- Types of pumping stations and distance to the water table

- Pump stations with built-in ejector

- Pumping stations with remote ejector

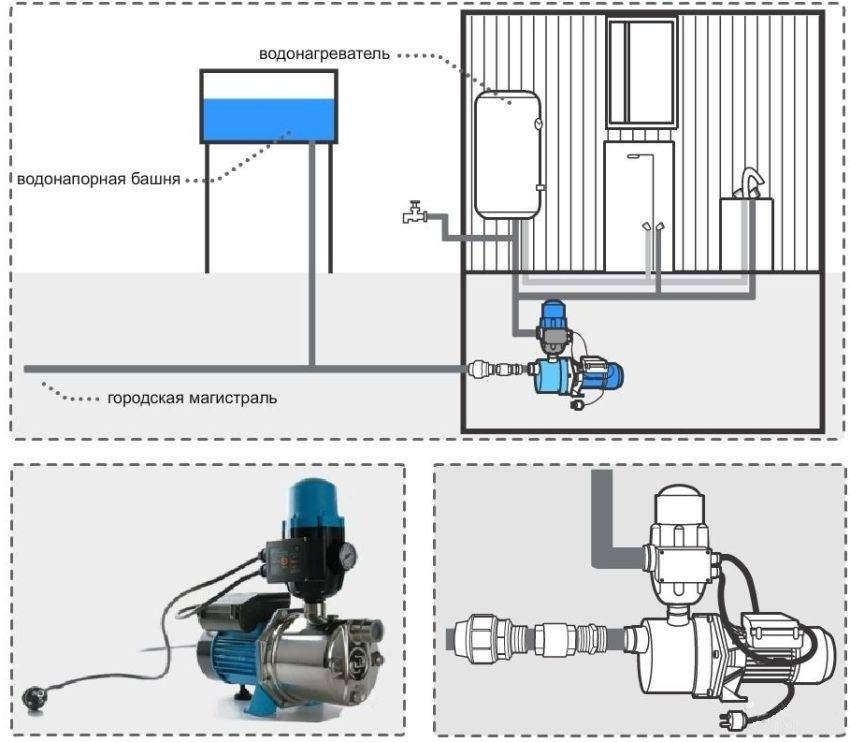

- Choosing a place to install

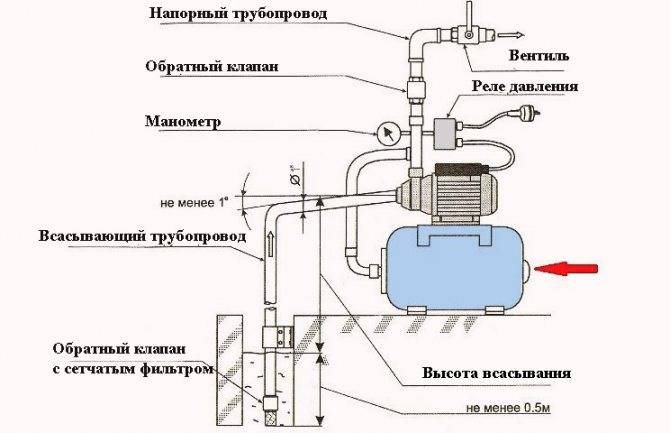

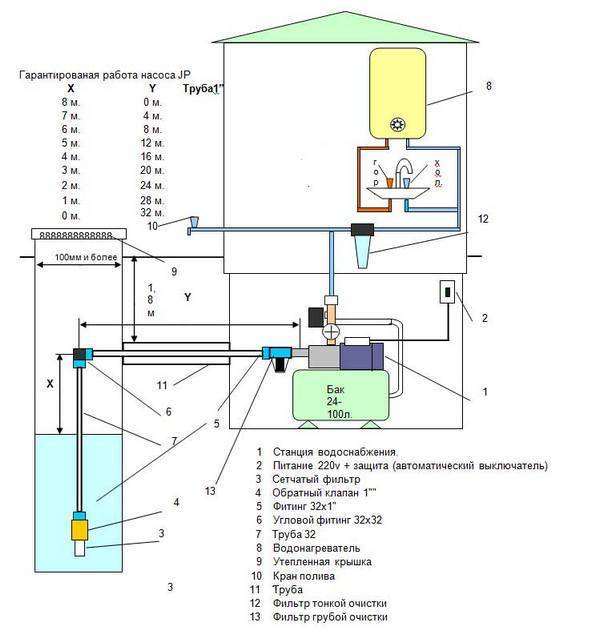

