- Operation and repair

- Required number of pumps

- Rating of popular models

- INTEX 28644

- Bestway 58383

- INTEX KRYSTAL CLEAR SALTWATER SYSTEM

- Aquaviva P350

- Heat pumps for swimming pools

- How a heat pump works

- Heat pump selection criteria

- The mechanism of action of pumps

- Service

- How to choose?

- Heat pumps

- Equipment task

- Advantages of heat pumps

- Criteria for equipment selection

- Operating principle

- Selection rules

- TOP-3 models with description and cost

- Submersible

- Bestway 58230

- JILEX 220/12

- Surface

- Kripsol Ninfa NK-33

- Hayward SP2503XE61EP33

- Types and the right choice

- surface models

- Submersible

- What is the pump for in the pool?

- How to install a heat pump in a house

- Which heating is better for a home - gas or heat pump

- Disadvantages of heat pumps

- Advantages of heat pumps

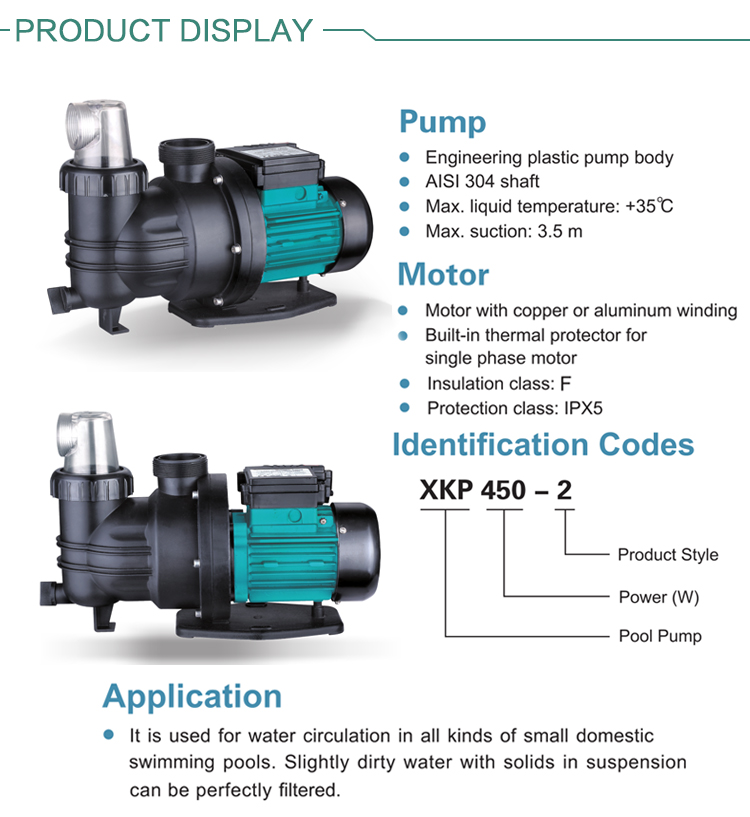

- Self-priming pumps

- How a heat pump works

Operation and repair

In most cases, installing pool pumps with your own hands does not cause much trouble. To connect equipment for pumping liquids, it is enough to follow the attached instructions, follow a number of simple rules.

For pressure and filtration models, it is necessary to prepare a waterproofing base

When operating indoors, it is important to maintain the temperature in it at least +5 degrees; when outdoors, the equipment is dismantled for the winter.

For the pump to work effectively, the height difference between the pump base and the water level in the pool should be between 0.5 and 3 m.

Rubber mats will help reduce noise and vibration during operation of the equipment.

The water suction pipe must be as short as possible. A strong slope of the line should be avoided, it is not recommended to change its direction.

When connecting to the network, it is recommended to equip the device with an automatic cut-off device that can protect the device from failure during power surges or short circuits.

Heat pumps are placed outside the pool, on a solid, level base.

The maximum length of the pipeline is up to 10 m.

