- Types of cisterns for the toilet

- Tank device with a button

- We dismantle the tank

- The most popular drain mechanisms are Cersanit, Gustavsberg, Geberit, Ifo and Alkaplast

- Types of fittings for flush cisterns

- Separate and combined options

- Materials for the manufacture of devices

- Place of water supply

- Causes of a malfunctioning toilet flush button

- Toilet button malfunctions

- Adjustment

- Elimination of sticking

- Elimination of failure

- Replacing the button with a new one

- Types of drain tank

- The internal device of the drain tank

- The purpose of the float

- overflow

- Inlet

- Release (drain)

- Siphon tank

- Slow water filling

- Features of the internal device

- The device of modern models

- Drain cisterns with button

Types of cisterns for the toilet

The flush tank is a container with a lid, equipped with a water supply mechanism and a drain device. According to the place of installation, the tanks are divided into three types:

- suspended;

- built into the wall;

- compacts.

The hanging tank is mounted on the wall above the toilet at a certain height and connected to the bowl with a drain pipe. A chain with a handle is attached to the lever of the flush device. The top location of the tank provides a high pressure of water when draining.

The built-in tank is a flat container made of high-strength polymer.She is equipped with hanging toilets. The container is hidden behind a decorative finish, only flush control buttons are mounted outside.

The compact cistern is installed on the back shelf of the toilet bowl. It is equipped with a lever or push-button mechanism. Water supply is carried out from the side or from below.

Classic toilet-compact with bottom water connection

Tank device with a button

The drain tank is a container that stores water for draining. For operation, the tank is equipped with fittings. Toilet cistern device with button:

- drain mechanism. The device connected to the button is responsible for draining the water. In the lower part, the drain mechanism is equipped with a sealed membrane that protects against the formation of water leakage into the toilet bowl;

Mechanism for draining water by pressing a button

The drain mechanism can be equipped with:

single button. Descent of water occurs at the touch of a button. In this case, all the liquid from the tank enters the toilet;

Drain button working in one mode

dual mode button. The button with several operating modes is divided into two parts: small and large. When using a smaller part, half of the liquid in the tank gets into the toilet. When the water is drained by the greater part of the button, the water is drained completely.

Drain button capable of working in two modes

Using a button with two operating modes allows you to save cold water.

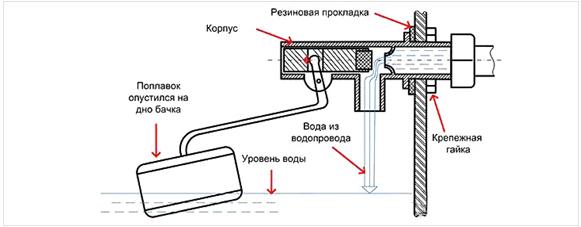

- filling valve responsible for the collection of water in the tank. The filling mechanism is equipped with a float that regulates the level of water in the tank. The mechanism may have:

Inlet valve with lateral water supply

bottom water supply

When installing a valve with a bottom connection, it is important to achieve complete tightness of the connection.

Water filling mechanism with bottom supply

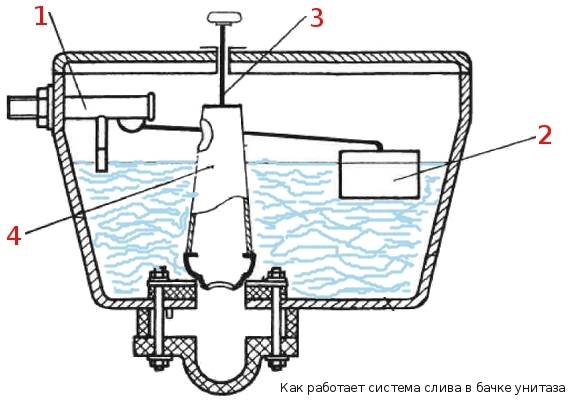

All fittings installed in the drain tank. interconnected. After pressing the button, the water is drained. In this case, the float of the filling valve sinks to the bottom of the tank and opens the inlet valve. Water begins to flow from the water supply and raise the float to the set level. When the container is full, the inlet valve will be automatically closed.

