- Types of submersible pumps

- Vibrating

- Centrifugal

- How to decide on the type of pump

- Submersible or surface pump for a well

- What you need to know about pump performance

- Pump head

- pump efficiency

- We clean the well

- Stages of work

- Decide on tasks and choose

- Application of drainage pumps

- Classification of drainage pumps

- Submersible drainage pumps

- Surface drainage pumps

- How to avoid mistakes when choosing a pump?

- Compact domestic pumping stations

- Calculator for calculating the required pressure for a drainage pump

- Overview of models and manufacturers

- Main unit installation requirements

- What to look for when choosing

- Overview of the best equipment

- The need for equipment and operating rules

- Conclusion

- Tips

- Unit selection

Types of submersible pumps

When pumping water in country houses, submersible pumps are most often used.

They are of two types:

- vibration;

- centrifugal structures.

Their difference lies in the way they work. Each model has its own working mechanism, differs in the way of pumping fluid.

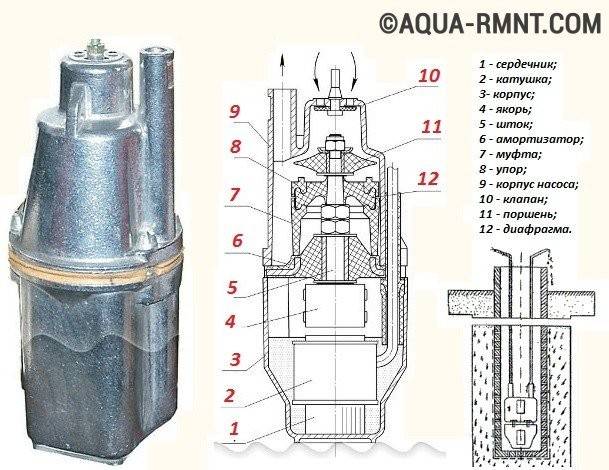

Vibrating

Vibrating pumps operate by vibrating the diaphragm.These fluctuations can be controlled and changed depending on the effect of electricity on the generated magnetic field created in the induction coil. Such products are powered by a general-purpose network with a voltage of 220 V. Their power is approximately 270 watts/hour, however it all depends on the installed motor.

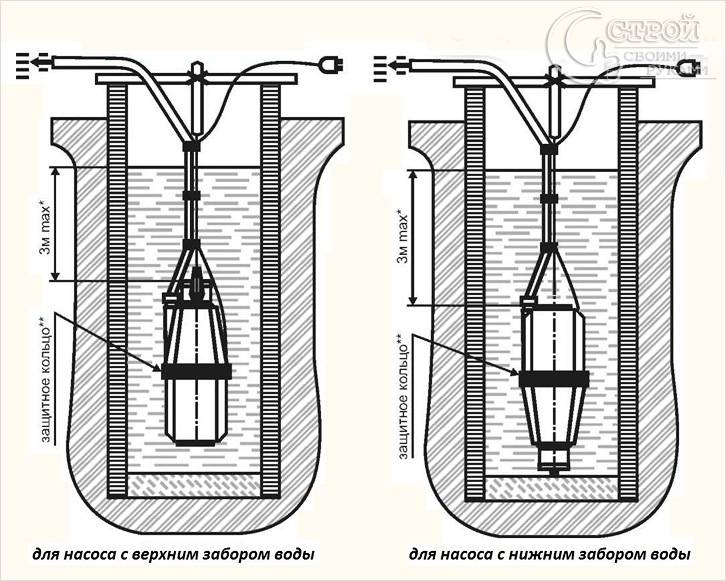

Vibration models are divided into designs with different liquid acceptance occurring at the top and bottom of the body:

- Designs with upper fluid intake do not overheat during operation. They do not mix water with sediment - therefore they are often used when cleaning a well well, as drainage pumps for pumping water from a well.

- Liquid-bottom designs require a quality filter and can overheat even during short periods of operation without coolant.

Vibration pumps do not have rubbing elements, they are distinguished by a long service life. They need filters.

Centrifugal

In centrifugal structures, a wheel with blades acts as a working element. This makes it possible to increase the productivity of the device; pumping liquid with small fractions of solid compounds is unacceptable here. The presence of sand or gravel will adversely affect the functionality of the device and the duration of operation. The main working element can be made of steel or durable polymer material.

