- Well parameters

- Overview of well-known manufacturers of mini pumps for pumping water

- Features of submersible models

- Submersible units

- Downhole pumps

- Drainage equipment

- Well units

- Criterias of choice

- Power Supply Options for Water Pumping Equipment

- Salient Features of Aquarium Pumps

- Household pump manufacturers

- Popular models of mud pumps

- Water pump: an overview of the varieties of hydraulic devices

- How to choose a fecal sewer pump

- Max head

- Suction/immersion depth

- Power

- Working temperature

- Automatic control

- How to connect?

- Features of manual equipment

Well parameters

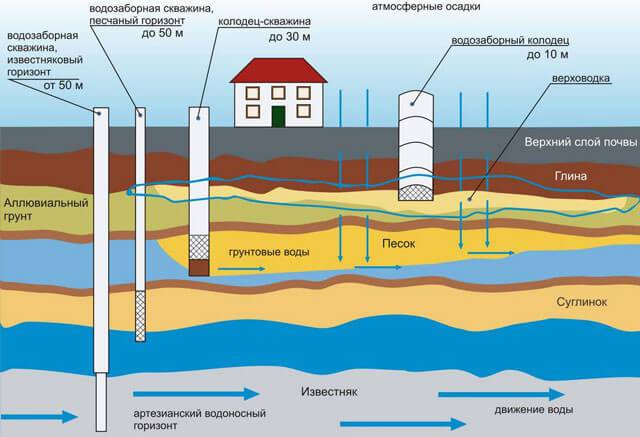

When deciding which pump is best for a well, you need to focus on the characteristics of the water intake point. We are talking about its static and dynamic level, debit, distance to the bottom, pipe diameter. If the well was drilled by a team of specialists, then they provide the site owner with a special document with relevant technical information. This also applies to the above parameters. If a lot of time has passed since the drilling of the well, all the parameters indicated in the technical data sheet require additional clarification.

It happens that the owners of the house build a water intake point on their own, or invite "shabashniks" for this.In this case, when choosing the best pump for a well, it is not possible to rely on documentation. There is only one way out - to take the appropriate measurements yourself, using simple tools. The static level is the distance between the surface of the water in the well and the surface of the earth. You can determine the distance using a simple rope with a load at the end (it is desirable that it has a cylindrical or conical shape). There is also an option with a plastic tube, tape measure or ruler.

Measurement procedure:

- It is recommended to refrain from using the well about an hour before it starts. This will allow you to get the maximum water level.

- Lower the rope with the load inside the wellbore until a characteristic sound indicates the contact of the load with water. As a rule, this sound is well audible.

- Having put a mark on the rope, pull it to the surface and measure the distance between its end and the mark. This will be the indicator of the static level.

The next parameter that you need to know to select a submersible pump for a well is the dynamic level. We are talking about the distance between the surface of the earth and the water in the well at the time of minimum filling. More thorough preparation is required for this measurement. Water is pumped out with a powerful pump (it can be rented or borrowed). In the process of emptying the shaft, the pump must be lowered lower and lower until the water stops decreasing. This level is considered the minimum. To determine the distance between water and the surface of the earth, the same procedure is followed as for determining the static level.

By comparing both indicators, it is possible to make a preliminary conclusion about the level of well productivity. This will greatly help in solving the problem of how to choose a pump for a well. A small difference between the two levels indicates a high rate of water column recovery. To service such a well, a high-capacity pump is required. In some cases, studies of an artesian well indicate the equality of the dynamic and static levels. This is an indicator of the high productivity of the hydraulic structure. As a rule, the most powerful one is recommended to select a pump for a well. Most often they also make a well for a well, which is very convenient and practical.

A high capacity index of the water intake point indicates that the pumping rate is approximately the same as the rate of replenishment of the volume of liquid from internal resources. The difference in levels in such cases is usually no more than 1 m. Information about the dynamic level will help in the process of determining which pump to choose for the well. The pump must be installed in such a way that the degree of its immersion is 2 m more than the dynamic level indicator. This will allow the device to be constantly in the water.