How a cistern valve works

We dismantle the tank

The old drain fittings of the tank cannot be replaced with a new one without completely dismantling the tank. Before starting work, it is necessary to shut off the water supply - if there is no shut-off valve on the supply to the tank, the cold water supply to the entire branch is shut off.

Next, water is drained from the tank. Using the keys, the side or bottom supply hose is removed, depending on the design of the tank.

The tank needs to be disconnected from the toilet bowl. It is fixed with two bolts, the nuts are located on the underside of the back shelf of the bowl. To unscrew them, you will need an adjustable wrench or open-end wrench. It is first recommended to lay a rag on the floor or substitute a container - the water remaining at the bottom of the tank will certainly pour out when the fasteners are removed.

If the tank was installed many years ago and the nuts are tightly rusted, the bolts are simply cut through - the hacksaw blade moves freely in the gap between the tank and the shelf of the bowl.

Mounting nuts are located on the underside of the toilet shelf

After unscrewing the nuts and removing the bolts, the tank is carefully removed from the toilet. Discard the old deformed rubber or polymer seal. Even if it has retained its elasticity, there is no guarantee that it will be able to seal the joint when reused.

The tank is placed on a flat surface. Unscrew the large plastic nut located on the side of the drain hole - it fixes the flushing mechanism. Also dismantle the water supply device on the side or bottom of the tank.

The container is inspected from all sides for cracks and chips. The inner surface is cleaned of accumulated sediment, rust particles. It is recommended to thoroughly rinse the tank from the inside so that when installing new fittings, solid particles do not get under the seals - they can break the tightness of the joints and cause a leak.

The most popular drain mechanisms are Cersanit, Gustavsberg, Geberit, Ifo and Alkaplast

Cersanit is a Polish company engaged in the production of bathroom products. Cersanit drain fittings can last 6-8 years. The price starts from 1400 rubles.

Gustavsberg is a Swedish manufacturer of plumbing fixtures. The cost of simple devices starts from 1300 rubles (the price without a nut for fastening and without a drain button). The warranty for some models of devices can reach 8-12 years.

Geberit is a Swiss brand. The products of this company are of excellent quality. 5-year warranty (subject to the rules of operation and installation technology). Price from 1300 rubles.

Ifo is a Swiss brand. One of the largest manufacturers of sanitary equipment. The cost of drain fittings starts from 900 rubles.

Alkaplast is a rebar from a Czech manufacturer. Guarantee for drain mechanisms from 6 years. Prices for Alcaplast devices start at 500 rubles.

Table with prices at which you can buy drain mechanisms from different manufacturers:

| Name | Price, rubles | |

| Alcaplast | With stop button | 560 |

| Single mode, A2000 | 830 | |

| SA2000S½ | 770 | |

| Ifo Hitta, Fargen, Orsa | 940 | |

| Ifo Frisk, Arret | 1200 | |

| Geberit | impulse | 2340 |

| 282.300.21.2 Double | 2800 | |

| 136.912.21.2 Double | 1330 | |

| Gustavsberg | Siamp | 1300 |

| Nordic, Artic, Logic | 2600 | |

| Cersanit | 1390 |

The greatest demand is for devices in which you can adjust the volume of discharged water, as this helps to significantly reduce its consumption.

You can repair, adjust or replace the toilet flush mechanism with your own hands. The main thing is to follow the instructions of the valve manufacturer. The drain mechanism will last a long time if all its parts and the tank are cleaned in a timely manner, and also used correctly.

With the increase in utility tariffs, the issue of saving water and electricity has become acute. Therefore, the demand for toilets with dual flushing has increased, which helps to save money by adjusting the water pressure. Now you do not need to wash off all the accumulated water and get big bills, now you can control the flow yourself, and for this you need to understand the principle of operation.

Types of fittings for flush cisterns

The principle of operation of a conventional tank is not complicated: it has a hole through which water enters and a place where water is discharged into the toilet. The first is closed by a special valve, the second - by a damper. When you press the lever or button, the damper rises, and the water, in whole or in part, enters the toilet, and then into the sewer.