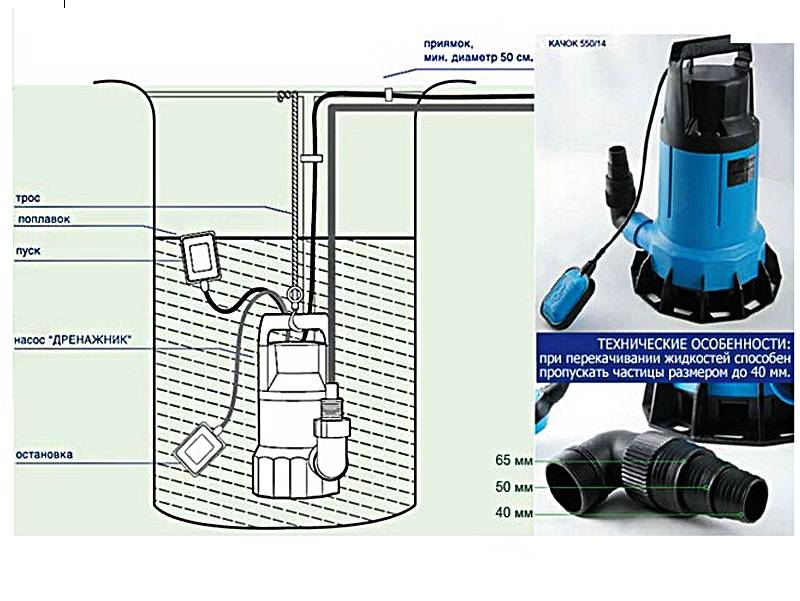

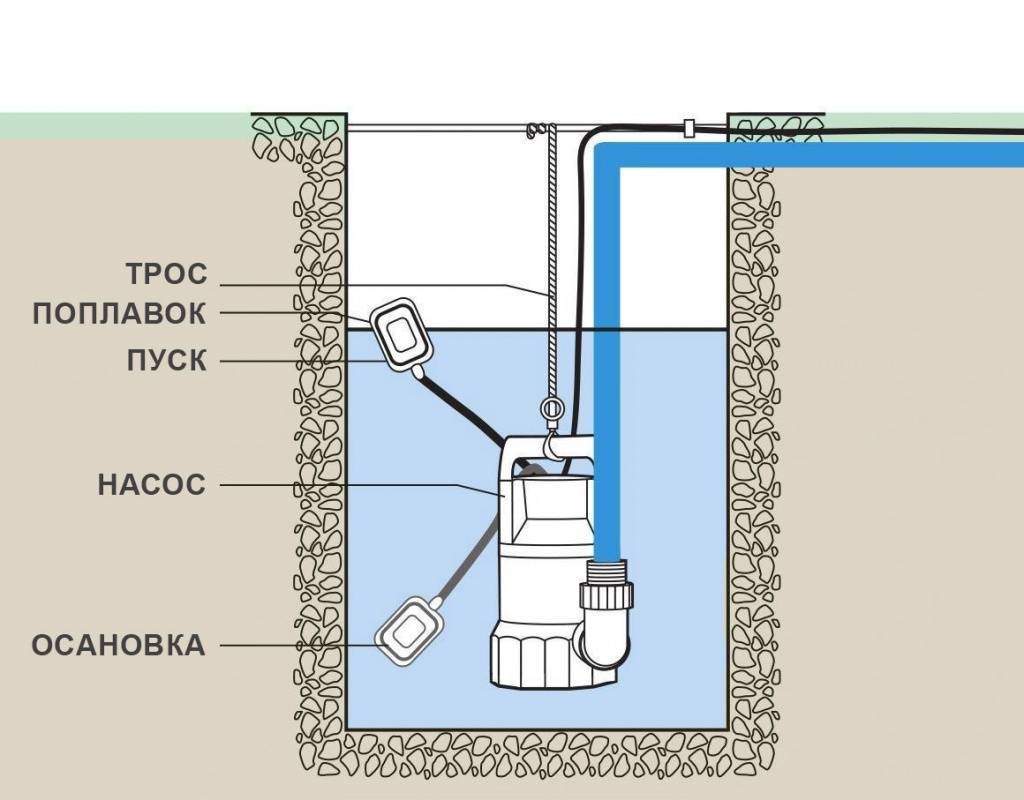

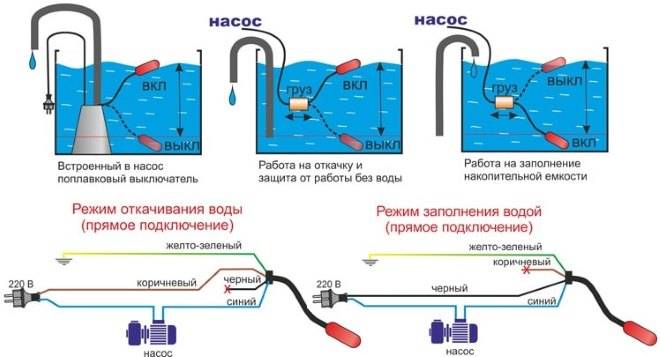

This allows you to make the work autonomous, devices with a float mechanism are used more often due to the simplicity and cheapness of the design.

The essence of the operation of the float switch is as follows:

- When the liquid level drops, the float drops, as a result of which the electrical contact opens. The motor is switched off and protected from overheating.

- Further, the liquid accumulates, and the float rises to a certain limit.

- Having reached the required level, the float closes the contacts and the electric motor turns on - the liquid begins to be pumped out.

It all depends on the correct adjustment of the float and the selected model. In addition, the liquid medium lubricates the rubbing contacts and cools against overheating. Overview of models with a float.

