- Operating tips

- Screwdriver nozzles: general information, main types of tips

- How to use a screwdriver with a tape nozzle

- The main types of nozzles for a screwdriver

- Characteristics of riveting nozzles for a screwdriver

- The main types of angle adapters for a screwdriver

- How to choose?

- Peculiarities

- For grinding and polishing

- Varieties

- What are the nozzles for a screwdriver called and what features do they have

Operating tips

- Before you start using a screwdriver, you should choose the right nozzle. It must correspond to the type of work and fit in diameter to the head of the fasteners.

- To insert a bit into a tool equipped with a keyless chuck, it must be pushed between the "cams" by gently turning the sleeve in a clockwise direction. If the design of the screwdriver has a key cartridge, then the bit is installed in a special socket and turned with a key until it is fully fixed in a clockwise direction. After the selected bit is set, the device can be connected to the network and begin direct work.

- To reduce or, conversely, increase the speed of rotation of the nozzle, you need to weaken or increase the impact on the start button.

- When the fastener is tightened, the limit sensor will automatically work and the device will stop working.

- When unscrewing the screw, the bit must be placed in the slot, while you must first set the rotation of the bit to work in the opposite direction.

- If during operation it is necessary to remove or change the nozzle, you must first turn on the reverse mode. When the bit has scrolled in the opposite direction, the ring holding it is compressed by hand, and the nozzle is easily removed and changed to another.

Screwdriver nozzles: general information, main types of tips

Like removable attachments for a drill, screwdriver bits belong to the category of devices that are aimed at expanding functionality. Thanks to them, this tool can be turned into a universal screwdriver or a compact machine for cutting metal sheets. The range of tips offered by manufacturers is very wide. With their help, you can perform construction work of any complexity at home, which made the screwdriver so popular.

To choose the right bits, you need to know the classification of products in this group

Some buyers do not see the difference between a drill and a screwdriver, but there is one. Moreover, these differences must be taken into account when choosing removable nozzles for certain jobs. Firstly, the rotational speed of a screwdriver is much less than that of a drill. Secondly, it has no moment of inertia. In other words, if you press the off button, the screwdriver will stop instantly, unlike a drill, which will rotate for some time.

All screwdrivers have a release clutch. She is designed to adjust twisting force. Some models do not have a cartridge.Instead, a hexagonal socket is installed in which the bits are fixed.

There are several types of tools, each of which can bring certain benefits:

- Small screwdrivers - used as a miniature electric screwdriver for repairing watches, phones and small appliances.

- Folding screwdrivers - such models are designed to work in a limited space where a conventional tool cannot reach. If the handle creates interference during operation, it can simply be removed.

- Drills-screwdrivers are designs that are hybrids. They combine the best properties of each tool.

Working nozzles for a screwdriver can be purchased in sets or individually

How to use a screwdriver with a tape nozzle

The tape nozzle cannot be called universal, since it is used exclusively for tightening self-tapping screws during the installation of drywall sheets. Many manufacturers have taken care of the convenience of users by equipping some models of screwdrivers with the ability to work without a tape. Such a tool allows you to tighten single self-tapping screws. To do this, you need to remove the tape, and then install an adapter and a bit of the appropriate size in its place. The process of installing a tape nozzle is somewhat more complicated.

How to change the nozzle on a belt type screwdriver? To do this, you must perform the following steps:

- An extended bit is included with the tool. It should be inserted into the removable nozzle before it is installed on the screwdriver.

- The nozzle is fixed in the screwdriver chuck.

- Next, you need to install on the tool "shop". This must be done so that not a self-tapping screw is located near the muzzle, but a protrusion of the tape.The supply of fasteners is carried out in automatic mode, which is activated after pressing the start button.

This completes the preparation of the tool for work. During operation, the screwdriver is pressed against the drywall. This is done so that the sheet is tacked and securely connected to the profile. Before starting work, it is desirable to apply markings on drywall. at appropriate places on the material with pencil or marker dots need to be made.

