- Preparatory stage

- Selecting the type of equipment

- Pipe selection

- Choice of accommodation

- Station connection options

- Scope and arrangement of surface pumps

- Types of pumping stations and distance to the water table

- Pump stations with built-in ejector

- Pumping stations with remote ejector

- Pump or pumping station: what's the difference?

- How to replace the pump in the well in case of an accident?

- Option number 1: we call deep pump repair specialists

- Option number 2: do-it-yourself pump replacement

- What do you need to know about a well?

- Features of the device of the pumping station

- What should be a good well?

- Types of pumps for wells and their functions

- Types of household pumps

- Types and features of installation of caissons

Preparatory stage

Before you start building a pumping station, you need to carry out several preliminary stages of work.

Selecting the type of equipment

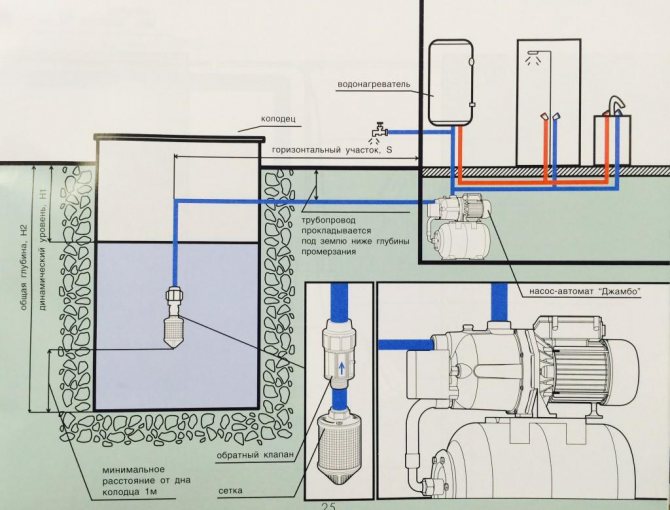

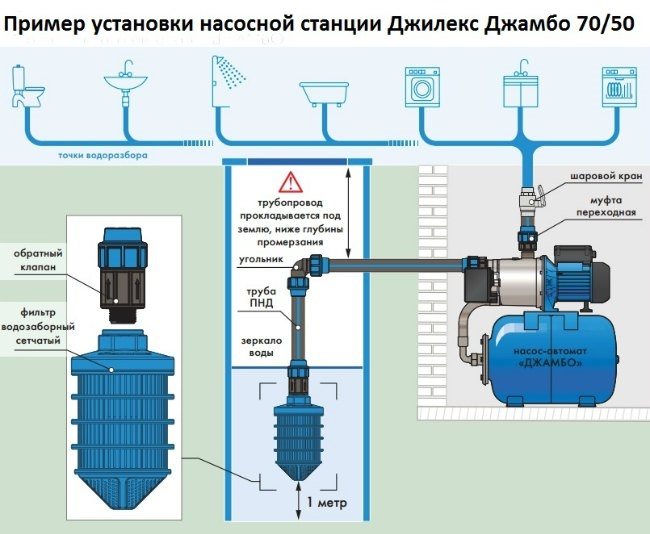

Connecting a surface ejector pump

For sand wells up to 20 meters deep, you can take a surface pump. He is able to raise water from a level of up to 9 meters. You can increase the productivity of the unit with a remote ejector. In this case, water will be taken from a depth of up to 18-20 meters, but with a lower capacity of the equipment.

For deep wells, it is worth buying a submersible pump. Deep is best.The device has the form of a flask, which is placed in the casing a meter from the bottom. The Danish pump Grundfos uses excellent characteristics, the price of which varies depending on the depth of immersion.

The rest of the equipment is selected according to the following technical parameters:

- power;

- performance;

- pressure;

- price.

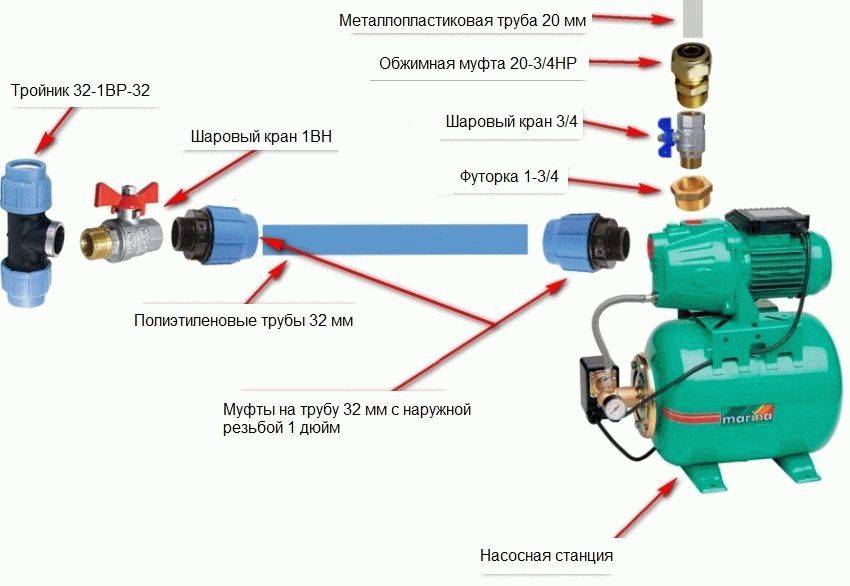

Pipe selection

Plumbing polyethylene pipes

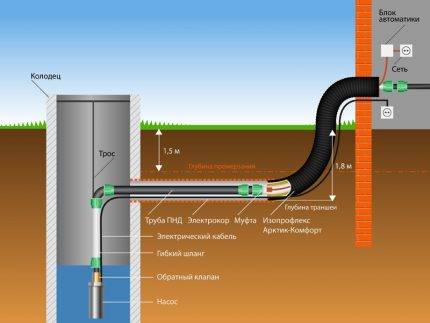

For the installation of water supply, you need to purchase pipes for the external and internal mains. It is better to lay the outer line using HDPE products. They are not afraid of temperature changes, static and dynamic soil pressure. They have a smooth inner surface, which ensures a normal flow of water.

Inside the house it is better to lay polypropylene pipes. Their installation is carried out by soldering. As a result, the melted polymer forms a perfectly sealed joint.

