- Three models

- Pros and cons

- Model range and specifications

- "Typhoon-1": maximum pressure - 16 m

- "Typhoon-2": maximum pressure - 90 m

- "Typhoon-3": automation unit and maximum head - 90 m

- Pumping stations “Typhoon”

- Features of choice

- Most popular model

- Features and disadvantages of pumps

- How to avoid breakdowns

- Vibration pump "Typhoon-2" - repair and modernization

- Scope and technical characteristics of Typhoon pumps

- Troubleshooting

- Reduced water pressure

- Engine not running

- Mounting Features

- Device and principle of operation

- Adjustment of Typhoon units

- Conclusions and useful video on the topic

Three models

Manufacturers supply three models to the markets at once - an early version and upgraded ones:

"Typhoon-1" modification BV-0.5-16-U5-M - the first version of the model. The diameter of the product is 10 centimeters, so it must be borne in mind that it can only be lowered into a shallow well with a diameter of 12.5 centimeters or more (there must be a gap between the body and the device for free movement). This model is designed to take water from wells, reserve tanks or tanks for irrigation, as well as from pools and ponds with clean water.

This is a high-performance household unit with a immersion depth of up to 16 m.The performance of this pump at a maximum immersion depth is 35 l / min, at a depth of 3 m - 50 l / min. The pumping apparatus is capable of pumping water from a depth of up to 8 m.

The equipment is equipped with a built-in overheating protection system and a two-channel water intake system for additional cooling of the case during operation.

"Typhoon-2" is a modernized device with the ability to draw water from a depth of up to 90 meters. This is one of the most popular models on the market, designed to work in wells with a diameter of 12.5 centimeters.

The main difference between the models is the working depth at which they can be used. The early version of the device refers to units operating at a relatively shallow depth (technical indicators are almost twice as high as those of competitors!). The upgraded model is a real downhole pump for wells, with an impressive capacity of up to 2,500 liters of water per hour.

The BV-0.25-40-U5M modification pump is capable of transporting water over a distance of 90 m, which includes pumping out of the wellbore, moving along the horizontal and vertical sections of the water supply to the consumer. This can only be very expensive imported pumps.

The performance of the electric pump depends on the distance between it and the working:

- 90-80 m - 8 l / min;

- 40 m - 15 l / min;

- 10 m - 30 l / min;

- 5 m - 40 l / min.

The pump is equipped with a built-in thermal protection and a two-channel water intake system for the best cooling. This pump is the base for the Typhoon domestic pumping station manufactured by Bosna LG.

Also, the models differ in the characteristics of thermal protection:

- BV-0.25-40-U5-M - marking of the deep model, indicating increased protection of the unit from overheating;

- BV-0.5-16-U5-M - marking of an early model, with weaker engine protection against overheating.

And the placement of the water inlet:

- basic model with lower water intake;

- upgraded with top.

The main characteristics of the base model:

- power - 240 watts;

- maximum pressure - 30 meters;

- productivity - 750 liters per hour;

- cable length - 10 meters.

Pros and cons

Advantages of both models:

- affordable price;

- long service life;

- reliability;

- quiet operation (devices are immersed in water);

- built-in overheating protection;

- reliable water cooling thanks to a two-channel intake;

- compact dimensions;

- high performance.

Flaws:

- for maintenance, the unit must be removed to the surface;

- high starting current.

"Typhoon-3" - electric pump BV-0.25-40-U5M with UZN (anti-interference device) - unique equipment for domestic use in conditions of unstable power supply. The unit is equipped with a UZN automation unit built into the power cord. UZN equalizes voltage drops in the network in the range of 190-250 V to the working one.

Voltage drops do not affect the performance of the pump in any way, do not lead to overheating and failure, which is especially important for summer residents with an unstable power supply system. The pump starts up smoothly, this is of great importance, because

starting currents for pumps of this type are quite large. The maximum immersion depth is 90 m, while the pump capacity is 8 l / min

The pump starts up smoothly, this is of great importance, because.starting currents for pumps of this type are quite large. The maximum immersion depth is 90 m, while the pump capacity is 8 l/min.

All Typhoon pumps are designed for continuous operation without stopping and have IPx8 waterproof ratings.