Overview of well-known manufacturers of mini pumps for pumping water

The Polish models of the well-known Aquael factory enjoy the recognized popularity. The units are equipped with modern energy-saving motors. O-rings are characterized by high quality workmanship, which reduces efficiency losses.

The small Juwel Eccoflow pumps are characterized by low noise levels and are equipped with filters with built-in adapters.

The small Juwel Eccoflow pumps are characterized by low noise levels and are equipped with filters with built-in adapters.

Powerful and productive models of vane units are offered by the German company Juwel Eccoflow. Small pumps for pumping water are characterized by low noise levels. Models are equipped with filters with built-in adapters.

Submersible pumps for pumping water from a small well are offered by AquaClear. The units are mainly used for aquariums. The performance of the devices is in the range of 480-1500 l / s, and the developed head is 0.7-1.7 m.

A well-known manufacturer of submersible mini-pumps is Eheim. Using the power regulator, you can change the performance of the unit. Such pumps can be used for aquariums, lawn irrigation and ornamental gardening.

The best pumps for aquariums are offered by Jebao. The equipment can be used for both fresh and salt water. Most models are equipped with a light sensor and a timer to stop the unit for 10 minutes. Using the controller, you can program the power and force of the movement of the water flow.

The best pumps for aquariums are Jebao products.

The best pumps for aquariums are Jebao products.

For mixing water in outdoor ponds and aquariums, compact pumps from Xilong can be installed. Models are characterized by a simple design, easy to install and operate. The units operate quietly, are reliable and durable.

Pumping equipment is presented today in a wide variety of species. Each of the models differs in design, scope, power, performance and working pressure.

When choosing a specific type of unit, it is important to be based on the technical characteristics of the device, suitable for fulfilling the stated requirements.

Features of submersible models

To successfully select a submersible pump for a well, as a rule, knowledge of the classification of these devices helps.

By type of device, submersible pumps are divided into two groups:

- Centrifugal. The main element here is a rotating disk with blades.

- Vibrating. For transporting water, they are equipped with special vibration membranes.

Knowing how the pump works will help determine if equipment operation will have a destructive effect on the wellbore. Vibration models are budget solutions. They are distinguished by ease of use and good performance, which is enough for servicing wells. However, taking into account the specifics of the work, experts do not advise using these mechanisms directly inside the mine. Although most of the reviews of the owners of personal plots say the opposite: in their case, the vibration pumps placed inside the shaft of the mine did not cause any harm to the structure.

Solving the problem which submersible pump choose - vibrating or centrifugal, you must be guided by common sense. The opinion of experts is based on the fact that with prolonged exposure to vibration, any nearby material suffers. Especially it concerns the walls of the well. The vibrations of the pump negatively affect the casing and the surrounding soil, which causes their gradual destruction. Due to vibration, the accumulation of silt and sand at the bottom of the source is noticeably accelerated. The danger is that this process is not immediately noticeable.

As a rule, at the initial stages of operation of vibration equipment, the well copes well with vibration exposure. Using this pump, it is convenient to swing and clean the shaft, without visible negative consequences. However, the process of gradual destruction from vibration, albeit slowly, but still occurs. This is especially true in situations where the vibration equipment is constantly running. Therefore, at first, with a slight loading of the well, the use of vibration technology is allowed. In the future, it is recommended to purchase a safer borehole centrifugal pump.

When choosing a centrifugal pump, the following criteria should be taken into account:

- Performance of pumping equipment.

- Instrument dimensions. They need to be compared with the diameter of the well casing.

- The total height of the shaft to which water will have to be raised.

- Specifics of installation and use of the device.

- The level of energy consumption.

- Details and features of warranty service.

For all the necessary explanations, you can contact a sales consultant who will help you decide on the best pump for a water well. As for the information that the manufacturer indicates in the technical data sheet, it must be borne in mind that we are talking about maximum, not average indicators. For the successful operation of equipment, it is necessary to provide for a certain margin of operational resource.