Move the screwdriver with a tape nozzle in the right direction, pressing it against the surface of the drywall

Installation work using a belt screwdriver is characterized by high speed and efficiency. All screws are recessed to the same depth, so the result is neat and of high quality.

It is desirable that the screwdriver has a function for fixing the start button. In this case, the tool will run continuously. The master will only need to move the screwdriver in accordance with the markup in the right direction, pressing it against the drywall surface. When the fastener is screwed, the knot snaps off, the tape with other self-tapping screws moves.

The list of nozzles that increase the functionality of a screwdriver does not end there. This article covers only the main ones.

To purchase a high-quality tip for a power tool, you need to pay attention to such nuances as the material of manufacture (molybdenum, tungsten, vanadium, chromium), the presence of a protective coating on the bit (titanium, nickel or diamond coating) and the reliability of the manufacturer.According to consumer reviews, the following companies are recognized as the best brands: Torx, Slot and Pozidriv

The nozzle is fixed in the screwdriver chuck

Being in a specialized store, you must definitely make sure that the seller has certificates confirming the quality of the products, because the service life of the nozzles depends on this. In addition, the buyer must be provided with a guarantee.

The main types of nozzles for a screwdriver

On sale you can find a lot of devices that expand the functionality of the power tool. The user can get, thanks to the nozzles for a screwdriver, pump, mixer, saw, polishing brush and other types of specialized equipment.

All removable devices are divided into three main groups:

- Combined nozzles.

- Tips for special purposes.

- Basic fittings.

The working element of the tips belonging to the main group has the form of a cruciform or hexagonal head. Such nozzles for a screwdriver are suitable for any type of self-tapping screws. They provide excellent adhesion to the fastener. In some nozzles, the heads are magnetized, which greatly facilitates the process of twisting. By technical characteristics and capabilities such tips are similar to screwdrivers.

Existing types of screwdriver bits differ in the shape of their working part

Combined type devices belong to the category of universal nozzles. Unlike the main tips, they have a working body on both sides. Each end of the combination bit has its own size and its own fastening system. For convenience in the course of work the unnecessary part of a tip is simply dismantled.

Bits for special purposes are mainly presented in the form of nozzles for a screwdriver for twisting wires. With their help, you can also control the depth of screwing in and out of fasteners located at an acute angle.

Characteristics of riveting nozzles for a screwdriver

Traditional rivets with a one-piece design are used extremely rarely. Many professionals prefer to use a welding machine. However, not every master has such equipment in his arsenal, and also has the skills necessary to work with it. In this case, the best option would be a rivet nozzle, which is installed on a screwdriver.

Rivet screwdriver bits can only be used on models with reverse drive

Such devices can be used on electric and battery tools for installing nut-type rivets and other fasteners having a core.

It should be noted that rivet screwdriver bits can only be used on those tool models that have a reversible drive. These devices are designed for mounting aluminum or steel fasteners, the diameter of which is in the range of 2.4-5 mm. They can also be used to install sleeves made from non-ferrous metals, whose diameter is not exceeds 25 mm.

If a battery-powered screwdriver will be used to install rivets, make sure that the battery voltage does not exceed 12 V. The installation process itself is not particularly difficult, and the nozzles are compact enough to be stored with a screwdriver in one case.

The main types of angle adapters for a screwdriver

Adapters with an angled design allow you to unscrew and tighten fasteners in hard-to-reach places. Such nozzles greatly simplify the work, because the tool can be held perpendicular to the surface, and the screws can be twisted at an angle, both on the left and on the right.

Corner adapters make it easier to work in hard-to-reach places

Taking into account the technical characteristics, as well as the functional purpose, there are two types of angle nozzles for a screwdriver:

- flexible;

- tough.

Nozzles with a flexible design use a flexible link to change the direction of the twisting axis. Externally, the device looks like a drill used in dental clinics for dental treatment. The removable tip consists of a flexible shaft that connects the working bit to the screwdriver's chuck. This type of nozzle facilitates and speeds up work in hard-to-reach places where you need to unscrew the screws.