All these tips help to connect the pumps more quickly and correctly. Of course, each type of equipment has its own subtleties that have to be taken into account, but general recommendations help you quickly find the right solution. When operating pumping systems, certain recommendations must also be observed.

Be sure to monitor the presence of a sufficient volume of liquid - any blockages, stagnation in the system are very dangerous, can lead to failure of the pumping equipment.

During the operation of the pool pump, its owner may be faced not only with the need for thorough water treatment, but also with the repair of failed equipment.

Among the common problems are the following.

Blocking the flow of water with air. It occurs when changing equipment and if it is located above the water level. In this case, if a circulation pump with a prefilter is used, it is necessary to turn on the equipment and wait until the filling occurs naturally (subject to the restrictions on the duration of dry running).Or pour liquid, and then make short starts for 5-10 seconds. In the absence of a built-in filtration system, a filler hole can be used for the same purposes, the actions continue until water appears, the sound of the equipment changes.

Problems with the pneumatic button on the control unit. Since it directly controls the inclusion of various types of pumping equipment, water attractions in the pool, the failed part will have to be replaced. With a piezo button, such problems no longer arise, the installation is similar, and you can increase the range of its placement.

Water does not circulate due to blockage in the system

To clean and unlock the hose, it will have to be disconnected from the system and mechanically "pierced" with a special tool for plumbing work or improvised means

It is important to handle the flexible liner with care, otherwise it may show breaks and cracks.

Filter clogged, water not circulating. To clean it, you will have to disassemble the pump of the cartridge cleaning element.

To do this, turn off the pump, turn the valve responsible for relieving pressure in a counterclockwise direction

Then you can open the filter and take out its contents, subjecting it to a thorough cleaning. After assembly, the system can be started again.

Water leak. If the pool water supply is poorly maintained, it can eventually leak at the connections. Most often, water leaks near the inlet and outlet, as well as at the filter attachment point. You can solve the problem by replacing the gaskets, tightening the connections. If a leak is found only on the inlet hose, the first step is to clean the filter.

Following these recommendations, you can easily cope with the tasks of maintaining and repairing pool pumps, and returning them to service after a breakdown.

In the next video, you will find tips on operating the pool pump.

Required number of pumps

The number of equipment is directly proportional to the size and volume of the reservoir. One pump for an inflatable pool or frame-type pond, supplied in the kit, will do the job. Water will go through a full cycle through all cleaning and heating systems in 6 hours.

Pumping unit for the pool

Larger stationary bowls require the installation of several pumps for water purification. The main mechanism filters the water, one creates a countercurrent, and the other starts the ultraviolet installation or drives the fountains. The more “chips” such as a jacuzzi, fountains, massage areas in the reservoir, the more pumps will be needed to filter the water in the pool.

Rating of popular models

Below is a rating consisting of four current pool filter models.

INTEX 28644

INTEX 28644 is a sand-based water filtration device. The diameter of the sand tank is 25 centimeters, and the power of the electric pump is 650 watts. This allows the INTEX to pump approximately 4,000 liters of water per hour, making it suitable for use even in relatively large pools. But the model is best suited for medium and small tanks.

INTEX is equipped with a branded filter tank with a special sand mixture. There are three types of tanks in total - each for a different level of water pollution and for different working conditions. They are purchased separately.

Bestway 58383

Bestway 58383 is a Chinese-made budget device for pool water filtration.It is equipped with a relatively weak pump, the power of which is only 29 watts. According to the manufacturer, it allows this model to pump up to 2,000 liters of liquid per hour. However, in practice, Bestway 58383 is capable of pumping about 600 - 700 liters per hour, which is much lower than the passport data.

Filtration is carried out in a cylindrical pump housing, where a special cartridge is installed. It is a plastic circle on which paper strips impregnated with an antiseptic are fixed. The strips are several millimeters apart from each other, so they are able to hold only fairly large debris. Smaller particles will simply pass through them. This significantly reduces the efficiency of the device.

