- Self connection

- Installation of a surface pump

- Submersible pump installation

- Typical connection errors

- Purpose and principle of operation of a pumping station for a well

- Installing a water pump in a private house

- Scheme of connecting a pumping station to a well in the country

- How to calculate the volume of a hydraulic accumulator?

- Water purification

- Models

- Types of pumping stations and distance to the water table

- Pump stations with built-in ejector

- Pumping stations with remote ejector

- Sanitary unit in pumping stations for water supply:

- Kinds

- Well pump control

- Plant commissioning and testing

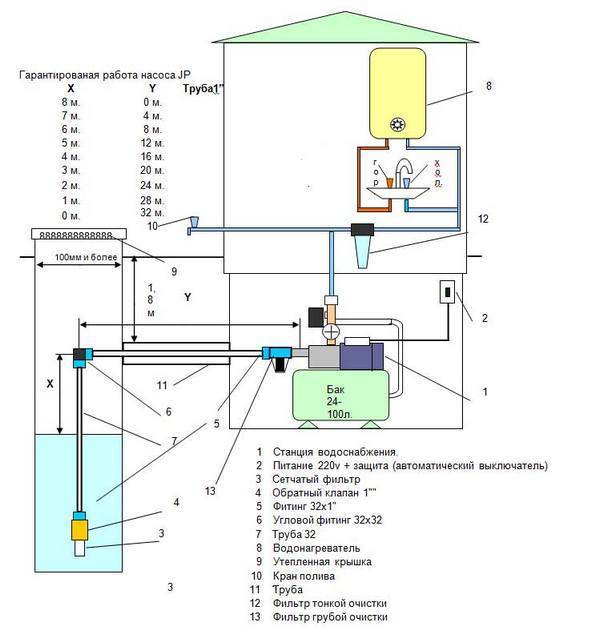

- Popular schemes for the implementation of water supply

- Well or well with a depth of more than 8 meters

- Well or well up to 8 meters deep

- Container with gravity water supply

- One- and two-pipe pumps - which ones to choose?

- Main types of wells

- Ordinary well

- Abyssinian well

- medium depth

- Artesian

- Number of pressure and suction pipelines:

Self connection

How to connect a well to a pump? You can do this with the help of professionals or on your own. The service of the masters will not cost so cheap, so more and more preference is given to installing on your own. This is not so difficult to do if you first study the procedure.

Consider the simplest pump circuit, which will help both in connection and operation.

A special pipe adapter is installed on the outlet pipe. Most often it is sold immediately with the unit. If not, you'll have to buy it. A coupling is screwed onto this adapter.

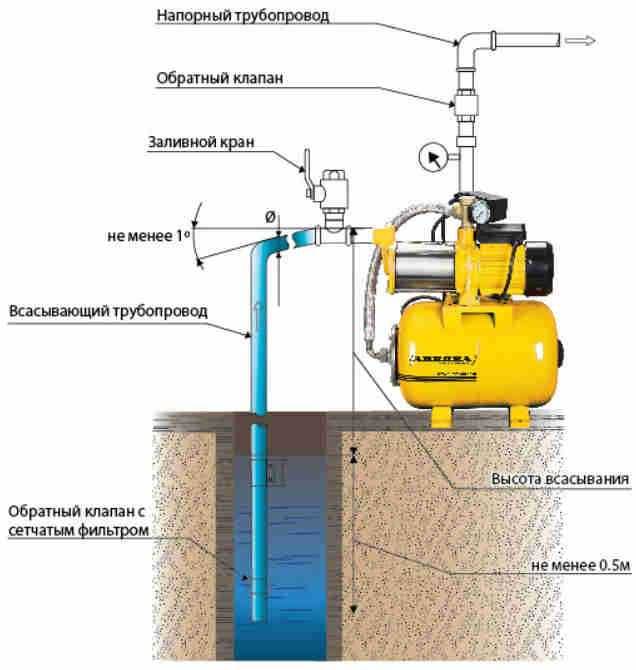

Installation of a surface pump

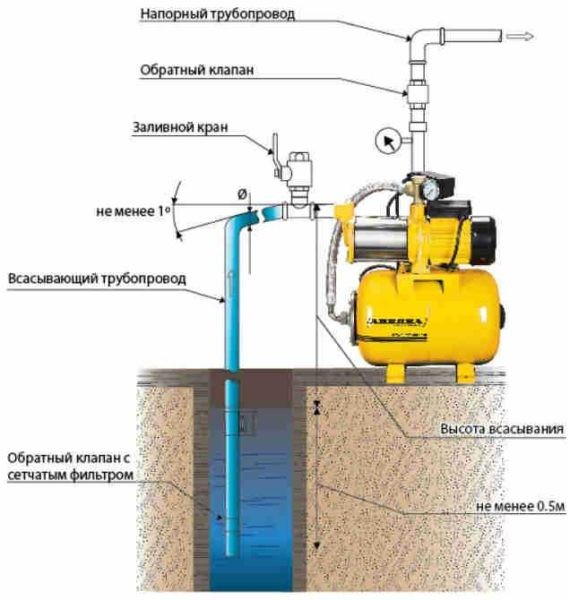

Installation of a surface pump in a well is carried out either indoors or directly above it. Connecting a surface pump to a well begins with the fact that a place should be dug in the ground for the device below the freezing level of the soil - a caisson.

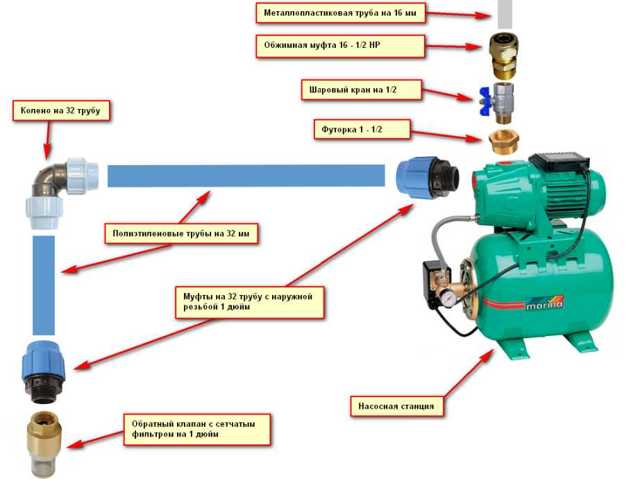

We start connecting the surface pump:

- we attach the hose we need to the suction part;

- a special valve should be fixed at the end of the hose. It prevents the water from draining back when the device is turned off;

- the filter element is attached to the check valve. It cleans the water from dirt and sand particles;

- the hose is immersed in the hole to the desired depth.

Installing a pump in a well with your own hands is not difficult at all if you have a tool.