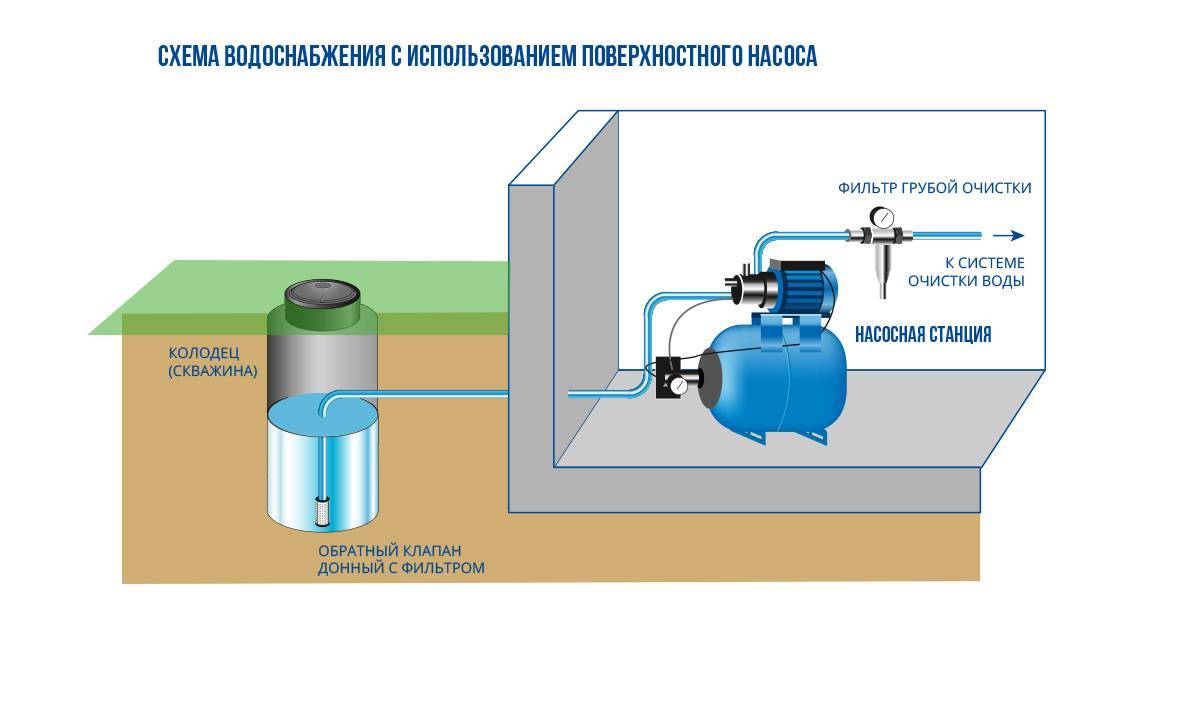

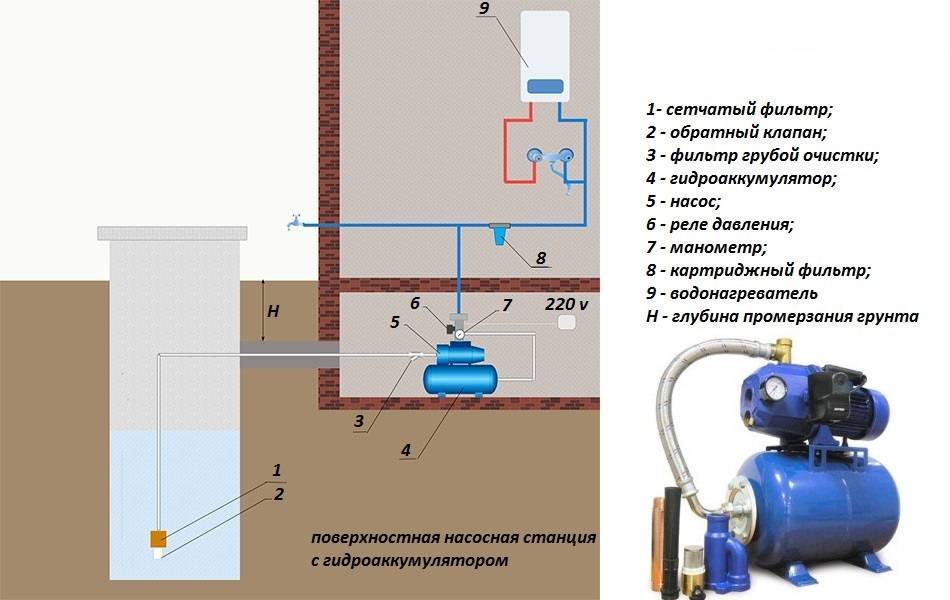

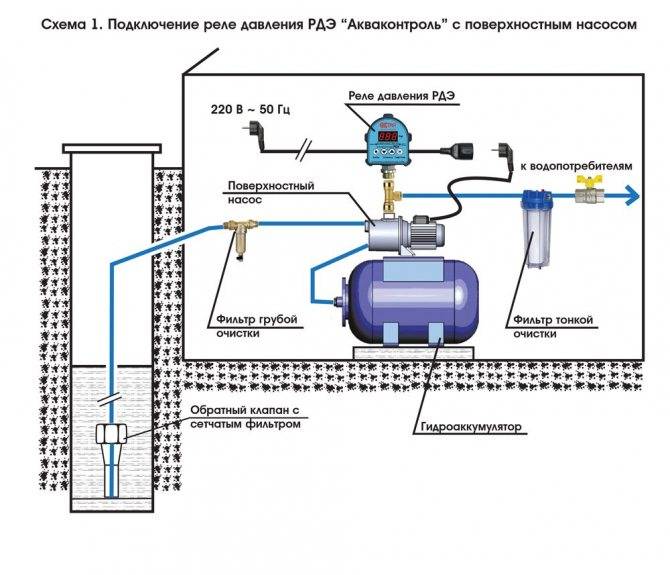

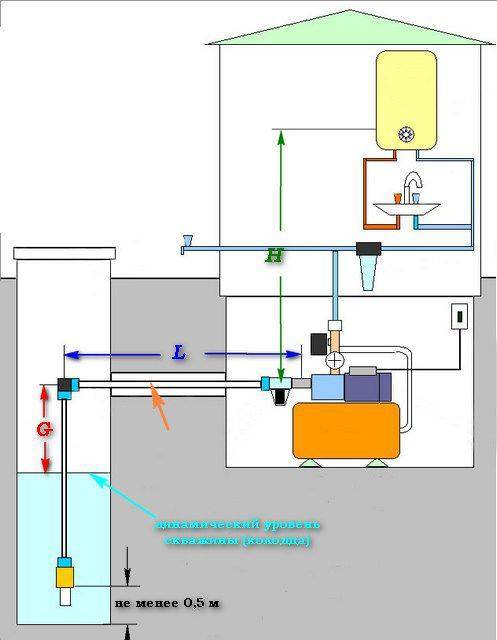

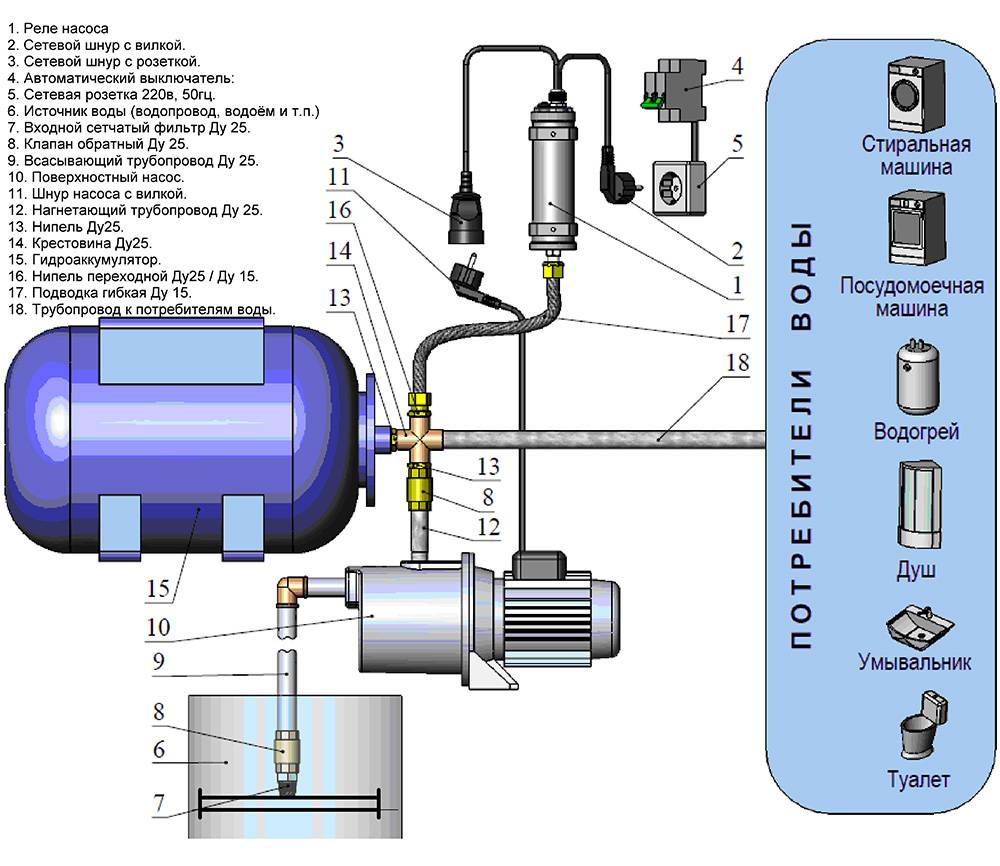

- Scheme of connecting a pumping station to a well in the country

- How to calculate the volume of a hydraulic accumulator?

