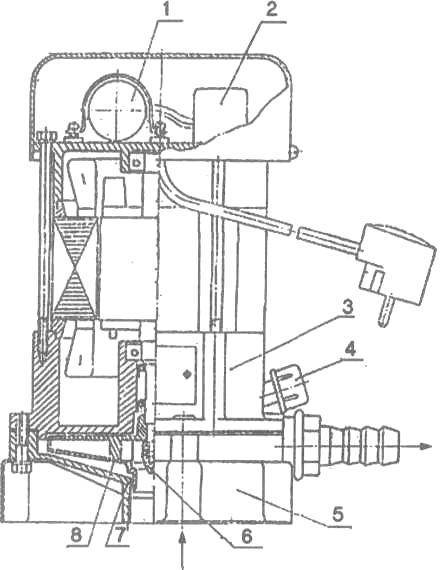

- Construction device

- Fundamentals of pump operation

- Rules for the use of pumps

- Pros and cons of Agidel models

- Agidel-M pump device

- External and internal sides

- Nuances of installation and features of operation

- Right choice

- Main characteristics

- Agidel. Replacing bearings and seals. Part 1.

- Natalia Sheid

- Svetozar Velesov

- Yura Dadashev

- Main characteristics

- How to troubleshoot pump operation

- How to repair the pump?

- Agidel pump repair, oil seal replacement

- Pump Agidel M

- Pump Agidel 10

- Features of Agidel pumps

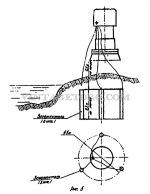

Construction device

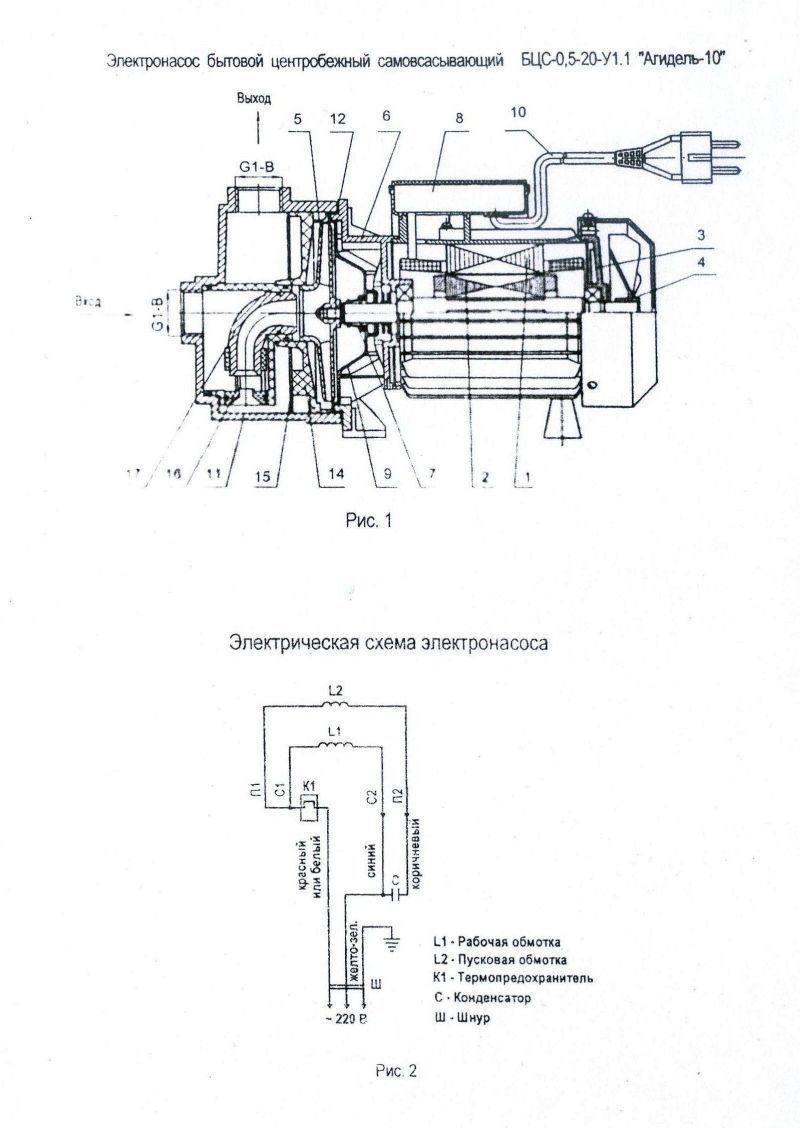

Pumps of modification M have two parts of a design: an electric motor with a centrifugal pump. Model 10 additionally has a jet pump. With the help of it, the liquid is self-absorbed, enters the chamber using a centrifugal device.

