- Which well needs which pump?

- Well characteristics accounting

- Static level measurement

- Dynamic level meter

- Debit definition

- Analysis of the nuances

- Centrifugal submersible pump

- Operating principle

- Pros and cons of the device

- Classification of centrifugal pumps

- The best screw pumps for wells

- Host 4NGV-30/100

- Daewoo DBP 2500

- Storm! WP9705DW

- Mr.Pump "Screw" 20/50 3101R

- Surface pump for a well 30 meters

- Types of pumps for wells

- The principle of operation and installation rules for surface pumps

- Types of submersible pumps for wells

- Centrifugal pumps for wells

- Vibratory Pump Applications

- vortex pumps

- Selection Options

- Water flow and pump performance

- Lifting height (pressure)

- Immersion depth

- Well diameter

- Types of pumps used

- Hand pumps

- Surface pumping stations

- Vibratory pumps

- Submersible centrifugal pumps

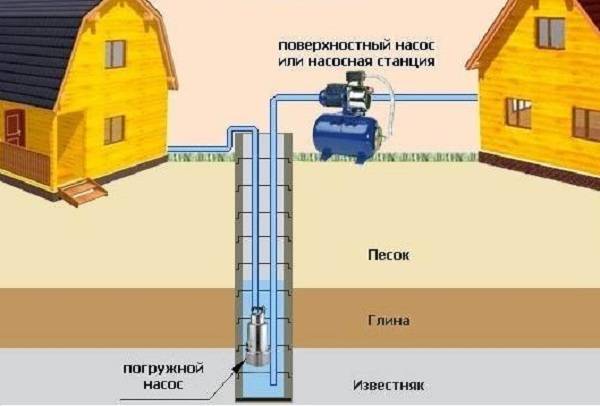

Which well needs which pump?

In doing so, the following indicators are taken into account:

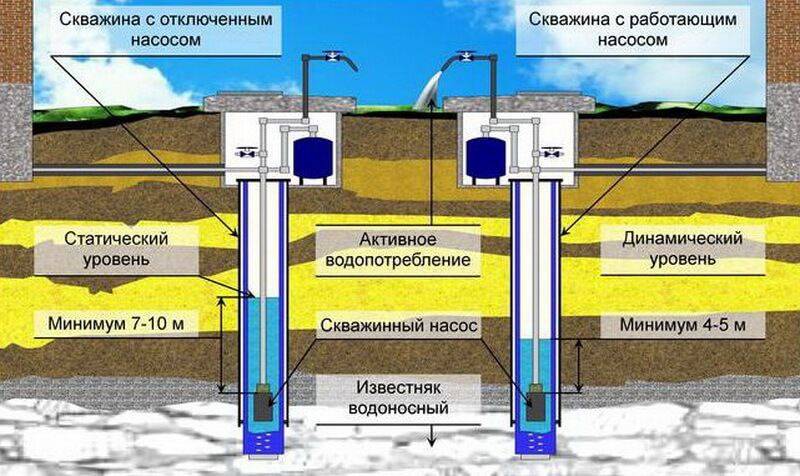

- static level. This definition is understood as the distance from the surface of the earth to the level of a permanent mirror of water located in the well.

- dynamic level. This term refers to the distance from the surface of the earth to the minimum indicator of water in the well.

- Debit. The volume of water that can be extracted from a given well in a given unit of time.

- The depth of the well to the bottom of the bottom.

- Casing pipe diameter.

You can get these characteristics in 2 ways:

- Based on documentation. If a well is drilled by a specialized company, then upon completion of the work, the owner is issued a technical passport. It includes all important features.

- Empirically with the help of measurements. This approach is necessary in case of self-drilling of a well or long-term non-use of a well.

