building, and the exhaust gases are emitted due to natural draft. To ensure it, ventilation ducts are arranged according to certain rules. One of them is that the upper level of the chimney must be located at least 500 mm above the roof ridge, or at the same level with it at certain distances from the ridge.The reason why the gas boiler blows out may be that these conditions are not met. Boiler units with natural draft are equipped with open combustion chambers or atmospheric burners, while the air for the burner is taken from inside the room.

In the second case, the boilers are equipped with a coaxial chimney, which is a “pipe in pipe” design, which is led out through the wall of the room. The air necessary to support combustion enters from the outside through the outer pipe, and combustion products are removed through the inner pipe. In forced draft boilers, closed combustion chambers are installed.

Conventional and coaxial degassing systems

And, finally, according to the method of ensuring the circulation of the coolant, boiler units are divided into volatile and non-volatile. In volatile boilers, there are circulation pumps powered by the mains and creating pressure in the heating system. In addition, volatile boilers are equipped with sophisticated automation that controls and maintains the established operating modes, including an electronic ignition system. Non-volatile heat generators do not require connection to electrical networks, and the movement of the coolant occurs due to natural pressure drops as a result of its heating. Ignition of non-volatile boilers can be done using a piezoelectric element by pressing a button.

Why is the pressure rising?

Rising pressure is a serious and dangerous situation. An increase in pressure in the system can only mean an increase in the amount of water.

This is due to the expansion of the coolant when heated.Any liquid is incompressible, so an increase in its volume can lead to a rupture of the heat exchanger, or, in the most serious case, provoke an explosion.

To exclude such a possibility, an expansion tank is used in the design of the boilers. It takes in an excess volume of water, compensating for its increase when heated.

An increase in pressure most often indicates a malfunction in the state of the expansion tank. Its design consists of a container and an elastic membrane installed approximately in the middle.

As fluid begins to rise, the membrane sags and makes room for excess water.

When the volume decreases, it returns to its previous position. If the membrane is torn or not firmly attached to the stacks of the expansion tank, the coolant will fill the entire volume of the tank.

When expanding, the water will have nowhere to go, which will provoke a constant increase in pressure. The solution to the problem is to restore the state of the membrane or replace the expansion tank with another, serviceable copy.

How to repair boiler codes?

Boiler overheat error

A gas boiler malfunction in the form of overheating may occur due to lack of circulation. In this case, you need to check the pump and filter. Maybe the overheating thermostat is broken.

Low system pressure

If the pressure does not rise when the boiler is heated, then the tightness of the system may simply be broken and the connections must be tightened, after which a little pressure should be added. If this problem arose almost immediately after installing the boiler, then you just need to remove the air through the automatic air vent and add a little water.

There is no gas boiler draft

If the boiler has an open combustion chamber, it is enough to see if it is clogged with something. If the combustion chamber is closed, then condensate drips from the outer pipe, getting into the inner one and freezing, in the winter season, it turns into an icicle, blocking the access of air to the boiler. To eliminate this problem, it is necessary to pour the formed icicle with hot water. Another foreign object can also get into the chimney.

The boiler does not ignite the flame when ignited

This indicates a malfunction of the gas valve in the boiler. To verify this, you can unscrew the hose and see if gas is supplied. If there is gas, then you should call a specialist who will replace this valve.

The boiler is kindled, but the flame immediately goes out

In this case, the panel may show a malfunction of the gas boiler in the form of a lack of ionization current. You need to check this by turning on the boiler again, turning the plug over, thereby changing the phases. If nothing has changed, then the operation of the ionization current may be disrupted due to any electrical work in the house. If the boiler periodically extinguishes the flame, then this is due to power surges and a stabilizer is needed.

The panel gives incorrect errors

Sometimes electronic board errors can occur. This happens from bad electricity and poor-quality power supply. From this, some parasitic charges arise on the boards, due to which such errors are observed. To eliminate this, you need to disconnect the boiler from the network and let it stand for about 30 minutes. The capacitors will discharge during this time and these unnecessary charges will disappear. After that, the boiler should work well.

In general, that's all. If the material was useful, do not forget to share it by clicking on the social media buttons below this text.

Also find out how to choose the right gas boiler so that there are no problems in the future:

Read also:

Why does the device go out

There can be several reasons for the attenuation of the burner:

- Stopping the gas supply. Turn off the boiler, wait for the resumption of supply.

- Unstable or missing voltage in the power supply network (for volatile Lemax boilers).

- Failure or operation of the thrust sensor. It is necessary to check whether it is there, whether the chimney is clogged. Sometimes cleaning the sensor contacts helps.

- The thermocouple contacts are oxidized and do not close. It should be cleaned with fine-grained sandpaper.