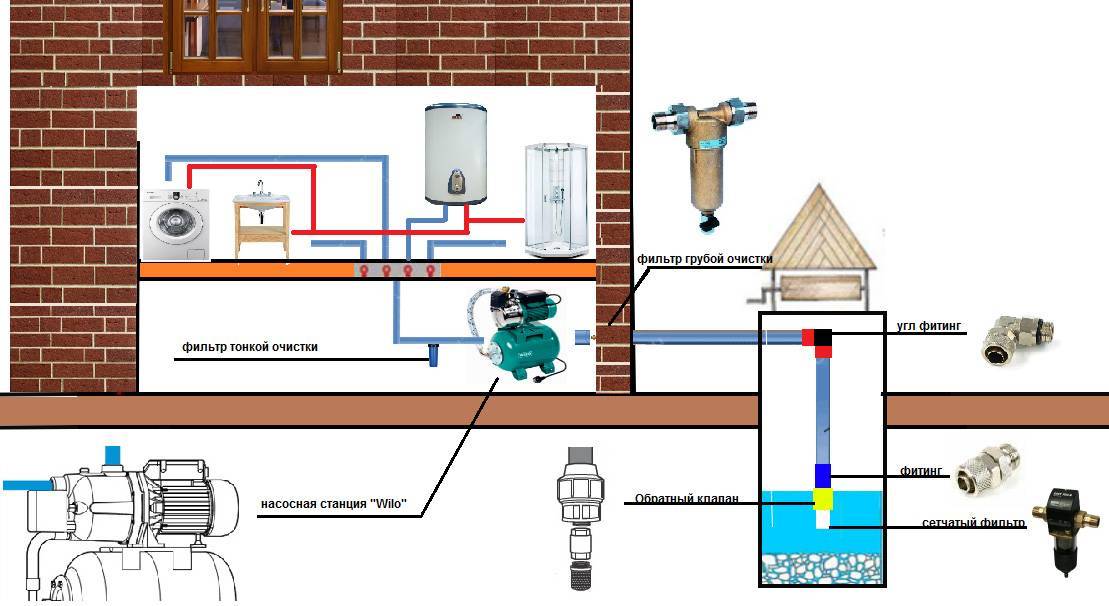

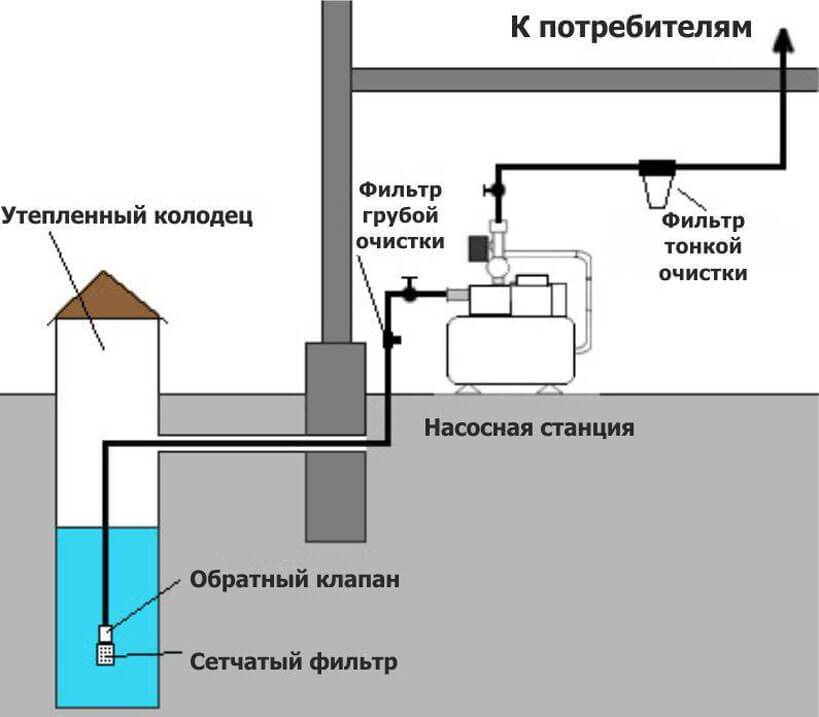

- Water purification

- Models

- Tips

- A few valuable tips

- Starting the pumping station

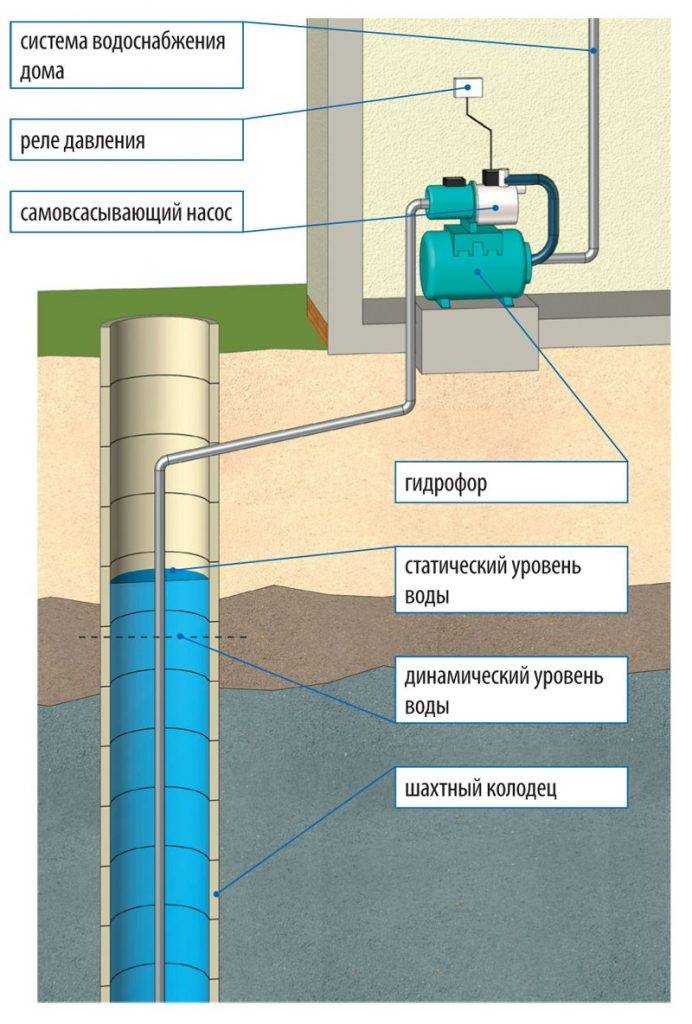

- Well types and pump selection

- Types of pumps

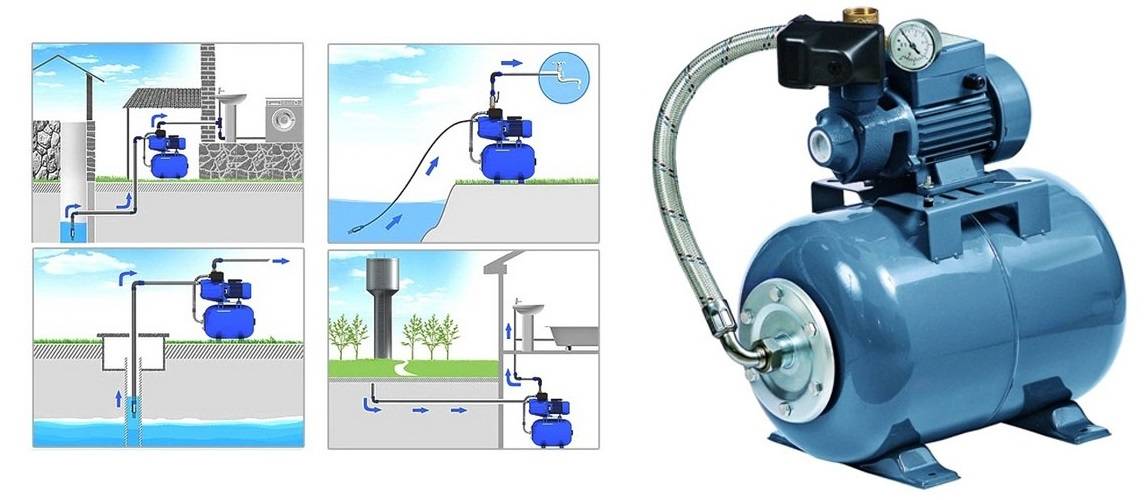

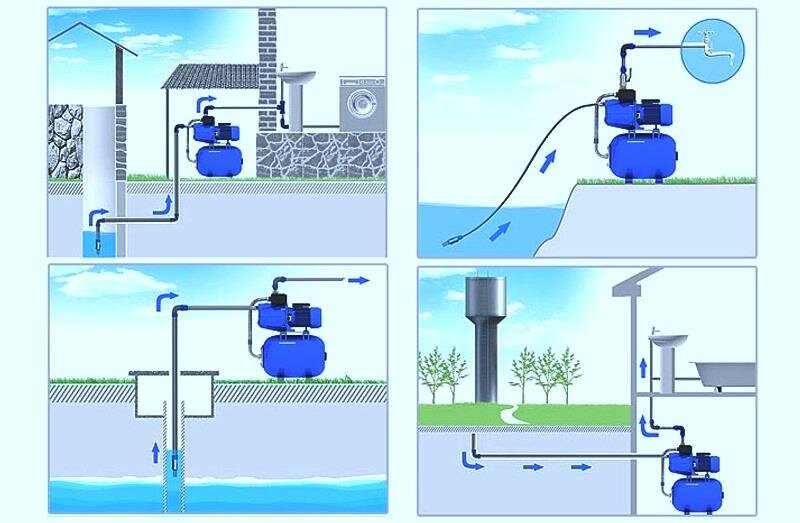

- Use of pumping systems

- Rating of pumping stations

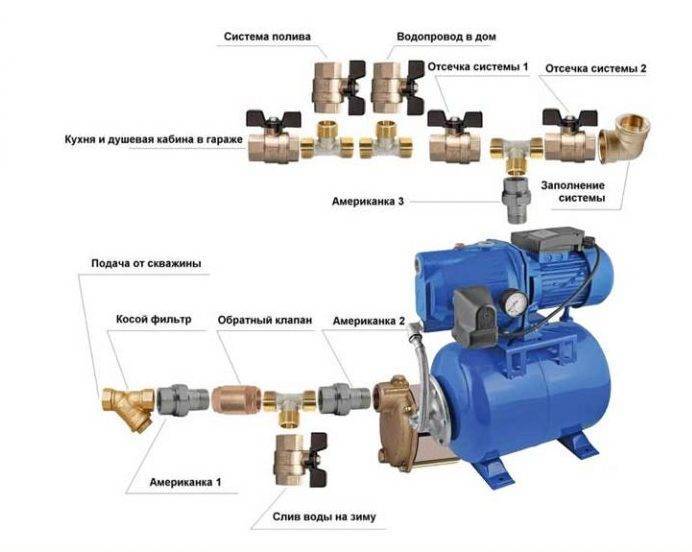

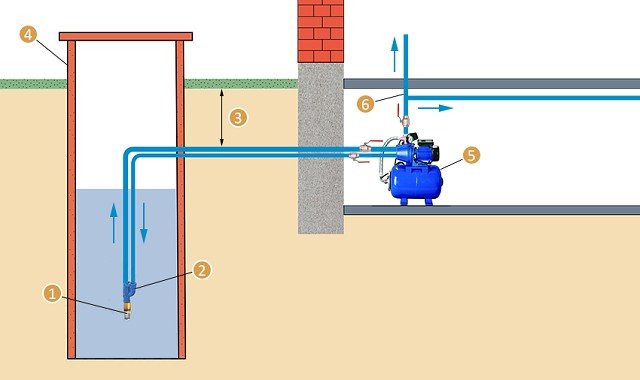

- Assembly and connection of a pumping station with a suction pump

Types of pumping stations and distance to the water table

There are pumping stations with a built-in and remote ejector. The built-in ejector is a structural element of the pump, the remote one is a separate external unit, immersed in the well. The choice in favor of one or another option depends primarily on the distance between the pumping station and the water surface.

From a technical point of view, the ejector is a fairly simple device. Its main structural element - the nozzle - is a branch pipe with a tapered end. Passing through the place of narrowing, the water acquires a noticeable acceleration. In accordance with Bernoulli's law, an area with low pressure is created around a stream moving at an increased speed, i.e., a rarefaction effect occurs.

Under the action of this vacuum, a new portion of water from the well is sucked into the pipe.As a result, the pump spends less energy to transport liquid to the surface. The efficiency of pumping equipment is increasing, as is the depth from which water can be pumped.

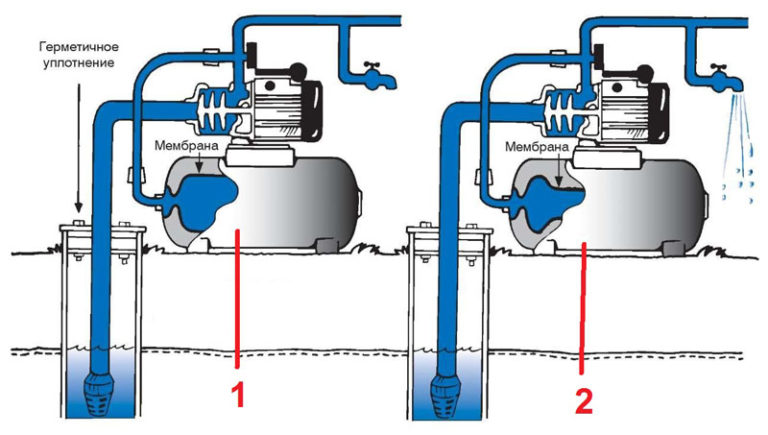

Pump stations with built-in ejector

Built-in ejectors are usually placed inside the pump casing or located in close proximity to it. This reduces the overall dimensions of the installation and somewhat simplifies the installation of the pumping station.