Well characteristics accounting

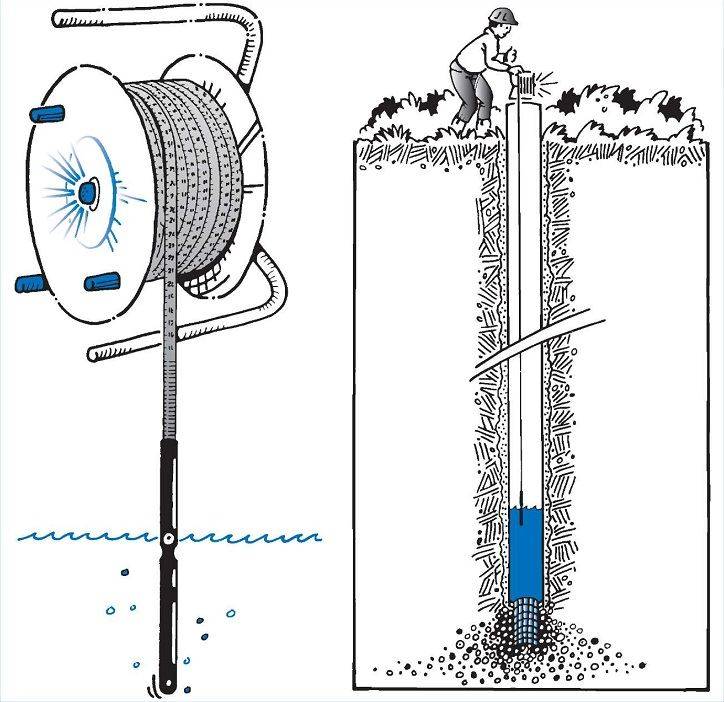

To measure the depth of the well to the water surface, you will need a rope and weight.

To measure the depth of the well to the water surface, you will need a rope and weight.

This will require:

- long rope (the length should be commensurate with the depth of the well);

- cargo in the form of a cylinder or cone without a bottom (it is tied to one end of the rope);

- roulette.

Static level measurement

During this time, the liquid level should reach the maximum. After that, the load begins to be lowered on a rope to a characteristic cotton.

This sound indicates that the load has reached the surface of the water. On the twine make a mark at ground level. The rope is completely removed and the distance from the mark to the load is measured. This indicator is a static level.

Dynamic level meter

First, a submersible borehole pump is lowered into it, after which water is pumped out. At first, the liquid level will decrease during pumping, so the pump will have to be lowered periodically. As soon as the water has ceased to decrease, it is considered that the minimum has been reached. The water level is determined using a rope and weight in a similar way.

The difference between static and dynamic levels is the well productivity

This indicator is important to consider when choosing a pump.If the difference between the levels is small, this indicates that the water column is quickly replenished.

With high performance, powerful pumps can be used. Some artesian wells do not have a difference between static and dynamic water levels.

Debit definition

To determine the well flow rate, you will need:

- pump;

- timer;

- a large capacity for water from a well (tank, barrel, bath) - the only requirement is to know the volume of this tank.

First of all, you need to pump water out of the well. To do this, the pump is placed as deep as possible. A squelching sound will be the signal for the lack of fluid. After that, you need to wait for the replenishment of the level. The speed of this process can be detected using a timer. As soon as the static level is restored, the water is pumped out again, but already in a container. You can determine the flow rate by dividing the number of liters of water received by minutes.

The pump into the well in diameter should be slightly smaller than the diameter of the casing pipe. This is necessary to ensure access to the device in case of breakdowns and regular maintenance.

Analysis of the nuances

It is possible to take into account only the technical indicators of the well in cases where drilling was performed by professional workers. According to statistics, artisanal wells are prone to rapid sanding and flooding.

Contamination of equipment leads to its breakdown. To prevent this, for such wells it is better to purchase a special pump designed to work in difficult conditions.

Another important criterion by which the types of borehole pumps are selected is the daily volume of water consumption. The average for a family of 3-4 people is 60-70 liters.If water is also needed for watering the garden and feeding livestock, then the average increases.

