- The device and principle of operation of water convectors

- Installation

- Water heating convectors built into the floor

- Floor types

- Water floors

- Electric floors

- Areas of use

- Advantages of water heating convectors

- What are electric convectors and how to choose them correctly

- Grates for convector

- Convector connection

- Selection, installation, connection of floor convectors

- decorative frame

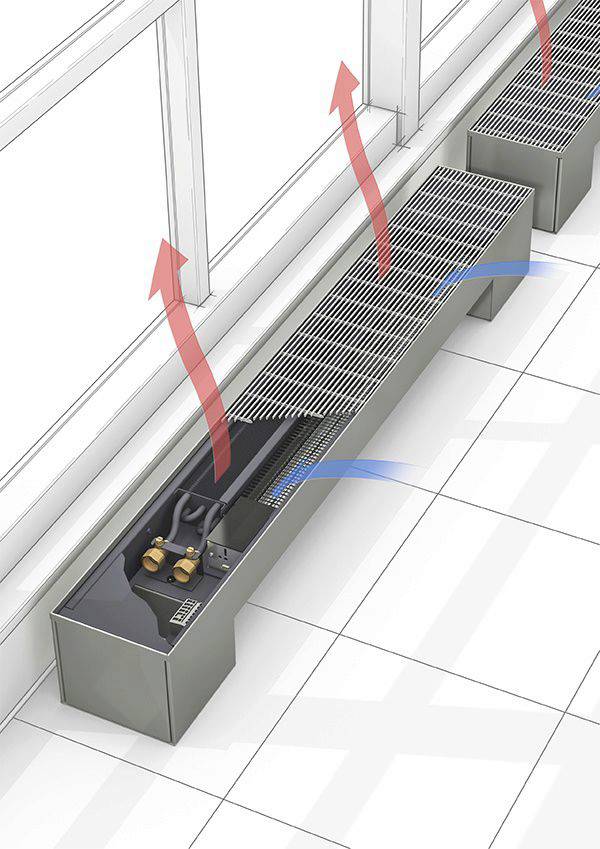

The device and principle of operation of water convectors

Delivery of thermal energy to heating devices is carried out by means of a coolant heated to a certain temperature. When using conventional heating batteries, most of the generated heat is given off to the walls and objects in the room. To improve efficiency, batteries are manufactured with ribs that provide convective air movement. The presence of fins significantly accelerates the heating of the premises.

The main advantage of convection is precisely the speed of heating the premises. The heated air gradually rises, thereby pushing cold air masses towards the convectors, where they are heated. It is due to this simple principle that rapid warm-up is achieved - the room becomes much warmer within 20-30 minutes after starting the heating.

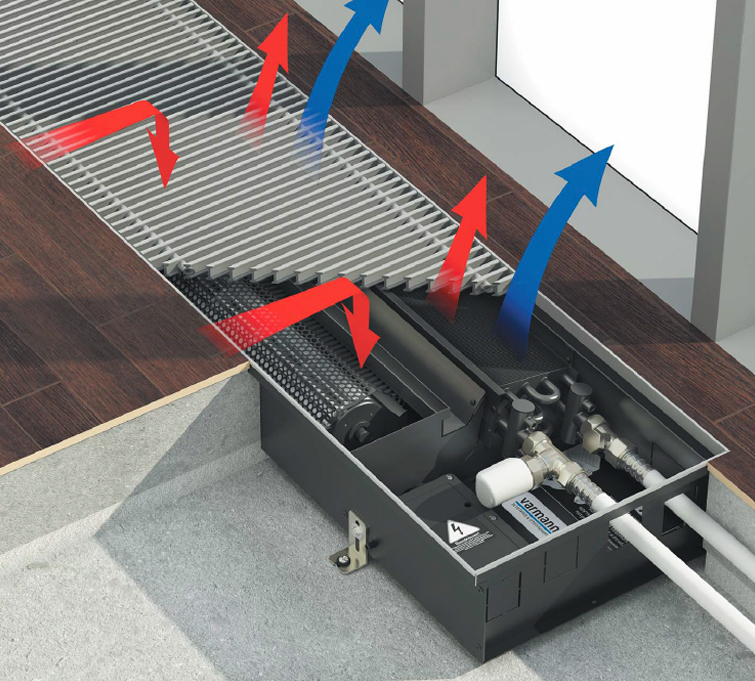

A convector-type water radiator operates according to a simple principle. First, a coolant passes through the internal cavities of the device, giving off heat to the metal fins. The air passing through the fins shifts upward, giving way to new, still cold air masses. To increase the heating efficiency and warm-up speed, some convectors are equipped with fans that provide forced air circulation.