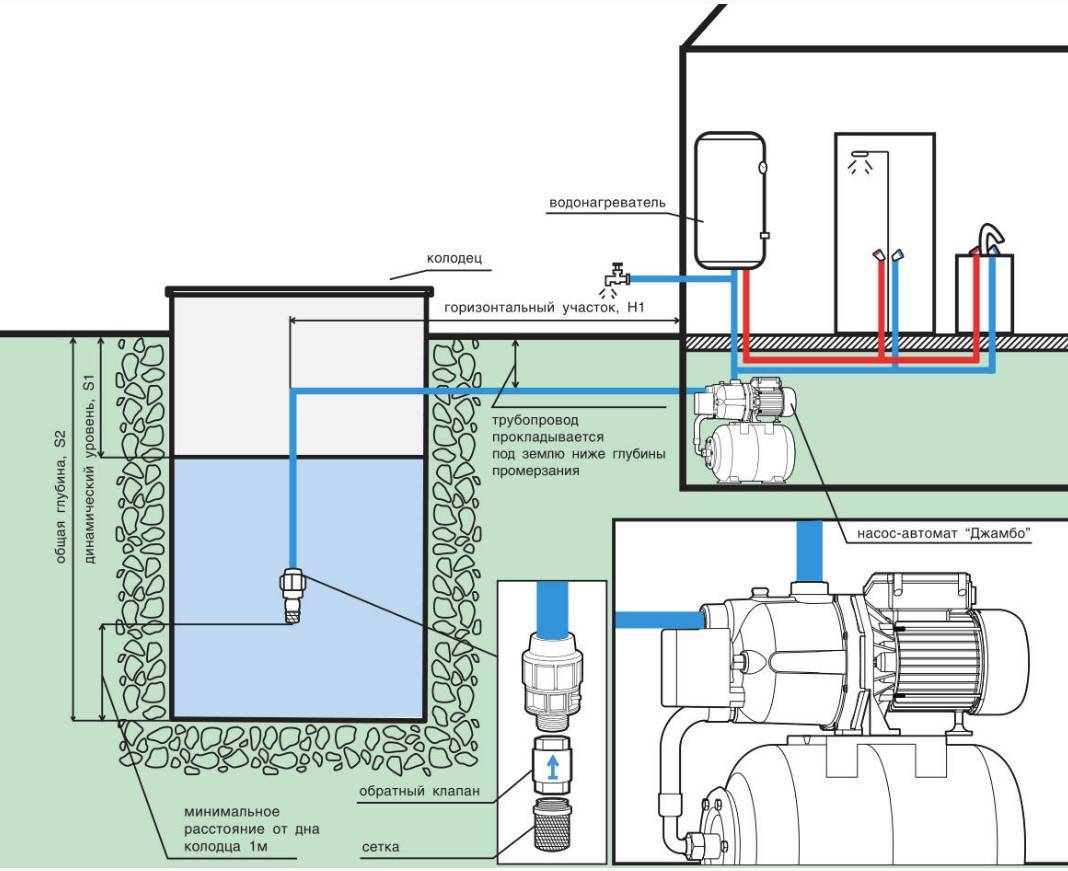

Choice of accommodation

Location of pumping equipment in the downhole caisson

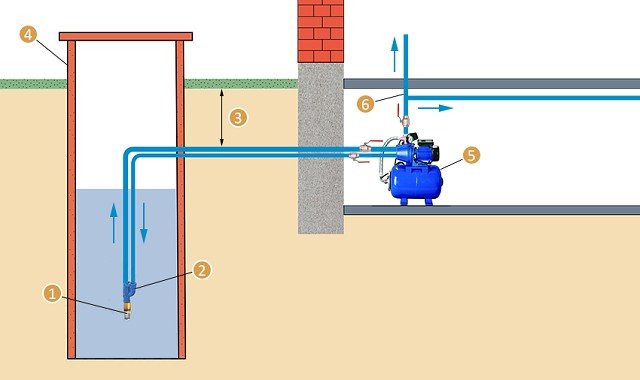

It is better to connect the water station to the well as close as possible to the hydraulic structure. There are several main places where you can install equipment:

Basement of a private cottage. It is always dry here, moderately warm. You do not have to spend money on the installation of a technical room and its insulation

But it is important to remember that a working pumping station makes very loud noises, which can cause discomfort to the residents of the house. You will need to soundproof the basement in order to install injection equipment in it.

Caisson

This is a special protective chamber, arranged at the very head of the well. The caisson is convenient in that it completely isolates all residents of the house from noise, protects equipment from precipitation, cold, and vandals.When installing a chamber, you can not be afraid that moisture will have a negative effect on the walls of the basement, even if we are talking about condensate.

There are several important principles that should be followed when choosing a location for installing a pumping station:

It is desirable to mount the equipment as close to the source as possible.

Access to technology should be free all year round.

It is important to ensure good ventilation of the room.

Station connection options

Connecting the pump through a downhole adapter

There are two ways to connect the pumping station to the pipeline:

- Through borehole adapter. This is a device that is a kind of adapter between the water intake pipe in the source shaft and the water pipes outside. Thanks to the borehole adapter, it is possible to draw the line out of the hydraulic structure immediately below the freezing point of the soil and at the same time save on the construction of the caisson.

- Through the head. In this case, you will have to take care of high-quality insulation of the upper part of the source. Otherwise, ice will form here in sub-zero temperatures. The system will stop working or break in one of the places.

This is interesting: The device and principle of operation of a classic water supply pumping station

Scope and arrangement of surface pumps

Example of use - watering the garden and garden with water from the nearest reservoir