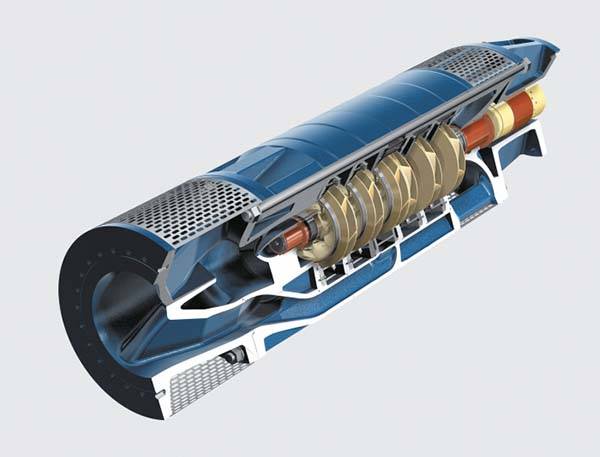

Centrifugal submersible pump

The centrifugal submersible pump is by far the most popular. It can be used not only for clean water from a well or a well, it also copes well with aggressive water, domestic sewage, and viscous liquids.

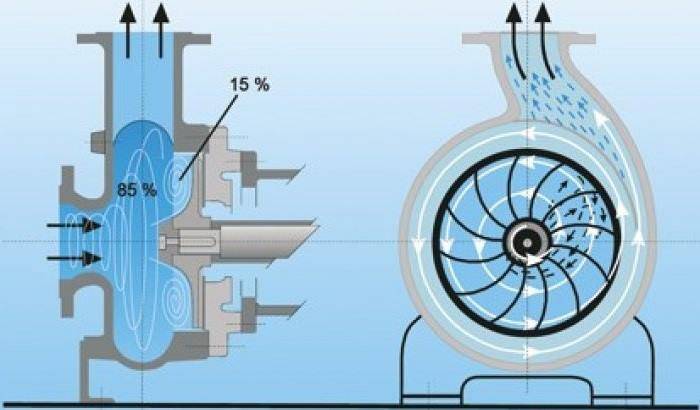

Operating principle

The principle of operation of a centrifugal pump is the rotation of the impeller, which forms the kinetic energy that goes to the particles of the substance, directly to the blades. The centrifugal force moves the liquid in the area of the impeller into the area of the unit casing. A new liquid moves to the empty place.

The movement of the liquid occurs due to the movement of the wheel, namely, in the process of movement, it is pressed against the walls of the housing, and then moves under pressure through a special injection hole. The entrance to the unit at this time has the lowest pressure indicator, but the area of the impeller, on the contrary, acquires the maximum indicator.

The most important feature of a centrifugal submersible pump is that it ensures uninterrupted water supply.

Pros and cons of the device

Positive properties of centrifugal pumps:

- simplicity and ease of use;

- allowable value;

- automatic control;

- maximum suction rate;

- very high efficiency;

- long service life.

There are also disadvantages in the operation of this type of pump. First of all, it upsets the fact that the absorption of water by the unit directly depends on the resistance of the network. That is why, sometimes there are interruptions in the water supply.It is also worth monitoring the water level during installation and if it does not reach the inlet pipe, manual filling will be required. If this is not done, the work process will be significantly disrupted.

Classification of centrifugal pumps

The classification of centrifugal pumps depends entirely on the features of use and technical characteristics.

Depending on the water suction parameters, the devices can be divided into:

- self-priming work with water containing an excess amount of gases, so even if the inlet pipe is not filled with water, nothing will change in the work;

- normally suction require the system to be completely filled with liquid.

The most popular centrifugal units are divided into the following types:

- single-stage horizontal devices with console type execution - they work only with liquids similar in composition to water;

- multi-stage horizontal - have the ability to deliver high pressure with a minimum amount of incoming fluid;

- sand - most often used in industrial enterprises, since they can easily cope with polluted wastewater;

- fecal - have the ability to pump a liquid containing a large amount of large pollutants.

Each of the types has its own purpose, so when choosing it will be very easy to decide on the option for yourself.

