- Types of hydroaccumulator tanks

- Specifications

- Choosing a location for a water supply station

- How to choose

- How to start a water supply system

- Why do you need a hydraulic accumulator

- Advantages of a hydraulic accumulator

- How does he work

- Overview of popular models

- The principle of operation of the accumulator

- Things to consider when making adjustments

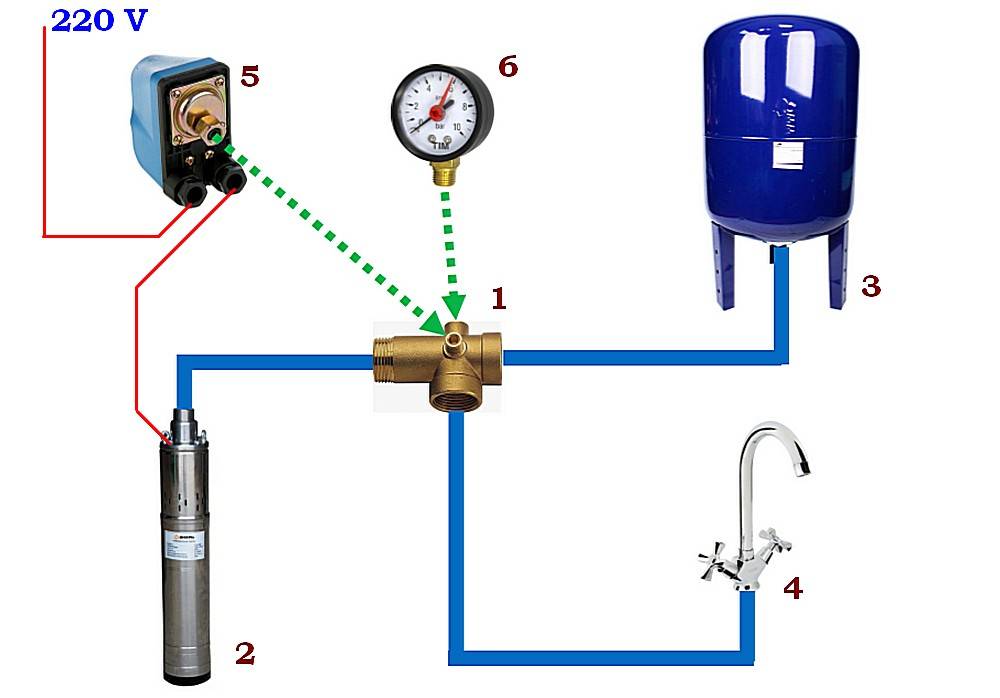

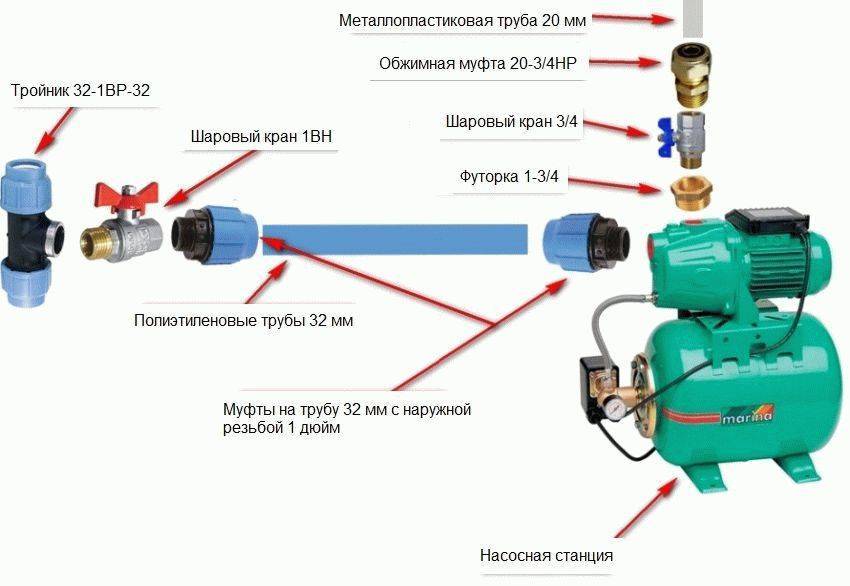

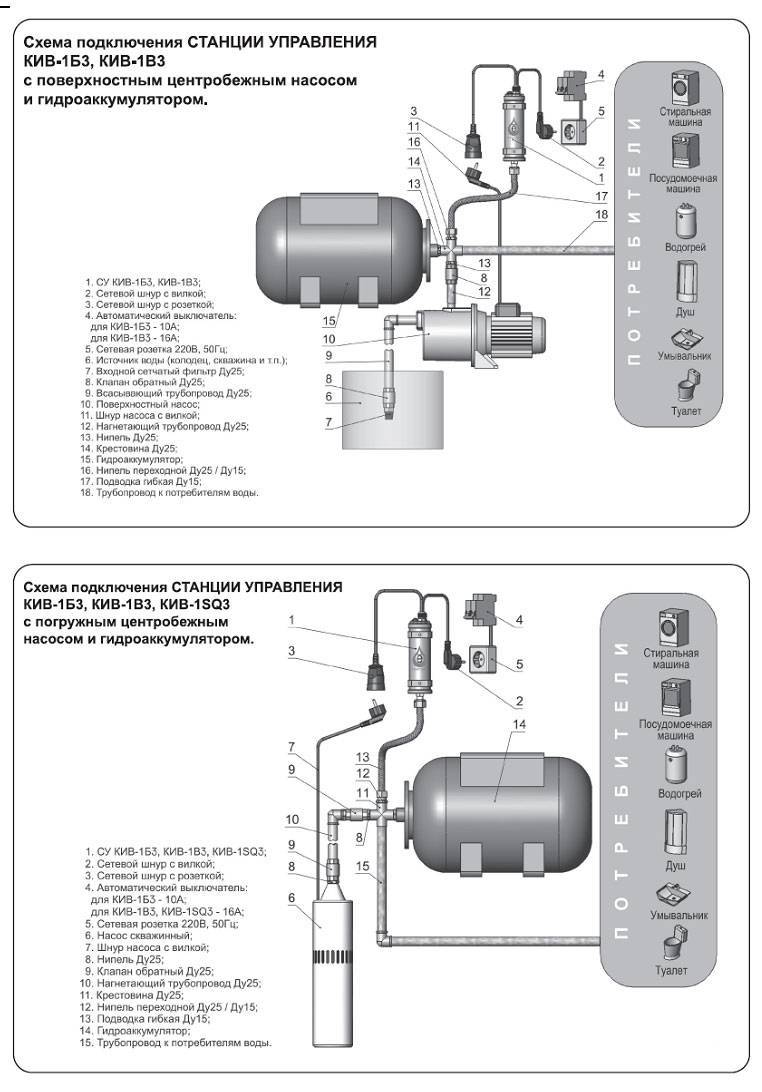

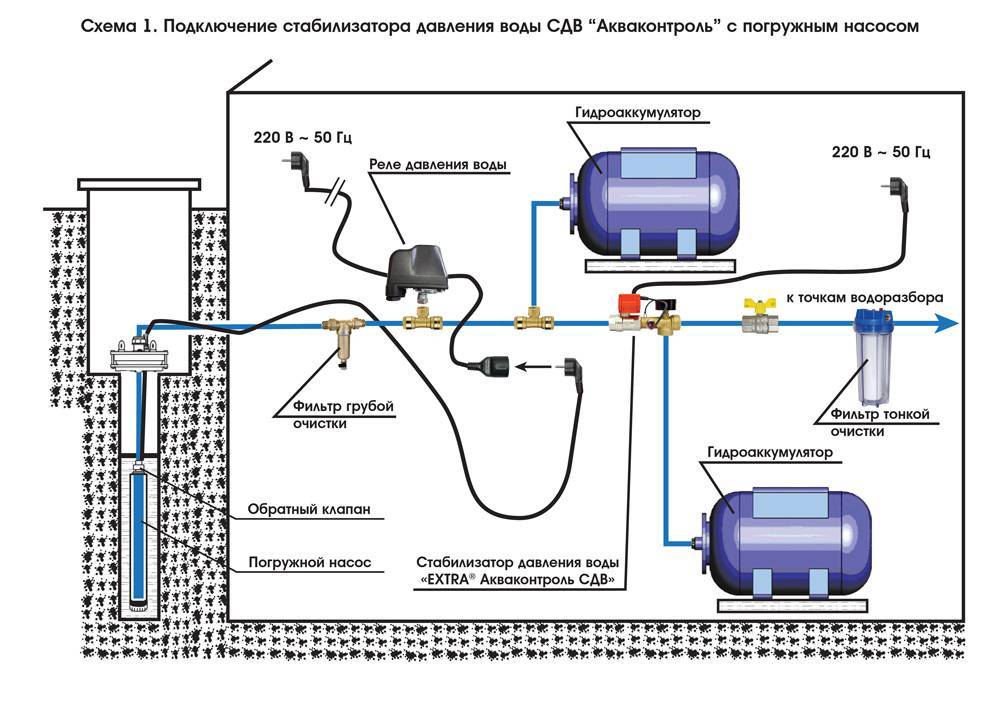

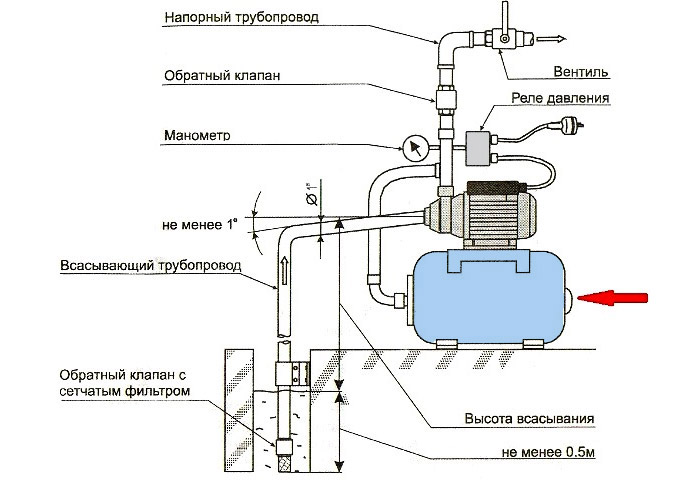

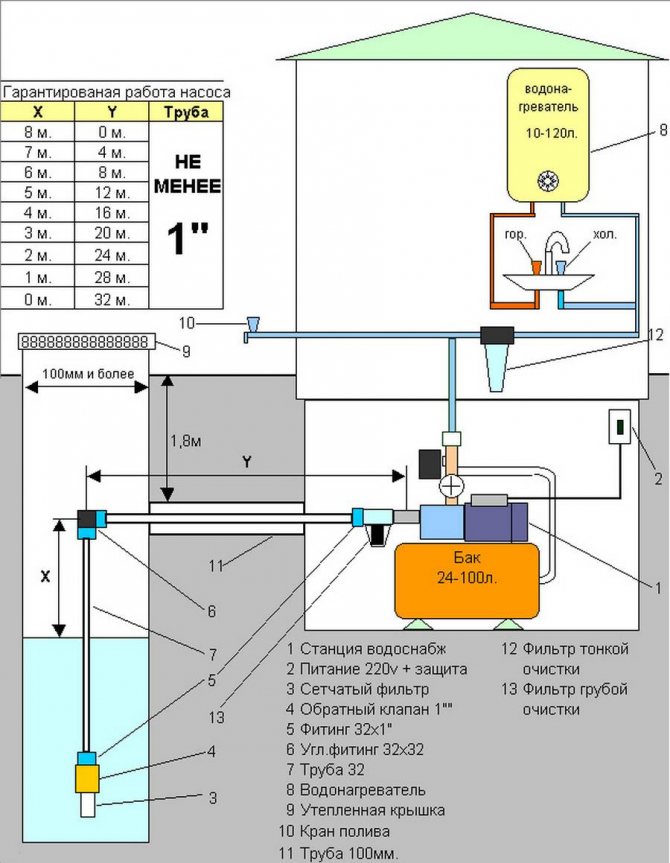

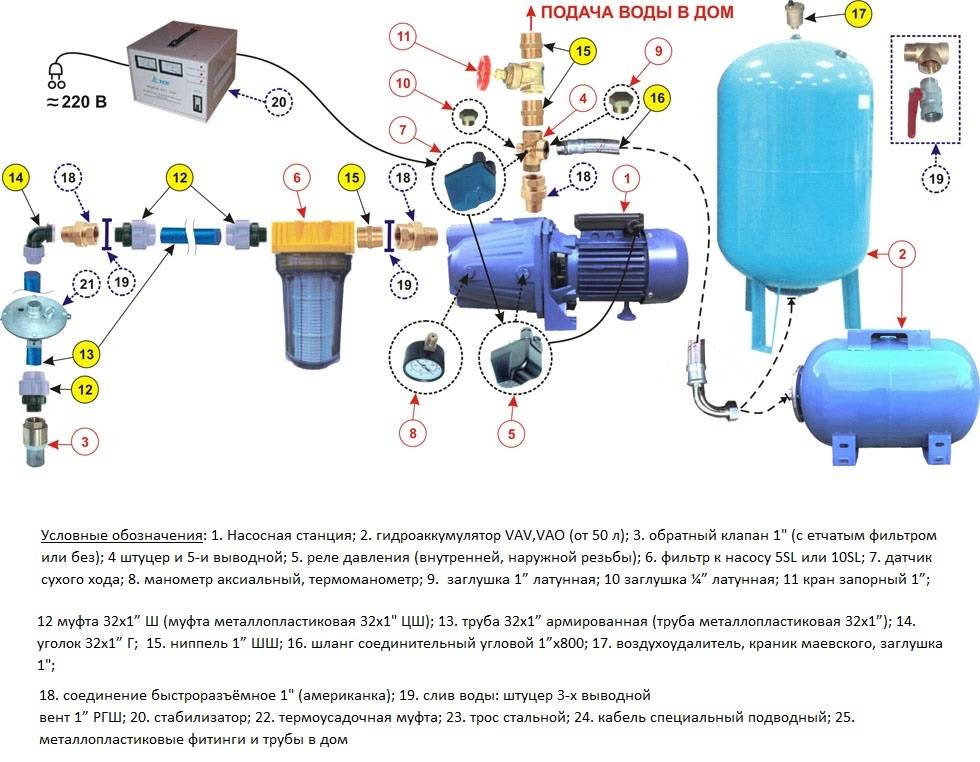

- Basic installation and connection diagrams

- The composition of the pumping station and the purpose of the parts

- The principle of operation of the pumping station

- Popular manufacturers and prices

- 2

Types of hydroaccumulator tanks

Hydraulic accumulators differ in the type of installation: they are horizontal and vertical. Vertical accumulators are good because it is easier to find a suitable place for their installation.

Both vertical and horizontal varieties are equipped with a nipple. Together with water, a certain amount of air also enters the device. It gradually accumulates inside and “eats” part of the volume of the hydraulic tank. In order for the device to work properly, it is necessary to bleed this air from time to time through this same nipple.

According to the type of installation, vertical and horizontal hydraulic accumulators are distinguished. They have some differences in the maintenance process, but the choice is largely influenced by the size of the installation site.

In hydraulic accumulators that are installed vertically, a nipple is provided that is designed specifically for this purpose. Just press it and wait for the air to leave the device. With horizontal tanks, things are a little more complicated. In addition to the nipple for bleeding air from the tank, a stopcock is installed, as well as a drain to the sewer.

