- Installation and layout of the station

- The main approaches to the choice of pumping equipment for a private house

- Popular brands

- What are the pumping stations for a private house

- Device

- Choosing a pumping station What does it consist of?

- Rating of the best pumping stations

- What to look for when buying?

- How to connect

- Place

- Food

- suction pipe

- Capacity

- Water pipes

- Ejector

- Add-ons and accessories

- Optional equipment

- Filters

- check valve

- Protective automation

- First meeting

- A special case

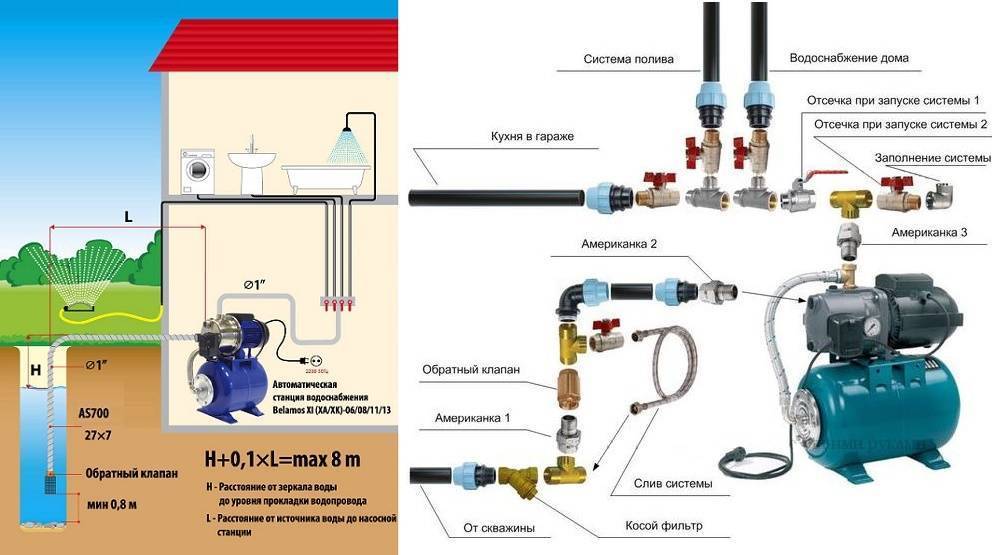

Installation and layout of the station

The installation of a pumping station in a private house is carried out either by specialists or by the owners. In the latter case, step-by-step instructions are often required. The first stage in it is the development of a scheme for installing equipment. You can draw on a computer or plain paper.

The second stage is the preparation of the station and filters, if they are not included in the basic package. You will also need a check valve, connectors, fum tape, a clerical knife, screwdrivers, watering pistols, supply hose and corrugated for fluid intake.