Such models demonstrate maximum efficiency when the suction height, i.e., the vertical distance from the pump inlet to the level of the water surface in the source, does not exceed 7-8 m.

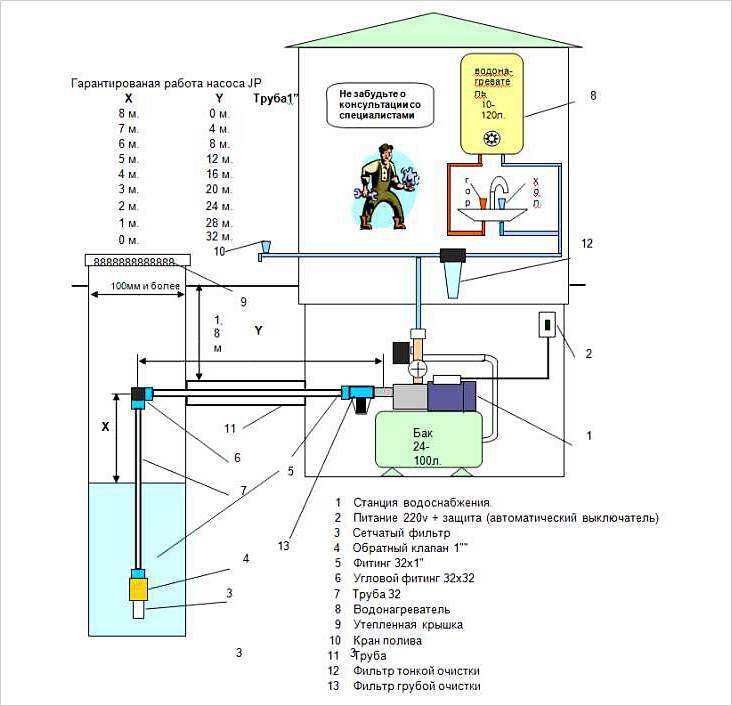

Of course, one should also take into account the horizontal distance from the well to the location of the pumping station. The longer the horizontal section, the smaller the depth from which the pump is able to lift water. For example, if the pump is installed directly above the water source, it will be able to lift water from a depth of 8 m. If the same pump is removed from the water intake point by 24 m, then the depth of water rise will decrease to 2.5 m.

In addition to low efficiency at large depths of the water table, such pumps have another obvious drawback - an increased noise level. The noise from the vibration of a running pump is added to the sound of water passing through the ejector nozzle. That is why it is better to install a pump with a built-in ejector in a separate utility room, outside a residential building.

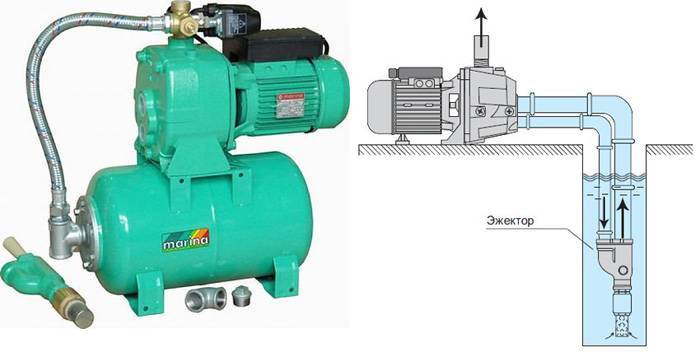

Pumping station with built-in ejector.

Pumping stations with remote ejector

The remote ejector, which is a separate small unit, unlike the built-in one, can be located at a considerable distance from the pump - it is connected to the part of the pipeline immersed in the well.

Remote ejector.

To operate a pumping station with an external ejector, a two-pipe system is required. One of the pipes is used to lift water from the well to the surface, while the second part of the raised water returns down to the ejector.

The need to lay two pipes imposes some restrictions on the minimum allowable well diameter, it is better to foresee this at the design stage of the device.

