- Buy or make your own

- How to choose a hydraulic gun

- Design, purpose and principle of operation of the hydraulic switch

- What is a hydraulic gun?

- Combining a heating manifold with a hydraulic arrow

- Functions

- Why do we need a hydraulic arrow: the principle of operation, purpose and calculations

- Heating hydraulic arrow device

- Additional equipment features

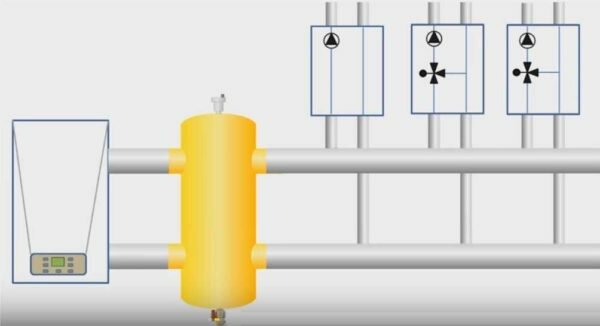

- The principle of operation of the hydraulic arrow in heating systems

- Hydraulic arrow in the heating system of a private house and its step-by-step installation with your own hands

- Hydrogun and its purpose

- Uniform heat distribution

- Pressure balancing

- Working with multiple boilers

- Installing a hydraulic arrow in a heating system: 5 general rules

- How to calculate the hydraulic arrow of the heating system using the formula

- What is a hydraulic arrow (hydraulic separator) in a heating system

- Purpose and principle of operation

- Operating modes

- When a hydraulic gun is needed

- When can I put

- How a hydraulic gun works in different cases

- Heating with 4-way mixer

- For neutral operation

- The boiler does not have enough power

- The flow on the primary circuit is larger than the coolant flow

- Manufacturing schemes

Buy or make your own

A ready-made set of European-assembled hydraulic guns with auxiliary equipment in the distribution network costs from 200 to 300 US dollars.

The user who purchases such a design will receive all the advantages of its operation in the heat supply system: fuel economy, reliable thermal and hydraulic conditions in the network and the durability of the main boiler equipment.

Simple hydraulic separator diagram

Simple hydraulic separator diagram

Factory assembly solves not only the distribution issues, but also the protection of the system from water hammer, corrosion and sludge deposits in the internal heating surfaces. All components of the structure are carefully calculated, manufactured using modern technology and set up at the factory.

Those home craftsmen who want to save on distributors, have locksmith experience and all the necessary equipment, can be advised to perform a hydraulic arrow on their own, since today there are quite detailed manufacturing methods and schemes on the Internet. The device belongs to complex hydraulic products and when performing them, the following must be taken into account:

- Spurs should have symmetrical, well-cut threads.

- The thickness of the walls of the nozzles is chosen the same.

- The quality of the welds must be high.

How to choose a hydraulic gun

A hydraulic gun works effectively only if it is properly selected. When choosing a distributor, the basic characteristics are the thermal output of the boiler and the total hourly water consumption for all boilers. It must not exceed the hourly water flow through the boiler circuit.

Next, pay attention to the design features of the hydraulic gun:

- section shape - square or round

- number of branch pipes: 4, 6 or 8 inputs/outputs;

- version of water supply/removal;

- nozzle installation method - on a common axis or with alternation.

Experts advise for wall-mounted boilers and hydraulic arrows to purchase ready-made designs with pressure gauges, an air vent and a sump to clean the water circuit from sludge.

