- Expert advice

- Selection of a pump for washing machine repair

- Drain pump replacement

- Replacing the pump through the bottom

- Replacement through the front cover

- Access to the pump after removing the bottom bar

- Through the back or side cover

- How to check the efficiency of the washing machine pump

- What is a pressure switch

- Testing the pump coil

- 4 Alternative option - a machine with a tank

- Step by step instructions - how to make a pump with your own hands?

- Types of washing machine pumps

- What pressure does the pump create?

- What damage could happen

- Diagnostics for vertical loading

- Front loading diagnostics

- What water pressure is needed for a washing machine?

- Types of malfunctions and repairs

- Removing the pump through the front panel

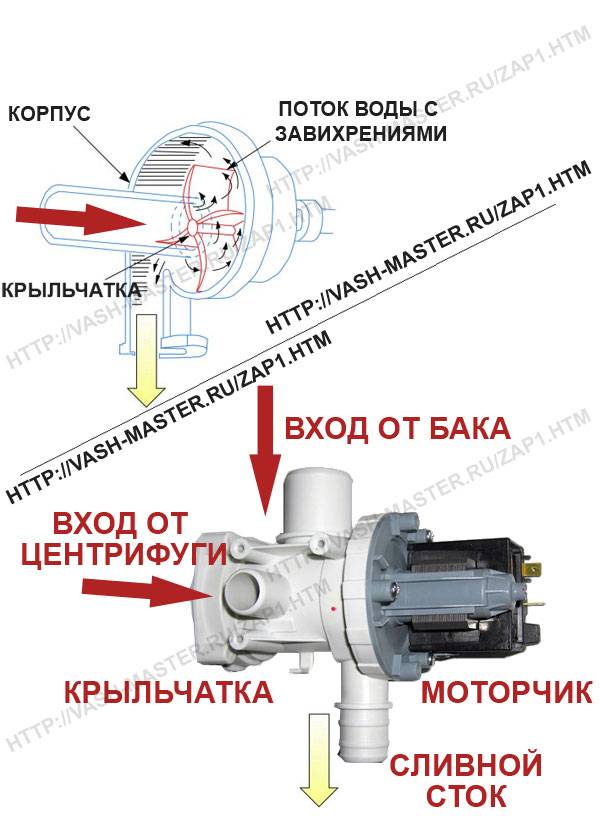

- Pump device

- Operating rules

Expert advice

Professional craftsmen servicing machines know several causes of breakdowns that do not lie on the surface, but affect the performance of the pump:

- Particularly “jumpy” machines can fray the power wires of the pump during washing. Then the pump will be externally serviceable, but it will not work and spin. To diagnose this problem, you will need to disassemble the device to the electronic control unit. This repair is quite labor intensive. Only a master can handle it, a beginner cannot repair it.

- In some cases, the program of the electronic control unit may fail.Such diagnostics and repairs will be performed only by a professional master with special equipment.

- Another rare malfunction is a blockage in the hose from the main tank to the snail with the pump. It can be determined by hand, squeezing different sections in turn. If necessary, the hose can be removed and cleaned under strong pressure from the tap.

Most often, craftsmen check the contact group and the impeller of the pump. If the cause of the breakdown does not concern these parts, the specialist simply replaces the entire assembly.

You can fix the pump of the washing machine with your own hands. This is a simple operation, especially if you have an assistant

When working, you must take precautions, do not forget about the remaining water in the tank and do not try to repair or solder the pump, if it does not concern the impeller or contact group

In everyday life, washing machines have long been indispensable. For smooth operation, you need to install it correctly. Well, if a breakdown occurs, read our articles on how to repair or replace the drum, pump, drain and pressure switch, bearings, heater, tank.

Selection of a pump for washing machine repair

If the pump has served for more than 5 years, and the diagnostics showed the need to replace it, you will need to purchase a new one. To increase the life of the pump, you need to choose it correctly.

When choosing a pump, consider the following parameters:

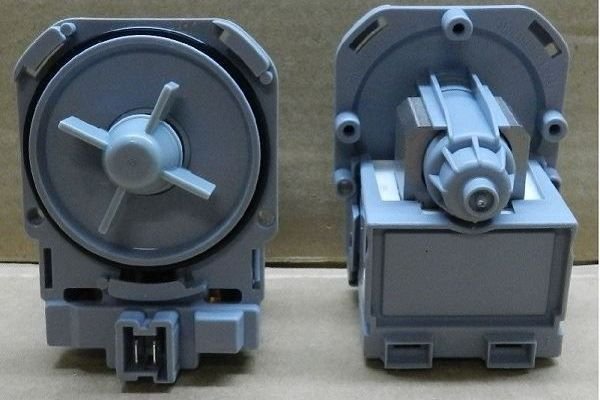

- Fastening to the cochlea: on 3 screws or 3, 4 and 8 latches. The fastenings of the new pump must be the same as those of the old one. Otherwise, it just won't fit.