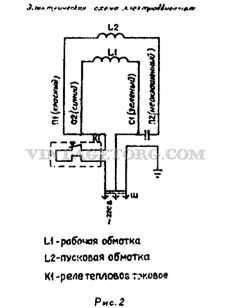

At the heart of the electric motor device is a stator, which has a built-in thermal fuse. It protects the winding of the device from overheating. The motor also consists of a rotor with a flange and a end shield. During operation, the parts are cooled by a vane fan equipped with a hood.

Fundamentals of pump operation

The principle of operation is based on centrifugal force, which affects the flow of fluid.The force comes from the rotation of the wheel mounted inside the rotor shaft. The flange has sealing cuffs so that water does not get into the engine.

Attention! The main reason for the breakdown of Agidel devices is water that has entered the engine, so the pumps should be well sealed from water. Inside the device, water enters through the valve for receiving, acting as a filter. It prevents the penetration of large elements, pieces of rock

This valve of brand M pumps serves as a shut-off valve when water is poured into the pump before starting.

It prevents the penetration of large elements, pieces of rock. This valve of brand M pumps serves as a shut-off valve when water is poured into the pump before starting.

Inside the device, water enters through the valve for receiving, acting as a filter. It prevents the penetration of large elements, pieces of rock. This valve of the M brand pumps serves as a shut-off valve when water is poured into the pump before starting.

The flange with body connector is equipped with seals made of rubber material. Pumping equipment of modification M is equipped with a screw to release excess air. To mount the pump in a vertical position, fasteners are inserted into the prepared holes. To install horizontally on the rack, special holes are made.

Rules for the use of pumps

Attention! You can install the pump in the basement, but the pressure level of the unit will decrease because the pump will be located far from the well

Pros and cons of Agidel models

Agidel electric pumps are considered reliable devices. They are used for watering the garden, for pumping liquid for domestic purposes.Pumps have many positive properties:

1.Affordable price.

2.easy operation.

3. You can replace individual parts.

4.Low energy consumption when working.

5.The units are reliable, durable.

Among the shortcomings, they note the inability to pump water from wells over 8 meters high. Units should be mounted near wells with water.

Important! There are many Chinese fakes of Agidel pumping devices on the market. They are made of plastic, have a low level of build quality.

Agidel-M pump device

The device is installed on a rigid base vertically. Water supply from a well and pumping over a distance of up to 35 meters is possible with a small motor with a power of 0.37 kW. If the well is up to 20 meters deep, an ejector is used, a remote working component. The pump motor remains on the surface.

Pump Agidel technical properties:

- lifting height - 7 m;

- productivity - 2, 9 cubic meters. m / hour;

- diameter - 23.8 cm;

- length - 25.4 cm;

- weight - 6 kg;

- price - 4600 rubles.

The specificity of the pump is the preparatory suction bay, including the working chamber. The device works exclusively at a positive temperature or in an insulated room. A lightweight Agidel water pump is used to lift water, placing it in a deep pit or arranging a raft that holds the pump on the mirror surface of the well from which water is drawn. Only the Agidel-10 pump can be sent to the voyage, which does not require refilling with water at start-up.

In accordance with the operating manual, the Agidel pump must pump the agent where the temperature is less than 40 0 C. Under these conditions, the motor operates without overheating. Before starting the device, water is poured; working “dry” will lead to an inevitable malfunction.The pump must be protected from the ingress of moisture and debris, from sub-zero temperatures.

First of all, use the grounding circuit of the pump, reliable insulation of all wire connections.