- Reverse, insufficient or excessive traction. The draft sensor responds to all situations by turning off the burner.

Problems with traction are most characteristic of non-volatile installations, where the stability of the unit depends on it.

If the draft is too weak, the sensor turns off the burner due to the possibility of smoke in the room.

Excessive draft is dangerous with the possibility of a flame failure on the burner, which will provoke the flow of gas into the room with unpredictable consequences. Therefore, an increase in draft against the set value is also an emergency, leading to a shutdown of the boiler.

Pump not working well

Users of gas boilers sometimes face various problems in the operation of the pumping unit. Such equipment stops pumping water if the rotor fails or a significant amount of air has accumulated in the inside. To exclude such a breakdown, it is necessary to unscrew the nut from the unit and drain the water, after which the axis is forcibly scrolled with a flat screwdriver.

Pump in a gas boiler

Separate equipment requires compliance with installation rules. It is advisable to install the pump before the gas boiler, which will extend the life of the heating system. This rule is associated with the presence of a high temperature regime at the outlet of the boiler, which can cause damage to the device. Of course, the design characteristics of the circulation pump must also be taken into account, as well as the need to mount a filter or sump directly in front of the pump.

Malfunctions of heating boilers

Common boiler failures include:

- coolant leakage;

- water hammer;

- after the burner is switched on, the blocking is activated;

- the burner does not turn on;

- fuel burns unevenly, undulating;

- soot is formed;

- performance degradation;

- during the operation of the burner, ignition is switched on;

- soot forms on the walls of the chimney, combustion chamber.

To fix the problem, you first need to determine the cause of the problem.

Built-in pump failure

An important part in the heating system is the circulation pump. The quality of heating and the functioning of hot water supply depend on its uninterrupted operation. There are several signs and causes of breakdowns:

There are several signs and causes of breakdowns:

- The unit makes unusual sounds. This is due to the oxidation of the shaft, the ingress of a foreign object into the structure, in case of problems with the power supply, air in the pipes, the dry running of the mechanism, and the appearance of cavitation.

- After turning on the boiler, the pump does not start. Perhaps there is no power supply, the fuse has tripped.

- After a short period of time after switching on, the structure turns off: limescale in the stator cup.

- Hot water does not turn on in a double-circuit boiler.

Also, the reasons for the poor performance of the circulation pump are poor pressure in the system, bearing wear, which causes additional vibrations in the line, and low pressure.

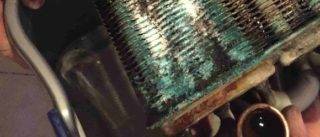

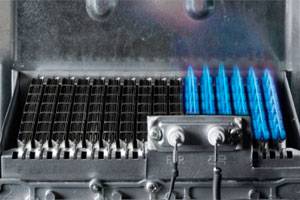

Clogged heat exchanger

Heated gases are transported through channels, which in the complex are called a heat exchanger. The design features are that the walls of the artery simultaneously perform the function of partitions of the water circuit, along which the coolant constantly moves, heating the metal surface. The combustion process is associated with intensive emission of flue gases, partly consisting of soot, tar, which create deposits inside the boiler, on the chimney. Therefore, the manufacturer recommends regular cleaning of the equipment at least once every 30 days and during the preparation of the device for the heating season.

When soot settles on surfaces, the performance of the mechanism decreases, fuel consumption increases, and the risk of costly breakdowns and internal combustion in the contaminated area increases.

Availability of automation

The automation of the Lemax gas boiler sometimes significantly expands the area of \u200b\u200buse of the device. Above is a list of some of the characteristics that should be followed when choosing heating gas equipment. Knowing them, you can independently determine the modification of the unit, which is the highest priority. Initially, you have to determine the heat loss of the building, and after that calculate the boiler power.

Other causes and remedies

If the gas boiler worked properly, and then began to constantly go out, then the problem often lies in the change in air flow in the room with the heat generator.Installing new sealed windows, tightly closing doors, kitchen hoods, ventilation systems - all this leads to a lack or excess of oxygen in the furnace. Initially, the thrust was designed for the same conditions, but they suddenly changed dramatically.

If the reason could not be found, we call the wizard

Here, it is often impossible to do without arranging a forced air flow into a room with a gas water heater. Moreover, the price of these additional systems often turns out to be such that it is better to look at electric boilers for heating a private house. They need a lot of electricity, but there will definitely be no problems with traction and smoke removal.

The gas boiler is an important component of the autonomous heating mode. Proper operation in the cold season pleases every owner and does not require additional intervention in the work process

However, there are times when the boiler suddenly goes out or turns off by itself some time after turning on. What to do and how to get rid of the presented problem, this article will tell.