- Method of connecting wires: "chip" and "terminals". If instead of a pump with a chip, you purchase a model with terminals in the form of terminals, you will need to cut the twin wires at the end, strip and install the terminals.

- Placement of the contact group.May be in the back or in front. The location doesn't really matter. This does not affect the operation of the pump.

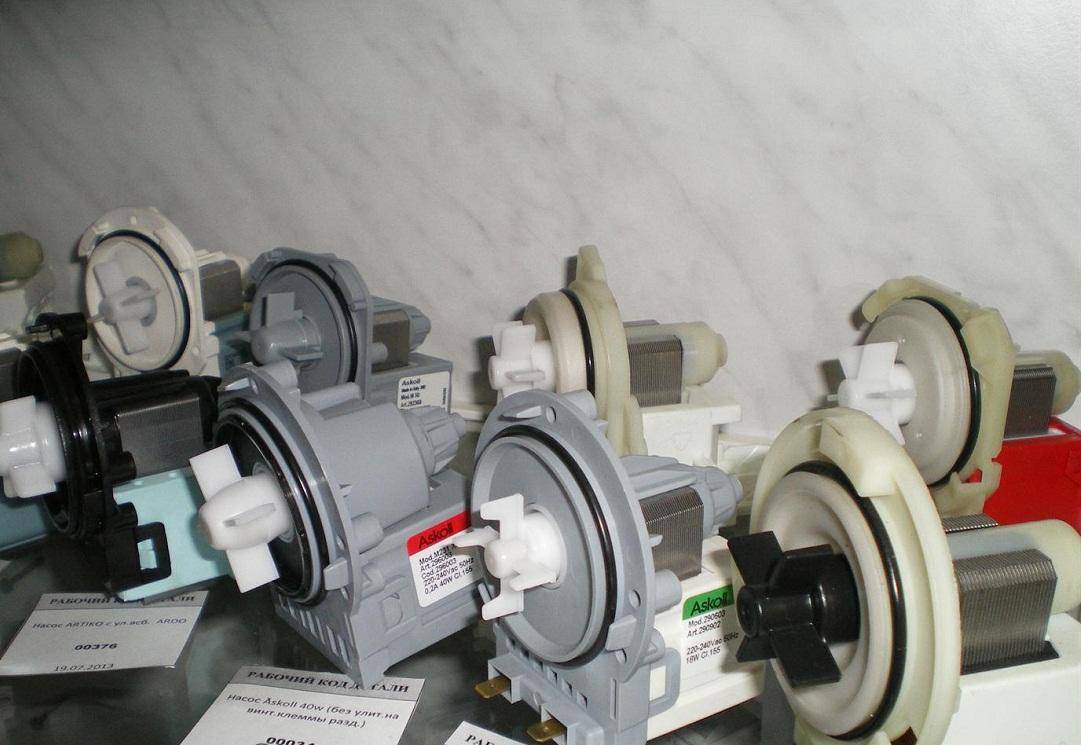

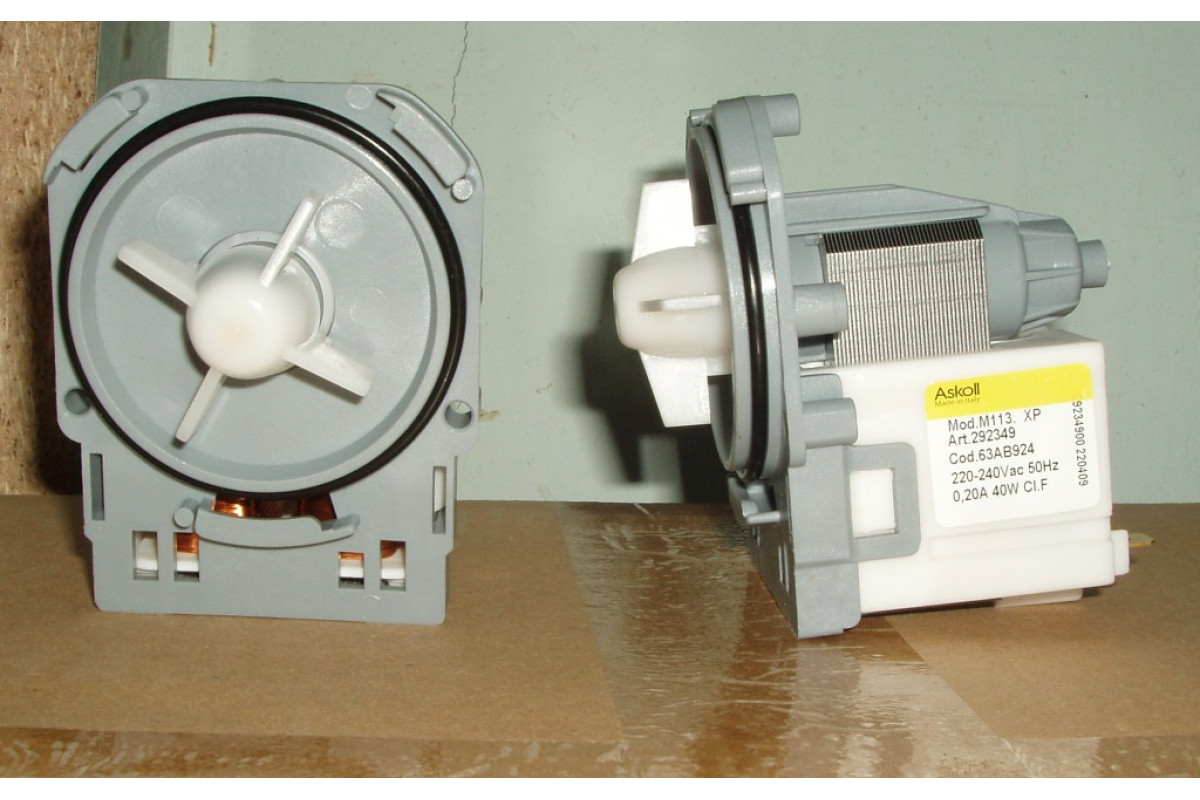

- Drain pump manufacturer. There are several universal brands: Coprecci, Arylux, Mainox, Hanning, Plaset, Askoll. Pumps from these manufacturers are interchangeable.

- Pump power indicated on the sticker. This parameter does not matter much, since it is approximately the same for all models.

It is difficult for an ordinary person to understand the design features of pumps, therefore, when choosing a new device, it is better to consult a professional.

Image gallery

Photo from

The chip model can be replaced with a pump with terminals by cutting the ends of the twin wires, stripping and installing the terminals

The placement of the contact group at the back does not have any effect on the operation of the washing machine pump

The front location of the contact group, like the back, does not matter much, as it does not affect the operation of the pump

Pump with an output in the form of a "chip"

Connecting the wires to the pump to the terminals

Rear location of the contact group

Placement of the contact group in front

The design variety of drain pumps is primarily determined by the features of the plastic pipe (snail) and debris filters combined with them. In modern models, manufacturers use three types of pumps:

- on three snail screws (Samsung, Indesit, Ardo);

- on three latches under the snail (AEG, Bosch);

- on eight latches under the snail (LG, Zanussi).