When compared with the Agidel M pump, a later modification, Agidel-10, has a horizontal layout and is several times more powerful. This unit does not need to be filled before starting, it provides independent suction. The pump weighs 9 kg, has a head of 30 m, provides pumping in a horizontal position for 50 meters. A productivity of 3.3 cubic meters per hour is sufficient for domestic needs.

External and internal sides

When buying a pump, be sure to pay attention to its technical characteristics. They are indicated in the passport and on the packaging. A high-quality pump Agidel 10 or m must be sold in a package that indicates the address of the manufacturer (Bashkiria,

Ufa), contact numbers that will help you contact the manufacturers in case of any problems, if, for example, you need to perform certain manipulations with the pump or when you need to repair the Agidel pump

A high-quality pump Agidel 10 or m is necessarily sold in a package that contains the address of the manufacturer (Bashkiria, Ufa), contact numbers that will help you contact the manufacturers in case of any problems, if, for example, you need to produce certain other manipulations with the pump or when repair of the Agidel pump is required.

As for the technical characteristics, they are basically universal for pumps of this class, whether it is an agidel m or some other form of pump. Its power is 370 W, the mains voltage is 220 V. The water intake level is 2.9 cubic meters per hour, the pressure is 22 liters.

Speaking about the external characteristics of the pump, it should be noted that it has retained its data since the time when the first such pump was created, which is about 40 years ago. Complete with it are immediately all the necessary components for water intake - nipples and valves.

The color of the Agidel 10 pump remains unchanged for the same huge amount of time, it is represented by a bright brown color, it also has brown, but slightly darker in tone, caps.

As for the type of this technical device, it is a surface vertical centrifugal pump. Its body is aluminum, all materials for parts (both internal and external) are produced exclusively in Russia. Its cap is made of polypropylene, and the inner winding is made of copper wire with a diameter of 5 mm.

Past tests show that this pumping device can operate without interruption for 5-6 hours without shutting down. In order to make it more convenient and safer to work, the pump is equipped with a special thermal fuse. This is necessary so that if a strong overheating suddenly occurs during operation, the pump will automatically turn off. Further, after the device cools down, its operation will continue. An additional advantage of choosing the Agidel pump is that its warranty period is quite significant, it is 30 months.

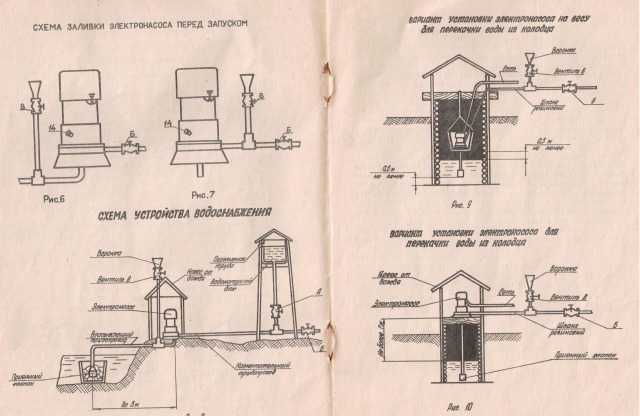

Nuances of installation and features of operation

Pumps "Agidel" should be installed on a flat hard surface. Usually they build a pedestal of reinforced concrete or a shield of thick boards. Model "Agidel-M" is installed vertically, and "Agidel-10" - horizontally.

If the pump is installed at some distance from the well, it should be taken into account that a 4-meter horizontal section of the suction pipeline in terms of hydraulic resistance is equivalent to a 1 m height difference.

L \u003d (7 - 5) x4 \u003d 8 m,

Where 7 is the maximum suction depth for Agidel pumps.