All this applies to models capable of accumulating a liquid volume of more than 50 liters. If the capacity of the model is less, then there are no special devices for removing air from the membrane cavity, regardless of the type of installation.

But the air from them still needs to be removed. To do this, water is periodically drained from the accumulator, and then the tank is refilled with water.

Before starting the procedure, turn off the power supply to the pressure switch and the pump, or the entire pumping station if the hydraulic tank is part of such a device. After that, you just need to open the nearest mixer.

The water is drained until the container is empty. Next, the valve is closed, the pressure switch and the pump are energized, the water will fill the tank of the accumulator in automatic mode.

Hydraulic accumulators with a blue body are used for cold water, and red ones for heating systems. You should not use these devices in other conditions, since they differ not only in color, but also in the material of the membrane, and the ability to tolerate a certain level of pressure.

Usually, tanks intended for autonomous engineering systems differ in color: blue and red. This is an extremely simple classification: if the hydraulic tank is blue, then it is intended for cold water supply systems, and if it is red, it is for installation in the heating circuit.

If the manufacturer has not designated its products with one of these colors, then the purpose of the device should be clarified in the technical data sheet of the product. In addition to color, these two types of accumulator differ mainly in the characteristics of the material used in the manufacture of the membrane.

In both cases, it is a high quality rubber designed for food contact. But in blue containers there are membranes designed for contact with cold water, and in red ones - with hot water.

Very often, a hydraulic accumulator is supplied as part of a pumping station, which is already equipped with a pressure switch, pressure gauge, surface pump and other elements.