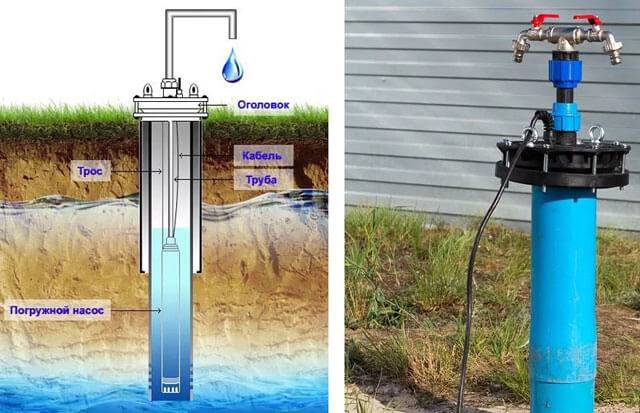

Submersible units

These devices are installed at the point of water intake. In this case, either the entire unit with the motor is immersed in the aquatic environment, or the electric motor is located above the surface of the water.Such pumping equipment can pump liquid from a considerable depth. It is characterized by high performance and efficient engine cooling.

Depending on the internal structure, the device is divided into the following types:

- vibration pumps are devices that suck up liquid due to an electromagnetic field and a vibration mechanism. Such operation of the device dictates special rules for its installation - at a certain distance from the bottom of the water intake, since the unit is able to lift silt, sand and other sediment from the bottom;

- centrifugal units work due to the torsion of the blades. When water gets on them, it is thrown onto the walls of the working chamber and transported outside under pressure.

Downhole pumps

These units are suitable for lifting water from the bottom of wells. These tools have an elongated cylindrical configuration and small dimensions that allow them to be lowered into the casing string. Such equipment can operate at considerable depth in artesian wells. The power of the device is quite impressive. Only lightly polluted or clean water is suitable for pumping.

Drainage equipment

This equipment is suitable for pumping contaminated water from reservoirs, flooded basements, pits, trenches, etc. However, there are also modifications that are designed to work in a slightly polluted environment.

The drain pump easily copes with water that contains a large amount of sand, grass, clay, silt or other small debris. And some models are equipped with chopping knives, like fecal pumps. The pumped water can be used for irrigation, watering the garden and technical needs.

Well units

Such pumps are suitable for pumping water from mine wells. The aquatic environment may contain a small amount of small impurities in the form of sand, clay and silt. Their main difference from borehole-type units is the immersion depth, which is relatively small. Such equipment is suitable for pumping clean water for the needs of drinking water supply.

The power, maximum pressure and performance of such equipment are quite impressive, but the dimensions of the device do not differ in compact dimensions. Well-type units boast quiet operation and low vibration.

Criterias of choice

Having a drain pump will help solve many of the problems associated with excess fluid after rains and showers, as well as help in the use of pools.

To select a device, it is necessary to clearly define its function.

- For example, when choosing a surface pump, you need to understand that it may not drain the pool completely, but only until a large amount of air begins to flow into the intake pipe.

- The pump for pumping water has a limitation and does not exceed 9 meters.

- The most suitable and in demand is a submersible pump, as it drains the tank almost to dryness, operates silently, and is not afraid of dirty water and large particles. The presence of a float will only add advantages to such a pump - the float switch will automatically turn off the pump after work is completed.

- Pump power is one of the selection criteria. The speed of pumping water depends on this indicator. If these are temporary pools, then inexpensive models with a plastic case are suitable for draining water: they are able to pump out about 10 cubic meters from the bottom. m per hour.For a stationary pool design, more powerful pumps with a metal casing are needed. They can pump out up to 30 cu. m per hour.

- For pumping water in pools with salt water, pumps with a body made of bronze are used - it does not corrode.

- The quietness of operation depends on the material of the pump housing. Plastic ones provide quiet operation, and metal ones are able to make a sound.

- When choosing a manufacturer, rely on the popularity and reputation of the brand, as well as customer reviews.

How to choose a pump for pumping water, see below.

