- Restoration instructions

- Training

- Restoration instructions

- Installing the acrylic liner

- Relaxation in a bath covered with colored acrylic

- Bath preparation for application

- Properties and features of acrylic dyes

- The main qualities of acrylic

- Composition selection

- Suite

- STACRIL ECOLOR

- PlastAll Classic

- Varieties of material

- Which manufacturers to choose?

- What is the application technology?

- Enamel technology

- Properties of liquid acrylic

- What is acrylic for plumbing restoration

- Curing time

- The term of activity of the mixed composition

- Lifetime

- Coating method

- Price

- Bath restoration with enamel

- Technology

- "Pros and cons"

- Prices

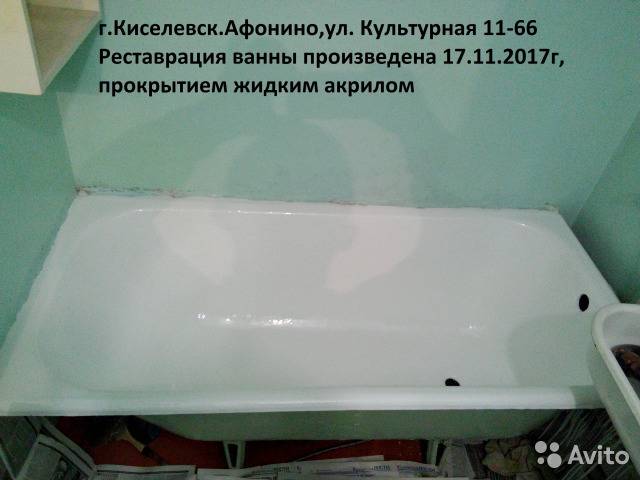

Restoration instructions

The quality of the final result depends on the quality of all stages of work.

Tools:

- drill, power matters: the more powerful, the better;

- nozzle for mixing the composition of small diameter - about 5 cm;

- building hair dryer to quickly dry the bath (you can get by with a household hair dryer);

- sandpaper waterproof paper No. 60-80;

- a screwdriver for unscrewing the drain;

- pliers for the same purpose;

- automotive putty with fiberglass - to eliminate large potholes and holes up to 15-20 cm in diameter;

- spatulas - used to stir putty;

- rubber spatulas for spreading the mixture;

- baking soda - for washing the bath;

- several pieces of latex gloves;

- hammer and chisel, if you need to remove the cast-iron drain;

- acrylic and hardener - a 1.5 m bath will take 3 kg of base and 400 g of hardener.

Training

Everything else is taken out of the room. Check the ceiling for cobwebs and dirt. It needs to be cleaned so that dirt from the ceiling does not fall on the damp coating.

The surface of the old bowl must be prepared before covering it with acrylic, and only then the mixture is distributed in bulk. Preparation includes a thorough stripping with soda.

The purpose of the work: removal of pollution, corrosion, delamination. Due to the processing, the surface becomes rough, fat-free. This means that the adhesion of liquid acrylic to the bath improves.

Processing is carried out with any abrasive tool - a grinder, sandpaper manually.

The surface is then thoroughly washed to remove any remaining dust. It is recommended to do this operation twice, observing how the surface is wetted. If dry islands remain or water collects in drops, then the surface is poorly processed, and you need to go through the problem area with soda and sandpaper. Instead of soda, acetone can be used as a degreaser.

Before drying the bowl, remove the siphon and overflow. After restoration, it is desirable to replace them with new ones. They also dismantle the shower hose with a watering can and the gander. The holes are wrapped with a rag and a bag is put on top of the mixer so that water does not drip into the bath.

After grinding, the surface is dried with a hair dryer, warming the bowl for 30 minutes. If moisture remains, the acrylic will not stick.

Then open a can of putty and mix a small amount of the composition with a hardener using two spatulas.It is necessary to knead the putty in small portions, because it hardens in just 2-3 minutes. Covers chips and cracks. Especially carefully you need to putty potholes on vertical surfaces. After 20-30 minutes, it is necessary to wipe the puttied areas with sandpaper.

Then all the debris is blown off the surface with a hairdryer or wiped with a rag. A container is placed under the drain hole, the floor is covered with newspapers. On this preparation can be considered completed.

Restoration instructions

Bulk acrylic bath

Having prepared the bath, proceed to the preparation of the repair composition. Open a jar of acrylic, removing the remnants of the substance on the lid and sending them to the container. With a rubber spatula, remove the composition from the walls into a bucket and wipe the spatula with a rag. This is done so that pieces of unmixed acrylic do not subsequently fall into the repair composition.