Model range and specifications

Bosna LG (Ukraine) produces three brands of submersible electric pumps for pure cold water "Typhoon" in a cast iron housing. All water pumps in this series are designed for work from the electrical network with a voltage of 220 V. The water intake is lower, which requires hanging these pumps at a certain distance from the bottom.

A small diameter of 10 cm makes it possible to use all models in wells from 12 cm in size. All Bosna LG equipment has a 12-month warranty. The pump is supplied with a coupling for connection with a hose or pipe.

"Typhoon-1": maximum pressure - 16 m

Electric pump "Typhoon-1" modification BV-0.5-16-U5-M is a high-performance household unit with an immersion depth of up to 16 m. The performance of this pump at a maximum immersion depth is 35 l / min, at a depth of 3 m - 50 l / min. The pumping apparatus is capable of pumping water from a depth of up to 8 m.

The equipment is equipped with a built-in overheating protection system and a two-channel water intake system for additional cooling of the case during operation.

"Typhoon-2": maximum pressure - 90 m

The BV-0.25-40-U5M modification pump is capable of transporting water over a distance of 90 m, which includes pumping out of the wellbore, moving along the horizontal and vertical sections of the water supply to the consumer. This can only be very expensive imported pumps.

The performance of the electric pump depends on the distance between it and the working:

- 90-80 m - 8 l / min;

- 40 m - 15 l / min;

- 10 m - 30 l / min;

- 5 m - 40 l / min.

The pump is equipped with a built-in thermal protection and a two-channel water intake system for the best cooling. This pump is the base for the Typhoon domestic pumping station manufactured by Bosna LG.

Typhoon pumps are several times superior to similar water pumps in terms of immersion depth and performance due to a special patented design solution

Typhoon pumps are several times superior to similar water pumps in terms of immersion depth and performance due to a special patented design solution

"Typhoon-3": automation unit and maximum head - 90 m

The electric pump BV-0.25-40-U5M with UZN (anti-interference device) is a unique equipment for domestic use in conditions of unstable power supply. The unit is equipped with a UZN automation unit built into the power cord. UZN equalizes voltage drops in the network in the range of 190-250 V to the working one.

Voltage drops do not affect the performance of the pump in any way, do not lead to overheating and failure, which is especially important for summer residents with an unstable power supply system. The pump starts up smoothly, this is of great importance, because

starting currents for pumps of this type are quite large. The maximum immersion depth is 90 m, while the pump capacity is 8 l / min

The pump starts up smoothly, this is of great importance, because. starting currents for pumps of this type are quite large. The maximum immersion depth is 90 m, while the pump capacity is 8 l/min.

All Typhoon pumps are designed for continuous operation without stopping and have IPx8 waterproof ratings.

"Typhoon-3" automatically turns off when the voltage exceeds the maximum allowable values and automatically turns on when the voltage in the mains returns to normal

"Typhoon-3" automatically turns off when the voltage exceeds the maximum allowable values and automatically turns on when the voltage in the mains returns to normal

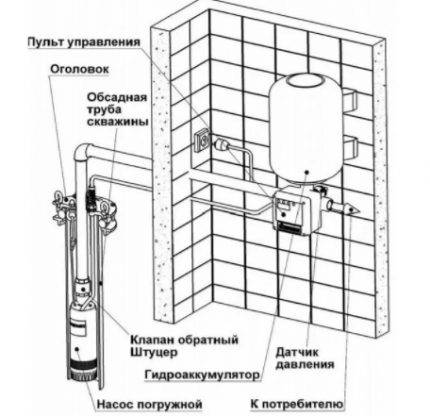

Pumping stations “Typhoon”

Unlike conventional pumping stations, which consist of a hydraulic accumulator, a pressure switch, a pressure gauge and various connecting fittings, the Typhoon station consists of a Typhoon-2 high-performance electric pump and an electronic control unit that allows you to control the pump in automatic mode.

The water pump "Typhoon-2" is connected through the controller, resulting in a full-fledged pumping station capable of providing water supply to a private house.

Pumping station "Typhoon" maintains a constant pressure in the water supply system, without changing the pressure and performance. The controller also provides a smooth start of the pump, which reduces the risk of water hammer and pump overload.

The device allows you to repeatedly turn off / off the pump without reducing its service life.

The pump, which is part of the pumping station, is reliably protected from dry running, if the water in the water source runs out. The controller will automatically turn off the unit, and when the normal water level is restored, it will automatically turn on.