The best screw pumps for wells

The principle of operation of such models is based on the action of a screw mechanism. The simplicity of the design determines the low cost and unpretentiousness of such pumps.A feature of their functioning is the creation of high pressure at low productivity. Screw pumps are used in shallow wells with low flow rates.

Host 4NGV-30/100

4.9

★★★★★

editorial score

95%

buyers recommend this product

Distinctive characteristics of the model are small dimensions and long service life. The body of the device is made of stainless steel, it is easy to install in the well and requires virtually no maintenance.

Engine power - 800 W, immersion depth does not exceed 15 m. The height of the water rise can reach 100 meters with a capacity of 30 liters per minute. This allows you to provide water to rooms located at a distance from the well or well.

Advantages:

- compact dimensions;

- resistance to corrosion;

- high engine power;

- low price.

Flaws:

noisy.

The host 4NGV-30/100 is used in private water supply systems. Productivity, small dimensions and enviable power of the device contribute to its installation even in hard-to-reach wells.

Daewoo DBP 2500

4.8

★★★★★

editorial score

93%

buyers recommend this product

The model attracts with ease of installation, durability and versatility of use. It can be used in wells containing turbid water with abrasive particles. Thanks to the presence of hooks on the body of the device, it is easy to submerge it in water and raise it to the surface.

The engine power is 1200 W, which allows pumping liquid to a height of up to 140 meters. The device is installed in narrow wells with a diameter of at least 110 millimeters and is capable of supplying almost 42 liters of water per minute.

Advantages:

- ease of installation and maintenance;

- work in contaminated water;

- convenience of diving;

- powerful engine.

Flaws:

- big weight;

- short power cable.

Daewoo DBP 2500 can be used for residential water supply. The stainless steel body and unpretentiousness to the quality of the liquid guarantee a long service life of the device.

Storm! WP9705DW

4.7

★★★★★

editorial score

87%

buyers recommend this product

Easy and safe immersion of the pump in water is provided by lugs on the body. Thanks to the hermetically sealed steel construction, important elements of the unit are reliably protected from damage and contamination.

The 550 W motor has an overload protection and provides the pump with a capacity of 26.6 liters per minute. The device can be lowered into water to a depth of 50 meters.

Advantages:

- light weight;

- convenience of diving;

- durability;

- low price.

Flaws:

low performance.

Storm! The WP9705DW is a compact and low cost solution for pumping water from deep wells. It is suitable for stable water supply of a plot or a private house in small volumes.

Mr.Pump "Screw" 20/50 3101R

4.7

★★★★★

editorial score

85%

buyers recommend this product

The features of the model are the built-in thermal relay and the small diameter of the structure. Thanks to this, the device can be installed in narrow wells, ensuring a stable supply of water without overheating the engine.

The case is made of stainless steel, has protection against contamination and ingress of foreign dense particles. Low power consumption and affordable price of the device favorably distinguish it from analogues.

Advantages:

- diameter - 90 mm;

- protection against overheating and pollution;

- profitability;

- long service life.

Flaws:

low power - 370 watts.

Mr.Pump Screw lifts liquid up to 50 meters.It is capable of long service life in narrow wells and dirty water.

Surface pump for a well 30 meters

With increasing depth, the pressure increases, so for a static level of 30 m, you will need a pump more powerful than the DP-100.

Surface pump with remote ejector LEO AJDm110/4H

The maximum suction height is 40 meters, which guarantees a certain power reserve for lifting water from a depth of 30 meters.

The manufacturer LEO launches a new type of flexible shaft pumps for deep wells.

It is installed at the wellhead. A flexible shaft is produced with a length of 25, 45 meters - the depth from which water can be pumped out. This type of pump is more semi-submersible than surface. They are mounted on a production string with a diameter of 50 mm. Can be an alternative to a hand pump.

The hydraulic part consists of 2 hoses inserted one into the other. A flexible shaft is passed inside, connected to a screw-type pump head.

screw pump

Despite its small size, the maximum capacity is 1.8 m3/h and the head is 90 meters. The hose is lowered into the well to a predetermined depth, the flexible shaft is connected to the shaft of the electric motor gearbox. The advantage of the pump is that the electric motor is at the top. In case of clogging of the pump, the flexible shaft is disconnected, the hose is pulled out, and washed.

