- Power calculation

- The main nuances of choosing a gas boiler

- Criteria for choosing double-circuit boilers

- How to connect a device for a boiler with two circuits

- Wiring diagram

- Direct heating device

- Indirect and combined heating

- Materials and tools

- Step-by-step installation and quality control

- Subtleties of work

- What is layered water heating?

- Physical principles of operation

- The best wall-mounted gas boilers

- Viessmann Vitopend 100-W A1HB003

- Baxi Eco Four 1.24F

- Vaillant AtmoTEC Plus VU 240/5-5

- Types of wall-mounted boilers

- By camera type

- Number of circuits

- traditional

- Calculation of the required boiler power

- Advantages

- Differences between floor and wall boilers

- The principle of operation and arrangement of gas boilers

- Prices: summary table

- Conclusions and useful video on the topic

Power calculation

The calculation of the power of a wall-mounted boiler for heating a house should be selected based on the values of heat loss at home. They are quite easy to calculate and you can do it yourself using ready-made calculators on the Internet. The value of heat loss is equal to the required value of the power of the gas boiler.

Pay attention to the designation of the boiler power. Some manufacturers indicate the rated power (excluding losses), others indicate the actual power (taking into account losses)

When specifying nominal values from the power, subtract the percentage of losses based on the efficiency data. Then you will get the actual power. That is, if the power of the cat is 26 kW, and the efficiency is 92%, then subtract 8% from 26 kW and get the very power that the boiler will definitely give you.

If you are going to buy a double-circuit boiler, then it is better to purchase a power of at least 24 kW. With such values, the boiler can easily produce the required amount of domestic hot water.

The main nuances of choosing a gas boiler

The absence or constant interruptions of centralized heating and hot water supply force the owners of cottages and city apartments to create their own autonomous systems.

Their main element is a boiler, which, by burning fuel, heats the coolant for the heating system and water for domestic needs.

The choice in favor of gas equipment is due to the cost-effectiveness of using gas as a fuel. All other options for combustible fuel are more expensive or give less heat at times.

Plus, modern heaters of this type do not require constant supervision. I connected the unit to the main pipe or cylinder, and it works smoothly as long as there is something to burn.

The use of natural gas is the optimal solution for heating a private house in terms of fuel costs and operating costs.

However, in order for the gas boiler to function properly and in optimal mode, it is necessary to choose it correctly when buying and regularly service it after connection.

There are many different in functionality and special modules within the models of this equipment. The purchase of a gas heating unit should be approached thoughtfully.

There are many criteria for choosing a gas boiler, but the main ones are:

- The power output by the device.

- Layout solution (number of circuits, body type and heat exchanger material).

- Place for installation.

- Availability of automation for safe operation.

All these questions are closely related. The lack of space for a large unit or the desire to mount a device with an aesthetic appearance in the kitchen forces you to choose a wall-mounted model of less power than the floor version. And the need to heat hot water for the washbasin and shower makes you look for a boiler with two circuits.

When choosing a heater, you should remember about the need to repair it, if there is no workshop for servicing the selected model nearby, then you should look for another option

Criteria for choosing double-circuit boilers

Equipment selection criteria on the example of Nuvol

An important parameter of the device is power - it determines whether the boiler can heat the room and at the same time supply the heated liquid without interruption. The required indicator is determined by the dimensions of the dwelling - the area and height of the ceilings. If there is a shortage of thermal insulation, power requirements increase.

The type of combustion chamber also matters. If it has an open design, the waste is discharged through a simple chimney. With a hermetically sealed chamber, the inlet and outlet of gases from the device are realized through a turbine mechanism. An economical option would be to purchase a condensing gas boiler with a boiler. Its design ensures more efficient use of fuel and lower fuel consumption. In addition, air pollution by combustion products is reduced.

How to connect a device for a boiler with two circuits

The boiler is selected, having decided on its type, location and volume relative to the power of the water heater. In indirect and combined type drives, it is recommended to provide additional protection against scale inside the coil.