How to decide on the type of pump

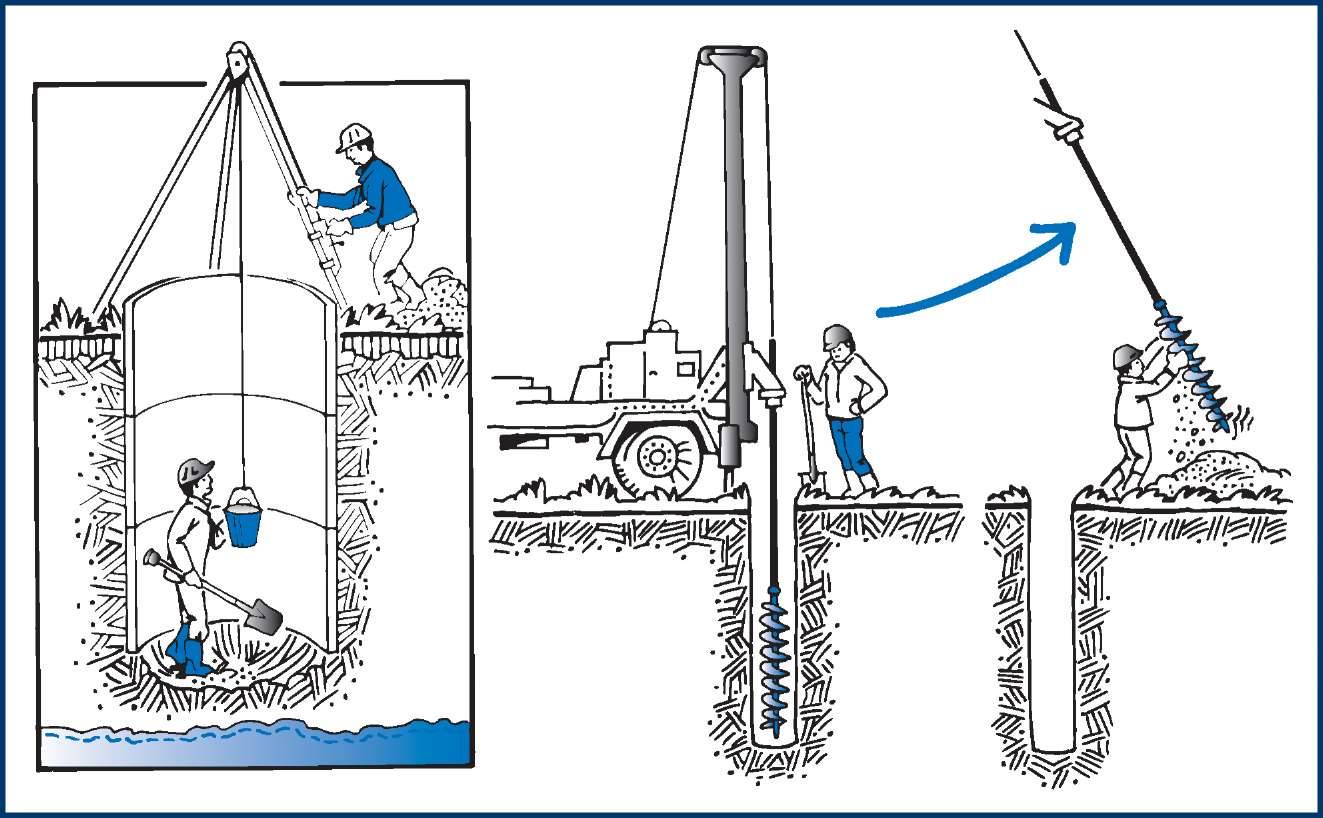

If you want to organize the water supply of a country house or summer cottage by digging your own well, you should also take care of the method of extracting water from it. The easiest way to solve this problem is with an electric pump. Before purchasing a suitable model, it is necessary to formulate the technical requirements for the unit, which will be discussed in this section.

Submersible or surface pump for a well

For domestic use, two main types of pumps are produced: submersible and surface. Their choice is largely determined by the depth of the well and the level of the water table relative to the surface of the earth.

Surface pumps are installed on specially equipped sites or in utility rooms. For fluid intake, they are equipped with a suction pipeline with a check valve that prevents spontaneous emptying of the system. At the moment of start-up, the impeller rotating at high speed creates a vacuum that sucks water from the well, which is then pushed out at high pressure through the discharge nozzle.

Surface pump installed near the well.

The theoretically possible suction head of such pumps cannot exceed 10.3 meters. In real conditions, depending on the design features and the quality of the pump, it reaches 5-9 meters. To reduce the distance to water, such units are installed in the immediate vicinity of the mouth of the well or inside it on rigid supports or a floating raft.

Surface pump installed inside the well.

Option to install a surface pump inside the well.

The advantages of such models:

- relatively low requirements for the tightness of the structure and the quality of the materials used;

- affordable price;

- simple maintenance.

There is a way to take water with a surface pump from a depth of 25-40 m using a lowering ejector. At the same time, the piping of the unit becomes more complicated and a significant part of the power spent on the operation of additional equipment is lost.

Pumping station with a remote ejector.

Submersible pumps are lowered directly into a well or other body of water used as a source of water. They do not have problems with suction and the risk of jet rupture, but there is a possibility of picking up soil particles or plant debris. They are usually equipped with a receiving mechanical filter. The body of such units is made of expensive stainless steel, and all current-carrying elements are placed in a sealed casing.

Strengths of such equipment:

- no problems with filling and suction;

- simple start;