Types of pumps for wells

All models are divided into:

- Submersible pumps. Devices are partially or completely immersed in water.

- Surface. They are used when the water level is not lower than 9 meters. Their installation can be carried out on the ground and a floating platform, but a prerequisite is that water does not get inside the engine.

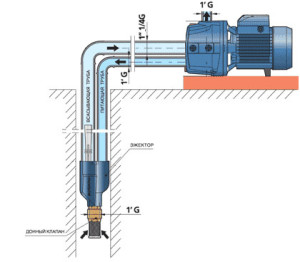

The principle of operation and installation rules for surface pumps

Installation of a surface pump

The operation of the well pump is as follows:

- A pump is mounted on the rotating shaft of the electric motor, on which there are holes for supplying and taking water.

- The intake is carried out by a sleeve or hose with a check valve. The element must be of good quality, otherwise depressurization of the unit may lead to the fact that the engine will not start.

- To increase the depth of water intake over 9 meters, you can use an external ejector, which is lowered under water along with a hose. In this case, when the pump is running, part of the water falls into the ejector, the pressure in the hose rises, which increases the pressure. But the strong noise generated by the installation does not allow using this option all the time.

- Installing a surface pump is very easy. The unit is placed near the well, a hose is lowered into the water, the device is connected to the network.

- It is better to install the pump in a heated room or in an insulated container.

Types of submersible pumps for wells

Manufacturers produce three types of submersible equipment:

- Centrifugal. These are the most expensive devices. Designed to lift water from a depth of more than 100 meters.

In its composition, sand can exceed 180 g / m. A feature of the units is greater power and increased productivity. - Vortex. With their help, water with an impurity content of up to 40 g / m3 can be pumped, and the depth of the wells is from 30 to 100 meters.

- Screw. The price of such devices is the smallest. They serve to organize water supply from wells, the depth of which is up to 15 meters or open reservoirs. The maximum presence of abrasive particles is 40 g/m.

For wells, deep-well pumps with high power are used.

Deep pumps

The optimal dimensions of such devices allow them to be installed in narrow wells. The length of the elongated pump cylinder is from 50 centimeters to 2.5 meters, and the outer diameter is about 10 centimeters.

If the question arises which pump to choose for a well of 15 meters, then a deep pump is the best solution. It is well suited for shaft wells, deep sand or artesian wells, process tanks. They are made using high quality stainless steel.

Centrifugal pumps for wells

Centrifugal pump

The features of the unit are:

- The design of the device includes an engine shaft on which a wheel is located, consisting of two plates connected by blades.

- The centrifugal force of the pump captures the water with the blades, and then throws it into the supply pipe. Centrifugal pumps are the most common type of equipment for wells. This is the most versatile mechanism.

- Their main purpose is to pump clean water. This indicates that there should not be even a small amount of sand in the water.

- The cost of centrifugal pumps depends on the number of stages and some design features.

- For domestic needs, single-stage pumps are most often used, however, if more water pressure is needed, multi-stage pumps should be chosen, where there are several operating wheels on one shaft.

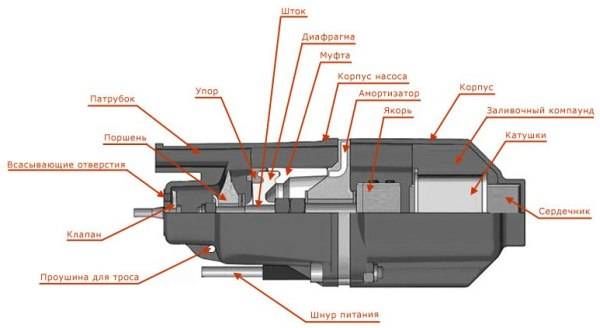

Vibratory Pump Applications

Vibration pumps are used for the following purposes:

Vibration pump device

- Pumping water from the tank. It can be used to drain a freshly dug well or clean it out if necessary.

