- The device and principle of operation of the KNS

- Compact mini stations

- KNS for a country house

- Equipment selection rules

- How sewage pumping stations SFA SANICUBIC are arranged

- Device diagram

- Purpose and principle of operation

- Maintenance of modular sewage pumping station

- Sewage pumping station for a private house

- Installation and maintenance of KNS

- Appointment of the KNS

- How is the KNS arranged and working?

- Types of sewer pumping stations

- Submersible KNS

- Console KNS

- Self-priming KNS

- Details

- How to choose equipment

- How to calculate parameters

- Installation work

The device and principle of operation of the KNS

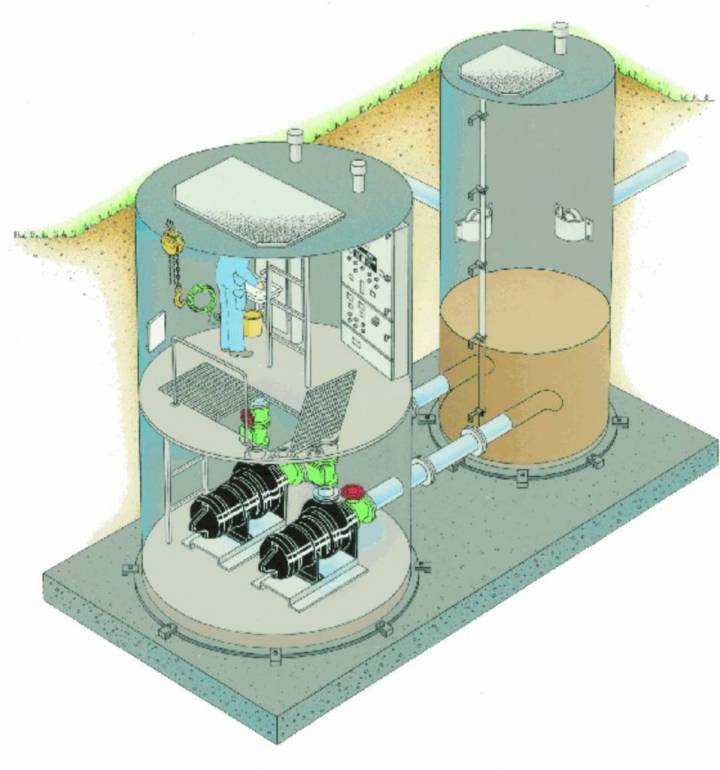

The device of modern KNS should be considered in two main options:

- sololift;

- sewerage station for a house or a cottage.

There are no fundamental differences between these devices. But sololifts are a single ready-made equipment that can be bought on the Internet and connected independently, and sewer stations are formed from separately sold parts for a specific external sewage project.

Compact mini stations

Portable SPS type "Sololift" have a compact appearance and are installed near plumbing equipment. It is installed either in the basement of the house, or in the bathroom itself.

Sololift provides drainage of sewage as it enters the body of the device (+)

The main structural units of the sololift are:

- hermetic housing with branch pipes and holes;

- engine;

- impeller with cutting edge;

- automation.

When water enters the device, the automation is activated and the engine is turned on. As a result, liquid is pumped from the inner tank into the pressure pipe. The impeller additionally crushes large fragments for effective removal of suspended particles and prevention of blockage.

When connecting to a mini-SPS using tees a large number of sewer inlets, it must be borne in mind that the pump performance may not be enough to pump the incoming liquid (+)

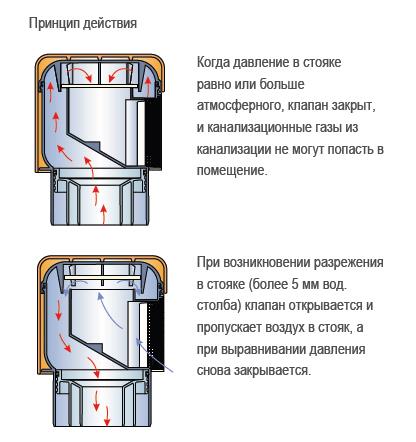

The body of the sololift can have 2-5 holes for connecting plumbing fixtures. An air valve is located on top of the device, which provides air leakage from the outside during pump operation. This prevents the water seal from breaking in the siphons of home equipment.

The performance of a portable mini-KNS is standard and theoretically calculated based on the number of supply pipes. After purchasing the equipment, it is enough to connect the pressure hose and sewer pipes to the body of the solofit, and then plug it into the socket.

KNS for a country house

The pumping station for a private house is usually large and dug into the ground. It will not be possible to find ready-made structural solutions of this type on the Internet, and to determine the estimated cost of equipment, you need to call store managers or leave a request on sellers' websites.

More durable are fiberglass and plastic containers.They do not require any maintenance and will last at least 50 years. The station is a sealed container with pumps inside.