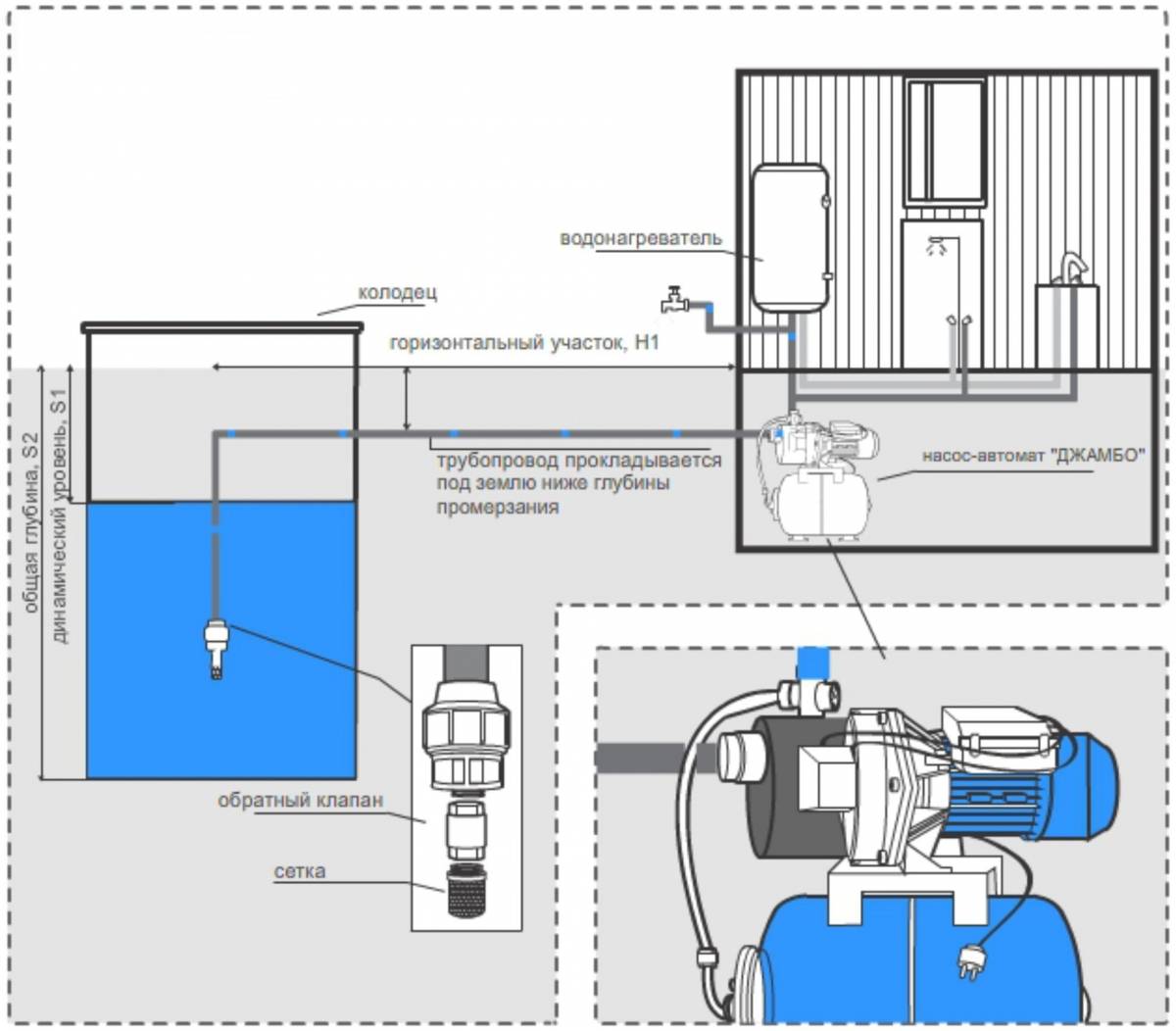

According to the scheme, the equipment is lowered into the well, wells, or installed on a "pedestal" in the utility room. In this case, a corrugation with a diameter of the pump outlet or more is supplied.

The connection is sealed with fum-tape. Simply put, this is a PTFE film.At the opposite end of the corrugated hose, a check valve of the intake type is placed.

Having dealt with the corrugation, you need to connect the station to the water supply system. connectors are used. Such adapter devices are used not only in the installation of pumps, but also when connecting to the Internet, TV signal.

After connecting the pump to the water supply system, the built-in filter or the filling head of the device is filled with water, the outlet connection is wrapped. This prepares the stations for operation.

The next step is to connect the cable from the pump to the outlet. Next, the faucets open slightly - you need to bleed the air. When the pump turns on and water is supplied, the taps are blocked. The system has been put into operation. Connecting a pumping station is considered easy, affordable for most homeowners to master.

The main approaches to the choice of pumping equipment for a private house

If you are going to choose a suitable station for an apartment or a country house, you must clearly understand the conditions for its operation and the technical characteristics that it must satisfy

First of all, pay attention to the type of water source. The suction depth of the unit must be selected in accordance with the level of the aquifer, taking into account the distance of the horizontal laying of the intake pipeline

This issue is closely related to the intended location of the pump.

The main parameters of the pumping station are:

- Maximum performance. Peak consumption for a family of 4-6 people living in a cottage rarely exceeds 1.5-2 m3 / h, but there are exceptions related to the type and number of installed plumbing equipment and other water consumption devices.