The hardener is poured into a jar. They take a drill and, clasping the bucket with their legs, at low speeds begin to knead acrylic, collecting from the walls and bottom. The batch lasts about 10 minutes. Then the composition is left alone for 5 minutes. The life of the material is 70 minutes, then it will thicken and lose fluidity.

Then the mixer is disconnected from the drill, making sure that the dirt from the cartridge does not get into the composition. Another 5 minutes knead the composition by hand.

The drain hole is plugged with a plastic cup. A jar of acrylic, carefully wiping its bottom, put in the bath. The whisk is pulled out and put there. Part of the composition is poured into a disposable glass with a volume of 0.5 liters.

The finished mixture is poured along the edge of the side, starting from the far left corner (for right-handers). The front wall is poured last, when the entire vertical surface near the wall is already filled.The outer edges are poured over so that the composition flows towards the floor. When all the mixture from the bucket has been used, it is turned over and left in the bath for the time being. Using a plastic spatula, form the sides: scoop acrylic from the bottom and coat the unfilled areas. Then fill the vertical surface of the bowl. The bucket and nozzle are removed from the bath. It is impossible to collect the rest of the material from the bucket.

The resulting streaks are removed with a spatula, scooping acrylic from the bottom and stretching it into bald spots with vertical movements. The material accumulated around the drain and on the bottom at the sides is distributed over the entire bottom.

Leave the bath until the acrylic is completely dry.

Installing the acrylic liner

Acrylic liner is an effective restoration method that extends the life of the bathtub by another 20 years or more. It is selected for each bath individually, since the insert must fit under the base in shape. It is quite difficult to determine which is better - a bulk bath or an acrylic liner. Both recovery methods are very effective. Having studied the essence and technology of these methods, you can choose the most appropriate one.

The master takes measurements, finds out from the customer the wishes about the color. The manufactured liner is installed only after the preparatory measures:

- Cleaning and degreasing the inner surface.

- Applying adhesive to the base and liner.

Acrylic liner is placed in the bathtub and pressed firmly

In this case, special attention is paid to the coincidence of the drain holes, the elimination of gaps. The press that holds the shape while the adhesive is curing is water.

Relaxation in a bath covered with colored acrylic

Our ancestors knew about the ability of color to affect well-being. For example, in Athens, a stone font was covered with red ocher. Even then, the water was endowed with healing properties. It was believed that in combination with yellow, these qualities were enhanced. Water, illuminated by the sun's rays through colored glass, raised the mood of a person.

The ancients attributed a certain energy to each shade. So, red gives protection and is suitable for insecure people. Orange relieves neurosis, recommended for public figures. Yellow suits everyone, it gives vitality. Green brings healing to the sick and wounded. The blue color of the sky will heal after psycho-emotional upheavals. Blue will give determination. Violet will give the energy of higher powers.

In modern life, achieving the desired shade of water is not easy. Firstly, the bathroom almost always has no windows and, accordingly, no sunlight. Secondly, colored lighting will not solve the problem of water coloring. Third, dyed sea salt added to water will scratch the acrylic. Fourthly, not everyone has the opportunity to color water with herbal decoctions.

Therefore, the colored acrylic coating for bathtubs was immediately appreciated as a practical means for relaxation and color therapy at affordable prices. To use, you just need to fill the tub with water.

If the room is equipped with good ventilation or a window, then aroma lamps can also be used to enhance the effect. The choice of oils today is unusually large. You can also place candles and admire the fire. The resulting ensemble of color, light and aroma will come in handy after the hard work of covering the bathtub with liquid acrylic, it will help to relax and unwind.

Bath preparation for application

Before restoring with bulk acrylic, the entire surface of the old bathtub must be prepared in advance. To do this, you will need the following materials: a plumbing cleaner, several sheets of sandpaper, rubberized gloves, a spatula, a drill and a nozzle for it.

Before restoring with bulk acrylic, the entire surface of the old bathtub must be prepared in advance. To do this, you will need the following materials: a plumbing cleaner, several sheets of sandpaper, rubberized gloves, a spatula, a drill and a nozzle for it.

It is also worth doing the following:

- Thoroughly clean the bath with any detergents. Baking soda can be used to degrease the surface.

- Remove all decorative trims on drains and adapters. Remove rust with sandpaper. If the layer is very large, you can use a nozzle from a drill.

