- Types of gas boilers

- Design features of modern models

- Which boiler is better to choose

- Classification by installation site

- Floor type boilers

- Features of wall equipment

- The nuances of parapet devices

- Pros and cons of gas boilers with a closed chamber

- Which gas boiler is better to buy

- Why choose floor standing boilers?

Types of gas boilers

On the market, you can equally likely meet gas boilers of both domestic and foreign production. The cost of both options can vary within a fairly wide range - the final price is affected by the country of manufacture, the technical characteristics of a particular model and a set of additional features. The selection of the appropriate option should always be based on these parameters.

One of the classification parameters is the installation method, depending on which two main types of gas boilers are distinguished:

- Floor. This category of boilers was originally designed for installation on the floor. As a rule, floor-standing household gas boilers are quite large, so you have to select a separate place for them. Due to their characteristics, such devices can provide the whole building with heat and hot water.Installation of floor boilers is quite simple, so there are no problems during this work.

- Wall. Such devices have fairly compact dimensions, high power and performance. Wall-mounted boilers are very popular - they can be found in most private homes. Due to good performance characteristics, such devices effectively supply the house with thermal energy and hot water, and good visual data allow you to harmoniously integrate a wall-mounted gas boiler into the interior of the room.

In addition to the installation method, gas boilers are also classified by the number of circuits, depending on which two categories of devices are distinguished:

- Single-circuit gas boilers. A distinctive feature of single-circuit boilers is the possibility of heating the building and the absence of other possibilities. As the name implies, in such devices there is one heating circuit designed to heat the coolant and supply it to the heating devices.

- Double-circuit gas boilers. This category of devices is a universal solution that allows you to provide the house not only with heat, but also with hot water. Versatility is achieved due to the presence of two independent circuits, one of which is designed to heat the coolant, which is then transferred to batteries, and the second is for heating water used in everyday life.

Design features of modern models

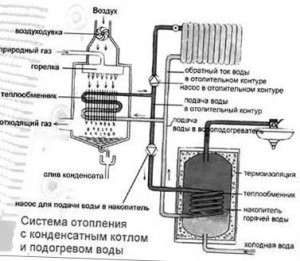

Initially, all boiler units were designed for gravity heating systems. In other words, the circulation of the coolant along the circuit was carried out due to the difference in the density of the hot and cold coolant. Warm water is lighter than cold water.Rising to the upper point of the heating system, it displaced the colder one, which caused the natural movement of the coolant along the circuit. The slightest mistake during installation, a miscalculation in the design of the heating system and calculations of the pipeline section could cause the coolant to stop, which reduced the efficiency of the boiler to zero.

Modern boiler units are equipped with powerful built-in circulation pumps, which move the heated coolant along the heating circuit in a matter of minutes.

When heated, the liquid expands (school physics course grade 5). With the expansion of the coolant, the pressure on the inner walls of the pipeline increases. The higher the heating, the greater the pressure in the pipeline. Excess fluid that has increased in volume is forced out into the expansion tank, which was usually installed at the top of the heating circuit.

…

Modern domestic boiler plants are equipped with a built-in expansion tank of the membrane type.

In the boiler units of the last century, two-stage gas burners were installed everywhere. The first had only two positions: work at 100% power and shutdown. Later developments of three-stage burners made it possible to regulate the gas supply by 50, 100%. Such operation of the gas burner device led to rapid wear of the device and high fuel consumption.

Modulating burners are used in modern gas heat generators, the power of which is automatically regulated depending on the temperature of the coolant, the operating mode of the installation, etc. This innovation has allowed modern boilers to save from 15 to 25% of gas.

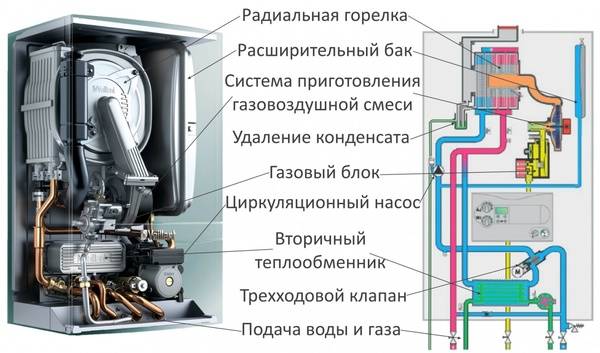

Conclusion: structurally, modern models of gas heating equipment differ from similar installations of the late 20th century by the presence of a built-in circulation pump, an integrated expansion tank and an automatic fuel supply and adjustment system. This is all that concerns the filling of boiler units. Significant changes have taken place in automation, which allowed the owner not to worry about safety when operating equipment. For a better understanding of the design, we recommend watching a video about the main components and elements of a gas heat generator:

Which boiler is better to choose

For manufacturing use:

- stainless steel. This is a budget option, although the parameters of steel heat exchangers allow you to get quite effective results. Typically, such nodes are installed on inexpensive medium-sized boilers;

- copper tube (coil). This option is used on expensive models of gas boilers. Copper has a high heat transfer coefficient, so the effect of using such heat exchangers is very high;

- cast iron. It is resistant to mechanical and thermal loads. For the manufacture of heat exchangers, gray ductile metal is used, which is resistant to drops or different liquid temperatures at individual points. Massive knots help to even out the degree of heating and soften sudden temperature changes.

Copper heat exchangers are considered the most preferable, but steel and cast iron assemblies are quite efficient and can provide high-quality heating of the OB.

There are two options for the output of combustion products:

- atmospheric. This is the traditional way to remove flue gases using natural furnace draft.The technique is well studied, but it is characterized by instability and strong dependence on external conditions. Most often used on non-volatile models;

- with a turbofan. The combustion chamber of such boilers is isolated from the outside atmosphere, so the combustion process and the removal of smoke are provided by a turbocharging fan. It supplies fresh air that supports the flame and displaces smoke into a specially designed chimney (coaxial).

Turbocharged boilers are considered more convenient designs for use in residential premises - there is no smell of smoke, oxygen does not burn out, the unit is completely safe.

However, such boilers need to be connected to the power supply network.

In addition to the main technical characteristics and price, the choice of a heating unit is influenced by the operating conditions and recommendations of specialists who regularly service gas-using installations in private homes.

Taking into account practical experience in the field of heating private housing and reviews of various types of natural gas heating equipment, we give the following recommendations for choosing a heat source:

There are situations when a suspended heat generator cannot be installed for various reasons, for example:

- in the kitchen, the walls are occupied by cabinets and household appliances;

- the building structure or its finish does not allow hanging a unit weighing 50 kg or more;

- there is no space on the walls in the boiler room or it is difficult to bring pipelines.

Then it remains to purchase a floor boiler of similar power and mount it in a convenient place. When we have decided on the installation method, we proceed to the choice of the heating installation according to the principle of operation.

Classification by installation site

According to the installation principle, boilers serving two communication circuits are floor, wall and parapet. Each option has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for himself, in which the equipment will be located conveniently, will not “eat up” the usable area and will not cause problems during operation.

Floor type boilers

Floor-standing units are high-power devices capable of heating and providing hot water not only to a standard apartment or residential building, but also to a large industrial premises, public building or structure.

If a double-circuit boiler is planned to be used not only for heating and supplying domestic hot water, but also for feeding warm water floors, the base unit is equipped with an additional circuit

Due to their large size and solid weight (up to 100 kg for some models), floor-standing gas boilers are not placed in the kitchen, but are placed in a separate room directly on the foundation or on the floor.

Features of wall equipment

The hinged appliance is a progressive type of household heating equipment. Due to its compact size, the installation of a geyser can be done in the kitchen or in other small spaces. It is combined with the interior solution of any type and organically fits into the overall design.

A double-circuit mounted boiler can be placed not only in the kitchen, but also in the pantry. It will take up a minimum of space and will not interfere with furniture or other household appliances.

Despite its small size, the wall-mounted boiler has the same functionality as the floor-standing device, but has less power. It consists of a burner, an expansion tank, a pump for the forced movement of the coolant, a pressure gauge and automatic sensors that make it possible to use the fuel resource with maximum efficiency.

All communication elements are "hidden" under a beautiful, modern body and do not spoil the appearance of the product.

The flow of gas to the burner is controlled by a built-in security system. In the event of an unexpected cessation of the resource supply, the unit will completely stop functioning. When the fuel begins to flow again, the automation automatically activates the equipment and the boiler continues to operate in standard mode.

The automatic control unit allows you to set the device to any operating parameters that are most suitable for the user. It is possible to set your own temperature regime for different times of the day, thus ensuring economical consumption of the fuel resource.

The nuances of parapet devices

The parapet boiler is a cross between a floor and wall unit. It has a closed combustion chamber and does not create harmful emissions. Does not require the arrangement of an additional chimney. The removal of combustion products is carried out through a coaxial chimney laid in the outer wall.