Pumps of the same type are interchangeable. For example, a Samsung pump is suitable for an Indesit brand car and vice versa.

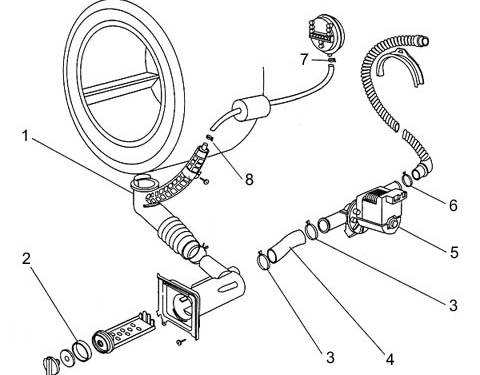

Drain pump replacement

The procedure for replacing the pump in the washing machine begins with the dismantling of the faulty device.But even before starting work, you must carefully study the documentation that comes with the machine. The fact is that machines of different manufacturers have a different device. It is necessary to understand the location of components and assemblies, and only after that take up a screwdriver.

For novice masters, it will not be superfluous to photograph each stage of work. You will get a kind of manual with pictures that will help you avoid mistakes during the assembly process. This is not difficult because cameras are built into most modern phones.

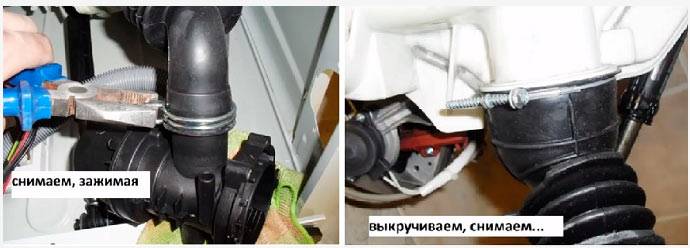

Replacing the pump through the bottom

It is enough to simply replace the pump in washing machines that allow replacement through the bottom panel. These are most models of Samsung, Indesit, LG, Ariston and some other manufacturers.

It is necessary to perform a sequence of simple steps:

- turn off the power;

- close the water

- put the car on its side, with the expectation that the pump is on top;

- remove the bottom panel;

- unscrew or remove the drain pump from the clamps;

- bring a container under it to drain the remaining water;

- loosen the clamps holding the supply hoses;

- remove the pump.

Be sure to clean the body (snail) from accumulated debris and only then install a new device.

Replacement through the front cover

Not all models allow replacing the pump in the previous way, for example, devices manufactured by Bosch, Siemens, AEG. Here you have to act in a different way - to get to the engine through the front cover.