- If there are chips and peeled enamel, use a spatula and sandpaper to carefully level the surface.

- If there are deep damages, scratches, potholes, they must be masked. It is best to use automotive putty, which dries on average in 10-20 minutes. Then smooth the surface with sandpaper.

- Rinse the surface with warm running water to wash away excess dust and remnants of old enamel. Pour hot water into the bath and drain it after 5-10 minutes. This is necessary to warm up the bath material.

- Dry the surface of the bath using a building hair dryer.

- Disconnect the drain hose so that the excess acrylic does not drain into the sewer, but onto the previously laid newspaper.

Now preparations for restoration are completed.

Properties and features of acrylic dyes

Can you paint with acrylics on fabric? Yes, painting with acrylics on clothes is one of the most famous ways to create a unique and striking piece. For drawing on fabric, there are different shades of paint. Acrylic is also produced in different forms - in jars, tubes or cans.

Work with acrylic paints

Work with acrylic paints

Acrylic painting does not require special skills or equipment. To work, you will need brushes, a container with diluting liquid or water, and the thing itself.

Dilution liquid

Dilution liquid

Acrylic is a "dense" paint, it can be applied in several layers, adding details or mixing with the bottom shade. Moderate application of fluid makes it thick and suitable for fabric work, but contours should be used.

This material has many advantages:

- They dry fairly quickly.

- You can mix colors, get new ones and use them in painting.

- Acrylic can be purchased at any craft store.

- The drawing really lasts a very long time and is not washed off;

- The patterns are vibrant.

Important! Acrylic paints are safe for children, but you need to be careful that the dye does not get into the eyes, mouth, or damaged areas of the skin that have not yet healed. There are also a few more important details associated with the use of this paint:

There are also a few more important details associated with the use of this paint:

It is worth paying attention to the expiration date of paints. From time to time they dry out, and can no longer be used for painting.

On the fabric, it can spread, which will greatly spoil the pattern.

Therefore, before work, it is recommended to apply a contour to a thing and have a sketch of the future finished work on hand.

It is not always possible to immediately get the right color when mixing.

Otherwise, working with acrylics is simple and suitable for beginners.

The main qualities of acrylic

The main advantage of acrylic is its durability. If you follow all rules for dealing with it, it will last a whole decade.The low thermal conductivity of the finishing material, and the additional application of mounting foam on the outside of the bath, will prolong the comfortable adoption of water procedures.

The restoration itself will take several hours. The curing time of the surface will depend on the quality of the material. Some types of acrylic paint set in a few hours, others in a couple of days.

Impacts and other physical influences will not leave cracks on the surface of the bath treated with acrylic. When exposed to sunlight, its color will not fade. Acrylic is resistant to chemicals, and is not washed off even with acidic liquids.

Manufacturers report how to use bulk acrylic. Diligent observance of all recommendations will reveal all the advantages of the finishing material.

This substance is completely safe for health. It is allowed to be used in any type of premises. Enamel and liquid acrylic are different finishing materials and there is nothing in common in their composition.

Composition selection

Do-it-yourself restoration of bathtubs with bulk acrylic has a number of nuances. The main thing is the quality of the selected material. To understand which acrylic is best for restoration, consider the most popular positions.

Suite

Development of the scientific and production company "EcoVanna" (Russia). Produces acrylic bath covers. Takes first place in the ranking of manufacturers of materials for the restoration of old bathtubs using acrylic. It is produced on the basis of raw materials of partners from Germany. The price is in the range of 1600 - 1900 rubles. Advantages:

- no solvent,

- packaging is designed for processing containers of 1.2 - 1.7 meters,

- the formula gives a high plasticity of the structure,

- the color scheme of the color scheme (LUX) has 8 shades,

- covering index - 100%,

- freezing time - days,

- high level of adhesion,

- operating period - 15 years.

STACRIL ECOLOR

Stacril Ecolor (Germany) - a combination of acrylate with epoxy resin. Difficult to use on its own. Another minus - stakril has a sharp unpleasant odor. Surface renewal with STACRIL ECOLOR acrylic during restoration is recommended to be carried out in a ventilated room. It also dries twice as long. Proponents of glass claim that:

- the resulting layer is twice as strong as the analogue,

- service life - at least 20 years,

- The paint adheres better to the old surface.