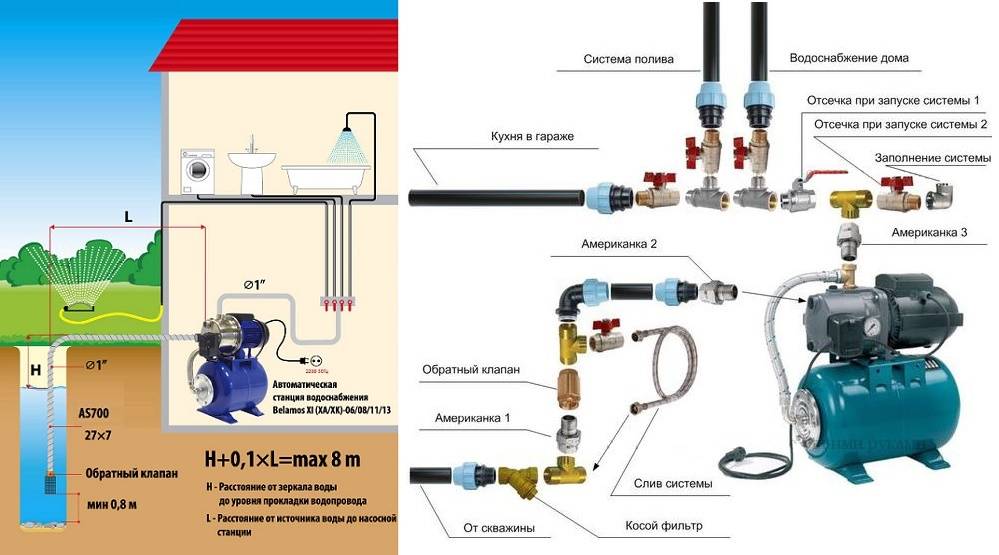

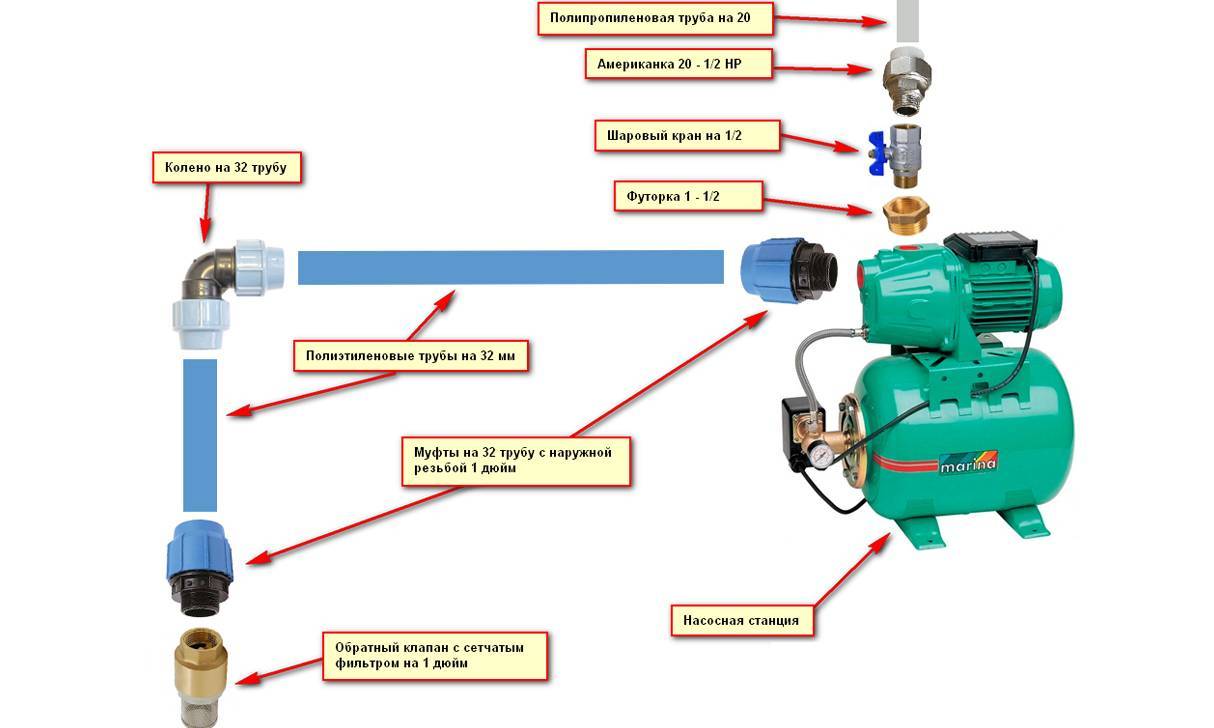

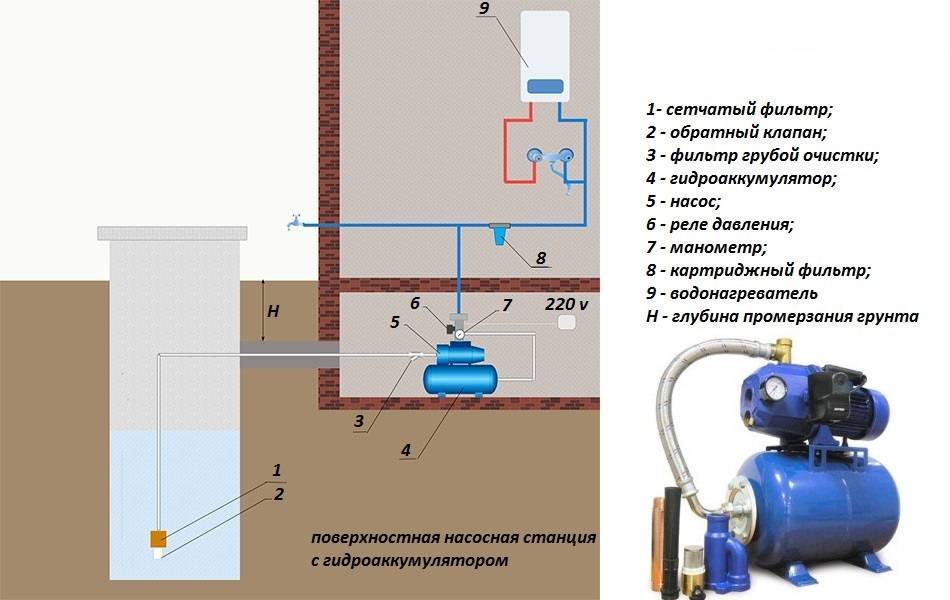

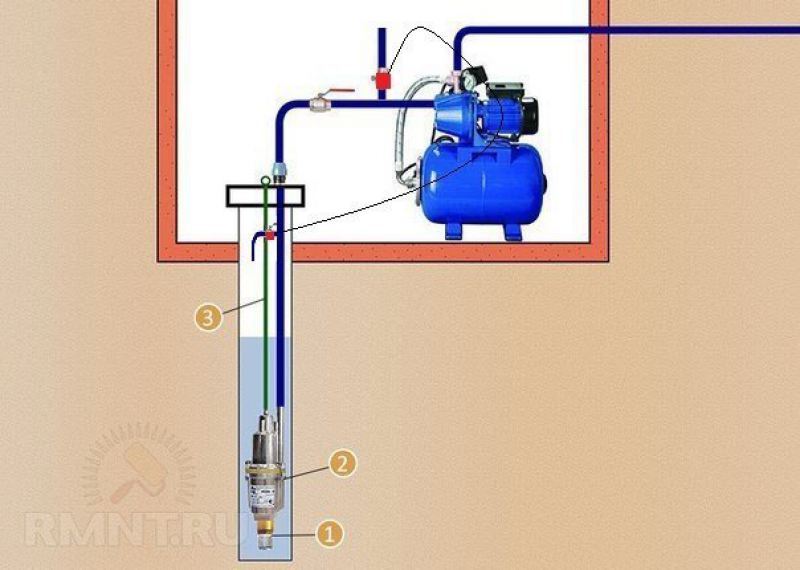

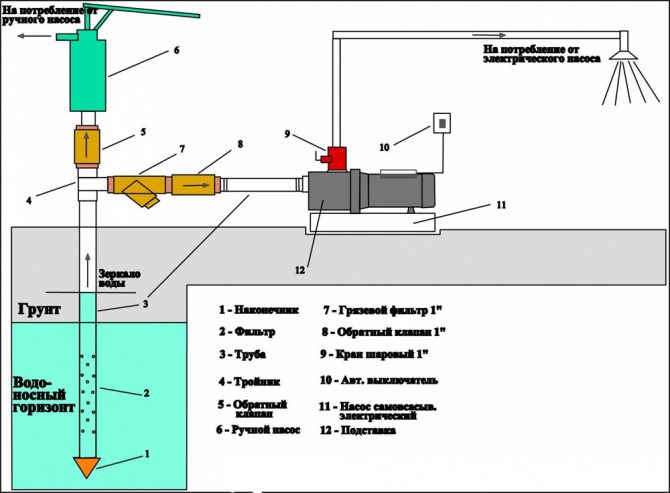

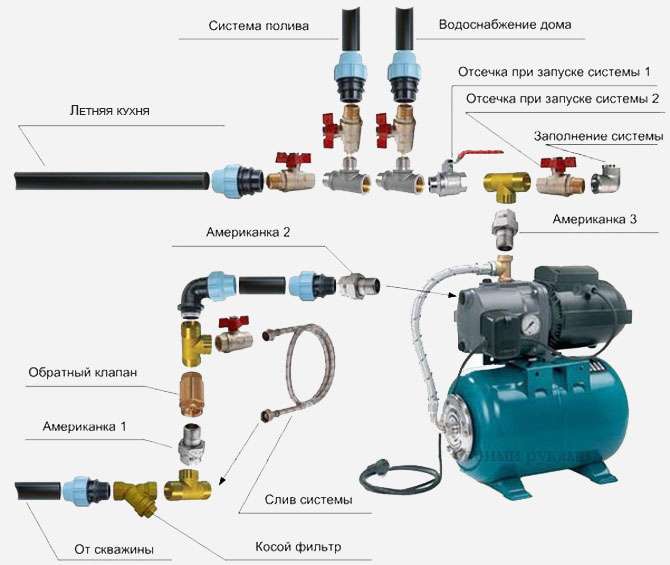

The connection diagram of the surface device is shown in the figure:

Scheme 1

Submersible pump installation

To install a deep well pump in a well, you must clearly follow the instructions. The submersible pump for wells is installed directly in the hole. Moreover, a certain gap between the device and the shaft must be maintained, otherwise it will simply burn out. You can find out the minimum distance between the walls in the instructions. How to connect a submersible pump?

The instructions for installing a submersible pump in a well are as follows:

- a check valve is mounted on the pump nozzle. It prevents the pipe from draining water when the device stops working;

- a special valve is attached to the suction part that filters the water;

- a hose is attached to the check valve, through which water will rise up;

- the power wire to the deep pump is attached to the discharge hose using special clips or ties made of polymer material;

- twine is inserted into the brackets of the upper part of the device body. It is on it that he will hang in the well;

- how to lower the pump into the well? This must be done carefully and exclusively with a rope.

