- Water connection

- Main types of wells

- Ordinary well

- Abyssinian well

- medium depth

- Artesian

- Starting the pumping station

- Water connection

- Automatic systems and elements that ensure control and reliable operation of the pumping station system

- What equipment is needed for arranging the structure

- Connection order: step by step instructions

- Selecting an installation site

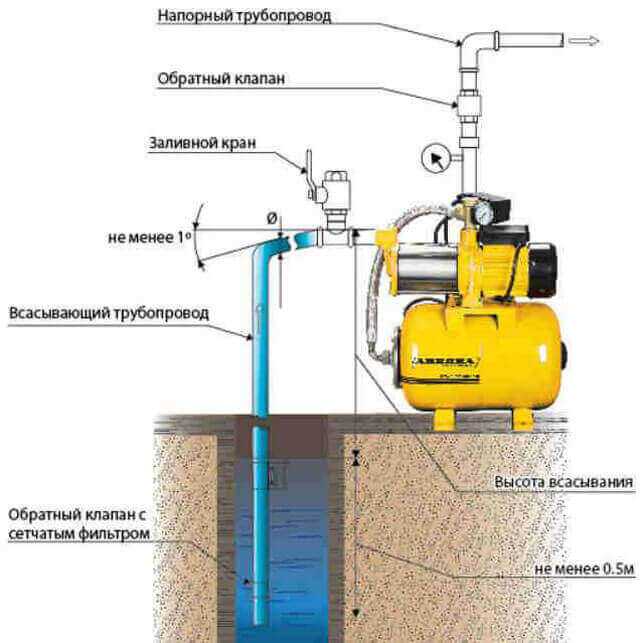

- How to determine the depth of suction

- Security Considerations

- Convenience and operating conditions

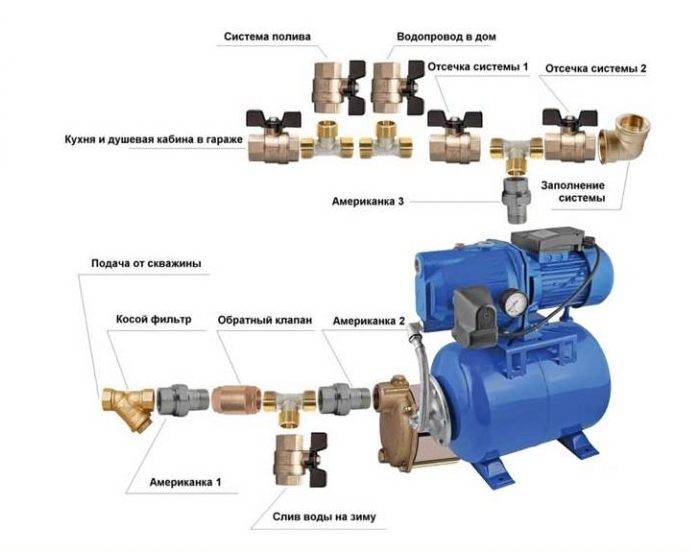

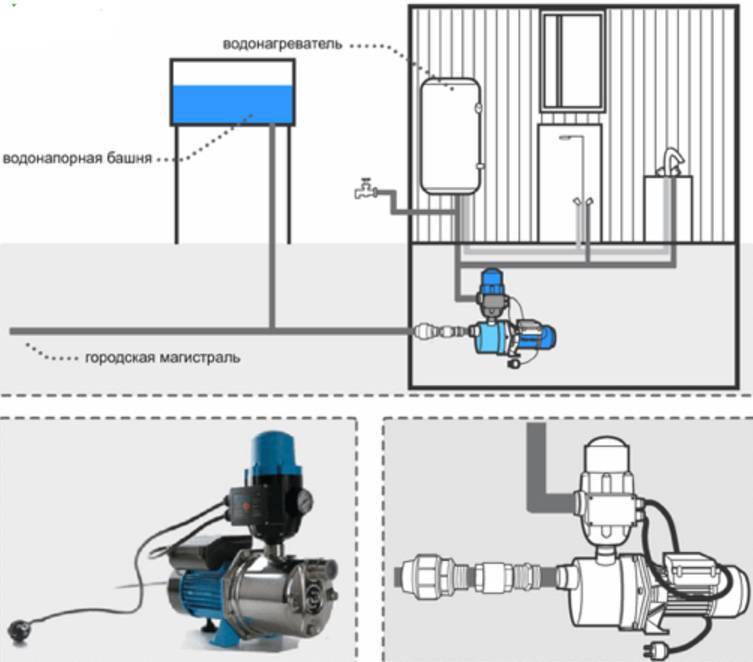

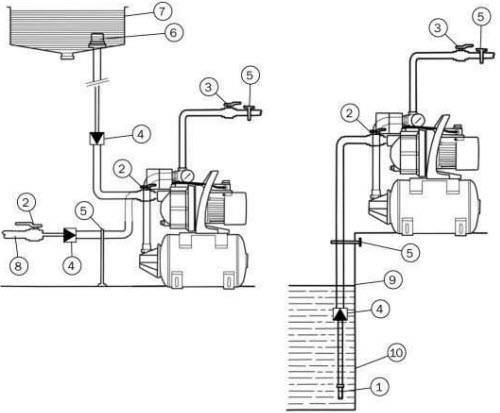

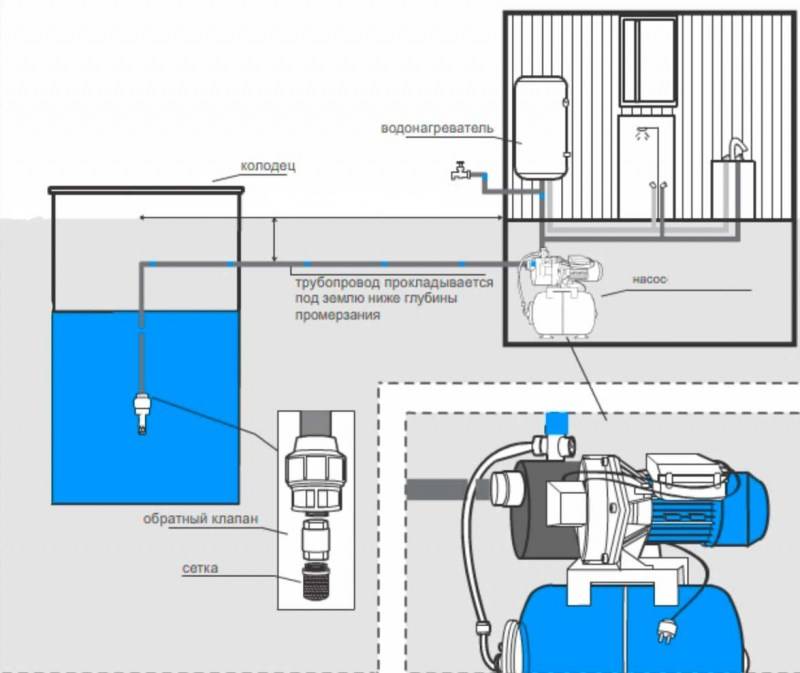

Water connection

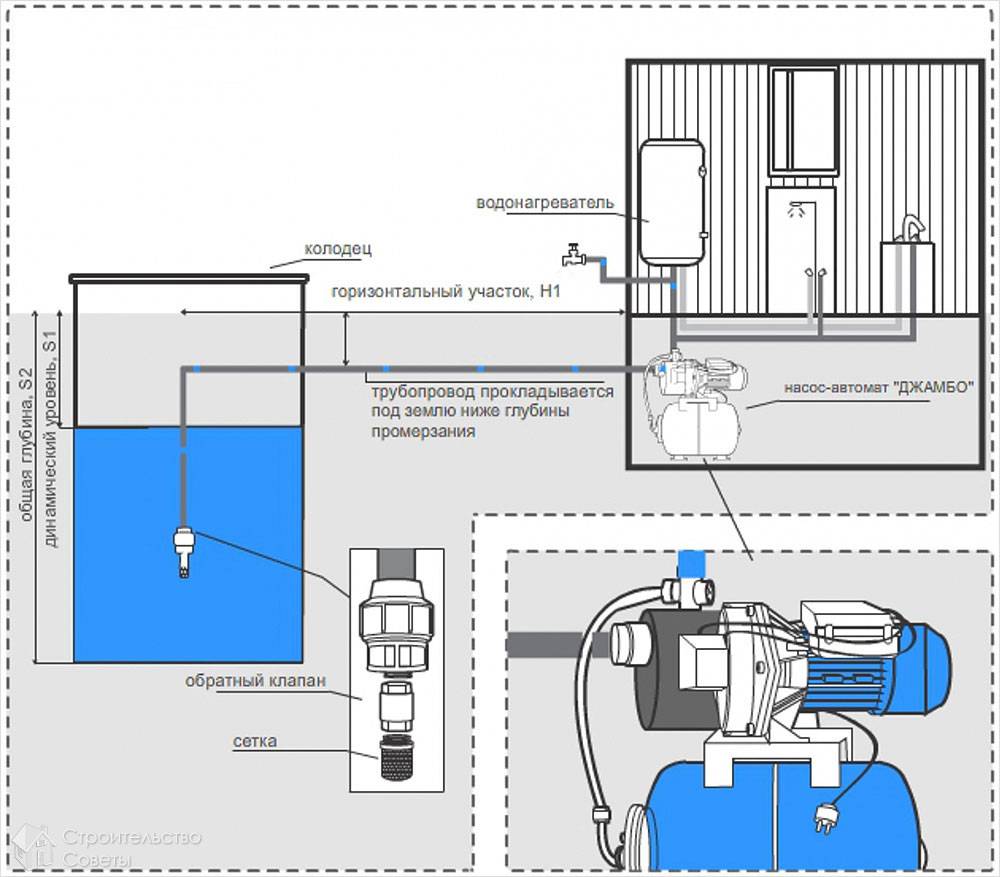

Connecting the pumping station to the water supply. (Click to enlarge)

As a rule, the pumping station is connected to the water supply in the event that there is not enough pressure for the heating equipment.