- compact dimensions.

During the operation of the submersible pump, it is necessary to monitor the condition of the receiving grate and prevent dry running in the event of a drop in the liquid level.

What you need to know about pump performance

The performance of the pump shows the maximum amount of water pumped by it per unit of time. It is expressed in m3/h or l/min. At the factory, it is determined under ideal conditions for the equipment. In reality, the flow rate is highly dependent on the hydraulic resistance of the system, which is usually shown in the performance curve attached to the data sheet.

When choosing a unit for a well, they are guided by the number of residents and plumbing fixtures, including the needs for watering the garden. Sometimes the fluid replenishment rate associated with the carrying capacity of the aquifer plays a decisive role. To smooth out peak loads when using not the most powerful models, pressure tanks with a supply of water or hydraulic storage tanks, which are part of pumping stations equipped with the manufacturer, help.

Pump head

The head of the pump is expressed in meters of liquid column. It is equal to the maximum height to which it can be raised, although the consumption in this case will be minimal. With a stable pumping mode, pressure is spent not only on overcoming the difference in elevation, but also on the hydraulic resistance of pipelines and fittings installed on them.

pump efficiency

The efficiency of a pump, like any other mechanism, shows the ratio of useful work to the amount of energy expended. The higher it is, the more economically the equipment is operated, the less will be the payment to power engineers. This indicator depends not only on the design of the machine pumping liquid, but also on the chosen water distribution scheme in your home. Usually, for submersible units, it is somewhat higher than for surface units, since they do not have to expend suction forces.

We clean the well

If the price of the work that a private company takes does not suit you, then it is quite possible to clean it yourself and save some money. But in return, you will have to spend your time and effort.

The well is cleaned with a pump more efficiently, it greatly facilitates the work. A mud pump for cleaning wells pumps out water without problems and you do not need to do it manually. So:

First of all, you need to check if there is an accumulation of gas dangerous to humans at the bottom of the well. This is done as follows: on a rope into a well, carefully lower a lit candle.