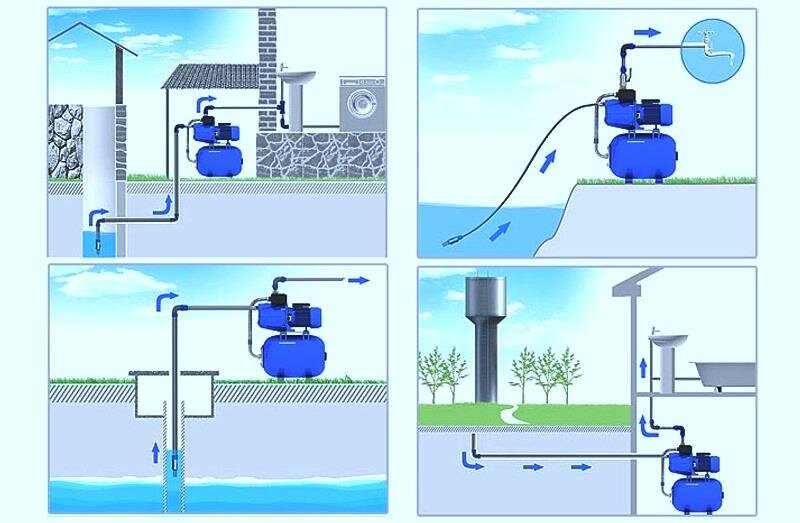

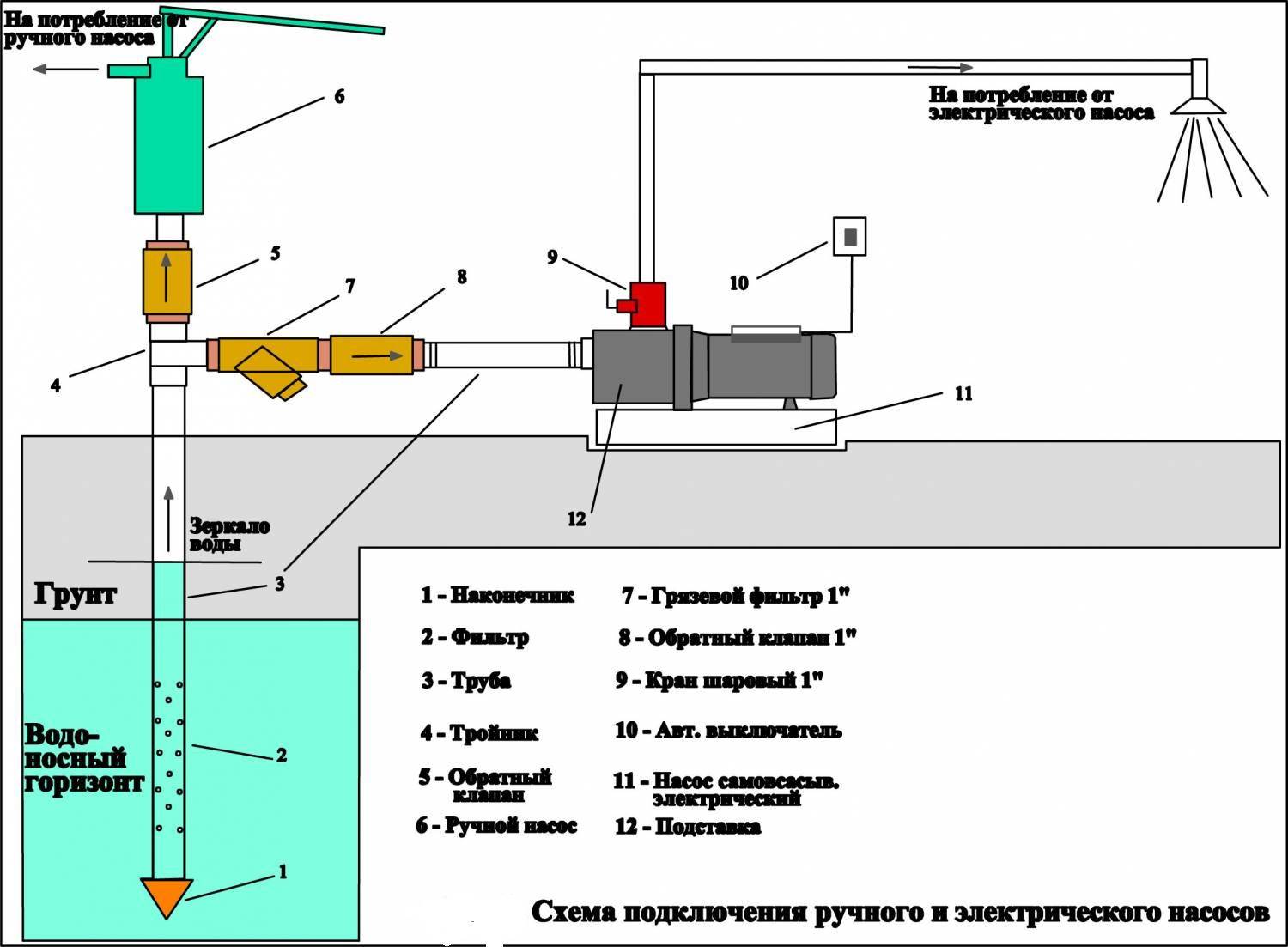

Surface pumps, unlike submersible ones, are located near the water source. Their body does not come into contact with the liquid, it enters the points of consumption through the inlet pipe.

Devices are used to deliver water to the house, to drain the basement after the spring flood, pumping fluid from the pool.It is possible to use for irrigation of the land - in this case, the pump is placed near the reservoir, and the hose is lowered into the water. Almost all appliances are powered by electricity, so you need a long power cable.

An important point is that the depth of the well should not exceed 10 meters, since all surface pumps have low power. Most often, groundwater occurs at this depth, which accumulates harmful substances from neighboring septic tanks. Mineral fertilizers are also washed out by rains into these reservoirs, so additional filters are placed in front of the entrance to the house.