Such a constructive solution, on the one hand, allows to significantly increase the distance from the pump to the water surface (from 7-8 m, as in pumps with built-in ejectors, to 20-40 m), but on the other hand, it leads to a decrease in the efficiency of the system to 30- 35%. However, having the opportunity to significantly increase the depth of water intake, you can easily put up with the latter.

If the distance to the water surface in your area is not too deep, then there is no need to install a pumping station directly near the source. This means that you have the opportunity to move the pump away from the well without a noticeable decrease in efficiency.

As a rule, such pumping stations are located directly in a residential building, for example, in the basement. This improves equipment life and simplifies system setup and maintenance procedures.

Another undoubted advantage of remote ejectors is a significant reduction in the noise level produced by a working pumping station. The noise of water passing through an ejector installed deep underground will no longer disturb the residents of the house.

Pumping station with a remote ejector.

Choosing a place to install

It is not difficult to make a pumping unit for a private house or cottage with your own hands. However, at the same time, it is necessary to solve the question of how and where to install the pumping station correctly. The place for installing a pumping station, on the correct choice and arrangement of which the efficiency of the equipment will depend, must meet certain requirements.

- If drilling a well or arranging a well on a personal plot has already been completed, then the pumping station is mounted as close as possible to the source of water supply.

- In order to protect pumping equipment from water freezing during the cold season, the installation site must be characterized by comfortable temperature conditions.

- Since pumping units require regular maintenance, free access must be provided to their installation site.

Based on the above requirements, a caisson or a separate and specially equipped room is used as a place to install a pumping station in a country house or in a private house.

Ideally, a place for a pumping station should be provided at the stage of building a house, allocating a separate room for this

Sometimes they install pumping units in buildings that already exist on the territory of the infield. Each of these options has its pros and cons, which should be discussed in more detail.

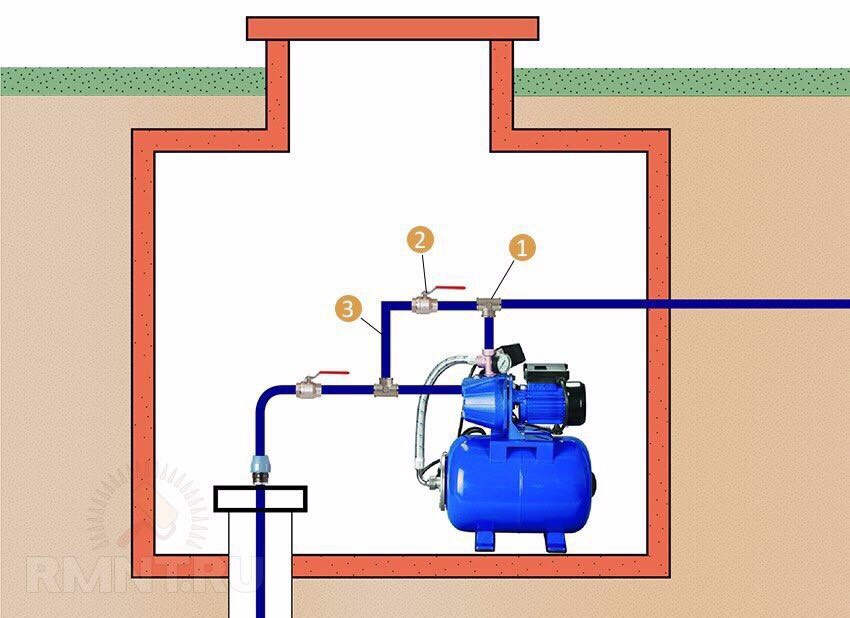

Placing a pumping station in a separate room in a building with a well drilled under the house

The scheme for installing a pumping station in the basement of a house is an almost ideal option for locating such equipment. With this installation scheme, easy access to the equipment is provided, and the issue of reducing the noise level generated during the operation of the station is also easily solved. This option will be most successful if the pump room is heated.

Placing a pumping station in a warm equipped basement

If the pumping unit is located in an outbuilding, quick access to it is somewhat difficult. But with such a scheme for connecting a pumping station, the problem with noise from the operation of the equipment is radically solved.

The station can be installed on a bracket in a sufficiently wide and deep well

Installing the station in a caisson will provide frost protection and complete sound insulation

Quite often, pumping stations are mounted in a caisson - a special tank that is installed above the head of the well, directly into the pit. A caisson can be either a plastic or metal container buried in the ground below its freezing level, or a permanent underground structure, the walls and base of which are made of concrete or finished with brickwork. It should be borne in mind that when installing a pumping station in a caisson, access to equipment is rather limited. In addition, if a connection scheme of this type is used for a pumping station, then the pipeline section between the pumping equipment and the building it serves must be carefully insulated or placed in the ground at a depth below the freezing level.