PlastAll Classic

PlastAll Classic is an acrylic coating for bathtubs. The two-component composition is the result of cooperation between the Russian association from the city of Togliatti "Plastol" and the Slovenian factory "Pabrek". Recommended for do-it-yourself bath restoration with liquid acrylic. Advantages:

- white color is guaranteed for 8 years,

- adhesion index - 100% to cast iron, steel, plastic surfaces,

- UV-resistance for at least 15 years,

- temperature stability: +120ºC,

- service life - 20 years,

- recommended for independent use,

- the formula does not contain toxic substances,

- high structural density allows covering even multi-coloured surfaces.

Varieties of material

Self-leveling acrylic creates a new and smooth surface for an old bathtub

Self-leveling acrylic creates a new and smooth surface for an old bathtub

There are several types of liquid emulsions, which include acrylic. These include:

- stacryl;

- liquid and bulk acrylic;

Some mistakenly believe that all these species are the name of one material, but this is not so. They are very similar to each other and, nevertheless, there are differences.

Liquid acrylic is also a two-component material, but it has become widespread relatively recently. This material lays down in a rather thin layer and forms a durable glossy surface.

Bulk acrylic is a viscous two-component emulsion based on epoxy resin. Restoration companies began using this composition just a few years ago. Therefore, it is too early to talk about the quality and service life of the acrylic coating in the bathroom.

Which manufacturers to choose?

PlastAll - considered a good bulk coating

PlastAll - considered a good bulk coating

Over the past ten years, many companies have appeared in the country that offer their services for the restoration of plumbing. But if you want to do the repair work yourself, information about the most popular material manufacturers will not hurt you:

- A well-known manufacturer of glass is the company "Ecolor". Their products collect positive feedback from people who have tried it in practice. Glass components are made in Germany. The fact that the composition dries for only 24 hours is important, and this is not so much for glass;

- Another well-known manufacturer of glass is PlastAll. Their acrylic bath enamel has good wear resistance, however, it dries for at least 36 hours;

- PlastAll also specializes in the production of poured acrylic. True, the drying time of such material increases to 48 hours;

- Ecovanna and YarLI make liquid formulations. According to the manufacturers, their emulsions are practically odorless, and the material is applied in an even and smooth layer.

What is the application technology?

Apply liquid by pouring onto the old surface

Apply liquid by pouring onto the old surface

The very technology of coating with acrylic baths is quite simple.Difficulties arise during the preparation of the surface for the application of the emulsion.

Stages of restoration work:

- first you need to dismantle the siphon so that the sewer does not clog with excess emulsion;

- the old layer of enamel is removed from the plumbing;

- the surface is degreased and primed;

- the coating must dry completely;

- then it is necessary to thoroughly mix all the components of the acrylic semi-finished product;

- a solvent is gradually added to the composition, after which dyes are added to the emulsion;

- apply the liquid mass very carefully with a thin stream;

- the liquid should be evenly distributed on the walls of the plumbing;

- if the emulsion begins to accumulate at the bottom, vent its excess into the drain hole. for this you can use a regular rubber spatula;

- after the acrylic coating of the old bath dries, plumbing can be used for its intended purpose.

Renovating plumbing with liquid acrylic is one of the inexpensive, but high-quality methods of restoration. By following the recommendations of the emulsion manufacturers indicated on the packaging, you will get a good quality composition. The use of high-quality materials is the key to successful restoration of plumbing, the coating of which will not deteriorate for many years.

Enamel technology

Enamel application

Surface primer

At this stage, it is important that no bubbles appear. Start at the top and move gradually towards the drain.

Mixing enamel and hardener according to factory instructions.

Application of the first coat using a brush or roller.

Drying for the time specified in the instructions.

Applying the next layer, and if necessary, then one more - finishing.

Complete polymerization of the coating, which occurs no earlier than in a week.

Each of the proposed methods has advantages and disadvantages. Which one to choose is up to you.