Power Supply Options for Water Pumping Equipment

The pump unit can be powered by electricity and by liquid fuel. The first type of devices for the operation of the engine uses alternating current, as a result of which it is completely dependent on the electrical network. Therefore, an electric water pump is selected if it is present.

It is very important to take into account the voltage in the network, since a specific model of the unit is designed for a certain number of phases

Liquid fuel pumps are equipped with an internal combustion engine. Such units are characterized by smaller dimensions, mobility and ease of operation, repair and maintenance.

There are two types of liquid fuel pump units - gasoline and diesel. Gasoline pumps use a gasoline-oil mixture as fuel, which is prepared in a certain ratio of components. Such units are much quieter and have a lower cost. However, they consume quite a lot of fuel, as a result of which they are not economical. Diesel units use diesel fuel as fuel.The pumps operate with increased noise levels, but are characterized by high efficiency.

Note! Pumps for pumping water 220 V are more expensive than liquid fuel units.

Pumps for pumping water can be powered by electricity or liquid fuels.

Salient Features of Aquarium Pumps

The aquarium pump, also known as a compressor, aerator or pump, is designed to circulate water in the tank in order to saturate it with oxygen for the normal life of its inhabitants. Aeration is carried out around the clock, providing a stable air exchange regime. Such pumps are used to mix the upper and lower layers of water in order to equalize the temperature of the liquid, thereby preventing its drops. The operation of the device contributes to the destruction of the oily unpleasant film that interferes with normal gas exchange.

The operation of an aquarium pump for pumping water is as follows. There is a motor inside the compressor. He takes oxygen from the room and drives it into the tube, pumping it to the sprayer, which is located in the aquarium.

The pump can work from a network or independently from batteries. There are single and dual channel models. The latter option is characterized by durability, small size, low noise level and high performance.

Based on the design components, pump pumps for an aquarium are vibrating and membrane. The first type is characterized by high power and durability. The equipment is quite noisy, creating vibrations. The piston unit is recommended for aquariums with a capacity of more than 200 l.

An aquarium pump is used to circulate water in a tank to saturate it with oxygen.

An aquarium pump is used to circulate water in a tank to saturate it with oxygen.

The diaphragm pump is virtually silent and has low power consumption. However, such a unit is characterized by poor performance, so it is advisable to use it for aquariums with a capacity of up to 150 liters.

Depending on the installation option, a distinction is made between surface and submersible water pumps 12 volts for aquarium. The first type is attached using special suction cups or clamps under water to the bottom of the aquarium. The surface version is installed outside the fish tank. It is only connected to air pipes.

Note! The surface aquarium pump is used for tanks of small capacity, when keeping particularly demanding fish.

Household pump manufacturers

When choosing a particular product, you need to study many of its characteristics, one of the most significant is the manufacturer. Two similar models, but made from different materials and with different quality standards, will show different results, the main thing is that a better product lasts longer. The construction equipment market is full of various brands, and when choosing a pump for pumping, it is worth taking a closer look at several names.

Pedrollo is an Italian company that produces excellent drainage pumps with a debris cutting function. The price of products ranges from 5,000 to 15,000 rubles. The Vortex model is intended for household needs. Belongs to the submersible type. It has a strong polymer body with reliable sealing. It can work in automatic mode, pumps out water from basements up to three meters high. The maximum fraction of solid inclusions in water is 20 mm in diameter.The material is resistant to natural liquids and household detergents. With a power of 0.4 kW, it works at a speed of 10.8 cubic meters. m / hour = 180 liters / min. The force of pressure is 7 meters. The maximum liquid temperature is 400 C. Reliable and unpretentious in maintenance. Produced directly in Italy.

Popular models of mud pumps

Gnome submersible pumps are considered one of the best offers from domestic manufacturers. The housing in such single-stage centrifugal devices is located vertically. The pump is equipped with asynchronous motors with squirrel-cage rotors. Such devices are great for pumping contaminated water, which includes about 10% abrasive impurities. However, the size of large particles should not exceed 5 mm.