If it is extinguished, then it is impossible to go down - there is an accumulation of gas, the concentration of which is dangerous for humans. Obviously the gas needs to be removed. This is done quite simply with a conventional vacuum cleaner.

You also need to know safety precautions. While in the mine, monitor your condition, and at the slightest deterioration, go upstairs.

We repeat once again that you should not be alone, the presence of a partner who will insure you is a must.

Stages of work

All work is done in several stages:

- Go down into the shaft and, using a metal brush, carefully clean the walls of dirt, moss, mucus and other deposits. Rinse several times with water.

- We begin to clean the bottom and water from debris. It is collected with a fine mesh. The filter, if present, must also be removed, cleaned of silt and sand, or replaced with a new one.

- Next, you need to disinfect the well. To do this, you need to know its volume, which is determined by multiplying its depth by the cross-sectional area.

- The well is cleaned with a pump.First, the pump for cleaning the wells must pump out all the water and then we pour or wipe the walls with a mop and a rag with a special solution (water with bleach - 20 g per 1 liter of water).

We pump out water

- Then we prepare a solution for water disinfection. While the water is collected in the well, we take a container and dilute the solution in it (200 mg of bleach per 1 liter of cold water), tightly close the lid and mix.

- Then we defend and pour into another container without sediment. Pour the solution into the well, mix, close so that the chlorine does not evaporate. The procedure must be repeated the next day.

- After disinfection, the water from the well must be removed. When it is typed, we pump it out again. We do this until the water stops smelling like bleach. However, you can’t drink it for another two weeks, and then it must be boiled.

Decide on tasks and choose

For pumping well water quite often a drainage pump for a well is used. They are used in cases where well water does not have a high degree of contamination.

Here the question will be about the volume of water. After all, there are low-power drainage pumps that are not able to withstand a large load, but in our time there are already models that have a sensor sensor for the drainage pump.

These are more powerful units, but, accordingly, their price is much higher. Consider the features of the application, varieties, as well as the pros and cons of these devices.

Application of drainage pumps

Let's immediately analyze what a drainage pump is, what it is and where it is used. Such devices are very useful under the following circumstances:

- If it is necessary to pump out water after accidents,

- When the water table rises high enough,

- In basements and basements with the accumulation of flood waters,

- In the event of prolonged and heavy rainfall,

- To clean artificially created water bodies, such as swimming pools, to comply with hygiene standards, they are cleaned using drainage pumps,

- For the organization of irrigation of large areas by drip,

- For decorative fountains, drainage pumps are used to supply water to them. A drainage pump with a chopper is often used here.

Classification of drainage pumps

Now let's see the drainage pump how to choose the right one. Now let's decide what the pump is for and where it should be used. You can also see everything in the photo. Such devices can be divided into two main groups.

Submersible drainage pumps

These devices are placed on the bottom of the object to be cleaned before use. They are quite popular among summer residents and owners of private houses, since the use of such devices is not difficult, they are easy to install and replace on their own.

Among other things, submersible pumps are not very expensive, which is also their strength. Depending on the principle of operation of the devices, there are:

Submersible pumps

- Submersible centrifugal pumps,

- Submersible vibration pumps.

In addition to the characteristics already listed, submersible drainage pumps have other features:

| Advantages | Flaws |

The advantages should be

| This type of drainage pumps has its drawbacks:

|

Surface drainage pumps

This is a non-submersible drainage pump. The video in this article will show you how it works. Such devices are not lowered entirely, but only a hose is placed in the water. They have their positive and negative sides. The advantages of surface devices include:

Surface pump

| Advantages | Flaws |

This design has several advantages:

| The disadvantages of surface-type pumps include the following:

|

How to avoid mistakes when choosing a pump?

On the modern construction market, the widest range of pumping equipment is presented, which differs both in its price and technical characteristics. The homeowner can choose both equipment from domestic and foreign manufacturers. Therefore, there should not be any special problems with choosing the right pump model.

On the modern construction market, the widest range of pumping equipment is presented, which differs both in its price and technical characteristics. The homeowner can choose both equipment from domestic and foreign manufacturers. Therefore, there should not be any special problems with choosing the right pump model.

If the pump is purchased for domestic needs, then there is no need to buy equipment that is too powerful, which has a high cost. It is better to give preference to a budget model, the price of which will pleasantly surprise the homeowner.