First of all, you need to unscrew the two fasteners located on the rear panel, then remove the case cover. Next, the crucial moment - the panel with the controls is removed. To do this, remove the dispenser, unscrew the two screws

Carefully remove the panel and place it on top of the machine

After that, loosen the clamp holding the cuff and fill it inside the tank. Remove the remaining fasteners that hold the front panel. Remove it by pulling it towards you.

The engine is open. It remains only to disconnect the power wires, unscrew the pump (in some models, remove it from the latches) and replace it with a new one.

Access to the pump after removing the bottom bar

Perhaps the easiest way to replace the pump was suggested by the manufacturers of Hansa washing machines. Access to the pump is extremely easy. There is no need to disassemble the machine, moreover, it does not even need to be moved. Simply remove the lower bar of the front cover, behind which the pump is located. Further replacement steps will not cause difficulties.

Through the back or side cover

In most cases, to replace the pump in top-loading washing machines, it is enough to remove one side panel. The Electrolux and Zanussi models allow access to the pump by removing the back panel. Similar actions should be carried out for the repair of machines of some less common manufacturers.

You can replace the pump in any washing machine, it is important to prepare, study its device, understand the principle of operation. Machines from different manufacturers are different, universal methods do not exist

But in any case, it is important not to forget to turn off the power and remove water from the machine before starting work.

How to check the efficiency of the washing machine pump

In the illustration: bottom view of the washing machine, the drain pump chip is disabled. 2 more pumps are visible (recirculation and irrigation).

Attention! When working with electrical devices, the safety regulations must be observed!

If the pump does not drain the water, then in order to check its performance and exclude suspicions of a malfunction of the electronic module, we proceed in the following way:

- After washing, leave the water in the tank or top it up so that the water level is slightly above the bottom of the drum.

- Disconnect the washer from the mains by removing the plug from the socket.

- We remove the front panel of the machine in order to have access to the pump connection terminals.

- Remove the chip or terminals, depending on the features of the model. We connect the terminals of a pre-prepared wire with a plug. We check the reliability of the fit and the absence of mutual contact of the contacts. Plug in the plug. If the water in the tank leaves, then the pump is in working condition. And the cause of the breakdown must be sought in the malfunction of the electronic module or other elements in the pump control circuit.

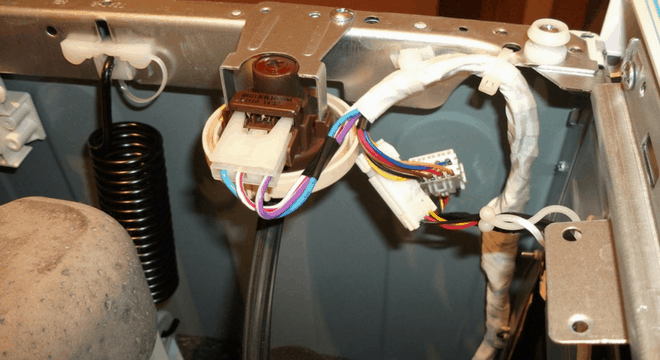

What is a pressure switch

When wondering what a water level sensor is, it is necessary to understand that any process associated with supplying water to a washing unit must be strictly regulated by a given program. By the principle of operation, the pressure switches of washing machines Lg, Samsung, Electrolux, Candy, Ariston or any other brands do not differ, but there may be differences in execution, appearance and characteristics. This device looks like a small plastic piece, most often round in shape, with electrical wiring connected to it and a tube from the washing tub reservoir.

The pressure switch in the washing machine is a device that controls the level of water in the tank, without which the operation of any unit is simply impossible.

The element is small and its replacement does not require a major investment, but the importance of this part is huge.

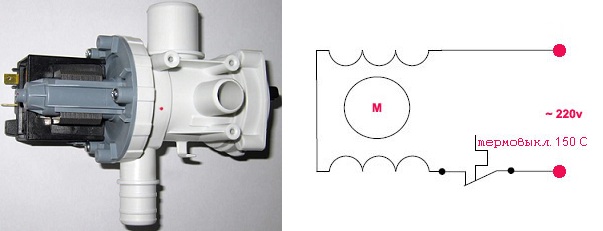

Testing the pump coil

The third method, which allows you to check the health of the pump, involves the use of a multimeter. During the ringing of the drain pump electric motor winding, the tester should show resistance in the region of 150-260 ohms. The algorithm of actions will be as follows:

- disconnect the machine from the mains;

- disconnect the pump connection contacts;

- turn on the multimeter by setting the resistance detection mode;

- attach the tester probes to the motor contacts.

If the instrument screen displays 0, you can diagnose a short circuit. When the multimeter shows an unreasonably large value, it will be a winding break. A reading that is significantly higher than the standard value will tell about damage to the stator winding.

4 Alternative option - a machine with a tank

With some effort, we can deceive the automation of the machine, assuring it of being connected to the water supply. But for this we need the skills of a locksmith and an electrician. But what about people who do not have such skills?

For private houses, there are special models of washing machines with a tank in which a pressure group is installed.