When the voltage in the electrical network rises above 250 V, the pump also automatically turns off.

Connecting the controller is very simple: you need to connect the plug of the electric cable of the Typhoon-2 pump to the socket of the electric pump control unit and the tube that transmits pressure to the pressure pipe from the pump to the water consumer. You can connect the controller yourself without involving a specialist.

Surface centrifugal pumps with the Typhoon logo are designed to transport clean water and liquids of the same consistency that do not include aggressive substances (+)

Surface centrifugal pumps with the Typhoon logo are designed to transport clean water and liquids of the same consistency that do not include aggressive substances (+)

Features of choice

The choice of device should also be based on the calculation of the depth of the source of autonomous water supply and its debit (productivity). The first model of the pump is ideal for wells up to 16 meters deep and with an average flow rate. It is desirable to lower the modernized device into a deep well with high productivity.

When drawing water from tanks and reservoirs, the pump can be immersed to a minimum depth of one meter. Both models are suitable for irrigation.

To equip an autonomous water supply system, it is necessary to connect a hydraulic accumulator with a capacity of 100 liters or more, equipped with an automatic control unit, to pumping equipment of this brand, which will significantly increase the service life of the product. The manufacturer guarantees that the pumps, subject to all operating rules, can last up to ten years.

Most popular model

Of the entire line of Typhoon vibration pumps manufactured by the enterprise, the most popular is Typhoon-2, which, with a power of 250 watts, can provide water lifting from a depth of 90 meters!

Unfortunately, the pump is not without small flaws that can lead to sudden failure.To avoid such troubles, you need to upgrade the device a little on your own.

It often happens that after some time of operation, the pump is buzzing, but does not give pressure. This means that the rubber piston and check valves need to be replaced. Check valves are easy to remove with a screwdriver when the pump cover is removed. They look like fungi made of rubber.

It will be easier to install new ones if their edges are smeared with liquid soap. Replacing a piston requires some skill, but is also not a problem for home repairs.

When replacing the piston, it will not be superfluous to remove carbon deposits in the chamber with a cloth and grind the electrical metal parts of the pump with fine sandpaper.

The symbol for electric pumps according to the standard includes data in the following sequence:

- its purpose and principle of operation: B - household, C - vibration;

- nominal flow rate in liters per second;

- nominal head in meters;

- operating conditions: U - in a zone with a temperate climate and high humidity;

- control method: M - devices have a remote control panel.

The markings for electric pumps of different brands may differ: if the letter M for Typhoon means the presence of a control panel, for Malysh the symbol M is the material for the manufacture of the water intake part of the housing (M - metal, P - plastic), in many models, the length of the electric cable is indicated at the end.

Features and disadvantages of pumps

As already mentioned, the products of this brand have enough good qualities, but it is fundamentally important to consider them in detail. So, the benefits include:

- possibility of application for wells and wells;

- inexpensive prices;

- work on the basis of vibration;

- the possibility of pumping water over long distances both vertically and horizontally;

- additional cooling due to a two-channel water intake system;

- water temperature varies from 1 to 35°C;

- built-in thermal protection;

- anticorrosion;

- long working hours.

The length of the cord is on average 7 m, which is quite enough for normal work. With proper operation of the pump and the necessary care, it can last about 10 years.

How to avoid breakdowns

To ensure the smooth operation of the water supply, it is necessary to take into account all pump specifications (pressure, capacity, power), follow the operating rules specified by the manufacturer in the instructions, and also regularly conduct technical inspections.

To ensure the smooth operation of the water supply, it is necessary to take into account all pump specifications (pressure, capacity, power), follow the operating rules specified by the manufacturer in the instructions, and also regularly conduct technical inspections.

During maintenance, the bolts on the housing are tightened. If malfunctions are noticed, the device is completely disassembled and their cause is clarified - the pistons and valves are inspected, and the engine compartment is fixed.

It is very important to consider the type of soil in which the well is arranged. Vibratory pumps of any brand have proven themselves on soils with coarse sand, quartz or crushed stone

Clay soils or soils containing fine sand create additional problems. When vibrating well or well very quickly silted up, and the pumps lose their efficiency.

