- Why do you need a hydraulic accumulator?

- Choice: built-in or external?

- Benefits of installing a hydraulic tank

- Is it easy to install a hydraulic accumulator

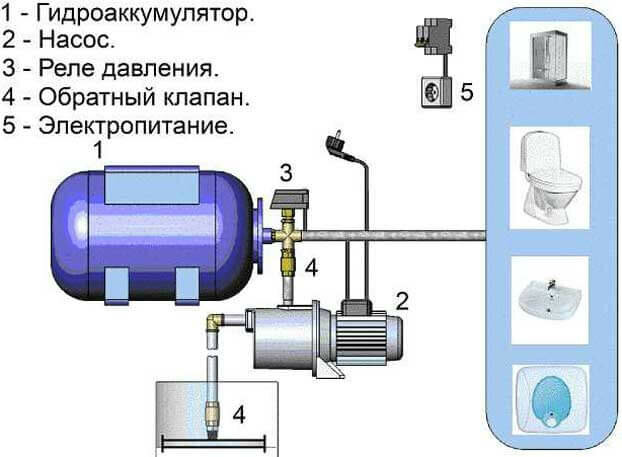

- The place of the tank in the water supply system

- When a hydraulic tank is not needed

- If the pump sucks air from the well. Why is air in the water from the well and what to do

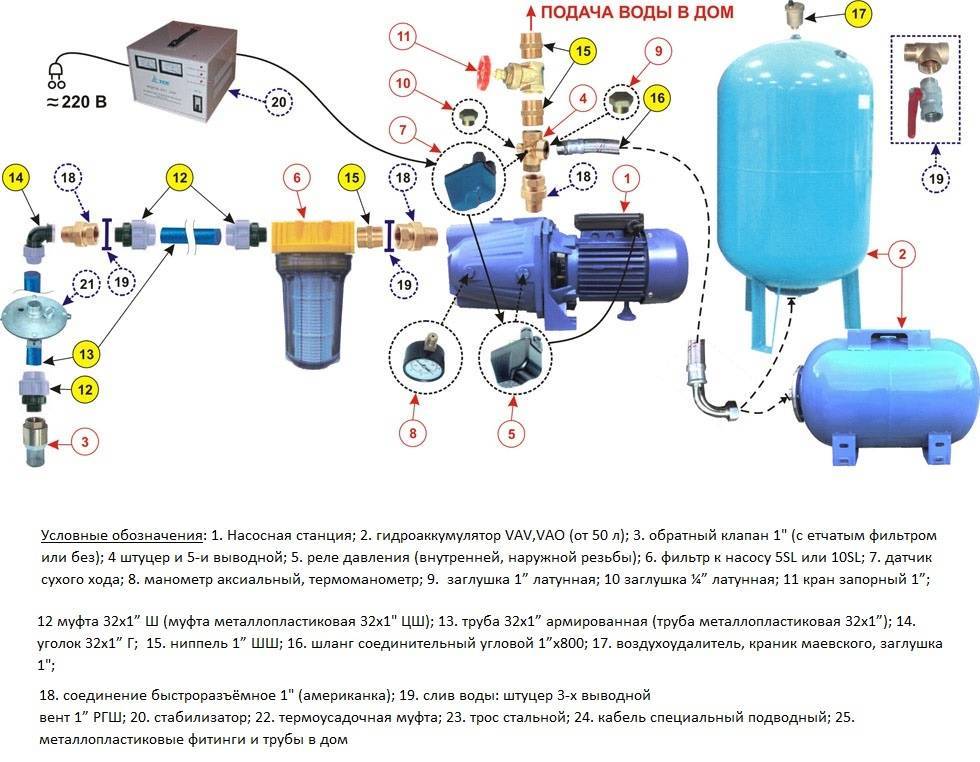

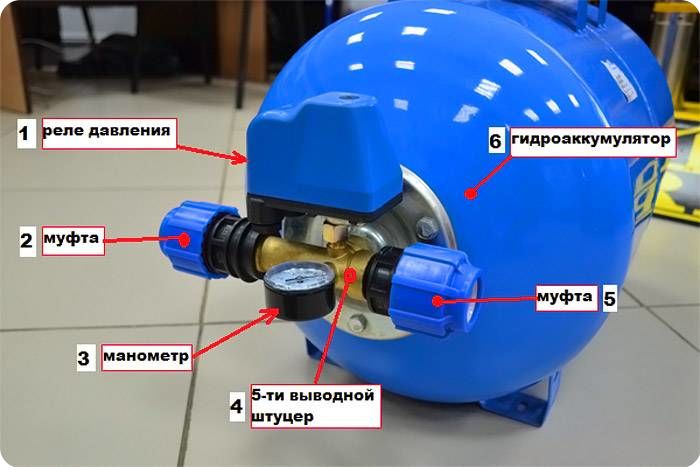

- Key components of the pumping unit

- The order of operation of the unit

- Breakdowns most commonly encountered

- The pump spins but does not pump water

- Repair and prevention of the hydraulic accumulator

- Causes of breakdowns and their elimination

- The principle of operation of the system without a hydraulic tank

- Device and principle of operation

- Install a pressure reducer

- Hydraulic accumulator - why is it

Why do you need a hydraulic accumulator?