In order to connect the system to the water supply, you need:

- The water pipe must be disconnected at a certain point.

- The end of the pipe that comes from the central line is connected to the storage tank.

- The pipe from the tank is connected to the inlet of the pump, and the pipe that is connected to its outlet goes to the pipe that leads to the house.

- Lay electrical wiring.

- Equipment adjustment.

Main types of wells

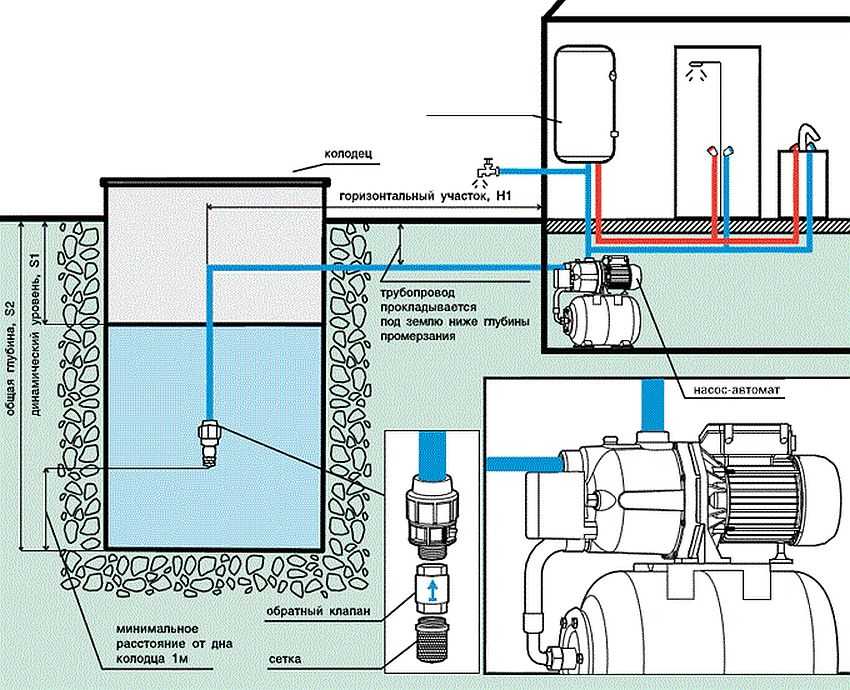

To date, there are several massive, time-tested structures that will ensure the flow of water from workings in the ground.Selection of the type of well is a responsible matter, which should be based on the results of hydrogeological surveys. The use of the type of well is dictated, along with the conditions on the site, by the needs of the owners for water. After all, the water supply schemes of a summer country house with a garden and a vegetable garden and a two-story house for year-round living of two families will be very different.

Ordinary well

This attribute of country life, familiar to everyone at least from movies and cartoons, is the easiest way to get water. Its depth rarely exceeds 4-5 meters, two or three cubes of water always accumulate at the bottom. When connecting a submersible pump and water conduit equipment to the house, it is quite possible to use a well for water supply. True, intensive use of such water will not work, and its quality leaves much to be desired.

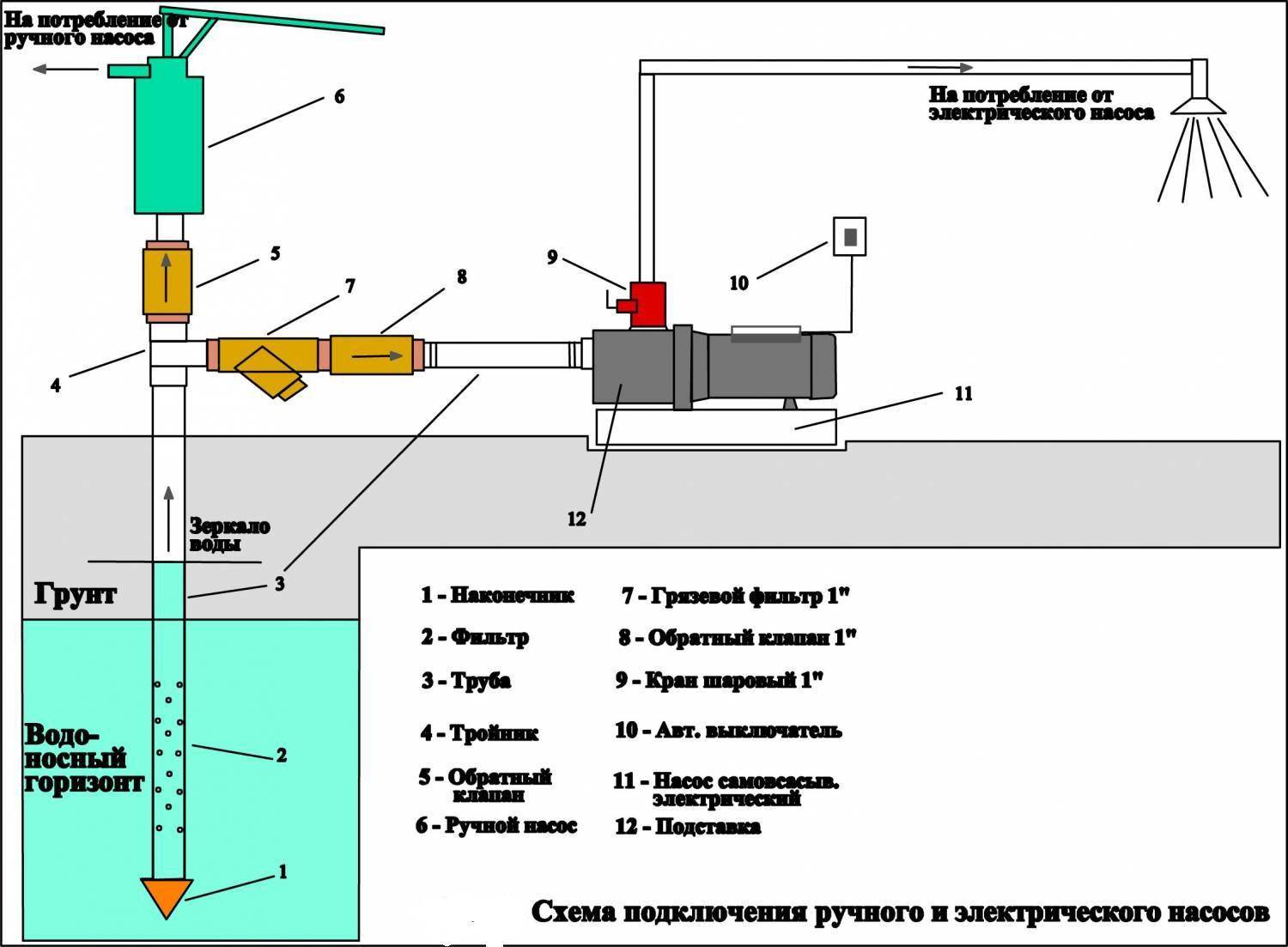

Abyssinian well

This name hides a system of thick-walled pipes with a mesh or perforated filter at the end. Pipes are hammered into the ground by a special device, colloquially referred to as a "woman". The intake end with the filter reaches the aquifer. At the top, either a manual or electric pump is arranged. The performance of this needle well is slightly greater than that of a standard well, and its installation is cheaper, but since there is no storage in the system, you will have to forget about intensive flow.

It is generally accepted that the water from the Abyssinian well is technical and is suitable only for irrigation. However, with a favorable hydrogeological situation, it may well be clean. Of course, you should not drink it without filtration and boiling, but you should wash and wash in it, since it is quite soft.

medium depth

Its second name is a well in the sand.For it, drilling is already being used to the aquifer sandy layer. Typically, the depth of this formation is 15–30 meters. To strengthen the structure, casing pipes are used - steel, and now cheaper and non-corrosive polymer pipes. Wells in the sand provide fairly clean water, which, however, is also better to pass through a filter and disinfectant. A well of medium depth has its own service life. Its failure is not even connected with the strength of the structure, but with the fact that the filter on the water intake is silted up. Over time, it becomes impossible to clean it, and you have to drill a new well. The average normal service life is about ten years. With active use, it is reduced.