For such people, modern industry has offered a ready-made option - a special automatic washing machine for rural areas with a built-in tank and a pressure pump.

Initially, such devices were intended for motor homes. Over time, manufacturers saw the potential in this niche and began to produce the simplest automatic washing machines that can be connected and used without plumbing.

The widest range of such machines is produced by Gorenje, and they cost 20-30 percent more than conventional machines.And we are talking about quite powerful front-loading units that can wash up to seven kilograms of laundry at a time.

In the design of such machines, a tank is provided, in which the pressure group (pump, relay, sensors) is also installed. Therefore, tricks with shut-off valves and containers are not needed here, as well as soldering skills. You buy a ready-made unit, pour water into the tank and wash it. Moreover, this option differs from a conventional washing machine only in dimensions (they are increased due to the tank), but not in functionality.

True, to arrange the drainage of wastewater, you still need an autonomous septic tank or an ordinary ditch. But even a completely inexperienced home craftsman can build a mini-sewer.

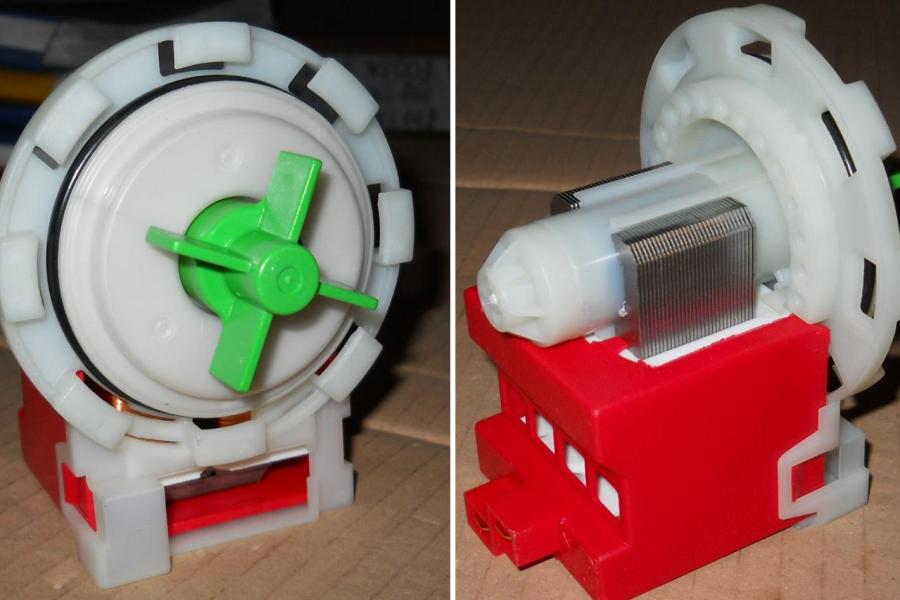

Step by step instructions - how to make a pump with your own hands?

Before starting work, check the contacts of the electric pump and the relay for compliance. They do this with the help of a tester, in turn applying its probes to the wires. If everything is in order, the wires can be connected. Further procedure:

- We make a protective cover. For this purpose, any plastic container, such as a jar, is suitable. Having made a hole in it to bring the wiring through it, place the relay inside the container. Here it will be safe - plastic will protect the device from precipitation.

- We connect the pump to the mains. Let's check her work.

- We install a tee at the pump outlet. We fasten the hoses to it and fix the connections with metal clamps.

- Take a plate of metal or duralumin. After drilling 6 holes for a 6 mm thread in it, fix the device. 4 holes - for mounting the pump, 2 - for mounting the plate.

- In a steel pin 15x800 mm 6 mm thick, make 2 holes.Mount the pump on the plate, and connect it to the pin with two bolts. Stick the pin into the ground - now it is both a support and a ground.

- Check the work of homemade. Immerse the end of the short hose into a tank filled with water. If instead of a barrel you used a closed container, make a hole in it for a hose. Seal the hole with sealant.

For the pump itself, they also make a “house” - for this purpose suitable plastic box. Holes for wires are pre-drilled in it. With the help of such a homemade product, you can water the garden and garden through a hose or organize convenient drip irrigation.

Please note that the old pump from the machine is not designed for long-term work without interruptions. Do not leave it on for a long time. Such watering can be perceived as auxiliary. With heavy loads, a mini-pump, created on the basis of spare parts for a washing machine, will not cope.

Types of washing machine pumps

In washing machines, more than fifty types of pumps are used, which have certain design differences.

All of them are divided into two types:

- Circulating. Provides movement of water in the machine. They are installed on expensive devices, for example, Bosch, Siemens and Hansa.

- Drain. The water is pumped out after each of the washing steps and after rinsing.

Many popular models use a single pump that performs the function of pumping and draining.

Pumps for pumping / circulating / draining water are made on an electromagnetic basis. In washers with dryers, in addition to them, there are also pumps made in the form of a small engine with an impeller (fan).