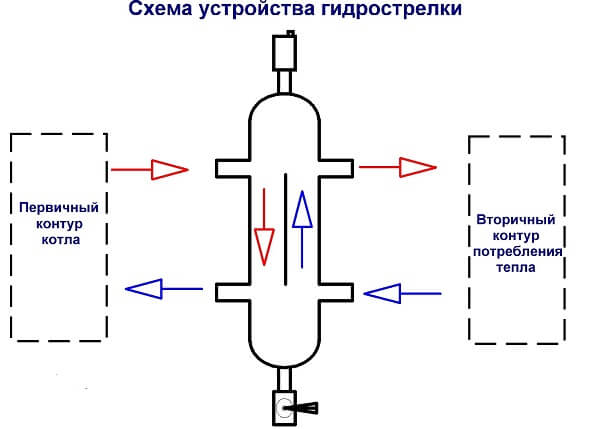

Design, purpose and principle of operation of the hydraulic switch

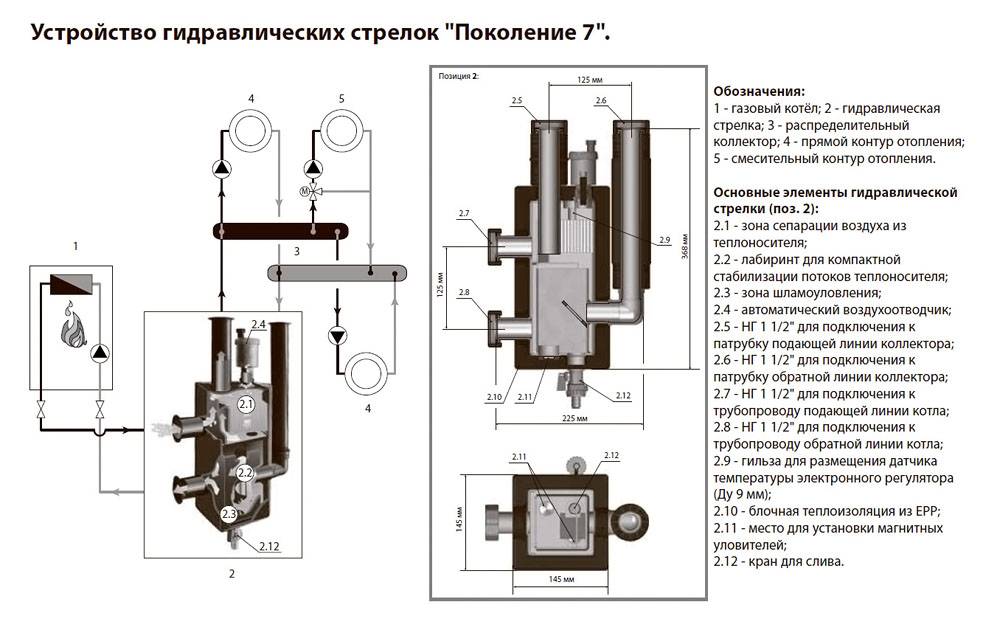

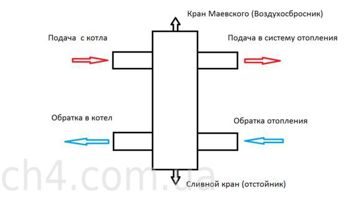

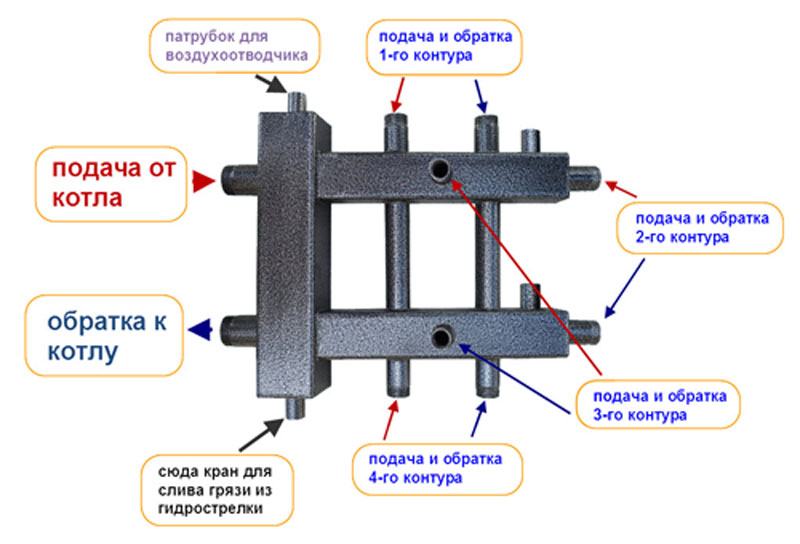

A hydraulic arrow for heating consists of a bronze or steel body with two pipes for connecting to the boiler circuit (supply pipe + return pipe), as well as several pipes (usually 2) for connecting heat consumer circuits. An automatic air vent is mounted in the upper part of the hydraulic separator through a ball valve or a shut-off valve, and a drainage (drain) valve is installed in the lower part. A special mesh is often installed inside the body of factory hydraulic arrows, which allows you to direct small air bubbles into the air vent.

The design of the Valtec VT model. VAR00.

The hydraulic arrow for heating performs the following functions:

- Maintaining the hydraulic balance of the system. Turning on / off one of the circuits does not affect the hydraulic characteristics of the remaining circuits;

- Ensuring the safety of cast-iron heat exchangers of boilers. The use of a hydraulic arrow allows you to protect cast iron heat exchangers from sudden temperature changes (for example, during repair work, when the circulation pump is turned off, or when the boiler is turned on for the first time). As you know, a sharp change in the temperature of the coolant adversely affects the cast-iron heat exchangers;

- Air vent. The hydraulic arrow for heating performs the functions of removing air from the heating system. To do this, in the upper part of the device there is a branch pipe for mounting an automatic air vent;

- Filling or draining the coolant.Most of both factory-made and self-made hydraulic switches are equipped with drain valves through which it is possible to fill or drain the coolant from the system;

- Cleaning the system from mechanical impurities. The low flow rate of the coolant in the hydraulic separator makes it an ideal device for collecting various mechanical impurities (scale, scale, rust, sand, and other sludge). Solid particles circulating in the heating system gradually accumulate in the lower part of the device, after which they can be removed through the drain cock. Some models of hydraulic arrows can be additionally equipped with magnetic traps that attract metal particles.

Scheme of a heating system using a hydraulic separator.

Advice! It is recommended to install the magnetic trap before filling the system with coolant, otherwise, when installing the trap, it will be necessary to drain the water from the hydraulic separator.

Hydraulic arrow for heating Gidruss.

The process of removing mechanical particles through the drain valve:

- Turn off the boiler and circulation pumps;

- After the coolant has cooled down, we block the section of the pipeline where the drain valve is located;

- We put on a hose of a suitable diameter on the drain tap, or, if space permits, we substitute a bucket or any other container;

- We open the tap, drain the coolant until clean water flows without contaminants;

- We close the drain valve, after which we open the blocked section of the pipeline;

- We subscribe the system and start the equipment.

What is a hydraulic gun?

This device may look like this:

Externally, the hydraulic arrows may differ from those shown in the photo, but the “essence” is the same for all of them: it is just a pipe to which six nozzles are welded. A pipe for a hydraulic arrow is suitable not only with a round section, but also with a square one:

The supply and return pipelines are connected to the branch pipes "protruding" from the sides. The topmost branch pipe - on the "crown" - for an automatic air vent. The lowest one is for the drain tap, through which the dirt that precipitates in the hydraulic gun in the form of sediment is removed.

How the hydraulic arrow is arranged can be seen in the following figure:

On the section we see that there is nothing inside the hydraulic gun - no “device”. The lower tap is on the side here, but from the bottom, as in the first two photos, it is better, because with the side position of the tap, the dirt that is below the tap will remain in the hydraulic gun.