Attention! It is forbidden to connect the boiler until the boiler is put into operation by the gas service

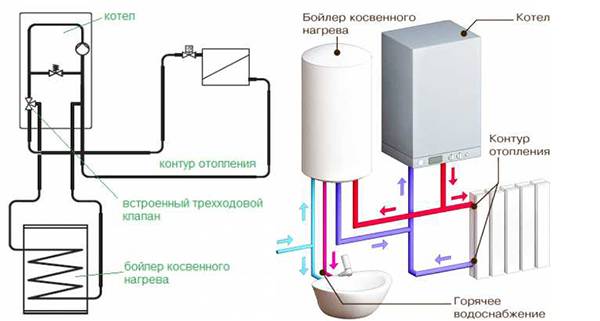

Wiring diagram

The connection diagram depends on the type of tank:

Direct heating device

The inlet pipe of the storage tank is connected to the cold water inlet. Outlet branch pipe - to the entrance to the second circuit of the boiler.

Cold water enters directly into the boiler, where it heats up to 60 ° C under the influence of a heating element.

From the boiler, the liquid is sent to the boiler, losing several degrees of temperature along the way. Passing through the second heat exchanger of the heating device, water restores losses and goes to the DHW system through the boiler outlet valve.

Indirect and combined heating

They have two additional branch pipes from coils. They are connected to the first circuit of the boiler. The scheme of work assumes that the heated coolant of the heating system will first pass through the storage coil, and only then go to the radiators.

Due to this, the main heating gradient of tap water is provided by a coil. Cold water is introduced directly into the accumulator, the heated liquid is discharged to the boiler's DHW circuit.

When clocking, that is, periodically turning the burner on and off by the automation of the boiler operating with an indirect heating boiler, it is recommended to change the tank connection scheme. Boiler clocking indicates that the water in the storage tank does not warm up to the required 60 °C.

The pipes of the DHW circuit of the water heater are muffled, the water from the boiler is immediately sent to consumers.The rate of heating of the liquid depends solely on the power of the heating system; it is impossible to operate this scheme in the summer.

Photo 3. Wiring diagram for an indirect water heating boiler for a double-circuit gas boiler.

Materials and tools

The internal elements of boilers are made of copper, steel or cast iron. Heating elements and coils are made of copper or steel. The steel walls of the tank are subject to corrosion, the service life does not exceed 15 years. Cast iron walls are twice as massive and more expensive, but they work properly for up to 90 years.

When installing a boiler, detachable pipe connections are provided. For this you need:

- tape measure, pencil, chalk;

- puncher with a set of drills (for making holes for the pipeline, wall mounting elements);

- adjustable and wrenches (models with ratchet are recommended);

- Screwdriver Set;

- pliers;

- wire cutters;

- means for sealing joints (flax, FUM tape, plumbing thread);

- sealants;

- shutoff valves, tees;

- fitting;

- pipes.

If it is not possible to arrange detachable connections, polypropylene pipes are used, which are welded on site.

Step-by-step installation and quality control

All work is carried out with the equipment turned off and the liquid removed from the system.

- Marking fasteners with a pencil or chalk. Drilling mounting holes.

- Checking the bearing capacity of the wall. Actual for hinged models. The fasteners supplied with the drive are installed on the wall, loaded with bags of cement or sand at the rate of a double supply.

If the wall material can withstand a load of 100 kg, then you can hang a boiler with a volume of up to 50 liters without fear.

- Placing the container on the wall or on the floor.

- Plumbing connection.

- Installation of overpressure valves along the water course.

- Installing an expansion tank.

- Filling with water and checking the tightness of the connections. If the system filled with water did not leak during an hour of inactivity, then the tightness of the joints is satisfactory.

- Turning on the equipment to the network, checking the operation.

Subtleties of work

If, when looking for heating equipment for your own house or apartment, the choice stops at a single-circuit boiler and it is planned to connect a boiler to it, then the following features of the boiler’s operation in tandem with this heat exchanger should be taken into account.

From the moment the boiler is turned on and until the water in it is completely heated, the heating system will not work on the DHW

Based on this trouble, it is necessary to choose a hot water heat exchanger according to the maximum water heating time, which would be enough to prevent freezing of heating pipes in the most extreme frost in the region of residence.

Choosing a boiler by power, linking it with the heated area of \u200b\u200bthe premises, not forgetting the climatic zone of residence, what the house is built from and whether its walls have thermal insulation - all this is important when choosing the power of the heating unit.

Having decided on the power, it is possible to say with accuracy whether such a boiler will pull the boiler water heating system or not.