Two-pipe and one-pipe heating system: errors and their elimination

In a private house, there are two options for piping: a two-pipe and one-pipe heating system. Previously, most preferred to install a single-pipe system, because it was believed that this was the most budget option. However, in this system it is difficult to adjust the temperature of the heat exchangers as they are farther from the boiler room. If in a single-pipe system the last battery remains the coldest (it is necessary to increase the sections), there is no return in such a system, and therefore there will be no problems when the battery return is cold.Therefore, it often happens that some of the batteries are cold in a private house, since the coolant flows through only one pipe.

In two-pipe wiring, there may be errors in the installation of shutoff valves, the boiler is connected incorrectly, the diameter of the outlets is incorrectly selected. For these reasons, with a two-pipe heating system, the last battery may be cold.

Violations in the connection of heat exchangers:

- The boiler heat exchanger is clogged - a common cause, then it will need to be flushed with special chemicals.

- Incorrect installation of the hydraulic part. As a result, poor circulation and low coolant temperature.

Now the reasons have become clear why cold batteries are in a private house and why one battery is cold in a 2-circuit boiler. Some problems can be fixed on your own, in more complex cases it is better to contact specialists. On our website you can find out why the battery is hot on top and cold on the bottom.

Boiler problems

All systems checked, but still no heat? So, it's still in the boiler itself. Let's figure out why it doesn't work. Faults may appear as follows:

- The burner does not turn on or burns weakly. Maybe the injectors are clogged. They can be cleaned with a soft brush or fine wire. In addition, air could get into the gas line (especially if the connection unit was disassembled). Usually in such cases, the gas boiler is blocked, and an error code lights up on the display. It is necessary to restart by resetting the lock (how to do this is written in the instructions);

- The burner does not turn on when trying to manually or automatically ignite. Perhaps the gap in the ignition electrode is broken, contact with the current-carrying wire has disappeared, or the air supply filter to the burner is clogged. Adjusting the gap on your own is quite difficult, but cleaning the filter and checking the wire connection is quite realistic;

- The burner goes out after some burning time. Perhaps the ionization electrode is dirty, the gap in it is broken, or the connecting wire is soldered off. You need to do the same as in the previous case;

- Flame break. With such a malfunction, the nozzle makes a lot of noise (or a characteristic whistle is heard from it). It is necessary to adjust the gas pressure on the igniter. Separation is also possible with excessively high draft and increased supply ventilation (air blows out the flame in the burner). This situation can arise, for example, if the height of the chimney pipe is too high;

- The boiler makes noise and spontaneously turns off. The cause may be a breakdown in the pump or the built-in fan (for turbocharged models), failure of the thermostat (water boils), separation or flashover of the flame.

In addition, some boiler models are phase-dependent, i.e. sensitive to changes in the location of the “phase” and “zero” contacts on the power wire. Quite often, you can fix a non-working boiler by simply changing the location of the electrical plug in the outlet (turning it 180 degrees).

Now, if none of the above helped, you can call a service specialist. And only if his diagnosis turns out to be disappointing, will he have to buy a new boiler.

Is the boiler always at fault?

In such cases, the main thing is not to panic.Obviously, a long downtime of the boiler in idle mode can lead to extremely undesirable consequences not only for the residents, but for the entire system as a whole - it can defrost and become unusable. Therefore, if something incomprehensible periodically starts to happen to the boiler - it suddenly goes out, the wind makes noise in the combustion chamber and blows out the flame, or any emergency icon lights up on the dashboard display, you need to quickly diagnose and determine the causes of the malfunction.

First of all, do not pay attention to the advice of "experts" who recommend "simply" changing the boiler and chimney. This is, of course, an effective method, but it can always be resorted to if nothing else remains.

As soon as one of the sensors gives a signal about a malfunction, the automation immediately turns on and gives the command to stop the entire system. So the main reason why the gas boiler goes out can be both in the thermal unit itself, and in some of the other nodes:

- gas pipeline;

- smoke exhaust system;

- heating and hot water circuits;

- electrical network.

Next, we'll look at the most common problems with a gas boiler, and explain why this usually happens.

Breakdowns of gas boiler units

Power surges can break the circulation pump. In this case, the fire will go out, and the boiler will make noise. To eliminate the breakdown, it is necessary to replace the circulation pump. If the pressure is set incorrectly, the flame will break away from the burner. The pressure needs to be adjusted correctly. In case of problems with the burner, the filters and the part itself become clogged.

If the thermocouple is burned out, then it will not give signals to the protective valve or will give incorrect ones. The valve will stop the gas supply. With such a problem, it is necessary to replace the thermocouple.

In modern gas boilers, an automatic system is installed that automatically reports the cause of the attenuation of the gas boiler. An error code will appear on the display of the equipment. Using the instructions, you can decrypt code and troubleshoot.