Vibration pump "Typhoon-2" - repair and modernization

Most of the vibration-type pumps offered on the modern market are not designed to work as part of a pumping station. The use of such a pump led to its early failure.Therefore, the Kyiv enterprise Bosna-LG launched the production of inexpensive vibration pumps designed for use in autonomous water supply systems. To date, one of the most popular models is the Typhoon-2 pump. With a power of 250 W, it is able to lift water from a depth of up to 90 m!

However, as sometimes happens with domestic manufacturers, a unique idea is completely devalued by poor assembly and small design errors, resulting in breakdowns. Let's take a closer look at some important points and improvements, the implementation of which turns such a pump into a “set-and-forget” product. To do this, we need: 1) hex socket wrenches for 5 and 5.5; 2) hammer; 3) 8 locknuts; 4) adjustable wrench; 5) montages; 6) a piece of clean cloth; 7) fine sandpaper;  some liquid soap. The last five points are necessary when performing an audit or repair.

some liquid soap. The last five points are necessary when performing an audit or repair.

"Typhoon-2" necessarily requires the installation of locknuts under the bolts, especially for the bottom cover bolts. The fact is that the very principle of operation of such a pump involves increased vibration, which negatively affects all bolted connections, causing them to disengage. The bottom cover, on which there are two fungus check valves, has a very small thickness of metal in the places of bolted connections with initially loose bolts, so unscrewing at least one causes a chain reaction of unscrewing the rest. As a result, the lid acquires partial mobility, and the water pressure seriously damages it. This photo clearly shows a chipped metal in the place of the unscrewed bolt.

A study of breakdown statistics suggests that the problem with the bottom cover is the most common. Therefore, whether it is a new or operated pump, we put locknuts. Unscrew the bolts with a socket wrench and install the locknuts.

Bolts must be tightened with force! The use of a mallet is allowed. Reworking the bonnet bolting is the first step to ensure long pump life. Any vibration pump, especially one operating as part of a pumping station, after a certain time will require an audit, which consists in replacing wearing parts. These include rubber pistons and check valves. The need for replacement is determined very simply - the pump is buzzing, but it does not create pressure. To replace the check valves, it is necessary to remove the cover and remove the fungi, carefully prying with a screwdriver. It is much easier to install new ones if their protruding part is lubricated with liquid soap, and then stretched with mounts. The main load is on the piston, therefore, after some time (depending on the intensity of operation), it may need to be replaced. To do this, you need to disassemble the pump housing.

Very often, a banal washer replacement allows you to increase the duration of this part.

Most often, the piston is damaged by the pressure washer, which is clearly visible in the photo.

The washer itself is curved in the shape of a plate, but during operation, its edges seem to cut the piston rubber. The higher the developed pressure, the faster the wear. You can slightly increase the duration of the piston by simply reversing the existing washer or replacing it. When making an audit, it is useful to remove the formed soot with a piece of matter.

We polish the electrical iron of the moving part with fine sandpaper - “zero”.

When reassembling the chassis, it is important to install the guides correctly. The removed ring itself with protrusions-ears is often not fixed in any way and rotates freely around its axis

These protrusions must necessarily coincide with the housing guides.

The gap formed between the body parts is tightened with bolts. It is also useful to put locknuts under these bolts. Tighten with a hammer. When operating the Typhoon-2 pump, you should always remember that the higher the pressure it develops, the faster the wear and subsequent revision. No wonder the nominal head is 40 m, and 90 m is the maximum.

Scope and technical characteristics of Typhoon pumps

The borehole pump Typhoon belongs to the vibration pumping units of medium power.

It has been successfully used for the following purposes:

- Providing residential, household buildings and industrial facilities with drinking water from wells of various types (for sand, limestone) and wells.

- Organization of irrigation of agricultural plantations in summer conditions.

The pumping equipment is intended for operation in conjunction with hydroaccumulating tanks and automatic control and monitoring systems.

Pump Typhoon Bosna LG (2,3)

Manufacturers offer three modifications of pumps that differ in pressure characteristics:

- To work at shallow depths, it is advisable to use the Typhoon-1 pump (head 30 m), it provides the most efficient performance when installed in wells up to 15-16 meters deep.

The pump Typhoon Bosna LG (2.3) has a pressure of 90 mm, it does an excellent job of supplying water from sources whose depth is 30-40 meters.

