- Scope of application

- Distinctive features

- Classification of pumps by type of construction

- Surface Models

- Submersible drainage devices

- Product classification

- The principle of operation of the drainage pump

- Drain pump selection criteria

- Characteristics of the pumped medium

- Materials used in manufacturing

- Type of circuit breaker

- Drain pump performance

- The pressure of the device for pumping water

- Outlet diameter

- Basic structural elements

- Which to choose?

- Drainage in the basement

Scope of application

The scope of drainage pumps is determined based on their design features:

- A series of prolonged rains, a spring flood or heavy snowmelt. Such a situation can lead to the fact that the storm sewer system will not fully cope with its intended purpose, which will result in the flooding of cellars, basements of buildings, basement floors, etc. In this case, installing a drainage pump in the basement will allow emergency drainage work .

- This unit can be installed on a stationary basis in the basement. A properly configured automation system will control the level of incoming groundwater and keep the room dry.

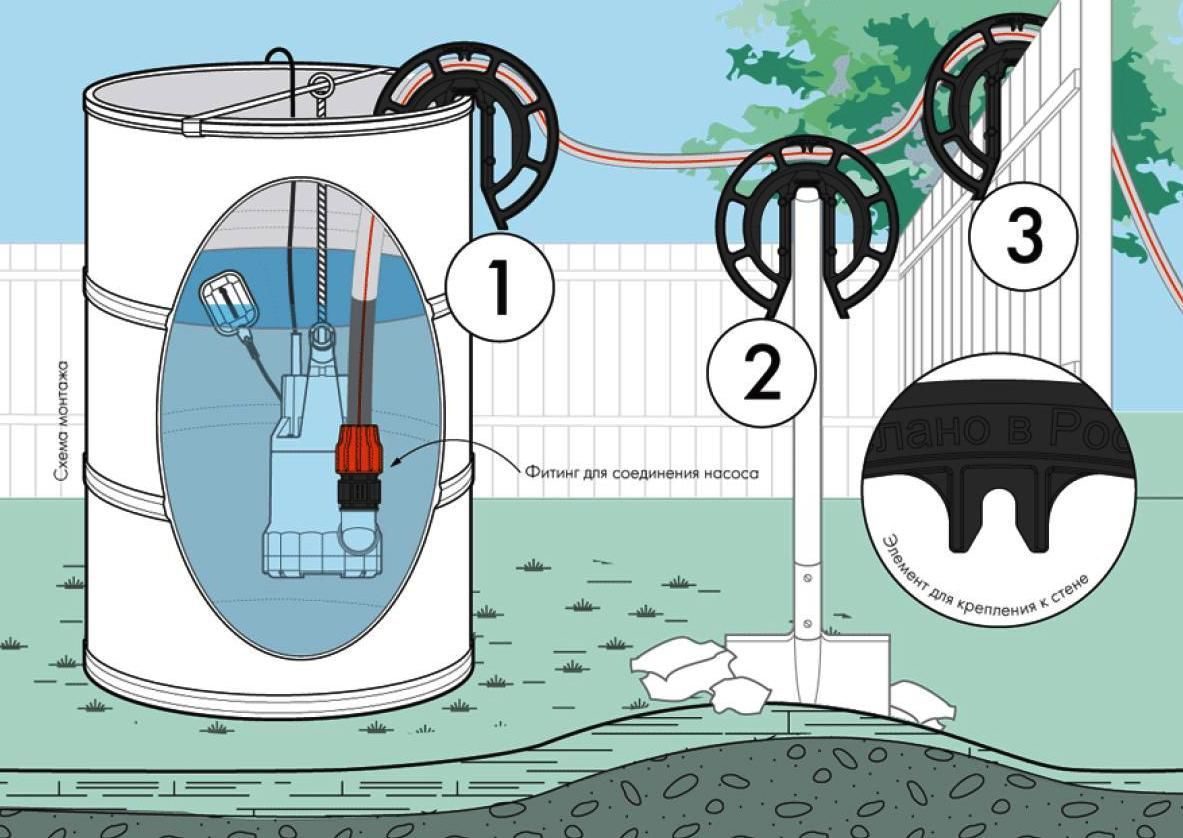

- Also, the installation of a drainage pump can be provided for servicing artificial reservoirs. Without this unit, it is impossible to maintain the required filling level in an artificial reservoir, to perform periodic drainage to replace and clean water.

- Accumulating tanks for drainage or domestic sewage, storm collectors. Provided that they do not provide for independent drainage of liquid.

- In addition, the installation of a drainage pump can be provided for discharging settled water into centralized collectors, natural reservoirs, filtration fields or pumping it into tanks for subsequent technological use.

- The current sanitary rules prohibit even small car washes and workshops from operating without local treatment facilities. Dirty water is collected in primary sewers and sumps, and then the sewage drain pump pumps it to the treatment plant tanks.

- These devices are actively used for irrigation agricultural work, they pump liquid from artificial and natural reservoirs to irrigated areas.

- This equipment is characterized by its versatility, it can be used not only for dirty, but also for clean water in autonomous water supply systems, filling high-lying containers.