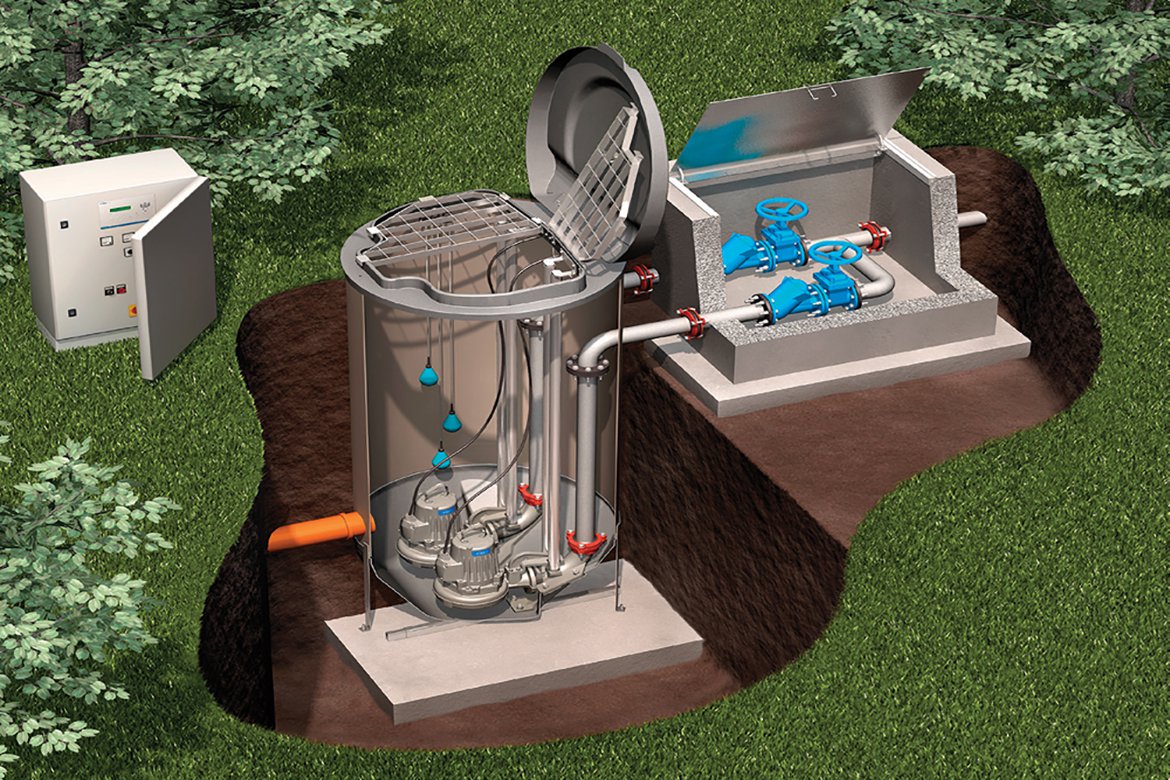

The main elements of the KNS for the house are:

- A storage tank made of plastic, fiberglass, concrete or metal with a volume of several cubic meters.

- Fecal pump. In daily operating stations, two pumps are installed: a working one and a reserve one, the task of which is to raise the wastewater to a certain level for their further movement through the pipes by gravity.

- A system of gravity water pipelines (supply and pressure discharge) that combines the internal sewerage, sewage pumping station and the subsequent collector. The system is equipped with gate valves and a check valve that allows fluid to flow in only one direction.

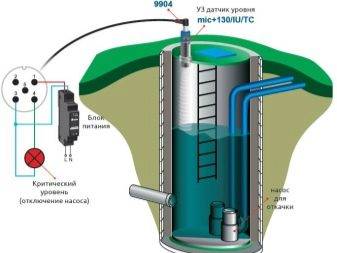

- Automation with float switches. It is recommended to install 3-4 floats at the same time, each of which is able to turn on the pump. They are inexpensive, so it is not worth saving on them.

Large domestic KNS have a principle of operation that is somewhat different from a sololift. The sewage tank is buried in the ground and connected to the drain pipe of the internal sewerage. When the level of sewage wastewater reaches the level set by adjusting the level, the float mechanism closes the network and turns on the pump.

The pumping of water stops only when the float reaches a level much lower than that which led to its inclusion. This scheme allows you to turn on pumping equipment less often, reducing operational loads.

Additional floats are intended to turn on the backup pump. The water level for starting them is set slightly higher than for the main pump.

This allows you to play it safe and turn on the backup equipment only in the event of a malfunction of the main one.

Additionally, KNS can be equipped with the following devices:

- flowmeter;

- lattice containers for filtering large debris;

- control and adjustment cabinets;

- ladder for descent into the tank;

- vortex flow regulator;

- sorption filters.

The choice of a set of equipment must be carried out only under the supervision of specialists. This will allow you to select components with the most appropriate characteristics and productivity.

Equipment selection rules

Next, the criteria will be analyzed, taking into account which it is necessary to choose sewer pumping equipment for private use. Analysis of industrial installations is beyond the scope of this review.

The goal when purchasing a sewage pumping station is to acquire equipment that is optimal in terms of power and other characteristics. It makes no sense to overpay for systems that will operate at 10-20% of the design capacity.

When choosing a CNS, the following parameters are taken into account:

- Maximum flow of processed effluents.

- transport distance.

- The difference in geodetic levels between the inlet pipe and the outlet of the pressure hose.

- The degree of pollution, fractional composition and structure of domestic wastewater. There are KNS, which grind large fractions of inclusions, preventing blockages in pumping equipment.

- The level of wastewater treatment required.

- Equipment dimensions.

There is no single formula for calculating the performance of pumping equipment, so the calculation algorithm and the necessary indicators must be indicated in the instructions for the purchased SPS.

A typical project for calculating the performance of pumping equipment includes the following steps:

- Determination of daily water consumption and volume of wastewater.

- Construction of an approximate schedule for the receipt of sewage wastewater during the day.