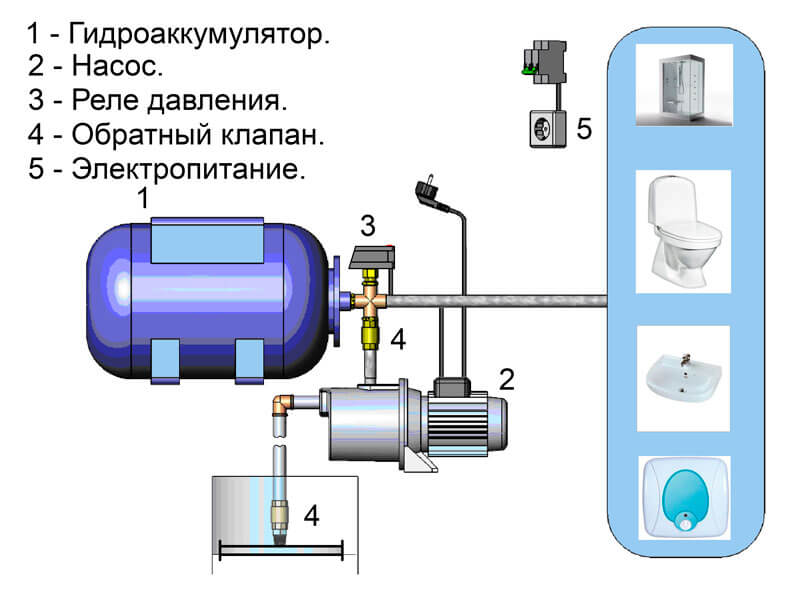

A hydraulic accumulator (in other words, a membrane tank, a hydraulic tank) is used to maintain stable pressure in the water supply system, protects the water pump from premature wear due to frequent switching on, protects water supply system from possible water hammer. In the event of a power outage, thanks to the hydraulic accumulator, you will always have a small supply of water.

Here are the main functions that a hydraulic accumulator performs in a water supply system:

- Protecting the pump from premature wear.Due to the water reserve in the membrane tank, when the water tap is opened, the pump will turn on only if the water supply in the tank runs out. Any pump has a certain rate of inclusions per hour, therefore, thanks to the accumulator, the pump will have a supply of unused inclusions, which will increase its service life.

- Maintenance of constant pressure in the plumbing system, protection against drops in water pressure. Due to pressure drops, when several taps are turned on at the same time, sharp fluctuations in water temperature occur, for example in the shower and in the kitchen. The hydraulic accumulator successfully copes with such unpleasant situations.

- Protection against water hammer, which can occur when the pump is turned on, and can spoil the pipeline in order.

- Maintaining a supply of water in the system, which allows you to use water even during a power outage, which happens quite often in our time. This feature is especially valuable in country houses.

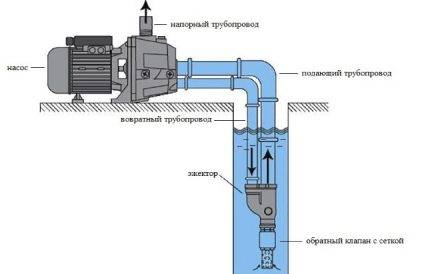

Choice: built-in or external?

Depending on the installation location, remote and built-in ejectors are distinguished. There is no big difference in the design features of these devices, but the location of the ejector still affects in some way both the installation of the pumping station and its operation.

So, built-in ejectors are usually placed inside the pump housing or in close proximity to it. As a result, the ejector takes up a minimum of space, and it does not have to be installed separately, it is enough to perform the usual installation of a pumping station or the pump itself.

In addition, the ejector located in the housing is reliably protected from contamination. Vacuum and reverse water intake is carried out directly in the pump housing.There is no need to install additional filters to protect the ejector from clogging with silt particles or sand.

remote pump room ejector stations are more difficult to install than the indoor model, but this option creates a much lower noise effect

remote pump room ejector stations are more difficult to install than the indoor model, but this option creates a much lower noise effect

However, it should be remembered that such a model demonstrates maximum efficiency at shallow depths, up to 10 meters. Pumps with a built-in ejector are designed for such relatively shallow sources, their advantage is that they provide an excellent head of incoming water.

As a result, these characteristics are enough to use water not only for domestic needs, but also for irrigation or other business operations. Another problem is the increased noise level, since the sound effect from the water passing through the ejector is added to the vibration of the running pump.

If a decision is made to install a pump with a built-in ejector, then you will have to take care of sound insulation especially carefully. Pumps or pumping stations with a built-in ejector are recommended to be installed outside the house, for example, in a separate building or in a well caisson.

The electric motor for a pump with an ejector must be more powerful than for a similar non-ejector model.

A remote or external ejector is installed at some distance from the pump, and this distance can be quite significant: 20-40 meters, some experts even consider 50 meters acceptable. Thus, a remote ejector can be placed directly in a water source, for example, in a well.

The external ejector not only increases the performance of the pump, but is designed to increase the depth of water intake from the source, which can reach 20-45 m

The external ejector not only increases the performance of the pump, but is designed to increase the depth of water intake from the source, which can reach 20-45 m

Of course, the noise from the operation of an ejector installed deep underground will no longer disturb the residents of the house. However, this type of device should be connected to the system using a recirculation pipe, through which water will return to the ejector.

The greater the installation depth of the device, the longer the pipe will have to be lowered into the well or well.

It is better to provide for the presence of another pipe in the well at the design stage of the device. Connecting a remote ejector also provides for the installation of a separate storage tank, from which water will be taken for recirculation.

Such a tank allows you to reduce the load on the surface pump, saving some amount of energy. It is worth noting that the efficiency of the external ejector is somewhat lower than that of the models built into the pump, however, the ability to significantly increase the depth of the intake forces one to come to terms with this drawback.

When using an external ejector, there is no need to place the pumping station directly next to the water source. It is quite possible to install it in the basement of a residential building. The distance to the source can vary within 20-40 meters, this will not affect the performance of pumping equipment.

Benefits of installing a hydraulic tank

There are a number of reasons why a hydraulic accumulator is needed in a water supply system:

The main task is that thanks to the hydraulic accumulator, the pump starts and stops less often. The engine does not overheat and does not fail longer.

In addition to creating a supply of water, the drive softens hydraulic shocks in the water supply system. The air contained inside the cylinder reduces pressure drops in the pipeline due to its compressibility

As a result, all elements of the system wear out less.

During a power outage, a reserve supply of water remains in the hydraulic tank, which is important in case of frequent power outages.