Installing a deep pump is not such a difficult task, which you can handle on your own.

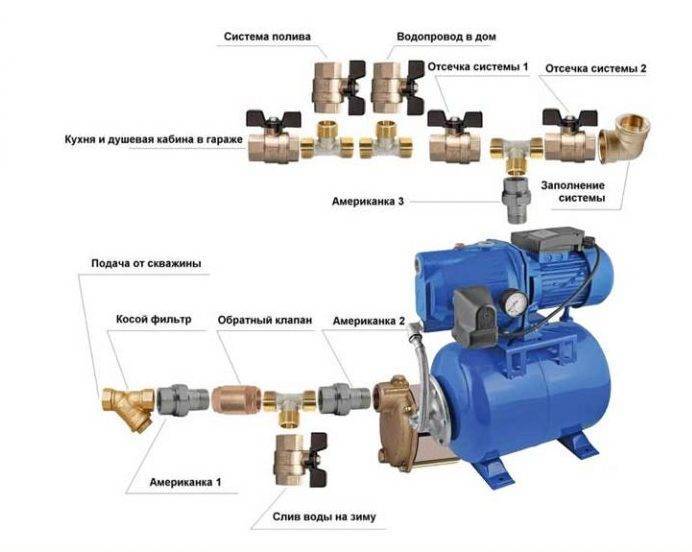

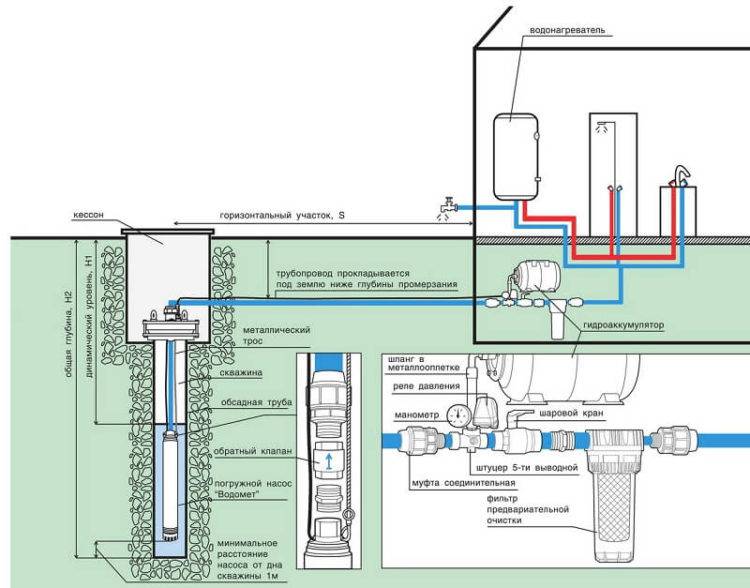

The connection diagram of the submersible type unit is shown in the figure.

Connection diagram 2

After diving to the desired depth, the rope must be fixed with special brackets. How deep should the pump be lowered? Usually the device is fixed a meter from the bottom. The installation depth of the deep pump also depends on the properties of the soil and the level of groundwater.

Typical connection errors

During installation, it is extremely important to avoid mistakes that will subsequently affect the future. The most typical of them when installing a pump in a well are as follows:

- incorrect determination of the unit suspension height;

- small cross section of the power cable;

- neglecting the installation of protection against voltage instability;

- insufficient diameter of the pipe for water supply;

- lack of a check valve in the system;

- incorrect selection or lack of instrumentation and control automation.

That's all. Now you know how to properly install the pump in the well. As you can see, it is not difficult to do it yourself, the main thing is to delve into all the nuances. Another tip - do not save on the pumping station. It is better to invest once and buy a quality device than to constantly repair a cheap one.And yet - before you install the pump in the well, watch the videos, which describe in detail all the nuances.

Purpose and principle of operation of a pumping station for a well

External view of the pumping station

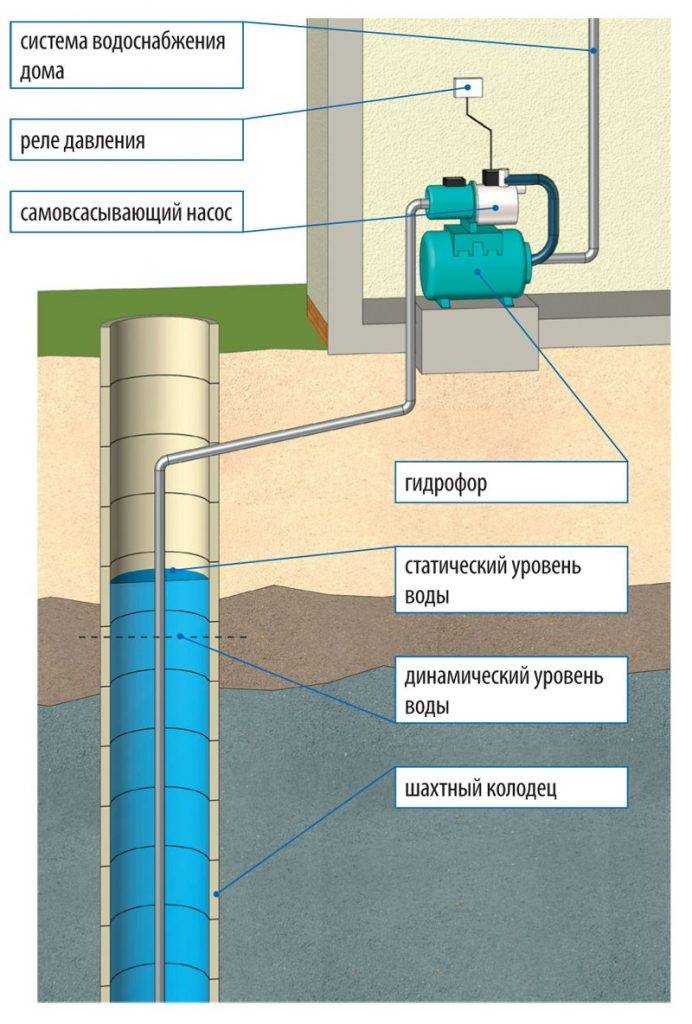

Pumping stations are special installations that consist of two parts - a hydraulic accumulator and a surface pump. This ensures the working pressure in the pipeline, and this allows the uninterrupted use of the washing machine or dishwasher.

The surface pump turns on automatically as soon as the water level in the accumulator (reservoir) drops, and not every time the water tap is opened. Such design features protect homeowners from the problems of water shortages. Another advantage of the hydraulic tank is that in case of emergency or emergency situations, there is always a supply of clean fluid from the source.

The principle of operation of water pumping units:

- The pump turns on, which transports water to the accumulator. During this time, the working pressure in the pipeline increases significantly.

- As soon as the household opens any faucet, the pressure in the system drops to 2.2 bar, the pressure switch is activated and the water pump restarts to replenish the wasted resources in the tank.

- As soon as all losses have been compensated, the pressure in the pipeline increases to 3 bar, the relay is activated again, which turns off the pump.

Installing a water pump in a private house

The process of connecting a station to resources depends on the type:

- good or well;

- centralized water supply.

- disconnection of the water supply;

- the free end of the city pipe with a pipe or a piece of pipe is connected to the battery;

- all nodes of the station are connected and located;

- checking system performance.

First start-up connection The first start-up of the pumping station is carried out to test the composite system.

For this you need:

1. Fill water through the dedicated plug or pump opening and all connected piping. Charging the pump must be carried out at the very top so that all the air is released.

second

Connect the pressure side of the system to the entire piping distribution in the house. Close the filling port of the pump if it is full. Check the air pressure in the tank. If it is below the value specified in the instructions, start the air using a conventional pump for the pump. In case of excess pressure in the threshold, bleach the air to the nominal value.

3. Connect the power supply through the socket. Water will begin to fill the highway and the battery.

The pump automatically switches off when it reaches a pressure of approximately 3 atm.

4. After the pump stops, open any cord in the house. The pressure must be reduced as indicated by the pressure gauge. If the meter readings differ from these parameters in the instructions, adjust them as recommended.

The cost of connecting the water supply system by third-party experts

- Placement in the basement or pallets;

- Laying pipes in a ditch from a well or from the end of the connection to the central water supply of the house;

- Battery storage;

- Installation and configuration of the automation system and electrical equipment;

- System health check.

Labor costs depend on the need to find a trench and the complexity of installing equipment.

For example, installation with attachment of equipment starts from 2500 to 3000 rubles.

The final assessment can be assessed comprehensively if the scope of the proposed services includes container installation, automation testing, pumping station piping. In this case, the total labor costs for the Moscow region are 7,000 rubles:

- suction in the central water supply network - 2,000;

- mandatory - 3,000;

- tank installation - 1,500.