Submersible pump Typhoon

Therefore, it should only be used to supply drinking water from wells and wells, the diameter of which must be at least 125 mm:

- The power consumption of the installation is 370 W. It is connected to a single-phase household power supply (220 V).

- The water consumption depends on the immersion depth of the pump, under the most favorable conditions it reaches 2.5 cubic meters of water per hour.

- The outer diameter of the unit body is 100 mm, the mass of the unit is only 4.6 kg.

- The Typhoon submersible pump does not require additional attachment to the walls of the well or well, it works when suspended on a cable or string.

Troubleshooting

To work with the pump you will need:

- wrench,

- socket wrenches (size 5 and 5.5 mm),

- a hammer,

- pliers.

Reduced water pressure

The cause is loose nuts, broken stem or valve wear.

The pump must be disassembled. To do this, the outer bolts on the body are untwisted. Then the nuts on the rod, located on top of the shock absorbers, are tightened. One of them can be locked (fixed for secure fastening). If the cause is worn valves, they must be replaced with new ones. A deformed rod cannot be restored.

Engine not running

The likely cause is cable damage or burnt coil windings.

A broken cable is easy to detect with a household tester. Filling the cable in the engine compartment with compound complicates its complete replacement. To fix the problem, it is necessary to remove the damaged part of the cable and build it up with a new one. To get to the magnetic coils, you need to disassemble the housing (separate the pump compartment from the engine compartment) and carefully remove the compound with a hammer and screwdriver. You can rewind yourself or take the coils to a repair shop.Repaired magnetic coils are installed on a sealant (suitable for use on car windows).

You will learn how to work with alternative energy sources in our article.

You can learn more about mercury in our material posted at the link.

Mounting Features

It should be noted that the manufacturer took care of the correct installation of the equipment and provided it with the appropriate package, which includes:

- coupling for mounting a pipe or hose (three-quarters);

- nylon cord for hanging and securing the unit;

- rubber protective ring.

To install the pump in a well or well, you must perform the following steps:

- a check valve is mounted to the branch pipe of the unit;

- a pipe (if plumbing is being installed) or a flexible hose is attached to the valve using a coupling;

- the power cable is attached to the pipe or hose using plastic clips (clips), the use of insulating tape is allowed;

- a protective ring made of rubber is put on the device, protecting it from impacts;

- a nylon cord is threaded into special safety holes in the upper part of the body and securely fixed in place (if the depth is small, a wire or a rubber band is additionally attached to the cord);

- the structure is lowered into the well or well with a cord - it is forbidden to hold the pump by the hose, pipe or power cable;

To lower the unit into a very deep well, it is better to use a tripod with a block installed in the center of the shaft.

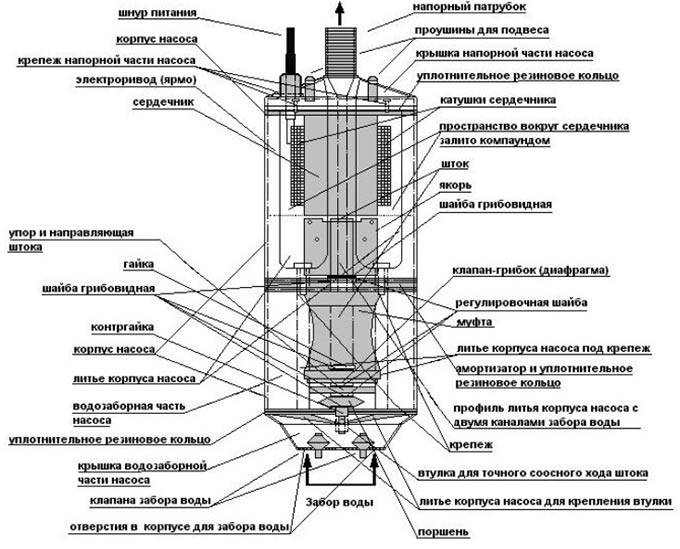

Device and principle of operation

The model belongs to submersible vibration units.Traditionally, for this type of pumping equipment, the body of the device is divided into two chambers - the first is designed for the engine and the magnetic coil, the second, made in the form of a cylinder, is used as a pump compartment, has a built-in anchor and pistons.

Water is taken in through a two-channel system - the pump compartment is equipped with two valves at once, providing inlet and free outflow of water in the absence of pressure.