- Calculation of the minimum and maximum sewer flow.

- Determination of the required capacity of the sewage pumping station, taking into account the pollution of wastewater.

After determining the above parameters, you can begin to select the appropriate equipment.

The price of KNS is affected by the brand of the manufacturer, the maintainability of the product, and the possibility of service. It is especially not recommended to purchase cheap pumps if they are expected to be used daily, and there are no reserve tanks or an additional pump to divert wastewater.

How sewage pumping stations SFA SANICUBIC are arranged

Any pumping station from SFA is equipped with one or two powerful motors. All waste enters the compartment with cutting knives, which quickly and effectively grind them. The pump then pumps all the waste into the sewer. Special valves prevent sewage from flowing back into the pump and completely eliminate the possibility of sewerage from the toilet bowl (or toilet bowls) during flooding. Also, all stations are equipped with the necessary taps to create routes of various lengths and configurations. If you want to choose one or another model of a pumping station, then you should first calculate the expected load on it, the approximate volumes of wastewater.

Any pumping station from SFA is equipped with one or two powerful motors. All waste enters the compartment with cutting knives, which quickly and effectively grind them. The pump then pumps all the waste into the sewer. Special valves prevent sewage from flowing back into the pump and completely eliminate the possibility of sewerage from the toilet bowl (or toilet bowls) during flooding. Also, all stations are equipped with the necessary taps to create routes of various lengths and configurations. If you want to choose one or another model of a pumping station, then you should first calculate the expected load on it, the approximate volumes of wastewater.

Any pumping station from SFA is reliable, durable, safe. These devices have international quality certificates. You can create the most comfortable conditions at home or at work with them quickly and easily.Check it out yourself!

SFA is the quality of every detail and a long service life. The French company has been operating for over 60 years and currently occupies a leading position in its field.

The main advantages of SFA fecal pumps with grinder:

- Silence of work (Series Silence) It is possible to establish in any private room, at the dacha or at office.

- Charcoal filter Prevents any odors

- Membrane way of actuationThe membrane automatically turns on the pump for pumping to the required level. This feature distinguishes SFA pumps from some other manufacturers, because other manufacturers often activate the pump for a certain time, for example, 10 seconds. But, you must admit, you don’t want to hear the noise of the pump for 10 seconds at all, if it takes 3-5 times less time to pump out!

- Automatic blocking of the vent when the level of drains rises above the critical level. This function does not require an electrical connection and allows you to fully evacuate the pump before pumping starts. This means that if you have a power outage, water will not spill out of the pump. There will be no flood!

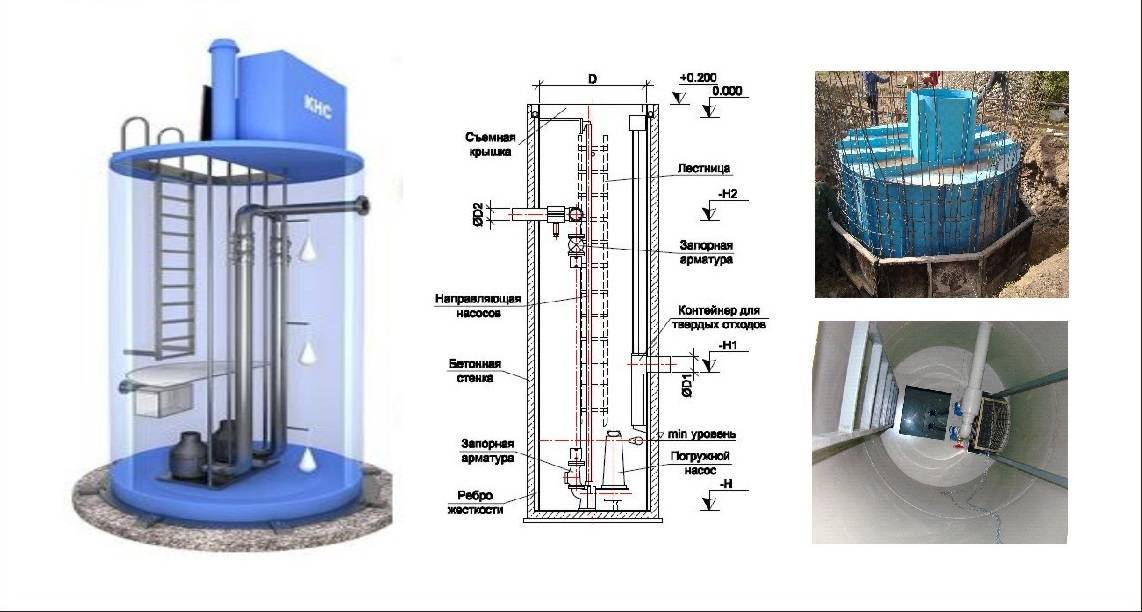

Device diagram

Different types of pumping stations for sewage differ from each other in design, but regardless of the modification, their main elements are a pump and a sealed tank in which waste products are collected. The tank with which the sewer pumping station is equipped can be made of concrete, plastic or metal.The task of the pump, which is equipped with a sewer station, is to raise the wastewater to a certain level, after which they enter the storage tank by gravity. After the tank is filled, wastewater is pumped out of it and transported to the place of their disposal.