Artesian

The deepest of domestic wells and serves much longer than all the others - about 80 years, or even more. But it has a tangible minus - high complexity and a large amount of work make the price very high. It's all about the depth at which drilling is carried out. An artesian well reaches a depth of more than 100 m. It passes through several soft and hard layers - loam, clay, water-bearing sand, until it reaches limestone or even harder rocks with aquifers.

A deep well in a stone does not need end casing and filters - after all, the water comes directly from the rocks, where sand is no longer found. In addition, at such a depth, water is under pressure and enters the system by gravity - a pump is already needed to supply water to the room. On the other hand, such water withdrawal already requires state registration. Well, the complexity of the work carried out determines their high cost.

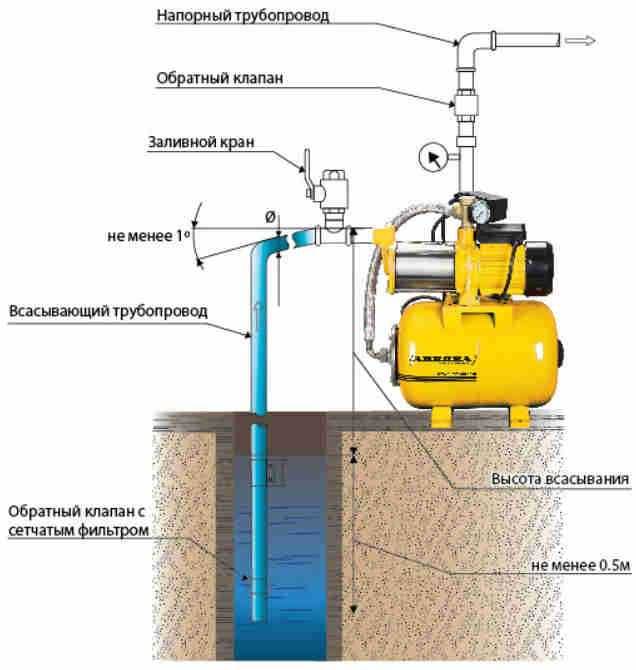

Starting the pumping station

In order to put the pumping station into operation, it is necessary to completely fill it and the supply pipeline with water. For this purpose, there is a special filler hole in the body. Pour water into it until it appears. We twist the plug into place, open the tap at the outlet to consumers and start the station. At first, water goes with air - air plugs come out, which formed during the filling of the pumping station. When the water flows in an even stream without air, your system has entered the operating mode, you can operate it.

If you filled in water, and the station still does not start - the water does not pump or comes in jerks - you need to figure it out. There are several possible reasons:

- there is no non-return valve on the suction pipeline lowered into the source, or it does not work;

- somewhere on the pipe there is a leaky connection through which air is leaking;

- the resistance of the pipeline is too high - you need a pipe of a larger diameter or with smoother walls (in the case of a metal pipe);

- water mirror is too low, not enough power.

To prevent damage to the equipment itself, you can start it by lowering the short supply pipeline into some kind of container (tank of water). If everything works, check the line, suction depth and check valve.

Water connection

Connecting the pumping station to the water supply. (Click to enlarge)

Connecting the pumping station to the water supply. (Click to enlarge)

As a rule, the pumping station is connected to the water supply in the event that there is not enough pressure for the heating equipment.

In order to connect the system to the water supply, you need:

- The water pipe must be disconnected at a certain point.

- The end of the pipe that comes from the central line is connected to the storage tank.

- The pipe from the tank is connected to the inlet of the pump, and the pipe that is connected to its outlet goes to the pipe that leads to the house.

- Lay electrical wiring.

- Equipment adjustment.