- Head.It must correspond to the installation height of consumption devices, taking into account the hydraulic resistance of pipelines.

- Engine power input, directly related to flow and pressure.

- The volume of the accumulator, on which the frequency of switching on the pump depends. In most cases, containers of 25-40 liters are chosen for an individual house.

If the hydraulic calculation of the pumping station shows some margin of opportunity, then it is better to install it in a heated room that is convenient for maintenance. In the case of using deep wells, you will have to use a submersible pump or pick up a surface model with an external ejector, equipping a caisson directly above the water intake.

The intended mode of operation of the station is of great importance. With a rare inclusion, it is better to buy a conventional pump for a manual water supply system, but for the sake of ease of use, they often opt for automated systems. They cost a little more, but they save on running costs.

Advice! In the process of communicating with the seller and studying the technical documentation, you need to make sure that the equipment meets the characteristics of the pumped medium. Drinking water systems must be made from safe materials. In the passport of the unit for hot water, the corresponding temperature range of use must be indicated.

Popular brands

The most popular water supply pumping stations for a private house today are Gileks Jumbo. They are low priced and good quality. They are produced with pumps made of cast iron (the letter “Ch” in the marking), polypropylene (it stands for “P”), and stainless steel (“H”). There are also numbers in the marking: “Jumbo 70-/50 P - 24.It is deciphered as follows: 70/50 - the maximum water flow is 70 liters per minute (productivity), the head is 50 meters, P is a polypropylene body, and the number 24 is the volume of the accumulator.

Pumping water supply stations for a private house Gileks outwardly similar to units from other manufacturers

The price of a pumping station for water supply at home Gileks starts at $ 100 (mini options with low power and for low flow in a polypropylene case). The most expensive unit with a stainless steel case costs about $350. There are also options with a borehole submersible pump. They can lift water from a depth of up to 30 meters, flow rate up to 1100 liters per hour. Such installations cost from $450-500.

Gileks pumping stations have installation requirements: the diameter of the suction pipeline must be no less than the diameter of the inlet. If the water rises from a depth of more than 4 meters and at the same time the distance from the water source to the house is more than 20 meters, the diameter of the pipe lowered from the well or well must be greater than the diameter of the inlet. This must be taken into account when installing the system and piping the pumping station.

Reviews of JILEX JAMBO 60/35P-24 (in a plastic case, cost $130) you can see in the photo below. This is part of the impressions left by the owners on the trading site.

Reviews of the pumping station water stations GILEX JUMBO 60/35P-24 (to increase the size of the picture, click on it with the right mouse button)

Grundfos pumping stations (Grundfos) work well with water supply at home. Their body is made of chrome steel, hydraulic accumulators for 24 and 50 liters. They work quietly and reliably, provide stable pressure in the system. The only drawback is that spare parts are not supplied to the Russian market.If, suddenly, something breaks, you will not find “native” elements. But it must be said that the units break down infrequently.

Prices for pumping stations with surface pumps start at $ 250 (power 0.85 kW, suction depth up to 8 m, capacity up to 3600 liters / hour, height 47 m). A more productive unit (4500 liters/hour with a higher power of 1.5 kW) of the same class costs twice as much - about $500. Reviews of the work are presented in the format of a photo that was taken on the website of one of the stores.

Reviews of Grundfos pumping stations for water supply at home or cottages (to increase the size of the picture, click on it with the right mouse button)

A series of Grundfos pumping stations with stainless steel pump housings is more expensive, but they also have protection against idling, overheating, water cooling. The prices for these installations are from $450. Modifications with borehole pumps are even more expensive - from $ 1200.

The water supply pumping stations for the Wilo house (Vilo) have proven themselves well. This is a more serious technique for ensuring high flow: up to four normally suction pumps can be installed at each station. The body is made of galvanized steel, the connecting pipes are made of stainless steel. Management - programmable processor, touch control panel. The performance of the pumps is smoothly regulated, which ensures a stable pressure in the system. The equipment is solid, but so are the prices - about $1000-1300.