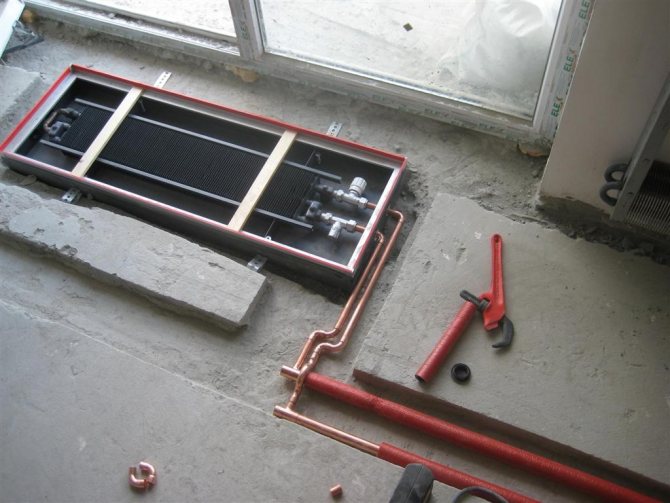

Installation

First stage of installation floor convectors are always prepare a special niche for installing the device. In the case of floor-mounted convectors, this can be either an ordinary concrete screed or installation in a raised floor. Both installation options for such convectors are possible only if the repair in the room has not yet been completed, and the floors have not yet been installed.

When choosing a niche for heating units, you should pay attention to the following indicators

- Hole depth. The depth of the niche should be approximately 10-15 mm greater than the height of the device itself. This figure is most often indicated by manufacturers in the user manual of individual models. Safety millimeters will allow you to correctly align the box of the device, as well as the grate with the floor level.

- Niche width and length. Here, experts advise adding to the dimensions of the device from 5 to 10 mm - so you can competently strengthen the body of the device and will not experience difficulties when laying communications.

- Distance from windows and walls. Experts recommend leaving 5 to 15 cm between the installed unit and the window (or panoramic windows). If we are talking about the distance from the device to the walls, then here it should be kept from 15 to 30 cm in order to avoid the formation of mold in the corners and the accumulation of heat only on the walls.

- Curtains.Curtains or tulle are an indispensable element in most style decisions. Keep in mind that they should not interfere with air circulation, therefore, they should not close the heaters from the room. The ideal option for built-in convectors would be small and light curtains in country or Provence style, blinds or twisted fabric models.

- insulation and heat loss. Illiterate placement of the heating device leads to a decrease in the heating efficiency and the efficiency of the device itself. When installing, be sure to use insulating material, otherwise all the heat generated by the unit will not heat the room, but the next 1-2 square meters of the floor

- Sustainability. The device is mounted to a state of complete stability and stability. To adjust a comfortable height, special supports or brackets can be used. As additional stabilization of the device in the niche, various fixing working solutions can be used. Such stabilization of the position of the unit is necessary for the future installation of pipe communications, which, with the slightest displacement of the wiring, can lead to flooding of the room and damage to the flooring.

When installing a water-powered convector built into the floor, there are only 2 ways to connect communications.

Flexible. Such a connection involves the use of flexible communications or hoses that supply the coolant to the heat exchanger. A definite plus of such a connection is that the communications are easily removed during the cleaning of the unit, and then freely fixed back. The disadvantage of such a connection is the relative fragility and vulnerability of flexible communications.

In the case of connecting an electric convector built into the floor, it is enough for you to correctly lay the wires and connect the device to a 220 volt network. Grounding in this case is not required, since communications in modern floor convectors are made a priori with grounding. Make sure that all wiring is hidden under the floor - so you protect yourself from injury, and the device itself from premature breakage.

Additional tips for installing floor convectors.

- Metal-plastic pipes or communications are considered the best material in tying built-in convectors. They simultaneously have sufficient strength for long-term use and ductility for easy placement in any laying conditions.