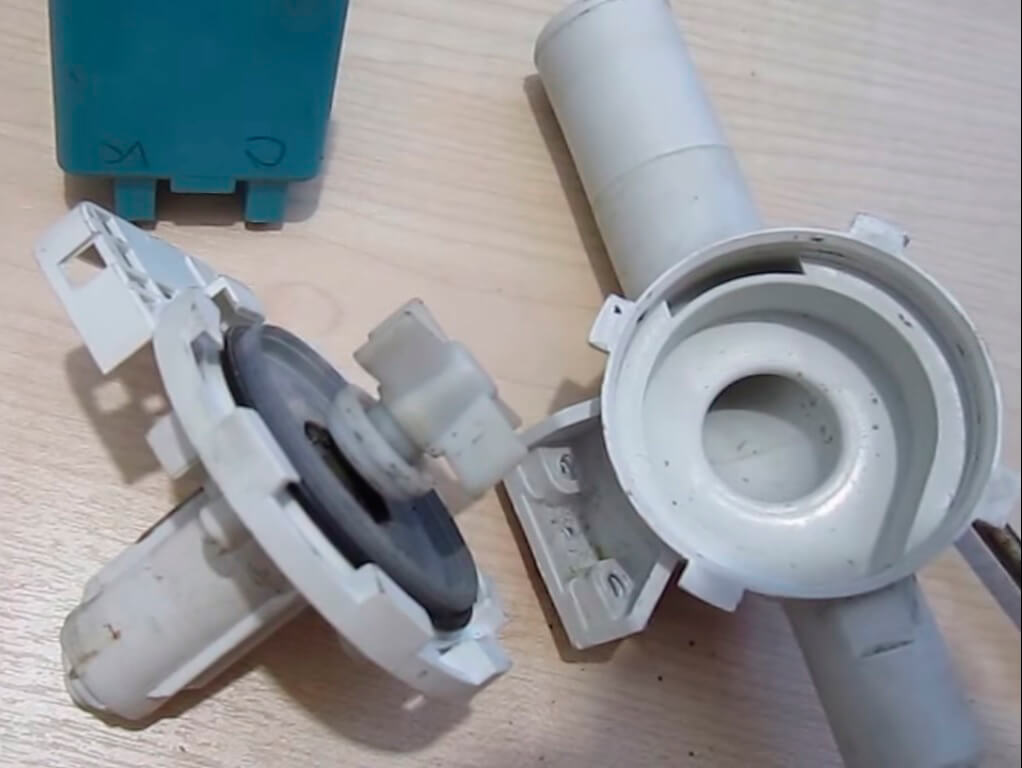

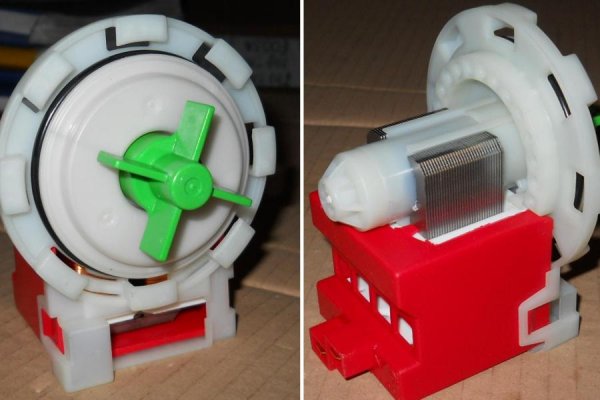

The design of the pump is quite simple, it consists of a stator, a rotor and an impeller.The rotor rotates in both directions, so when the impeller is blocked by foreign objects, it jerks in different directions.

The most reliable are synchronous pumps with a magnetic rotor, characterized by high power and miniature size.

The pump is considered one of the most important elements of the washing mechanism. Its type may differ depending on the manufacturer's brand and design features.

Structurally, the drain pump or pump, as it is also called, is a unit consisting of two units. One of them is a motor with an impeller, the second is a plastic pipe called a snail.

On one side of the pipe there is a seat for the engine, on the other - a recess for the filter cover. With proper operation, the snail, unlike a motor with an impeller, is almost indestructible.

In older models, the pump has two impellers: one of them is used to cool the engine, the second to circulate water. A feature of these devices is an oil seal that prevents water from flowing from the snail into the motor. Modern machines have one impeller, and there are no oil seals, since the electrical and mechanical parts are separated.

The average duration of the pump is 3-7 years, but the problem may occur even earlier. This happens when the appliance is not properly used, when various small objects fall into it. They block the impeller, which leads to pump failure.

Particularly costly will be repairs after the combustion of the electronic control module due to a short circuit in the winding. Pump failure is a standard situation that occurs during the long service life of the unit and the intensive frequency of operation of the device.

What pressure does the pump create?

There are different models of injection equipment on the market. Consider the most popular options. The proposed equipment increases the pressure to 3.5–6 bar. All models are protected against overheating.