Wilo pumping stations are suitable for the water supply of a large house with a significant flow rate. This equipment belongs to the class of professional

How to make an autonomous water supply in a house connected to a centralized water supply, with poor pressure, or provide yourself on an ongoing basis with hourly water supply, see the following video. And all this with the help of a pumping station and a water storage tank.

What are the pumping stations for a private house

A pumping station for a private house can be surface or submerged. The first involves the location of the equipment at a maximum depth of 9 meters. Centrifugal models are capable of lifting water from there.

Their alternative is vortex stations deepened by only a few meters. They increase fluid pressure in the system and are compact. The centrifugal stations are massive. Vortex is easier to mount, connect to nodes.

Maintenance is also simplified due to the minimum depth and miniaturization. Repair of vortex models is more profitable than centrifugal ones, and the cost of the stations themselves is budgetary. Costing more and decently deepening, centrifugal pumps break less often, give a greater efficiency.

Nine-meter deepening of surface stations is not enough for effective noise isolation. In order to make it acceptable, the equipment is placed in annexes or caissons - chambers located in water-saturated layers. Surface stations do not mind airing the system. Pumps also do an excellent job with dirty water flows.

Submersible pumps lift water already from a depth of 50 meters. This is maximum. Deep work involves the installation of the system in the well. Maintenance of the equipment there is problematic. On the other hand, the warranty period of installations is longer than that of surface ones. In addition, deep pumps are protected from overheating, dry running, because they are completely immersed in water.

The model range and the list of possible technical characteristics of stations of the category are larger. Another plus is the absence of complex installation, it is enough to lower the pump into the well. Noise does not reach the surface from there.

Deep water pumping stations for a private house are more expensive than surface ones. The choice for submersible options often falls when it is not possible to bring water closer to the surface.

We have to lower the system to the carrier layers. The equipment is connected to the ground by a safety cable. Its break leads to the fall of the pump to the bottom of the well. From there, only specialists can get the system.

Some homeowners pull on an electrical cable when a safety cable breaks. Raising the system through the sky is not always possible. More often the pump gets stuck, being damaged and blocking the work of the well.

Surface and submerged stations are manual and automatic. In the latter case, the liquid level in the tank is controlled by the system. The installation starts automatically when the minimum value is reached.

The stations are divided according to their purpose. Some pump water into the house. In others, the pump pushes the drains to the septic tank. The last option is sewerage pumping station. For a private house, it may be required when it is not possible to provide the desired slope of the drain system. This prevents the waste from flowing.

The pumping station eliminates the problem and allows you not to organize a cesspool, transporting sewer masses to the septic tank. Sometimes it is not possible in principle to organize the slope of the runoff system. The objects of assignment are in the basement. They make swimming pools, laundries. Drains will not leave them by gravity.

There are 2 pumps in sewer stations - main and backup.They are connected to compact containers. The backup pump is activated by a sensor that reacts to a critical level of wastewater. The measure excludes 100% filling of the tank. It can be made of metal or fiberglass. The latter material excludes chemical reactions with sewage.

This is interesting: Shallow strip foundation for the house: we explain the essence

Device

Scheme of a water supply pumping station Why should a pumping station be chosen to provide water supply to a private house?

Because this choice eliminates, ceteris paribus, the need for independent selection of individual elements of the water supply station.

It is already fully equipped for automatic operation.

There is no need to further study and compare the technical characteristics of its individual elements.

The current station consists of:

- a hydraulic accumulator (damper tank), which is necessary to store and distribute a supply of water under a set pressure;

- directly to the pump itself;

- automatic pressure switch, which gives a command to start and turn off the pump according to the set parameters;

- check valve, it does not allow water to flow back into the source when the pump stops, preventing it from starting dry;

- power sockets.

Choosing a pumping station What does it consist of?

To choose the right pumping station, we must first find out what it consists of: what parts are used for it, and what you need to pay attention to directly when buying a particular model. Pumping station - photo

Pumping station - photo

So, first we need to make sure that the pump is equipped with a check valve.It is designed to increase the life of the device and maximize the level of safety in operation. Its main functions include protecting the pump from running “idle”, in other words, if the flow of water suddenly stops, it will not draw in air instead of it.