- Communications, regardless of their type, should be embedded in a concrete coating or covered with a raised floor. There should be no extra connections or switches in this section of laying communications, which is why purely metal options are impractical here. In the case of laying a raised floor, it is possible to install communications of any type, however, metal-plastic or polypropylene remains the recommended materials here.

- When installing the unit and then laying the grille or decorative frame, gaps and free space between the decking may be formed. Experts advise filling it with silicone.

- The installation of the pipes of the circuit to the device should be carried out using special union nuts (they are also called "Americans").

Water heating convectors built into the floor

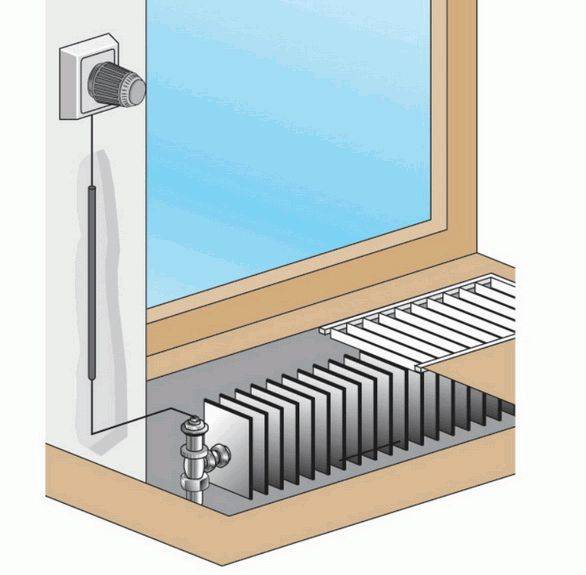

There is another type of heating convectors, which is very different from those discussed above and therefore stands apart. They are unusual in their place of installation - in a niche located below the floor level. With a high degree of probability, such heating devices can be found in commercial or office premises with large panoramic windows, against which ordinary radiators or convectors will not look quite appropriate.

In cottages and apartments, such convectors are also installed, but usually only in cases where the lower edge of the window is located no higher than 150-300 mm from the floor level. It is allowed to embed heating convectors in the window sill.