After that, the damper returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens the hole for water to enter. The tank is filled to a certain level, after which the inlet is blocked. The supply and shutoff of water are regulated by a special valve.

A cistern fitting is a simple mechanical device that draws water into a sanitary container and drains it when a lever or button is pressed.

There are separate and combined designs of fittings that collect the volume of water necessary for flushing and drain it after activating the flushing device.

Separate and combined options

The separate version has been used for many decades. It is considered cheaper and easier to repair and set up. With this design, the filling valve and the damper are installed separately, they are not connected to each other.

The shut-off valve for the tank is designed in such a way that it is easy to install, dismantle or change its height.

To control the inflow and outflow of water, a float sensor is used, in the role of which even a piece of ordinary foam is sometimes used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to raise the damper or open the valve. This is a typical option for models made in retro style, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with a double button have been very popular, which allow you to empty the tank not only completely, but also halfway to save some of the water.

The separate version of the fittings is convenient in that you can repair and adjust individual parts of the system separately.

Combined type fittings are used in high-end plumbing, here the drain and inlet of water are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks, the system will need to be completely dismantled for repair. The setup can also be a little tricky.

The fittings for the toilet cistern with side and bottom water supply are different in design, but the principles of setting up and repairing them are very similar

Materials for the manufacture of devices

Most often, toilet fittings are made of polymeric materials. Usually, the more expensive such a system is, the more reliable it is, but this method does not give clear guarantees. There are fakes of well-known brands, and quite reliable and inexpensive domestic products. An ordinary buyer can only try to find a good seller and hope for good luck.

Fittings made of bronze and brass alloys are considered much more reliable, and it is much more difficult to fake such devices. But the cost of these mechanisms will be much higher than that of plastic products.

Metal filling is usually used in high-end plumbing. With proper configuration and installation, such a mechanism functions smoothly for many years.

In bottom-fed toilets, the inlet and shut-off valve are very close. When adjusting the valve, make sure that the moving parts do not touch.

Place of water supply

An important point is the place where water enters the toilet. It can be carried out from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant for others.

If the water comes from below, it happens almost silently.The lower water supply to the tank is more typical for new models released abroad.

But traditional cisterns of domestic production usually have a lateral water supply. The advantage of this option is the relatively low cost. The installation is also different. The elements of the lower water supply can be installed in the tank even before its installation. But the side feed is mounted only after the tank is installed on the toilet bowl.

To replace the fittings, they are selected taking into account the option of supplying water to the sanitary tank, it can be side or bottom

Causes of a malfunctioning toilet flush button

There are several reasons why a button fails. However, there are only two main ones:

- elements are worn out and simply become unusable;

- armature settings have gone astray - because of this, failures begin in the entire mechanism.

Let's take a closer look at each of the problems. Most often, the drain mechanism is made of plastic. On expensive models, it is more durable, so the service life of such a mechanism is not limited to 2-3 years.

On budget models of toilet bowls, the mechanism can fail after a year of intensive use. Unfortunately, in many cases, it will not be possible to fix the breakdown, since the mechanism is simply beyond repair, which means that some elements will have to be replaced. Given the low cost, this will not hit the wallet much.

Since the drain mechanism consists of several separate parts, it is initially worth figuring out which of the elements has broken down, and only then go to the store for new parts.

Toilet button malfunctions

All signs of a malfunction of the toilet flush button can be classified as follows:

- insufficient volume of water for flushing (full or partial);

- sticking;

- sinking (falling).

In the first case, it is not about how to repair the button, but about adjustment.

Adjustment

The volume of a full flush is adjusted using a float - its position on the rod relative to the overflow tube ensures the water level in the fully filled tank. The standard recommendation is that the supply cut-off should occur when the water table is 15-20 mm below the edge of the overflow:

- Float setting. At the bottom feed valve, the rack and pinion is disengaged in the float, which is then moved up or down along the guide. Similarly, the side feed valve is adjusted - the only difference is in the relative position of the float and the shutoff valves of the water supply.