SPS device of the middle class

Often, the design scheme of a household sewage pumping station includes two pumps, while the second of them is a backup and is used in cases where the main one is out of order. Several pumps are mandatory equipped with sewage pumping stations serving industrial and municipal enterprises, characterized by a large volume of wastewater. Pumping equipment for SPS can be of various types. Thus, domestic sewage pumping stations are usually equipped with pumps with a cutting mechanism, with which the fecal matter and other inclusions contained in wastewater are crushed. Such pumps are not installed at industrial stations, since solid inclusions contained in the wastewater of industrial enterprises, getting into the cutting mechanism of the pump, can lead to its breakdown.

The device and connection of a small-sized SPS, located indoors

In private homes, mini sewage pumping stations are often installed, the pumps of which are connected directly to the toilet bowls. Such an aesthetically designed KNS (a real mini-system equipped with a pump with a cutting mechanism and a small storage tank) is usually installed directly in the bathroom.

Serial models of sewage pumping stations are equipped with polymer tanks that are buried in the ground, while the neck of such a tank for sewage pumping stations is located on the surface, which facilitates scheduled inspections, maintenance and repair of the tank, if necessary. The neck of the storage tank before the start of operation of the SPS is closed with a lid, which can be made of polymeric material or metal. The connection of such a tank to the sewer system, through which wastewater enters it, is carried out using nozzles. In order for wastewater to enter the storage tank evenly, a special bumper is provided in its design, and the water wall is responsible for ensuring that no turbulence occurs in the liquid medium.

KNS are divided by layout into horizontal (left) and vertical (right)

In equipping sewer pumping stations for a private house, there are control devices and automatic control mechanisms. Additional elements supplied by industrial sewage systems and installations for servicing the home sewer system include:

- a source that provides backup power to the equipment that is part of the SPS;

- pressure gauges, pressure sensors, elements of valves;

- equipment that provides cleaning of pumps and connecting pipes.

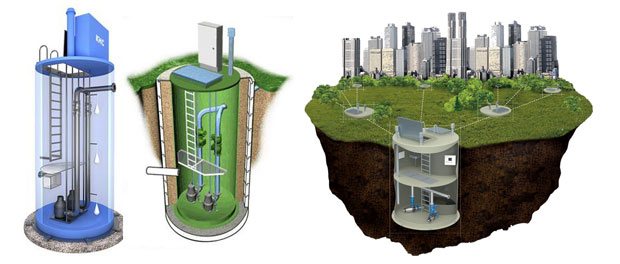

According to the design, KNS are with submersible pumps, dry design and multi-section