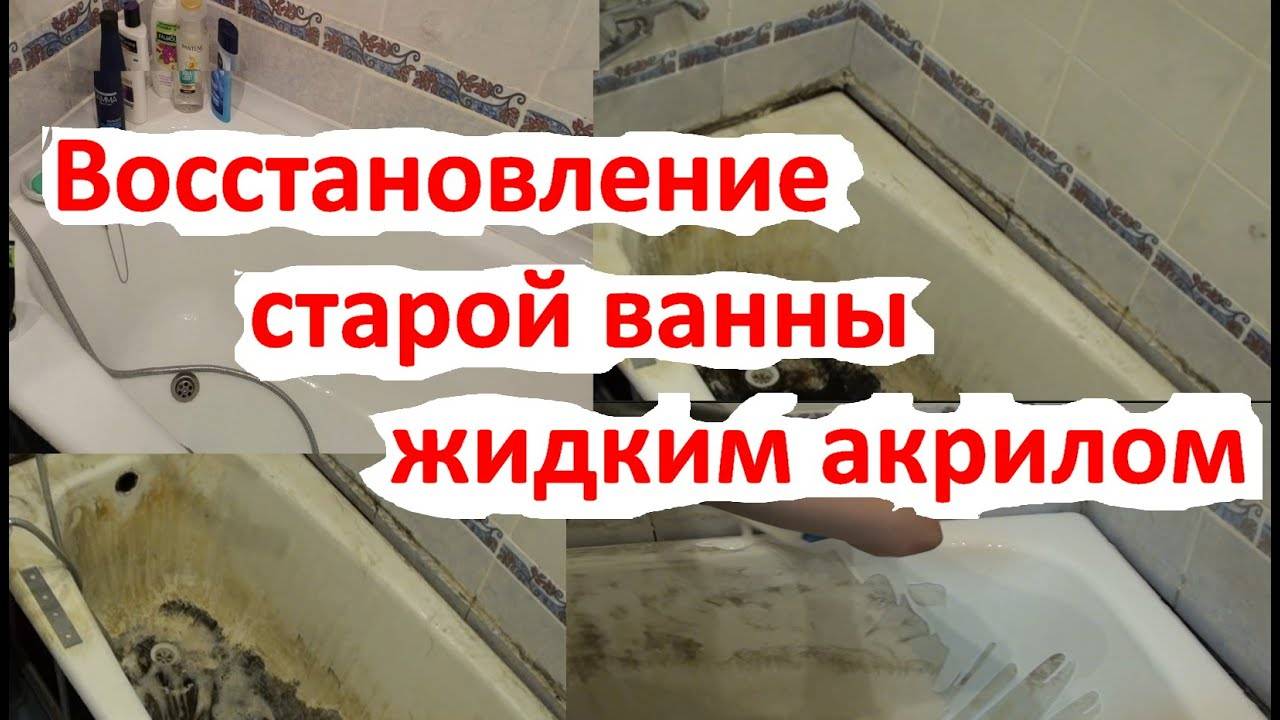

Properties of liquid acrylic

After some time, cracks and chips may appear on the surface of each bath. They spoil the appearance of plumbing products and can cause mechanical damage to the skin.

In addition, cleaning chemistries based on abrasive particles can cause premature flaking of fine particles. In places of deformation of the enameled coating, a large amount of dirt and pathogenic bacteria accumulate, which have a significant harm to human health.

There are several options for restoring bathtubs with liquid acrylic. They include:

- installation of acrylic liners. Filling with a liquid composition is carried out in places of chips and deep cracks;

- liquid enamel coating. In this case, surface filling of the entire area of the bathing bowl is performed;

- pouring method. Here, a three-layer filling of the bathroom is carried out. This increases the service life of plumbing equipment.

Liquid acrylic is a two-component solution with a high density. It consists of a base and a hardener. There are a number of advantages of such material. These include:

- long-term operation;

- protection against daily stress;

- has good thermal insulation.

Where to buy liquid acrylic for the bathroom? You can buy a similar composition at any hardware store. Here are different volumes of liquid depending on the area of the bathing bowl.

Filling the bathtub with liquid acrylic provides additional sound insulation.

What is acrylic for plumbing restoration

Liquid acrylic is a two-component mixture consisting of an acrylic base and a hardener. The components are mixed before starting the restoration.

When choosing an acrylic composition, you should pay attention to the following characteristics in order to acquire a truly suitable material

Curing time

The faster the solution hardens on the surface of the product, the lower the strength of the coating. The full curing process should take about 2-4 days. Of course, this causes some inconvenience due to the inability to use the bath, but such a time is necessary for the complete polymerization of the material and its sufficient strength.

The term of activity of the mixed composition

To get a smooth smooth surface of the bathroom, the restoration of the product cannot be interrupted, and the solution is made immediately in the amount necessary for work. But the mixture begins to polymerize not only on the walls of the bath, but also in the container, which leads to a deterioration in its fluidity, to the appearance of streaks and spots on the surface of the product. The optimal period for the activity of the solution is 60-70 minutes (approximately this time is required to cover the old bathtub with an acrylic composition).

Lifetime

Usually 20 years is indicated, but with proper care of the product, it can be longer. Be sure to take into account the ratio of the service life and the polymerization time of the composition with acrylic. If it is indicated that the bath can be used already a few hours after acrylic coating, then the service life of the material is greatly overestimated.