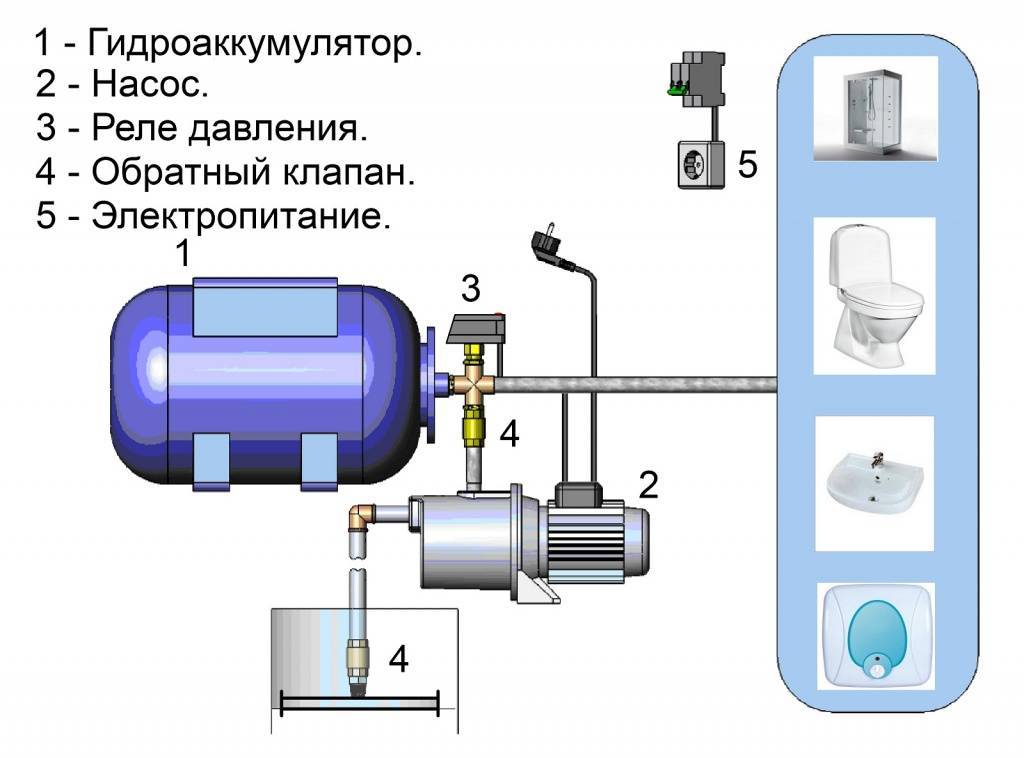

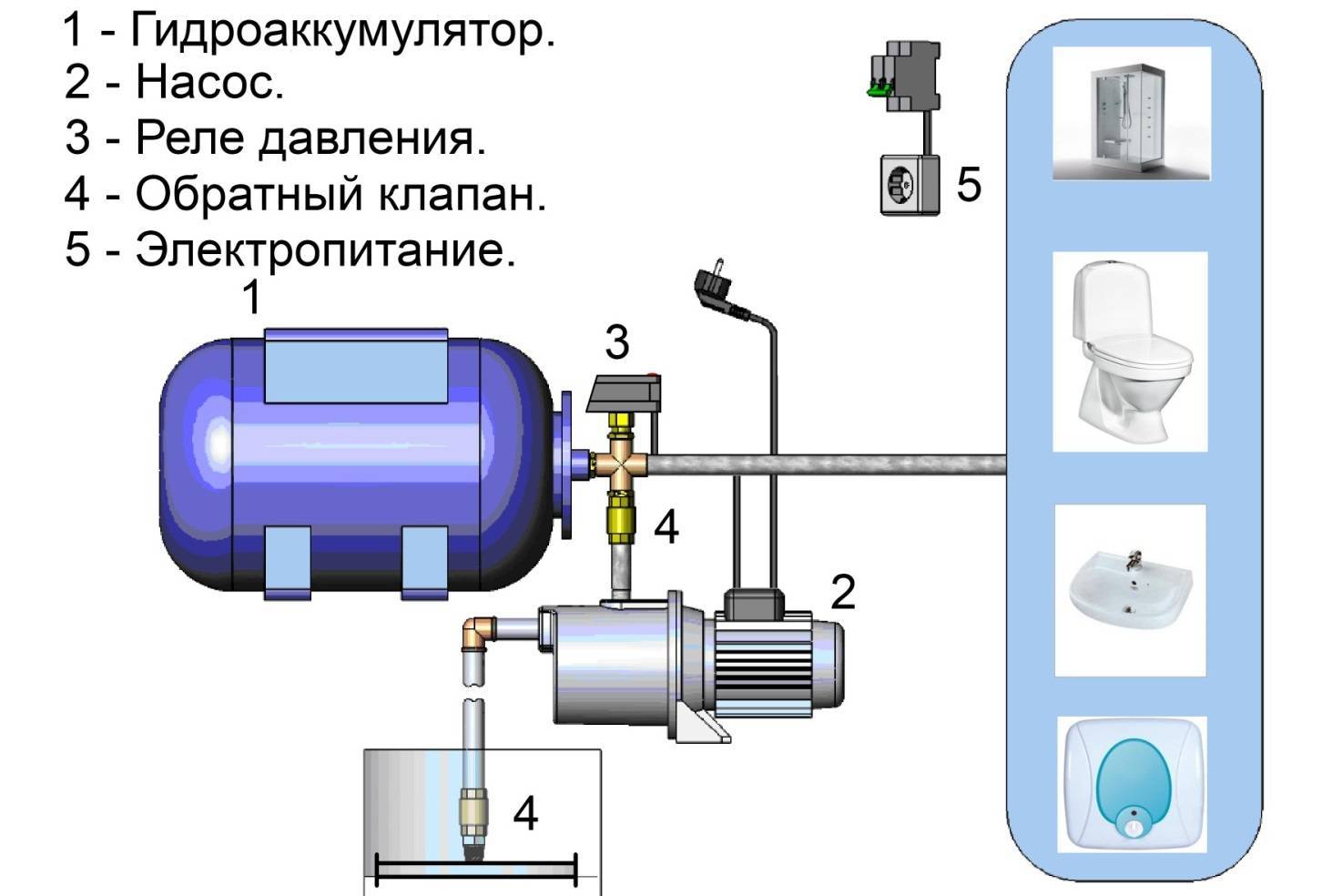

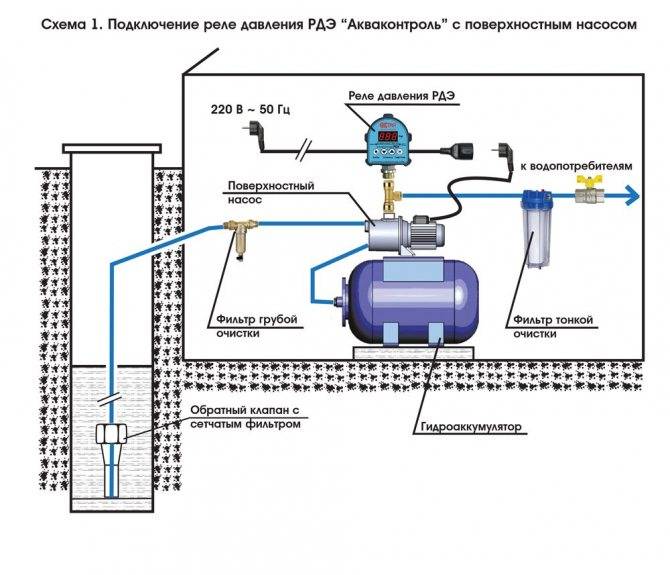

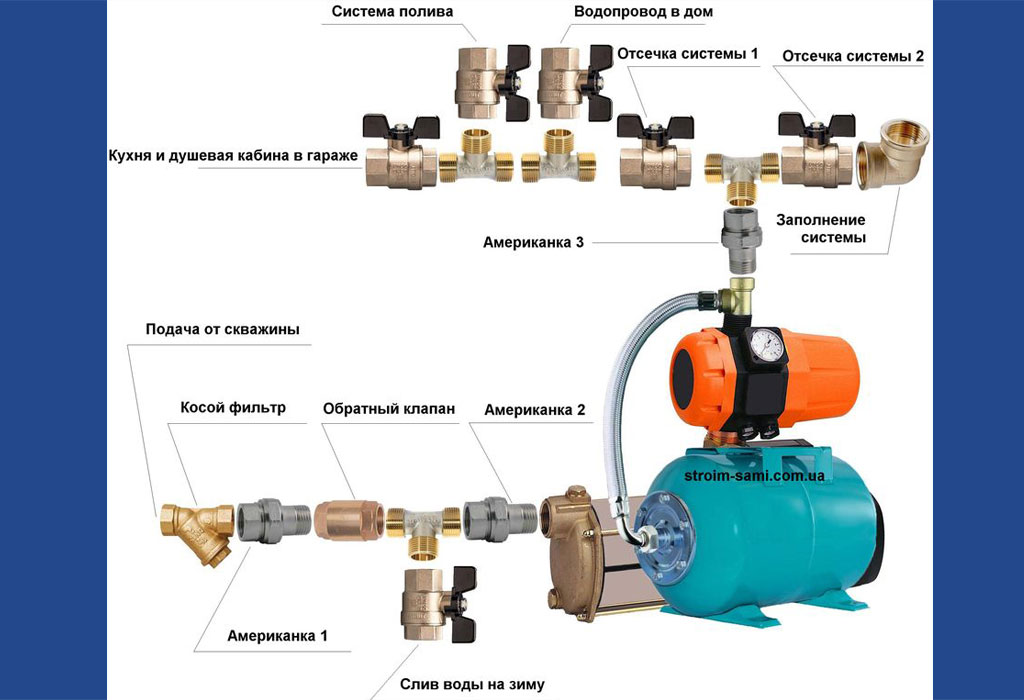

Automatic systems and elements that ensure control and reliable operation of the pumping station system

It is necessary to say in more detail about modern systems as part of pumping stations that will ensure uninterrupted water supply to your home, as well as guarantee long-term operation of the pump.

So, when implementing a pumping station of any type, it is necessary to implement the following automation systems: - Protection against dry running of the pump (“Protection against “dry running” for a well pump using a pressure switch and level sensors.

Electrical circuit for protecting the pump from "dry running");

- The use of a pressure switch or electrocontact pressure gauge (signaling) to maintain pressure in the water supply system (“Water pressure switch (installation, characteristics, design, configuration)” and the article “Electrocontact pressure gauge (signaling) (principle of operation, application, design, marking and types) for water supply systems”.

In addition, if you are assembling a pumping station, which is said from A to Z, then information on choosing a receiver “Hydraulic receiver (hydraulic accumulator) for a house water pumping station (selection, design)”, as well as information on pipe installation “ Installation of metal-plastic (metal-polymer) pipes with threaded fittings”, “Do-it-yourself soldering of plastic (polypropylene) pipes”.

Now, having already a certain amount of information, and, accordingly, knowledge, we hope that the selection of components, as well as the assembly and connection of your pumping station will take place more deliberately, faster, and also with minimal deviations and errors.