Rigid adapters are a short attachment that changes the direction of the axis of rotation mechanically. Unlike the previous version, the cartridge of this device is much stronger. Rigid adapters allow installation and removal of fasteners from any side. These bits are commonly used in professional screwdrivers, where the motor is designed for high loads and strong vibrations.

There are two types of angled screwdriver bits: flexible and rigid.

How to choose?

Since the construction market today is represented by a huge selection of screwdriver bits, it is difficult for novice craftsmen to make the right choice in favor of a particular product.

Therefore, when going shopping, it is important to consider the following points

Material

Particular attention should be paid to the material from which the bat is made. Experts recommend collecting nozzles made of tungsten, vanadium, molybdenum and chromium

Steel bits have many disadvantages, they wear out quickly and do not provide quality work.

- Place of purchase. It is advisable to purchase such tools in specialized stores, and not in the market. Their quality and duration of operation will depend on this. In addition, sellers must provide product certificates and give a warranty period. If the nozzles are needed only once, then you can buy cheaper options.

- Protective covering. It is best to give preference to bits that have a titanium coating. They are the most resistant, durable and are not inferior in performance to nickel and diamond coated tips. Also good bits, in which the protective layer is made of tungsten. They are not afraid of corrosion and work much longer than those that are released without coating.

- Trademark. Recently, nozzles from various manufacturers can be found on sale. They differ not only in price, but also in technical characteristics. Slot, Torx and Pozidriv branded bits received good reviews. They are of high quality, durable and reliable in operation. As for the price issue, these manufacturers produce nozzles of various prices.

About, how to use screwdriver bits, see the next video.

Peculiarities

A screwdriver attachment is a device that turns an electrical device into a metal cutting machine and a universal screwdriver.The use of accessories for a screwdriver has made it a popular household tool that allows you to carry out construction work of any complexity at home.

Nozzles are easy to put on and remove from the device, and also have a number of advantages:

- simple operation;

- processing of material with an even cut and without burrs;

- multifunctionality;

- high performance;

- ease of maintenance.

As for the disadvantages, there are none, except that some types are expensive.

In addition, a screwdriver with nozzles is in many ways inferior in efficiency and productivity to professional devices, since it is a simplified household version of the tool. At the same time, in terms of drilling speed, many nozzles can compete with devices for cutting and polishing metal. They are also indispensable when mounting the roof and when screwing various fasteners.

Screwdriver bits can be sold as a set with the device, or separately.

Do not use damaged or previously used self-tapping screws for fasteners. When twisting them, the edges of the bit can be damaged, and it will quickly fail.

For grinding and polishing

If you install a nozzle on a drill for grinding and polishing, you can carry out the following work:

- Polish metal, wood and glass surfaces.

- Grind metal, as well as parts from it.

- Remove corrosion, nicks, scale on old coatings.

- Sand glass edges.

The advantage of grinding attachments for a drill is that for such work there is no need to buy equipment that has a rather high price.And if you use nozzles, you can perfectly cope with these tasks, the surface will remain perfectly smooth and even. And another positive thing is that they can be used to process hard-to-reach places that cannot be reached with other tools.

If you bought a drill attachment to process wood or other material, you should first carefully read the information, since different types of equipment will require different power and number of revolutions on the tool.

Grinding and polishing attachments are a regular rod on which grinding material, such as felt, foam rubber and sandpaper, will be attached.

Varieties

There are the following types of equipment:

- disk;

- plate;

- fan;

- end;

- drum;

- cup.

These devices will be divided not only by the type of construction, but also by the degree of rigidity: they can be hard, super soft, soft or embossed.