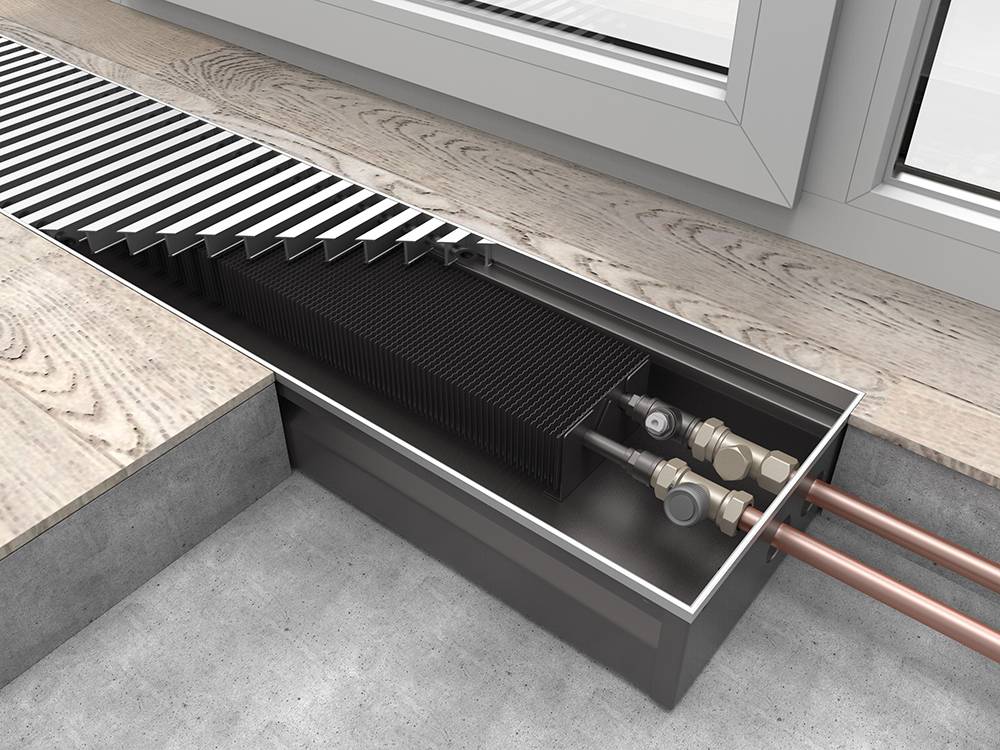

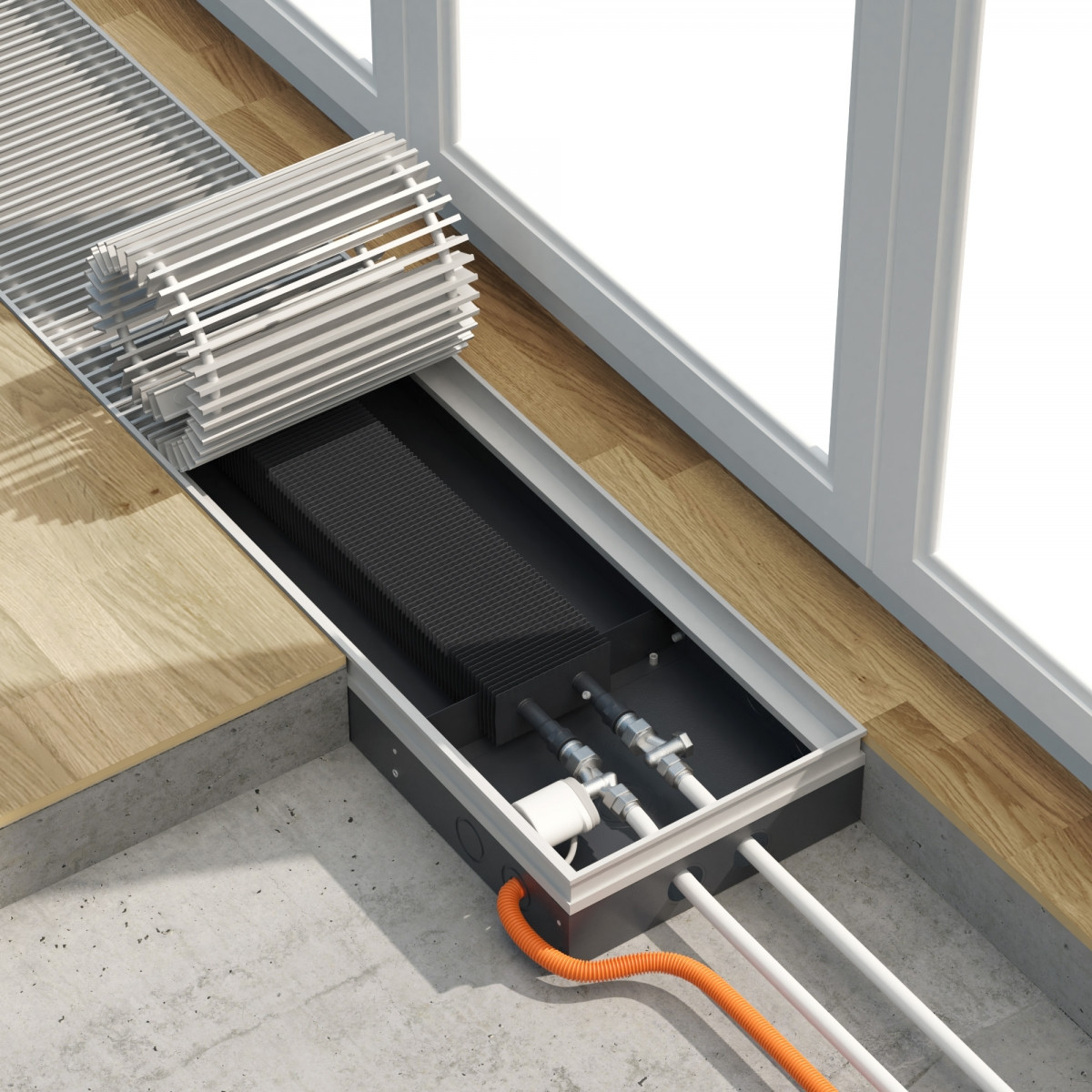

Water heating convector built into the floor.