A parapet-type boiler is the best option for heating equipment for small rooms with a weak ventilation system. The device is designed in such a way that during operation it does not emit combustion products into the atmosphere of the room in which it is installed.

The device is mainly used to provide hot water and full heating for small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but despite such low performance, the unit successfully copes with the tasks.

The main advantage of parapet equipment is the ability to connect heating and water supply communications to the central gas system and pipelines from any side convenient for the user.

Pros and cons of gas boilers with a closed chamber

Closed boilers outperform open devices in many ways. The user does not need to make any effort to provide heat in the house. The following advantages of such devices can be distinguished:

- installation does not require a separate room. Installation is possible in any place where there is a supply to the gas pipe and an electrical outlet;

- exhaust gases exit through a pipe laid through the wall, and not through a vertical chimney, so there is no need to equip it;

- the boiler is powered by electricity and does not depend on natural ventilation;

- the functionality of the heating equipment does not affect the level of oxygen in the room, because all his activities are carried out outside;

- due to the intake of air from the street, closed units have a high efficiency, are characterized by complete combustion of fuel and save its consumption.

The disadvantage of closed boilers is their dependence on electricity. If for some reason there is no electricity, then in severe frosts the house may freeze. There is also a possibility of freezing of the combustion chamber due to a short coaxial pipe.

Which gas boiler is better to buy

The power of thermal equipment is the first thing to determine before buying. It is calculated through the heating area, taking into account the climatic zone. At first, with a standard ceiling height of up to 3 m, you can get by with simple calculations: multiply the area of \u200b\u200bhousing by the coefficient for your region, and divide the total by 10. As a result, you will get the approximate boiler power in kW.

Power factors for different regions of Russia:

1. southern region 0.7-0.9

2. middle band 1-1.2

3. moderately cold climate 1.2-1.5

4. northern region 1.5-2

According to the calculation, a 10-12 kW boiler is required for a house with an area of 100 squares in the middle lane. When buying a two-circuit unit, the total power will increase by 20%.

Not only the organization of space, but also the safety of using gas equipment depends on the method of installing the boiler. Wall mounting will save space, but the compactness of the model will entail a number of technical limitations. The burner, exchanger, pump and control electronics will be too close to each other, which will create a stressful temperature regime for their operation and complicate maintenance.

Compact wall models have power limitations - they are more suitable for an apartment than for a private house. Floor boilers, as a rule, are installed in separate rooms, so their overall dimensions, as well as thermal power, are not limited by anything but common sense.

The types of gas burners do not depend on the type of boiler chosen, but determine the principle of its operation and performance:

- Atmospheric burners are inexpensive and virtually silent. But they burn out the air in the room and have a low efficiency.

- Supercharged are equipped with an air blower coming from outside. Boilers with such burners are efficient and do not require mandatory installation in a separate room.

- Power-controlled modulating burners can be equipped with a second heating stage or electronically controlled heat output. Their efficiency and economy increases simultaneously with the price of the boiler.

Why choose floor standing boilers?

Manufacturers of gas boilers produce a variety of modifications of heating appliances. All of them can be divided into floor and wall devices.

The latter are compact and have good performance characteristics. And yet, many prefer outdoor equipment, which is explained by its significant advantages.

The advantages of floor boilers include:

- Great power. The design of the devices is such that they are capable of delivering much more power than wall-mounted counterparts.

- The presence of non-volatile models capable of permanently or temporarily working with a coolant moving without using a pump.

- Equipment durability and reliability. Properly selected and installed boiler, subject to proper operation, can work for 50 years or more.

- Economy and ease of operation. Floor boilers, unlike wall-mounted ones, are most often produced without built-in automation and additional equipment. This greatly simplifies the maintenance of devices, their repair and extends the service life.

Of course, the use of outdoor equipment involves some inconveniences and limitations.These include the mandatory presence of a separate room - an equipped boiler room, in which the boiler should be placed.

There are a number of requirements for such premises, each of them must be strictly observed. Otherwise, it will not be possible to obtain permission to install and start gas equipment.

Gas boilers in the floor version are large and massive, but at the same time they are more powerful, reliable and durable compared to wall-mounted counterparts

The dimensions of the furnace or boiler room are selected based on the fact that not only the boiler, but also all the necessary additional equipment can fit here. The requirements of SNiP are also taken into account.

The need for furnace equipment increases the cost of installing the boiler. In addition, the arrangement of the chimney, floor preparation, etc. will also be required. Accordingly, the cost of installing a floor-standing boiler will be much higher than a wall-mounted one.