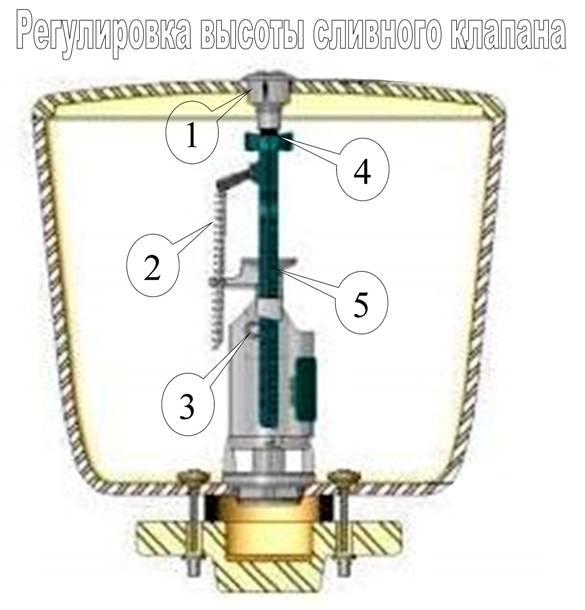

- Adjusting the button of the drain tank comes down to moving the overflow tube relative to the “glass” of the button mechanism and adjusting its height. To do this, unscrew the fixing nut on the tube, disconnect the rod, move the tube to the desired position and tighten the nut. Then, pressing the petals on the glass and moving the guides, set the height of the entire mechanism. At the final stage, the rod is snapped back on the overflow tube retainer.

The fittings of a two-level tank also have a small flush float, which must be moved along its own rack guide on the overflow tube. The position of this float determines the amount of water in a partial flush.

But if the button sinks or sticks, then what to do - adjustment or repair, can be decided only after finding out the cause of the malfunction.

Elimination of sticking

Button sticking can have different causes and manifestations. To eliminate sticking, you need to get to the fittings. For this:

- shut off the supply of cold water to the tank (if there is no separate valve, close the common tap on the riser);

- unscrew the retaining ring;

- remove the button from the seat;

- remove the tank lid;

- determine the cause of the sticking.

If the tank, and therefore the fittings, are new, then sticking can occur when the button is “excessively” pressed hard. The reason is a rough surface or burrs on the plastic parts of the armature, which lock the button and prevent it from returning to its original state. In this case, you just need to clean the problem area.

As another reason for the button sticking, there may be a misalignment or displacement of the push lever that moves the rod. To restore the operation of the tank, it is necessary to re-adjust and tune the mechanism.

The third reason is the accumulated deposits in the button socket (dust, debris, plaque). The problem is solved by simply cleaning and flushing this working unit.

If the drain stops working due to wear or breakage of any part, then you will need to completely replace the entire mechanism with a new one that matches the model of the tank.

Elimination of failure

One of the common reasons why the button in the toilet cistern sinks (fails) is the incorrect setting of the mechanism.

For the behavior of the adjustment you need:

- shut off the water supply;

- completely drain the water from the tank;

- remove the button and tank cover;

- dismantle the mechanism;

- adjust the height of the overflow edge relative to the water surface;

- adjust the height of the mechanism, taking into account that the fully pressed button should not touch the overflow tube;

- adjust the floats for full and partial drain.

Another reason for failure is the failure of the return spring of the pusher, which the button presses on. And in cases where the button assembly is non-separable, the button will need to be replaced.

Replacing the button with a new one

If the button assembly fails, there is no need to change the entire drain valve. You can fix the problem by replacing the toilet bowl button. But it must be the same model as the broken part. Work is carried out in the following sequence:

- remove the faulty assembly by disconnecting it from the tank lid;

- check the settings of the drain valve and the float of the shut-off valves on the water supply;

- install a new button, check the operation of the drain device.

If the toilet tank was released a long time ago, or the model is so rare that it is not possible to find “spare parts” for it, then you will have to completely replace the entire drain valve with a new one that fits its installation dimensions.

Types of drain tank

Toilet bowls are divided into several types. Types differ in the type of escapement device, in the material of manufacture and in the method of installation.

According to the location of the trigger lever of the tank:

top; side

According to the material from which the tank is made:

- plastic;

- ceramic;

- cast iron.