Blue devices are capable of withstanding higher pressures than red containers. It is not recommended to use accumulators designed for domestic hot water systems for cold water and vice versa. Incorrect operating conditions will lead to rapid wear of the membrane, the hydraulic tank will have to be repaired or even completely replaced.

Specifications

Regardless of the depth of the well (8.10, 15 or 20 meters), all pumping stations are divided into domestic and industrial. For a private house, household units are used. However, they may have different performance characteristics.

In order for your unit to meet the needs of the family in water, as well as the parameters of the hydraulic structure, it is necessary to pay attention to the following technical characteristics when choosing:

equipment power, measured in W;

device performance in cubic meters per hour (this characteristic is selected after determining the needs of residents for water);

liquid suction height or the maximum mark to which the pump can raise water (these characteristics depend on the depth of the water intake, for example, for wells with a depth of 15-20 meters, you need an aggregate with an indicator of at least 20-25 m, and for wells with a depth of 8 meters, a device with a value 10 m);

the volume of the accumulator in liters (there are units with a volume of 15, 20, 25, 50 and even 60 liters);

pressure (in this characteristic, it is necessary to take into account not only the depth of the water mirror, but also the length of the horizontal pipeline);

additional protective functions will not interfere (protection against "dry running" and overheating);

it is also important to consider the type of pump being used. For example, a submersible pump is mounted in a well, so it does not make noise during operation, but it is more difficult to repair and maintain it.

A surface-type unit is easier to maintain and repair, but makes more noise during operation.