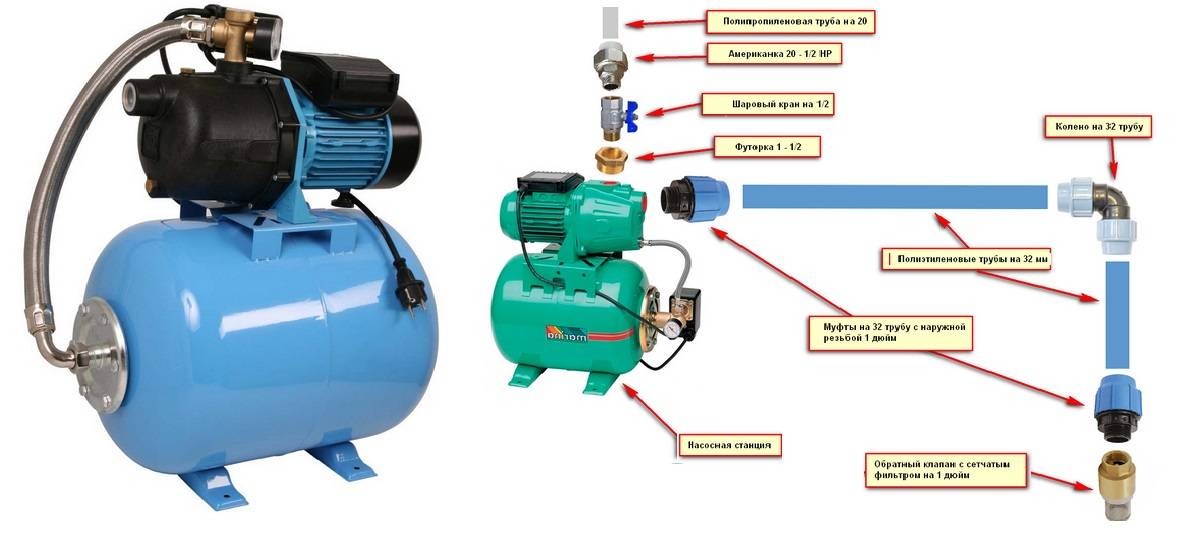

Is it easy to install a hydraulic accumulator

Summer residents immediately panic when they hear that the accumulator must be connected to the water supply system. They think that pipes can suddenly burst and then the entire summer cottage, together with the house, will be filled with water. This is not true.

The installation of the accumulator takes place according to the standard and proven scheme. A lot of summer residents integrated their tanks along it. And they did an excellent job. To do this, they purchased all the necessary components in the form of nipples, pumps and fittings.

To put it in the right place, you need to determine the water flow parameter for the whole house. Determine the power of the pump and the volume of the accumulator. It is also worth knowing the location of the main water supply units.

- hoses;

- Pipes;

- Fitting;

- Nipples;

- Cranes and so on.

Then look at the installation diagram and just do everything as indicated there.

At first glance, it seems that installing a tank is a difficult task. This is not true. Decide on a place, look at the schemes that the water supply has. Buy the connection parts and simply connect the tank to the general water supply.

The place of the tank in the water supply system

In water supply systems, the accumulator is located after the pump, in front of the inlet pipe. In this place, it is able to control pressure and perform protective functions, for example, during a water hammer.Water hammer occurs when the valve is suddenly closed and the pump is running at the same time. By inertia, the liquid moves towards the exit, when it is blocked from moving, a reverse wave occurs. It collides with the oncoming mass of liquid and the pipes are damaged. The absence of a counter flow prevents the line from breaking.

Some buyers confuse the storage tank with the expansion tank. The second is designed to compensate for fluid losses when it is heated and is installed in heating systems. When the liquid evaporates, an additional portion comes from the water supply.

In the event of a power outage, there is a small supply of water that can be used for domestic needs.

When a hydraulic tank is not needed

In irrigation systems, a hydraulic accumulator is not needed, since with a constant open tap, the pump will work without turning off. If there is a storage capacity in this scheme, the equipment will often turn on, which will lead to premature resource depletion.

When buying a pump with an automatic system that assumes a smooth start of the engine, the GA is also not needed. Water hammer does not threaten pipes, since the fluid flow moves slowly.

If the pump sucks air from the well. Why is air in the water from the well and what to do

Residents of private houses, dachas, country houses often urgently need to install a pumping structure for pumping water from a well or well. For some, this is the only way to have water indoors. Therefore, when, one day, the pump stops buzzing, it is urgently necessary to understand the origin of the breakdown.

If the pumping station stops pumping water, it is urgent to find the cause of the breakdown

Often the stumbling block is the air that enters the pump along with the liquid. Everything can be prevented, only initially you need to find out what elements the pumping structure is assembled from.