By installation method:

- wall installation;

- installation on the toilet shelf;

Each type of flush tank has an internal device that performs the work of filling water into the tank, adjusting the rate of water in it and flushing.

The device of a ceramic drain tank consists of:

- filling valve;

- overflow;

- drain valve.

toilet cistern device

The internal device of the drain tank

The purpose of the toilet cistern and its internal structure is the implementation of work:

- for filling water into a tank,

- adjusting the rate of water in it

- and the implementation of the flush itself

The purpose of the float

A float emerges from the water.

The purpose of the float ball valve is directed to:

- for supplying water to the tank,

- its dosage and rate.

The principle of operation of the float valve is that when there is enough water in the tank, the float pops up, setting in motion a special plug with a lever, which blocks the access of water to the tank.

overflow

The overflow is responsible for directing excess water into the toilet. It is needed so that the tank does not overflow, and water does not pour over its edge. This mechanism is usually made in the form of a small plastic tube and is located in the center of the tank. That is why, if the water level in the toilet bowl is not properly adjusted, water constantly leaks into the bowl.

Inlet

The design of the filling fittings includes an inlet valve 5 of the rod type. Its operation is controlled by the float of the toilet bowl 3, acting on the cut-off rod through a brass rocker. A similar system is called a float valve and is still used in a slightly modified form.

Figure 2

Figure 3 will help you better understand the operation of the filling unit. It shows the water level 1 after the storage tank has been emptied, after which the float mechanism 2 (including the rocker arm or spoke lever 3) is in the lower position. The upper part of the rocker 3 placed in the body of the faucet (valve) 4 shifted the pusher rod 5 with the elastic gasket 6 to the left, which activated the water supply through the inlet 8 and the inlet 10.As the container is filled, the lower end of the lever moves upwards, and its upper arm accordingly shifts the pusher to the right and gradually closes the spout opening, pressing gasket 6 towards it.

The faucet is fixed on the wall of the tank with a fixing nut 9 from the outside. The threaded connection of the tap is sealed with a rubber gasket 7 from the inside. To dampen the noise of the falling jet 11, a tube of a suitable diameter is additionally put on the outlet fitting of the inlet valve, lowering its lower end below the minimum water level.

Figure 3

Release (drain)

Adjusting the toilet cistern cannot be complete without adjusting the outlet and overflow units. Their schemes are shown in figure (diagram) 2 - plumbing fixtures with lever-type drain mechanisms. But, despite the similar types of drives (rocker 4), they have fundamental differences in the principles of operation.

Siphon tank

Figure 2a shows a drain system using siphon chamber 1. The curved cavity solves two problems at once:

Serves as a fixed height overflow.

- The liquid level in the right receiving part of the siphon cavity always corresponds to the adjusted water level in the tank, it cannot be higher than the dividing wall. If the toilet float 3 is set incorrectly - it does not have time to close the inlet valve 5, then the liquid flows into the left side of the siphon (air) and flows out through the flush pipe.

- Supports (automates) the release of liquid, allowing you to release the handle 6 immediately after activation. At the beginning of the flush cycle, the water rushes down under the raised valve 2.When it is in the down position, the flow continues through the curved siphon tube due to the vacuum created by the flow falling at high speed in the vertical flush pipe. An effective pressure drop caused by a moving liquid is only possible with a sufficiently high placement of the sanitary cistern.

Sanitary fixtures made according to scheme 2a no longer meet modern aesthetic requirements. At the same time, they are characterized by too large and unregulated water consumption.

Slow water filling

The low rate of water entering the toilet bowl is associated with clogged filters. Repair work is carried out in the following order:

- turning the faucet handle, we turn off the water entering the toilet bowl from the cold water supply system;

- we unscrew the flexible connection from the water supply valve to the toilet, located either from below or from the side, depending on the model of the sanitary ware;

- in a clogged hose, we eliminate the blockage and check the water pressure in the water supply by lowering the end of the flexible hose into the toilet, if its length is enough;

- otherwise, we use a five-liter plastic bottle or canister to drain the water;

- turn on the tap, if the pressure is good, then proceed to clean the water supply valve from accumulated debris;

- this part is not available in all models of toilet bowls, but if it is, it needs to be cleaned;

- we pull out the filter from the valve with the help of pliers, grabbing the part by a small pin;

- we wash the removed grate in the sink under a stream of clean water from clogged solid particles and from accumulated mucus;

- then we put the washed filter in place, turn on the water and see if the problem is fixed or not.