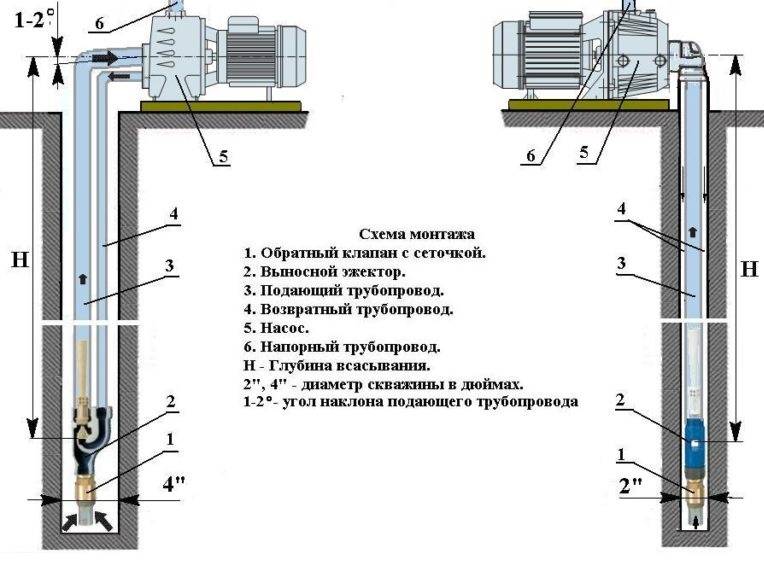

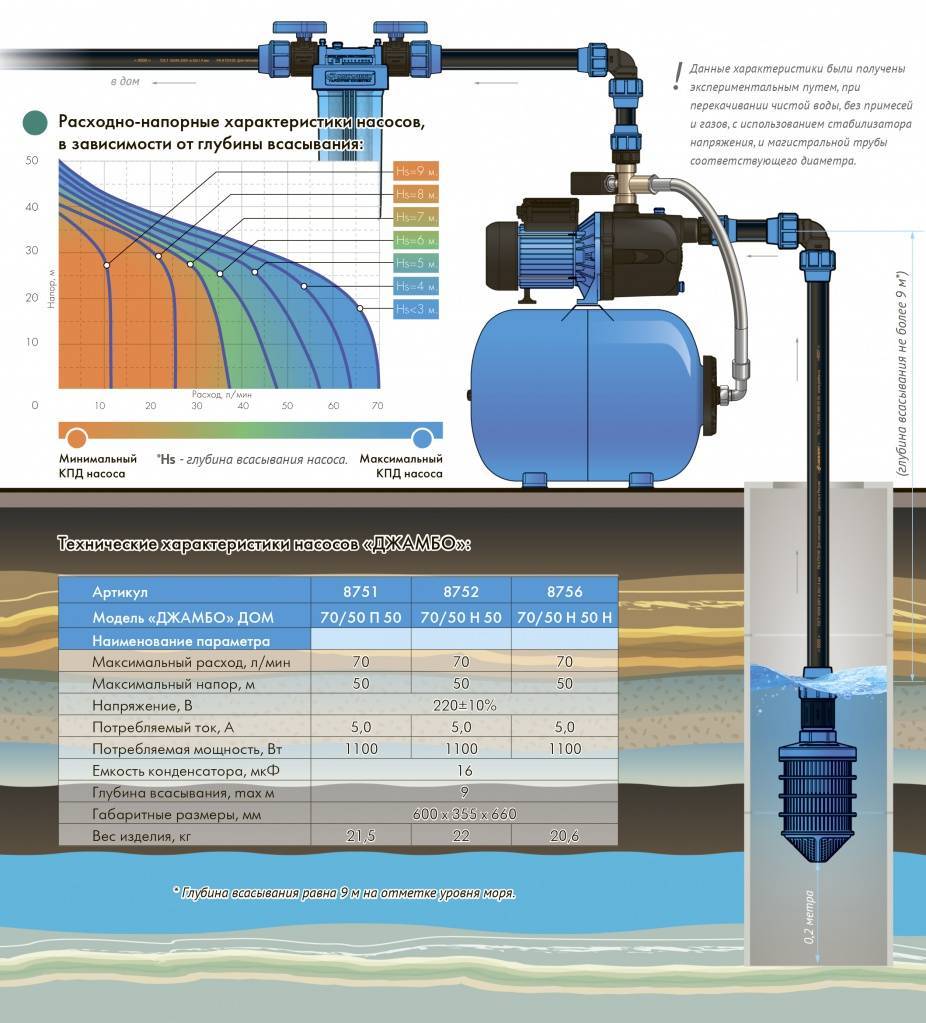

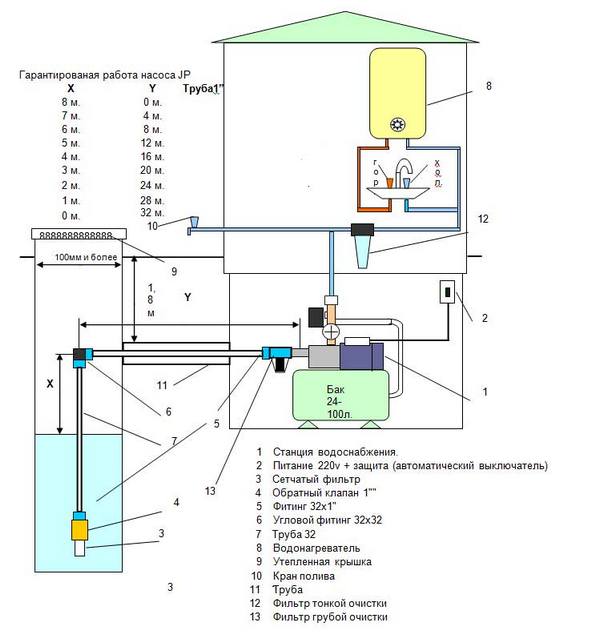

Types of pumping stations and distance to the water table

Distinguish pumping stations with built-in and remote ejector. The built-in ejector is a structural element of the pump, the remote one is a separate external unit, immersed in the well. The choice in favor of one or another option depends primarily on the distance between the pumping station and the water surface.

From a technical point of view, the ejector is a fairly simple device. Its main structural element - the nozzle - is a branch pipe with a tapered end. Passing through the place of narrowing, the water acquires a noticeable acceleration. In accordance with Bernoulli's law, an area with low pressure is created around a stream moving at an increased speed, i.e., a rarefaction effect occurs.

Under the action of this vacuum, a new portion of water from the well is sucked into the pipe. As a result, the pump spends less energy to transport liquid to the surface. The efficiency of pumping equipment is increasing, as is the depth from which water can be pumped.

Pump stations with built-in ejector

Built-in ejectors are usually placed inside the pump casing or located in close proximity to it. This reduces the overall dimensions of the installation and somewhat simplifies the installation of the pumping station.

Such models demonstrate maximum efficiency when the suction height, i.e., the vertical distance from the pump inlet to the level of the water surface in the source, does not exceed 7-8 m.

Of course, one should also take into account the horizontal distance from the well to the location of the pumping station. The longer the horizontal section, the smaller the depth from which the pump is able to lift water. For example, if the pump is installed directly above the water source, it will be able to lift water from a depth of 8 m. If the same pump is removed from the water intake point by 24 m, then the depth of water rise will decrease to 2.5 m.

In addition to low efficiency at large depths of the water table, such pumps have another obvious drawback - an increased noise level. The noise from the vibration of a running pump is added to the sound of water passing through the ejector nozzle. That is why it is better to install a pump with a built-in ejector in a separate utility room, outside a residential building.

Pumping station with built-in ejector.

Pumping stations with remote ejector

The remote ejector, which is a separate small unit, unlike the built-in one, can be located at a considerable distance from the pump - it is connected to the part of the pipeline immersed in the well.

Remote ejector.

To operate a pumping station with an external ejector, a two-pipe system is required.One of the pipes is used to lift water from the well to the surface, while the second part of the raised water returns down to the ejector.

The need to lay two pipes imposes some restrictions on the minimum allowable well diameter, it is better to foresee this at the design stage of the device.

Such a constructive solution, on the one hand, allows to significantly increase the distance from the pump to the water surface (from 7-8 m, as in pumps with built-in ejectors, to 20-40 m), but on the other hand, it leads to a decrease in the efficiency of the system to 30- 35%. However, having the opportunity to significantly increase the depth of water intake, you can easily put up with the latter.