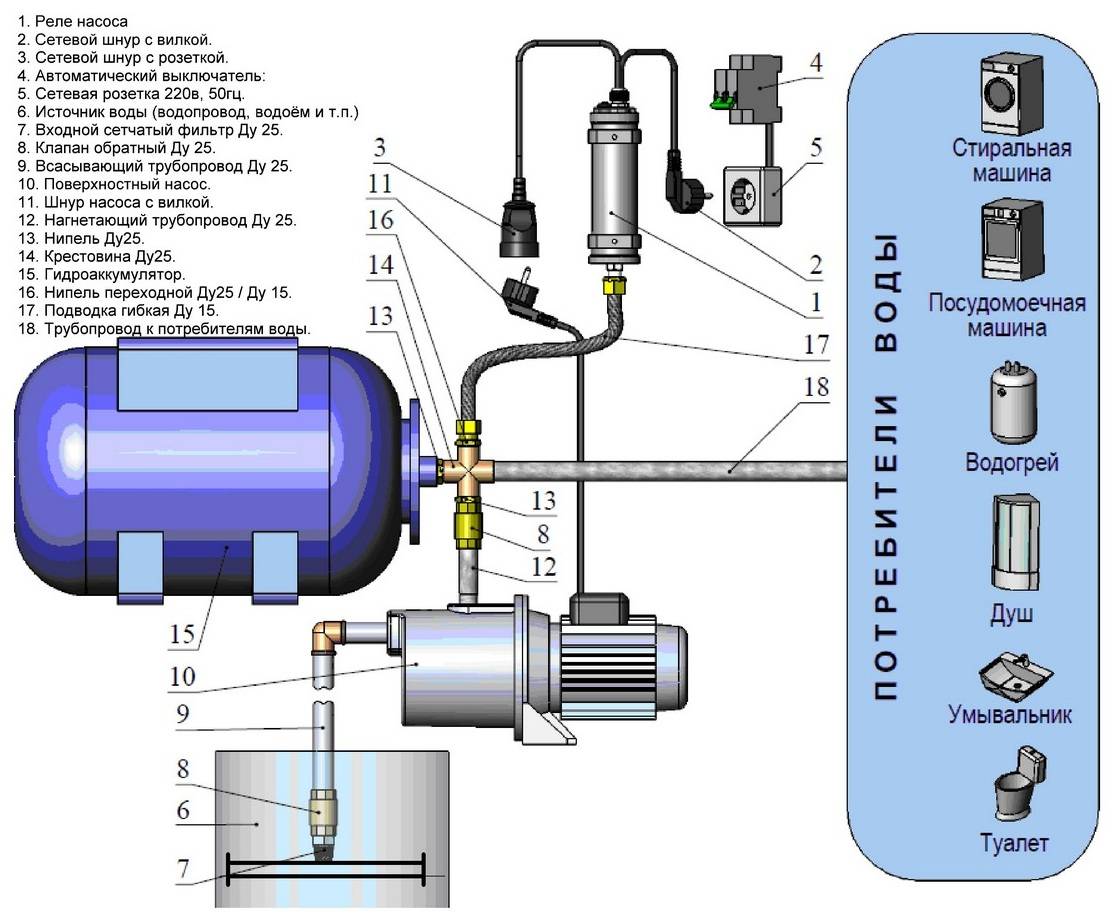

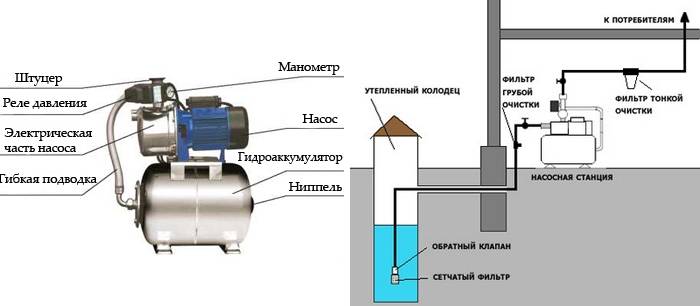

Key components of the pumping unit

There are many varieties of stations, but the main components are common to all.

- Self-priming pump. Principle of operation: the pump independently draws liquid from the recess with the help of a tube, one end of which is in the well, the other is connected to the equipment.

The pump is located a short distance from the water tank. The depth of the tube is also adjustable. - All units are equipped with a hydraulic accumulator. The vessel, using the energy of compressed gas or a spring, transfers liquid under pressure to the hydraulic system. It accumulates hydraulic fluid and releases it at the right time, thereby avoiding water surges in the system. Outside, it is metal, inside there is a rubber membrane, above it there is a gas cavity filled with nitrogen, and a hydraulic cavity. Water is filled until the pressure in both cavities is equal.

- Electrical engine. Through the coupling, it is connected to the pump, and with the relay - using the electrical circuit. Due to the fact that the pump does not turn on for short liquid intakes, the motor does not wear out.

- Air outlet.

- collector element.

- Pressure gauge. It allows you to monitor the level of pressure.

- Relay. By changing the pressure, by opening / closing the contacts, it supports the independent operation of the equipment.

The main purpose of pumping stations is to maintain continuous pressure in the water supply structure.

In order for all components to function like a clock, it is important to correctly select the required volume of the hydraulic accumulator and control the connection between the regulator and the pump itself

The order of operation of the unit

When turned on, the electric motor is the first to come into play, it starts the pump, and it pumps the gradually incoming liquid into the accumulator. When the accumulator is full to the limit, excess pressure will be created and the pump will turn off. When the faucet is turned off in the house, the pressure decreases and the pump starts working again.

The house has a battery connected to the water supply. The pipes fill with water when the pump starts. When the pressure in the station reaches the required peak, the pump is switched off.

The pump unit will solve the difficulty of supplying water to houses, baths, summer kitchens, outbuildings and other premises on the territory of your site. Having familiarized yourself with the details of the operation of the station, it is necessary to study the possible causes of the failure of the device and ways to eliminate them.

Breakdowns most commonly encountered

In the process of using any equipment, there comes a moment when it either wears out or breaks.

So in the second case, it would be important for the owner to understand the causes of damage. Here is a short list of grounds that disrupt the operation of the pumping station:

- no electricity - trite, but also not excluded, since the operation of the unit directly depends on the electric current;

- the pipeline is not filled with liquid;

- pump malfunction;

- hydraulic accumulator broken;

- damaged automation;

- cracks in the hull.

The pump spins but does not pump water

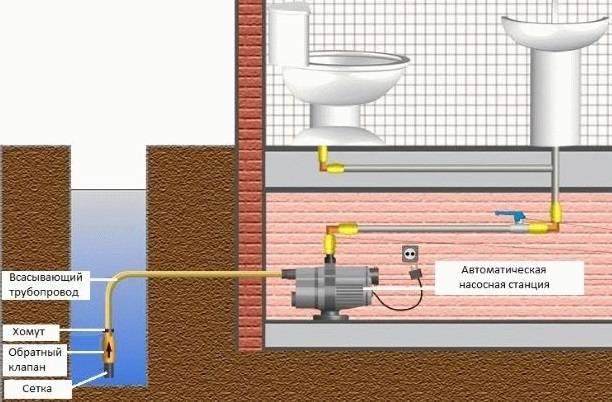

What to do when the station does not pump water? A frequent cause of failure is the lack of fluid in the pipes or in the pump itself.It happens that the unit is functioning, but the water is not pumping. Then you should inspect the tightness of the entire water supply, if there are any places where the pipes are poorly connected.

Check that the pump is not empty. The check valve is not working properly. The throughput must be one-way. This is one of the most important parts of the station, because, after the pump is turned off, it prevents water from flowing back into the well.