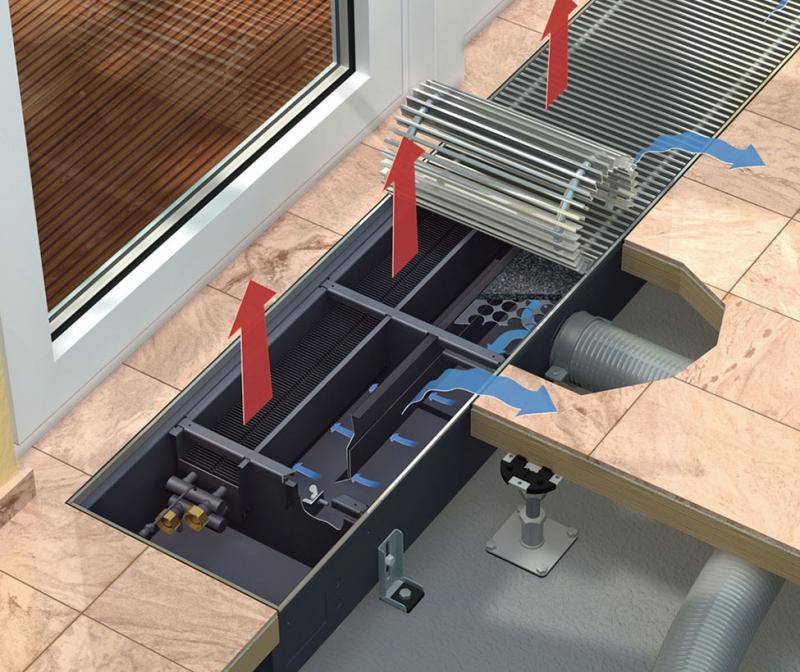

The height of the body of convectors built into the floor can vary from 50 to 130 mm, and the length can reach 3 m. floor through which heated air rises.

Most often, such gratings are made of steel, aluminum or plastic, but sometimes you can find cast iron, marble or, for example, wood. Whatever material the grate is made of, it must be strong enough so that you, passing by, are not afraid to step on it.

In the case of large French windows, floor convectors are an indispensable option for heating equipment. On the one hand, and we have already mentioned this, they, being located below the floor level, do not interfere with the review. On the other hand, it is these convectors that most effectively heat a room with floor-to-ceiling windows.Cold air from the window enters the convector through the grate, and from there it exits in the same way already warm.

To install a floor convector, it is necessary to prepare in advance a niche in the floor with a depth of 100 to 300 mm. However, installation can also be carried out at the stage of floor screeding. It should be borne in mind that not every convector can be used for floor installation.

The limiting factor in this case will be the height of the instrument case. Powerful models with a height of several tens of centimeters are not intended for installation in rooms located on the upper floors of the building. Of course, the installation of floor convectors should be planned in advance - even at the stage of building construction. The exception is low-power low models that allow installation in a screed.

Underfloor water heating convectors, unlike wall-mounted or floor-mounted ones, often have in their design a fan for forced air supply to the heat exchanger, as well as a drainage system for collecting and removing condensate from the device case.

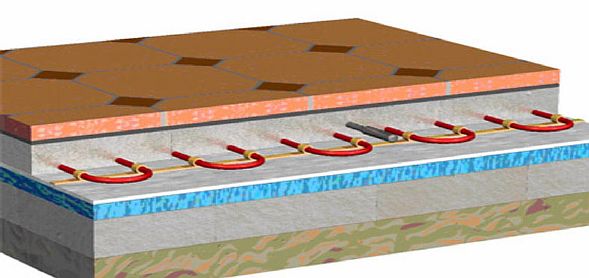

Floor types

The physics of the process of heating underfloor heating differs from radiator heating in the absence of convection of hot air masses. In them, the air, heating up, rises to the ceiling.

There are two types of underfloor heating on the market today - electric and water.

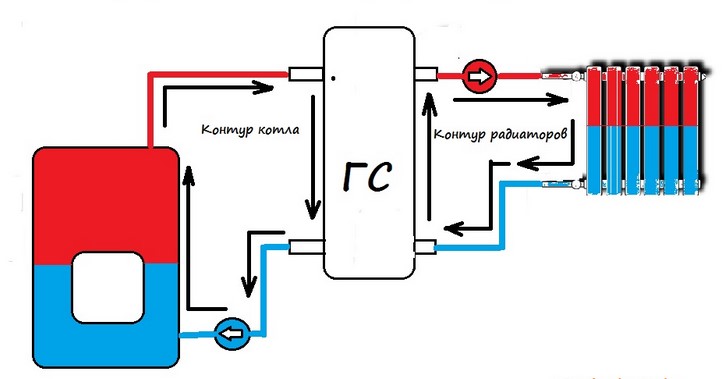

Water floors

The water floor resembles a standard heating system, the only difference is in the location of the pipes through which the coolant circulates.