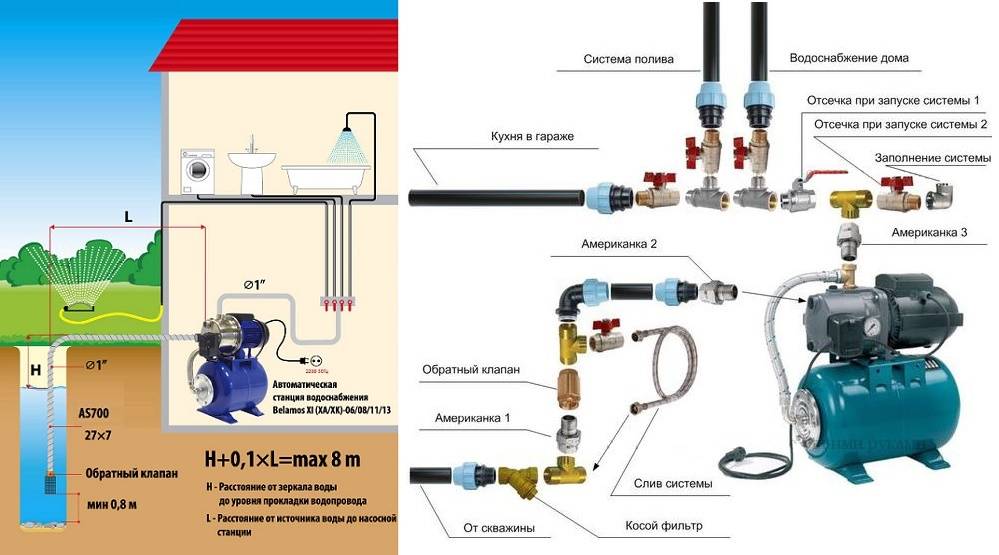

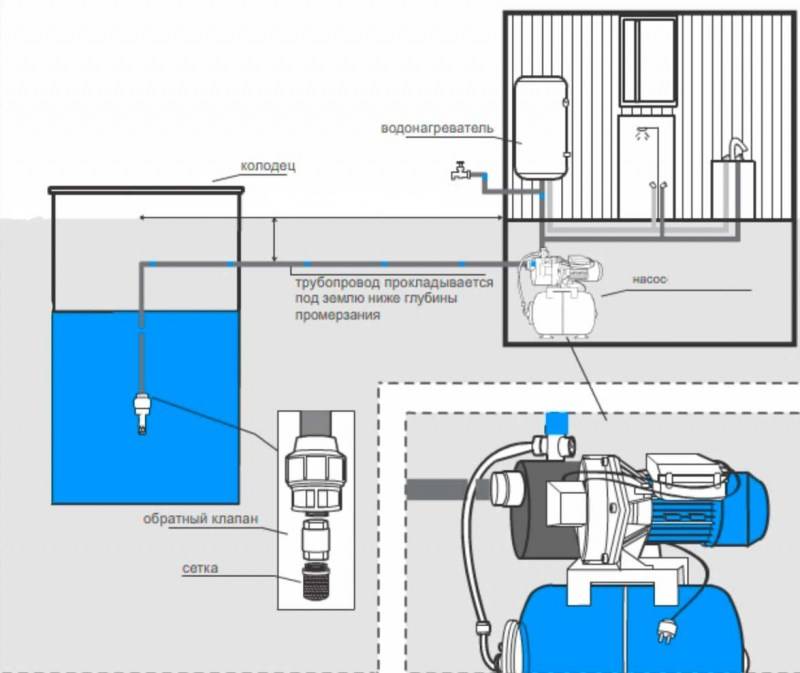

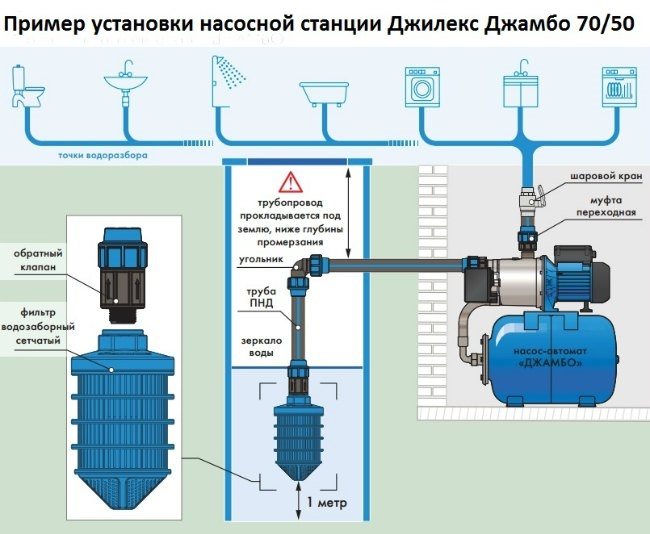

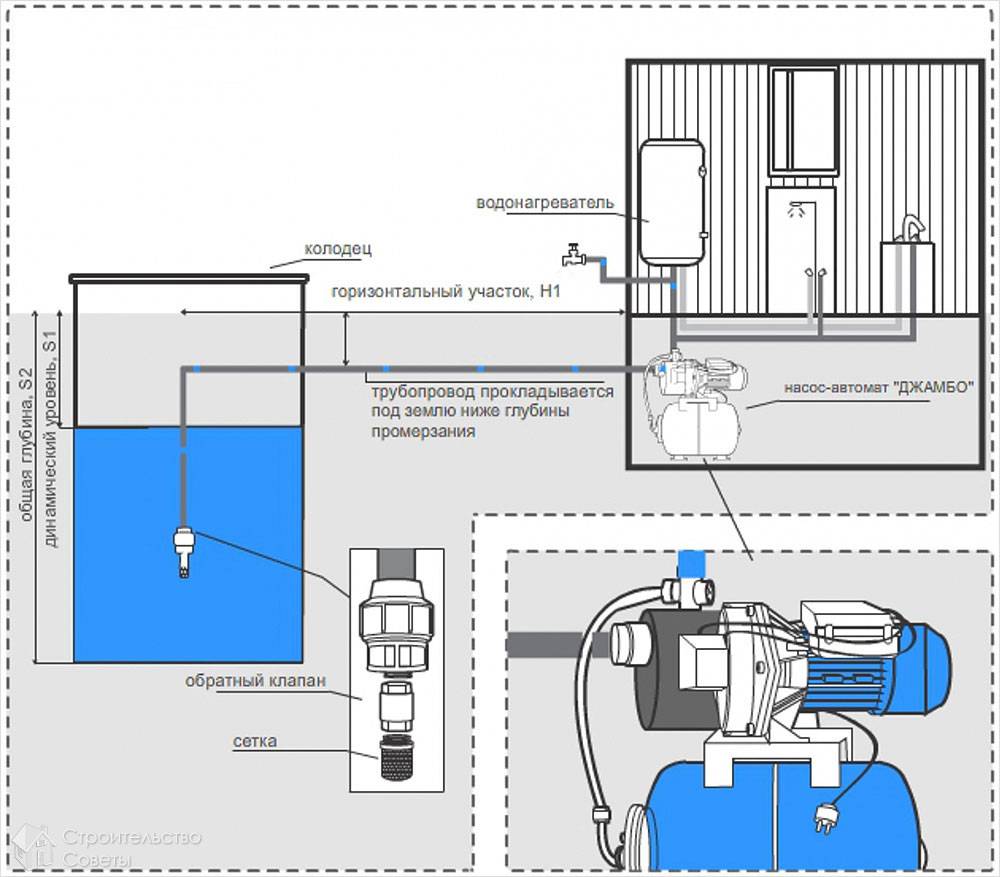

Scheme of connecting a pumping station to a well in the country

The pumping station can be placed inside the well, if there is a place for this, in addition, utility rooms are often allocated for it in the house itself or in the room

Pay attention to the depth at which the pipeline will be. The pipe must not only be insulated, but also placed below the freezing depth of the soil, so that during the cold season the water in it does not freeze

In order for the system to work correctly, you need to choose not only the type of pump, but also the depth at which it will work. The deeper the water source and the farther it is from the building, the more powerful the pump itself must be. There should be a filter at the end of the pipe, it is located between the pipe and the pump, protecting the latter from debris entering the mechanism.

Devices usually write at what depth they are designed, but it is worth taking a more powerful one, since the calculation is carried out only from the bottom of the well to its surface, not taking into account the distance to the building. It is easy to calculate: 1 meter of the vertical location of the pipe is 10 meters of its horizontal location, since it is easier to supply water in this plane.

Depending on the type and power of the pump, the pressure may be stronger or weaker. It can also be calculated. On average, the pump provides 1.5 atmospheres, but this is not enough pressure for the normal operation of the same washing machine or hydromassage, the water heater may require a higher temperature.

In order to control the pressure, the equipment is equipped with a barometer. Depending on the pressure parameter, the size of the storage tank is also calculated. Station performance also plays an important role. This parameter indicates how many cubic meters per minute the pump is capable of delivering.You need to calculate based on peak water consumption, that is, when all the taps in the house are open or several consumer electrical appliances are working. In order to calculate which pumping station is suitable for giving in a well, you need to know the performance. To do this, add up the number of water supply points.

From the point of view of power supply, it is more convenient to use those systems that are powered by a 22-volt network. Some stations operate 380 V phases, but such motors are not always convenient, because a three-phase connection is not available in every home. The power of a household station may vary, on average it is 500-2000 watts. Based on this parameter, RCDs and other devices are selected that will work in conjunction with the station. In order to prevent the design from overheating, many manufacturers install automation that will turn off the pumps in the event of an emergency load. The protection also works if there is no water in the source when power surges occur.

How to calculate the volume of a hydraulic accumulator?

The size of the tank determines how often the pump motor will turn on. The larger it is, the less often the installation works, which allows you to save on electricity, increase the resource of the system. Too large a hydraulic accumulator takes up a lot of space, so a medium-sized one is usually used. It holds 24 liters. This is enough for a small house in which a family of three lives.

Trailer work accumulator expansion tank

If up to 5 people live in the house, then it is better to install the tank at 50 liters, respectively, if more than 6, it should be at least 100 liters.It is worth noting that the standard tanks of many stations hold 2 liters, such a hydraulic tank can only cope with water hammer and maintain the required pressure, it is better not to save money and immediately replace it with a large one. It is the number of water users in the house that will determine which pumping station to choose for a summer residence.

Water purification

Do not forget that the water from the well, even if it is suitable for drinking, may have impurities, for example, sand, small stones, various debris can get into it, which can be disposed of using a special system for water purification. The most commonly used filters. They are placed outside so that it is convenient to change them. They can have different fractions and purify water to varying degrees. At the outlet, deep fine filters are used.

Models

- Gilex.

- Vortex.

- Ergus.

- Bison.

- gardena.

- Wilo SE.

- Karcher.

- Pedrollo.

- grundfos.

- Wilo.

- Poplar.

- Unipump.

- Aquario.

- Aquarius.

- Biral.

- S.F.A.

- Vortex.

- waterstry.

- Zota.

- Belamos.

- Pedrollo.

Before choosing a pumping station for a summer residence with a well, it will not be superfluous to find out how things are with the maintenance of the products of the selected manufacturer, are there any nearest dealers who can provide spare parts.