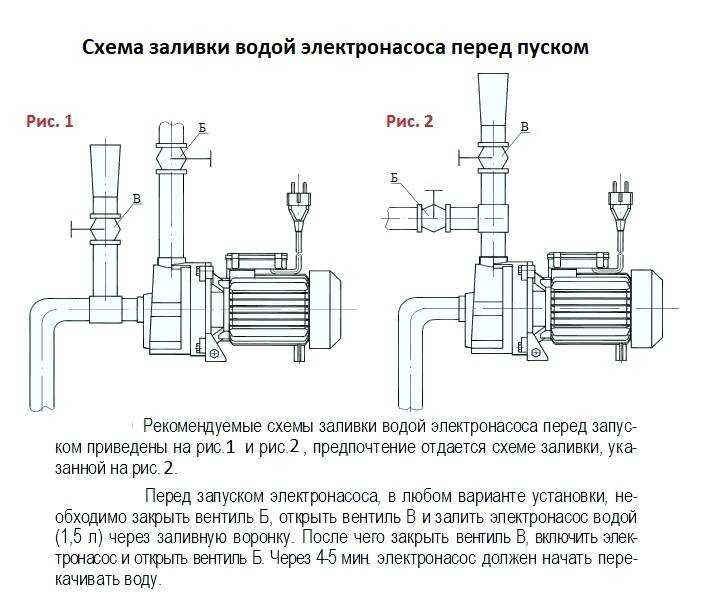

Before starting, the working chamber and the suction pipe of the pump must be filled with water.

Many sources published on the Web report that the Agidel-10 model does not need this, but the manufacturer's website does not say anything about this. The owners of these units, discussing this issue on the forums, consider it necessary to fill in both models.

In order to prevent water from leaking out of the suction line during short pump downtimes, a non-return valve should be installed at the end of the suction line. This item comes bundled with Agidel pumps but users report that they don't hold water well. The newly minted owners of Agidel are recommended to replace the standard valve with a more reliable one, equipped with a brass spool. Then you will have to fill the pump only once a season (with relatively short downtime).

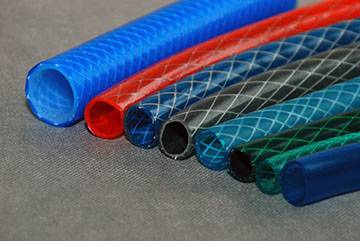

Must be used as a suction line reinforced hose - ordinary rubber or silicone will compress with atmospheric pressure.

The actual performance of Agidel pumps, like other centrifugal units, depends on the hydraulic resistance of the pressure pipeline and the height to which water is supplied (relative to the pump axis).

The actual performance of Agidel pumps, like other centrifugal units, depends on the hydraulic resistance of the pressure pipeline and the height to which water is supplied (relative to the pump axis).

It should be understood that the data indicated in the characteristics of maximum pressure and performance are mutually exclusive.

If the unit has to develop the maximum head, the performance will be much less than the specified one, and vice versa - the maximum performance will take place only at the minimum pressure.

To understand how much water the pump will pump at a specific pressure value, you need to analyze the so-called pressure characteristic, which has the form of a graph or table.

Right choice

If it is proposed to buy exactly the pump of this company, then when choosing it, you must be careful and first of all look at its external characteristics

Since cases of counterfeiting of this product have recently become more frequent (both from China and from neighboring countries), attention is drawn to the fact that the colors of the pump housing and cap always remain the same. They do not change on the impeller under the cap. Accordingly, if you suddenly saw a similar package and it seems to you that this is the same pump, but its color is somewhat different (not bright brown on the body and not dark on the cap), then you have a fake and it is best to refrain from purchasing it

An important note is that all connections in this device are made with slotted screws. Speaking about the production process, this is quite difficult to do, so in fakes you can see that the connections are made with ordinary hex bolts

Accordingly, if you suddenly saw a similar package and it seems to you that this is the same pump, but its color is somewhat different (not bright brown on the body and not dark on the cap), then you have a fake and it is best to refrain from purchasing it.An important note is that all connections in this device are made with slotted screws. Speaking about the production process, this is quite difficult to do, so in fakes you can see that the connections are made with ordinary hex bolts.

The final important difference from analogues and fakes is that the pump rotor shaft is made of stainless steel. This allows you to use the device for as long as possible, since no corrosion is terrible for him. All other analogues use ordinary 45 steel, which after a short period of time will begin to rust, respectively, all the bolts will also rust, and you will not be able to disassemble the device to carry out repairs, even if the correct connection scheme for the Agidel 10 device is used.

All these factors indicate that the cost of the pump is quite high.

If you see a pump on the store counter at a significantly lower price, then this is a low-quality product.