Over 50 different models of this brand are available to private homeowners to choose from, the operation of which can be carried out in a wide variety of conditions. Devices of the brand "Gnome" can be operated both in domestic and industrial conditions. Such products are often used in housing and communal services, in special drainage and irrigation mechanisms, as well as in oil refineries.

A device with average quality characteristics can pump out 16 cubic meters of water per hour with a head of up to 16 m, the dimensions of such pumps are 480x25 mm, and the weight is 28 kg.

Unilift Grundfos are dirty water pumps manufactured by one of the leading German manufacturers, used for pumping accumulated sewage as well as drainage water. The wheel in such one-stage systems is half closed, and the operating mode can be manual and automatic.Special devices are being developed for pumping dirty water from narrow wells, equipped with a check valve, which is mounted on the outlet pipe by means of a rotating disk mechanism. The case in such pumps is all-metal. They are equipped with synchronous single-phase or three-phase motors. To prevent overheating, the motors are equipped with special thermal relays.

Cutty by Speroni are submersible fecal pumps manufactured with a special patented technology. Such devices are often used in the sewer systems of private houses in order to consistently remove the contents of storage tanks. For similar purposes, such devices can be used even in agriculture. Such pumps have a fairly high power rating. Cutty 150 pumps consume 1.1 kW, give water pressure to a height of 15 m, pump 21 cubic meters of water per hour.

Patriot F 400 are Chinese-made pumps that are quite popular in the domestic market. This brand is registered in the USA, but the equipment is made in China. Such devices are used in everyday life and industry, they are able to interact with water containing solid fragments up to 35 mm wide. Those. such pumps can be used both in flooded basements, and in sewers, or some kind of pits.

Aurora ASP 900 D is another Chinese-made product in a fairly high-quality performance. These are centrifugal pumps for dirty water, the body of which is made of stainless steel, capable of interacting with solids up to 35 mm thick.The main distinguishing features of such technical devices are ease of use, high reliability, and comparative cheapness. The recommended price of such pumps is approximately 5,000 rubles. Thanks to float switches, the pumps are reliably protected from dry running. The motor power is 900 W, the pump gives a pressure of 9 m, supplies water in a volume of 14,000 l / h.

Water pump: an overview of the varieties of hydraulic devices

A water pump is a hydraulic device that sucks, pumps and moves fluid from one point to another. In one of the articles we talked about garden pumps. In this article, we will talk about the types of pumps for pumping water according to the principle of operation.

Garden pump: the heart of an artificial water source (read more)

This happens according to the principle of transferring kinetic or potential energy to the medium. Water units are presented in several varieties and differ in design, power, performance, efficiency, head and pressure.

Pumps for pumping water differ among themselves in power, design and performance.

How to choose a fecal sewer pump

If you need equipment for pumping wastewater, then it is important to pay attention to several characteristics of the device when buying. The mechanism will work for a long time if we take into account:

The mechanism will work for a long time if we take into account:

- required performance;

- sewer pipe diameter;

- total amount of wastewater;

- immersion depth of the pump;

- pressure;

- type of mechanism;

- pump power;

- additional options - chopper, liquid volume control;

- the manufacturer's company.

Max head

This characteristic indicates the pressure that the pump can create. This is the second most important indicator of the effectiveness of the mechanism. It is measured in meters, as this allows you to understand to what height the pump is capable of pumping liquid. It is necessary to choose such a pump so that its pressure is sufficient to lift the liquid to the required height. Great pressure can be obtained only by using expensive, high-performance devices.

Suction/immersion depth

It is necessary to take into account the characteristic of the device, which depends on the location of the personal plot - the depth of immersion. This indicator is determined by the purpose of the mechanism, and affects the ability to pump wastewater, it happens in the range of 3-20 m.

Power

When choosing a suitable pump for pumping sewage, consider its power. This directly affects the performance of the equipment, the ability to pump out viscous substances containing solid particles and the cost of electricity during operation. This characteristic affects the pressure, the power depends on the manufacturer and model.

Working temperature

Any fecal pumps designed for domestic sewers are divided into 2 types:

- For cold wastewater - the temperature of the liquid does not exceed 45 degrees;

- For hot wastewater - liquid temperature up to 90 degrees.