To make it easier for you to choose a unit suitable for a country house, we give approximate technical characteristics of such a device:

the power of the device should be in the range of 0.7-1.6 kW;

depending on the size of the family, a station with a capacity of 3-7 cubic meters per hour will suffice;

lifting height depends on the depth of the well or well;

the volume of the hydraulic tank for one person is 25 liters, with an increase in family members, the volume of the storage tank should increase proportionally;

the choice of the device for the maximum pressure should be done taking into account the depth of the hydraulic structure, the length of the horizontal pipeline leading from the unit to the house, as well as the height of the house (if there are water consumption points on the upper floors: bathrooms or bathrooms);

well, if the device will have protection against "dry" operation

This is especially important for hydraulic structures characterized by unstable water levels. Then the pump will not be able to pump out all the water and run idle;

in addition, a surface-type pumping station will need protection against motor overheating

The thing is that in submersible units, the motor is constantly in the water, so it is effectively cooled. But the motor of a surface station can easily overheat and fail. To prevent this from happening, you need protection against overheating, which will work in time and turn off the pump.

Choosing a location for a water supply station

When choosing a location for a pumping station, it is necessary to focus on the characteristics of the hydraulic pump. Every ten meters of a horizontal pipe between the water source and the pump reduces its suction capacity by 1 m. If they are supposed to be separated by more than ten meters, then the model of the pump unit must be selected with an increased suction depth.

The automatic station of the autonomous water supply system can be located:

- on the street in a caisson near the well;

- in an insulated pavilion built specifically for pumping equipment;

- in the basement of the house.

The stationary outdoor option provides for the arrangement of a caisson and the laying of a pressure pipe from it to the cottage below the freezing level of the soil. When installing a year-round pipeline, laying it below the seasonal freezing depth is mandatory. When arranging temporary summer highways for the period of residence in the country, the pipeline is not buried below 40 - 60 cm or is laid on the surface.

If you install the station in the basement or basement, then you do not have to be afraid of the pump freezing in winter. It is only necessary to lay the suction pipe below the freezing line of the soil so that it does not freeze in extreme cold. Often a well is drilled right in the house, then the length of the pipeline is significantly reduced. But not in every cottage such drilling is possible.

Installation of water supply pumping stations in a separate building is possible only if the equipment is operated during a period of positive temperatures. However, for areas with very low winter temperatures, this option, designed to function all year round, needs to be insulated or a heating system installed. It is better to immediately mount the pumping station right in the heated house.

How to choose

The main working body of the hydraulic tank is the membrane. Its service life depends on the quality of the material. The best for today are membranes made of food rubber (vulcanized rubber plates). The body material matters only in membrane type tanks. In those in which a “pear” is installed, water is in contact only with rubber and the material of the case does not matter.

The flange should be made of thick galvanized steel, but stainless steel is better

What is really important in tanks with "pears" is the flange. It is usually made from galvanized steel.

In this case, the thickness of the metal is important. If it is only 1 mm, after about a year and a half of operation, a hole will appear in the metal of the flange, the tank will lose its tightness and the system will stop working. Moreover, the guarantee is only a year, although the declared service life is 10-15 years. The flange usually rots after the end of the warranty period. There is no way to weld it - a very thin metal.You have to look for a new flange in service centers or buy a new tank.

So, if you want the accumulator to serve for a long time, look for a flange made of thick galvanized steel or thin, but made of stainless steel.

How to start a water supply system

You should start by preparing the source of water intake. If there is already a well or a well, then it is recommended to first drain 2-3 m3 of water from it, make a control sampling and send the water for laboratory analysis (biological and chemical). For this, you can contact the Sanitary and Epidemiological Station at the place of residence or private laboratories. The results of the analysis are necessary in order to know in advance what types of filters will need to be installed on the water supply (depending on whether the water will be used for cooking).

Tap water treatment

Also, if necessary, strengthen and clean the source of water intake. Available options:

- Well. Water from such sources is most often the lowest quality (with a large amount of impurities, limestone, sand), therefore, such systems have to be supplemented with a full-fledged filter station, including coarse and fine filters, as well as a reverse osmosis system. In the presence of bacterial contamination, filters are also installed for preliminary disinfection of water, and before eating it must be boiled.

- Well. The best option is a deep-water well (over 30 meters deep). In such sources, the water in most cases is clean, ready for consumption. In such systems, only a coarse and fine filter is installed. It is highly desirable that the well pipeline be made of PVC plastic (food grade).Metal pipes are subject to corrosion, after 2-3 years plaque forms on them, and after 10 years the well is simply clogged without the possibility of cleaning it.

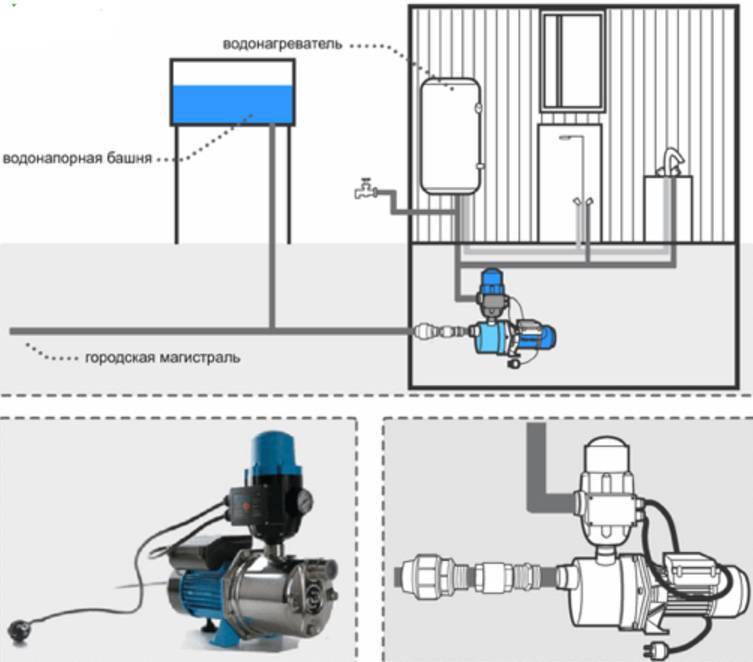

- Hydraulic accumulator. In fact, this is an ordinary container, into which water is poured from water carriers. Filters in such a system are installed only basic (coarse and carbon). If the tower is used as a hydraulic accumulator, then you can do without a pumping station, since the water pressure in the water supply system is provided by the cistern itself (if it is above the level of the water supply at home).