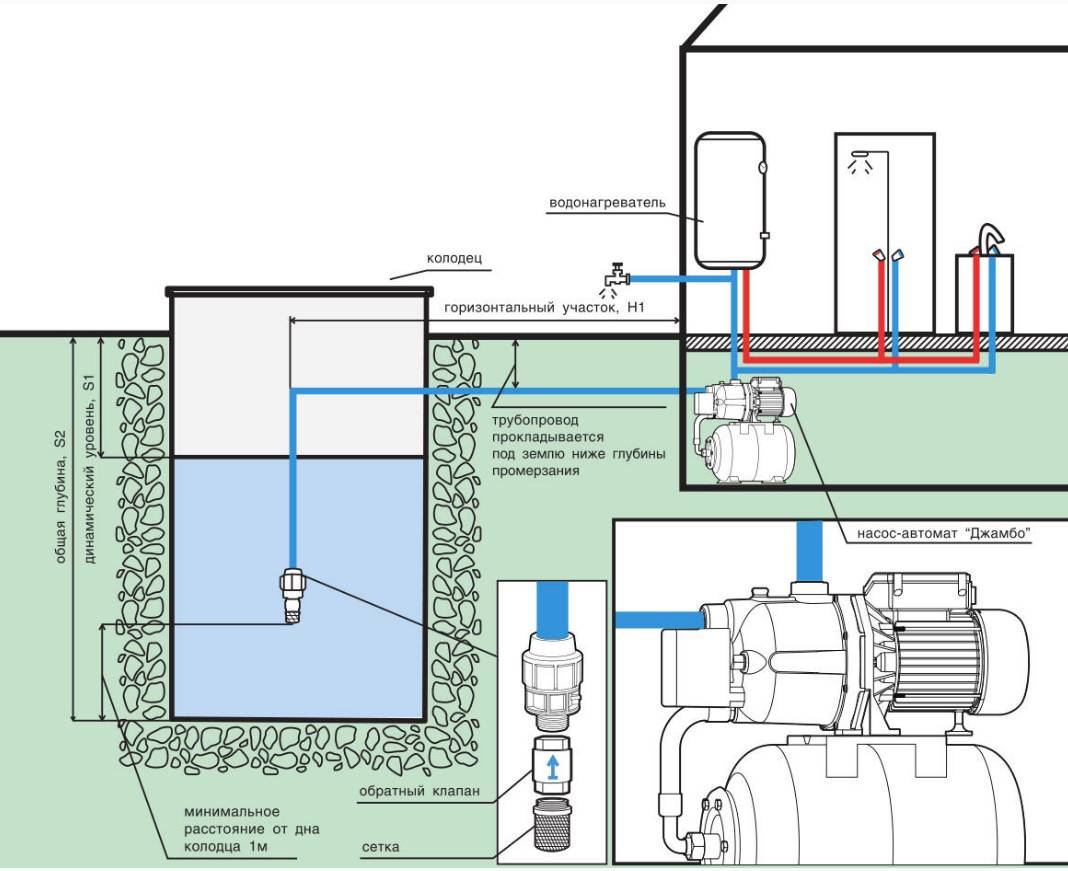

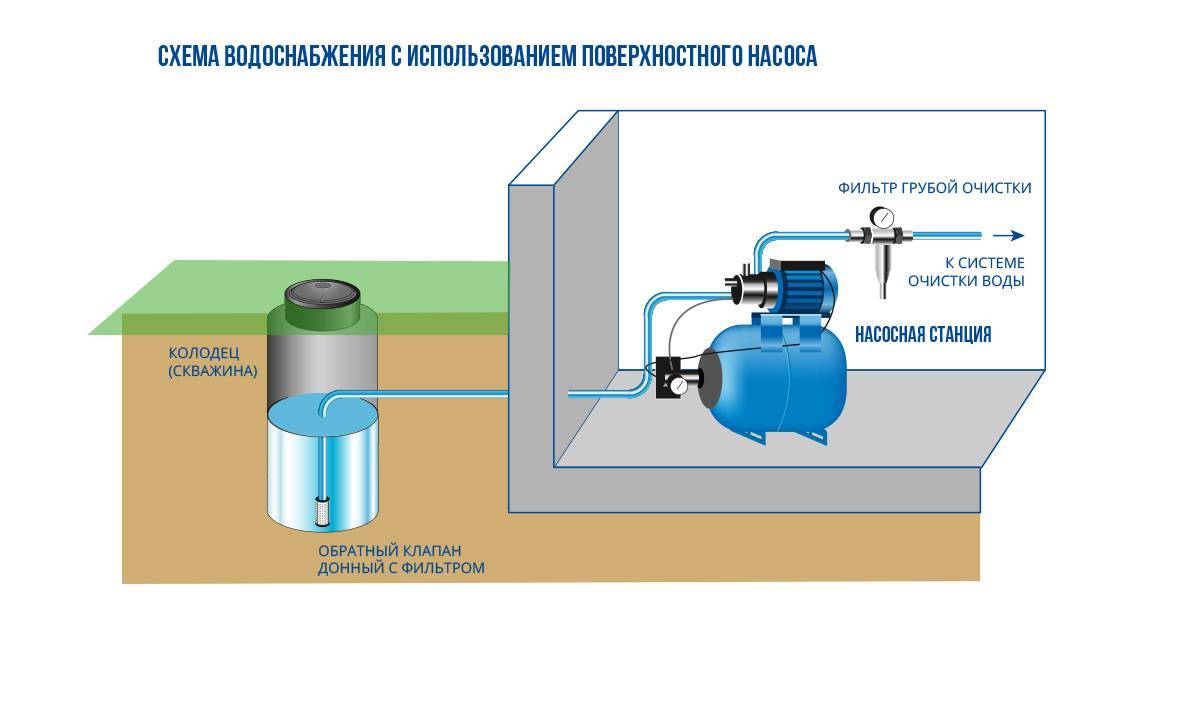

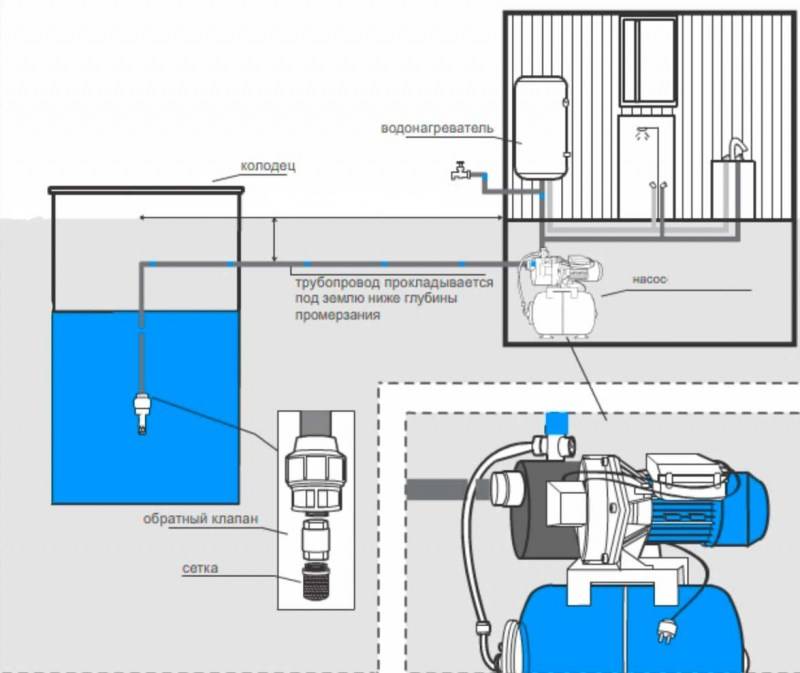

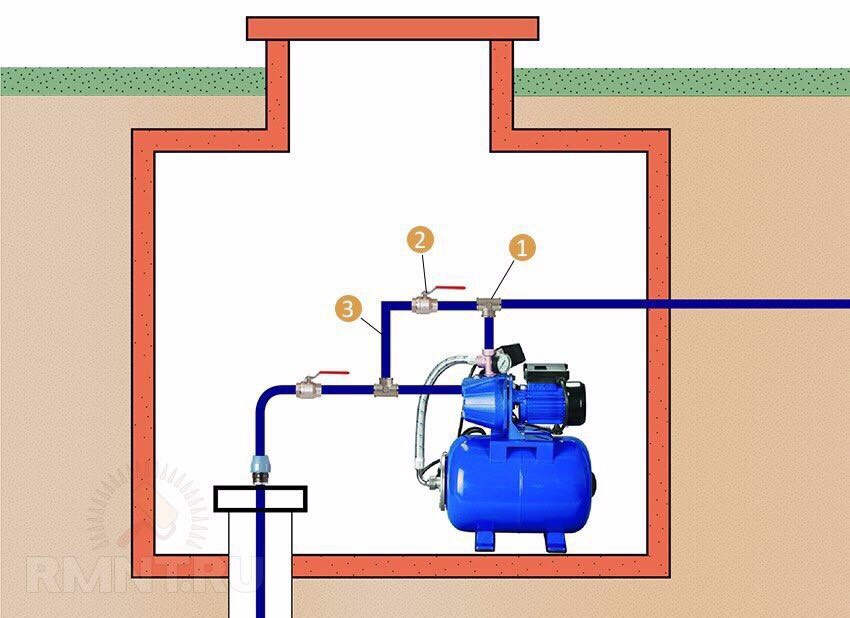

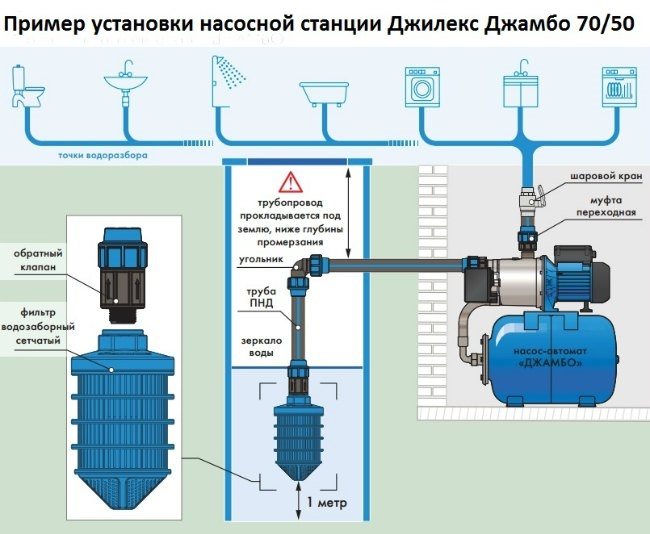

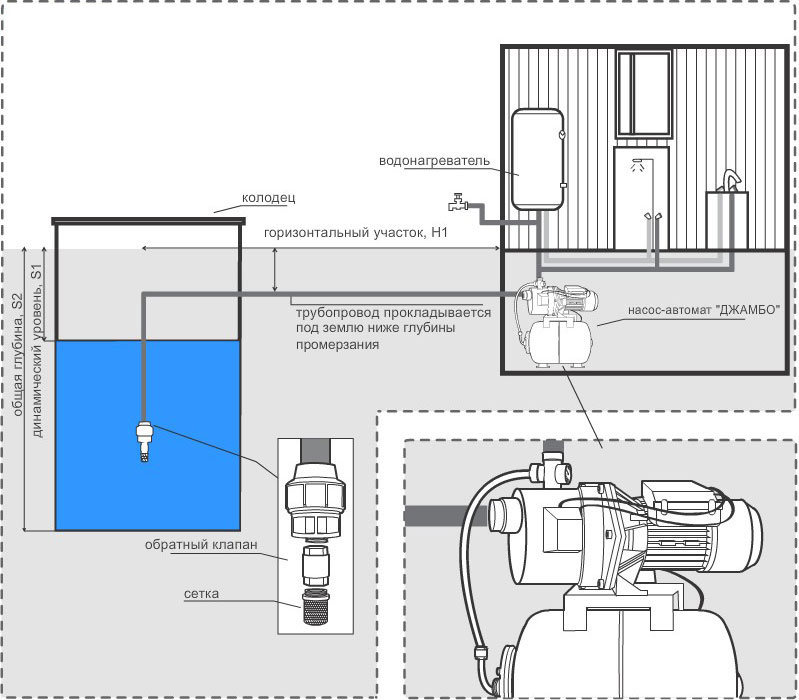

Scheme of connecting a pumping station to a well in the country

The pumping station can be placed inside the well, if there is a place for this, in addition, utility rooms are often allocated for it in the house itself or in the room

Pay attention to the depth at which the pipeline will be. The pipe must not only be insulated, but also placed below the freezing depth of the soil, so that during the cold season the water in it does not freeze

In order for the system to work correctly, you need to choose not only the type of pump, but also the depth at which it will work. The deeper the water source and the farther it is from the building, the more powerful the pump itself must be. There should be a filter at the end of the pipe, it is located between the pipe and the pump, protecting the latter from debris entering the mechanism.

Devices usually write at what depth they are designed, but it is worth taking a more powerful one, since the calculation is carried out only from the bottom of the well to its surface, not taking into account the distance to the building. It is easy to calculate: 1 meter of the vertical location of the pipe is 10 meters of its horizontal location, since it is easier to supply water in this plane.

Depending on the type and power of the pump, the pressure may be stronger or weaker. It can also be calculated.On average, the pump provides 1.5 atmospheres, but this is not enough pressure for the normal operation of the same washing machine or hydromassage, the water heater may require a higher temperature.

In order to control the pressure, the equipment is equipped with a barometer. Depending on the pressure parameter, the size of the storage tank is also calculated. Station performance also plays an important role. This parameter indicates how many cubic meters per minute the pump is capable of delivering. You need to calculate based on peak water consumption, that is, when all the taps in the house are open or several consumer electrical appliances are working. In order to calculate which pumping station is suitable for giving in a well, you need to know the performance. To do this, add up the number of water supply points.

From the point of view of power supply, it is more convenient to use those systems that are powered by a 22-volt network. Some stations operate 380 V phases, but such motors are not always convenient, because a three-phase connection is not available in every home. The power of a household station may vary, on average it is 500-2000 watts. Based on this parameter, RCDs and other devices are selected that will work in conjunction with the station. In order to prevent the design from overheating, many manufacturers install automation that will turn off the pumps in the event of an emergency load. The protection also works if there is no water in the source when power surges occur.