The water lifting depth of this pump is up to 8 m. When the pump is not in use, it is recommended to clean it in a dry, warm place. Of course, you can leave it in a cool room, but this will shorten its service life. If you follow all the manufacturer's recommendations for the next season (in spring), you will be able to use the Agidel 10 pump to the fullest again, as if you had just purchased it. If water suddenly gets into the engine, the engine may ignite, as a result, the connection will become impossible and the pump will have to be changed.

If you are an amateur gardener or a professional gardener, you need to select a pump with high quality and care.If you decide to save money and pay a price slightly lower than the one indicated earlier, you may be sold a fake. As a result, you will have to buy new equipment, such as bearings.

Main characteristics

Compact device operating on the centrifugal principle. It is placed on the surface in a vertical position. The model without an ejector is designed to lift water from wells up to seven meters deep. And if you use an ejector with this unit, the efficiency of the pump will double, and the owners will be able to receive water from a depth of up to 15 meters.

The movement of water is provided when the electric motor is turned on by rotating the shaft with blades located on the axial sleeve. The liquid inside the pumping chamber is displaced into the pipeline under the influence of centrifugal force. And in the center of the impeller there is a zone of low pressure, which ensures a continuous flow of water from the well through the intake hose.

- a pressure of 20 meters is created;

- productivity - 2.9 cubic meters per hour;

- power - 370 watts.

Advantages:

- low price;

- the possibility of application at a sufficient depth when using an ejector;

- ease of maintenance and operation;

- high reliability;

- low power consumption.

the unit is afraid of dry running (it is necessary to fill in water at the beginning of operation).

The average price is from 4,500 rubles.

This is a more powerful and overall model of a self-priming vortex type. It is placed on the surface in a horizontal position. The main advantage of the unit is the possibility of a “dry start”. That is, at the first start-up, the pump does not need to be filled with water.

Turning on the pump starts the rotation of the impeller (impeller), which creates a vacuum and causes air to be sucked in.The water in the housing is mixed with air. The movement of water and air creates a vacuum zone, which ensures the suction of liquid through the intake hose. The remaining air is removed through a special technical opening. Further, the unit functions as a standard centrifugal pump, the operation of which was described above.

- pressure up to 30 meters;

- productivity - 3.3 cubic meters per hour;

- power - 700 watts.

- budget cost;

- long service life;

- the unit is not afraid of dry running;

- ease of maintenance;

- reliability.

- can not be used at a depth of more than seven meters;

- relatively high power consumption.

The price is from 6,000 to 7,500 rubles.

If we compare the technical data, it becomes clear that the second pump has better performance and is able to create more pressure. The main advantage of the first type model is low power consumption (370 watts) and light weight. It is allowed to use an ejector with it, which is important for owners of wells and wells fifteen meters deep. If power is not the main choice for owners when buying a pump, you can safely purchase a more economical and compact model. In terms of build quality and service life, the units are no different.

When installing pumps of this brand, three main parameters should be followed:

- positive operating temperature;

- as close as possible to the source of water;

- flat mounting surface.

Obviously, the ideal solution would be to equip an insulated caisson chamber with a flat bottom. In such conditions, the equipment will be able to work even in the winter cold.A close location to a well or well is required due to the sensitivity of the equipment to depth - this is an indicator from 7 to 15 meters, depending on the model and the presence of an ejector.

It is allowed to install directly on the head of the well or the cover of the well (this is a good solution for summer use). The caisson is set up five or ten meters from the house below the freezing point of the soil.

A good solution would be to mount it on a special raft, which is then lowered into the well. But in this case, there will be a problem with connecting the electrical cable. It needs to be extended and waterproofed. The standard cable length is 1.5 meters.

Experts recommend using Agidel-10 for installation in a caisson or mounting on a raft for year-round use. And for seasonal use, Agidel-M should be used - a unit that requires adding water before starting and is extremely sensitive to low air temperatures. It can be installed on a flat surface near the well or attached to a special bracket at the head of the well.

For the winter, the pump is dismantled, dried and stored in a warm room for storage.

Agidel. Replacing bearings and seals. Part 1.