- Connection to a centralized water supply network. The simplest option, but not in all cities, the water in such systems fully complies with sanitary and epidemiological standards. The reason is simple - plumbing systems are not restored for 20 - 40 years, while their maintenance should be performed annually. Yes, and the laying of centralized water supply systems is now carried out only in large cities with a population of one million.

The installation of such a water tower eliminates the need for a pumping station. The water pressure in the pipes is provided by the force of attraction acting on the lower layers of water in the tank

The installation of such a water tower eliminates the need for a pumping station. The water pressure in the pipes is provided by the force of attraction acting on the lower layers of water in the tank

As for the results of water analysis, even the most polluted (including those exceeding the permissible norm of bacteria) today can be made drinking water using filter stations. It is not cheap, so experts recommend installing a separate input to the house. That is, one pipe is for drinking, the second is for technical needs (bathroom, toilet). In this case, filters are installed only for the entry of a drinking pipe.

An analysis is a must.If there is an overestimated level of nitrates without a reverse osmosis filter, it does not make sense to install a water supply system - such water is even unsuitable for technical needs

An analysis is a must.If there is an overestimated level of nitrates without a reverse osmosis filter, it does not make sense to install a water supply system - such water is even unsuitable for technical needs

Why do you need a hydraulic accumulator

Both a well and a well may have insufficient flow (see Well flow - how to find out if you have enough water). In other words, they are not always able to dispense as much water as you need at one time. Sometimes this problem does not occur immediately, but after several years of operation of the source.

It is logical that in this case the house should have a supply of water. But not in buckets and jars, but in the system itself. And this can be done if you include a hydraulic accumulator or a storage tank in the water supply scheme.

Advantages of a hydraulic accumulator

The storage tank is, as they say, "the last century." It is inconvenient and not practical.

Judge for yourself:

- It must be installed above the water-consuming premises, that is, in the attic. This means that it needs to be insulated, otherwise the water will freeze in winter.

- No one cancels the risk of leaks and overfilling the tank. It's rare, but it happens. The consequences are easy to imagine.

- Water from the storage tank is supplied to the devices under the pressure of its own weight. And this is not enough for the normal operation of plumbing fixtures and especially household appliances - a washing machine and a dishwasher.

Water supply system with storage tank

The obvious conclusion suggests itself: it makes sense to include storage capacity in the system only in small houses for summer use that are not equipped with modern appliances. If you live in the house all the time, a water supply scheme from a hydraulic accumulator is more suitable for you.

And that's why:

- This is a more advanced device - it allows you to adjust the pressure in the system according to your needs;

- The hydraulic tank should also be in a warm room, but this task is easier to solve, since it does not need to be raised to the highest point. For installation, a caisson above the well, and the basement of the house, and any technical room are suitable;

- Accordingly, possible leaks are not so terrible: water will not wet the floors, will not spoil repairs and furniture.

Water supply system with hydraulic accumulator

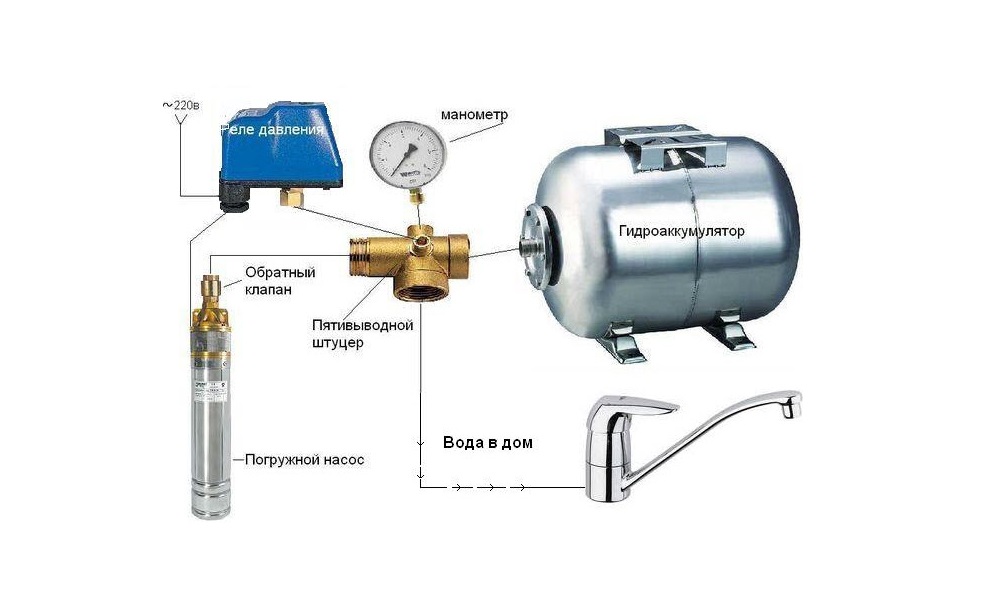

How does he work

A hydraulic accumulator is a sealed container, divided inside into two sections. A rubber diaphragm or a hollow "pear" can act as a separator.

Water enters one section, and air enters the other, which, as the first section is filled, compresses, creating pressure on the diaphragm.

Hydraulic accumulator device

As the tank empties while dispensing water, the air pressure drops. When it reaches the limiting minimum value, the pressure switch is activated, which starts the pump. He pumps water into the tank again until the pressure reaches its maximum.

Hydraulic accumulator with pressure switch and pressure gauge

As a result:

- We have a constant pressure in the system;

- The pump does not turn on with each turn of the tap, so its parts wear out less and last longer;

- The water supply scheme with a hydraulic accumulator allows you to always have a supply of water in case of its large analysis and the inability of the source to produce the required volume at a time.

The volume of the tank is selected based on the needs of the family. It can be both 5 and 500 liters.

Overview of popular models

There are two types of pressure switches: mechanical and electronic, the latter are much more expensive and rarely used.A wide range of devices from domestic and foreign manufacturers is presented on the market, facilitating the choice of the required model.

RDM-5 Dzhileks (15 USD) is the most popular high-quality model from a domestic manufacturer.

Characteristics

- range: 1.0 - 4.6 atm.;

- minimum difference: 1 atm.;

- operating current: maximum 10 A.;

- protection class: IP 44;

- factory settings: 1.4 atm. and 2.8 atm.