Tips

- After the water supply in the house is established with the help of a pumping station, it needs to be serviced periodically. First of all, it is required to constantly monitor the condition of the coarse filter and, if necessary, clean it. If this is not done, then the performance of the station will decrease, and the water will go in jerks.In the event that the filter is completely clogged, the pump will run in idle mode, and as a result, the station will turn off. How often you have to clean the filter depends on the amount of impurities in the water.

- It is advisable to check the pressure in the air compartment of the accumulator once a month, after downtime, repair or conservation for the winter. It should be at the level of 1.2-1.5 atmospheres. If necessary, air must be pumped up using a compressor or a car pump. If the station is used exclusively during the summer period, it is imperative to drain the water from the system before frosts come.

- When installing, it is better to use pipes with a value greater than the calculated one. This will compensate for various bends, turns, as well as the thickness of the foundation, if the station is installed in the house.

- It is best to tighten parts during installation or repair with a key. If this operation is performed by hand, leaks may appear in the future.

- When the pumping station is connected, to regulate it and determine the pressure level at which it turns off, approximately two liters of water must be poured into the receiving device. After that, the pump is put into operation. At the moment when the station is turned off, it is necessary to register the level of water pressure. You also need to know the pressure value when the station starts automatically.

How to connect a pumping station, see the following video.

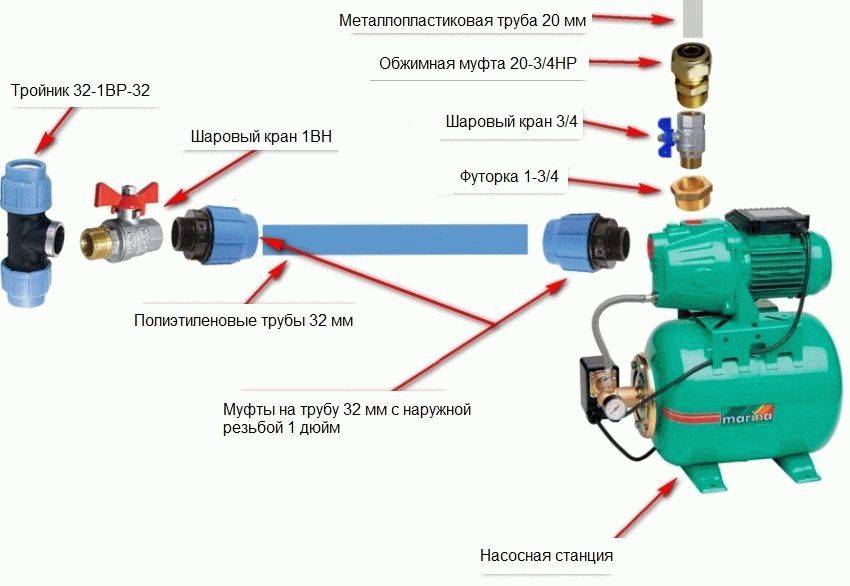

A few valuable tips

Threaded connections must be tightened with a wrench, not by hand, to ensure the necessary tightness.To connect fittings, protective devices and the pumping station itself, it is better to use pipes whose diameter is slightly larger than the calculated one in order to compensate for the load increased due to bends in the main.

The recirculation line will protect the pump and will increase the water pressure in the system. A tee is required to install the return line.

To protect the pump from idling, a recirculation line can be installed. To do this, tees are placed on the supply and suction pipes and the free pipes are connected by a return line.

A valve should be placed on it, which allows you to control the intensity of the reverse flow. Such an addition will improve the pressure, but will somewhat reduce the performance of the device.

A bracket can be used as a base for the pumping station, but it must be level on shock absorbing pads so that vibration is minimal

The pumping station is placed on a perfectly flat base, equipped with shock-absorbing pads. This will reduce the vibration impact and also reduce the amount of noise.

Approximately every three months it is necessary to check:

- condition of joints for leaks.

- the condition of the filters for timely cleaning.

- relay settings for their correction;

- the condition of the hydraulic tank to determine the location of leaks.

If the pressure level in the HA does not meet the required level, it is easy to pump it up using a compressor or pump. On large containers, a nipple connection is provided for this. If liquid flows from the hole, then the internal membrane is torn and needs to be replaced.

Starting the pumping station

In order to put the pumping station into operation, it is necessary to completely fill it and the supply pipeline with water.For this purpose, there is a special filler hole in the body. Pour water into it until it appears. We twist the plug into place, open the tap at the outlet to consumers and start the station. At first, water goes with air - air plugs come out, which formed during the filling of the pumping station. When the water flows in an even stream without air, your system has entered the operating mode, you can operate it.

If you filled in water, and the station still does not start - the water does not pump or comes in jerks - you need to figure it out. There are several possible reasons:

- there is no non-return valve on the suction pipeline lowered into the source, or it does not work;

- somewhere on the pipe there is a leaky connection through which air is leaking;

- the resistance of the pipeline is too high - you need a pipe of a larger diameter or with smoother walls (in the case of a metal pipe);

- water mirror is too low, not enough power.

To prevent damage to the equipment itself, you can start it by lowering the short supply pipeline into some kind of container (tank of water). If everything works, check the line, suction depth and check valve.

Well types and pump selection

For autonomous water supply, two types of wells are used: “for sand” and “for lime”. In the first case, drilling is carried out to an aquifer of coarse sand, in the second case, to aquiferous porous limestone formations. Each locality has its own characteristics in terms of the occurrence of such layers, but the common thing is that the depth of drilling into sand is much smaller and is usually in the range of 15–35 m.

1. Well for limestone. 2. Well on the sand. 3. Abyssinian well

It is easier to drill sand wells, but they have low productivity, and during long breaks in work (for example, seasonal residence), there is a threat of silting of the galloon filter.

The "heart" of any autonomous water supply system is the pump. Both the sand well and the lime well operate with submersible pumps. The pump is selected depending on the depth of the well and the required performance of the system, and this directly affects its price.

Many different models of borehole pumps are produced and among them it is necessary to choose the best option in terms of technical characteristics and dimensions.

There is another type of well - the Abyssinian well. The difference is that the well is not drilled, but pierced. The “working” lower section of the pipe has a pointed tip, which literally breaks through the soil to the aquifer. As well as for a sand well, this pipe section has a perforation closed with a galloon mesh filter, and in order to keep the filter in place during the puncture, the diameter at the tip is larger than that of the pipe. The pipe itself performs two functions at the same time - casing and transporting water.

Initially, the Abyssinian well was conceived to work with a hand pump. Now, for the water supply of private houses from the Abyssinian well, surface pumps are used, which, taking into account the depth of the caisson, can work with wells up to 10 meters (and even then, provided that the pipe diameter is not more than 1.5 inches). The advantages of this type of well include:

- ease of manufacture (provided that there is no outcrop of rock on the site);

- the possibility of arranging the head not in the caisson, but in the basement (under the house, garage, outbuilding);

- low cost pumps.

Flaws:

- short service life;

- poor performance;

- unsatisfactory water quality in regions with poor ecology.

Types of pumps

If groundwater is deeper than eight meters, it is better to purchase more efficient submersible pumps designed to draw water from wells or wells.

Use of pumping systems

For comfortable water supply of a country house and a garden plot, pumping stations are used. This equipment, in addition to the pump, includes a storage tank and an automatic switch-on system when using water. The water tank is filled to the required level, when water is consumed for domestic needs, the automation turns on the pump and replenishes the water in the tank. The cost of pumping stations starts from 5 thousand rubles.

Rating of pumping stations

Before writing the rating, customer reviews were analyzed, consultations were held with sellers and plumbers. The selection took into account many characteristics, and the most important were the following:

- The volume of the accumulator;

- Maximum head and suction depth;

- Power;

- Current consumption;

- Noise level;

- Required temperature and water quality (pure or with impurities);

- throughput;

- The presence of a frequency converter, pressure sensor and ejector;

- Is there built-in protection against overload, dry running, leakage and overheating;

- Strength and stability of the body;

- Dimensions and weight;

- Mounting method - vertical or horizontal;

- Duration of the warranty period.

Ease of use and value for money were also important parameters.The review is presented by 7 leaders who were selected as a result of a thorough analysis of 20 applicants.