Views: 30 835

Natalia Sheid

Such a question, the lower bearing remained in the seat and not at anchor, how to remove it. After all, the bottom seals prevent it from being knocked out

Svetozar Velesov

Decided to buy Sturm WP 9751A! Almost a copy of my Soviet Agidel from 1980! I also proceeded from those considerations that spare parts with Agidel can be interchangeable! Bought! Set! Launched! . If I had hearing loss, I wouldn't have heard the engine running! There are some turns, but the impression is that it does not have 510 watts, but 5.1! Some half dead! There is no that Agidel power and there is nothing at the output! Doesn't swing! I closed the place where the gasket should be observed (but not observed) with sealant, no result! What could be the reason? Kindly clarify the situation if you know!

I started to change the bearings, disassembled it, and blew the water inside the engine, dried it out, everything changed, it works, why the water got in, the seals were still alive, the spring did not burst, can you tell

Good day. both seals spring down?

Yura Dadashev

Hello Igor. I have a big request to you, tell me how to change the rotation of the pump in the opposite direction. Think it's possible? Thank you.

if on the contrary it turns .. how will the polarity change.

Main characteristics

The movement of water is provided when the electric motor is turned on by rotating the shaft with blades located on the axial sleeve. The liquid inside the pumping chamber is displaced into the pipeline under the influence of centrifugal force. And in the center of the impeller there is a zone of low pressure, which ensures a continuous flow of water from the well through the intake hose.

- a pressure of 20 meters is created;

- productivity - 2.9 cubic meters per hour;

- power - 370 watts.

- low price;

- the possibility of application at a sufficient depth when using an ejector;

- ease of maintenance and operation;

- high reliability;

- low power consumption.

the unit is afraid of dry running (it is necessary to fill in water at the beginning of operation).

The average price is from 4,500 rubles.

This is a more powerful and overall model of a self-priming vortex type. It is placed on the surface in a horizontal position. The main advantage of the unit is the possibility of a “dry start”. That is, at the first start-up, the pump does not need to be filled with water.

- pressure up to 30 meters;

- productivity - 3.3 cubic meters per hour;

- power - 700 watts.

- budget cost;

- long service life;

- the unit is not afraid of dry running;

- ease of maintenance;

- reliability.

- can not be used at a depth of more than seven meters;

- relatively high power consumption.

The price is from 6,000 to 7,500 rubles.

When installing pumps of this brand, three main parameters should be followed:

- positive operating temperature;

- as close as possible to the source of water;

- flat mounting surface.

It is allowed to install directly on the head of the well or the cover of the well (this is a good solution for summer use). The caisson is set up five or ten meters from the house below the freezing point of the soil.

A good solution would be to mount it on a special raft, which is then lowered into the well. But in this case, there will be a problem with connecting the electrical cable. It needs to be extended and waterproofed. The standard cable length is 1.5 meters.

Experts recommend using Agidel-10 for installation in a caisson or mounting on a raft for year-round use. And for seasonal use, Agidel-M should be used - a unit that requires adding water before starting and is extremely sensitive to low air temperatures.It can be installed on a flat surface near the well or attached to a special bracket at the head of the well.

For the winter, the pump is dismantled, dried and stored in a warm room for storage.

How to troubleshoot pump operation

The kit comes with instructions. The Agidel pump will work properly if you follow the rules prescribed by the manufacturer. If you notice that the water supply is very weak, then the reason for this may be the use of the wrong hose for the water intake. If water is sucked from the well with the help of a rubber device, rarefied air can form, which leads to compression of the walls. This may interfere with normal fluid flow. Experts recommend using a hose reinforced with a plastic spiral.

So, you have purchased the Agidel device. The pump, for which you can purchase spare parts from the supplier, will serve you for a long time. To exclude the possibility of its imminent breakdown, it is necessary to take care of the correct functioning of the equipment. The current repair of the device is associated with the replacement of seals, since if they fail, then you may encounter a problem of leaks in the drainage hole.

To replace it, you will need to unscrew the 3 bolts that are located on the case. The master must remove the casing and unscrew the 4 bolts that are located in the engine. Next, you can remove the motor housing, disconnect the snail and unscrew the bolts. The master will need to remove the gasket and unscrew the nut holding the impeller. Then the anchor is removed, which can be helped with a blow of a hammer. After he left the housing, seals must be found in the impeller.They are removed in such a way as not to damage the insert between them. At the final stage, you need to install new oil seals, which are separated by an insert. You must assemble the pump yourself in reverse order.