Conventional batteries are located on the wall, while the contour of the warm floor is under the floor covering.

The most important part of the device is metal-plastic or polypropylene pipes, which are often filled with concrete screed, although it happens that pipes are laid in a flat “dry” way.

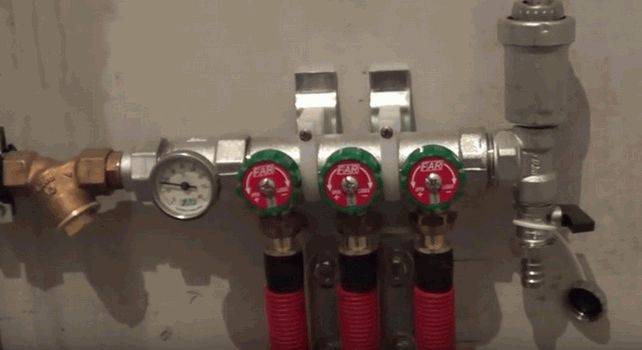

The kit includes a heater (gas, electric or wood), a manifold assembly with a circulation pump and a temperature control device.

Electric floors

The design of electric floors is simpler than that of water floors, and the cost of their installation is cheaper. They consist of heating elements and a thermostat. Such floors work from the mains. Designed for areas up to 30 m2. To prevent overheating of the heating elements, it is not recommended to place heavy furniture on them.

Electric floors are divided into:

- Cable - a cable with conductive wires acts as a heating element.

- Mats are the same cable floors, only the wire is fixed on a special polymer mesh with a certain pitch.

- Infrared - consist of two layers of lavsan metallized film, between which there are heating strips, and copper or silver wires, current flows through them.

- Rod - a modern type, which is also an infrared device. Unlike film, it has carbon rods instead of plates.

Areas of use

The extensive scope of application is largely determined by the main advantages of water convectors:

- Quick warm up. It takes much less time to warm up a room in which a water heating convector is installed compared to traditional radiators.

- High efficiency.Due to the special design and unique principle of operation, the efficiency of convectors can reach about 95% - and this is one of the highest rates in the field of heating equipment.

- Compactness. Heating convectors are relatively small in size, so they do not require much space for installation. In addition, compactness allows the use of such devices without harm to the interior of the heated room.

In addition to the advantages already described, it is also worth noting the ease of maintenance of convectors, the cleaning of which comes down to periodic cleaning of dust. For cleaning, a regular vacuum cleaner of sufficient power is quite suitable. True, there is also the need for internal cleaning at least twice a month, aimed at preventing contamination of the system from the inside - but this work is also carried out without any problems.

Advantages of water heating convectors

- Modern water convectors are more efficient and economical than conventional radiators. The following advantages can be distinguished:

- The principle of convection is used. The air is heated, and not the body of the device (as in conventional radiators). As a rule, the case is heated to a temperature of no more than 40-45 ° C, which allows them to be used in kindergartens without a protective wooden casing, as is the case with cast-iron radiators. Touching the body of the device, the child will not be able to get burned.

- High heat transfer with low energy consumption.

- Resistance of materials to corrosion. For the manufacture of high-quality water heating convectors, copper, aluminum and stainless steel are used. This allows them to be placed in rooms with high humidity.

- The compactness of the heating system and low weight.

- High rate of space heating.

- Doesn't dry out the air.

- The presence of a thermostat allows you to adjust the temperature.

- Unique design and high quality of heating devices and components.

Kampmann Katherm NK.

What are electric convectors and how to choose them correctly

Electric convectors are distinguished by the following features:

- form factor and mounting type;

- heating element device (heating element);

- the presence of additional functionality.

Which is better to choose a convector for space heating

Each manufacturer has its own approach to the production of electric convectors. Some are guided by the most simple and budgetary devices, others are trying to create "smart" electric convectors with increased efficiency, while others can find borderline options.