How to calculate the volume of a hydraulic accumulator?

The size of the tank determines how often the pump motor will turn on. The larger it is, the less often the installation works, which allows you to save on electricity, increase the resource of the system.Too large a hydraulic accumulator takes up a lot of space, so a medium-sized one is usually used. It holds 24 liters. This is enough for a small house in which a family of three lives.

Trailer work accumulator expansion tank

If up to 5 people live in the house, then it is better to install the tank at 50 liters, respectively, if more than 6, it should be at least 100 liters. It is worth noting that the standard tanks of many stations hold 2 liters, such a hydraulic tank can only cope with water hammer and maintain the required pressure, it is better not to save money and immediately replace it with a large one. It is the number of water users in the house that will determine which pumping station to choose for a summer residence.

Water purification

Do not forget that the water from the well, even if it is suitable for drinking, may have impurities, for example, sand, small stones, various debris can get into it, which can be disposed of using a special system for water purification. The most commonly used filters. They are placed outside so that it is convenient to change them. They can have different fractions and purify water to varying degrees. At the outlet, deep fine filters are used.

Models

- Gilex.

- Vortex.

- Ergus.

- Bison.

- gardena.

- Wilo SE.

- Karcher.

- Pedrollo.

- grundfos.

- Wilo.

- Poplar.

- Unipump.

- Aquario.

- Aquarius.

- Biral.

- S.F.A.

- Vortex.

- waterstry.

- Zota.

- Belamos.

- Pedrollo.

Before choosing a pumping station for a summer residence with a well, it will not be superfluous to find out how things are with the maintenance of the products of the selected manufacturer, are there any nearest dealers who can provide spare parts.

Types of pumping stations and distance to the water table

There are pumping stations with a built-in and remote ejector.The built-in ejector is a structural element of the pump, the remote one is a separate external unit, immersed in the well. The choice in favor of one or another option depends primarily on the distance between the pumping station and the water surface.

From a technical point of view, the ejector is a fairly simple device. Its main structural element - the nozzle - is a branch pipe with a tapered end. Passing through the place of narrowing, the water acquires a noticeable acceleration. In accordance with Bernoulli's law, an area with low pressure is created around a stream moving at an increased speed, i.e., a rarefaction effect occurs.

Under the action of this vacuum, a new portion of water from the well is sucked into the pipe. As a result, the pump spends less energy to transport liquid to the surface. The efficiency of pumping equipment is increasing, as is the depth from which water can be pumped.