When choosing a suitable product, you need to pay attention to the following characteristics:

- performance options;

- pressure level.

The performance of a pump is the volume of water that it is able to pump over a certain period of time. It is necessary to calculate how much water enters the collector, and for how long it must be pumped out. Based on these parameters, a pump with the required level of performance is selected.

The pressure pumped by the pump is also an important characteristic when choosing a device model. It is determined based on the following indicators:

- the distance to which water must be diverted;

- the height of the water.

These parameters directly affect the quality of operation of such equipment and are indicated in the technical documentation attached to the device.

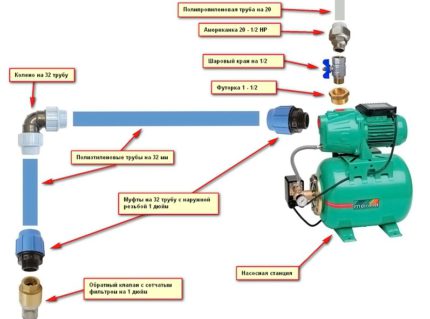

Compact domestic pumping stations

For the uninterrupted and efficient functioning of autonomous water supply systems for cottages and private houses in automatic mode, compact pumping stations have been increasingly used in recent years. The use of such stations, which include several technical devices, allows minimizing human participation in controlling the operation of pumping equipment due to automation elements. The compact dimensions of household pumping stations for pumping water, which, despite their small size, are characterized by high performance and are able to create good pressure in the pipeline system, allow such equipment to be installed in any convenient place, including in the basement of a residential building.

The household pumping station includes the following technical devices:

- submersible centrifugal pump pumping water from an underground source;

- filtering plant, in which water from an underground source is purified from solid inclusions;

- a circulation pump designed to pump water from the filter unit to the station's hydraulic accumulator;

- a hydraulic accumulator, the internal chamber of which, filled with water, is equipped with a special membrane (the task of this device is to maintain a constant pressure of the liquid medium in the autonomous water supply system, and also to provide this system with water at those moments when the station pump does not work due to a breakdown or lack of power).

Automatic pumping station for individual water supply systems and small garden plots

The operation of a household pumping station in automatic mode is provided by a pressure switch that automatically turns off the pumping equipment if the water pressure level in the accumulator rises to a critical level, and also turns it on when such pressure falls below the permissible value.

Mini-pumps are actively used not only in everyday life, but also in industry, in particular in food industry enterprises. For pumping liquid and viscous media used in technological processes at enterprises in this industry, special food pumps are needed, the structural elements of which are made of materials that are highly resistant to oxidation and do not emit harmful substances into the pumped medium.

Calculator for calculating the required pressure for a drainage pump

Automatic calculation of pump head.

Any pump has limitations on the depth from which it can pump fluid. Another important metric is productivity. It shows the volume of liquid that the unit is able to pump. The weakest devices have a capacity not exceeding 100 l / min. The choice for this parameter depends on the conditions in which the equipment is to operate.

If large volumes are pumped, the performance is chosen as large as possible. Inefficient equipment is enough to pump out the water that comes in little by little. The main thing is that less liquid is collected in the storage tank than the pump can pump out.

When calculating the required pressure, take into account:

- the difference in height between the water intake level and the highest point of the main;

- horizontal distance from the bottom of the intake hose to the end of the pipeline;

- diameter of pipes, hoses.

In the proposed calculator, you must specify all the parameters and get the result.

Overview of models and manufacturers

The selection of equipment begins with an inspection of how much this or that model costs.

But it is important to pay attention to the manufacturer. Here are some options for equipment for pumping / pumping water, which is well-deservedly popular:

- Water cannon - equipment designed to pump flows from a well / well. The throughput of insoluble inclusions is low, the price is from $ 80

- The kid is a design ideal for summer cottages. Low performance affects the low price (from $ 40).

- A brook is a device for supplying water from wells and wells of medium depth. Unpretentiousness to the percentage of pollution, excellent performance, ease of installation and lightness of the device are complemented by a low cost (from $ 30), but the duration of operation is no more than 3-5 years.