Genebre 3781 1/4″ ($10) is a Spanish-made budget model.

Characteristics

- case material: plastic;

- pressure: top 10 atm.;

- connection: threaded 1.4 inches;

- weight: 0.4 kg.

Italtecnica PM / 5-3W (13 USD) is an inexpensive device from an Italian manufacturer with a built-in pressure gauge.

Characteristics

- maximum current: 12A;

- working pressure: maximum 5 atm.;

- lower: adjustment range 1 - 2.5 atm.;

- upper: range 1.8 - 4.5 atm.

The pressure switch is the most important element in the water intake system, which provides automatic individual water supply to the house. It is located next to the accumulator, the operating mode is set by means of adjusting screws inside the housing.

When organizing autonomous water supply in a private house, pumping equipment is used to raise water. In order for the water supply to be stable, it is necessary to select it correctly, since each type has its own technical characteristics and features.

For efficient and trouble-free operation of the pump and the entire water supply system, it is necessary to purchase and install an automation kit for the pump, taking into account the characteristics of the well or well, the water level and its expected flow rate.

The vibration pump is chosen when the amount of water spent per day does not exceed 1 cubic meter.It is inexpensive, does not create problems during operation and maintenance, and its repair is simple. But if water is consumed from 1 to 4 cubic meters or water is located at a distance of 50 m, it is better to purchase a centrifugal model.

Usually the kit includes:

- operating relay, which is responsible for supplying and blocking voltage to the pump at the time of emptying or filling the system; the device can be immediately configured at the factory, and self-configuration for specific conditions is also allowed:

- a collector that supplies and distributes water to all points of consumption;

- pressure gauge for measuring pressure.

Manufacturers offer ready-made pumping stations adapted to specific requirements, but a self-assembled system will work most efficiently. The system is also equipped with a sensor that blocks its operation during dry running: it disconnects the engine from power.

The safety of the equipment operation is ensured by overload protection sensors and the integrity of the main pipeline, as well as a power regulator.

The principle of operation of the accumulator

The operation of all hydraulic accumulators is based on a single principle - a membrane chamber with water, made of a polymer material, is surrounded on all sides by air pumped under a certain pressure, regulated by a special sensor.

Therefore, the liquid pressure in the membrane chamber, and hence in the entire domestic plumbing system, is always stabilized by the air gap. This means:

- The domestic plumbing system is 100% protected against water hammer of all kinds, as it is equipped with a sensor that opens a control valve that relieves excess pressure.

- In case of an unplanned power outage, the user always has a supply of 50-100 liters of water, depending on the capacity, to ensure life.

- The liquid level sensor in the tank, connected to the switch on the pump supplying water to the system, is configured in such a way that it turns on the water supply pump only when necessary. This, firstly, reduces energy consumption, and secondly, increases the durability of pump parts.

- The water in the accumulator tank does not come into contact with water, so the replacement of the metal tank will never be required due to wear and tear from corrosion.

All these indicators ensure the smooth operation of the home plumbing system.

Things to consider when making adjustments

If you are going to independently adjust the operation of the relay of the pumping station, you must not miss some important points:

- You can not set the "upper" pressure, which is more than 80% of the maximum for this relay model. It is usually indicated in the instructions or on the packaging and, most often, is 5-5.5 bar (atm.). If you need to set it to a higher level in your home system, then you need to choose a switch with a higher maximum pressure.

- Before increasing the pressure on the pump (“upper”), it is necessary to look at its characteristics, whether it can develop such pressure. Otherwise, the pump, being unable to create it, will work without turning off, and the relay will not turn it off, because the set limit will not be reached. Usually the pump head is given in meters of water column. Approximately 1 m of water. Art. = 0.1 bar (atm.). In addition, it is necessary to take into account the hydraulic losses in the system.

- When adjusting, it is not necessary to tighten the nuts of the regulators to failure - the relay may generally stop working.

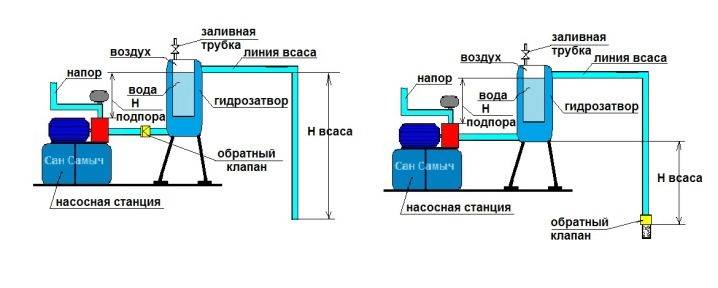

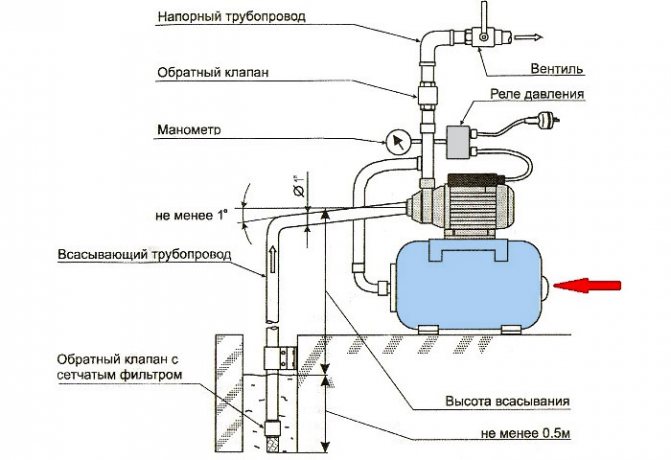

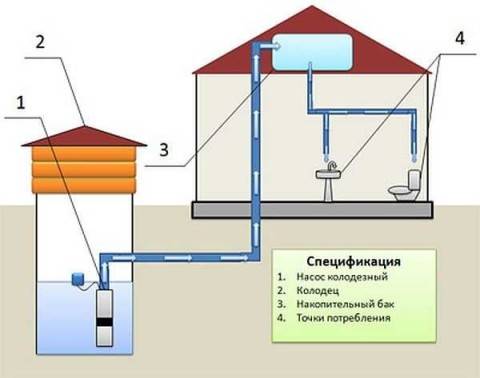

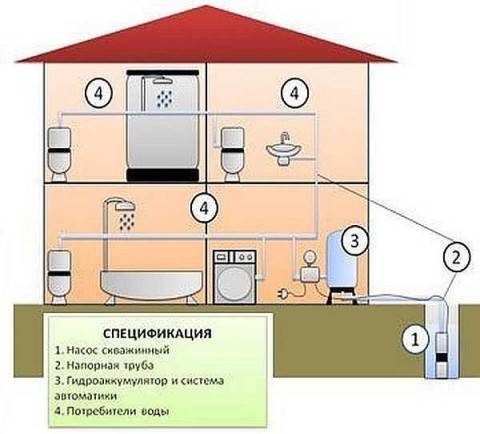

Basic installation and connection diagrams

The most common schemes are:

- Scheme of direct connection of the device to the supply pipeline.