- Raising water from a tank for domestic use.

- Water supply from an open source such as lakes, pools, rivers, etc.

- Water supply from a pre-filled container, which can include a cistern, tank, etc.

- Pumping water from a flooded room, basement, trench, etc.

- Pumping water from a well can also be done using a vibration pump, but reviews on the use of this unit in such conditions vary greatly. Some speak positively about the operation of the pump, using it for years, while others talk about a damaged well and collapse of the foundation.

vortex pumps

The design of the apparatus is somewhat similar to centrifugal, their main working chamber is equipped with a rotating wheel with blades. The shape of the working chamber and wheel blades of the devices differ from centrifugal ones. In addition to centrifugal swirling of water, they also create powerful turbulence, as a result of which a powerful liquid pressure is organized at the outlet (3-9 times more than centrifugal ones). This achieves a reduction in the number of working chambers without reducing pressure and productivity.

The simplicity of the design was reflected in the price of the submersible device. Its cost is lower. Such devices will not be damaged by air during pumping, so they are used in production. Vortex turbulent stations are used for pumping dispersion mixtures saturated with gases.

The disadvantage is the sensitivity to fluid contamination. Also, these are the most wearing units (you need to take care of replacing parts). For these reasons, they are not very popular with summer residents.

Selection Options

Well pumps are easy to distinguish even by their appearance. They are an elongated cylinder made of stainless steel or plastic.Naturally, stainless steel models are more expensive - the steel must be of high quality (usually food grade AISI304). Pumps in a plastic case are much cheaper. Although they are made of a special impact-resistant plastic, they must be handled with care - it still does not tolerate shock loads very well. All other parameters will have to be selected.

Brief technical characteristics of the pump for the well

Water flow and pump performance

In order for the water in the house or in the country to be with sufficient pressure, equipment is needed that can deliver the required volume of liquid. This parameter is called pump performance, measured in liters or milliliters (grams) per unit of time:

- ml/s - milliliters per second;

- l / min - liters per minute;

- l / h or cubic / h (m3 / h) - liters or cubic meters per hour (one cubic meter is equal to 1000 liters).

Borehole pumps can lift from 20 liters/min to 200 liters/min. The more productive the unit, the greater the power consumption and the higher the price. Therefore, we choose this parameter with a reasonable margin.

One of the key parameters for selecting a well pump is performance

The required amount of water is calculated by two methods. The first takes into account the number of people living and the total expense. If four people live in the house, then the water consumption per day will be at the rate of 800 liters (200 l / person). If there is not only water supply from the well, but also irrigation, then some more moisture must be added. We divide the total amount by 12 (not by 24 hours, because at night we use water supply to a minimum). We get how much we will spend on average per hour. Dividing it by 60, we get the required pump performance.

For example, for a family of four and watering a small garden, it takes 1,500 liters per day. Divide by 12, we get 125 liters / hour. In a minute it will be 2.08 l / min. If you often have guests, you may need a little more water, so we can increase the consumption by about 20%. Then you will need to look for a pump with a capacity of about 2.2-2.3 liters per minute.

Lifting height (pressure)

When choosing a pump for a well, you will inevitably study the technical specifications. There are parameters such as lifting height and immersion depth. Lifting height - also called pressure - is a calculated value. It takes into account the depth from which the pump will pump water, the height to which it must be raised in the house, the length of the horizontal section and the resistance of the pipes. Calculated according to the formula:

The formula for calculating the pump head

An example of calculating the required pressure. Let it be necessary to raise water from a depth (pump installation site) of 35 meters. The horizontal section is 25 meters, which equates to 2.5 meters of elevation. The house is two-story, the highest point is a shower on the second floor at a height of 4.5 m. Now we consider: 35 m + 2.5 m + 4.5 m = 42 m. We multiply this figure by the correction factor: 42 * 1.1 5 = 48.3 m. That is, the minimum pressure or lifting height is 50 meters.