How to repair the pump?

If you need to change the seal, you will have to actually completely disassemble the device, because it is used on the motor shaft. To do this, you need to take several steps:

- we find three fixing bolts located on the top of the case;

- they need to be unscrewed, after which the casing should be removed;

- then you have to unscrew a few more mounting bolts (usually four of them), these elements hold the engine;

- then carefully remove the motor housing, gaining access to the snail;

- the latter is also removed;

- the gasket under the impeller must be removed;

- unscrew the nut that secures the impeller;

- the anchor axis is removed from the latter;

- then you need to remove the anchor, bearing, after which - the first seal, separator and second seal;

- prepare new seals and install;

- installation of other elements is carried out in the reverse order.

When repairing the pumping device, care must be taken. You also need to prepare a place in advance for the consistent placement of all the extracted parts. Mounting bolts should be placed in separate containers.

Attention! Without experience and knowledge, the pump can be damaged. In this case, serious repairs will be required, and these are completely different costs.

When preparing to repair the pump, you should immediately purchase two seals of the desired type. Replacement must be done in pairs. After all, even if only one is worn out, the second is likely to fail very quickly. As a result, you will have to disassemble and assemble the pump twice.

Remember that the seal must be pressed into place. You need to act carefully. Careless handling of the seal can lead to its deformation. The origin of the part also matters. Poor quality seals are quite common. Therefore, when buying, you need to specify the manufacturer of the products. Do not despair if you cannot install the gland yourself. In this case, you need to contact the masters. Their skills will help to complete the procedure efficiently and quickly. At the same time, workshops often give guarantees, which means that if the problem recurs, it can be solved for free.

An easy way to check the result is to inspect the pump for leaks. If it is missing, the problem is solved.

Agidel pump repair, oil seal replacement

Here - I recently wrote about a small problem with my Agidel-M pump. The oil seal, or cuff, sealing the engine shaft at the point of attachment of the water pump is worn out. I successfully found oil seals at the Chekhov market in Kazan, I bought 6 pieces at once. There are two of them in the pump, it’s easier to change in pairs, and it’s probably right in a pair, although it happens that only one is changed. I remembered about the camera only after I dismantled the pump and dug out both glands, but nevertheless, everything should be clear from the following photographs.

Here is the Agidel pump with the pump removed, the motor turned down.

To replace the stuffing box on top of the pump, you don’t need to unscrew anything, you need to remove the bottom platform by unscrewing 4 bolts by 13 (more convenient with a socket head on a ratchet). The nut is located in a deep narrow well. so you will definitely need a socket wrench (head), and a narrow one.Below, for comparison, is a regular head for a regular crank. This will not pass into a narrow well. In my hand I have a suitable head, found in the bins. It is under a thin collar, 6-7 millimeters.

Well, we unscrewed the impeller, after that it remains only to unscrew the 4 screws with which the pump is attached to the pump housing, and pull off this same pump.

Next, you need to decide whether we change both oil seals or only one, if both, then we simply knock them out of their seat. You can do this again with a head of a suitable diameter, or you can make a drift out of wood. I found a head

In the photo, new oil seals are already pressed in, so they are so clean and black. The old ones look like this:

If we change only one gland, then the upper (outer) one will have to be picked out from the underside of the pump. Between the oil seals is a plastic bushing of complex shape, do not damage it.

New seals must be pressed into place one at a time. You will need a vice. We take the first gland, find a suitable object, round, with a diameter equal to the gland.

and press it gently into place. Then we insert a plastic sleeve and press in the second oil seal. Well, that's all, puts the pump on the motor, fasten it, fix the impeller and assemble everything together with the lower casing.

Next, we turn on the pump, make sure that the flow from the drainage hole has stopped, the pump has stopped catching air and is working as it should. Bingo.

PS No wonder I bought these oil seals in reserve. One still messed up while trying to push it without a vice. With the right tool, work here for half an hour

Add this page to social media networks:

Current article rating: 17

You can put your rating by clicking on the corresponding arrow:

Go to section:

knocked out the seals and did not remember which side to insert them. tell me. thanks. my number is 89323441832

It's all there in the photo if you look closely. Especially the last two photos.