Coating method

Acrylic for the restoration of an old bath should be applied only by pouring.If other methods of applying the material are indicated on the packaging, then it is not recommended to purchase it, most likely, this is a less durable Stakryl.

Price

This is not the main indicator. The price varies, taking into account additional components that give strength to the composition and taking into account the name of the manufacturer. On average, the price is from 1500 rubles for a capacity of 3-3.5 kg.

Bath restoration with enamel

This is the oldest way to restore a bathtub. It is similar to the usual surface painting.

There are two types of enamel sold in stores:

- for professional application

- for self.

Technology

The sequence of actions for enameling includes 2 stages:

- surface cleaning,

- enamel application.

- Enamel is selected first. It should be designed specifically for baths, because other types of enamel emit harmful substances when in contact with hot water.

- The surface of the bath is cleaned of old enamel with any abrasive. For this purpose, you can use sandpaper or a grinder. Rust stains must be carefully cleaned.

- The resulting crumb is washed off and the bath is degreased with a solvent.

- Enamel is poorly distributed over a cold surface, so the bath must be warmed up before applying the first layer. To do this, pour hot water into the container and leave for 10-15 minutes. Then the water is drained and the surface is wiped dry.

- Enamel is applied with a roller, brush or sprayer. This is done very carefully, from the sides to the bottom, so that there are no streaks. The bath should be covered in 2-4 layers. Each subsequent layer is applied 15–20 minutes after the previous one. The total thickness of the coating should be 1–1.5 mm.

- The tub should now be dry. This will take about 7 days.

The bath is ready for use.

"Pros and cons"

Advantages of enamelling:

- the cheapest way;

- a large selection of coating colors;

- no need to dismantle either the tile or the drain with overflow;

- suitable for all types of baths: cast iron and iron with any wall thickness.

Disadvantages of enamelling:

- the service life of the coating is no more than 5 years (often less);

- work takes at least 3 hours, the enamel dries for a long time (5-7 days);

- the coating is hard, sensitive to shock and high temperatures;

- due to the thinness of the enamel layer, the coating cannot paint over serious damage and rust spots;

- the enamel quickly turns yellow, and it is not recommended to wash it with abrasive substances.

Prices

Prices for enameling a bath with material and enameling work in Moscow, St. Petersburg and various cities of Russia of various companies can be viewed in the table below.

| Company | Office adress | Telephone | Price |

| Moscow, Restoration of bathtubs | Voronezhskaya st., 14 K | 8 (495) 221-75-50 | 2500–3200 |

| Moscow, San-Techno | st. Academician Koroleva, 13 | 8 (495) 514-66-30, 8 (495) 517-02-32 | 3000–3500 |

| Saint Petersburg, Colorit | st. Chugunnaya, 20 | 8 (812) 987-45-49 | 1890–2190 |

| St. Petersburg, Lenremont | st. Reshetnikova, 5 | 8 (800) 555-45-10 | 2480 |

| St. Petersburg, 1001 baths | st. Novosibirskaya, 6 | 8 (812) 988-32-85 | 2100–2490 |

| St. Petersburg, Mastervanna | st. Shipbuilders, 19, building 1 | 8 (812) 917-02-21 | 1700 |

| St. Petersburg, Petersburg master | st. Simonova, d. 9, k. 3 | 7 (812)332-52-75 | 2190 |

| Yekaterinburg, Alrom | Bilimbaevskaya st., 19 | 8 (343) 345-98-66 | 2700 |

| Novosibirsk, Expert-N | st. Microdistrict Gorsky, 69, of. 3 | 8 (383) 375-15-02 | 2490 |

| Chelyabinsk, Alrom | st. 250 years of Chelyabinsk, 11 | 8 (351) 776-39-16 | 2700 |

| Chelyabinsk, EcoDom | st. Goncharenko, 81 | 8 (351) 959-82-96 | 2800 |

| Samara, Ecovanna | st. Avrory, d. 110K, of. 116. | 8 (846) 215-00-13, 8 (846)222-22-22 | 2600 |

| Nizhny Novgorod, Vanna-Service | Tonkinskaya st., 1 | 8 (831) 415-02-76 | 2800 |

| Izhevsk, IzhTeploLife | 8(341) 255-15-10 | 2500 | |

| Izhevsk, StroyTeh | st. Dzerzhinsky, d. 60. | 8 (341) 232-22-28 | 2100 |