View of a contaminated valve removed from the water inlet mechanism into the drain tank. After cleaning the part, water enters the toilet bowl at a faster rate

If the problem is not resolved after washing the filter and the flexible hose, then we flush the entire water supply valve by removing it from the tank, after removing the toilet lid.

After all the steps described above, the problem is usually solved. The algorithm for repairing a toilet cistern with a button in the case of slow filling with water is clearly shown in the video.

Features of the internal device

The basis of the flush tank for the toilet includes 2 systems - an automatic water intake system and a water drain mechanism. If you know the principle of operation of either system, then it is easy to troubleshoot the problems that have arisen. To make it easier to understand the mechanism of the flush tank, you should first familiarize yourself with the diagram of the old toilet cisterns, since their systems are more understandable and simpler than modern mechanisms.

The device of the old barrel

Tanks of old designs consist of elements for supplying water to the tank, as well as a drain device. An inlet valve with a float is included in the water supply mechanism, and a lever and pears are included in the drain system, as well as a drain valve. There is also a special tube, the function of which is to remove excess water in the tank without using the drain hole.

The normal operation of the entire structure depends on the reliable operation of the water supply elements. In the image below, you can see in more detail the scheme of automatic water supply. The inlet valve is connected to the float using a curly lever.One end of this lever is connected to a piston that either shuts off the water or opens the water.

Float mechanism device

When there is no water in the tank, the float is in its lowest position, so the piston is in the depressed position and water enters the tank through the pipe. As soon as the float rises and takes its extreme upper position, the piston will immediately shut off the water supply to the tank.

This design is quite simple, primitive, but effective. If you partially bend the curly lever, you can adjust the level of water intake in the tank. The disadvantage of the mechanism is that the system is quite noisy.

Water is drained from the tank using another mechanism, which consists of a pear blocking the drain hole. A chain is connected to the pear, which in turn is connected to the lever. By pressing this lever, the pear rises up and the water immediately flows out of the tank. When all the water has drained out, the pear will drop down and close the drain hole again. At the same moment, the float drops to its extreme position, opening the valve for supplying water to the tank. And so every time, after draining the water from the tank.

Toilet bowl device | Operating principle

Watch this video on YouTube

The device of modern models

Tanks that have a lower water supply to the tank make less noise. Therefore, we can safely say that this is a more modern version of the device. The inlet valve is hidden inside the tank, which is a tube-shaped structure. In the photo below, this is a gray tube that is connected to the float.

Construction of a modern cistern

The mechanism works in the same way as in older systems, so when the float is lowered, the valve is open and water enters the tank.When the water in the tank has reached a certain level, the float rises and blocks the valve, after which water can no longer flow into the tank. The water drain system also works in the same way, since the valve opens when the lever is pressed. The water overflow system functions in a similar way, but the tube is led into the same hole to drain the water.

Drain cisterns with button

Despite the fact that a button is used as a lever in these tank designs, the water inlet mechanism has not undergone major changes, but the drain system is somewhat different.

With button

The photo shows a similar system, which is mainly used in domestic designs. It is believed that this is a fairly reliable and not expensive system. Imported cisterns use a slightly different mechanism. As a rule, they practice a lower water supply and a different drain / overflow device scheme, which can be seen in the photo below.

Imported fittings

There are several options for such systems:

- With one button.

- The water drains when pressed, and the drain stops when pressed again.

- With two buttons responsible for different amounts of water releasing into the drain hole.

And although the mechanism works in a completely different way, its principle of operation remains the same. In this design, by pressing the button, the drain is blocked, while the glass rises, and the rack remains in the mechanism itself. This is precisely the difference in the design of the mechanism itself. Drainage is regulated using a special rotary nut or a special lever.

Drain mechanism for a ceramic tank manufactured by Alca Plast, model A2000

Watch this video on YouTube