In addition, we must make sure that the device has an inlet filter (its main function is to protect the system and the check valve, in particular, from possible ingress of contaminants from the outside). If necessary, such a filter can always be dismantled and cleaned.

Move on. The pumping unit must also be equipped with a special tank, divided into two parts: water will be placed in the first, and air in the second, but at very high pressure. In this case, the device, even after a power outage, has the ability to function for a certain time. Thus, this tank will be a kind of battery. In addition, the air in one of the parts of the tank is designed to supply water. So that it does not get back into the system, a check valve is installed. It turns out that the water simply has no other way out, except for the water supply system.

The design of the pumping station

It should be noted that the presence of such a reservoir in the pumping station provides the owner with several undeniable advantages:

- The service life of the device is increased, as the number of on / off is significantly reduced.

- The reservoir constantly contains a certain supply of water "for a rainy day", from twenty-five to fifty liters, depending on the dimensions of the product.This reserve is quite useful for household needs when the power supply stops.

- In addition, a certain pressure is formed in the system, which will be enough to carry water to the kitchen, toilet or bathroom.

- Finally, you do not need to equip an additional storage tank in the attic of the house.

Rating of the best pumping stations

| A photo | Name | Rating | Price | |

|---|---|---|---|---|

| Rating of pumping stations of the budget category | ||||

| #1 | | AQUAROBOT M 5-10N | 99 / 100 | |

| #2 | | PRORAB 8810 SCH | 98 / 100 | |

| #3 | | CALIBER SVD-160/1.5 | 97 / 100 | |

| Rating of pumping stations of the middle price category | ||||

| #1 | | JILEX Jumbo 70/50 N-24 | 99 / 100 | |

| #2 | | AQUAROBOT JS 60 | 98 / 100 | |

| #3 | | DAB AQUAJET 132M | 97 / 100 | |

| #4 | | Denzel PS1000X | 96 / 100 | |

| #5 | | VORTEX ASV-800 | 95 / 100 1 - voice | |

| The best pumping station for a premium private home | ||||

| #1 | | Grundfos CMBE 3-62 | 99 / 100 | |

| #2 | | Wilo HMC 605 | 98 / 100 | |

| #3 | | DAB E.Sybox | 97 / 100 | |

| Rating of pumping stations for summer cottages | ||||

| #1 | | Grundfos Hydrojet JPB 5/24 | 99 / 100 1 - voice | |

| #2 | | Quattro Elementi Automatico 800 Ci Deep | 98 / 100 | |

| #3 | | CALIBER SVD-770Ch+E | 97 / 100 |

What to look for when buying?

The first thing you need to pay attention to before buying is power. In different models, it varies in the range of 0.6-1.5 kW

For a small room, a unit of 0.6-0.7 kW is suitable, for medium-sized ones with several water intake points - 0.75-1.2 kW, for spacious and dimensional houses with household communications and an irrigation system - 1.2-1.5 kW .

It is not necessary to buy the most powerful station on the market. It will quickly empty the well reservoir and require a lot of electricity, which is not advisable, especially when there are no more than 3-4 resource consumption points in the house.

It is not necessary to buy the most powerful station on the market. It will quickly empty the well reservoir and require a lot of electricity, which is not advisable, especially when there are no more than 3-4 resource consumption points in the house.

Throughput matters a lot. The larger it is, the more convenient and easier it is to use the home plumbing system.But the indicator of the station should not exceed the capabilities of the well, otherwise there will definitely be drops in the work.

For a small country house, where the owners are regularly located only in the summer season, and in autumn and winter they appear from time to time, a station with a capacity of up to 3 cubic meters per hour is enough. For a cottage of permanent residence, it is worth taking a model with an indicator of up to 4 cubic meters / h.

We also recommend reading our other article, where we talked in detail about how to choose a pumping station for a summer residence.

If you need to connect an irrigation system to communications, it is recommended to consider devices that can pass up to 5-5.5 cubic meters / h through themselves.