Cup

The cup attachment can be used for sanding wood or other surfaces. Such a device consists of a rod, on which a cartridge and a body resembling a cup are fixed. Inside the cup there is a large amount of bristles of different stiffness. Usually such a nozzle is used in order to remove corrosion from the old coating. There are also models that have very soft polishing materials: foam rubber, felt. The body is made of durable plastic or metal. If you bought a soft nozzle for a drill, then it can be used to polish the car cover.

Disc and platter

Disc equipment consists of a rod, grinding material and a body. The difference from the previous model lies in the direction of the bristles. In this option, it will be directed from the center to the edges of the disk. You need to use such a nozzle very carefully, since you can easily spoil any coating. The bristles are either steel wire or brass.

The plate equipment is made according to the same principle as for grinding devices. But instead of a thread, it is equipped with a fixed or movable rod, which is fixed in a cartridge. Sandpaper must be fastened with special Velcro.

It is recommended to buy a cymbal nozzle, which has a movable shaft, with a rubber or soft thick layer between the Velcro and the base. Then it will be possible to adjust the required angle of inclination of the drill and smoothly repeat the contour of the material being processed.

If work is being done using a rigid plate, it will be very difficult to control. And if you can make a slight slope, it will noticeably deepen into the surface of the product. As a result, the metal can simply be damaged. That is why it is better to use a firmly fixed tool.

Fan, drum and end

The fan nozzle looks like a small disk in the center, and petals of sandpaper or other similar material are attached to its edges. With the help of such a nozzle, you can process hard-to-reach places, cavities inside or grind a hole, since the equipment will take absolutely any shape. The device is mounted in the drill chuck in the same way as in the previous types.

The drum equipment is made in the form of a rod with a cylinder, which is covered with sandpaper on top.It differs from the plate nozzle in that the surface to be processed is parallel to the cartridge, and not perpendicular. Processing can be subjected to glass, metal or wood. Usually used to sharpen the end of glass. There are hard and soft depending on the purpose of the purchase.

End equipment looks like a rod, at the end of which the necessary processing material is fixed. This equipment works on the principle of a file. It is very easy to enlarge holes with it, as well as remove nicks and make smooth edges.

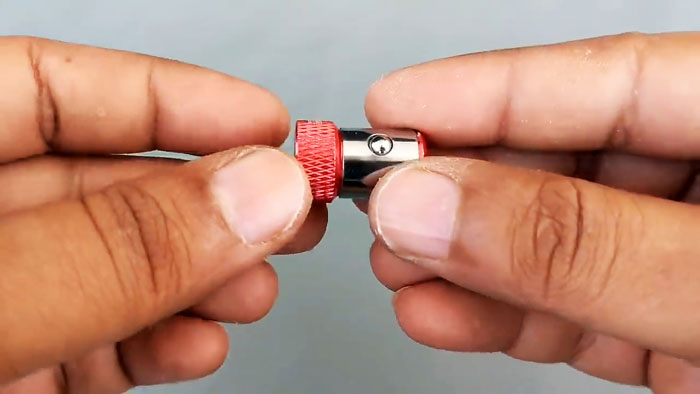

What are the nozzles for a screwdriver called and what features do they have

Removable nozzles that are installed on a screwdriver are called bits. These devices are inserted into the cartridge. Bits are cross-shaped, square, slotted, hex, star-shaped, etc. The buyer can purchase a nozzle for any type of screw.

In order for the fastener to hold tightly on the bit, you need to choose the right size and shape. The nozzle must exactly match the notches on the screw. Otherwise, you can not only ruin the bits and break the tool, but also get injured. Using a special holder completely solves this problem. With it, you can install any type of bit on a screwdriver, regardless of its length and size.

There are several types of holders:

- On a magnetic base - equipped with a built-in magnet. It attracts the bit along with the screw, so there is no chance that the nozzle and fasteners will be poorly fixed.

- For long self-tapping screws - it looks like a tube that fixes the self-tapping screw in the process of twisting, preventing it from loosening.

- For hex bits.

The classification of products by size and type will help you navigate in an extensive assortment.

These are not all existing types of holders, the list only lists the main ones and the most popular ones.