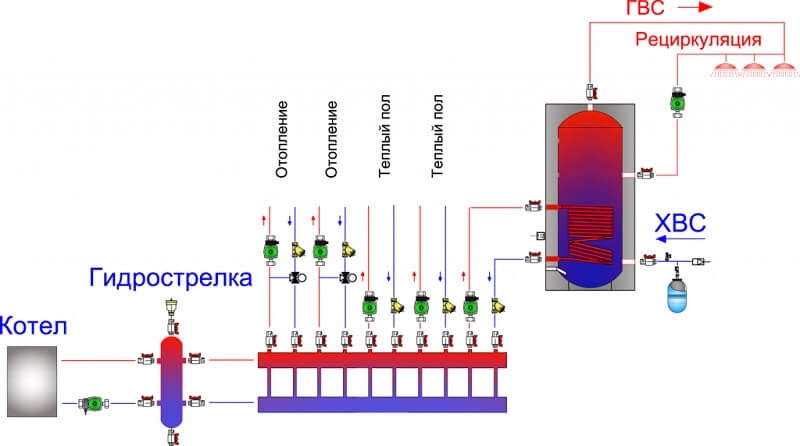

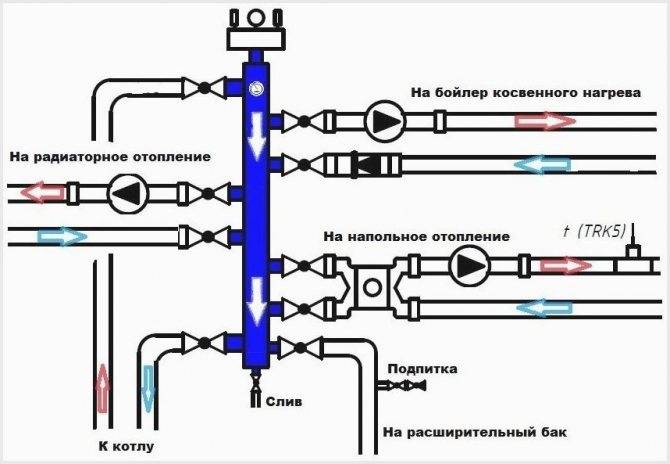

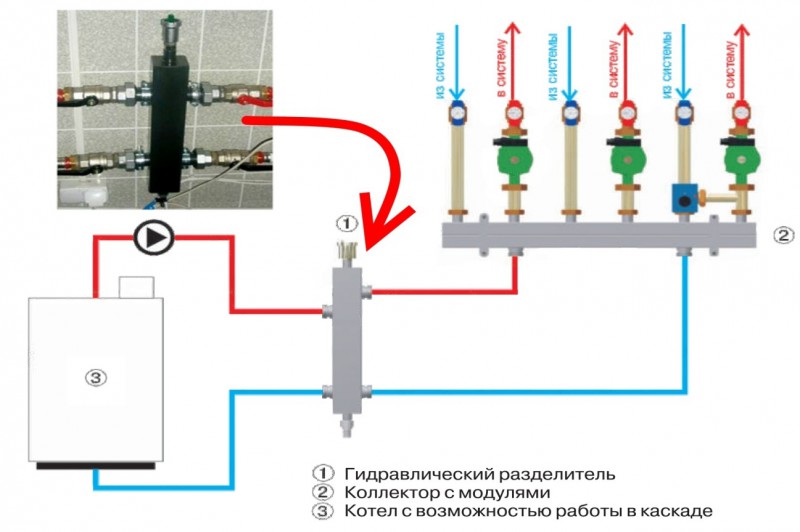

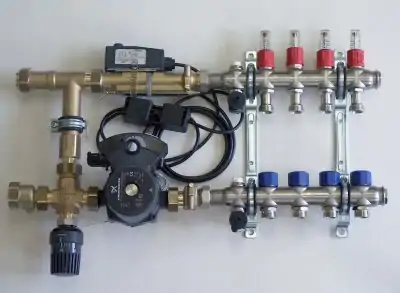

Combining a heating manifold with a hydraulic arrow

Small houses are heated by a boiler with a built-in pump. Secondary circuits are connected to the boiler through a hydraulic arrow. Independent circuits of residential buildings with a large area (from 150 m 2) are connected through a comb, the hydraulic separator will be bulky.

Which pipes for underfloor heating are better and more convenient to use. Technical characteristics of each type of pipe products used for underfloor heating.

The distribution manifold is mounted after the hydraulic gun. The device consists of two independent parts that combine jumpers. According to the number of secondary circuits, branch pipes are cut in pairs.

The distributing comb facilitates operation and repair of the equipment. The shut-off and control valves of the heat supply system of the house are located in one place. The enlarged manifold diameter ensures even flow between the individual circuits.

The use of a hydraulic arrow will save the boiler from thermal shock

The separator and the coplanar distribution manifold form the hydraulic module. The compact unit is convenient for the cramped conditions of small boiler rooms.

Mounting releases are provided for tying with an asterisk:

- low-pressure circuit of underfloor heating is connected from below;

- high-pressure radiator circuit - from above;

- heat exchanger - on the side, on the opposite side of the hydraulic arrow.

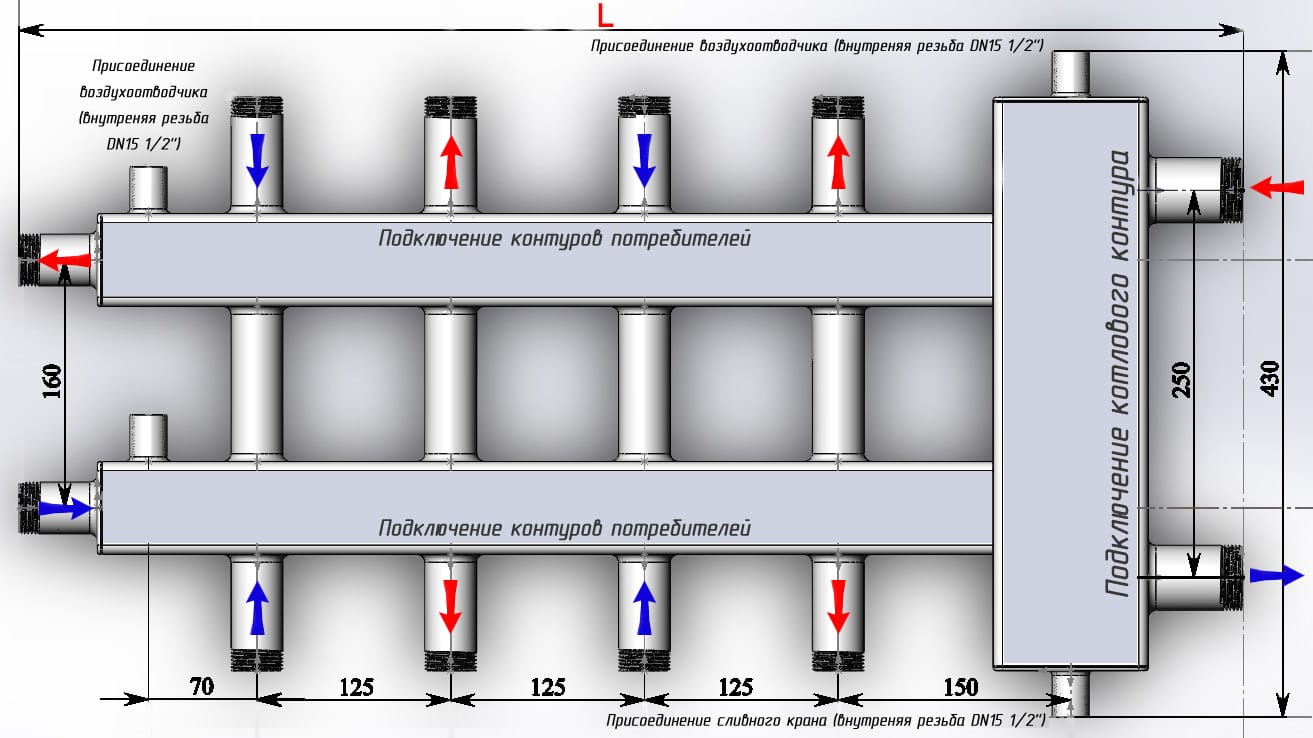

The figure shows a hydraulic arrow with a collector. The manufacturing scheme provides for the installation of balancing valves between the supply / return manifolds:

Scheme of a hydraulic arrow with a collector

Control valves provide maximum flow and pressure on the circuits farthest from the hydraulic gun. Balancing reduces the processes of improper throttling of the flow, allows you to achieve the estimated supply of coolant.

Important! An autonomous heating system refers to systems operating with a high ambient temperature under pressure (including a hydraulic arrow for heating a private house). A specialist with a sufficient stock of knowledge in heat engineering, experience and work skills (electric and gas welding, plumbing, working with hand-held power tools) can make a heating arrow with their own hands.

Numerous Internet sites offer step-by-step instructions for making a hydraulic arrow for heating, videos can also help in this process.

A specialist with a sufficient stock of knowledge in heat engineering, experience and work skills (electric and gas welding, plumbing, working with hand-held power tools) can make a heating hydraulic arrow with their own hands.Numerous Internet sites offer step-by-step instructions for making a hydraulic arrow for heating, videos can also help in this process.

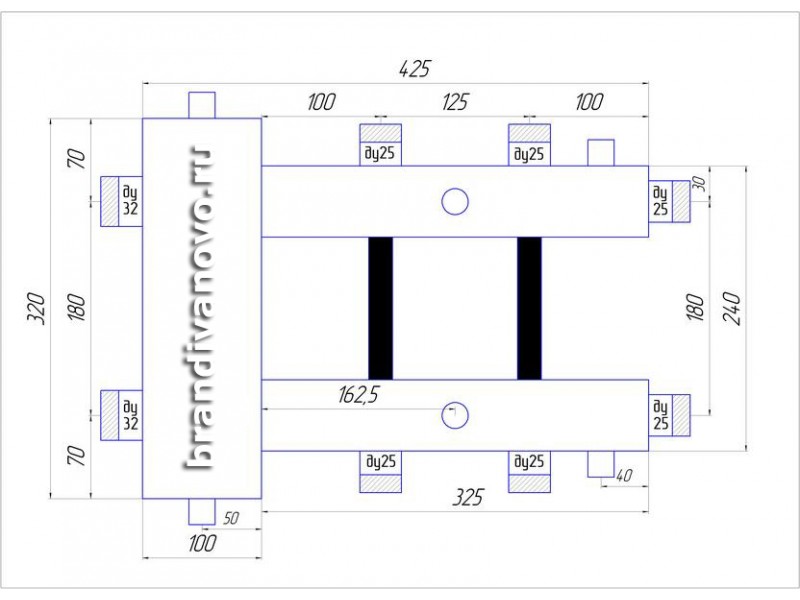

Dimensions of the heating manifold with a hydraulic arrow

Theoretical knowledge will help to draw up diagrams and drawings of a heating hydraulic switch, make an individual order for equipment in a specialized organization, and control the work of a contractor. Entrusting the manufacture of critical components of the heating system to non-professionals is dangerous to life and health. It should be remembered that equipment damaged due to the fault of the owner is not subject to warranty repair and return.