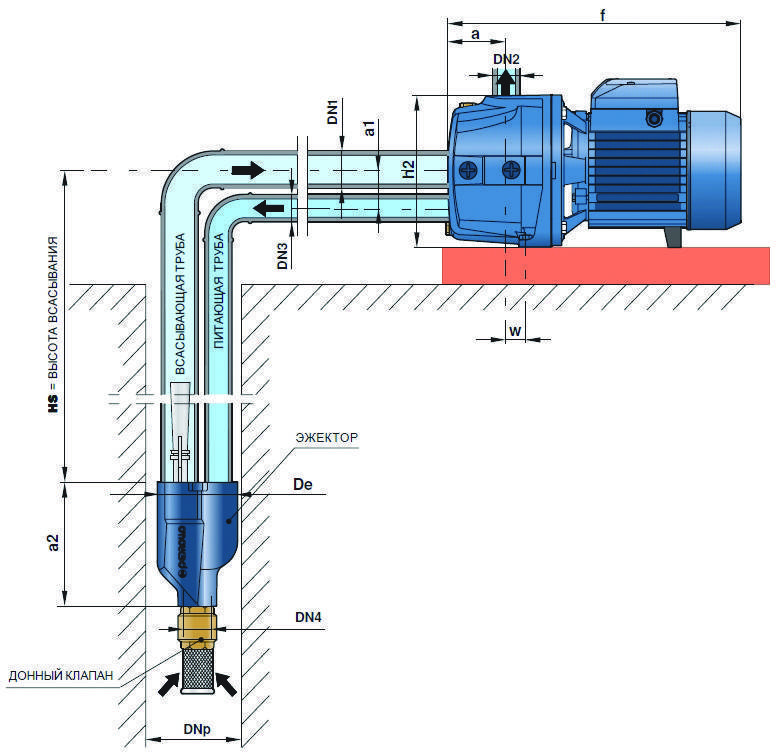

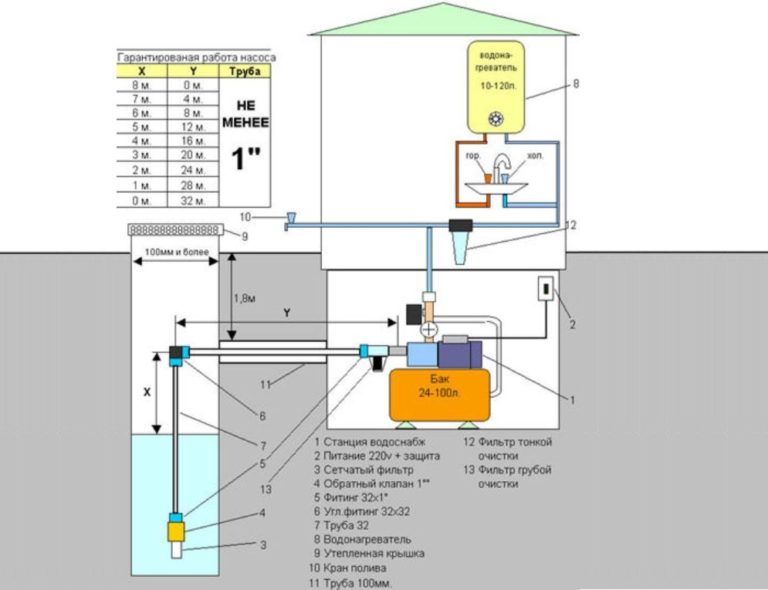

Pump stations with built-in ejector

Built-in ejectors are usually placed inside the pump casing or located in close proximity to it. This reduces the overall dimensions of the installation and somewhat simplifies the installation of the pumping station.

Such models demonstrate maximum efficiency when the suction height, i.e., the vertical distance from the pump inlet to the level of the water surface in the source, does not exceed 7-8 m.

Of course, one should also take into account the horizontal distance from the well to the location of the pumping station. The longer the horizontal section, the smaller the depth from which the pump is able to lift water. For example, if the pump is installed directly above a water source, it will be able to lift water from a depth of 8 m.If the same pump is removed from the water intake point by 24 m, then the depth of water rise will decrease to 2.5 m.

In addition to low efficiency at large depths of the water table, such pumps have another obvious drawback - an increased noise level. The noise from the vibration of a running pump is added to the sound of water passing through the ejector nozzle. That is why it is better to install a pump with a built-in ejector in a separate utility room, outside a residential building.

Pumping station with built-in ejector.

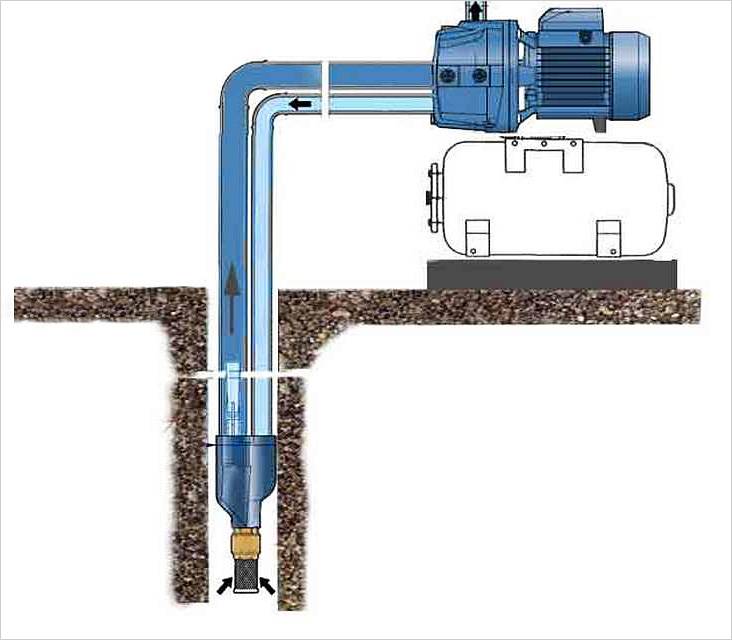

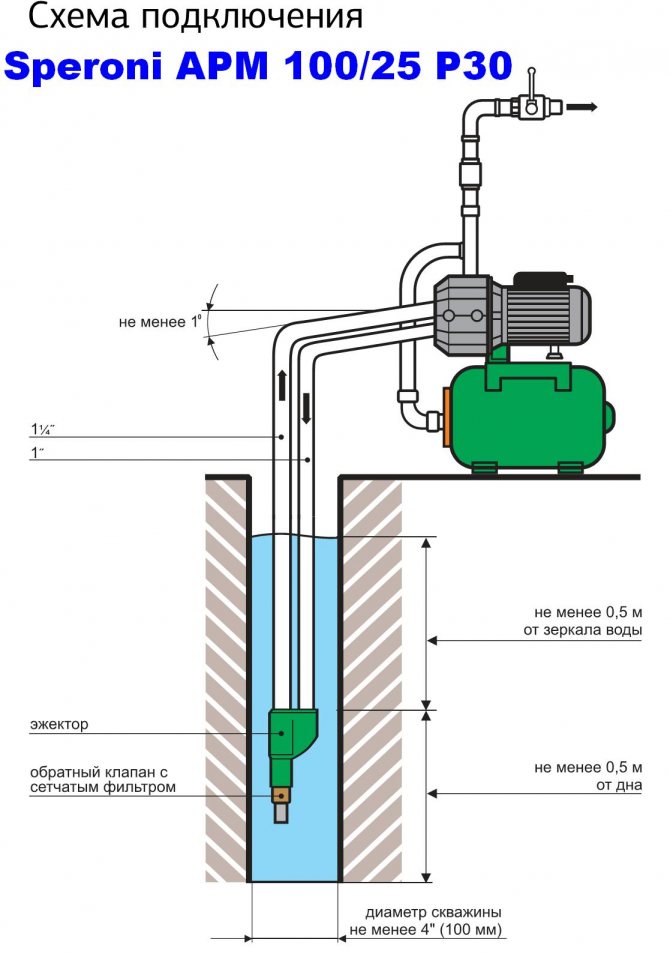

Pumping stations with remote ejector

The remote ejector, which is a separate small unit, unlike the built-in one, can be located at a considerable distance from the pump - it is connected to the part of the pipeline immersed in the well.

Remote ejector.

To operate a pumping station with an external ejector, a two-pipe system is required. One of the pipes is used to lift water from the well to the surface, while the second part of the raised water returns down to the ejector.

The need to lay two pipes imposes some restrictions on the minimum allowable well diameter, it is better to foresee this at the design stage of the device.

Such a constructive solution, on the one hand, allows to significantly increase the distance from the pump to the water surface (from 7-8 m, as in pumps with built-in ejectors, to 20-40 m), but on the other hand, it leads to a decrease in the efficiency of the system to 30- 35%. However, having the opportunity to significantly increase the depth of water intake, you can easily put up with the latter.

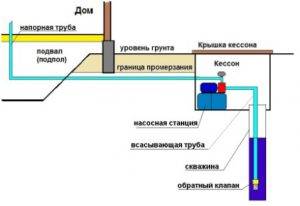

If the distance to the water surface in your area is not too deep, then there is no need to install a pumping station directly near the source.This means that you have the opportunity to move the pump away from the well without a noticeable decrease in efficiency.

As a rule, such pumping stations are located directly in a residential building, for example, in the basement. This improves equipment life and simplifies system setup and maintenance procedures.

Another undoubted advantage of remote ejectors is a significant reduction in the noise level produced by a working pumping station. The noise of water passing through an ejector installed deep underground will no longer disturb the residents of the house.