Purpose and principle of operation

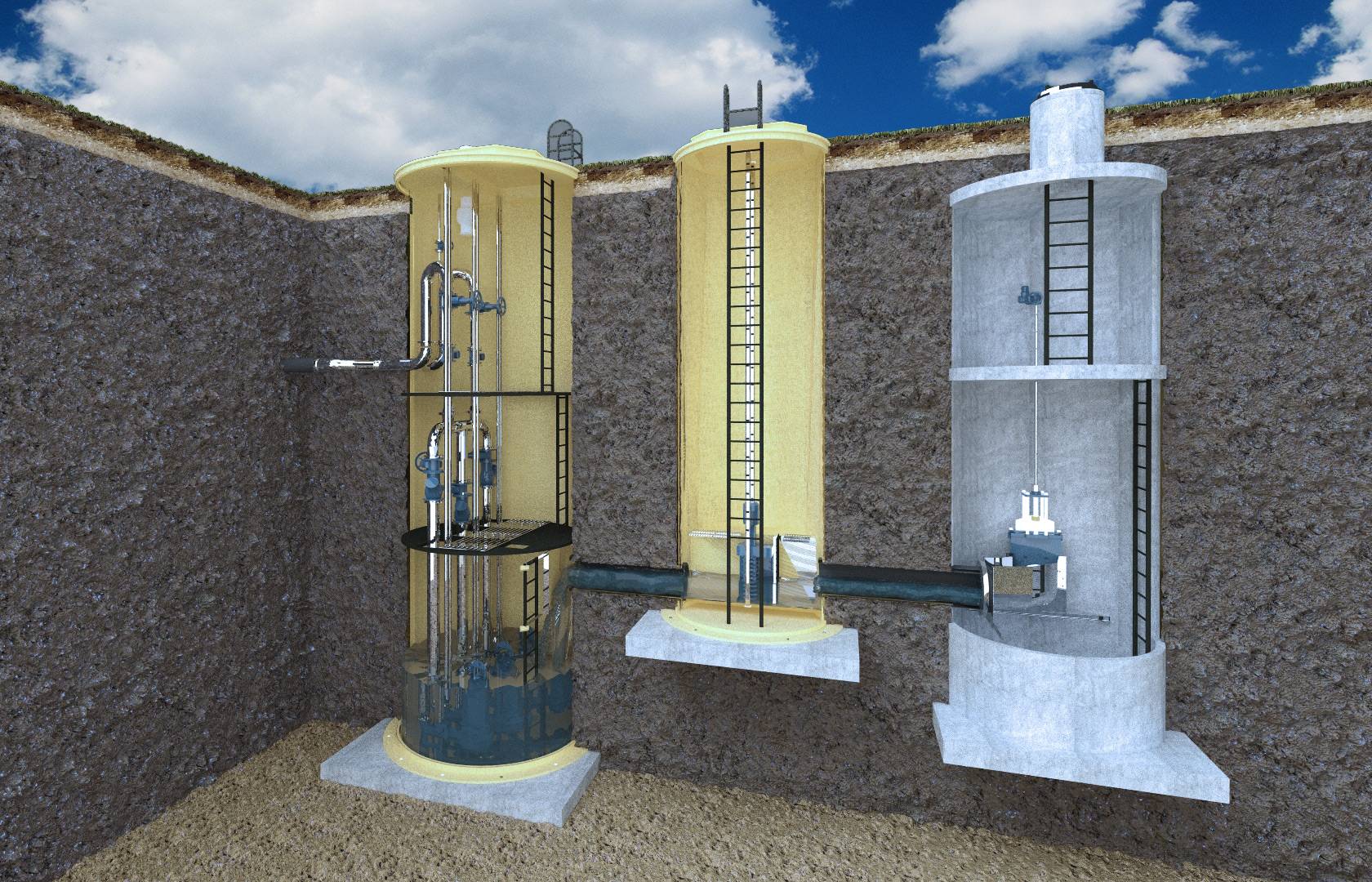

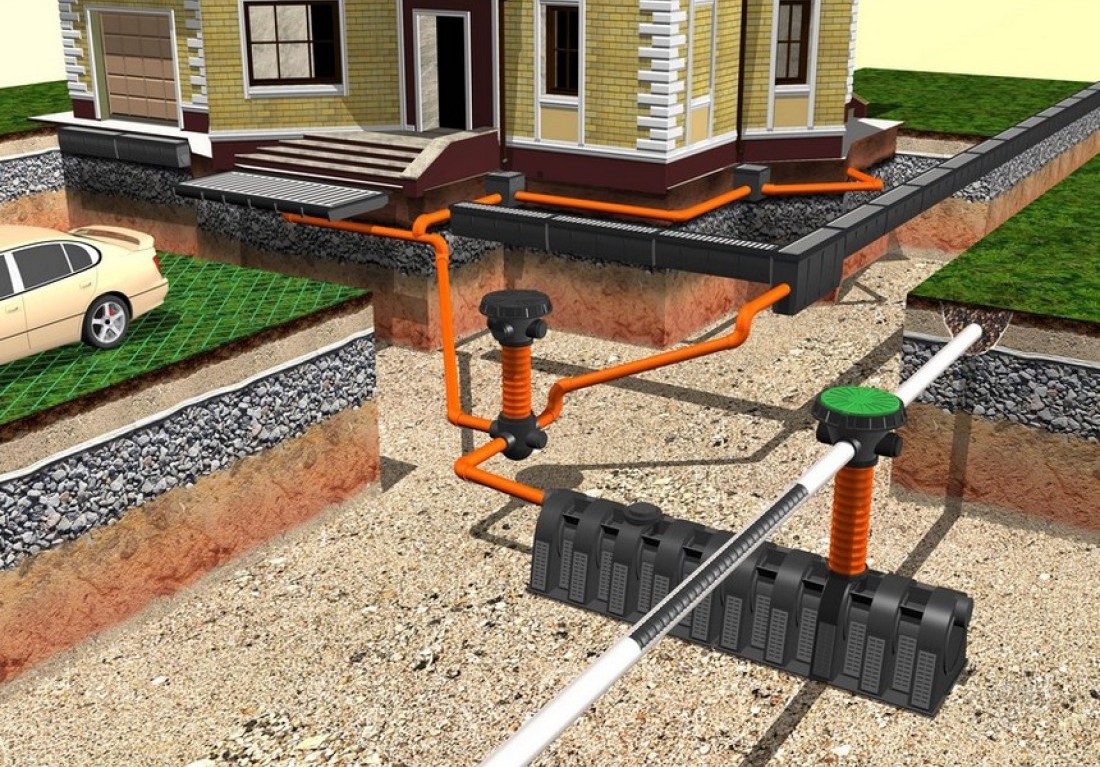

Sewer stations are intended for pumping rainwater and sewer masses in cases where their movement by gravity is impossible or difficult.This occurs when it is not possible to organize the slope of the drain pipe, when the sewage and toilet facilities are located below the level of the receiving collectors or cesspools, as well as when they are located far from the source of the drain. The stations are widely used in cottage settlements, country estates and industrial facilities, the significant distance of which does not allow them to connect to the central sewer networks.

The principle of operation for all CNS is approximately the same. Contaminated effluents flow into a receiving tank, from which, using pumping equipment, they are pumped into the pressure pipeline system. Further, the masses are inside the distribution chamber, from where they go through the pipeline system to the sewage treatment plant or the sewerage collector. All stations are equipped with a valve that does not allow the liquid to flow back, and ensures its movement in only one direction.

The stations are equipped with an automatic control system. So, monitoring of the level of effluents is carried out by float sensors, which are located at different levels. In the event of a serious accident and failure of both pumps, sensors set to a critical level for the system automatically turn on an alarm, notifying owners that the system cannot cope with the volume of sewage masses or is out of order. During repair work or start-up, the station switches to manual control mode.

Stationary mini-stations with a chopper work on a similar principle. At the moment when liquid masses enter the device, automatic sensors are triggered, which, in turn, start the engine.As a result, the liquid from the tank is pumped into the pressure pipe, through which it goes to the collector. For more efficient disposal of sewage, compact stations are equipped with a special impeller, which grinds large fragments, which prevents the possibility of pipe clogging. Usually in the body of the sololift there are from 2 to 5 holes designed to connect plumbing: toilets, sinks, sinks and showers. At the top of the station there is an air valve that provides air supply during the operation of the pump, and excludes the disruption of hydraulic seals in the siphon of the device.