When only chilled liquid enters the sewer, it is better to use models designed for cold water, but it is not forbidden to install pumps for hot water (but they are more expensive). These pumps are used in private homes.Hot water enters the sewer system from the washing machine and dishwasher and during emergency discharges of the coolant from the heating system.

Automatic control

To control the pump when pumping wastewater manually, you will have to turn it on and off all the time, and this is inconvenient. You will often need to be near the equipment. It is better to purchase devices that include:

- Float - an element that determines the height of wastewater in the tank, it allows you to turn on and off the equipment in time;

- Thermal relay - a device that is triggered when the electric motor is significantly heated, this allows you to turn off the power to the pump in a timely manner, preventing overheating.

To reduce the risk of clogging the grinder pump, manufacturers sometimes install a self-cleaning device for the crushing large particles. This makes it possible to increase the life of the equipment without stops and interruptions in operation. Self-cleaning of the grinder further reduces the risk of overheating of the electric motor.

The most efficient and most reliable fecal pumps are devices with a metal case and working part. For this, stainless steel and cast iron are used. Plastic products cost less, but when working in an aggressive environment, they will fail faster.

How to connect?

In order to connect the equipment, two tubes must be connected. One - for the suction of water from the pool, the other - for its release outside the structure. The pumps can be powered by electricity or by a diesel unit. When working on electricity, you must first determine the pump into the water at a distance provided by the model instructions, and then connect the cable to the network.Diesel turns on by pressing a button.

During operation, it is necessary to follow some rules that will extend the life of the device:

- the pump must not run without water;

- during a large volume of pumping out, allow the device to rest if it works for more than 4 hours;

- surface models are installed only on a flat, ventilated surface;

- All pumps must be serviced by specialists.

Features of manual equipment

A hand pump allows you to pump fluid from a well, equipped on the site, to the point of selection, with little effort. The flow rate here is much lower than in automatic devices. But manually pumping a bucket of water is not difficult - even a teenager can handle this task.

However, lever mechanisms have a number of significant advantages.

Key positions include:

- autonomy - the device can be used where there is no electrical network, or the cost of electricity is too high, and it is not economically profitable to connect powerful equipment;

- small material costs for the acquisition - a manual unit is much cheaper than an automatic one and there is not always a real need to pay a significant amount of money for equipment that will not be operated in a constant mode;

- versatility - hand pumps on the market are presented in a wide range, you can choose the right device for both deep and shallow wells;

- maintainability - if any components of the lever models fail, they are very easily and quickly replaced;

- simple installation - installation does not require specialized knowledge and is carried out without the use of a specific, expensive tool:

- elementary use - for the pump to start supplying water, you only need to raise and lower the handle several times, even a child, a woman or a pensioner can easily cope with this task.

The equipment has only two drawbacks. The first is the physical effort required to obtain liquid for drinking or watering. In this regard, automatic pumps that pump water from a well without direct human intervention win.

An aesthetically attractive pump with a lever mechanism can be not only a practical and convenient device for supplying water, but also an original decoration of a summer cottage

An aesthetically attractive pump with a lever mechanism can be not only a practical and convenient device for supplying water, but also an original decoration of a summer cottage

The second is a small performance compared to automatic units.

However, this cannot be considered a complete disadvantage. After all, such models are intended for installation in places where there is no need for constantly flowing water from the tap or uninterrupted supply is simply impossible to organize physically.

Hand pumps with plastic body are only suitable for summer use. Cast iron and metal units normally operate year-round. Need insulation in case of a sharp change in temperature conditions

Hand pumps with plastic body are only suitable for summer use. Cast iron and metal units normally operate year-round. Need insulation in case of a sharp change in temperature conditions

Typically, hand pumps are used in summer cottages, visited only in summer, and in places where there are problems with a constant supply of electricity.

Also, manual models are used as an accompanying option for water supply. So, it will be quite difficult to provide the beds with vegetables with the necessary amount of water every day. A hand pump will help to cope with this task, and without the extra cost of paying for electricity.