The working chambers are separated by an elastic diaphragm and a shock absorber, which ensures the tightness of the engine compartment. The electric drive includes two magnetic coils, a pressure pipe and a core - all parts are filled with epoxy compound to prevent water ingress and ensure the reliability of the structure.

The principle of operation of the unit is based on the use of oscillations of the armature and pistons caused by the electromagnetic field of the coils. Particular reliability of the design is provided by the brand's patented form of the bushing and stem guide.

All modifications of the water vibration pump "Typhoon" include three main components:

- vibration part. It consists of a shock absorber, diaphragm, coupling, rod. An anchor is located at one end of the rod, and a piston at the other. There is a certain distance between the shock absorber and the diaphragm, both elements guide the rod during the operation of the electric pump and ensure its tightness, preventing water from entering the part of the housing where the electric drive is located.

- Water intake part. It is a cavity, at the top of which there is a glass with holes for taking pumped water and a check valve that prevents backflow even in cases where the pump is turned off.

- Electrical part.It consists of a core, two coils and a suction outlet. These parts are located in the body and filled with a compound with quartz sand fractions.

The compound fixes the electromagnet and insulates the windings of the coils, protecting them from water penetration. Quartz sand increases heat dissipation from the electric drive part.

The core is a U-shaped figure of plates made of transformer steel. An enamel wire with a certain number of turns is wound on the core, insulated with a special varnish coating.

The principle of operation is based on alternating current, which, with the help of a shock absorber, is converted into mechanical vibrations transmitted to the piston and armature. Water enters the pump through the water intake holes and ends up in the chamber where the piston and valves are located.

The piston, under the influence of vibrations, begins to reciprocate, creating a hydraulic shock in a glass with holes. The valves close the holes, and the water enters the chamber, from where it is ejected under pressure through a two-channel system into the outgoing pressure pipe.

Adjustment of Typhoon units

Like other vibration-type electric pumps, Typhoons need to be adjusted in order for the equipment to work with the required parameters. Adjustment is the selection of the optimal distance between the armature and the core, as well as between the valves and the working piston.

To set the working gap between the core and the armature, it is necessary that the voltage in the mains is exactly 220 V. This can be achieved using a power supply stabilizer. Low voltage reduces the performance and pressure characteristics of the vibration pump, and high voltage leads to excessive load.

On average, the gap between the core and the armature for the normal operation of the unit is 4.3-5 mm. If you have special tools, you can independently adjust this indicator, however, given the complexity of disassembling and reassembling the electric drive part of the pump, it is better to entrust this adjustment to the service center specialists.

You can independently adjust the position of the washers on the rod, located between the anchor and the shock absorber. Washers are responsible for the performance characteristics of the electric pump, as well as for its efficiency.

By adding washers you get better performance

Here it is important not to fix the washers too close to each other, because. this will lead to a collision between the armature and the core

In the process of connecting the submersible pump, it must be ensured that there are no leaks in the water supply system, because. they can cause unstable water supply (+)

In the process of connecting the submersible pump, it must be ensured that there are no leaks in the water supply system, because. they can cause unstable water supply (+)

The washers that are under the piston are responsible for the overall pressure of the pump by acting on the working piston. If you add washers here, then the piston will fit more tightly and the pressure will increase, reducing the washers - we reduce the pressure.

By adjusting, you can achieve optimal performance of the Typhoon electric pump, for example, reduce the pressure, while increasing productivity and efficiency.

It is recommended to adjust Typhoon pumps if one of its parameters does not correspond to those indicated in the passport, when they are not related to voltage fluctuations in the mains

It is recommended to adjust Typhoon pumps if one of its parameters does not correspond to those indicated in the passport, when they are not related to voltage fluctuations in the mains

Conclusions and useful video on the topic

Overview of the Typhoon-2 electric pump:

Overview of the Typhoon-3 electric pump with USN:

Ukrainian-made electric pumps "Typhoon" are distinguished by high performance, and they have no analogues in terms of immersion depth.The ratio of cost and quality of these pumps is the most optimal.

The equipment is perfect for those owners who are looking for an electric pump for year-round water supply to a private house from deep artesian wells or open water sources.

Do you have personal experience in installing and operating a Typhoon pump? Do you want to share your impressions of using it or ask questions on the topic? Please leave comments - the feedback form is located below.