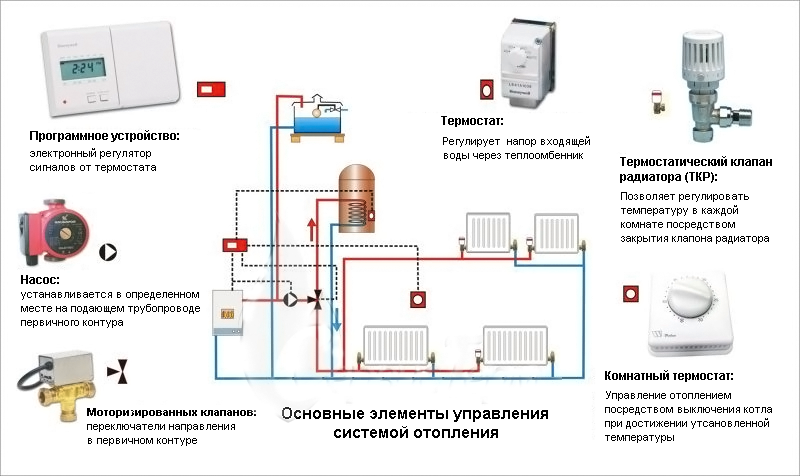

Functions

Why do we need a hydraulic gun and what functions does it perform:

- The purpose of the hydraulic separator is to perform hydrodynamic balancing in the heating system. It is an additional node. The hydraulic arrow protects the boiler heat exchanger, made using cast iron, from the likelihood of thermal shock. In addition, this equipment protects your system from damage in the event of automatic shutdown of hot water departments, underfloor heating, etc. This device must be installed during the installation of the heating system with boilers equipped with cast-iron heat exchangers.

- The use of a hydraulic separator is necessary when installing multi-circuit heating systems. In this case, the device prevents the influence of the circuits of one on the other, and ensures their uninterrupted functioning.

- In the case of correct calculations of the dimensions and characteristics of the hydromechanical plan, equipment of this kind is capable of performing the option of a sump, eliminating formations of a mechanical nature from the coolant cavity, represented by rust, scale, and sludge.

- Along with all of the above, another function of this device is the removal of air from the coolant, which significantly prevents the oxidation process.

Why do we need a hydraulic arrow: the principle of operation, purpose and calculations

Many heating systems in private households are unbalanced. The hydraulic arrow allows you to separate the circuit of the heating unit and the secondary circuit of the heating system. This improves the quality and reliability of the system.

Features of the device

When choosing a hydraulic arrow, you need to carefully study the principle of operation, purpose and calculations, as well as find out the advantages of the device:

- the separator is necessary to ensure that the technical specifications are met;

- the device maintains temperature and hydraulic balance;

- parallel connection provides minimum losses of thermal energy, productivity and pressure;

- protects the boiler from thermal shock, and also equalizes the circulation in the circuits;

- allows you to save fuel and electricity;

- a constant volume of water is maintained;

- reduces hydraulic resistance.

Operation of the device with a four-way mixer

Features of the operation of the hydraulic arrow allow you to normalize the hydrodynamic processes in the system.

Useful information! Timely elimination of impurities allows you to extend the life of meters, heaters and valves.

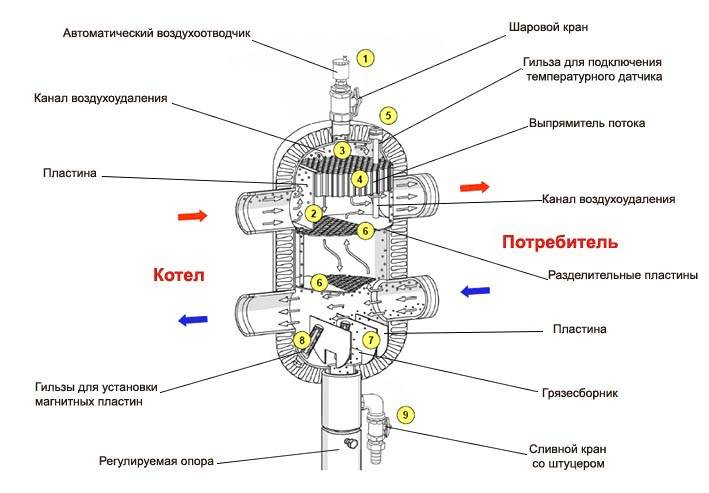

Heating hydraulic arrow device

Before you buy a hydraulic arrow for heating, you need to understand the structure of the structure.

The internal structure of modern equipment

The hydraulic separator is a vertical vessel made of large-diameter pipes with special end caps. The dimensions of the structure depend on the length and volume of the circuits, as well as on the power. In this case, the metal case is mounted on support racks, and small-sized products are mounted on brackets.

Connection to the heating pipeline is made using threads and flanges. Stainless steel, copper or polypropylene is used as a material for the hydraulic gun. In this case, the body is treated with an anti-corrosion agent.

Note! Polymer products are used in a system with a 14-35 kW boiler. Making such a device with your own hands requires professional skills.

Additional equipment features

The principle of operation, purpose and calculations of the hydraulic arrow can be learned and performed independently. The new models have the functions of a separator, a separator and a temperature controller. The thermostatic valve provides a temperature gradient for the secondary circuits. The elimination of oxygen from the coolant reduces the risk of erosion of the internal surfaces of the equipment. Removing excess particles increases the life of the impeller.

Inside the device there are perforated partitions that divide the internal volume in half. This does not create additional resistance.

The diagram shows the device in section

Useful information! Complex equipment requires a temperature sensor, a pressure gauge and a line to power the system.