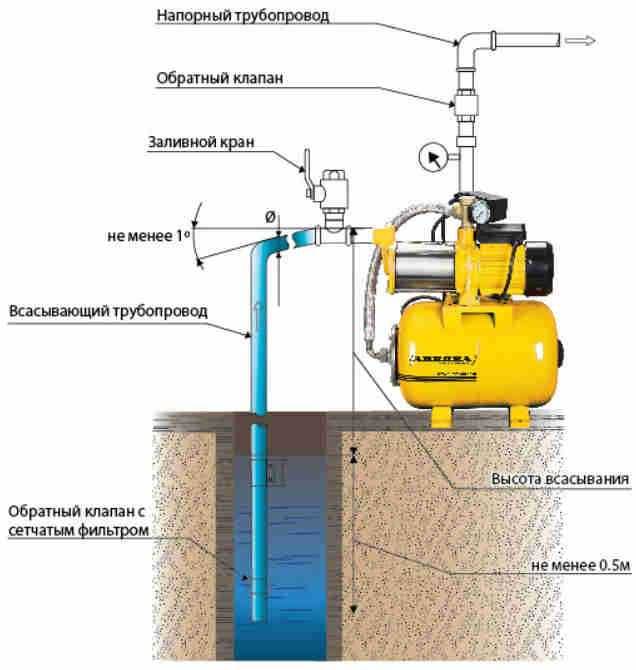

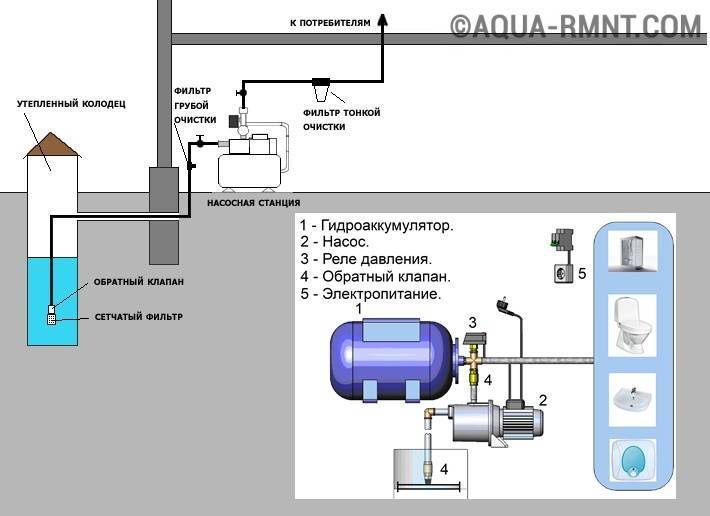

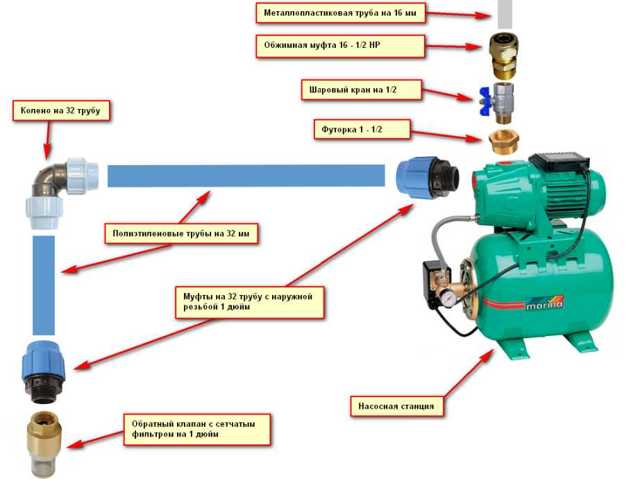

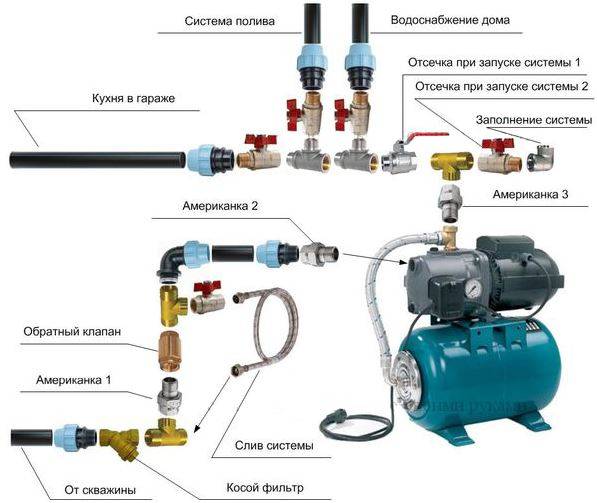

Assembly and connection of a pumping station with a suction pump

Description of the assembly and composition of the first version of our pumping station, we will begin with suction pump stations. This solution has its pluses, which, upon closer examination, automatically become minuses.

Let's try to "dig" to those and others, having examined in more detail all the features of a station with a suction pump. The first significant plus of such pumping stations is their wide distribution and the ability to meet "ready-made solutions".

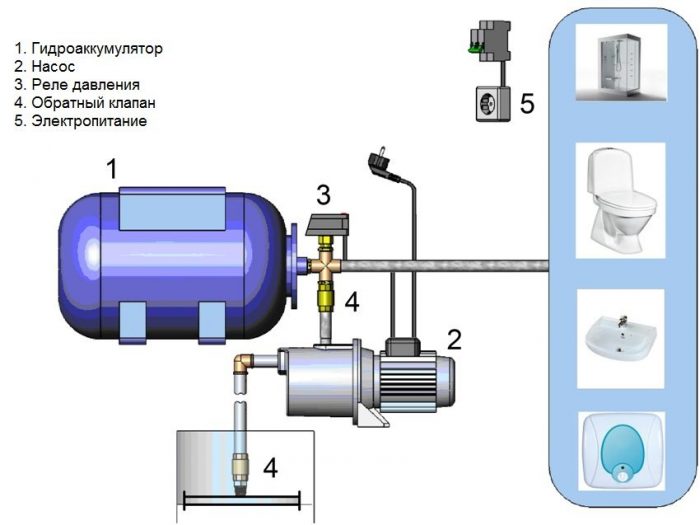

By "ready-made solutions" we mean pre-assembled kits consisting of a receiver, a pump, a piping between them, a pressure control switch, a pressure gauge. Such kits are good in that you will not need to collect an already certain part of the plumbing and elements to provide water supply. The second advantage of such a station is that the pump and all the main elements of the system are above the ground, which greatly facilitates their maintenance and replacement.

The disadvantages of a pumping station with a suction pump will be that the characteristics that are already included in the pre-assembled pumping stations may turn out to be unacceptable for you. So, for example, the receiver will be small or the pump will not provide the proper suction lift. In addition, the suction pump will require high tightness from the suction pipe, and a check valve will also be needed to keep the water column from the well to the pump.

Otherwise, you will need to constantly add water to the nozzle to prevent air build-up and keep the pump running.

The assembly (diagram) of a pumping station with a suction pump is carried out according to the following principle

Please note that when calculating the length of the suction pipe, one vertical meter equals one horizontal meter (1:4). That is, when calculating the suction height, when choosing a pump (pumping station), it is necessary to take into account the length of the suction pipe, both vertically and horizontally. The characteristic of the ascent depth is given conditionally (8 meters), for your station this indicator may be different. See the specifications in the passport for the pumping station or pump. I would also like to additionally note the presence of a tap to fill the suction pipe with water

See the specifications in the passport for the pumping station or pump. I would also like to additionally note the presence of a tap to fill the suction pipe with water

The characteristic of the ascent depth is given conditionally (8 meters), for your station this indicator may be different. See the specifications in the passport for the pumping station or pump. Also, in addition, I would like to note the presence of a tap to fill the suction pipe with water.

This system is not shown in the picture above, but is shown in the photo below. (yellow funnel - pipe - tap on a tee)

Naturally, all connections must guarantee maximum tightness, and all shut-off and control valves of the water supply system must be in good order.