Maintenance of modular sewage pumping station

The automatic sewage pumping station, which diverts domestic wastewater from the house (cottage), has a rather low intensity of work. Therefore, it is sufficient to carry out routine inspection and maintenance of the sewage pumping station once a season (once a month in winter). The order is as follows:

- The readings on the control panel are compared with the working (design). The discrepancy should not exceed 10%.

- Periodically, manually, the waste bin basket is emptied.

- Loose fastenings of the manhole, stairs and platforms are pulled up.

- At least once a year, the sewage pumping station (walls and bottom) should be cleaned with water from an irrigation hose under pressure.

- The condition of the valves is checked from the service platform by trial opening and closing of valves. The readings of the pressure gauge on the pressure pipeline and the gas analyzer are checked against the performance data.

Repair. If the pump emits extraneous noise during pumping, then the system is disconnected from the power supply and the shut-off valve is closed. The apparatus is removed along the guides to the surface, washed with cold water and inspected. If necessary, change the gaskets, bearings, tighten the fasteners.After inspection (repair), the equipment is returned to its working position, making sure that the automatic clutch snaps into place.

Sewage pumping station for a private house

The sewer pumping station (SPS) for a private house consists of a storage tank and a compartment with a group of pumps. Thus, there is no need to deepen pipelines and wells - the pressure system can function perfectly without an artificial slope.

The purpose of installing a sewage pumping station is to solve the problem with arbitrary effluents and the forced removal of effluents and large fractions of organic matter and garbage contained in domestic wastewater to the collector (if possible and the tie-in is allowed), or to bio-treatment stations, mandatory for an autonomous sewer system of a private house.

Fundamentally, the design and operation of the KNS differs from a conventional pumping station - these are the parameters of the pumping equipment. A powerful and dirt-resistant fecal pump with a grinder and sensors is used to control the filling level of the tank and turn on the pumps. The pumping station makes the installation of the entire system much easier and less time consuming. This is due to the fact that this equipment does not require the construction of an additional well. The station is installed vertically on a flat, concreted platform. Then a pipeline and cables are connected to it, after which they are covered with earth. Backfilling is carried out with simultaneous filling of the station with water, this will help to avoid deformation of the hull from the load created by the soil.

The material of the tank is a durable polymer capable of withstanding temperature changes and soil pressure without deformation. The placement of the tank is possible both deep and closer to the surface, which is required for control and maintenance: the station tank has a neck and an inspection hatch.

KNS placement is possible in different options:

- Recessed - at ground level only the manhole cover;

- High - only part of the tank sinks into the ground;

- Surface - the entire station or household unit is mounted above ground level - an option for mounting mini-stations, which are increasingly used to ensure the operation of the sewer system in a house and even in high-rise apartments, while the household unit is located next to the toilet.

You can control the pumping equipment of the SPS in various modes:

- Manual mode: constant operator control and manual activation of all necessary processes.

- Remote work. A mini control room is equipped, and all the commands necessary for the operation of the system are given from the remote control.

- Offline work. The system of control and measurement sensors ensures complete autonomy of the station. Including actions in emergency situations - in case of failure of the main pumping equipment, the backup is switched on, in the event of a power outage, the system switches to backup power, and so on.

For a modern house and cottage, only complete autonomy of the KNS with the possibility of control is relevant, although manually controlled mini-stations are still not uncommon in private homes.

The technical capabilities of domestic SPS vary greatly by model, and the most important parameter is by type of flow:

- For the removal of domestic sewage from a house, cottage, any building from which it is required to divert used water and domestic fecal effluents.

- Industrial sewage pumping stations differ from domestic ones in the huge power of the equipment and the ability to clean and deactivate aggressive effluents, chemicals that are dangerous to humans. In household sewage pumping stations, automatic systems for flushing nodes and protecting the system from chemical aggression are rarely provided.

- SPS for the storm sewer system. It has nothing to do with household drains, it is mounted in order to radically improve the operation of the stormwater drain. When storm sewers cannot cope with peak flows, the entire drainage complex is at risk - in such cases, storm water sewage systems become the solution to the problem.