Heating engineers believe that a boiler installation can only function normally with a boiler with a capacity of at least 24 kW. Another expert figure is that the boiler takes up to 50% of the power from the boiler. These are the numbers you need to focus on when choosing a gas boiler model for your home.And to prevent a situation where a 35 kW boiler is installed with an estimated power consumption for heating of 25 kW, and the boiler will take 17 kW. As a result, a boiler power deficit of 7 kW is formed.

It is also worth noting the fact that in some cases a boiler with a large capacity is required, with a capacity of 200 and even 500 liters.

What is layered water heating?

There are two types of boilers that can work with boilers - with indirect or layered heating. In an indirect heating boiler, the water will heat up longer, and much more. So, when using layered heating, a shower can be taken after 5 minutes, and indirect heating will allow this to be done no earlier than 20 minutes after the boiler is turned on.

In double-circuit boilers with stratified heating boilers, the water is heated by an instantaneous water heater. Most often it is a plate radiator, but there are also other designs, for example, a pipe in a pipe. Heat transfer occurs from the heated coolant to cold tap water. The streams are separated by a thin sheet of metal, so that heat transfer is very efficient.

For condensing boilers, an additional heat exchanger has proven to be advantageous, as helps the condensation of water vapor containing the so-called. latent heat of combustion products. But this is more true for double-circuit, and not for single-circuit condensing boilers.

Water is supplied to the stratified heating boilers from the instantaneous water heater, i.e. already hot. That is why such boilers are able to prepare hot water faster than indirect heating boilers, where you have to wait until the entire tank is heated. The difference is more noticeable after a break in the operation of the boiler.

The advantage of stratified heating boilers is that the hot water entering the tank occupies the top layer, while at the bottom it can remain cool. Stratification makes it possible to get hot water from the tap already 5 minutes after turning on the boiler. In boilers paired with an indirect heating boiler, you will have to wait at least 20 minutes until the internal heat exchanger heats up a large amount of water. You have to wait longer also because with indirect heating, the water is heated from below, as a result of which it is constantly mixed due to convection.

Of course, the indirect heating time depends on the size of the heat exchanger, the capacity of the boiler and the power of the burner. So, the fastest water will heat up with a large boiler power and a large heat exchanger. However, the larger the heat exchanger, the less space remains in the boiler for water, and the high power of the boiler will be due to the fact that the burner will often turn off in heating mode, and, accordingly, will work faster.

Layered boilers do not have a heat exchanger, so their entire internal volume (with the exception of thermal insulation, if any) is occupied by water. It is estimated that stratified heating boilers are 1.5 times more productive than indirect heating boilers. This means that layer-by-layer heating, among other things, saves space. Thus, if it is not possible to allocate a boiler room in the house, then double-circuit boilers with layer heating boiler is the most reasonable solution.

Why do you need a boiler at all? This question is often asked by people who are far from the topic, but they do not always receive an exhaustive answer to it. A boiler of any type increases the comfort of using hot water.So, a double-circuit boiler with a boiler is able to provide a large and stable pressure of hot water at several points of water intake, while a similar boiler, but without a boiler, when the second tap is turned on, will not have time to heat the water to the desired temperature with the same pressure. In addition, there are situations when a small pressure of hot water is needed. Boilers in this case will cope with the task, and in instantaneous water heaters, the lower limit of pressure is limited.

As for the dimensions of double-circuit boilers with layered heating boilers, there are compromises here. The smallest boiler has a volume of only 20 liters. It can even have a wall-mounted double-circuit boiler, not much larger in size than a similar boiler without a boiler.

A floor-standing boiler with a built-in boiler looks like a refrigerator. You can even find a place for it in the kitchen. Of course, small boilers will not provide many taps at the same time, so they need to be selected taking into account the peak consumption of hot water. A large boiler will also be needed in order to serve a modern shower panel with hydromassage or quickly take a hot bath. A boiler capable of such tasks must contain 250-300 liters of water, which means it must be separate. The maximum volume of built-in boilers is 100 liters.

Speaking about the comfort of using hot water, one cannot fail to mention such an important point as the distance from the boiler to the draw-off point. If it exceeds 5 m, then the DHW system must be circulating, otherwise it will take a long time to wait for hot water.

Physical principles of operation

Mounted gas boilers are mainly designed for heating residential premises.