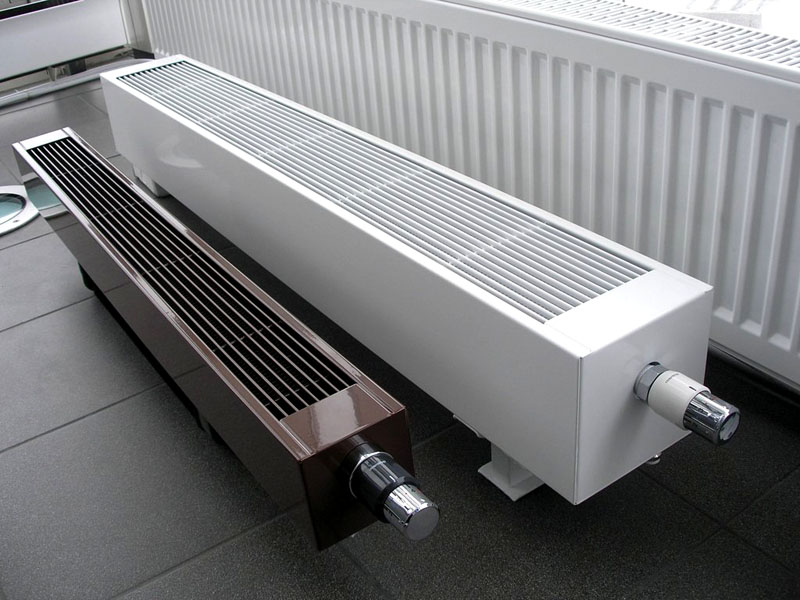

According to the type of installation, convectors are divided as follows:

- wall convectors, which are fixed with fasteners on the wall;

- floor convectors (often with wheels) that do not require any installation;

- universal convectors that can be both placed on the floor and hung on the walls.

Usually wall convectors are somewhat more compact than their floor counterparts. In addition, they are made as flat as possible so that they look harmoniously in the room and do not violate the design. Floor convectors are not so elegant, but they are easier to use and do not require installation.

Floor convectors

Three types of heating elements can be used in electric convectors:

- tubular metal heating element. It is not afraid of moisture and overheating, but it makes noise during operation and is not very effective - it will take more time to warm up the room;

- needle heating element, which is made of special nickel or chrome threads. Such heaters are the most budgetary, but they are afraid of moisture and overheating. They are somewhat more efficient than tubular ones, but still not good enough;

- monolithic heating elements. Such convectors are the most expensive, but the efficiency of such devices is the highest. At the same time, the minimum amount of electricity is spent on heating the room. For residential premises it is recommended to choose this type of convectors. They are more expensive, but pay off in the long run with lower electricity bills and better performance.

Another important feature of some convectors is the presence of additional functions. Some convectors have a timer mode or can work according to a specific schedule. In addition, there are devices with automatic switching off and on depending on the ambient temperature. Recently, "smart convectors" have appeared with the possibility of remote control, "memory" modes, the presence of built-in Wi-Fi modules and other functionality.

Convector with additional function

Additional functions are important - electric convectors are becoming more economical and convenient. On the other hand, you have to overpay for them, so when buying a convector, you need to weigh all the pros and cons and choose the option that best fits your needs and budget. If the convector is the only source of heat in the house, then it makes sense to invest in an expensive and efficient device. For household needs or non-residential premises (for example, for a garage, for a barn), ordinary budget convectors without additional functions are suitable.The main thing when choosing is to be guided first of all by needs, and only then by cost and other characteristics.

Grates for convector

When choosing a grate for a convector, the question becomes wooden or aluminum. It really all depends on individual preference. I would like to emphasize that wooden gratings are made only from natural wood. To protect the grate made of wood, staining or varnishing is recommended. Aluminum gratings are considered more wear-resistant, as they additionally undergo an anodizing process. All gratings can withstand a load of 40 kg per bar. The only point is that the wooden grating is more prone to external wear, that is, rubbing from walking on it will be more visible.

Convector connection

Hydraulic connection

There are two options for connecting to the heating system: it is flexible and rigid. Each type has its own advantages.