- Scheme with a storage tank.

Direct connection involves placing the station between the water intake and the intra-house pipeline. Water is directly sucked from the well and supplied to the consumer. With this installation scheme, the equipment is located in a heated room - in the basement or basement. This is due to the fear of low temperatures. Freezing water inside the device can cause it to fail.

However, in regions with relatively mild winters, it is allowed to place a water station directly at the top of the well. To do this, a well buried in the ground is built above it, which is insulated to prevent freezing of water inside the pipeline. If necessary, an electric heating wire can be used. We will discuss in more detail all aspects of choosing an installation site below.

The scheme for connecting a station with a storage tank looks a little different. Water from the source is not supplied directly to the in-house system, but to a special volumetric storage tank. The pumping station itself is located between the storage tank and the internal pipeline. Water is pumped to the points of water intake by the station pump from the storage tank.

Thus, in such a scheme, two pumps are used:

- Deep well pump that pumps water into the storage tank.

- A pumping station that supplies water from a storage tank to a water supply system.

The advantage of the scheme with a storage tank is the presence of a sufficiently large amount of water in it. The volume of the tank can be several hundred liters, and even cubic meters, and the average volume of the damper tank of the station is 20-50 liters. Also, a similar version of the water supply system is suitable for artesian wells, when one way or another it is necessary to use a deep pump.