Mounted gas boilers operate as follows: gaseous fuel is supplied to the combustion chamber through a pipeline through a burner. Here it is mixed with oxygen from atmospheric air, and after ignition by a spark from a special device, intensive oxidation occurs with the release of a large amount of energy. Heat is transferred through the metal or ceramic walls of the heat exchanger to the liquid.

Heating occurs until a certain temperature is reached, after which the thermostat interrupts the gas supply. Constant circulation of water ensures reliable cooling of the heat exchanger. The temperature sensor resumes the supply of fuel to the burner upon reaching the set value. Gas heating boilers operate mainly in automatic mode.

As a result of the operation of the burner, a large amount of combustion products is formed, which are released into the atmosphere. This may be due to natural traction or forced. Modern boilers can emit burnt gas both through vertical chimneys and through horizontal ones - through the outer walls of the building. Such hinged ones have coaxial cylindrical channels and closed chambers.

The best wall-mounted gas boilers

This section presents single-circuit space heating systems placed on the wall. They are compact and easy to maintain, although they have some limitations in functionality.

Viessmann Vitopend 100-W A1HB003

4.9

★★★★★

editorial score

89%

buyers recommend this product

The A1HB line includes three boilers with a capacity of 24, 30 and 34 kW. This is enough to heat housing up to 250 m2. All cases are equally compact: 725x400x340 mm - there is a place for such units in any room.

Viessmann boilers are assembled on a single modular platform, which simplifies their installation and maintenance. In addition, there is no need to leave additional space near the body, so any Vitopend can be combined with kitchen furniture if there is a free corner for it.

Advantages:

- Low gas consumption - no more than 3.5 m3 / h in the older model;

- The hydroblock is equipped with quick-detachable connectors;

- Auto-adjustment of power depending on the outside temperature;

- Efficiency up to 93%;

- New coaxial chimney system with frost protection;

- Intelligent control with self-diagnosis function;

- Possibility of switching to liquefied gas.

Flaws:

There is no remote control.

Viessmann provides an opportunity to choose a boiler for an apartment of any size. The appearance and dimensions for the entire line are absolutely the same - the models differ only in performance and, accordingly, in gas consumption.

Baxi Eco Four 1.24F

4.8

★★★★★

editorial score

88%

buyers recommend this product

See review

Despite the prestige of the brand, the Eco Four model is relatively inexpensive. The boiler has a flat body measuring 730x400x299 mm, which allows it to be hung flush with kitchen cabinets. When used in northern latitudes, such a unit can heat an apartment up to 150 m².

Boilers of the fourth generation were developed taking into account our operating conditions. That is why the presented model works even at a gas inlet pressure reduced to 5 mbar. In addition, it has two separate thermostats: for heating radiators and the "warm floor" system.

Advantages:

- Built-in water flow meter;

- Pump with air outlet and post-circulation mode;

- It is possible to connect to solar collectors;

- Dual-mode thermal control;

- Pressure switch for protection against low coolant pressure;

- You can connect a remote thermostat and remote control.

Flaws:

Uninformative built-in display.

As for Baxi, the price of the Eco Four is very attractive. In addition, this is an excellent solution for placement in a small kitchen or studio apartment.

Vaillant AtmoTEC Plus VU 240/5-5

4.7

★★★★★

editorial score

87%

buyers recommend this product

This boiler has all possible means of protection: gas control, pressure switch with safety valve, pump air vent. Here, overheating of the carrier and combustion chamber, freezing of liquid in the system and in the chimney are completely excluded. The built-in auto-diagnostics helps to monitor the correct operation of all systems.

AtmoTEC is adapted for operation in Russia: it takes into account the low quality of main gas and can operate on LNG. The control of the programmer is fully automated, and the panel itself is covered with a neat decorative cover.

Advantages:

- Volumetric expansion tank 10 l;

- Low gas consumption - 2.8 m³ / h (or 1.9 m³ / h when connected to a cylinder);

- Virtually eternal chromium-nickel burner;

- Possibility of combination with other heaters;

- Minimum side clearance for installation is 1 cm.

Flaws:

Classic (atmospheric) chimney.

The dimensions of the boiler are 800x440x338 mm and the maximum power of 36 kW is more suitable for a private house than for a city apartment. Although in a spacious kitchen there will be no problems with its placement.