Wilo PB-088EA. It costs 3,800 rubles. 3.5 bar. Temperature - 2-60 °C. Installation - horizontal or vertical. Throughput - 2.4 cubic meters / hour.

Grundfos UPA 15-90. The price is 5,500 rubles. Passes 1.5 cubic meters / hour. Installation - vertical. For clean water only. 6 bar. Noise - 35 dB.

Gileks Jumbo 60/35 P-24. The price is 5,400 rubles. 3.6 cubic meters / hour.

Marina Cam 80/22. Surface pumping station. It costs about 9,000 rubles.

The maximum pressure in the above models is 9.8, 35 and 32 m, respectively.

What damage could happen

What caused the malfunction:

- Worn gaskets due to frequent use.

- Defective parts, improper transportation of the machine.

- Malfunction of the rod that secures the shock absorber.

Whatever breakdown occurs, it is important to know how to restore the shock absorber in the washing machine with your own hands.

Diagnostics for vertical loading

If the shock absorbers or dampers are damaged, a specific noise is heard - a knock during washing, coming from the inside. There may be distortion of the housing or strong vibration.

Diagnostics for vertical loading is performed as follows.

- Press the top of the tank with your hand. If you feel that there is no resistance, and after you remove your hand, it continues to sway, then the time has come for repair.

- Watch the drum spin. If it is tight or creaking, it means that the parts are not lubricated at all.

- Disassemble the machine, remove the back cover. Press down on the tank again and force it down, then release it sharply.If the tank jumped up and no longer moves, then the shock absorbers are normal.

These simple diagnostic methods will help determine if the dampers of the washing machine need repair.

Front loading diagnostics

Diagnostics of the washing machine during front loading occurs in a different way.

- Press firmly on the tank at the top and look at the cuff of the hatch seal. If folds form on it, then repair is needed.

- Be sure to note how much the tank drops when pressed.

Normally, during pressing, no wrinkles should appear on the seal and the tank should not sag when it is loaded.

If all these shortcomings are found, the device should be repaired.

What water pressure is needed for a washing machine?

Water supply to the washing machine must be carried out under pressure, which is not lower than the value specified in the technical documentation. The developers of CMA decided that a quick filling of the tank is a prerequisite for productive washing. Europe and Japan have their own standards of living, in which there is no place for problems with water supply. Russia is not limited to megacities, and somewhere in the outback, water supply standards are not even suspected.

The lack of pressure does not always end with a refusal to work, it happens that the SMA starts up, but all processes are slow: the tank takes a long time to fill, the powder is poorly washed off, and the quality of the wash drops. We find out what pressure is needed for a washing machine, depending on its brand:

- CMA from Zanussi, Electrolux, LG, Samsung and Daewoo - 0.3 bar. There are models with inlet valves rated at 0.4 bar. Work is largely dependent on the software.

- Ariston, Beko, AEG, Indesit, Candy and Whirlpool - 0.4 bar. Many "Indesites" work at lower values.

- Bosch and Miele generally require 0.5 bar.

- Kuppersbusch - 0.8–0.9 bar. There are models operating at 0.5 bar.

In rural water supply systems, the pressure is at the level of 0.1 bar and even less.

Types of malfunctions and repairs

If the Samsung washing machine is constantly in use, then over time there will come a moment when it will not turn on. The cause of the problem may be hiding in the water pump, which will need to be removed. Therefore, it is advisable for each owner of the unit to know how to check and change the pump, as well as clean and replace the filter.

In the case when an unusual crack of the unit is heard, you need to try to disassemble it. To carry out this procedure, it is worth knowing the device of the equipment, the nuances of the connection, only then it will be possible to repair the case or correct the situation when the impeller flies.

Depending on the washing mode, the pump may turn on and off several times. Due to the high load, this element may fail. Samsung pump malfunctions include the following:

- frequent connection of thermal protection on the winding of the electric motor;

- clogged impeller, which often causes interruptions in work;

- impeller blades broken by mechanical action;

- wear of the bushing, which is located on the motor shaft;

- scrolling and falling out of the impeller;

- occurrence of short circuits;

- breakage of turns that are located on the motor.

Each of the above breakdowns can be the basis for repairing the pump. It is often recommended to carry out repair procedures when minor damage is detected, for example, debris getting into the impeller, minor damage to the blade. All other problems require replacing the pump in the washing machine.

Since the pump is located in the lower half of the machine, under the tank, it can be reached through the bottom or after dismantling the front panel. The replacement of the pump in Samsung technology must be carried out through the bottom.

Dismantling the pump includes the following activities:

- disconnecting the machine from the electricity network;

- blocking water before performing procedures;

- neat laying of the machine on the side - so that the pump is located on top;

- release of the bottom of the equipment from the protective panel - for this, snap fasteners are removed;

- dismantling of the protective cover;

- unscrewing the nodal fastening screws that are near the valve;

- careful pulling out of the pump;

- disconnecting the power wires of the pump;

- loosening the clamps that secure the hoses that are located above the prepared container;

- detaching the snail, if any.