Diagram of a pumping station valve that can become clogged with debris

It happens that the valve is clogged and does not physically close, debris, salt, grains of sand can get into it. Accordingly, the liquid does not reach the pump. We solve the problem.

Before spinning the unit, we advise you to check the voltage of the electric current. It happens that it is below normal, and the pump is simply unable to turn on. Etc

Repair and prevention of the hydraulic accumulator

Even the simplest hydraulic tanks require attention and care, like any device that works and benefits.

The reasons for repairing a hydraulic accumulator are different. These are corrosion, dents in the body, violation of the integrity of the membrane or violation of the tightness of the tank. There are also many other reasons that oblige the owner to repair the hydraulic tank. In order to prevent serious damage, it is necessary to regularly inspect the surface of the accumulator, monitor its operation in order to prevent possible problems. It is not enough to inspect the GA twice a year, as stipulated in the instructions

After all, one malfunction can be eliminated today, and tomorrow not to pay attention to another problem that has arisen, which over the course of six months will turn into an irreparable one and can lead to the failure of the hydraulic tank. Therefore, the accumulator must be inspected at every opportunity, so as not to miss the slightest malfunctions, and to repair them in time.

Causes of breakdowns and their elimination

The reason for the failure of the expansion tank may be too frequent switching on / off of the pump, water outlet through the valve, low water pressure, low air pressure (lower than calculated), low water pressure after the pump.

How to troubleshoot a hydraulic accumulator with your own hands? The reason for repairing the accumulator can be low air pressure or its absence in the membrane tank, damage to the membrane, damage to the housing, a large difference in pressure when the pump is turned on and off, or an incorrectly selected volume of the hydraulic tank.

Troubleshooting can be done as follows:

- to increase the air pressure, it is necessary to force it through the tank nipple with a garage pump or compressor;

- a damaged membrane can be repaired at a service center;

- the damaged case and its tightness are also eliminated in the service center;

- you can correct the difference in pressure by setting too large a differential in accordance with the frequency of switching on the pump;

- The sufficiency of the tank volume must be determined before it is installed in the system.