Types of wall-mounted boilers

When choosing a gas boiler for heating a private house from a wall-mounted option, you will definitely come across different varieties. Therefore, we will break them down by type and explain the difference.

By camera type

Wall-mounted boilers, like floor-standing ones, come with open and closed combustion chamber. With an open (atomic) combustion chamber, oxygen for gas combustion is taken from the room where the boiler is installed. For such a unit, a full-fledged chimney is mounted for better traction. Such models are less common, but still have a place to be. The main disadvantage is lower performance.

Boilers with a closed combustion chamber (turbocharged boilers) are distinguished by the fact that oxygen for gas combustion is also taken from the street. Included with such devices are coaxial chimneys (pipe in pipe). Oxygen enters from one pipe, exhaust gases exit from the other. The chimney is only 1 meter long, which, if desired, can be further extended by 3 meters. Such models are characterized by high performance with an efficiency of 91% and can be installed in residential premises.

Number of circuits

Wall-mounted boilers can not only provide heating to the house, but also provide hot water directly. This is especially convenient when you do not have extra space or simply do not want to use boilers for some reason.

If the boiler is capable of producing heat only for heating, then it is called single-circuit. If it is also able to give hot water, then this is called a double-circuit one.

Double-circuit models come with a biothermal heat exchanger and monothermal. In the first case, hot water and heating are heated in one heat exchanger, in the second case, in different ones. Monothermal options are considered more common and preferred.

traditional

There are traditional boilers, which are called convection boilers, and there are also condensing boilers.The latter are considered more economical, but they show their effectiveness only in low-temperature heating systems (water-heated floor and others). Also, condensing models are more expensive than traditional ones.

In most tasks, a traditional wall-mounted boiler as the main source of heat for a private house will be enough for your eyes. The cost difference between them is not much different. But if you have water floors throughout your house, then why not look in the direction of an even more economical solution.

Calculation of the required boiler power

When calculating the power, the area of \u200b\u200bthe house, the number of windows, the degree of wall insulation, climate are taken into account

When calculating the power, the area of \u200b\u200bthe house, the number of windows, the degree of wall insulation, climate are taken into account

Before buying, it is important to calculate the optimal heat output. The roughest method relies on the area of the dwelling: it is assumed that 1 kW of power is needed to service every 10 m2 (if the height of the room does not exceed 3 m) and 20-30% of the margin is added to the result

However, the situation is influenced by a number of factors that are not taken into account in this method: climate, sources of heat loss, the amount of heated water consumed, installations of forced circulation of air masses.

A more accurate calculation will be obtained if we enter the specific coefficient determined by climatic conditions into the formula: for the south of the CIS it will be 0.7-0.9, for the central region of the European part of Russia - 1-1.1, for the northern regions 1.3- 1.4. Then the formula will take the form: N=S*k/10, where N is the power in kW, S is the area in m2, k is the coefficient. If the boiler is purchased for heating and water supply at the same time, the result is multiplied by 1.25.

Advantages

Modern models of gas boilers with a single heating circuit for heating the heating system could be called primitive water heating devices if they were not equipped with high-precision control and instrumentation to ensure the reliability and safety of all cycles of work. To solve the problems of regulation and safety of boilers, an automatic boiler protection system with gas flow and pressure regulators, valves that regulate the flow, temperature and pressure of heated water, all kinds of sensors, devices and safety devices is aimed. This is the main advantage of gas boilers.

Other important benefits:

- simplicity of design and installation of the boiler, which includes a combustion chamber with a gas burner, a loop heat exchanger in the furnace, a system of collectors and pipelines, pumping equipment;

- efficiency achieved by automation and adjustment work for optimal and efficient fuel combustion, admixture processes and regulation of coolant parameters in accordance with the standards;

- the ability to connect boilers to cascade heating systems within cities and large towns, which allows not only centrally managing the system, but also providing reliable and high-quality heat supply to consumers in residential areas, quarters, microdistricts, as well as enterprises whose boiler houses are included in the cascade;

- more environmentally friendly emissions of gas combustion products into the atmosphere compared to similar boilers using liquid and solid fuels.