The assembly of the unit should be carried out in the reverse order. The process of replacing the technical unit of a Samsung washing machine will not take much time. You can do all the work with your own hands or by contacting a specialist. According to the advice of professionals, when replacing a pump, it is worth using original parts, since others can not only not eliminate the malfunction, but also cause irreparable damage to the machine.

In order for the pump to work for a long time and without interruption, it is necessary to regularly monitor its condition and follow these recommendations:

- before washing, you need to check all the pockets in the clothes to prevent the ingress of various objects into the pump;

- use only high-quality special detergents that contain anti-scale additives;

- install a filter on the water supply, which will limit the penetration of rust particles into the unit;

- Soaking is recommended before washing heavily soiled items.

The pump of the washing machine is the heart of the unit, the quality of washing, rinsing and spinning depends on its operation. All owners of Samsung equipment should remember that as soon as the machine starts to work worse or there are noticeable signs of breakdown, you need to immediately start repairing it.

Samsung washing machine pump repair is presented in the video below.

Removing the pump through the front panel

The pump of the washing machine "Bosch", "Siemens" and some other brands is replaced after removing the front panel of the unit, since the bottom of such machines is closed.

Dismantling the drain pump is as follows:

- First of all, you need to remove the top cover of the unit. To do this, unscrew the fastening screws at the back of the machine, and then push the cover away from you from the side of the front panel.

- The next step is to remove the control panel. For this purpose, the detergent tray is removed and the screws securing the panel are unscrewed. After removing the screws, the panel is carefully laid on top of the unit so as not to damage the connecting wires.

- There is a drain valve under the plastic protective panel, which must be removed carefully above the tank in order to drain the remaining water.

- Then it is necessary to remove the sealing collar from the loading hatch.

- Thus, having dismantled the front panel, we will get access to the pump.

- Having unscrewed the fixing screws of the pump and the front wall, you can proceed to dismantle the pump.

- After loosening the clamps on the pump nozzles, remove the connecting hoses.

After performing all these operations, we inspect the pump and impeller. In case of minor breakdowns, we clean the pump parts from contamination. Installing a new drain pump is done in reverse order.

In top-loading washing machines, the pump is removed through the rear wall.

Pump device

The pump of the washing machine is called a small power asynchronous motor, which is equipped with a magnetic rotor, rotation speed about 3000 rpm/min

Pumps (drain) may differ in appearance (“snails”), as well as integrated filters that stop a variety of debris and small objects in dirty water.

Modern high-rise SMAs have only two types of pumps:

- Drain;

- Circular;

Drains pump out dirty water after the completion of the washing process, circular ones are responsible for the circulation of water in the washing and rinsing modes. Other less expensive machines have only drain pumps.

Drains pump out dirty water after the completion of the washing process, circular ones are responsible for the circulation of water in the washing and rinsing modes. Other less expensive machines have only drain pumps.

In its design, the rotor of the pump (drain) is somewhat similar to a cylindrical magnet.

The blades (which are fixed on the rotor axis) are deployed at an angle of 180 degrees to it.

When the drain device starts, the rotor comes into play first, after which the blades begin to spin. The core of the engine is equipped with two windings that are connected to each other. Their resistance together is about 200 ohms.

If you raise a conversation about low-power washing machines, then their external fitting will always be located in the middle of the case. It has special valves (rubber) of reverse action, which do not give water a chance to get into the tray of the washing machine from the drain tube.

Under the pressure of the liquid, the valve opens, and when the pressure from the water supply network stops, the valve immediately closes.

Other drain pumps of a different type only allow liquid to flow in one predetermined direction.

Other drain pumps of a different type only allow liquid to flow in one predetermined direction.

In such designs, in order to prevent gravity flow of the liquid, special cuffs are used for sealing. These cuffs do not give water a chance to get into the bearing. The shaft (rotary) in such a device will pass through the main collar sleeve, which will be equipped on both sides with corrugations and crimping from a special spring ring.

Before installing the cuff into the sleeve, it is pre-treated with a special lubricant so that a large layer of this lubricant appears on the surface of the cuff. This move increases the life of the element.

Operating rules

If you properly care for the pump for an automatic type washing machine, then its service life will last an average of about 10 years.

In order for this period not to decrease, you need:

- Provide the machine with clean water (it is necessary to check the pockets in your things before washing for the presence of foreign objects and remove them, it is also better to remove pieces of dried dirt before putting the thing in the drum);

- Monitor the performance and serviceability of filters;

- Do not let scale appear (use special tools for this);

- Completely empty the drum of water at the end of the washing process (wait until the water disappears from the tank to 100%).

If the pump breaks, no one ever repairs it, but buys a new one. It is not the owner who must do this, but the master, a specialist called from the center.

TOP stores of washing machines and household appliances:

- /- household appliances store, a large catalog of washing machines

- Inexpensive hardware store.

- — profitable modern online store of home appliances

- — a modern online store of home appliances and electronics, cheaper than offline stores!