Despite not very good characteristics, due to its low price (about 1,500 rubles), Bestway 58383 is perfect for collapsible country pools of small volume.

INTEX KRYSTAL CLEAR SALTWATER SYSTEM

INTEX KRYSTAL CLEAR SALTWATER SYSTEM - chloride filter for the pool. For the operation of the chlorine generator, it is necessary to purchase an electric pump, since this model does not have its own unit for pumping water. The device works from a household power supply with a voltage of 220/230 Volts. Also, INTEX KRYSTAL CLEAR SALTWATER SYSTEM does not have a filtration device for the accumulation of debris and dirt.

However, it can be installed optionally. INTEX KRYSTAL CLEAR SALTWATER SYSTEM uses common table salt as a reagent. A small amount of this substance must be dissolved in water before turning on the device.

Aquaviva P350

Aquaviva P350 is a sand filter designed for medium sized frame pools. It is capable of pumping approximately 4,000 liters of water per hour. A distinctive feature of Aquaviva P350 is a 20 kg sand tank, which ensures thorough water filtration and does not allow even fine particles to pass through.

Heat pumps for swimming pools

In most of our country, summer is coming to an end very quickly. During the night or in cloudy weather, the water in the pool cools down. It is expensive to heat a pool with traditional heaters.

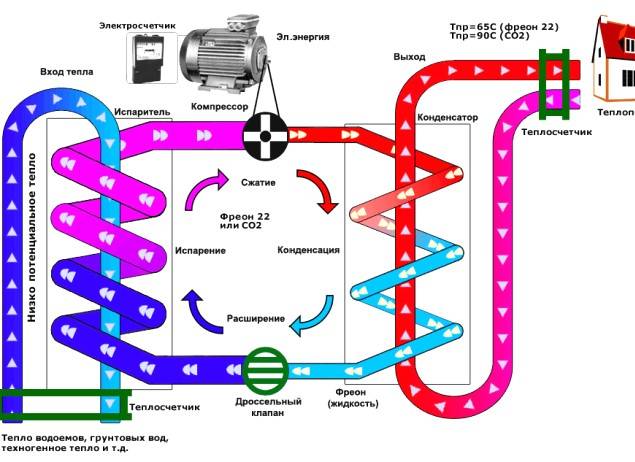

How a heat pump works

The principle of operation of a heat pump can be clearly seen on the example of a domestic refrigerator. The composition of the heat pump includes: heat exchanger, compressor, evaporator.

Freon circulates in the heat pump system - a gas that can turn into a liquid state at room temperature. During the transition of the phase state of freon, heat is taken from the environment and then the circulating water is heated in the heat exchanger.

In short, the refrigerator is the opposite: the environment is cooled, the water is heated.

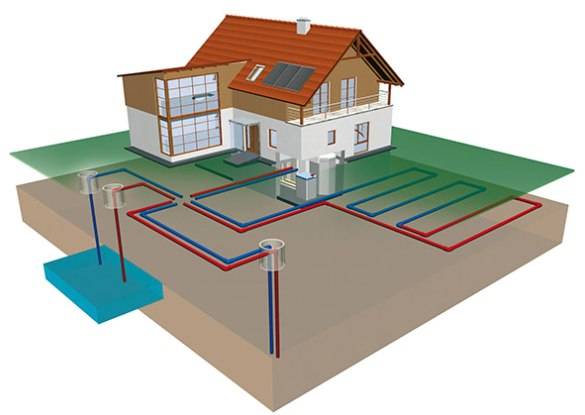

According to the interaction with the environment, there are three types of heat pumps: ground-water, water-water, air-water.

Pool heat pumps not only heat the water, but also maintain its stable temperature.

Heat pump selection criteria

Each type of pump has its own circuit installation rules. For ground-water pumps, horizontal or vertical pipes are required.