Electrical connection

You have chosen a convector with a fan, then you need to take into account such a moment as connecting to the electrical network. Since the fans used in convectors are usually 12 V, and in the network 220, it is necessary to purchase a convector module (transformer). The module controls the room thermostat and vice versa. The room thermostat measures the temperature in the room using a built-in sensor and maintains its value at the level of the set value.At the same time, it can control servo drives and smoothly adjust the fan speed. Some manufacturers provide for the possibility of laying the transformer in a box with a convector, which simplifies installation work.

Selection, installation, connection of floor convectors

High window heating issue

The problem of heating rooms with high windows, as well as rooms with external doors (near the door, the radiator is also not very happy) is solved with the help of floor convectors.

Therefore, near a high window, or at a door, a thermal curtain is formed.

This solves the problem of the cold zone. And also the issue of design is removed (many people think that this is the main thing), - instead of pipes and radiators, an elegant narrow strip of grating appears on the walls in the floor under the window opening.

Features of heating with convectors

A conventional heating radiator directly heats the air in the room, and also transfers significant energy by thermal radiation. At the same time, the direction of air flow is rather multidirectional - up and to the side, the flow is reflected from the window sill deep into the room ...

Uneven heating of the room.

This is especially important for large rooms where powerful underfloor heaters are installed in accordance with the heat loss calculation. It can be especially cold in the opposite lower corner, where there is practically no air circulation. The main circulation flow is located in the immediate vicinity of the convectors.

The hottest air is concentrated at large windows, with thermal insulation qualities many times less than at the wall. As a result, increased heat leakage from the room.Also, the concentration of hot air near the ceiling leads to higher heat leakage through the ceiling.

A directed air jet is accompanied by a large dust flow. The sanitary condition and ecology are deteriorating.

The devices themselves are subject to rapid contamination, not practical - they require cleaning. Garbage falls through the grate. The often-finned heat exchanger becomes clogged with dust and requires special cleaning. Some operators talk about the need for annual dismantling and cleaning with a jet of water and detergent.

Installation is carried out during the arrangement of floors, it requires increased thermal insulation (as well as a warm floor). Installation in an already renovated room is often simply not possible - for example, there is not enough height of the subfloor. Or fraught with great difficulties.

But these shortcomings can be almost completely minimized - how ? - read on.

Construction of floor convectors

The basis of the floor convector is a heat exchanger. It is made in the form of a set of closely spaced metal plates fixed on a metal pipeline, from which heat is supplied.

At the ends of the pipeline - adapters for connecting shut-off and control valves.

How to install

The convector is installed on the base of the floor: rough screed, floor slab, logs, and hides inside the rough floor to its full height.

General installation scheme of a floor convector with floors on the ground.

The distance from the window to the body of the device is no more than 300 mm.

Connection

It is better if the convectors are connected by a pipeline with a reliable oxygen barrier made of aluminum foil, i.e. from metal-plastic.

It is recommended to lay the pipeline for floor devices in a heat-insulating sheath in the form of felt, corrugated tube.

The pipeline diameter is 16 mm.

A pair - a thermostat - a servo drive is selected as a complete set.

Which water convector to choose and how to apply

In order to level the disadvantages of heating with convectors, it is advisable to install another heater in the room. Experts recommend using underfloor heating.

It is also useful to provide sufficient power with a lower temperature of the heater itself, in order to reduce the air flow rate while increasing its volume. Those. use wider and more powerful convectors that will provide the required energy with a lower coolant temperature.

Calculation of heating power “which never makes a mistake” - the total power of heating appliances at home - from 100 W per m2. area, with “decent” insulation (Moscow region). But then the amount is unevenly distributed over the rooms, depending on the length of the outer walls, the area of glazing.

In modern houses under construction, panoramic windows with heated floors and underfloor convectors are increasingly gaining popularity.

decorative frame

Many manufacturers offer convector framing, this is necessary first of all in order to close the joints, often tilers do not perfectly fit the tiles to the convector and gaps and crevices remain, in such cases the framing is installed. It comes in two types: U-shaped and F-shaped. U-shaped is less noticeable, as it does not lie on the floor.The F-shaped one lies on top and is 1-2 mm wide, thereby completely hiding the joint between the convector and the floor, but in this case the grate is slightly higher than the floor, that is, a slight rise is formed. If without a frame, then the floor, convector and grate are on the same level.