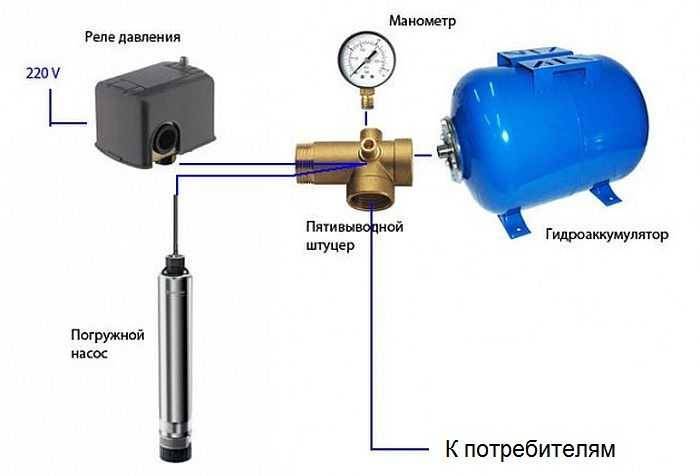

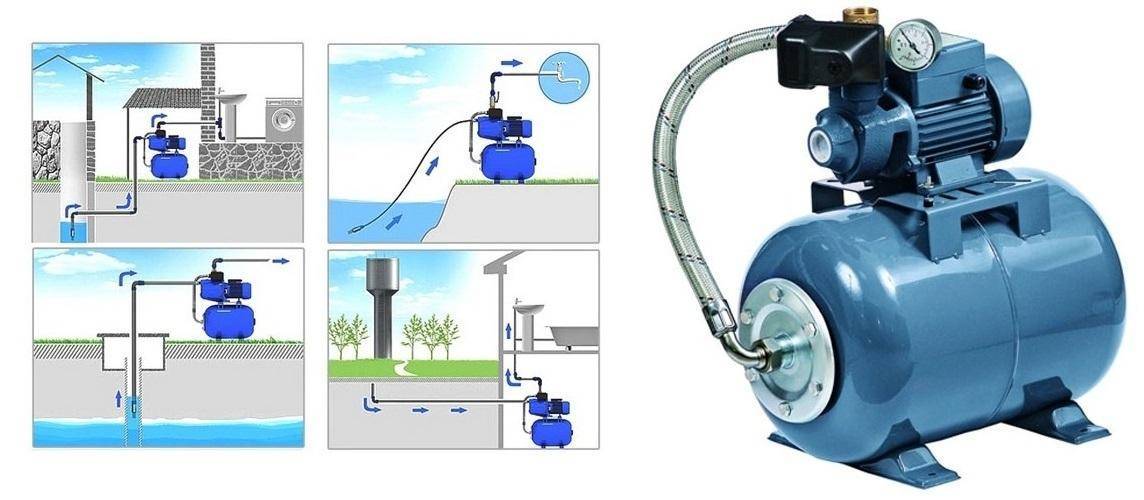

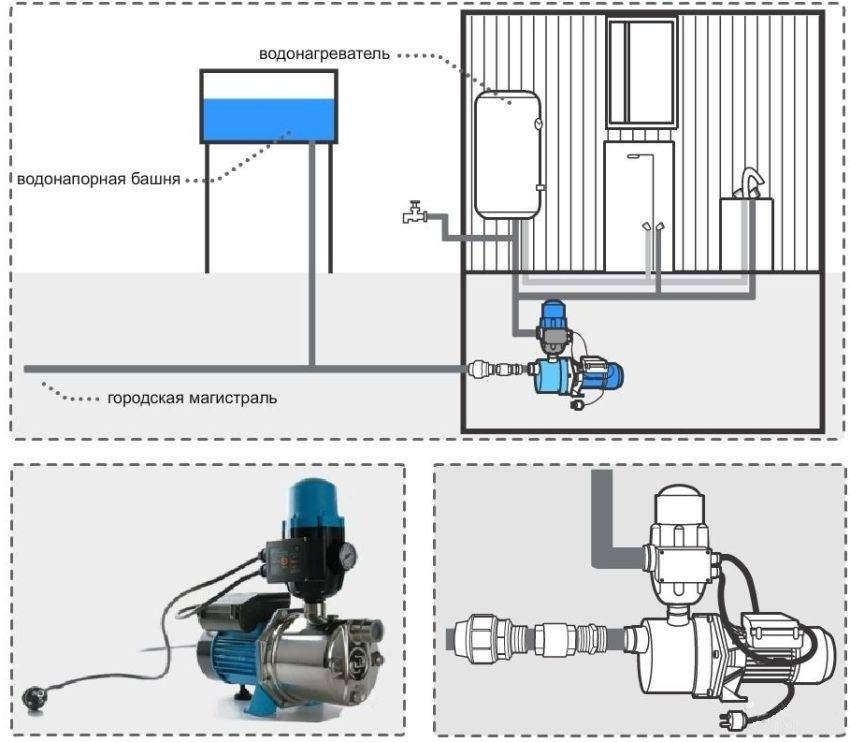

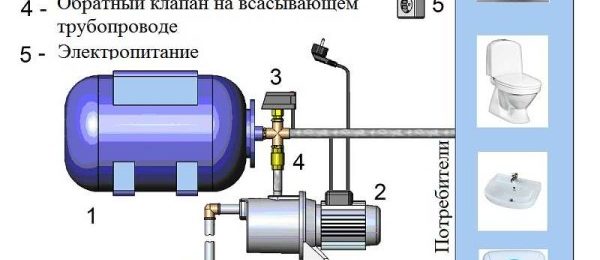

The principle of operation of the system without a hydraulic tank

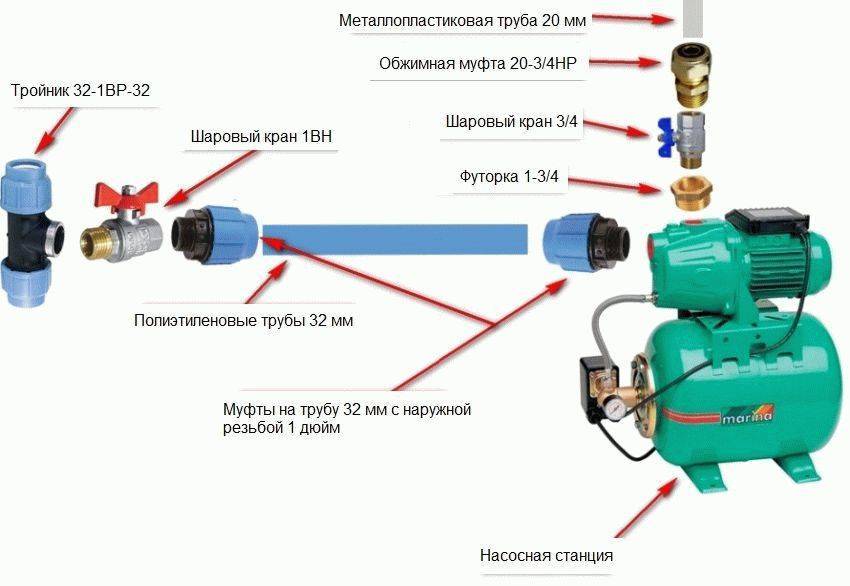

The equipment that pumps water works the same way: it takes liquid from a source - a well, a well - and pumps it into the house, to the points of water intake. The pump can be both submersible and surface.

The role of connecting lines is performed by pipelines made of polypropylene pipes or flexible hoses. In the same way, water is supplied to the bathhouse, garage, summer kitchen, swimming pool.

So that water can be used in autumn or early spring, it is recommended to insulate the well, and bury the pipes to a depth of 70-80 cm - then the liquid will not freeze even during frosts

The difference concerns the use of additional devices, such as a hydraulic accumulator, a pressure switch, etc. It is extremely dangerous to install pumping equipment without means of control and adjustment - primarily for the equipment itself.

The simplest example of equipment for providing summer cottage residents with water is the AL-KO garden pump. With it, you can water the plants, organize a shower, fill the pool with water

If you need a large amount of water or a more stable supply, another important element is included in the circuit - a storage tank. First, water enters it, and only then - to consumers.

When using domestic pumps, the liquid volume is usually between 2 and 6 m³/h. This amount is usually enough if the station is connected to a well or well and serves a country house.

The pump functions are controlled by a pressure switch responsible for adjusting the pressure. For control, it is easiest to install a pressure gauge, which is usually equipped with automation of pumping stations.

In the absence of a hydraulic accumulator, the pressure switch is connected directly to the pumping station or integrated together with the dry-running switch into the pipeline

In addition to equipment for pumping water, you will need an electrical cable, a mains connection point and ground terminals.If the ready-made solution does not meet the requirements, the station parts can be purchased separately, and then assembled at the installation site. The main condition is the correspondence of the elements of the system according to the characteristics.

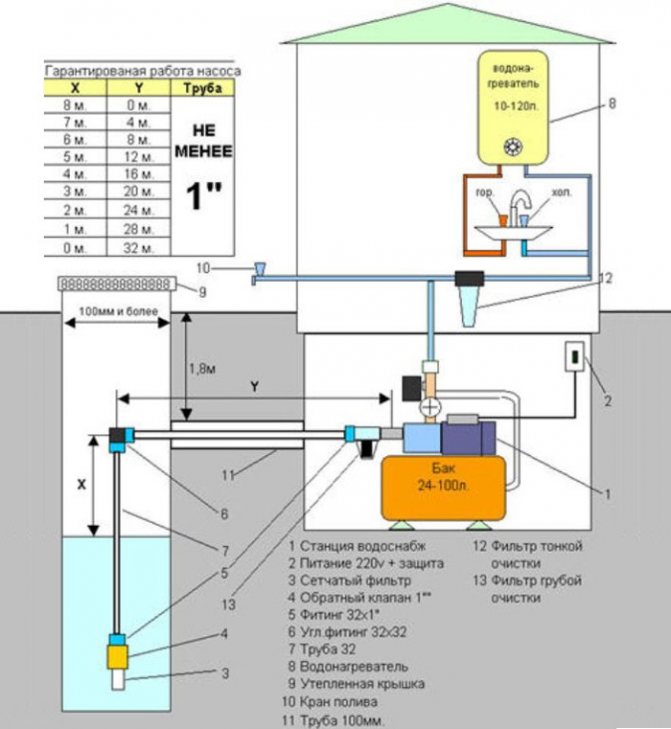

Device and principle of operation

In order to understand how a pumping station works for a summer residence or a private house, one should take a closer look at its device and the main functional elements. Consider their sequence in the direction of water movement.