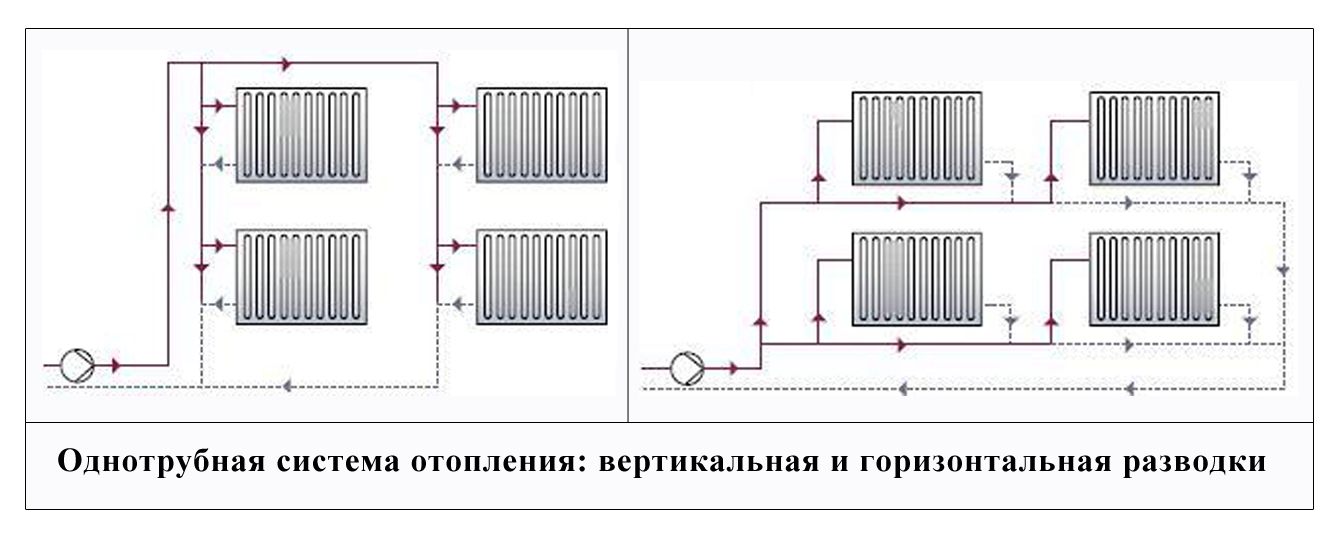

The principle of operation of the hydraulic arrow in heating systems

The choice of a hydraulic arrow depends on the speed mode of the coolant. In this case, the buffer zone separates the heating circuit and the heating boiler.

There are the following schemes for connecting a hydraulic gun:

neutral scheme of operation, in which all parameters correspond to the calculated values. At the same time, the design has sufficient total power;

Using the underfloor heating circuit

a certain scheme is applied if the boiler does not have sufficient power. With a lack of flow, the admixture of a cooled coolant is required. When the temperature difference triggered thermal sensors;

Heating system diagram

the volume of flow in the primary circuit is greater than the consumption of the coolant in the secondary circuit. In this case, the heating unit operates in optimal mode. When the pumps in the second circuit are turned off, the coolant moves through the hydraulic arrow along the first circuit.

Option to use a hydraulic gun

The performance of the circulation pump must be 10% higher than the pressure of the pumps in the secondary circuit.

Features of the system

This table shows some models and their cost.

Hydraulic arrow in the heating system of a private house and its step-by-step installation with your own hands

For the manufacture of hydraulic arrows, you can use a metal pipe or container. This will reduce costs, especially if you can do the welding work yourself (semi-automatically). You can also contact an experienced specialist. After making the water gun, it needs to be insulated.

Step 1. We take the necessary tools and spare parts

You will need:

-

Welding machine (argon);

-

Profiled pipe of the required diameter;

-

Plug for air release;

-

Plug for sludge output;

-

Branch pipes (at least 4).

Step 2. Weld the top and bottom bottom

Since the hydraulic arrow is made from a pipe or tank, the pipes and the bottom must be welded on both sides with argon welding

It is important to consider that the quality of work must be at a high level. It is also desirable to use a drawing, albeit made by hand, but indicating the required parameters.

Step 3. We divide the capacity of the hydraulic separator

The capacity for the hydraulic arrow must be divided into several components:

-

From the bottom bottom to the lower nozzles, the distance should be 10-20 cm. It is here that rust, scale, sand and other debris will collect.

-

The distance from the top of the appliance to the top nozzle should be approximately 10 cm.

The inlet and outlet top connections must be at a distance regulated by the temperature gradient. They can be both on the same level and with a shift. The higher the outlet pipe is located, the higher the operating temperature in it.

If the outlet pipe is located below the inlet pipe, then the hot stream will enter it after the entire volume has been completely heated. With this arrangement, a smooth heating system will be obtained. If the top nozzles are on the same axis, this will lead to the formation of a direct flow with poor air separation, which may lead to air locks.

It is important to pay attention to the location of the upper inlet pipe. It should not be at the highest point, as this excludes the movement of the hot stream. Thus, there will be no mixing of cold and hot water, which will make the installation of a water gun pointless.

Thus, there will be no mixing of cold and hot water, which will make the installation of a water gun pointless.

Step 4. Checking the device

Testing of the device is carried out after completion of the welding work. To check, all holes are hermetically sealed, except for one, through which water is drawn into the hydraulic gun. After filling, the last hole is also hermetically sealed, and the hydraulic arrow is left for a day. This method allows you to detect the absence of leaks.

Read the material on the topic: How to choose accessories for pipes

Hydrogun and its purpose

It is easy to assemble a hydraulic arrow for heating yourself using a welding machine and pipe sections of the required length. To do this, you need to find a suitable drawing and select materials.

We examined the principle of operation of the heating hydraulic arrow - it simply distributes the coolant over several circuits. Its main task is to create ideal conditions for the operation of the secondary and primary circuits. The primary circuit includes a heating boiler with pipes connected to a hydraulic switch. The secondary circuits are everything else. With equal pressure in the entire circuit, the boiler operates in a sparing mode - part of the heated coolant enters the return pipe, which reduces the load on the heat source.

If there is a low-power boiler in the system, and the heating has a high capacity, conditions are created for supplying the coolant from the return pipe to the supply pipe, bypassing the boiler (partially). In this case, the equipment is practically worn out - heat exchangers can become unusable in the shortest possible time.

Uniform heat distribution

Ideally balanced heating is a uniform temperature throughout the house, equal pressure in the secondary circuits and a balanced load on the boiler. In this case, the task of the hydraulic arrow is simple - it “distributes” the coolant into several circuits, each of which has a circulation pump. By adjusting its performance and the supply of coolant, you can achieve a uniform temperature throughout the house.

The most important thing is that thanks to this distribution, there will be no cold circuits in the house, since the coolant will flow into each pipe, and not just where it is easier.

The principle of operation of the hydraulic gun

Pressure balancing

An imbalance in the heating system can affect the stability of its operation. A long circuit needs one pressure, a shorter circuit needs another. The same applies to underfloor heating and boilers. If the system had one large pump for all circuits at once, there would be overloads in some places - it could break pipes or a heat exchanger in a storage water heater. The hydraulic gun will distribute the pressure and allow you to properly balance all circuits.

Working with multiple boilers

There are heating systems with two or even three boilers (sometimes more). Such solutions allow you to heat a fairly large area or use one of the boilers as a reserve. If not serial, but parallel connection of equipment is used, then this is done through a hydraulic arrow. At the same time, this helps to neutralize the mutual influence of the secondary circuits on each other.

The hydraulic arrow allows you to achieve balance in heating systems of any complexity. Two or three boilers, five or seven circuits - the degree may be different.It also reveals the potential for system expansion. For example, in the future, one more boiler, a heated towel rail, a summer kitchen with a separate heating circuit can be connected here. All these works can be carried out even on the move, without stopping the boiler equipment while maintaining the heating of the building.