- The Gileks range is equipment designed for domestic use in both water supply and sewerage systems. Excellent practical qualities, work with different depths, unpretentiousness to pollution, a very long service life and good maintainability are the obvious advantages of the brand. Equipment cost from $200

- Belamos - models are used to supply clean drinking water and irrigation. They have a built-in control unit, which facilitates the use of the units, and can work in manual, automatic and scheduled modes. There is also a filter to improve the quality of the supplied flow, overload protection, productivity up to 2800 l / h, supply depth up to 8 meters. Price from 150 $

- Gardena is a brand of high reliability equipment.Universal devices are able to cope with the supply of liquid without interruption to high floors, be used for irrigation and at the same time are unpretentious to pollution, as they are equipped with a high-quality filter. Power up to 4000 l / h, ready for use immediately after purchase, the presence of 2 outlets for the hose (for irrigation and drinking water), a low noise threshold and a drainage tube for draining liquid add pluses to the device. Price from 120 $

- Aquarius is an ideal pump for wells up to 45 meters deep. The reliability of the unit is confirmed by the execution of parts made of brass and stainless steel, there is a thermal relay, as well as a complete non-susceptibility to power supply drops (performance will decrease, and the device will not break). Silent operation is also a plus, but it is better to use the unit on clean streams. Price from 120 $

- Whirlwind - pumps for deep wells (from 60 meters). Chrome-plated parts, durable housing, head up to 100 meters and price from $ 100 are the pluses of the unit. But energy consumption up to 1100 W is a drawback. However, the presence of overheating protection functions, smooth running, high pressure, high-quality assembly exceed the shortcomings.

All presented models from the Russian manufacturer have unique features - they are adapted to power outages, are resistant to mechanical stress and are easy to install. For users who prefer more expensive units, there are alternative options:

- The Grundfos range is an offer from German manufacturers. The company is engaged in the production of equipment for supplying and pumping liquids from wells, wells, tanks. The devices are equipped with sensors for overheating, overload, protection against dry running and voltage surges.Such functionality significantly extends the life of devices, but raises the price to $ 150. However, no matter how much the units cost, they deserve their price - the brand, according to consumers, is considered a leader in its field.

- Unipump is a brand of equipment indicated for use in wells with a high content of insoluble inclusions (up to 100 g/cubic meter). Feeding height up to 52 meters, productivity up to 4.8 m3/hour. There is overheating protection, soft start, automatic operation, but you will have to be careful in use if the liquid is very hard. The price is from $ 110, efficiency and noiselessness are pluses, but a weak network drive is a minus of equipment.

A preliminary analysis of the needs, the design of the water intake source, determining the length of the flow and the functional features of the water supply will allow not only to choose a good quality device, but also to correctly determine exactly how many pumps will be needed to uninterruptedly supply water to a house, household or suburban area.

Main unit installation requirements

The station itself should also be installed according to certain rules. It is bolted to the base. The base is preferably concrete. A rigid steel frame made of profiled rolled products is allowed. Its design is welded or bolted.

It is very useful to install on a gasket made of a thick sheet of hard rubber - this shock absorber will reduce shock loads when turned on and reduce the noise of operation.

Much less frequently, for these purposes, spring steel shock absorbers are used, placed under the base, according to the type of attachment of the exciter eccentric of the vibrating table.

But such a mount, with the slightest loosening or violation of the adjustment, is capable of breaking the mounting sockets on the base of the station and creating unnecessary loads on the water fittings - too large an amplitude of oscillation. So the best option would be a hard rubber sheet up to 3 centimeters thick. Rigidity is about the same as that of a summer car tire tread.

It is important to pay due attention to the electrical part. Be sure to connect the station case to the ground loop - regardless of the choice of installation location. It is very useful to use an RCD (residual current device - the second name of this mechanism is a “differential current device”) - especially if the option with a caisson is chosen or the installation was made directly in the well

It is very useful to use an RCD (residual current device - the second name of this mechanism is a “differential current device”) - especially if the option with a caisson is chosen or the installation was made directly in the well.

It makes no sense to unnecessarily complicate the wiring diagram. We only do what is necessary

It makes no sense to unnecessarily complicate the wiring diagram. We only do what is necessary

In any case, the station must have an individual protective electrical circuit - at least a circuit breaker with a trip current slightly higher than the rated starting current of the installation.

In addition, the service life of the electrical part of the station is positively affected by the presence of stabilizers, network filters and uninterruptible power supplies.Maybe they will not be able to have a significant effect on the engine itself, but such an addition will be very useful for the electronics as part of the station's automation unit.

What to look for when choosing

drainage view

One of the main criteria for choosing such a unit is the degree of contamination. As a rule, this parameter is determined by the maximum size of the particles of pollution that the pump is able to "digest".