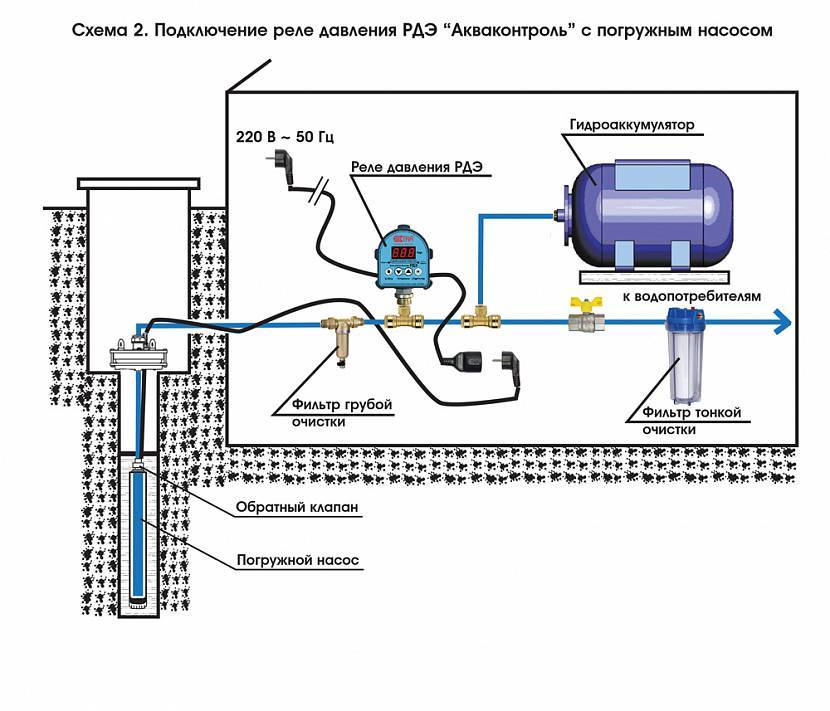

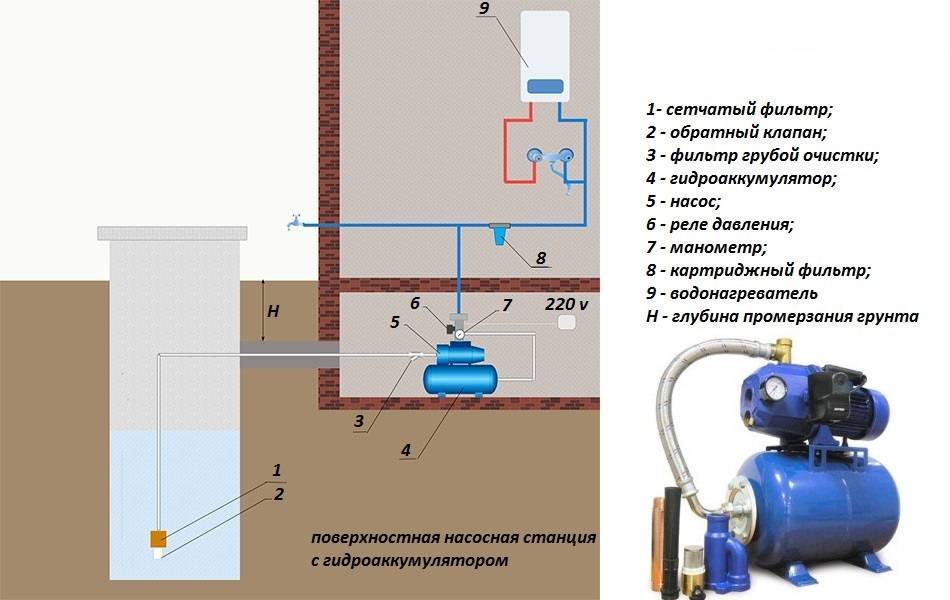

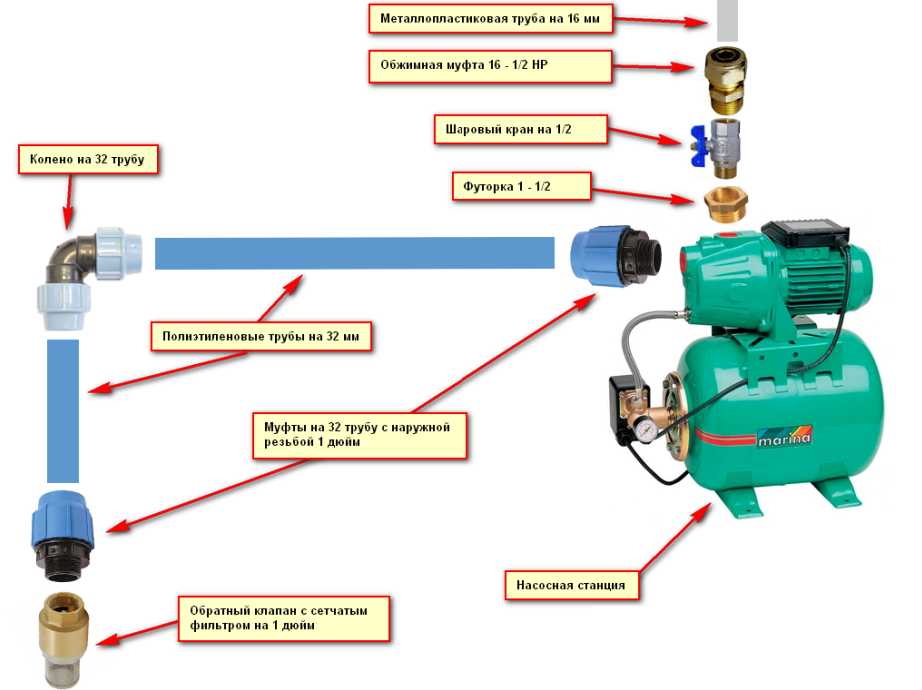

The composition of the pumping station and the purpose of the parts

A pumping station is a collection of separate devices interconnected. To understand how to repair a pumping station, you need to know what it consists of, how each of the parts works. Then troubleshooting is easier. The composition of the pumping station:

- Submersible or surface pump. Pumps water from a well or well, maintains a stable pressure in the system. It is connected to the house with pipes.

-

A check valve must be installed on the pipeline. It does not allow water to drain from the pipes back into the well or well when the pump is turned off. It is usually installed at the end of the pipe, lowered into the water.

- Hydraulic accumulator or membrane tank. Metal hermetic container, divided into two halves by an elastic membrane. In one, air (an inert gas) is under pressure, in the other, until a certain pressure is created, water is pumped. A hydraulic accumulator is necessary to reduce the number of pump starts and extend its service life. Creates and maintains the required pressure in the system and a small reserve supply of water in case of station inoperability.

- Block of control and management of the pumping station. Usually this is a pressure gauge and pressure switch, installed between the pump and the accumulator. A manometer is a control device that allows you to evaluate the pressure in the system.The pressure switch controls the operation of the pump - it gives commands to turn it on and off. The pump is turned on when the lower pressure threshold in the system is reached (usually 1-1.6 atm), and it is turned off when the upper threshold is reached (for one-story buildings 2.6-3 atm).

Each of the parts is responsible for a certain parameter, but one type of malfunction can be caused by the failure of various devices.

The principle of operation of the pumping station

Now let's look at how all these devices work. When the system is first started, the pump pumps water into the accumulator until the pressure in it (and in the system) equals the upper threshold set on the pressure switch. While there is no water flow, the pressure is stable, the pump is off.

Each part does its job

A faucet was opened somewhere, the water was drained, etc. For a while, water comes from the accumulator. When its quantity decreases so much that the pressure in the accumulator drops below the threshold, the pressure switch is activated and turns on the pump, which pumps water again. It turns off again, the pressure switch, when the upper threshold is reached - the shutdown threshold.

If there is a constant flow of water (a bath is taken, watering the garden / vegetable garden is turned on), the pump works for a long time: until the required pressure is created in the accumulator. This happens periodically even when all taps are open, since the pump supplies less water than flows out of all points of analysis. After the flow has stopped, the station works for some time, creating the required reserve in the gyroaccumulator, then turns off and turns on after the water flow appears again.

Popular manufacturers and prices

According to consumer reviews, today the relay of the Danish company Danfoss is more popular, its pressure range is 0.2-8 bar. The cost of such equipment is about 3000 rubles. A device from the German manufacturer Grundfos with similar characteristics already costs 4,500 rubles. Italian Italtecnica equipment with standard settings will cost about 500 rubles.

Domestic devices of the company "Dzhileks" are almost identical to Italian ones, but their cost is about 300 rubles. Thus, domestically produced products turn out to be much lower in cost, and in terms of their characteristics, they are practically not inferior to Western models.

2

According to the type of energy storage, the devices we are interested in come with mechanical and pneumatic storage. The first of these function due to the kinetics of a spring or load. Mechanical tanks are characterized by a large number of operational disadvantages (large geometric dimensions, high system inertia), so they are not used for domestic water supply systems. At the same time, it is worth noting that such devices do not need to be recharged and powered from external electrical sources.

Pneumatic storage units are more common. They function by compressing water under gas pressure (or vice versa) and are divided into the following types: piston; with a pear or with a balloon; membrane. Piston devices are recommended for cases when it is required to constantly have a sufficiently large supply of water (500–600 liters). Their cost is low, but in private dwellings such installations are operated extremely rarely.

Membrane tanks have small sizes. They are convenient to use.They are most often used for water supply systems of private housing construction. More simple balloon units are also actively used. Such devices are easy to install (you can install them yourself) and maintain (if necessary, any home master can easily replace a failed rubber bulb or a leaky tank). Although the need for repair of balloon accumulators is rare. They are truly durable and reliable.

Membrane tank for a private house

According to their purpose, storage tanks are divided into the following types:

- for heating systems;

- for hot water;

- for cold water.

And according to the method of installation, vertical and horizontal units are distinguished. Both the first and the second function in exactly the same way. Vertical hydraulic tanks with a volume of more than 100 liters usually have a special valve. It makes it possible to bleed air from the water supply network. Horizontal devices are supplied with a separate mount. An external pump is fixed to it.

Also, expansion tanks for differ in their volume. On sale there are also very small units, designed for 2-5 liters, and real giants for 500 liters or more. For private houses, it is recommended to purchase hydraulic accumulators for 100 or 80 liters.