The volume of the internal water storage tank in standard stations ranges from 18 to 100 liters. Most often, buyers choose tanks from 25 to 50 liters. This size is considered optimal for a family of 3-4 people. If friends or relatives often come to visit, it is worth taking a more spacious unit.

In order not to suffer from a temporary lack of water under any circumstances, it is worth paying attention to modules with a hydraulic tank of about 100 liters. You will have to pay more, but a good supply of water will never be superfluous in the house. Case material is not particularly important

It is possible to use pumping stations integrated into technopolymer blocks. They will cost significantly less. You will have to pay an additional amount for an anodized steel case, but on the other hand, the station can be located not only in the house, but also on the street

The body material is not particularly important. It is possible to use pumping stations integrated into technopolymer blocks. They will cost significantly less.For a steel case with an anodized coating, you will have to pay an additional amount, but on the other hand, the station will be located not only in the house, but also on the street.

The sound background of the work is of great importance. For placement in residential premises, you need to look for the most quiet devices that do not interfere with a comfortable stay. More powerful units that sound loud should preferably be placed in basements or outbuildings, where their noise will not annoy anyone.

How to connect

How to install and connect a pumping station with your own hands?

Place

It can be installed:

In the caisson of the well;

The pump is installed in the caisson

In an insulated house built over a well;

The station stands directly above the well

In the basement or basement of a country house (of course, at a small distance from the water source).

The main requirement for the installation site of the pump is a positive temperature. Freezing of water in a membrane tank or working chamber will mean the early termination of the career of the pumping station.

Food

The vast majority of entry-level pumping stations are powered by a single phase and are connected to a conventional outlet. The minimum cross section of copper wiring is 2x1.5 mm2. Grounding is not required, but desirable.

In most cases, the station is supplied with a power cord with a regular Euro plug.

suction pipe

It is connected to the suction pipe of the pump through a fitting or adapter.

There are two mandatory requirements for the suction pipe:

- It must have rigid or reinforced walls. If you try to use an ordinary garden hose as a suction hose, when you start the pump, it will be instantly flattened by atmospheric pressure;

Hose reinforced with steel wire

- Its diameter should not be less than the size of the inlet on the working chamber of the pump, otherwise it will limit the performance of the station.

A non-return valve is installed at the end of the suction pipe.

Valve at the end of the hose

When water is supplied from a source with a significant amount of suspension or sand, it is supplied with a strainer. The function of the valve is to prevent water from spilling out of the membrane tank and the water supply after the pump has stopped.

Inch valve with mesh

Capacity

How to organize the supply of water from a storage tank using a pumping station?

- The tank is installed in any warm room with a solid foundation (usually in the basement, underground or basement of the house);

- A tie-in (brass or stainless steel) with the same diameter as that of the inlet pipe of the station is mounted just above the bottom of the tank;

Brass tap for tank

- The tie-in is equipped with a tap that allows you to cut off the pump from the tank;

- A non-return valve is installed on the pump inlet. The arrow on its body should point to the pump. As with the suction pipe, it will prevent the backflow of water when the impeller stops.

Water is supplied to the water supply from a tank installed in the basement.

Water pipes

Automatic stations do not need additional control equipment and are connected directly to the water supply. If you are using ceramic faucets (with cartridges or faucets rotating 180 degrees), it is advisable to provide the inlet with a mechanical cleaning filter: suspensions and sand are detrimental to ceramics.

Mechanical filter at the water inlet to the house

Osmotic filter for drinking water preparation

Ejector

The ejector is connected to the pump by two pipes - suction and pressure.As a pressure pipe, a HDPE pipe (made of low-pressure polyethylene) is usually used.

There is only one subtlety in installing the ejector: if it is equipped with a long plastic socket at the outlet for connecting the suction pipe, a brass or galvanized pipe should be installed between the adapter fitting for a HDPE pipe or hose and the ejector. It will protect the socket from breakage when the suction line is bent.

So the ejector is connected to the pressure and suction pipes

Add-ons and accessories

The following additions ensure safe and long operation of the pumping station:

- Check valve for safe operation and long service life of the equipment;

- Removable inlet filter protecting the HC from contamination.