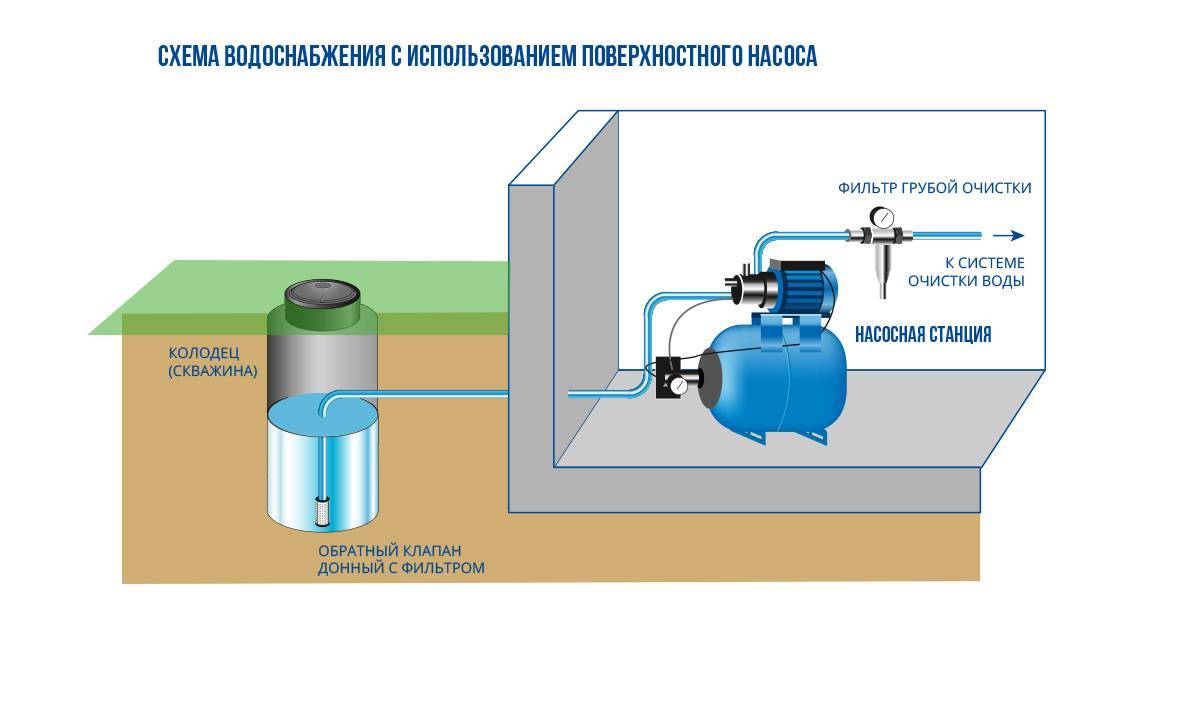

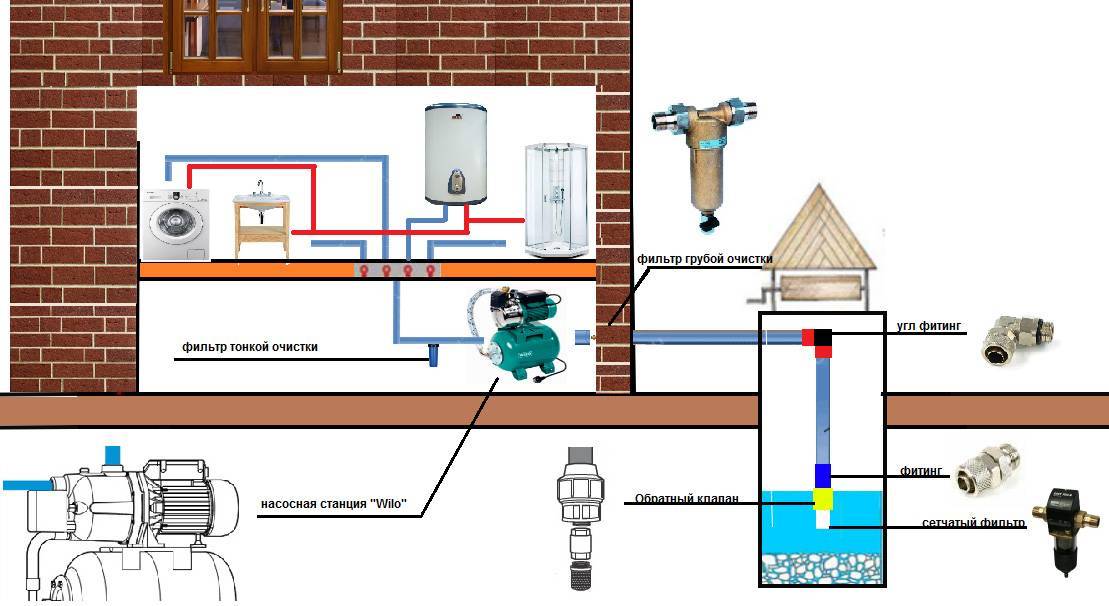

The problem of water supply is at the forefront of creating a comfortable living environment in the country. This most often helps to solve the problem of connecting the pumping station to the water. Communications to provide a home is not just a banal plumbing facility with liquid Gander, after all, a complete home water supply system.

The need for an independent water supply, the basic needs of rural dwellers, leads to the constant use of water for cooking, sanitary and domestic use, as well as refrigerants in the heating system.

Household pumps are not always faced with such a variety of work functions.

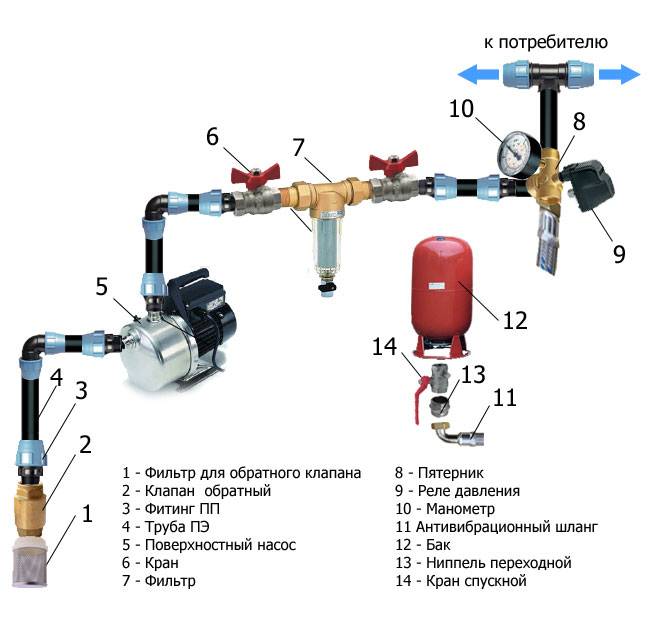

In addition, installing a pumping station in a private home allows evacuation and supply of water to increase system pressure if the existing pump is not strong enough to deliver liquids to the right place on the surface, in the garden, in the garden or at home. It offers various models on the market, but only a few components for a sufficient distribution of the base model, which is reflected in each pump installation system:

- storage tank;

- pump;

- control relay;

- non-return valve that does not allow leakage;

- filter.

A filter is needed, otherwise the grain of the grains will lead to rapid abrasive wear of machine parts.

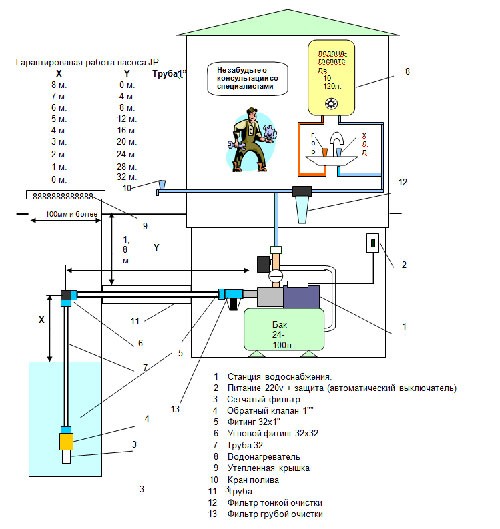

Equipment location

The installation and operation of the pumping station ensures long-term reliable operation of the equipment, subject to the following conditions:

- when installing the station in a bunker, it is placed below the level of soil freezing in winter, which is at least two meters;

- The place where the station is installed (basement or casson) must be heated in winter;

- When assembling the connection plan by hand, it is necessary to prepare a stand, which is then installed on the station in order to prevent groundwater floods.

It is important!

Do not touch the equipment with walls so that the mechanical vibration of the operating mechanism does not affect the room.

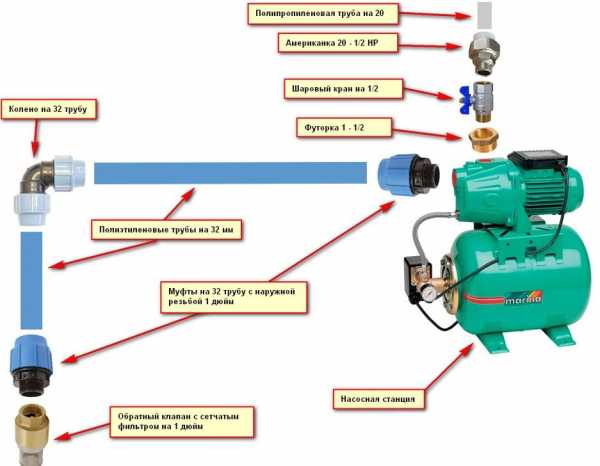

What equipment is needed for arranging the structure

To equip an artesian well with your own hands, you will need:

- water lifting equipment;

- cap;

- hydraulic tank;

- additional equipment for pressure, level, water flow control;

- frost protection: pit, caisson or adapter.

When buying a submersible pump, it is important to correctly calculate the required power. The model is selected according to performance and diameter. You can’t save on this equipment, because

the performance of the entire water supply system of the site depends on it

You can’t save on this equipment, because. the performance of the entire water supply system of the site depends on it.

The best option is a model in a high-strength hermetic case, equipped with sensors, filter units, and automation. As for brands, Grundfos water-lifting equipment deserves special attention.

Typically, a submersible pump is installed at a height of about 1-1.5 m from the bottom of the hydraulic structure, however, in an artesian well, it can be located much higher, because. pressure waters rise above the horizon.

The immersion depth for an artesian source should be calculated based on the indicators of static and dynamic water levels.

To keep artesian water crystal clear, the production pipe must be protected from debris, surface water and other adverse environmental factors. This structural element is used to securely fasten the submersible pump cable.

The head consists of a cover, clamps, carabiner, flange and seal. Models of industrial production do not need to be welded to the casing, they are fastened with bolts that press the cover against the seal, thus ensuring a complete seal of the wellhead. Features of mounting homemade heads depend on the design of the devices.

The hydraulic accumulator is an important unit of an autonomous water supply system. It is necessary to ensure the normal operation of the water supply, protect the pump from constant on-off and prevent water hammer. The battery is a water tank, additionally equipped with pressure sensors and automation.

When the pump is turned on, water first enters the tank, and from it is supplied to the draw-off points. The water levels at which the pump turns on and off can be controlled using pressure sensors. On sale there are hydraulic tanks with a capacity of 10 to 1000 liters. Each well owner can choose the model that best suits their system.

The well must be protected from freezing. For these purposes, you can make a pit, install a caisson, an adapter. The traditional option is a pit. It is a small pit, the walls of which are reinforced with concrete or brickwork.From above, the structure is closed with a heavy lid with a hatch. It is undesirable to install any equipment in the pit, because even with good waterproofing, the walls still let moisture through, the design is not airtight.

A more modern and technological analogue of the pit is the caisson. This design is best purchased at a specialized store. Industrial production caissons are pre-designed to accommodate all the necessary equipment. Plastic models are well insulated and airtight. Metal caissons often need additional insulation.

For a single-pipe artesian well, an arrangement using a pitless adapter is suitable. In this case, the function of the protective structure is performed by the casing pipe itself. The adapter can only be installed if the column is made of metal. There are serious difficulties with the operation of a plastic pipe, and the service life of the structure may be short-lived.