Installation and maintenance of KNS

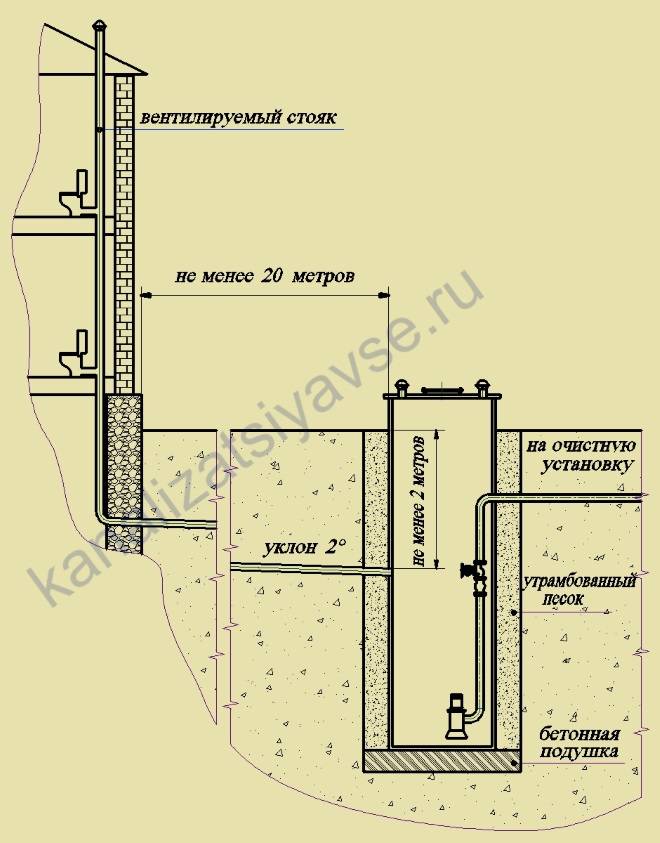

In accordance with the requirements of SNiP 2.04.03-85, the distance from the sewage pumping station to residential buildings is taken depending on the capacity of the station. If this parameter is ≤ 200 m3/day, then the sanitary protection zone (SPZ) should be at least 15 meters. The specific average daily water consumption per person is 0.16-0.23 m3/day. A family of 5 consumes about one cubic meter of water per day. If the drains after the sewage pumping station are settled in a septic tank, then the flow rate is accepted with a 3-day supply. In any case, a simple calculation shows that the capacity of the station will be less than 200 cubic meters, which means that 15 meters is the minimum that you need to focus on. But, in the end, everything is decided by the KNS project. After approvals, there may be five meters of CVD there - the inspectors will not say a word to you.

Installation of KNS

Installation of KNS

Installation of SPS (modular) will take place in the following order:

- A pit is dug out mechanically. The bottom is compacted with a layer of gravel.Top - 10 cm of compacted sand.

- The formwork of the reinforced concrete base of the KNS is assembled, after which the pouring is carried out. The concrete layer should be no thinner than 30 cm.

- When the concrete gains brand strength (28 days), the installation of the sewage pumping station begins. The container is leveled, and its base is attached to the foundation slab with anchors. If there is a danger of the station being pushed out by groundwater, then its body is “loaded” with ready-mixed concrete.

- Produce layer-by-layer (50 cm each) backfilling and tamping of the soil. In the process, gravity and pressure pipelines are connected.

- Pumps are lowered into the tank, connected to guides and pipelines. Install float sensors.

- Electricity is supplied to the station and the control cabinet, grounding is made.

- The above-ground part of the tank is insulated.

Appointment of the KNS

Sewerage systems operate on a gravity principle. Liquids move independently through a system of pipes installed with a slight slope. This simplifies the composition of the network, makes it simpler and cheaper. However, the terrain, buildings, structures and other obstacles often do not allow for the correct position of the pipes. If the house is in a lowland, and the sewer is located above the level, the independent flow of liquids becomes impossible. We have to pump waste with the help of special equipment. For this, SPS (sewage pumping stations) are used, the principle of operation of which is based on the reception of effluents and their transfer to another container. It is located at a certain height, provides the usual movement of waste under the action of gravity.

Automatic sewer pumping station (SPS) is designed to supply

drains from a lower level to a higher one under pressure. For this, they are used

mud (fecal) pumps,

installed in the receiving chamber. They transfer wastewater to a reservoir located

at a higher level. From there, the liquid flows by gravity into the collector. Stop

The sewage pumping station stops the discharge of wastewater, so the condition of the equipment is always

is under close control.

Installation of a sewage pumping station -

forced event. If it is possible to do without it, no one

will waste money and energy. However, waste transfer

impossible in any other way. Often there are situations when the use of QNS

becomes the only way to connect the house to the central system.

How is the KNS arranged and working?

The best mobile application for experienced BPlayers has appeared and you can absolutely free download 1xBet on your Android phone with all the latest updates and discover sports betting in a new way.

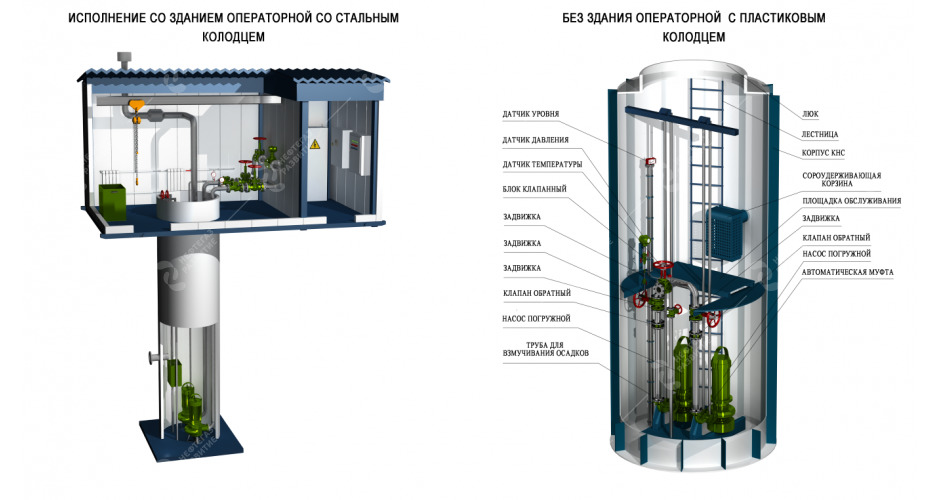

The sewer station, regardless of power and size, has the following key structural elements:

- frame;

- coarse mesh filter;

- submersible pump;

- float sensors of the liquid level with a pump operation control system;

- inlet and outlet pipelines with shut-off valves (taps, valves).