If the distance to the water surface in your area is not too deep, then there is no need to install a pumping station directly near the source. This means that you have the opportunity to move the pump away from the well without a noticeable decrease in efficiency.

As a rule, such pumping stations are located directly in a residential building, for example, in the basement. This improves equipment life and simplifies system setup and maintenance procedures.

Another undoubted advantage of remote ejectors is a significant reduction in the noise level produced by a working pumping station. The noise of water passing through an ejector installed deep underground will no longer disturb the residents of the house.

Pumping station with a remote ejector.

Pump or pumping station: what's the difference?

Indeed, do you really need a pumping station in the country? Isn't it easier to buy a conventional submersible pump that does not require much maintenance and is cheaper?

This option is the most common, in particular in summer cottages, where the owners live only in the summer, but far from the most effective.

The principle of operation of the pump is as follows: the device turns on and starts pumping water at the moment the water tap is opened, the toilet bowl is flushed, the watering hose is connected, and turns off after the plumbing devices are turned off.

It is possible that once again, opening the tap, you will not find water in it. This can happen for two reasons:

- the water level in the well has dropped significantly, and the pump simply has nothing to pump. Until the source is filled to the desired level, the device will be "silent";

- the pump cannot work effectively during power surges in the network, and often such surges lead to a breakdown of the device.

When using a pumping station, water interruptions can be avoided because it includes a tank for backup water storage. If the supply of liquid from the well stops, the pump automatically starts pumping water from the tank. In addition, pumping equipment creates stable pressure and provides good water pressure in the tap.

The submersible pump may stop working if the water level in the well or well is insufficient (+)

The submersible pump may stop working if the water level in the well or well is insufficient (+)

Another advantage of using a pumping station is the ability to pump water from a well of a very small diameter by lowering a 2.5 cm hose into it. This circumstance is of particular importance in a summer cottage, since there is no need to equip a major artesian well.

How to replace the pump in the well in case of an accident?

The need to replace the pump rarely occurs, mainly due to the fact that the pump was installed incorrectly in the well. The cause of the accident may lie in the incorrectly selected automatic power supply, and in the low power of the pump itself. For example, if it is designed for a 50-meter dive, but in fact it is installed at a depth of 80 meters, then repairs will be needed in a few months.

The automatic power supply is set to working, and from such a depth a weak pump simply cannot lift it. As a result of constant work without shutting down, it quickly breaks down.

As in any situation, there are two ways out: we call repair specialists or we do everything ourselves.

Option number 1: we call deep pump repair specialists

First of all, this option is suitable for those who do not understand pumping equipment. Professionals can objectively assess the situation, identify the causes that led to equipment failures. Perhaps only the automatic power supply is not working properly, and the pump itself is in working condition. In this case, it is enough to properly configure it.

Another plus for those who have already decided that such repairs are beyond their power is the guarantee that the contractor gives. Also, in addition to the basic work, you will be fully configured for the entire water supply system. Of course, you need to pay for such services, and if we are talking about replacing the pump, then the amount will be impressive.

Option number 2: do-it-yourself pump replacement

On your own, the replacement of the pump in the well is carried out only if you are sure that it is malfunctioning. If in doubt, it is better to consult a specialist.

It is simply impossible to do this work alone, you will need the help of at least five more people: at a depth of 100 meters, a pump with a cable and suspension weighs about 250 kilograms.

First of all, you need to prepare a metalwork tool, an electric soldering iron, a building hair dryer, a heat-shrink sleeve, scissors and consumables.

Then we disconnect the wellhead pipeline and the pump power cable from the main line going to the house. After that, unscrew the tightening element.

When lifting the pump, be sure to use a safety rope. If the pump fails, it will be impossible to raise it, which means that the well will also be used in the future.

The pump raised to the surface is disconnected from the line. We inspect the pump, if it is still in working order, replace the connecting mechanism, coupling and check valve. The old ones, most likely, have already lost their working properties, so it is better to put in new ones. If the old pump cannot be repaired, install a new one.

- Next, we connect the main pipeline with the pump, solder the power cable, remembering the tightness of the connection and the heat shrink sleeve. We attach a safety cable, check its tension.

We prepare the new pump for diving, solder the power cable and attach the safety cable

- Installation of a deep well pump in a well must be carried out with the utmost care. It is undesirable to allow contact with the walls of the casing.

The pump must be lowered into the well very carefully - we make sure that it does not hit the wall

- We tighten the borehole head, attach the fittings to the piping and configure the automation in accordance with the specified parameters.

We set up automatic power supply in accordance with the specified working pressure parameters

The most convenient option for organizing water supply in a suburban area is a well. The submersible pump runs quietly, and if the installation and commissioning were done correctly, then next time you will have to look into the well very soon.

One of the main problems with submersible pump installation is the reluctance of the pump to go through the casing connection.

As a rule, in this connection there is a decrease in the diameter of the casing pipe. Therefore, purchasing a pump with a smaller outer diameter (3 inch pumps) is always preferable.

What do you need to know about a well?

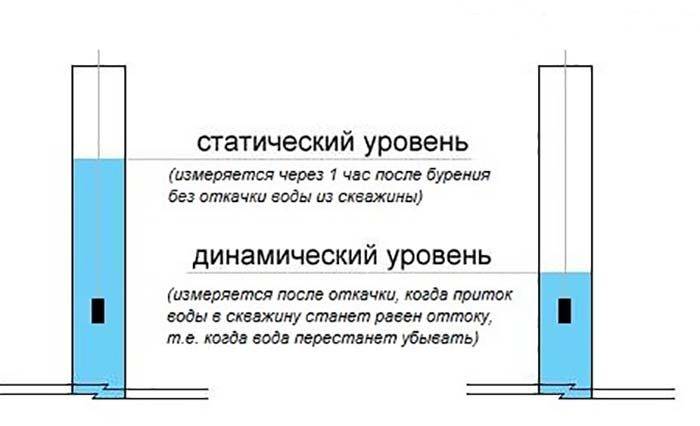

Each aquifer is individual in terms of the main indicators that characterize it. This refers not only to the diameter of the casing pipe and the total depth (distance from the mouth to the bottom), but also such indicators:

- static water level;

- dynamic water level;

- well debit (inflow).

These data are always in the passport of the aquifer, and they directly affect not only the immersion depth of the borehole pump, but also the choice of its optimal power and performance. Let's look at what each of these characteristics means and how it affects the installation depth of the water pump.

If water is not taken from the well for a certain period, a constant level will be established in the casing cavity. The resulting water column balances the pressure in the aquifers, which is stable there. For this reason, the level is static, that is, constant.It may vary slightly throughout the year depending on the hydrological situation and the intensity of water intake from a given aquifer by adjacent wells. As a rule, the deeper the well, the more stable this well indicator.