In any case, pipe laying must be carried out at a depth of at least 2-3 meters - to the freezing depth. From above it is impossible to plant trees with a powerful root system.

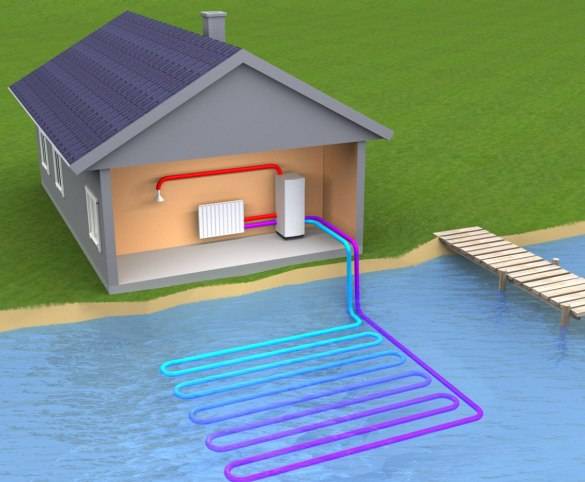

Water-to-water pumps use the energy of reservoirs.Such pumps are an advantageous option, since they do not require excavation of the previous type of pumps.

In these systems, laying to a freezing depth of 2-3 meters is also required. The distance from the reservoir to the pool should not be more than 100 meters.

Air-to-water systems do not require complex piping and are easy to install. However, air-to-water pumps are less efficient, as they extract the thermal energy of the air and depend on its temperature at a particular time period.

When choosing an air-to-water heat pump, consider:

- pump installation location (sun or shade);

- average air temperature;

- pool volume;

- pool type (outdoor or indoor).

Regardless of the chosen heat pump system, on average, approximately 5-8 kW of thermal energy is generated per 1 kW of electricity consumed. Modern heat pump systems are able to heat even an outdoor pool all year round.

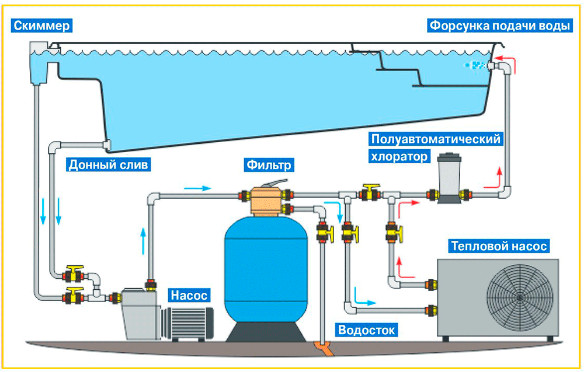

The mechanism of action of pumps

Despite the large selection of devices, the mechanism of operation remains identical:

- With the help of a pump, water under pressure is pumped into the device.

- Passage through a coarse mesh to trap large particles.

- Returning to the first chamber, it contains a grid with smaller cells, eliminating medium-sized debris.

- Transition through the main filter element.

- Go through the return hose back to the pool.

In order for the water to be cleaned quickly and efficiently, it is recommended to install hoses for inlet and outlet in different directions. The recommended number of cleanses per day is 2-3 times.

Service

The main type of maintenance is washing or changing the filter element. For cartridge-type equipment, it is easiest to replace the filter element.At sand pumps, the filter material is washed with a reverse flow of water. Do the same with washing diatomaceous earth filters.

The extent to which the filter element is clogged is judged by the condition of the water in the pool and by the operation of the pump. For cartridge devices, the filter element has to be washed up to 1 time per week. Sand and diatomite filters are washed much less frequently.

Chlorine filters require a starting backfill of table salt. On average, salt consumption is 3 kg per 1 cu. m of water. The exact data is indicated in the technical description for a specific model. The controller built into the chlorine generator informs about the need to add salt.

How to choose?

The pool must be of high quality and reliable. When choosing the size and shape, you should focus on the area where the product will be installed.

If the ground is not flat, then you should pay attention to sets with bedding for the bottom.