The body can be cubic or cylindrical (more often the second). For its manufacture, polymers of the appropriate quality are used, less often metals. From above, the hull is equipped with a hatch that gives access to the inside of the sewage pumping station for inspection and repair. Often a ladder is installed inside (in more powerful models).The housing is equipped with a ventilation system, which is mandatory in sewer stations.

The purpose of the filter is to trap large solid objects that could damage the pump or liquid level control system. They are especially relevant in stations that are designed to effectively remove melt and sedimentary water from the house, with which gravel, small stones, and fragments of wood are often washed away. The filter, retaining only large solid inclusions, does not create obstacles for liquid waste, having a high throughput.

Wastewater enters the filter device from the incoming pipeline by gravity. After passing the filter, the liquid gradually fills the tank (station body) to a certain level, after which the pump turns on and begins to throw sewage water into the outlet pipeline, through which the liquid flows by gravity into the septic tank or central sewer.

The operation of pumping equipment is controlled by an automation unit, the sensors for which are floats that change their position depending on the liquid level. When the floats reach the upper control mark, the pump turns on, the lower one turns off. Such a control system makes the work of the CNS autonomous, not requiring outside participation. All that is required of the homeowner is an occasional (once every six months) inspection and cleaning of the filter.

Types of sewer pumping stations

The development of drainage and treatment systems differs in the type of pumping equipment used, since such devices are the main working components of the sewage pumping station. It is they who are engaged in pumping domestic sewage or storm water, industrial waste and sludge.Based on this, sewer stations are equipped with the following pumps:

- submersible;

- console;

- self-priming.

Submersible KNS

Submersible pressure devices are always in the water itself (submerged state). Such systems are made from materials that are resistant to aggressive liquid media. Pumping equipment of this type is very convenient because it takes up little space. Since the pumps are constantly submerged, there is no need to prepare a separate site for them and additional piping.

Submersible sewage pumping stations have a number of advantages:

- high reliability;

- ease of drafting a development and operation project;

- less regular maintenance work;

- efficient operation at low temperatures;

- the system is cooled by the flowing liquid;

- the devices are versatile as they can also be used for dry installation.

Console KNS

Console sewer systems operate on dry-installation pumps. They are usually used for industrial purposes. The pumps used are not intended for modular standard stations, since their installation requires specially preparing a separate foundation and correctly connecting the pipe interchange. It is better to entrust the commissioning of such systems to professionals. Cantilever type pumps are installed openly on objects, so access to them is facilitated.

Console KNS have the following advantages:

- reliability;

- easy and quick access to system elements and control panel;

- ease of maintenance;

- the ability to change performance due to the correct selection of the electric motor and other devices.

Self-priming KNS

Self-priming KNS work on fecal pumps of dry installation. Usually they are used by industrial and municipal enterprises (KP) for pumping highly polluted liquid or surface storm water with solid particles at various industrial facilities, on the territory of large settlements, for cleaning parks in Moscow and other cities of the Moscow region, etc. Such devices are easy to use. maintenance, as the motor is flanged to prevent clogging of the system.

Self-priming KNS have the following advantages:

- easy to maintain due to the unique retractable block design;

- little prone to clogging;

- work at a negative temperature (this can be done by connecting special heating elements);

- able to pump sewage, which contains solid particles and coarse sediment;

- are the most hermetic devices, because they have a double mechanical seal.

Details

Varieties of pumping stations for the home. Compact devices are placed behind the toilet, or near the exit from the room, they pump wastewater into the septic tank. The device is a piece of equipment in a plastic case that operates silently. They consist of a submersible mechanism, sometimes equipped with whining elements. Larger SPSs have a high capacity. They include a septic tank equipped with a submersible pump. It works. When you need to clean the tank, either you need to redirect sewage to a common highway, or to a special sewage truck.

The most common is the option of a device installed permanently. It has two or three submersible pumps.With the help of them, drains go beyond the territory of the house into the sump. Using a fecal pump, the effluent is pumped to another septic tank to be filtered through the soil.

How to choose equipment

To serve a multi-storey building, you need to have a large storage tank, as well as several pumping devices for pumping wastewater

It is important that the pumps have cutting elements in order to break up large particles in the waste and not clog the pipe.

How to calculate parameters

When buying a pumping station, you do not need to purchase an expensive device. You need to rely on the following parameters:

1.The size of the device must be suitable for the home to be served. In a private house, it is necessary to install a household appliance that will fit on one square meter.

1.The size of the device must be suitable for the home to be served. In a private house, it is necessary to install a household appliance that will fit on one square meter.

2. the amount of waste that is expected to be processed. The parameter depends on the number of people who live in the house.

3. remoteness of the house from the septic tank.

4. the level of the height of the pipe that sucks in and releases drains.

5. performance level, which depends on the quality of wastewater, their pollution.

Attention! You can install a compact station for the home with your own hands. Large stations consist of several parts that are designed to work in specific conditions.

Installation work

Attention! Household stations in the house are serviced regularly. Pumps can become clogged if they don't have cutting parts

Pros and cons of pumping stations. Pumping stations improve the performance of all sewers. They help to eliminate odors, do not allow drains to move in the opposite direction. Apparatus should be serviced, cleaned periodically, and this implies monetary costs. Pumping stations are expensive, the brand, body material, and structural complexity of the device affect the price.If properly installed, the device will last more than ten years.

Attention! We must beware of Chinese fakes, you should not buy very cheap devices.