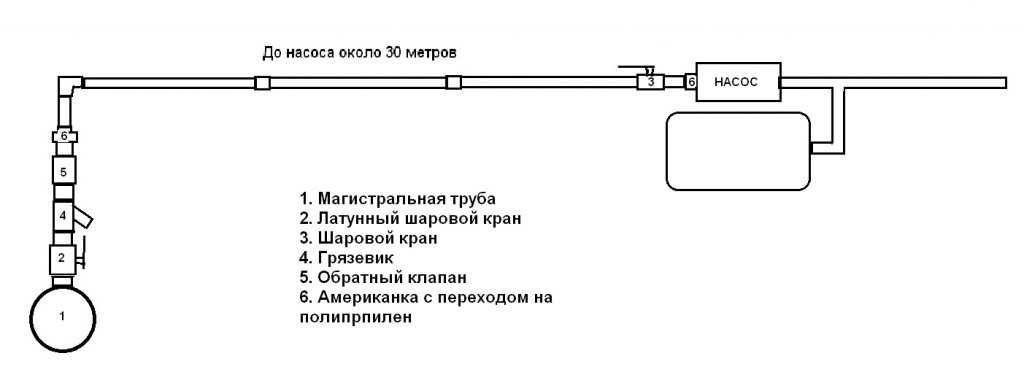

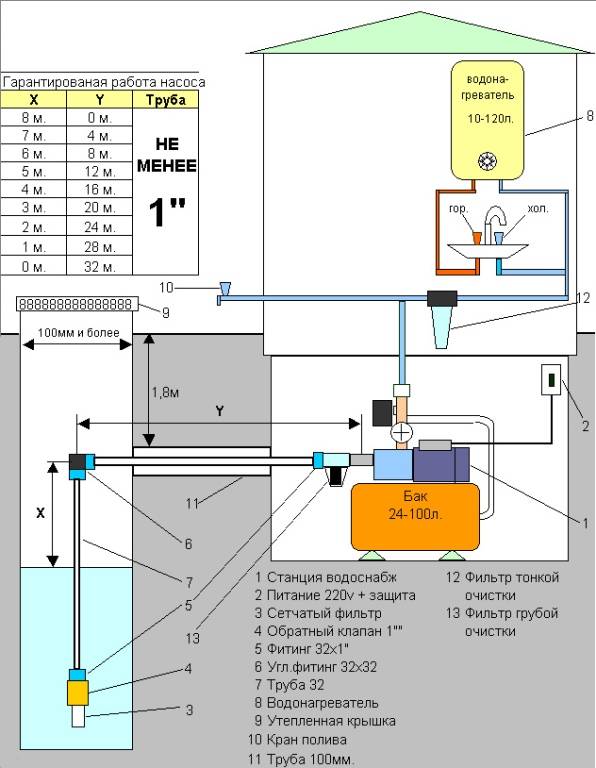

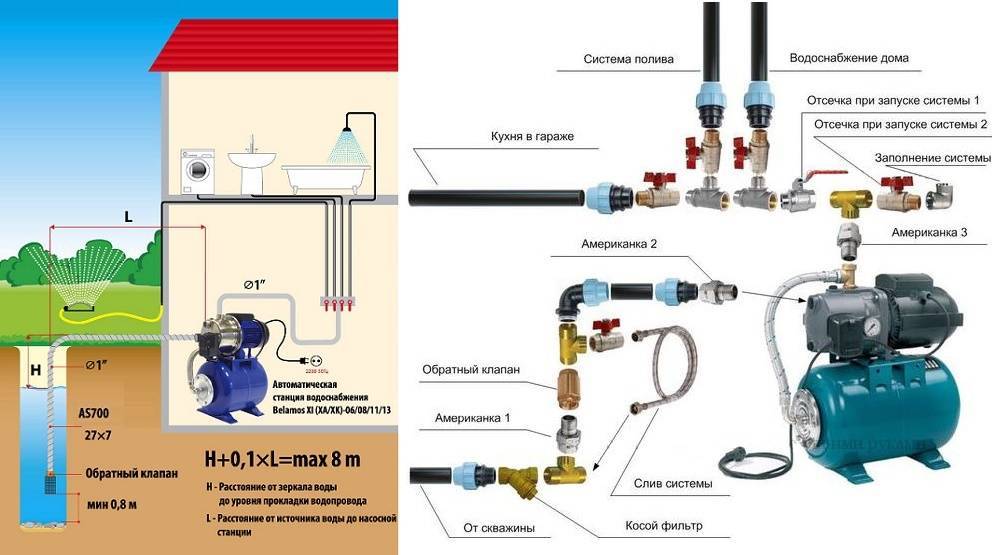

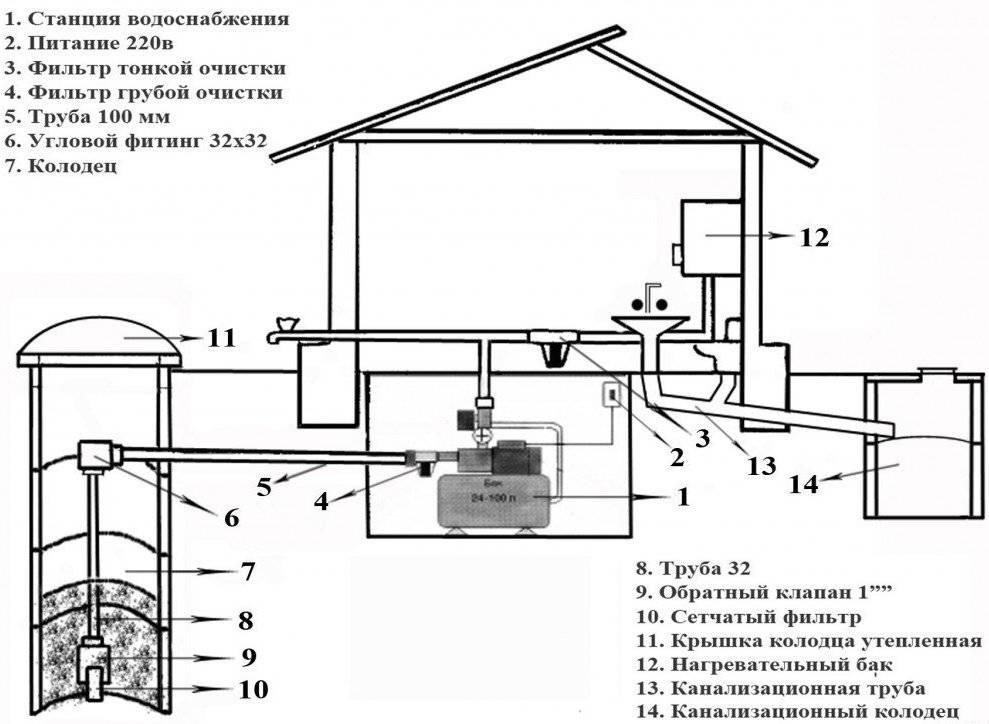

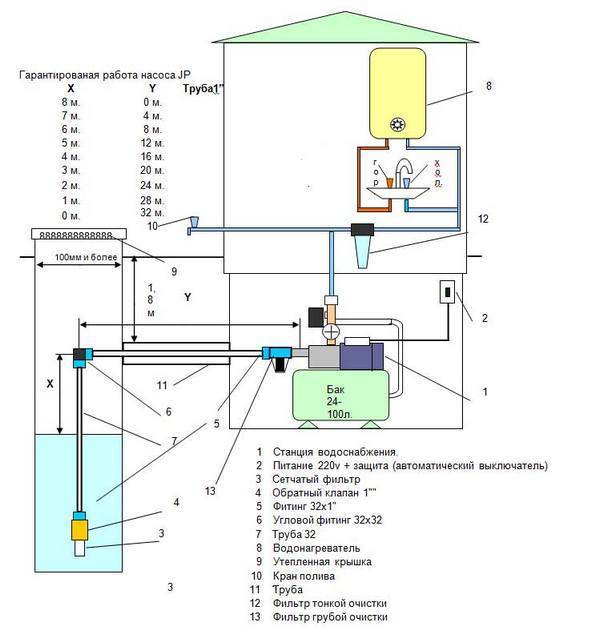

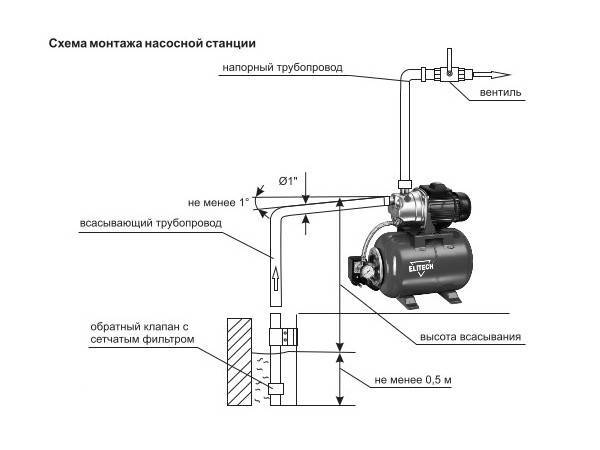

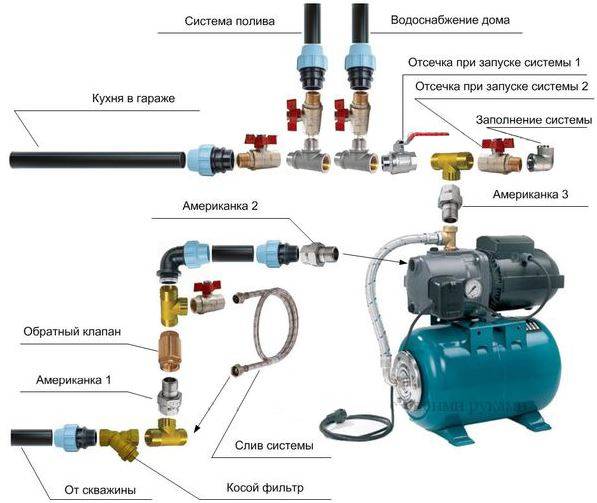

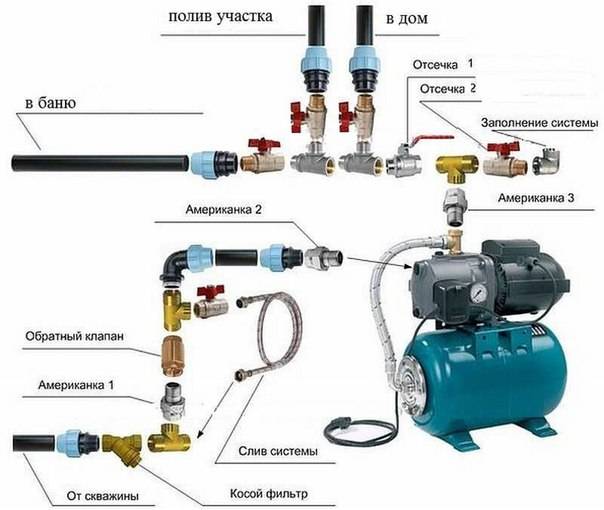

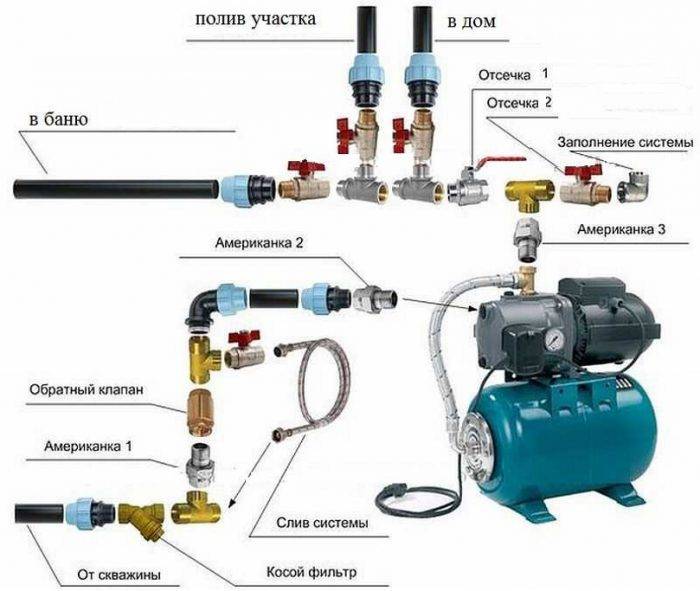

Connection order: step by step instructions

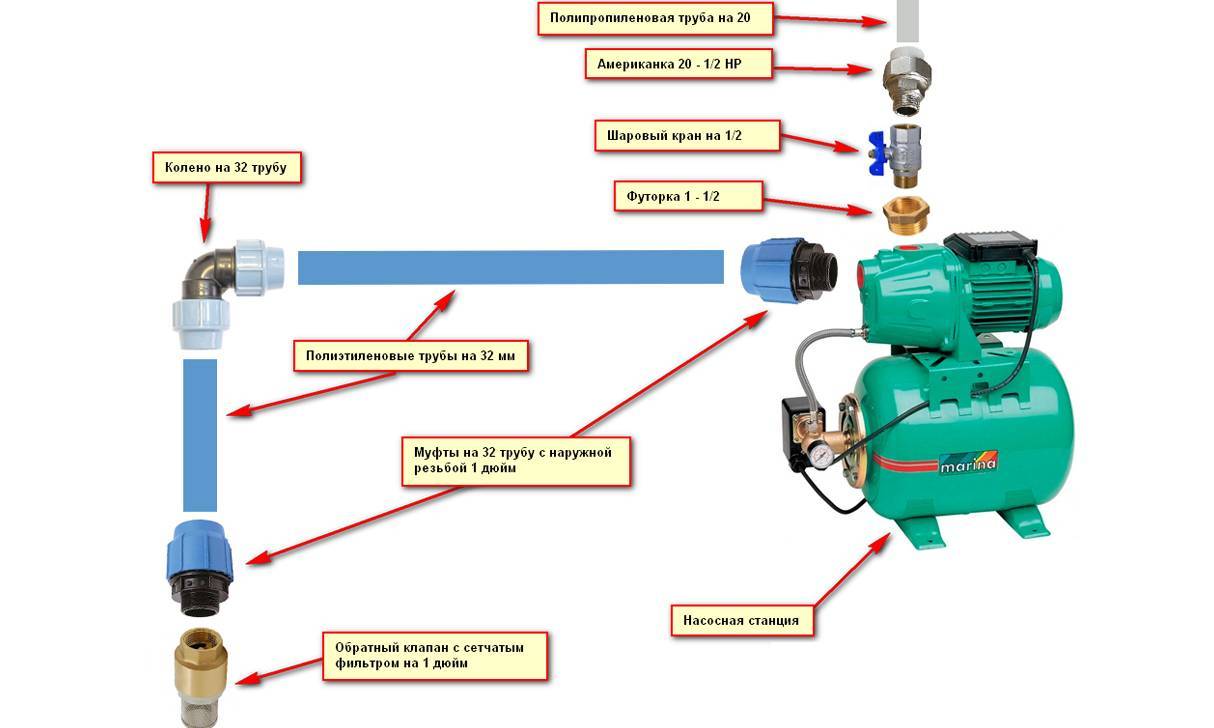

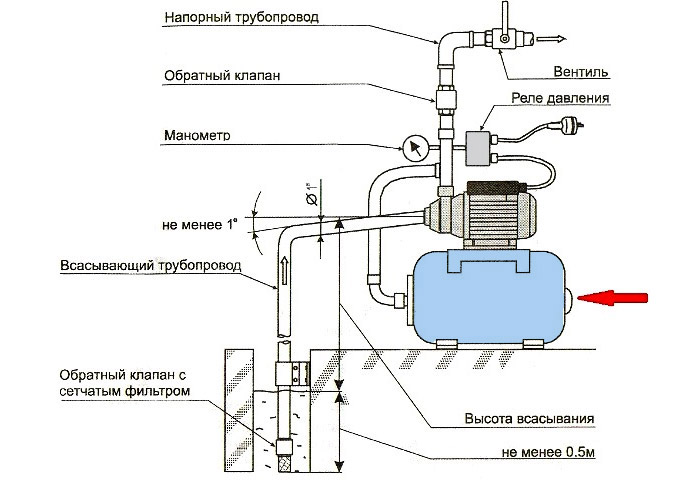

Not everyone knows how to properly connect a pumping station. When installing block equipment, the assembly implies the combination of pressure and suction pipelines. A filter with valves is connected to the pipe immersed in the well, it is brought out through an adapter or head.

The suction line is carefully sealed. Otherwise, air will enter the water supply system, which will disable the pump. The pressure part is supplied with a valve.

12 steps to connect a pumping station:

It is worth considering how the pumping station is connected to the well when choosing modular equipment. Connecting a well to a pumping station includes the following steps:

- Hydraulic accumulator harness. First of all, a fitting with 5 nozzles is mounted.It is connected directly. After that, they set up and install a protective relay, a pressure gauge and a water inlet. The remaining outlet is used to connect the pressure pipe. Submersible pumps are installed in wells with a depth of more than 10 m. This avoids the problems caused by the need to install an ejector and a suction part.

- Pipeline outlet. Produced through the head of the source. Pressure pipes are laid in a trench leading to the house. Elements should be located below the freezing depth of the soil.

- Connection to the electrical network. During the installation process, the starting block of the station is installed, the output is connected to it with copper wires. The pump must be powered by a separate automatic switch.

After the assembly process is completed, the tightness of the joints is evaluated. For the first time, the accumulator is filled slowly so as not to violate the integrity of the membrane.