Important selection principles.

Children's pool should be chosen based on the age of the child. Babies under 2 years old need shallow products, and after 3 years - up to 50 cm.

Materials must be safe

It is important to check the quality of the product. It is worth noting that a good pool has practically no seams.

The bottom must be covered with non-slip material.

It is worth giving preference to models with hard sides.

Pump quality matters

It is necessary to know in advance how long it takes to fill the pool with water completely.

Heat pumps

In fact, such installations cannot be called only pumps, because they do not transfer water, but heat that is available in the environment.

This is especially important for us, since summer in most of the country does not please the weather for long, and the swimming season is quickly coming to an end.Even on cloudy but warm summer days, the water cools overnight and becomes completely uncomfortable.

Heat pumps are an ideal option: these systems effectively and efficiently solve this problem.

Equipment task

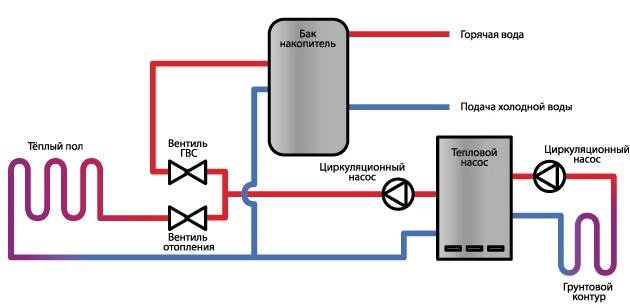

The principle of operation of the pump for the pool (conventional unit) is different from how this installation functions. It can be compared to a refrigerator that suddenly changed its mode of operation, or a split system that works for heating. The composition of any heat pump includes a compressor, an evaporator and a heat exchanger. In this system, just like in climate technology, the refrigerant Freon circulates.

It is a gas that can go into a liquid state even at room temperature. With such a transformation, heat is taken from the environment, and then transferred to water. There are three types of installations: air-to-water, water-to-water and ground-to-water. As a rule, for swimming pools, pumps “steal” heat energy from the air. This is the simplest, relatively cheap way to solve the problem.

Advantages of heat pumps

If we consider electric heaters and this alternative, then the thermal installation will be the undisputed leader. To be sure, it is enough to get acquainted with the advantages of this water heating method in a swimming pool. These include:

- complete independence from fuel;

- comfortable liquid temperature - up to 60 °;

- long service life - up to 20 years or more;

- convenience: no noise, easy installation, easy maintenance;

- fully automatic control of water temperature in the tank;

- saving electricity, its devices spend neatly and little: spending 1 kW, they produce and transfer 5-8 kW of thermal energy.

Criteria for equipment selection

Knowing all the parameters of the tank is the first condition.To choose the optimal model, it is necessary to take into account the type of artificial reservoir, its volume, depth, desired water temperature, installation location (shade or sun). No less important is the climate of the area, the air temperature.

On sale there are heat pumps designed for pools of different sizes: from 30 to 150 m3. If the installation is needed for very large bowls, a combination of several heat pumps is possible. Such equipment is able to maintain a comfortable water temperature throughout the year, but to a greater extent this applies to indoor pools.

The principle of operation of a pool pump is very simple, but only if we consider conventional models that do one job - water filtration. However, units that perform several functions will save the owners from a painful choice and provide maximum comfort.

At the end of the topic - a popular video about pumps that are used to maintain pools:

Operating principle

The submersible type pump combines both the pump itself and the electric motor in a common sealed housing. Its principle of operation is the same for garden and drainage options. The motor rotates the blades of the wheel, and the chamber is filled with water.

Under the action of centrifugal force, the liquid is displaced and enters the sewer. The opening for the fence can be both above and below. The first will not allow all the water to be poured out, but the drain will not be clogged with large leaves and silt. The second will empty the pool to a centimeter, but the cleanliness of the bottom will need to be carefully monitored.