Installing a hydraulic arrow in a heating system: 5 general rules

It does not matter how the hydraulic gun is fixed - it can be fixed both vertically and horizontally. The angle of inclination is also not important.

Only the direction of the end pipes needs to be taken into account. The operation of the air vent and the possibility of cleaning from sludge depend on their location.

The hydraulic arrow is mounted immediately after the shut-off valves of the boiler.

The installation location is selected depending on the scheme of the heating system. However, it is important to remember that the low loss header must be installed as close to the boiler as possible. For a collector circuit, a hydraulic arrow is installed in front of the boiler.

If it is necessary to connect an additional pump, then the hydraulic arrow is installed between the pump and the outlet pipe leading to the heating device.

When using a solid fuel boiler, the hydraulic arrow is connected to the output-input. This method helps to choose the optimal and individual temperature for each component of the system.

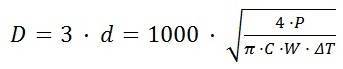

How to calculate the hydraulic arrow of the heating system using the formula

A hydraulic arrow for any heating system is selected or manufactured taking into account two parameters:

-

The number of nozzles (calculated based on the number of circuits);

-

The diameter (or area) of the cross section of the body.

The number of nozzles is quite simple to calculate, but to determine the diameter, you need to calculate by calculating the cross-sectional area.The formula for this purpose looks like this:

S = G / 3600 ʋ, where:

S is the cross-sectional area of the pipe, m2;

G is the coolant flow rate, m3/h;

ʋ is the flow velocity, assumed to be 0.1 m/s.

Such a low coolant flow rate is explained by the need to provide a zone of zero pressure. As the speed increases, so will the pressure.

The flow rate of the heat carrier can be determined based on the required consumption of the heat output of the heating system. If you plan to use an element with a circular cross section, then it will not be difficult to calculate the diameter of the hydraulic arrow. To do this, you need to take the formula for the area of a circle and determine the size of the pipe:

D = √4S/ π

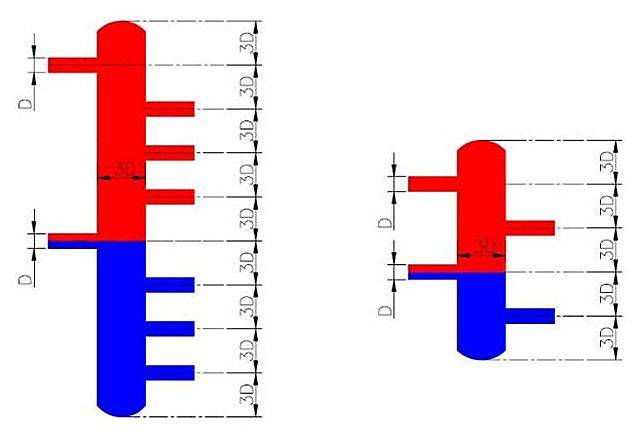

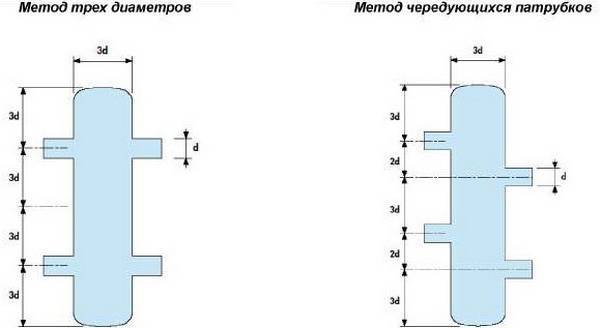

If you decide to assemble the hydraulic arrow yourself, then you need to pay attention to the location of the nozzles on it. In order not to arrange them haphazardly, you need to calculate the distance between the tie-ins, based on the diameter of the pipes to be mounted

To do this, you can use one of the following methods:

-

Method of three diameters;

-

The method of alternating nozzles.

What is a hydraulic arrow (hydraulic separator) in a heating system

The correct name for this device is a hydraulic arrow or hydraulic separator.

It is a piece of a round or square pipe with welded nozzles. Usually there is nothing inside. In some cases, there may be two grids. One (above) for a better “discharge” of air bubbles, the second (below) for screening out contaminants.

Examples of industrial water guns

In the heating system, the hydraulic arrow is placed between the boiler and consumers - heating circuits. Can be positioned both horizontally and vertically. Most often placed vertically.With this arrangement, an automatic air vent is placed in the upper part, and a stopcock is placed below. Some of the water with accumulated dirt is periodically drained through the tap.

Where is the hydraulic separator placed in the heating system

That is, it turns out that a vertically placed hydraulic separator, simultaneously with the main functions, removes air and makes it possible to remove sludge.

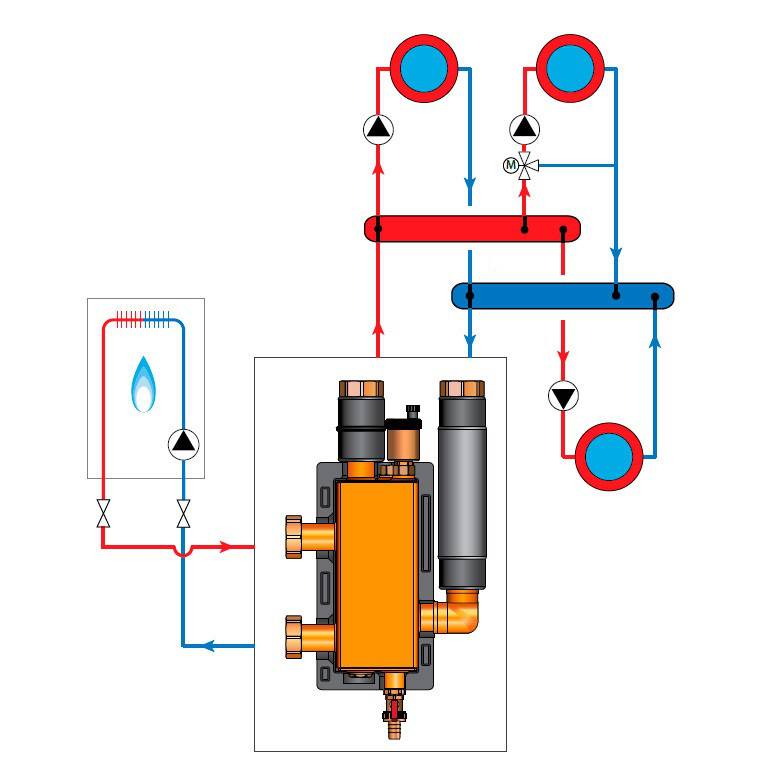

Purpose and principle of operation

A hydraulic gun is needed for branched systems in which several pumps are installed. It provides the required coolant flow for all pumps, regardless of their performance. That is, in other words, it serves for hydraulic decoupling of the heating system pumps. Therefore, this device is also called a hydraulic separator or hydraulic separator.

Schematic representation of the hydraulic arrow and its place in the heating system

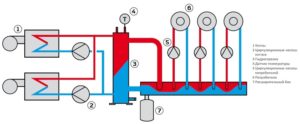

A hydraulic arrow is installed if the system has several pumps: one on the boiler circuit, the rest on the heating circuits (radiators, water floor heating, indirect heating boiler). For correct operation, their performance is selected so that the boiler pump can pump a little more coolant (10-20%) than is required for the rest of the system.