Pumping station with a remote ejector.

Sanitary unit in pumping stations for water supply:

In the pumping station, regardless of the degree of its automation, a sanitary unit (toilet and sink), a room and a locker for storing the clothes of the operating personnel (on-duty repair team) should be provided. When the pumping station is located at a distance of no more than 30 m from industrial buildings with sanitary facilities, it is allowed not to provide a sanitary unit.

In pumping stations above water wells, a sanitary unit should not be provided. For a pumping station located outside a settlement or facility, toilet cabins are installed within the territory.

Kinds

To fit the HC, you first need to take into account the capabilities of the well and take the model just below this limit. But if the limit is less than 1.7 cu. m / h, then you will have to forget about the National Assembly: the motor will not provide constant pressure and interruptions in water are inevitable.

Household pumps have a capacity of 1.5 to 9 cubic meters.m / h, is determined by the number of water points (kitchen, toilet, bathroom, washing machine or dishwasher).

Water consumption at the point: 0.35 cubic meters m/h X 5 \u003d 1.75 cu. m/h In this case, you can limit yourself to NS with a capacity of 2 cubic meters. m / h (the stock does not hurt).

The capacity of the tank also depends on the points of consumption.

The average capacity of the tap is 12 liters, therefore, in our case, a tank of 60 liters is suitable. The instructions usually indicate the maximum that this model can provide.

Well data is obtained by using any motor to measure the volume of fluid pumped out. The level of the mirror will be prompted by a nut on a thread lowered into the well.

There are three types of pumps on the domestic market:

- The station with a centrifugal self-priming pump and a built-in ejector with a water pressure of up to 40 m and a suction depth of up to 9 m is the most popular. But its main advantage is its low susceptibility to air. To start the NS, open the lid and fill it with water to the brim. After pumping air, the motor will give water. Excess air escapes through a faucet or valve.

- Centrifugal self-priming pumps with an external ejector are suitable for wells with a depth of up to 45 m. They are mounted in a boiler room or other utility room. An ejector with two pipes is placed in a well. One supplies water to the ejector for suction, the second for lifting.

This type of HC is very sensitive to air and pollution, but allows it to be used in the house by lowering the ejector into the well at a distance of up to 40 m.

- Submersible pumps operate in areas with groundwater levels up to 10 m. They are lowered to the water level, pumped up and lifted up. The suction height is 8m, and they can push out to a greater height.

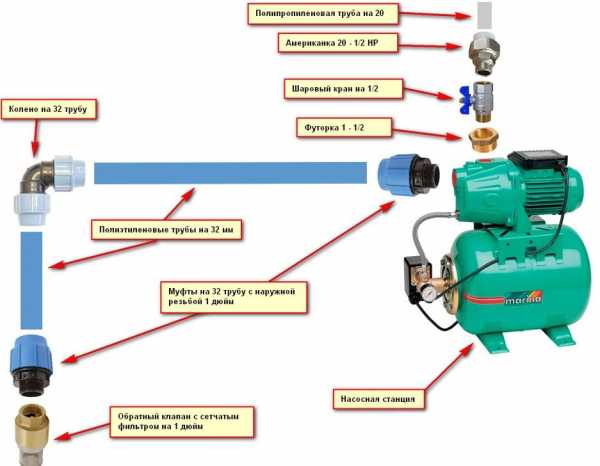

So, we determined the amount of water for a comfortable stay.We calculated the capacity of the pumping station and chose the type and location. Left to buy:

- Pump;

- Hydraulic accumulator;

- Pipes for external water supply (preferably polymeric);

- Automatic protection system;

- Faucets;

- Valves;

- gate valves;

- Cranes;

- Flexible hoses;

- Compression and press fittings

If there is no well on the site yet, it can be made by installing reinforcement around the rings, scalding it. This will save you from floaters and shifting rings.

The sooner you plan the water supply at home, the better the result will be. Ideally, the station operates autonomously. Every year we check the air pressure in the accumulator using a pressure gauge - that's all prevention. I really wish you were like that.

Views:

457

Well pump control

Submersible systems are equipped with pump control stations. They are responsible for automatic, remote and manual control using three-phase electric motors, which are separate units. Stations contribute to the protection of pumps from emergency situations.

The specified value of pipeline pressure is also maintained. The automatic station performs many functions. It is responsible for automatically turning the pump on and off if the level of the liquid being pumped decreases or rises.

Control station functions:

- Protection of electric pumps from "idling", if the level of the pumped liquid decreases.

- Prevention of short circuit in the electric motor.

- Restoration of the pump operation mode after the emergency impact stops.

- Motor protection in case of impeller failure.

The pumping station should be serviced from time to time

The choice of control system should depend on the ultimate goal of its use.Connection planning should assume the presence of a technical passport

Particular attention should be paid to the operational properties of the object.

Plant commissioning and testing

The first start-up after installation or the restoration of the system's performance after a long "dry" period is simple, although it requires certain manipulations. Its purpose is to fill the system with water before the first connection to the network.

This is a simple procedure that does not require special skills. There is a plug on the pump that needs to be removed.

A simple funnel is inserted into the hole, through which the system is filled - it is important to fill in the supply pipe and the pump with a hydraulic accumulator. A little patience is required at this stage - it is important not to leave air bubbles. Pour water up to the neck of the cork, which is then twisted again

Then, with a simple automobile pressure gauge, the air pressure in the accumulator is checked. The system is ready to start

Pour water up to the neck of the cork, which is then twisted again. Then, with a simple automobile pressure gauge, the air pressure in the accumulator is checked. The system is ready to start.

To make it clearer how to test a pumping station, we have prepared 2 galleries for you.

Part 1:

Image gallery

Photo from

Fittings (elements for connecting water pipes or hoses to the unit) are not included in the kit, so they are purchased separately

We connect a pipe to the upper hole of the accumulator, through which water will go to the points of analysis in the house (shower, toilet, sink)

By means of a fitting, we also connect a hose or pipe for taking water from a well to the side hole

Do not forget to equip the end of the intake pipe with a check valve that ensures stable operation and the required pressure.

Before pouring water into the pipe, we check the tightness of all connections - the tightness of the fittings and the quality of the tightening of the union nuts

To test the quality of the pumping station, we fill the tank with clean water. When installing the pump at the well, we check whether the water level allows the use of the pump

Before starting work, pour 1.5-2 liters of water into the pumping equipment through a special hole

Step 1 - installation of the pumping station at the selected location

Step 2 - Installing the Water Supply Fitting

Step 3 - connecting the system that provides the house with water

Step 4 - connecting the pipe leading to the well

Step 5 - install a check valve at the end of the pipe (hose)

Step 6 - Leak Testing the Complete System

Step 7 - Filling the tank with water (or checking the water level in the well)

Step 8 - a set of water to create the desired pressure

Part 2:

Image gallery

Photo from

For the station to work, it remains to connect the power supply. We find the power cord, unwind it and plug it into a 220 V outlet

Do not forget to press the "Start" button, which is usually located on the side of the case

We turn on the pressure switch to start the pump, and wait for the pressure gauge needle to reach the desired mark

When the pressure in the accumulator reaches the desired level, it will automatically turn off.

To check the correct functioning of the pumping station, we turn on one of the taps, for example, in the bathroom or in the kitchen

We monitor the operation of the pumping station, pay attention to the speed of water supply, pressure force, performance

When the water in the tank (or in the well) runs out, the dry-running protection automatically turns on and the pump stops working.

Step 9 - Lowering the end of the hose into the water

Step 10 - connecting the station to the power supply system

Step 11 - Introduction to the working state by pressing the button

Step 12 - start the pressure switch

Step 13 - the accumulator is gaining the set pressure

Step 14 - opening the tap at the water supply point

Step 15 - Check Station Functionality

Step 16 - Automatic Dry-Run Shutdown

Popular schemes for the implementation of water supply

Well or well with a depth of more than 8 meters

When lifting water from a depth of more than 8 meters, the best solution would be to use a submersible pump. When choosing, the maximum height of the water column, power, and the presence of filters are taken into account. The body must not come into contact with the walls of the well.

Advantages:

- reliable supply with high pressure;

- exclusion of freezing of the pump;

- simple drain from the system into the well;

- lack of noise of the working pump;

- use of better quality water from the second or third aquifer.

The disadvantages include:

- high cost of well construction and the pump itself;

- impossibility of service of the pump.