Surface electric pumps can be vortex, centrifugal and with an external ejector.The latter are almost never produced now, they were replaced by submersible ones.

Vortex ones are not applicable for country pools, because they wear out from sand. For pools, only centrifugal ones are suitable.

Centrifugal models have wheels that drive a working shaft supported by bearings. The wheels build up pressure, the water rises, then drains through the outlet pipe. All electric pumps have a relay sensor, it trips when the water supply stops.

Selection rules

The following selection criteria are followed:

- high power, allowing you to quickly pump water;

- energy saving;

- noise should be absent or low;

- long warranty period, not less than 1 year;

- appropriate price: the better and better the internal content, the higher it is;

- simple installation and operation;

- rare need to replace the cleaning component (cartridge, sand).

When the choice is made, the device is bought. After arriving home, they immediately check the performance. The warranty period is limited, it is better to immediately check the functionality, the ability to purify water.

TOP-3 models with description and cost

Consider several popular models of pumps for pumping water out of the pool.

Submersible

Among the submersible pumps, the following samples can be distinguished:

Bestway 58230

The drainage pump is immersed in water for pumping, which allows you to collect silt and small debris from the lower (bottom) tiers of the bowl. Model performance - 3 m3 / hour, power - 85 watts. The cost of the pump is 4200 rubles.

Drainage pump with a capacity of 3.6 m3/hour. Permissible immersion depth - 122 cm. Model price - 2800 rubles.

JILEX 220/12

Powerful pump capable of pumping up to 13 m3/h. Suitable for large bowls.Can be submerged in water up to 8 m, equipped with a float switch. The price of the model is 5300 rubles. Read reviews here.

Surface

The best models of surface pumps are:

Productivity — 7 m3/hour (at a pressure of 8 m). It is intended for work with bowls no more than 28 m3. Price - 9000 rubles.

Kripsol Ninfa NK-33

Pump power - 330 watts. Productivity - 8.4 m3 / h (at a pressure of 6 m). Housing made of polypropylene reinforced with fiberglass. The cost of the pump is 16,000 rubles.

Hayward SP2503XE61EP33

Productivity — 4,8 m3/hour. Housing made of polypropylene reinforced with fiberglass. The impeller is Noryl, fixed on a stainless steel sleeve. Price - 24000 rubles.

Surface models of pumps are installed in separate chambers or boxes, not far from the bowl. As a rule, they are used to work with stationary bowls - composite or concrete pools indoors.

Types and the right choice

Such units are submersible and surface. Their main difference is their ability to work in dirty water. Surface ones are suitable for slightly contaminated liquids with solid particles up to 1 cm. Submersible ones do not deteriorate even from debris 3-5 cm in diameter and are suitable for very dirty water bodies, not only pools, but also ponds.

The choice of device is made depending on its power, the diameter of the intake hole, the volume and pollution of the reservoir, and the predicted frequency of use.

A unit with a multi-channel impeller allows only fine debris to pass through; for heavily polluted water, choose pumps with a single-channel impeller. The impeller can be open, this is installed in drainage pumps for pumping water from the pool.

The larger the solid particles in the water, the more important it is to choose an electrical appliance in a durable housing. Instead of plastic for dirty water, take the unit in a steel or even cast iron case.

surface models

Their main advantage is the ease of construction and ease of installation.

It is not a problem to remove such a unit immediately after use, this is especially important if the weather is bad or you are about to leave and are worried about its safety. They provide efficient pumping at depths up to 5 m.

Devices are switched off at an overheat automatically, have protection against electric shock. It is convenient to use a surface electric pump if there are several reservoirs on the site. To start, you just need to lower the suction hose into the water and plug the unit into the network.

Surface pumps can be produced in metal and plastic cases. The first are shock-resistant and have a longer service life. The latter are cheaper and quieter. Despite all the convenience of electric pumps, surface pumps are still too low-power for continuous use.