Due to the fact that all equipment manufacturers have the same inch connectors, there are no problems connecting these important pumping "accessories". We recommend choosing a rigid, corrugated, reinforced suction hose so that it does not deform under pressure. Better yet, use a pipe of the right size with the appropriate connector to connect to the pump.

Optional equipment

In addition to the electric pump, hydraulic accumulator and control automation, the kit of any pumping station without fail includes:

- connecting fittings, including a flexible hose connecting the pump to the hydraulic accumulator;

- a manometer that measures the pressure of the liquid in the system and makes it easier to control the operation of the pump,

- non-return valve that prevents the supply line from emptying when the pump is turned off;

- filters that prevent mechanical impurities from entering the pump;

- pump cutouts.

Filters

Centrifugal pumps are characterized by increased demands on the purity of the pumped liquid

It is very important that there are no abrasive particles (silt, sand, etc.) in the water passing through the pump, as well as long-fibre inclusions with linear dimensions of more than 2 mm (algae, blades of grass, wood chips)

The maximum allowable amount of mechanical impurities is 100 g/m3. To protect the pump from failure and its individual components from premature wear as a result of pumping water containing foreign matter, a coarse mesh filter will help.

It is mounted at the end of the intake pipe and cuts off large debris floating in the water column or on its surface.

After the station, cartridge fine filters are installed, which further purify the water, which is sent to the consumer. However, they have nothing to do with the pumping station.

check valve

In order for the pump to be able to start pumping water at any time, it is necessary that the supply line is always full. That is why the water intake system of pumping stations is equipped with a check valve installed immediately after the coarse strainer.

The presence of a check valve will save you from having to wait a long time each time until the water rises into the pump from the well, and, more importantly, it will save the pump from running in the “dry” start-up mode, which is fraught with equipment failure. Water intake pipe with non-return valve

Water intake pipe with non-return valve.

Protective automation

Our electrical networks cannot boast of stability, and the voltage often “walks” in a fairly wide range. A circuit breaker will help protect expensive equipment from power surges.If this component is not included in your station kit, it can (and should!) be purchased separately. It will not be superfluous to have a protective shutdown in case of overheating of the pump.

The dry run protection system is another element that is necessary to extend the life of the pumping station. It is especially important in cases where the productivity of the well is not constant. A sensor placed in the well will give a signal to turn off the pump as soon as the water level falls below the minimum limit. This will prevent overheating and failure of the pump due to pumping air.

First meeting

A pumping station is several devices mounted on a common frame.

The list of equipment includes:

- Pump (usually centrifugal surface);

- Hydraulic accumulator (a container divided by an elastic membrane into a pair of compartments - filled with nitrogen or air and intended for water);

- Pressure switch. It controls the power supply of the pump depending on the current pressure in the water supply and accumulator;

Mandatory components of a water supply station

At many pumping stations, the manufacturer installs a pressure gauge that allows you to visually control the current pressure.

Pumping station for giving Alco with a built-in pressure gauge

Let's imagine how a pumping station works for a summer residence:

- When power is applied, the pressure switch turns on the pump;

- He sucks in water, pumps it into the accumulator and then into the water supply. At the same time, the pressure of the gas compressed in the air compartment of the accumulator gradually increases;

- When the pressure reaches the upper threshold of the relay, the pump turns off;

- As the water flows, the pressure gradually drops. The pressure is provided by air compressed in the accumulator;

- When the pressure reaches the lower threshold of the relay, the cycle repeats.

Calculation of the water column at a pressure of 1 kgf / cm2 (760 mm Hg)

A special case

The suction depth limitation is successfully bypassed by surface pumps with an external ejector and stations based on them. For what?

The ejector of such a pump is an open nozzle directed into the suction pipe. The flow of water supplied to the nozzle under pressure through the pressure pipe entrains the water masses surrounding the nozzle.

In this case, the suction depth depends to a large extent on the flow rate (read - on the pump power) and can reach 50 meters.

Scheme of the ejector

Aquatica Leo 2100/25. Price - 11000 rubles