Differences between floor and wall boilers

As a rule, a wall-mounted single or double-circuit atmospheric gas boiler is a kind of mini-boiler room with a built-in expansion tank, a circulation pump, and an electronic control board. Options for equipping with a valve for connecting an indirect heating heater and weather-dependent programmers are possible.

The main advantage of a wall-mounted boiler is its compactness, light weight, high functionality, ease of installation. Such a unit is ideal for installation in cramped conditions, operation in a residential area is allowed. Modern mounted boilers have sufficient power to heat a house up to 200 sq.m.

Compact wall-mounted gas boiler fits perfectly into the modern interior of the room

Compact wall-mounted gas boiler fits perfectly into the modern interior of the room

Floor boilers have large overall dimensions, and their weight can be 3 times higher than the weight of a wall-mounted boiler with similar parameters. This is due to the fact that floor-standing units, unlike wall-mounted units, are equipped with cast-iron heat exchangers.

The service life of such boilers is 20-25 years. At the same time, wall-mounted boilers with steel or copper heat exchangers will last you 8-10 years.

The principle of operation and arrangement of gas boilers

A gas boiler is a wall-mounted or floor-standing unit, predominantly of a rectangular-parallelepiped shape, which generates energy during the combustion of fuel and thereby ensures the functioning of heating and hot water supply systems.

In general, the boiler consists of the following elements:

1. Housing;

2. Burner;

3. Heat exchanger;

4. Circulation pump;

5. Branch for products of combustion;

6. Block of control and management.

Depending on the design, the boiler operates in one of several modes - according to a simplified scheme: gas is supplied to the burner, which is turned on by a piezoelectric element or electricity; the fuel ignites and heats the coolant through the heat exchanger; the latter, with the help of a pump, is forcibly circulated in the heating system.

During operation, an important role is played by safety systems that prevent overheating, freezing, gas leakage, pump blocking and other troubles.

In the operation of the units there are individual features. In the variant with a 2-circuit model, hot water supply is additionally arranged. In the case of an open firebox, combustion products are removed through the chimney, with a closed chamber - through a coaxial pipe. In condensation models, steam energy is also used.

Prices: summary table

| Model | power, kWt | Number of circuits | Efficiency, % | Gas consumption, m³/hour | Cost, rub. |

| BAXI ECO Four 1.24 | 24 | 1 | 91,2 | 2,78 | 40 000-45 000 |

| Protherm Panther 25 KTO | 25 | 1 | 92,8 | 2,8 | 47 000-53 000 |

| Viessmann Vitopend 100-W A1HB | 24 | 1 | 91 | 2,77 | 36 600-45 000 |

| BAXI Duo-tec Compact 1.24 | 24 | 1 | 105,7 | 2,61 | 56 000-62 000 |

| Rinnai BR-UE30 | 29,1 | 1 | 92,5 | 2,87 | 59 900-67 000 |

| BAXI ECO-4s 24F | 24 | 2 | 92,9 | 2,73 | 36 500-42 200 |

| BAXI LUNA-3 240 Fi 25 | 25 | 2 | 92,9 | 2,84 | 51 000-58 000 |

| Vaillant turboFIT VUW 242/5-2 | 23,7 | 2 | 93,5 | 2,66 | 41 600-48 000 |

Conclusion

Wall-mounted gas boilers are economical, convenient and practical heating equipment. They are able not only to heat the room, but also to give hot water. Choosing is not so difficult, if you understand all the characteristics. But it’s not worth buying the first one that comes across, because the comfort and coziness in your home depends on the boiler.

Conclusions and useful video on the topic

Recommendations for connecting a gas boiler to a chimney:

Single-circuit boiler or double-circuit, which is preferable:

It is almost impossible to give an unambiguous answer about the optimal configuration of the boiler.Since the unit must not only correspond to the size of the room, but also to the requirements put forward to it. Based on the most important criteria for choosing a device, you can create a prototype of an ideal boiler, with which it will be easier to choose a specific model.

With similar technical parameters, preference should be given to the model that is higher in the presented TOP-15 of the best gas boilers. Since the rating is based not only on the popularity of the brand, but also on the popularity of the product in the modern market. It is based on in-depth market analysis and user feedback.

Do you want to talk about how you chose and installed an atmospheric gas unit in your own heating system? Do you have useful information on the topic of the article? Please leave comments, ask questions, post photos in the block form below.