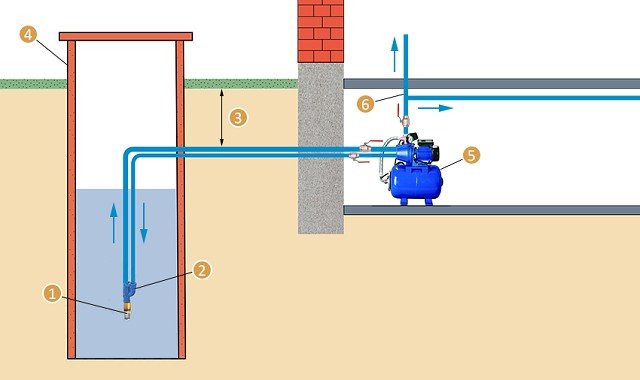

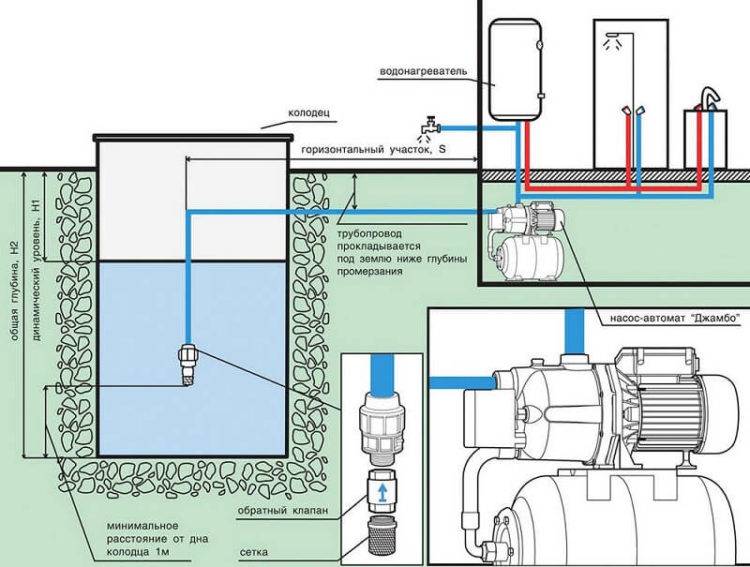

Well or well up to 8 meters deep

To lift water, you can use a pumping station, and a vibration pump from a well.

The advantages of this scheme:

- lower cost in comparison with a submersible pump and an artesian well;

- the possibility of servicing the pump;

- from the well you can take water with a bucket, in the absence of electricity.

This scheme has many more disadvantages:

- unreliable feed from a depth of more than 5 meters;

- noisy operation of the pumping station;

- for work in winter, the pumping station must be located in a warm room, therefore, the room must be located near the source (no further than 10 meters);

- rise of insufficiently pure water from the first aquifer;

- draining is difficult, you need to think over the scheme in advance;

- a small amount of hydroaccumulator at the station.

Water pressure in the water supply system in an apartment and a private house: what is the standard measured in

Home water supply is common. We get used to it so much that we only remember it when a malfunction occurs. For example, the pressure decreases, and household appliances stop working ....

Container with gravity water supply

Outdated water supply system. Its use can be justified by using a low-power pump with a water source with a small debit (flow rate). The pump during long-term uninterrupted operation, fills the tank, which can be spent just as long. The only advantage is the reserve supply of water if the pump managed to fill it before the power outage.

There are a lot of shortcomings, so we will reflect the most significant:

- load on the attic floor;

- very weak pressure, it is necessary to install household equipment taking into account this factor;

- you will need an additional pump if the pressure does not suit;

- if the automation fails, overflow from the tank is possible, it becomes necessary to drain;

- the tank and outlet must be insulated for operation in winter.

A modern alternative to a pressure tank will be a 250-500 liter storage tank, even taking into account the return of water 1/3 of its volume. Such a tank can be installed in any insulated place. Only at the entrance to the house, after the fine filter, a check valve is installed to prevent the water from draining from the tank for irrigation needs.In this case, the pump is selected, not according to the consumption of liters per minute by consumers during peak hours. And according to the debit of the water source, if it is much less than required. But at the same time, the pump must create sufficient pressure so that the pressure in the storage tank at the end of the set is at least 1.0 bar, preferably more. Taking into account the subsequent flow, the pressure will drop to 0.5-0.3 bar, and this is the minimum value for a domestic water supply.

High-quality autonomous water supply is quite possible. It depends on the literacy of the specialists who install the plumbing in the house, and the financial capabilities of the customer. The choice of water source is important. And it’s good if the owner of the house understands these issues before he starts arranging the water supply system.

Video lesson on an open water supply system:

Views:

254

One- and two-pipe pumps - which ones to choose?

Installation and connection of a household pumping station is carried out only in cases when a well is drilled in a country house with a depth of no more than 20 m. If the aquifers lie in the ground below, there will be no sense from a compact pump. In such situations, a special submersible pump should be installed.

When selecting the equipment of interest to us, one should pay attention to its technical parameters and modes of operation, and not only to the cost of the pumping station. First of all, it is necessary to determine the type of suction pipeline. Pumping station

Pumping station

It happens:

- ejector (in other words - two-pipe);

- single-pipe.

Single tube stations are very simple in design. In them, the liquid from the well enters the body of the pumping equipment used through the only available line.Do-it-yourself installation of such a unit is done without problems, and quickly enough. Pumps with two pipes are structurally more complex device. But the efficiency of its functioning is many times higher and more reliable than single-pipe equipment.

In the ejector pumping station, the rise of water is provided by a vacuum, which is formed due to a special wheel. It was originally installed in the unit. The increase in rarefaction is due to the inertia of the fluid, which makes a circular motion when the equipment is turned on. Due to this scheme, pumps with two pipes are always characterized by low power, while having a high efficiency. They are able to lift liquid from great depths. Therefore, the installation of a two-pipe pumping station is recommended for depths of 10–20 m. If the well depth is less than 10 m, feel free to install equipment with one line. It will do its job one hundred percent.

Main types of wells

To date, there are several massive, time-tested structures that will ensure the flow of water from workings in the ground. Selection of the type of well is a responsible matter, which should be based on the results of hydrogeological surveys. The use of the type of well is dictated, along with the conditions on the site, by the needs of the owners for water. After all, the water supply schemes of a summer country house with a garden and a vegetable garden and a two-story house for year-round living of two families will be very different.

Ordinary well

This attribute of country life, familiar to everyone at least from movies and cartoons, is the easiest way to get water. Its depth rarely exceeds 4-5 meters, two or three cubes of water always accumulate at the bottom.When connecting a submersible pump and water conduit equipment to the house, it is quite possible to use a well for water supply. True, intensive use of such water will not work, and its quality leaves much to be desired.

Abyssinian well

This name hides a system of thick-walled pipes with a mesh or perforated filter at the end. Pipes are hammered into the ground by a special device, colloquially referred to as a "woman". The intake end with the filter reaches the aquifer. At the top, either a manual or electric pump is arranged. The performance of this needle well is slightly greater than that of a standard well, and its installation is cheaper, but since there is no storage in the system, you will have to forget about intensive flow.

It is generally accepted that the water from the Abyssinian well is technical and is suitable only for irrigation. However, with a favorable hydrogeological situation, it may well be clean. Of course, you should not drink it without filtration and boiling, but you should wash and wash in it, since it is quite soft.

medium depth

Its second name is a well in the sand. For it, drilling is already being used to the aquifer sandy layer. Typically, the depth of this formation is 15–30 meters. To strengthen the structure, casing pipes are used - steel, and now cheaper and non-corrosive polymer pipes. Wells in the sand provide fairly clean water, which, however, is also better to pass through a filter and disinfectant. A well of medium depth has its own service life. Its failure is not even connected with the strength of the structure, but with the fact that the filter on the water intake is silted up. Over time, it becomes impossible to clean it, and you have to drill a new well.The average normal service life is about ten years. With active use, it is reduced.

Artesian

The deepest of domestic wells and serves much longer than all the others - about 80 years, or even more. But it has a tangible minus - high complexity and a large amount of work make the price very high. It's all about the depth at which drilling is carried out. An artesian well reaches a depth of more than 100 m. It passes through several soft and hard layers - loam, clay, water-bearing sand, until it reaches limestone or even harder rocks with aquifers.

A deep well in a stone does not need end casing and filters - after all, the water comes directly from the rocks, where sand is no longer found. In addition, at such a depth, water is under pressure and enters the system by gravity - a pump is already needed to supply water to the room. On the other hand, such water withdrawal already requires state registration. Well, the complexity of the work carried out determines their high cost.

Number of pressure and suction pipelines:

The number of suction lines to the pumping station, regardless of the number and groups of installed pumps, including fire pumps, must be at least two. When turning off one line, the rest should be designed to skip the full design flow for pumping stations of categories I and II and 70% of the design flow for category III. The device of one suction line is allowed for category III pumping stations.

The number of pressure lines from pumping stations of categories I and II must be at least two. For category III pumping stations, one pressure line is allowed.

The pressure line of each pump must be equipped with a shut-off valve and a check valve installed between the pump and the shut-off valve.

When installing mounting inserts, they should be placed between the shut-off valve and the non-return valve.