This indicator depends on two factors:

- pump performance;

- water inflow into the well.

That is, the dynamic level is not constant, because it is possible to replace the pump with another one with different characteristics, the debit of the well can also undergo changes in the process of silting. But just this characteristic of the aquifer is of most interest when choosing the correct immersion depth of the water pump. Indeed, in order for the submersible pump not to be dry during the water intake process, it is necessary to put it below the minimum dynamic level in the casing pipe by at least a meter. This is due to the features of borehole pumps, which you will learn about later.

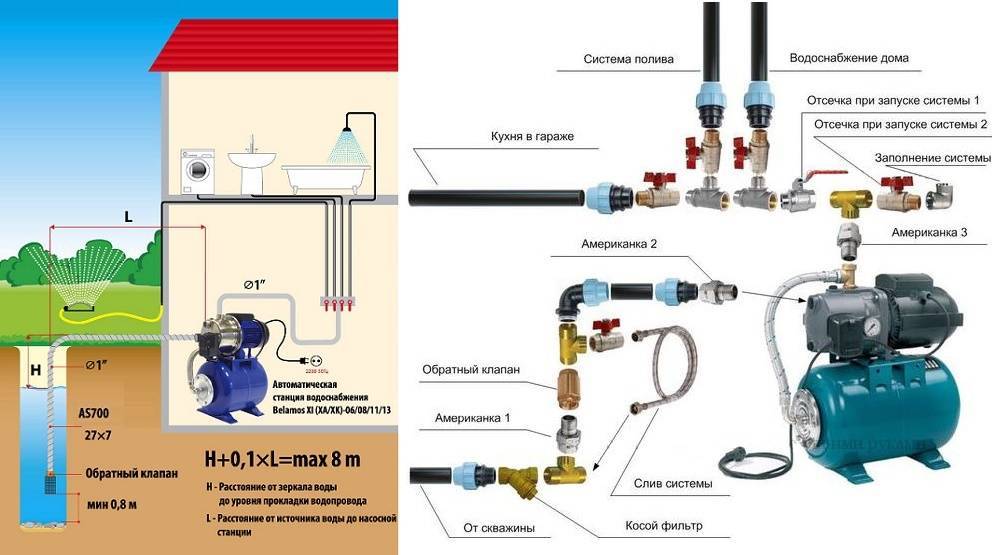

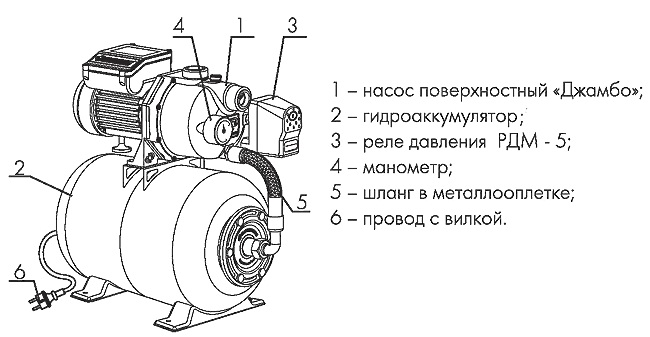

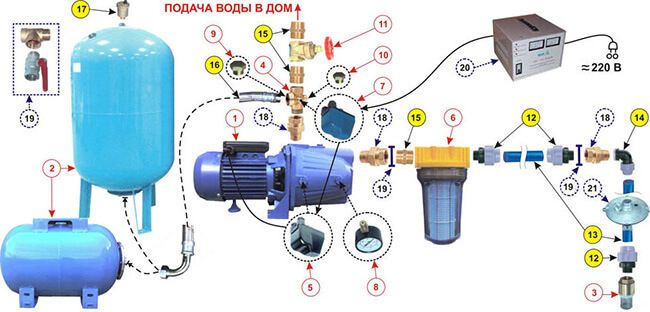

Features of the device of the pumping station

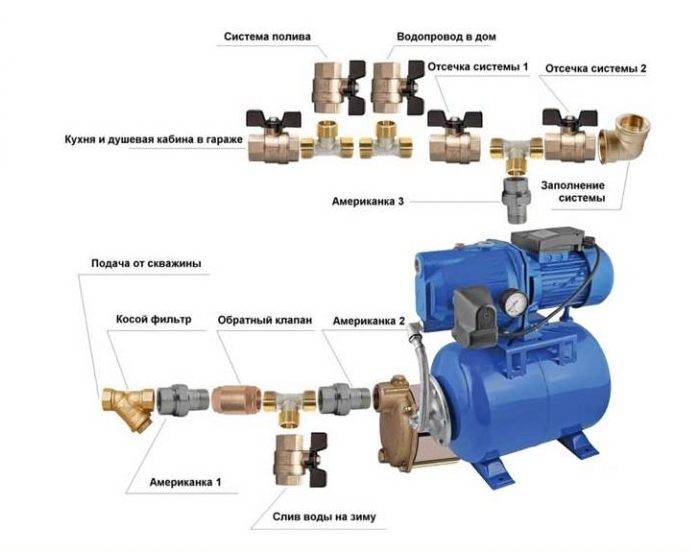

Autonomous water supply based on the pumping station includes a set of devices that provide automatic water supply to the house. To organize a comfortable autonomous water supply, it is necessary to choose a suitable pumping unit, connect it correctly and configure it.

If the installation is done correctly and the requirements for operation are observed, it will last a very long time. The house will always have clean water under pressure, allowing the use of modern appliances: from a conventional shower and washing machine to a dishwasher and a jacuzzi.

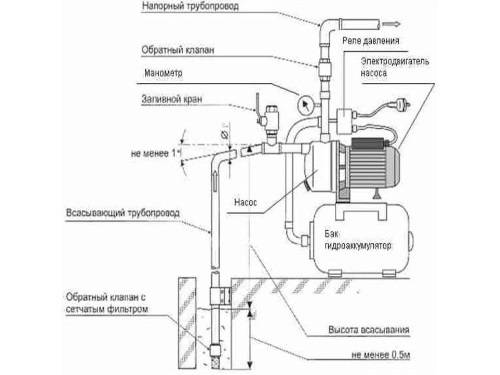

The pumping station consists of three main elements:

- a pump that supplies water;

- hydroaccumulator, where water is stored under pressure;

- control block.

The pump pumps water into a hydraulic accumulator (HA), which is a tank with an internal insert made of an elastic material, often called a membrane or pear because of its shape.