The criterion is the depth of the well. The larger the parameter the more performance you need a pump to successfully lift the water.

The final, but also important factor is the design features of the equipment. These include the location of the suction hole, the material from which the device case is made, maintainability. This factor is little influenced by the conditions in which the pump will operate, for the most part they affect the performance of the device, and very much depend on its price and manufacturer.

Overview of the best equipment

Model NPC - 400D

Let us dwell in more detail on specific models of pumps. To begin with, consider the submersible centrifugal pump NPTs - 400D, the Chinese company Caliber. The power of this model is 400 W, the productivity is about 7000 l / h, it is able to work on depth up to 7 meters.

The size of the passed particles is 5 mm. Made from cheap plastic. The weight is 5 kilograms. It is distinguished by its simplicity and relatively low price - a little over 2,000 rubles. Cheap, not whimsical, perfect for a summer cottage.

Now consider for comparison the German submersible drainage pump SDP 7000 of the well-known company Karcher.With a lower power of 320 W, this unit has the same capacity (about 7000 l / h) as the Chinese. However, it surpasses it in the depth of immersion - it is able to cope with a distance of 8 meters. And also according to the maximum size of solid particles, this device is able to cope with pollution with a diameter of 20 mm. It surpasses its predecessor in terms of performance. In the equipment of this brand, everything is thought out to the smallest detail.

Model SDP 7000

Its body is made of high-quality, ultra-durable materials. It features a comfortable, ergonomic circular handle allowing it to be carried comfortably.

You should also pay attention to the optimized connecting pipe, which allows you to connect any hoses without adapters, including large sizes.

This device is equipped with a float switch with an adjustable level, which will allow it to be used in automatic mode.

Perhaps its only drawback is the price of 5,000 rubles, but is it a lot for all the listed advantages? You decide.

The need for equipment and operating rules

The desire to have a source of clean water in your home leads to considerable expenses for its maintenance. Regular cleaning alone can require a large investment. But they can be significantly reduced if you use a pump to clean the wells. Well drainage pumps are suitable for this purpose. However, only the right pump can work effectively.

Thanks to the regular use of such equipment, you can achieve amazing results and enjoy exceptionally clean water.But for this it is necessary to comply with the requirements specified in the operating instructions. Indeed, as a rule, submersible equipment is used for such purposes, the serviceability of which cannot be visually verified.

This feature requires good tightness, for which the pumps of these models have a special chamber filled with oil, which protects the unit's engine from contact with water. It should be regularly checked for the presence of the required amount of composition in it and, if necessary, gravy is made.

After a long operation of the equipment, the oil must be replaced, usually this process is carried out after 200-250 hours of operation.

Only by observing all these rules, you can ensure long-term and reliable operation of the pump for cleaning wells.

Conclusion

Having considered all the features of drainage equipment, you can easily choose the model that meets your specific requirements. If its seasonal operation is expected in the country, then you can limit yourself to an inexpensive pump of domestic production. For permanent residence outside the city, a more powerful and at the same time expensive model will be required. But in any case, you should not purchase equipment from unknown companies, very often it turns out to be of low quality. Saving on it, you risk getting untreated water, unsuitable for food.

Tips

Even the most reliable and well designed well can have mud deposits. But in any case, ordinary water pumps are unacceptable for cleaning; only specialized units should be used. It is impossible to violate the standards prescribed by the manufacturer for the depth of laying under water, for the height of the water column, for the duration of continuous action, and so on.Filters are a very useful thing, even if they are not included, it is recommended to buy such equipment additionally. When you have to put the pump near the house, it is advisable to choose options with a cast-iron or plastic case, they make less noise than steel.

It is recommended to purchase only compatible accessories with the pump:

- hydraulic accumulators;

- water return valves;

- automatics against dry running;

- Surge Protectors;

- relays and gauges.

How to choose a well pump, see the following video.

Unit selection

The selection should be carried out depending on where the drainage pump is planned to be installed (in a well, septic tank, basement, etc.). It is advisable to install equipment of this type in a pit with a depth of 400 to 600 mm. This will protect the basement from water ingress.

Additionally, the unit can be equipped with a vertical float mechanism that will start the pump as the recess fills, while the floor remains dry.

If it is necessary to drain the tank as much as possible, the installation of the drainage pump in the well is carried out on a hard surface. In this case, the unit will start when the drains rise by a few centimeters.