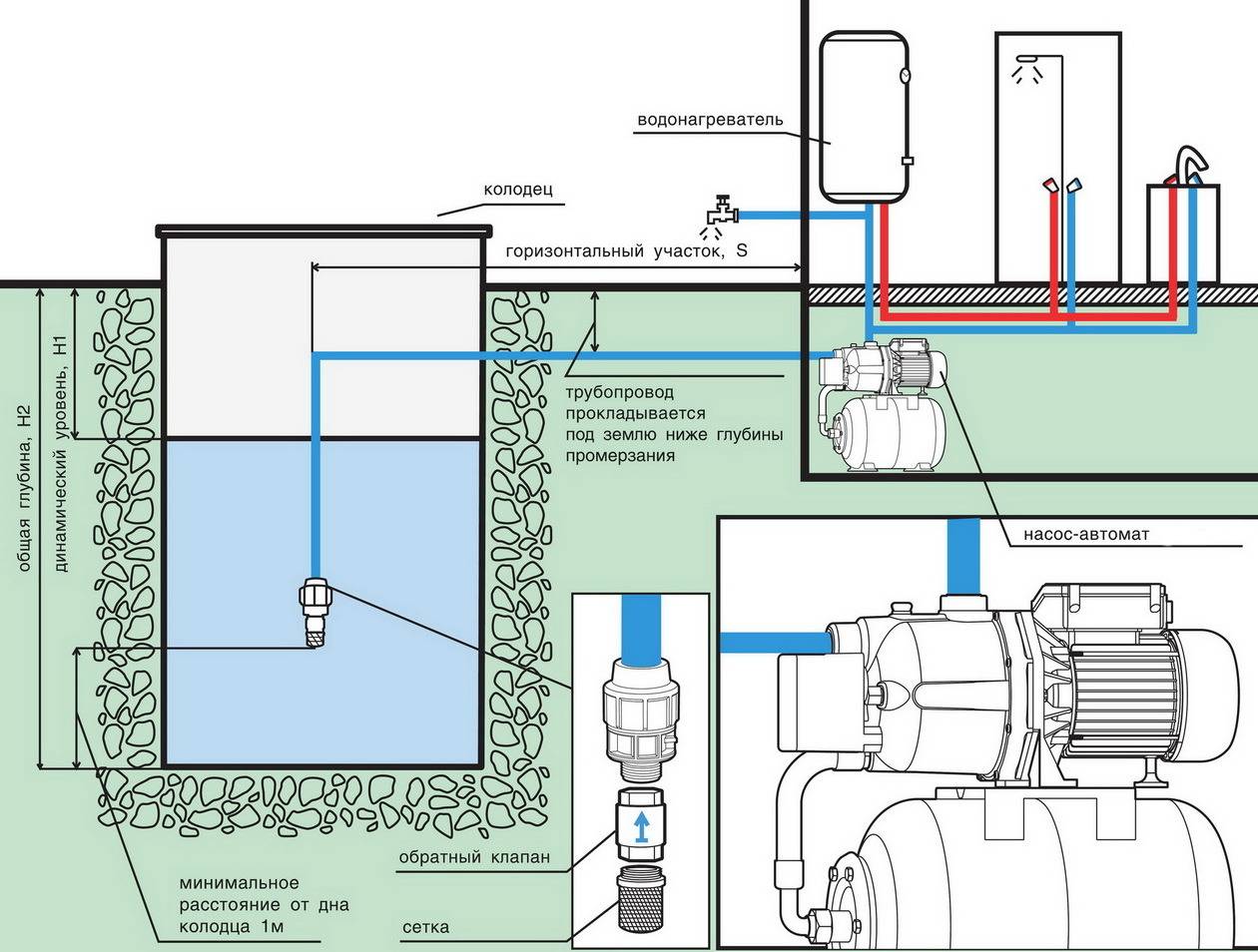

- A water intake located in a well or well is equipped with a filter mesh that prevents relatively large particles of impurities from entering the system. A non-return valve is also located here to prevent the reverse flow of water when the pressure drops or the pump stops working.

- The suction line is the section of the pipeline from the water intake to the pump.

- The operation of a centrifugal pump creates a vacuum in the pipeline supplying liquid from the source, which contributes to its intensive rise, and excess pressure in the line leading to water consumption points to ensure the flow of water through communications. To optimize the operation of the system, the pump is equipped with a pressure gauge and a pressure switch. the settings of which ensure the switching on and off of the pumping unit when critical values are reached.

- The principle of operation of a pumping station for a summer residence would be incomprehensible without clarification - the relay settings are set taking into account the characteristics of the pump, the volume and required pressure in the accumulator and other parameters.

- Systems are equipped with tanks from which water is supplied to the pipeline.

The photo shows a diagram of a water supply device based on a pumping station with a hydraulic accumulator

The photo shows a diagram of a water supply device based on a pumping station with a hydraulic accumulator

Thus, the principle of operation of a pumping station for a house in stages is as follows:

- When the pump is turned on, water rises from the source, fills the system and the hydraulic accumulator until a certain pressure or level is reached. After that, the pump is turned off.

- When water is consumed (opening a faucet, using a shower or water-consuming equipment), the pressure or level in the system decreases, which contributes to the supply of fluid from the accumulator chamber / storage tank. Thus, the flow of water from the accumulator is carried out until a critical pressure / level value is reached. After that, the pump is turned on again and the cycle repeats.