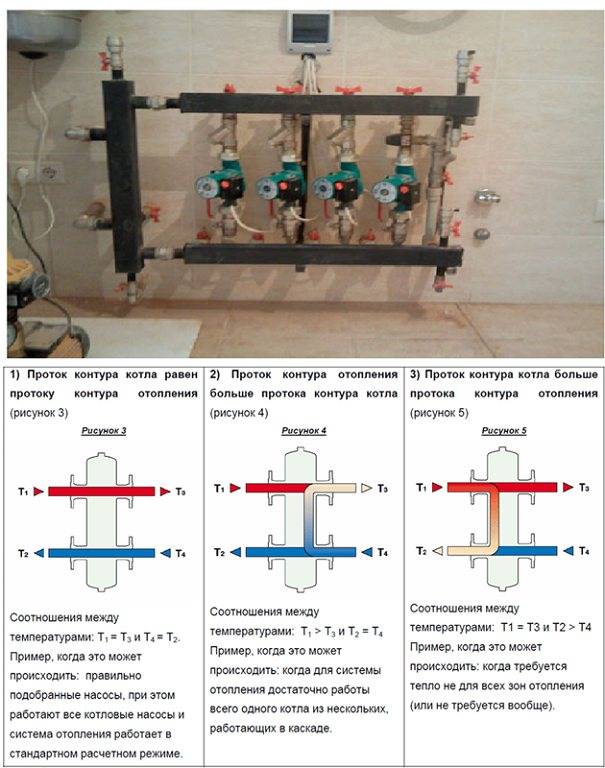

Operating modes

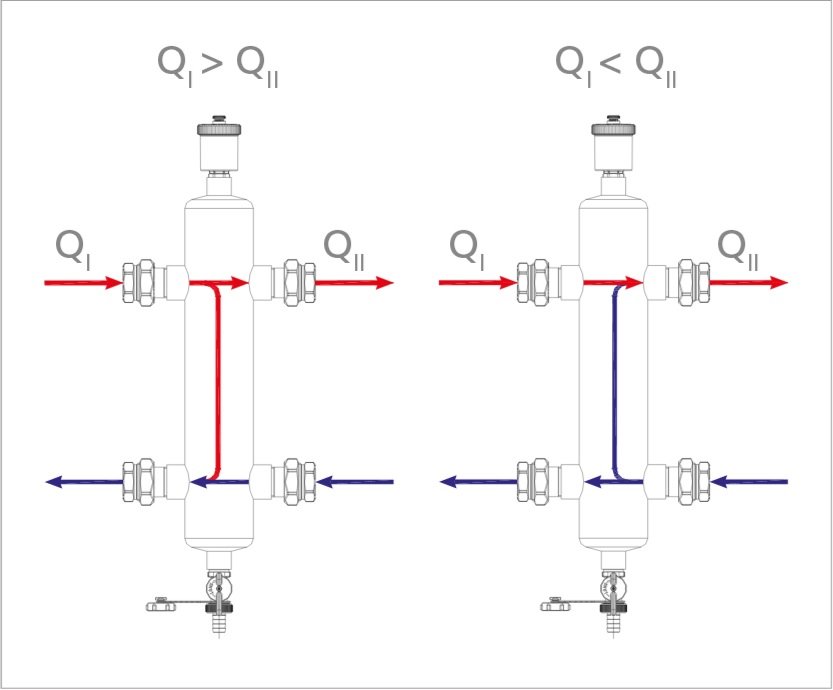

Theoretically, there are three modes of operation of the heating system with a hydraulic arrow. They are shown in the figure below.

The first is when the boiler pump pumps exactly the same amount of coolant as the entire heating system requires.

Possible modes of operation of the heating system with a hydraulic separator

The second mode of operation of the hydraulic arrow is when the flow rate of the heating circuits is greater than the power of the boiler pump (middle figure). This situation is dangerous for the system and should not be allowed.It is possible if the boiler pump has too little capacity. In this case, to ensure the required flow rate, the heating medium from the return will be supplied to the circuits together with the heated coolant from the boiler. This mode of operation is not normal and the boiler will quickly fail.

The third mode of operation is when the boiler pump supplies more heated coolant than the heating circuits require (right figure). In this case, part of the heated coolant is returned to the boiler. As a result, the temperature of the incoming coolant rises, it works in a sparing mode. This is the normal mode of operation of the heating system with a hydraulic arrow.

When a hydraulic gun is needed

A hydraulic arrow for heating is 100% needed if the system has several boilers operating in a cascade. Moreover, they must work simultaneously (at least most of the time). Here, for correct operation, a hydraulic separator is the best way out.

In the presence of two simultaneously operating boilers (in a cascade), a hydraulic arrow is the best option

Another hydraulic arrow for heating can be useful for boilers with a cast-iron heat exchanger. In the tank of the hydraulic separator, there is a constant mixing of warm and cold water. This reduces the temperature delta at the outlet and inlet of the boiler. For a cast-iron heat exchanger, this is a boon. But a bypass with a three-way adjustable valve will cope with the same task and it will cost much less. So even for cast-iron boilers in small heating systems, with approximately the same flow rate, it is quite possible to do without connecting a hydraulic arrow.

When can I put

If there is only one pump in the heating system - on the boiler, the hydraulic arrow is not needed at all.

The installation of a hydraulic gun is justified under the following conditions:

- There are three or more circuits, all of very different capacities (different volume of the circuit, different temperatures are required). In this case, even with perfectly accurate selection of pumps and calculation of parameters, there is a possibility of unstable operation of the system. For example, a situation often occurs when, when the floor heating pump is turned on, the radiators freeze. In this case, hydraulic decoupling of the pumps is needed and therefore a hydraulic arrow is installed.

- In addition to radiators, there is a water-heated floor that heats large areas. Yes, it can be connected through a collector and a mixing unit, but it can make the boiler pump work in extreme mode. If your heating pumps often burn, you most likely need to install a hydraulic gun.

- In a system of medium or large volume (with two or more pumps), you are going to install automatic control equipment - according to the temperature of the coolant or air temperature. At the same time, you do not want / cannot regulate the system manually (with taps).

An example of a heating system with a hydraulic arrow

How a hydraulic gun works in different cases

The principle of operation of the hydraulic gun differs depending on the purpose of its use and the type of systems in which it is installed.

Heating with 4-way mixer

To describe the scheme of heating operation with a 4-way mixer, first you need to imagine a square, on each side of which there are holes of equal width. From all these compartments, either cold or hot water flows.

There are only 3 modes in the system: fully open, fully closed and intermediate.Let's start the analysis with a completely closed one.

As we know, warm streams of air or hot water come out straight from the boiler, and cold streams come out of the heating system (the water left the boiler, made a circle and cooled down).

If the entire system is closed, i.e., does not work, then warm water constantly overflows through the hydraulic separator, without leaving anywhere, flowing constantly in one circle and returning back to the boiler.

The same situation occurs with a cold stream of water or air, which is not reheated, remaining cold until open. These liquids do not mix and do not transfer heat to each other, circulating strictly along their contour.