The task of the pumping station is to ensure a constant supply of water to the house at a sufficiently high level of pressure in the water supply system

The task of the pumping station is to ensure a constant supply of water to the house at a sufficiently high level of pressure in the water supply system

The more water in the accumulator, the stronger the membrane resists, the higher the pressure inside the tank. When the liquid flows from the HA to the water supply, the pressure decreases. The pressure switch detects these changes and then turns the pump on or off.

It works like this:

- Water fills the tank.

- The pressure rises to the upper set limit.

- The pressure switch turns off the pump, the water flow stops.

- When water is turned on, it begins to decrease from the HA.

- There is a decrease in pressure to the lower limit.

- The pressure switch turns on the pump, the tank is filled with water.

If you remove the relay and the accumulator from the circuit, the pump will need to be turned on and off every time the water is opened and closed, i.e. Often. As a result, even a very good pump will break down quickly.

The use of a hydraulic accumulator provides owners with additional bonuses. Water is supplied to the system under a certain constant pressure.

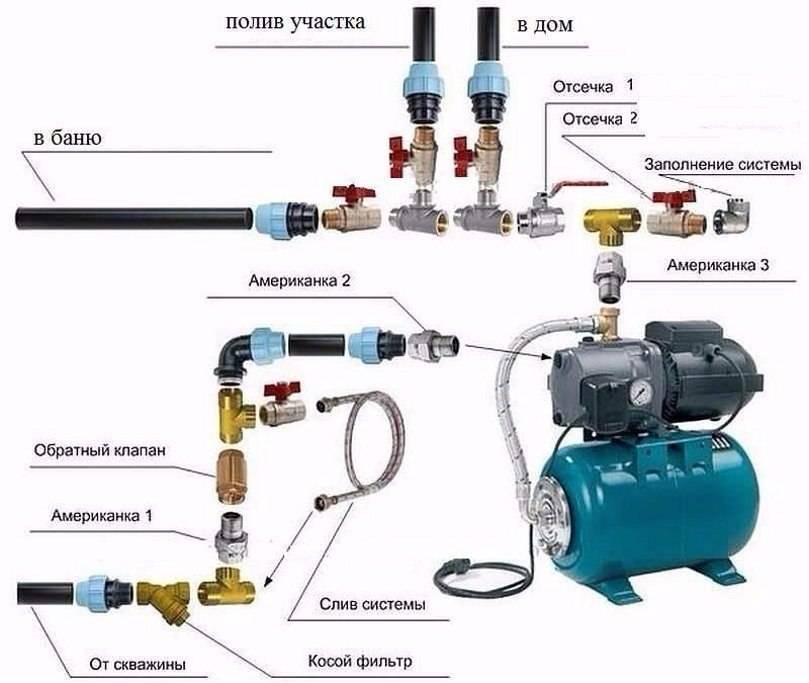

All components and materials necessary for connection should be prepared in advance. They must match the size of the nozzles of the existing equipment, adapters may be needed for successful installation.

Good pressure is needed not only to comfortably take a shower, but also for the operation of an automatic washing machine or dishwasher, hydromassage and other benefits of civilization.

In addition, some (about 20 liters), but the necessary supply of water is stored in the tank if the equipment stops working. Sometimes this volume is enough to stretch until the problem is fixed.

What should be a good well?

To begin with, choose a place for the well. It must meet several requirements:

- be located in a place where the aquifer is as close to the surface as possible;

- be located as close to home as possible;

- be removed at a considerable distance from possible sources of pollution: cesspools, places where pets are kept, etc.

If such a place is chosen, work can begin. Significant volumes of soil will be excavated during the process. In order not to pollute the site, you should take care of a suitable place for the excavated earth in advance. For example, it can be used to improve backyard terrain.

The walls of modern wells are most often reinforced with concrete rings, since this is the fastest and relatively inexpensive way to complete all the necessary work.

Various materials are used to form the walls of the well: brick, stone, logs, etc. But the vast majority of modern wells are made of concrete rings.

This is an affordable and relatively inexpensive material, reliable in operation and easy to install. Of course, the gaps between the rings are carefully sealed and covered with waterproofing materials.

Concrete rings for the well must be of high quality, which will ensure their long-term operation and high quality of the water supplied to the house.

When choosing rings for a well, there are several important points to consider:

- use special concrete rings for wells that have not been in use;

- remember that cheap rings, especially used ones, have a reduced durability resource and may have pollution that will affect the quality of well water;

- it is unacceptable to use rings with cracks or other technical defects;

- when accepting the rings delivered to the facility, measure their height and other parameters with your own tape measure, especially if the construction of the well is entrusted to a team that receives payment depending on the number of rings.

Another important point is the debit of the well, i.e. the amount of water that can be obtained in a short period of time. To determine this indicator, water is pumped out, and then its volume is measured.

To make a well from concrete rings, they dig a shaft into which the rings are gradually lowered, placing them one on top of the other. The correctness of the installation is checked by a plumb line. It is also necessary to ensure that the mine is sufficiently spacious and level.

Is there a well on the property? This does not mean that you can immediately purchase pumping equipment. First, you should check the design for compliance with the requirements for water supply of a private house from a well: its depth, debit, etc.

In any case, cleaning must be carried out before installation of the system. If it is necessary to deepen an existing well, the water is pumped out, the shaft is deepened and its walls are reinforced with concrete rings of a smaller diameter.