Gas boilers go out most often for the reasons given above. If it was not possible to independently identify or fix the problem, it is recommended to contact specialists. In modern devices, a complex scheme of work, which is not always easy to understand.

Sensors need to be checked periodically.

You should also pay attention to the condition of the chimney. To prevent damage due to power surges, you must install a voltage stabilizer

In this case, it will be possible to avoid problems with the electronics of the gas boiler.

Mechanical equipment is not so demanding on voltage.

In this case, you will avoid many problems with the operation of a gas boiler.

Sincerely, Baltgazservice

Heat loss does not match the boiler output

The constant operation of the boiler may be due to insufficient power of the device. The coolant, having passed through the pipes, returns, and by this time, the water did not have time to heat up due to insufficient power. Therefore, the gas boiler does not turn off. The power of the boiler is selected based on a number of key parameters:

- the area of heated premises and the number of storeys of the building;

- features of the climate of the region;

- the materials from which the house is built, the quality of thermal insulation materials, the quality of seams, window insulation, the number of chambers of window profiles, etc.

- the quantity and volume of all heating devices and pipe circuits installed in the system, additional buffer tanks, separators;

- temperature level to be maintained.

It is best to entrust the calculation of the boiler power to a professional or use special formulas or online calculators that allow you to determine the main characteristic of the boiler as accurately as possible, taking into account all the parameters.

Often, a simple formula is used to calculate power, which is defined as 1 kilowatt of power per 10 square meters. m. heated room. In this case, several correction factors are used that take into account climatic conditions, the degree of thermal insulation of the house and other parameters.

In addition to choosing the boiler itself, it is important to correctly select the remaining components of the system, pipes with the appropriate section to ensure the required throughput

Features of ignition of gas heating boilers

Each heater is equipped with automatic equipment. The ignition procedure depends on its design and features. Modern boilers are equipped with piezo ignition or automatic start. Rarely in villages, but still there are old KST boilers that are able to operate on solid fuel and gas. When re-equipping, heating appliances were equipped with primitive automation, where the ignition of the igniter is carried out with matches.

Ignition features depend on the automation of the gas boiler

Regardless of the model of the boiler and its automation, preparatory measures are carried out before ignition:

- Before the first start after the summer season, all components of the gas supply line, automatics are checked for the absence of gas leakage. Make it easy with soapy water. If gas is etched on a thread or connection, soap bubbles will appear.

- It is not superfluous to check the heating system itself for leaks. Make sure you have enough coolant. To do this, in a closed system, the pressure is checked on a pressure gauge. If the heating is gravity, make sure that the expansion tank is filled with water.

- After the repair, a lot of dust is generated in the house. With the help of draft, it partially enters the boiler furnace, settles on the burners. A similar situation is observed if the heater in the country has stood idle for a long time. Before ignition, all burner units are tried to be cleaned with a vacuum cleaner or other devices.

- Immediately before starting the ignition, check the presence of traction. Make it easy with a strip of paper. If it is pulled inside the firebox, then there is traction.

After the preparatory measures, they proceed to the process of ignition of the boiler itself.

To properly ignite a gas appliance, you need to know the features of automation Important! When using a new gas boiler for the first time, carefully read the instructions from the manufacturer. The ignition process begins with the opening of the gas supply valve to the boiler from the main line

If the heating is equipped with a circulation pump, be sure to put it into operation. Further actions depend on the features of automation:

The ignition process begins with the opening of the gas supply valve to the boiler from the main line. If the heating is equipped with a circulation pump, be sure to put it into operation. Further actions depend on the features of automation:

Old KSTs with ancient automatics are lit manually. First, a burning match or torch is inserted into the window, gas is supplied by the regulator. After igniting the igniter, let it warm up for a couple of minutes. The regulator lever is moved to the next position. The main burners are ignited.

Modern budget boilers are also started manually, but with the help of a piezoelectric element. Press the flame regulator with one hand. Continuing to hold it, with the second hand press the button of the piezoelectric element. With each action, a click occurs, and a spark is formed near the igniter on the electrodes. The action continues until the flame appears. After the igniter lights up, the regulator is held for about 30 seconds to heat up the thermocouple. Now it can be released and rotated to ignite the main burner.

Expensive gas boilers are equipped with electronic start. There are even models that are controlled from a remote control. Ignition of such devices is carried out with one click of the "Start" button. Then the automation will do everything itself

It is only important not to forget to connect the unit to the mains.

Setting up automation is trusted only by a specialist. Each gas automation has its own characteristics. The regulators are marked with numbers, asterisks, circles. They indicate different positions at which a spark is supplied, the burner is ignited, and the temperature is set. All the nuances of a particular model are described in the manufacturer's instructions. It must be studied before proceeding with the ignition.