Install a pressure reducer

We set the pressure reducer to 1.5-2 bar

This device has several types of construction (piston or membrane). In this case, we will focus on the design of the piston type. This is the so-called additional pressure limiting element in the system after the pumping station relay. Usually a pressure of 4 bar is also considered a high indicator. On the gearbox, you can set 1-1.5 bar, which will ensure stable operation of the entire system as a whole.

Let's repeat it again for complete clarity. The pressure switch at the station eliminates the general overload from stationary networks. The pressure reducer provides comfortable conditions for the use of water supply networks in the house.

An inquisitive reader may have a technically correct question: why is it necessary to use two options for pressure relief. You can safely set, for example, 1.5 on the relay of the pumping station. The whole secret lies in the operating parameters of the accumulator.To fill it with water, it is necessary to create an increased pressure of more than 4 bar. Therefore, schematically, the entire water supply system is divided into two zones, high and low pressure.

First, there is a connection from the pump to the expansion tank (high pressure zone), then from the tank through the reducer to the central water supply (low pressure zone). With a strong desire, the entire structure can be assembled with your own hands. The main thing is compliance with the calculations and the procedure for established actions. Installation on a well is as real as connecting to a centralized water supply.

For complete clarity, when summing up, it is necessary to note the following options necessary for the stable operation of the entire water supply. Namely:

- Use filter elements.

- Understand the operation of the pumping station, the relay according to the instructions.

- Be sure to use hydraulic accumulators.

- Use a pressure reducer.

As a rule, such equipment can have a decent cost. But if you calculate in advance the possible options for classic, outdated water supply schemes, then the difference is obvious. In the first, the comfort of operation is immediately violated. The station is constantly working (noise, hum of the electric motor). The pressure in the network is either too low, or vice versa, breaks all connections and internal parts of the taps.

Without filter elements, the moving parts of the pump, the working areas of regulators and valves become clogged. And if the fence is carried out from a well, then cleaning agents are simply necessary. The storage tank will not interfere in case of lack of water for a while.As a result, when carrying out preliminary calculations, it becomes obvious that the installation of a pumping station according to the presented scheme is an excellent option for long-term use with minimal maintenance costs.

Read also:

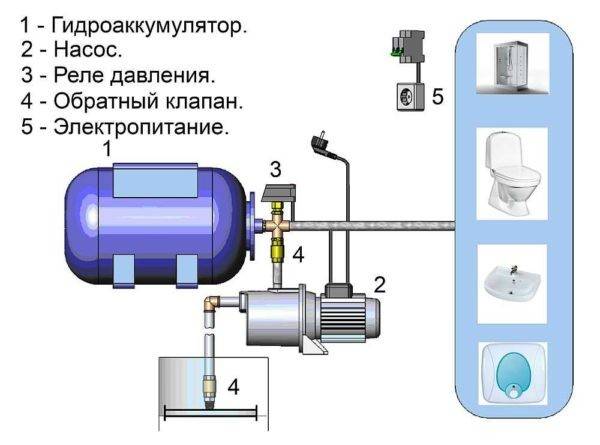

Hydraulic accumulator - why is it

There are several main purposes that a hydraulic accumulator serves in a water supply system. First of all, its installation allows you to create the necessary pressure in the network. Also, a small amount of water is stored in the accumulator. For example, if for some reason the pump cannot pump water, then you can use it. The volume of water determines the internal volume of the accumulator

And most importantly, its presence in the water supply system of a private house prevents the formation of water hammer.

A hydraulic accumulator means a special metal tank. In order to maintain stable pressure inside it, it is equipped with special equipment. The water supply scheme for a well with a hydraulic accumulator is relatively simple, and if you follow all the instructions in this article, then you can do the connection yourself.

In most cases, the hydraulic accumulator for water supply systems uses the principle of compressed air energy. It consists of a partition, for example, it can be a rubber membrane or a rubber pear. So, the essence of the operation of the entire water supply system with a hydraulic accumulator is as follows. Pumping equipment pumps water into the tank. As the tank fills up, pressure forms inside it, as the water presses on the pear. This whole process is controlled by a pressure sensor.

This is important so that the pump can turn off.As soon as a faucet opens in a room with water, the water is pushed out through the energy of a rubber bulb or membrane

As soon as the pressure in the accumulator drops, a sensor is activated that sends a signal to the pump, and it turns on. Thus, the accumulator is filled with water again. Pumping is carried out until the shutdown signal is triggered.

As you can see, in addition to connecting the accumulator itself, it is important to correctly calculate the pressure in the water supply accumulator. For this purpose, you can use the manufacturer's recommendations, which are indicated in the passport. Today, there are two types of hydraulic accumulator:

Today, there are two types of hydraulic accumulator:

- Open type.

- closed type.

As for the open type, it is used extremely rarely. And this is not surprising, because it has a number of negative aspects, including:

- High water evaporation rate. As a result, it is necessary to constantly pump up water.

- Moreover, installing a hydraulic accumulator for open-type water supply systems with your own hands will be much more expensive. This is due to the fact that it is necessary to take measures that will exclude the possibility of freezing water. Moreover, it is necessary to install additional automation, which will eliminate the possibility of water overflow.

- An important minus is that when water comes into contact with oxygen, its aggressiveness towards metal parts increases. As a result, this leads to the formation of corrosion on the metal, and this significantly reduces the service life.

Among other things, there are models that are placed in a vertical or horizontal position.If the area of \u200b\u200bthe caisson or other room where the installation and connection of the accumulator to the water supply system is minimal, then the vertical direction is selected. For horizontal, a special platform is required. The tank itself has special mounting feet for mounting.

Important! On sale you can find a hydraulic accumulator for a water supply system in blue and red. Blue color for cold plumbing. It differs from red in that the tank itself is capable of operating under conditions of much higher pressure.

Plus, food rubber is used inside the structure.

It differs from red in that the tank itself is capable of operating under conditions of much greater pressure. Plus, food rubber is used inside the structure.