A HUGE REQUEST to the manufacturer TO COMPLETE your product (electric pump) with the tools NECESSARY when REPLACING OLD oil seals with NEW ones - if they (the tools) are AVAILABLE, THE WHOLE procedure for REPLACING OLD oil seals with NEW ones by the user's own forces SHALL BE IN 30 minutes. HOWEVER, in practice, in real life - DUE TO THE LACK of NECESSARY tools from the user - LEAVES for this event (REPLACEMENT OF OLD oil seals with NEW ones) 1-3 days (and MORE.) - the user is JUST LOOKING FOR (cursing and cursing) the MISSING tool. IS IT SO DIFFICULT TO COMPLETE the electric pump with cheap tools. HOW MUCH nerves and time will be saved for consumers.

Eugene, I fully support you. But, unfortunately, the manufacturer will never read this, and if he does, he will not even wince.

Leave your comment:

Pump Agidel M

The Agidel M device is inferior in power, but has its own characteristics:

The inlet valve of the Agidel m pump should be placed at a distance of no more than 0.35 m from the bottom of the source so that dirt and sand are not sucked in.

It is recommended to install the water pump on a hard, level ground. It is also recommended to build protection for the pump from exposure to rain and sunlight.

Also, the Agidel M system should first be filled with water. This can be done using the manual column.

Pump Agidel 10

The features of this device are as follows:

The scope of Agidel water pumps is not very wide, but sufficient to meet the basic needs:

When using an Agidel pump machine of any model, it should be remembered that the shorter the distance from the pump to the water source, the more efficient the unit will work.

General design:

Features of Agidel pumps

The Agidel water pump does not require complete immersion, it is enough to lower the suction hoses into the water. The device is safe to use because the wires are not in the water.

In the upper part of the pump on the cover there are ventilation holes through which air is exchanged. Under the cover there is a fan impeller designed to cool the electric motor.

The devices are not intended for operation in winter. But if there is no other option for supplying water, it should, if possible, be transferred to a room with a temperature above 0 ° C. You can also dig a hole, concrete it, insulate it and put a pump there.

The body and impeller are made of a special aluminum alloy, which is recommended for food contact. Despite the fact that Agidel pumps are adapted for operation in open water, it is recommended to additionally install a bottom filter. So the device will last longer.

Operating rules

Agidel water pumps should only be used at positive ambient temperatures.

The device must be grounded.

Avoid idling. Water must first be filled.

Do not touch the casing of a running pump.

Make sure that no water gets into the motor.

Do not allow the device to work with chemicals.

Troubleshooting

If the Agidel water pump is under warranty, then if a malfunction is detected, contact the supplier or the place where the device was purchased.If the warranty is over, some malfunctions can be fixed by yourself.

Leakage of water in the drain hole

With this malfunction, the seals should be replaced. To do this, you will need to perform the following steps:

Remove the casing - unscrew the 3 bolts in the upper part of the casing.

Remove the electric motor housing - unscrew 4 bolts.

Disconnect the snail, which is attached, also on 4 bolts.

Remove rubber seal.

Unscrew the impeller fastening nut.

Get the anchor axle.

Find the oil seals in the impeller, carefully remove them and replace them.

Assemble in reverse order.

Weak pressure

If the water supply is weak or intermittent, this may be due to an unsuitable water intake hose. Discharged air can form inside the rubber hoses, which compresses the walls of the hose, which prevents the flow of water. It is recommended to use a reinforced sleeve with a plastic spiral.

Attention! Beware of fakes

Due to the fact that instead of new Agidel pumps, old models or fakes are often sold, the manufacturer points out a number of features in the appearance of the device that you should pay attention to so as not to be deceived when buying:

Package. The original pump is supplied in a hard cardboard box bearing the manufacturer's information.

The color of the original device is dark orange, and the cap is brown.

Pump wire with capacitor box only.

The serial number stamped on the cover must match the number on the warranty card.

The connection bolts are hexagonal at the bottom and slotted screws at the top.

The body must be made of metal, not plastic.

Video about Agidel pump

The pump manufacturer Agidel designates the service life of its devices as 5 years and gives a 30-month warranty. In practice, if the Agidel pump has been operated properly according to the instructions, then only occasionally lubricate the parts and periodically clean the device.