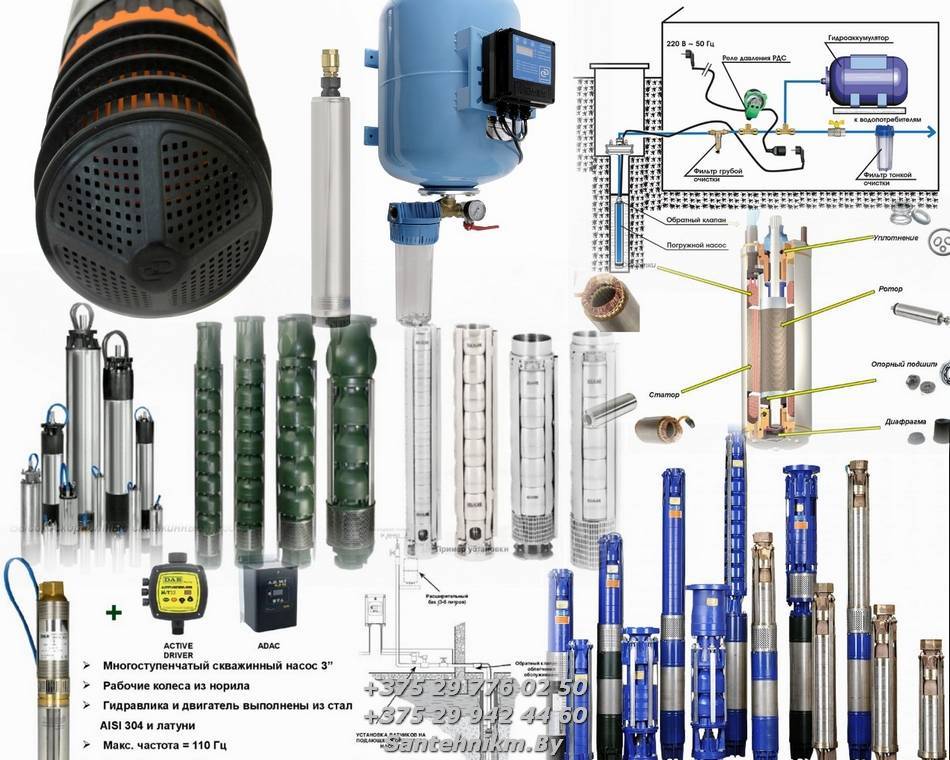

Types of pumps for wells and their functions

Well water pumps can be submerged into narrow wells to great depths or mounted on the surface. The principle of operation of the device and its installation is as follows:

- Its main elements are impellers mounted on a single shaft.

- Their rotation occurs in diffusers, which ensures the movement of liquid.

- After passing the liquid through all the wheels, it exits the device through a special discharge valve.

- The movement of the liquid occurs due to pressure drops, which are summed up on all impellers.

There are several types of such equipment:

- Centrifugal. Such a pump allows the supply of clean water to be provided without major contaminants.

- Screw. This is the most common device, capable of pumping liquid with an admixture of particles per cubic meter no more than 300 grams.

- Vortex. Transfers only purified water.

Despite the differences, all types of pumps serve to perform similar functions:

- Supply groundwater to private houses and cottages.

- Participate in the organization of irrigation systems.

- Pump liquid into tanks and containers.

- Provide comprehensive water supply in automatic mode.

When choosing a pump for a site, the following criteria are taken into account:

- The original dimensions of the equipment. They must be taken into account to ensure certain technological tolerances when placing the pump in the well.

- Power source of electricity. Borehole pumps are made single- and three-phase.

- Device power. This parameter must be determined in advance based on the calculated pressure and water consumption.

- Pump cost. In this case, it is necessary that the price-quality ratio of the equipment is chosen correctly.

Types of household pumps

Pumps for wells are divided into submersible and surface. Such units have some advantages over the rest:

- Large water intake depth, which is not available for pumps of any other type.

- Ease of installation.

- No moving parts.

- Low noise level.

- Long service life.

The photo shows the types of submersible borehole pumps.

Submersible borehole pumps

Tip: It is very important to follow the competent and proper arrangement of equipment, use only high-quality materials. Violation of installation technology or the use of poor materials can lead to:. Violation of installation technology or the use of poor materials can lead to:

Violation of installation technology or the use of poor materials can lead to:

- Breakage of the pump.

- its premature failure.

- When dismantling, the impossibility of lifting the pump.

Types and features of installation of caissons

The uninterrupted operation of the well is designed to provide a caisson, an insulated waterproof container with the necessary equipment inside.

Usually a pump, shut-off valves, measuring instruments, automation, filters, etc. are mounted in it. Buildings are made from different materials. The most common:

Plastic. They are distinguished by excellent thermal insulation, which allows even without additional insulation to maintain the temperature inside the caisson at the level of 5C. Durability, excellent waterproofing characteristics, which makes it possible to avoid additional costs for insulation work, reasonable price, especially in comparison with other options. In addition, the system is quite easy to install due to its low weight. The main disadvantage is low rigidity, which can provoke deformation of the structure and damage to equipment.However, it is easy to deal with it by filling the container around the perimeter with cement mortar with a layer of 80-100 mm.

Plastic caissons have excellent thermal insulation, which allows them to be installed without additional insulation.

Steel. Most often, the arrangement of a water well is carried out with just such a design. The material allows you to make a caisson of any desired shape, while not requiring much effort. It will be enough just to weld the parts together and treat the structure from the inside and outside with a special anti-corrosion coating. For a high-quality container, metal 4 mm thick will be quite enough. You can also find ready-made structures on sale, but their purchase will cost much more than self-production.

There are various forms of steel caissons - for various needs

Reinforced concrete. Very strong and durable installations, previously extremely common. Due to their shortcomings, today they are used much less frequently. Their cost is very high, and special equipment is required for installation, which is due to the large weight of the equipment. For the same reason, over time, the concrete caisson sags, deforming the pipelines inside it.

Concrete has insufficient thermal insulation, which can cause water in the pump to freeze in severe frosts, and poor waterproofing, since concrete is hygroscopic

Here is an approximate scheme for installing equipment in a caisson and connecting communications:

Scheme of installation of equipment in the caisson

If you are going to complete the arrangement of the well with your own hands, it is worth getting acquainted with the stages of installing the caisson. They are almost the same for any type of structure, with slight nuances depending on the material of the equipment. Let's consider the stages of installing a steel tank:

Pit preparation. We dig a hole, the diameter of which is 20-30 cm greater than the diameter of the caisson. The depth must be calculated so that the neck of the structure rises about 15 cm above ground level. This way, it will be possible to avoid flooding the tank during the flood and heavy rainfall.

Casing sleeve installation. We make a hole in the bottom of the container. It can be positioned traditionally in the center or shifted as needed for equipment installation. A sleeve 10-15 cm long must be welded to the hole. Its diameter must be greater than the diameter of the casing pipe. Be sure to check that the sleeve can be easily put on the pipe.

Installation of nipples for the withdrawal of water pipes. We weld them into the wall of the container.

Caisson installation. We cut the casing pipe at ground level. We put the container on the bars above the pit so that the sleeve on the bottom of the container “dresses” on the pipe

We check that the axes of the caisson and the casing exactly match, then carefully remove the bars and carefully lower the structure down the casing. We install the container in the pit strictly vertically and fix it with bars. We weld the pipe to the bottom, while sealing the caisson

Through the nipples we start water pipes into the structure

We weld a pipe to the bottom, while sealing the caisson. Through the nipples we start water pipes into the structure.

Backfilling of the building.

The caisson is “put on” on the casing pipe and carefully lowered into the pit

It should be noted that, in principle, it is possible to equip a well without a caisson, but only if a heated building is located near it, in which the equipment is located.

The convenience of such a system is undeniable - all nodes are easily accessible.However, the disadvantages are also significant: it takes up a lot of space in the room and most often makes a lot of noise.