In the intermediate mode, these liquids begin to mix. At the same time, the temperature is often slightly above average, because all the steam accumulated during the closed regime period goes outside and begins to warm the cold streams. Thus, the floors are usually heated so that the legs do not burn.

In the open mode, the hot and cold water channels do not intersect again, but compensate for each other's losses. What does it mean. Imagine a square again. Streams of hot air or water exit from one end and enter the heating system, while the cold liquid, leaving it, moves to the sides of the boiler, where it warms up. And such a process of replenishing constantly hot water with cold water and vice versa is almost a perpetual motion machine, if you do not take into account that the heat is irretrievably gone.

For neutral operation

The ideal operating mode of the hydraulic separator is the moment when the amount of hot and cold water is approximately the same and does not require regulation.

This usually happens when the boiler is running constantly and without interruption - very rarely, because there is always an error.

The boiler does not have enough power

Based on this problem, they put a temperature sensor, or, in our case, a hydraulic arrow. Having received a signal from the built-in temperature sensor, the hydraulic separator switches to different modes: either open or closed.

Attention! This ensures the safety of the boiler, which can simply break overnight due to temperature and pressure fluctuations. By distilling water, cooling or heating, the hydraulic arrow helps the boiler to cope with the balancing of thermodynamics in order to continue working.

The flow on the primary circuit is larger than the coolant flow

As mentioned above, if the hot stream is too hot to enter the boiler, then through the hydraulic arrow it enters the system, which guarantees the separation of the stream into two parts, the second will cool and go into the heating system along with cold water or steam, and the hot part will be greatly reduced and will no longer pose a threat to an already hot boiler.

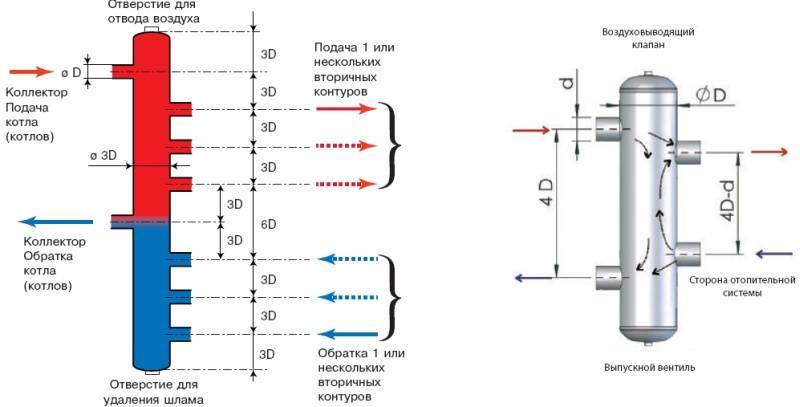

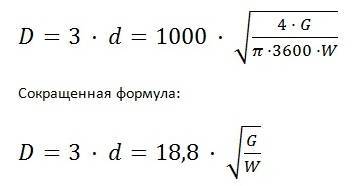

Manufacturing schemes

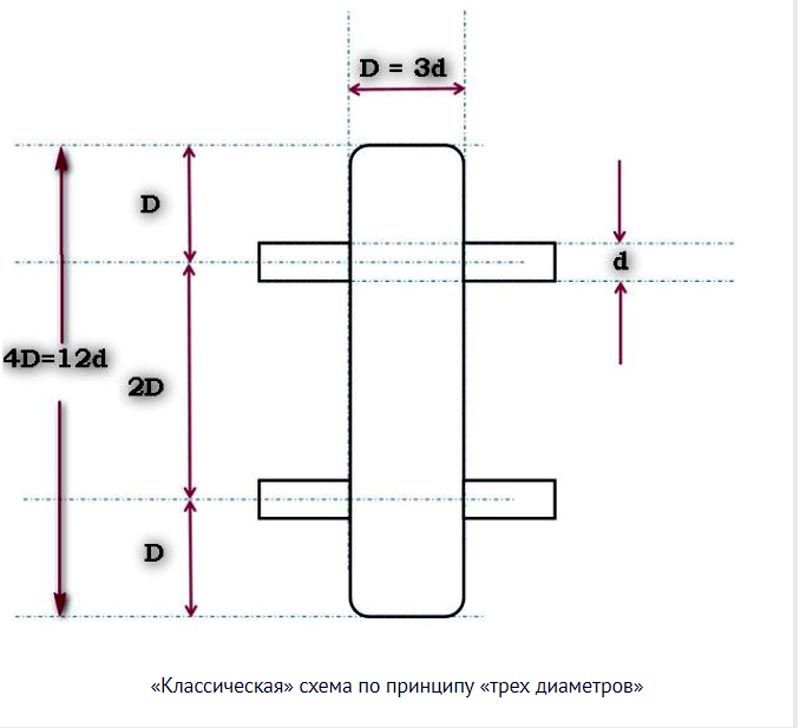

Industrial-made hydraulic arrows are not cheap and many make them with their own hands. In this case, you need to make preliminary calculations. The main design dimensions are shown in the figure below.

As can be seen from the figure, the diameter of the hydraulic arrow itself is taken equal to three diameters of the inlet pipes, so the calculations are reduced mainly to determining the diameter of the hydraulic arrow.

The figure shows two options for hydraulic guns. The purpose of the second option is better than the first one in that the water, when crossing the supply pipeline, is freed from air bubbles, and when it returns, it gets rid of sludge better.

The calculation comes down mainly to determining the diameter of the hydraulic arrow:

- D is the diameter of the hydraulic arrow in mm;

- d is the diameter of the inlet in mm, usually taken equal to D / 3;

- 1000 - conversion factor meters in mm;

- P - boiler power in kJ;

- π is the number pi = 3.14;

- C - heat capacity of the coolant (water - 4.183 kJ / kg C °);

- W - the maximum vertical speed of water movement in the hydraulic arrow, m / s, usually taken equal to 0.1 m / s;

- ΔT is the temperature difference of the heat carrier at the inlet and outlet of the boiler, С°.

You can also calculate using the following formula:

where:

- Q is the coolant flow rate, m³/s;

- V is the speed of water movement in the hydraulic arrow, m/s;

Also, to calculate the diameter of the hydraulic arrow, there is such a formula:

where:

- G - consumption, m³ / hour;

- W is the speed of water movement, m/s;

The height of the hydraulic arrow can be any and is limited only by the height of the ceiling in the room.

If you make the diameter of the hydraulic arrow large enough, you can get two in one: a hydraulic arrow and a heat accumulator, the so-called capacitive separator.

As can be seen from the figure, this type of hydraulic arrow has a large volume, about 300 liters or more, therefore, in addition to fulfilling its main task, it is also capable of accumulating heat. The use of a hydraulic arrow of this type is especially justified when heating with a solid fuel boiler, as it is able to smooth out the temperature fluctuations of the heating boiler and store the thermal energy of the boiler after the end of combustion for quite a long time.

You need to know some of the nuances when using this type of hydraulic gun:

- Firstly, such a hydraulic arrow must be insulated, because otherwise it will heat the boiler room, and not give off heat to the heating system.

- The boiler will produce less power.This is due to the fact that a high temperature of the coolant is required, and automatic equipment is installed on the boilers, which will automatically reduce its power to reduce the outlet temperature.