If there is a hydraulic accumulator in the water supply system of the house, it is not the distance to the highest point that is taken into account, but its resistance. It depends on the pressure in the tank. One atmosphere is equal to 10 meters of pressure. That is, if the pressure in the GA is 2 atm, when calculating, instead of the height of the house, substitute 20 m.

Immersion depth

Another important parameter in the technical specifications is the immersion depth. This is the amount with which the pump can pump out water. It varies from 8-10 m for very low-power models to 200 m and more. That is, when choosing a pump for a well, you need to look at both characteristics at once.

For different wells, the depth of immersion is different

How to determine how deep to lower the pump? This figure should be in the passport for the well. It depends on the total depth of the well, its size (diameter) and flow rate (the rate at which water arrives). In general, the recommendations are as follows: the pump should be at least 15-20 meters below the water surface, but even lower is better. When the pump is turned on, the liquid level drops by 3-8 meters. The amount remaining above it is pumped out. If the pump is very productive, it pumps quickly, it must be lowered lower, otherwise it will often turn off due to lack of water.

Well diameter

An important role in the selection of equipment is played by the diameter of the well. Most domestic well pumps have sizes from 70 mm to 102 mm. In general, this parameter is usually measured in inches. If so, then the easiest way to find three and four inch specimens. The rest are made to order.

The well pump must fit in the casing

Types of pumps used

It is impossible to answer unambiguously the question of which pump is better for a well. It all depends on financial capabilities, operating conditions. In practice, various devices are used to lift water.

Hand pumps

Hand pumps

If the depth of the well does not exceed 7-8 meters, and the required flow rate is small, it is quite possible to install a manual pumping unit for a summer residence.Such a pump does not require power supply, it has a simple design, it is quite enough to provide a small suburban area. Such pumps are also used when installed at a water intake point in the yard.

Of course, it will not work to automate such an installation, but it is quite possible to use it as a backup pump.

Surface pumping stations

Surface pumping stations

Used to supply water from shallow depths. When deciding which pump is needed for a well, this option should be considered only if it is possible to install it in a specially equipped caisson or if the well is located in the basement. In these cases, a pumping station with a small receiver (storage tank) will be very effective.

The maximum depth of the well is 7-8 meters, when installing the unit, special attention must be paid to the reliability of the check valve. The pressure line of such a pump must be constantly filled with water; dry start-up adversely affects the durability of the electric motor

The choice of models of surface pumps is quite wide, you can choose a model with a capacity of up to 100 liters per minute, with an appropriate drive.

Vibratory pumps

Vibratory pumps

These pumps have a simple design and can be used to supply water from a depth of no more than 40-50 meters (the most powerful and expensive models). The bulk of pumps of this type belongs to the budget class, and has the appropriate characteristics. For installation in wells, it is recommended to use only modern models of devices, this is due to the fact that some modifications can have a significant destructive effect on the casing.

The principle of operation is based on the high-frequency oscillatory movement of the membrane, which provides the required performance. It is worth mentioning that the working life of such pumping units is insignificant, the main area of application is wells and wells for sand

It is worth paying attention to these devices when deciding which pump to pump the well, while preference should be given to installations with a lower water intake

Submersible centrifugal pumps

Submersible centrifugal pumps

Devices of this type are considered the most effective equipment for installation in wells. They can be used for installation even in artesian wells of considerable depth.

The existing range of units allows you to choose a submersible pump for a well with various parameters, the advantages of devices of this type include the following characteristics:

- High performance with small overall dimensions, there is a choice for wells of all main sections.

- Excellent pressure characteristics.

- Significant working resource and reliability.

- Does not have a destructive effect on the casing pipe.

Pumps of this type can be equipped with various automation systems, they do not require expensive maintenance.

Any mistake in the selection of equipment will lead to a significant decrease in its performance. According to many experts, it is centrifugal pumps that are ideal for well construction.

Published: 13.09.2014