It is better to use them no more than once a week, which is enough to change the water in most pools. Due to the fact that the maximum particle size in the water that will not damage the pump is only 1 cm, the devices should be used in not too polluted water bodies, for example, pools under a canopy.

Submersible

Pumps of this type, pumping water from the pool, can be domestic and industrial. For a summer residence, a household model is enough. Its power is much higher than that of the surface, this option is suitable for frequent pumping or a large reservoir.

The device is imperceptible, its body is sealed and, as the name implies, is under water.The submersible unit has wide working windows through which debris up to 5 cm in diameter passes. But if the particles are larger, a filter will have to be installed at the inlet.

Pay attention to the installation depth. If it is less than a meter, the submersible electric pump may work poorly and even fail. For its high-quality work, the bottom of the pool should not be made evenly, but with a bowl, the device is placed in its deepest place. This will pump out all the water, and then the pump will turn off automatically.

For heavily polluted water bodies, drainage pumps can be used. They cope with all waste, suitable for wastewater. Before pumping, the liquid passes through a grinder, where large particles are crushed under pressure, then the liquid is drained.

What is the pump for in the pool?

A pump is a device for pumping liquid. The number of pumping devices in the pool depends on the complexity of the entire reservoir system and on the volume of water.

The number is also affected by the presence of special zones: spa, hydromassage, fountains, sports, amusement areas.

Several types of pumps are involved in maintaining and ensuring the normal operation of the pool:

- Pump for pumping water. It is required to fill an artificial reservoir, to empty the tank in case of repair, sanitary care, conservation for the winter.

- Circulation pump. Providing the movement of water to the cleaning and heating units and back.

- Heat pump. It is used in the case of an alternative system for obtaining thermal energy instead of the traditional heating option.

- Pump for creating countercurrent. It is used in the organization of hydromassages, water attractions, waterfalls and similar special effects.

All these pumps have their own specifics. The purpose of the further review is to show the diversity and principles for choosing pumping equipment for the water world of pools.

How to install a heat pump in a house

- It is possible to place modern heat pumps in the basements of residential buildings. This is especially true for geothermal equipment with the connection of an inclined bush circuit. In this case, the well for the collector can be located directly under the house, in the basement.

- Requirements for installing a heat pump in an apartment building. Be sure to install a backup heat source. In winter season, the defrost module will stop for 3-4 seconds. At this point, you will need to compensate for the lack of heat.

- The pump is installed in any room that is large enough to accommodate the storage tank and provide unhindered access to all components of the system for maintenance.

To start heating the house with a heat pump, you need to invest money. Subsequently, the costs will fully pay off. The time required to reach zero is 3-8 years.

Which heating is better for a home - gas or heat pump

Energy-saving technologies for the home are slowly but surely replacing traditional types of heating. The only thing holding back the widespread adoption of installations is the need for a significant initial investment of money.

Most manufacturers have been working on reducing the cost of technology for a long time, therefore, the prospects for using heat pumps in heating systems for private houses are quite optimistic.In the near future, we can expect an increase in the number of sales by 10-15%.

Heat pumps are not limited to domestic use only. It is possible to use heat pumps in heating multi-storey buildings, as well as industrial facilities. If we compare the effectiveness of the use of gas boilers and heat pumps, we can clearly see what prospects exist for each type of equipment.

Disadvantages of heat pumps

The main disadvantage, especially noticeable when operating in apartment buildings, is the dependence of heat pumps on temperature fluctuations. And if geothermal models are more or less resistant to changing weather conditions, then air stations sharply reduce productivity if the temperature drops to -15 ° C.

Installation of heat pumps with an earth circuit costs an additional 30-40% of the total cost. The work requires the involvement of specialized machinery and equipment. The price for modern models can reach 1200-1400 thousand rubles.

In comparison, the purchase and installation of a gas boiler will cost only 200 thousand rubles. The efficiency of gas equipment does not depend on external factors, and installation takes 1-2 days at the most.