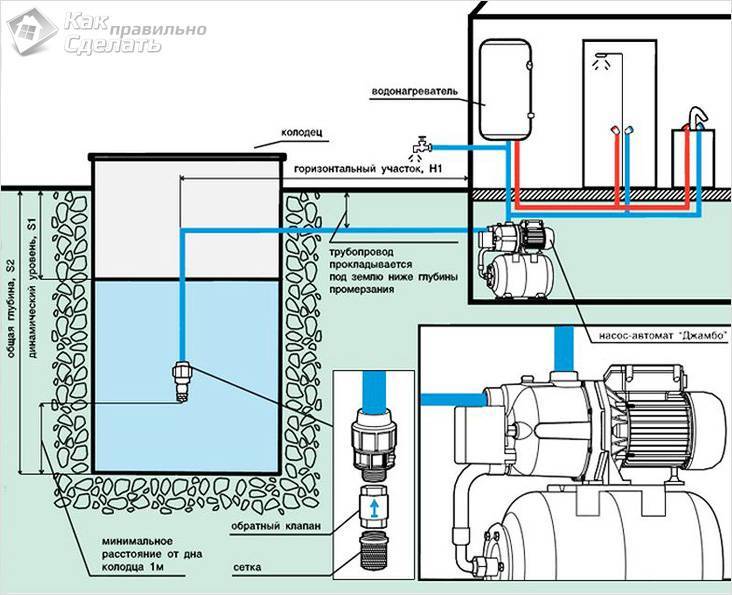

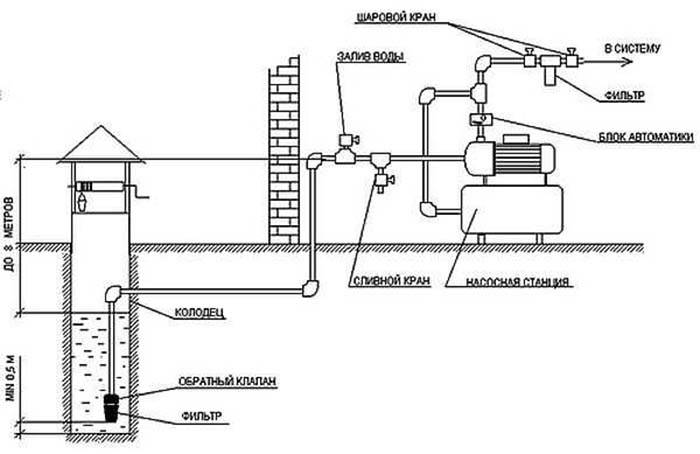

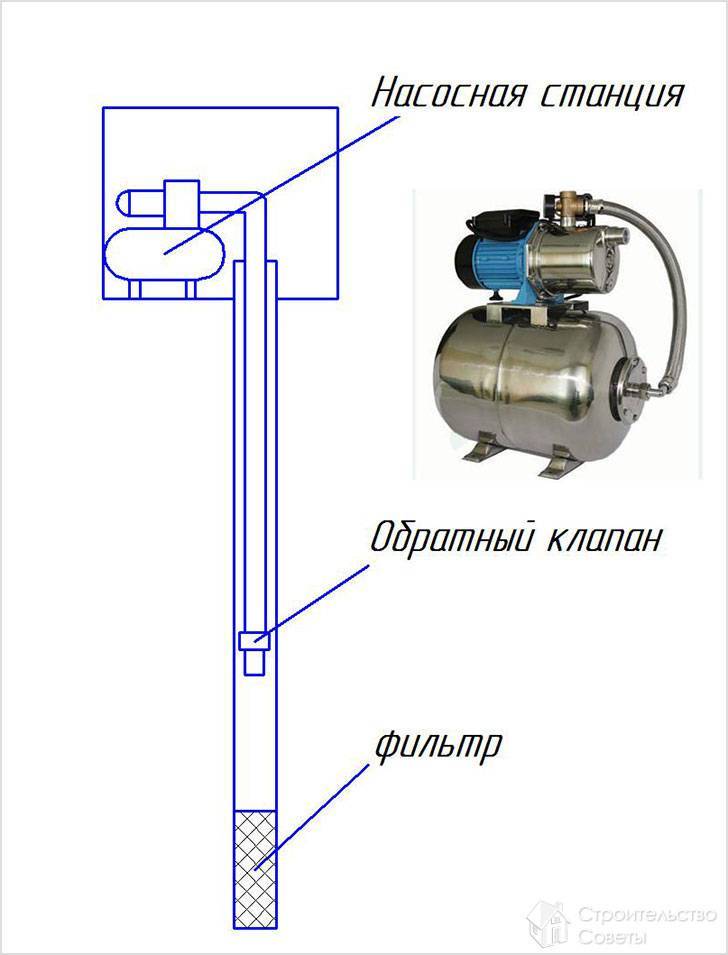

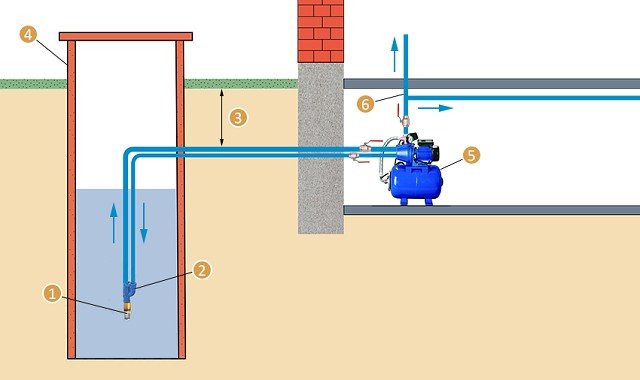

Selecting an installation site

Pumping stations are installed near a water source - a well or a well - in a specially equipped pit - a caisson. The second option is in the utility room in the house. The third is on a shelf in the well (such a number will not work with a well), and the fourth is in the underground.

Installation of a pumping station in the subfield - the noise from its operation may be too loud

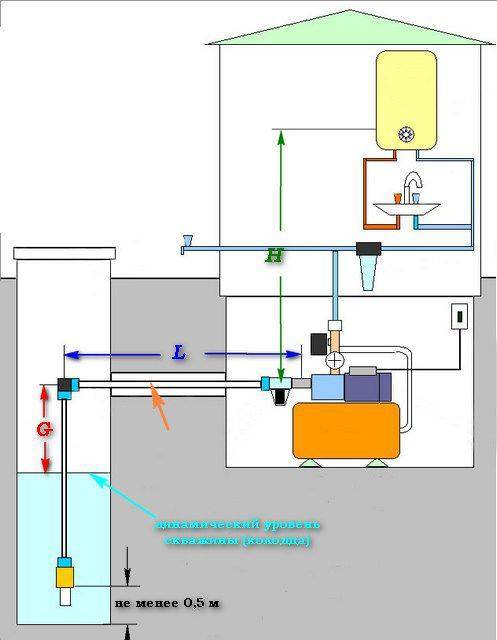

How to determine the depth of suction

When choosing a place, they are primarily guided by technical characteristics - the maximum suction depth of the pump (from where the pump can lift water). The thing is that the maximum lifting depth of pumping stations is 8-9 meters.

Suction depth - the distance from the water surface to the pump.The supply pipeline can be lowered to any depth, it will pump water from the level of the water mirror.

Wells often have a greater depth than 8-9 meters. In this case, you will have to use other equipment - a submersible pump or a pumping station with an ejector. In this case, water can be supplied from 20-30 meters, which is usually enough. The disadvantage of this solution is expensive equipment.

Suction depth - a characteristic that determines the installation method

If you are only a meter away from being able to install conventional equipment, you can put the station in a well or above a well. A shelf is attached to the wall in the well, in the case of a well, a pit is deepened.

When calculating, do not forget that the level of the water mirror "floats" - in the summer it usually goes down. If your suction depth is on the verge, there may simply be no water during this period. Later, when the level rises, the water supply will resume.

Security Considerations

Another point to consider is the safety of the equipment. If the installation of a pumping station is supposed to be near a house with permanent residence, there are fewer problems - you can choose any option, even in a small shed. Only one condition - it should not freeze through in winter.

The installation of a pumping station in a barn is suitable for permanent residence and the condition of insulation / heating for the winter

If this is a dacha where they do not live permanently, the matter is more complicated - it is necessary to arrange such a room that is not striking. The safest way to install a pumping station is in the house. Although they can carry it away in this case.

The second place where you can install a pumping station is a buried camouflaged caisson.

Scheme of installing a pumping station in a well

The third is on a shelf in the well. Only in this case, the traditional house for the well is not worth doing. You need a steel lid, which is locked with a reliable lock (weld loops to the ring, make slots in the lid, on which to hang constipation). Although, a good cover can also be hidden under the house. Only the design must be thought out so that it does not interfere.

Convenience and operating conditions

Installing a pumping station in the house is good for everyone, except that the equipment makes noise during operation. If there is a separate room with good sound insulation and it is possible according to the technical characteristics, no problem. Often they make a similar room in the basement or in the basement. If there is no basement, you can make a box in the underground. Access to it is through a hatch. This box, in addition to sound insulation, must also have good thermal insulation - the operating temperature range starts from + 5 ° C.

To reduce the noise level, the station can be placed on thick rubber to dampen vibration (created by a cooling fan). In this case, even installation in the house is possible, but the sound will certainly still be.

Caisson from concrete rings

If you stopped at the installation of a pumping station in a caisson, it must also be insulated and also waterproof. Usually, ready-made reinforced concrete containers are used for these purposes, but a caisson can be made from concrete rings (like a well). Install the ring with the bottom down, the ring with the lid on top. Another option is to lay it out of brick, pour concrete on the floor. But this method is suitable for dry areas - the groundwater level should be lower by a meter below the depth of the caisson.

The depth of the caisson is such that the equipment is installed below the freezing level. Expanded polystyrene insulation. Better extruded.Then you also get waterproofing at the same time.

For a caisson of concrete rings, it is convenient to use a shell (if you find a suitable diameter). But you can also slab polystyrene foam, cut into strips and glue it. For rectangular pits and structures, slabs are suitable that can be glued to walls using bituminous mastic. Lubricate the wall, apply insulation, you can additionally fix it with a pair of nails / dowels.