Advantages of heat pumps

Economic efficiency is the main advantage of heat pumps. Financial costs during the heating season are less than natural gas, almost three times less. You don't need any permissions to connect. The exception is geothermal equipment, you will have to formalize the right to drill wells. The operation of heat pumps is absolutely safe and environmentally friendly.

The main heating of the house with the help of a heat pump has significant advantages over the operation of gas boilers, but due to the high cost of equipment using low-grade energy, they are inferior to them in popularity.

Calculation of power and temperature of a warm water floor

Self-priming pumps

The most common type of products are self-priming pool pumps.

They can be installed above or below the liquid level. They are great for those cases where it is not possible to install the device under the pool. It is advisable to install it as low as possible, since raising water requires serious energy costs.

When choosing such a unit, you need to consider many factors. If you neglect this step, there is a high probability that the device will not work properly. Important aspects:

- The throughput of the pool filters must correspond to the technical performance of the pump.

- The diameter of the pressure and suction pipe.

- Permissible amount of pumped fluid that meets the necessary sanitary standards.

- A sufficient indicator of the duration of the device.

- Noise level.

- The materials used in the manufacture of the product.

- The presence of a viewing window that allows you to monitor the level of filling of the filter.

It is recommended to pay attention to all the above factors for effective work

How a heat pump works

The simplest example that clearly explains the principle of operation of heat pumps is a household refrigerator. We all know that in his freezer, food is cooled due to the circulation of the refrigerant. Taking away the internal heat, the refrigerator throws it out.Therefore, the freezer compartment is cold, and the rear grill of the device is always hot.

The principle of operation of a heat pump is the opposite. Taking heat from the environment, it transfers it to the house. Figuratively speaking, the “freezer” of this device is located on the street, and the hot grill is in the house.

Depending on the type of external heat source and the environment that collects energy, heat pumps are divided into four types:

Installations of the first type extract heat from the ground using tubular collectors or probes. In the external circuit of such a pump, a non-freezing liquid circulates, transferring heat to the evaporation tank. Here, thermal energy is transferred to freon, which moves in a closed circuit between the compressor and the throttle valve. The heated refrigerant enters the condenser tank, where it gives off the heat it receives to the water sent to the heating system. The heat exchange cycle is repeated as long as the unit is connected to the mains.

Heat pump operation diagram

The principle of operation of a water heat pump is no different from a ground heat pump. The only difference is that it is powered by water, not soil.

An air source heat pump does not need a large external collector to collect heat. It simply pumps street air through itself, extracting precious calories from it. Secondary heat exchange in this case occurs through water (warm floors) or through air (air heating system).

Assessing the economic side of the issue, it should be noted that the "soil-water" installation requires the largest financial investments. To install its heat-receiving probes, it is necessary to drill deep wells or remove soil over a large area for laying the collector.

The ground source heat pump cannot operate without an external piping system or deep wells with heat sensing probes

In second place is the water heat pump, delivered to the customer on a turnkey basis. For its operation, digging of the earth and drilling of wells is not required. It is enough to immerse a sufficient number of flexible pipes in the reservoir, through which the coolant will circulate.

Air-to-air and air-to-water units are the cheapest, since they do not need to install external heat receivers.

A feature of the installation of most heat pump systems is their connection not to heating radiators, but to a warm floor. This is due to the fact that the maximum heating of water is carried out to a temperature of + 45 ° C, which is optimal for a warm floor, but insufficient for the normal operation of the radiator.

An advantageous feature for the owner of the operation of this unit is the possibility of a reverse mode - transfer during the hot period of the year to cooling the premises. In this case, excess heat is absorbed by the underfloor heating pipeline and removed by the pump to the ground, water or air.

A simplified block diagram of a ground heat pump plant looks like this:

In addition to the heat pump, ground circuit and underfloor heating, we see here two circulation pumps, shut-off valves for hot water and heating, as well as a tank that accumulates hot water for domestic use.