Distinctive features

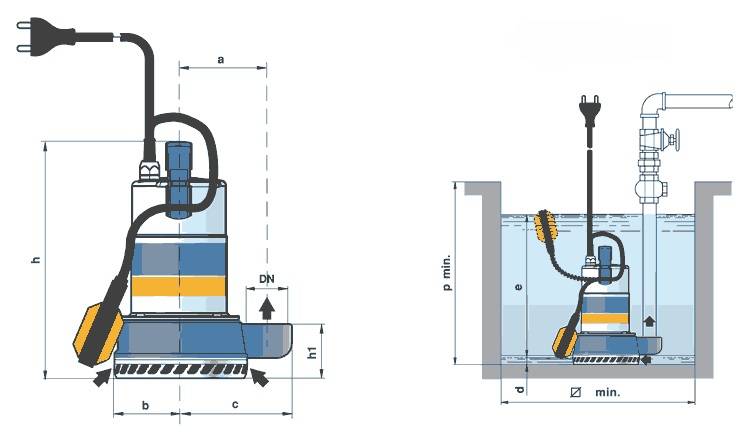

Drain pump device

Drain pump device

Sewer drains have different temperatures. The fecal pump is made in such a way that it can pump hot liquids without problems. Drainage is not designed for such work, therefore it cannot be installed instead of fecal. At the same time, the latter can be used in the drainage system.

Drainage pumps used in everyday life are mainly made of durable plastic. or stainless steel. Fecal models made of steel or cast iron. There is also a purely constructive difference between fecal and drainage pumps. It is based on the principle of operation of each device.

The drainage pump passes the pumped water through itself, so its electric motor is enclosed in a special sealed chamber so that the liquid does not get on the electrical part of the motor. In fecal models, a snail is installed, in which has a suction pipe, located at the bottom, and an outlet pipe located on the side of the apparatus. Inside the snail is an impeller with or without knives. The pumped contaminated liquid enters the volute chamber, where the impurities are broken by the impeller and knives and thrown sideways through the outlet pipe, which is connected to a pipe or hose.

The pump motor is located in its housing and is not protected by anything, because liquids do not pass through the unit. It is always dry. But to ensure its cooling, the design provides for a chamber filled with oil. It not only cools the motor, but also acts as a lubricant for the shaft and bearings.

There is also a price difference. Drainage pumps are cheaper than fecal pumps. For example, a pump of the Drainazhnik brand, with a capacity of 225 l / min, a liquid lifting height of 12 m, with a 590 W electric motor, costs 4300-4500 rubles. With almost the same technical characteristics, a fecal device costs 6300-6500 rubles.

Classification of pumps by type of construction

The variety of pumping equipment is divided into two categories: surface and submersible units.

Surface Models

Surface units are designed to be installed above the tank. The case of devices of this type is placed on a flat surface in a dry place. Water is pumped out through a sleeve lowered into the tank: a PVC pipe or a rubber hose.

Surface pumps are mobile and easy to operate: it is convenient to carry them around the site, installing them in the right place temporarily or permanently

Any model of surface execution has two pipes:

- input - ensures the flow of wastewater from a filled tank;

- output - diverts effluents outside the devastated structure.

Such devices can operate automatically. To implement automatic operation, a float mechanism is attached to the toggle switch, which reacts to the liquid level in the tank.

It is immersed in the pumped liquid along with the hose. When the water rises above a certain mark, the float sensors are triggered, which controls the start of the pump.

The main advantages of submersible units are:

- ease of installation and dismantling;

- maintenance of the device is reduced only to timely cleaning and lubrication of parts.

But such aggregates are not suitable for deep sources. They are designed to work at a suction height in the range of 8-12 m.

It should also be borne in mind that when connecting such a pump to the sewer system, you need to know exactly the cross section of the pipeline, since the unit is connected to it using pipes.

Image gallery

Photo from

Emergency drains

Pump float switch

Durable fiberglass body

Connecting the water supply pipe

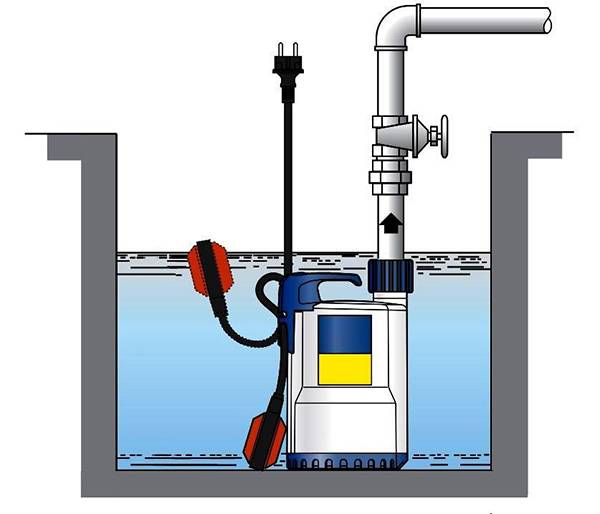

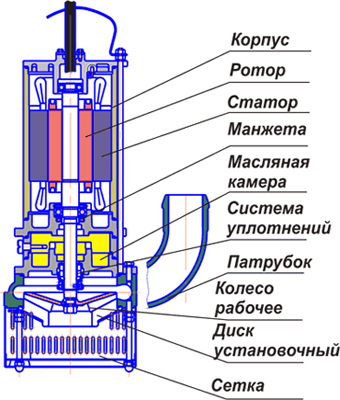

Submersible drainage devices

Immersion instruments operate in much the same way as surface drainage pumps are also working. But they are more designed for pumping water from deep trenches or cleaning wells.

Wastewater is pumped by the pump itself without the use of hoses and nozzles. The mesh filter located at the bottom of the pump protects the elements of the unit from hard ground, sand and insoluble particles.

Maximum immersion depth pumps for different models usually do not exceed 50 m. But they cannot be used when emptying shallow reservoirs and reservoirs, the depth of which does not reach 20 m. To be able to operate submersible devices in shallow trenches, it is necessary to apply additional engine cooling with water.

Submersible units are installed on the bottom of the tank, and water is sucked directly through the grate located in the lower part of the body

The installation depth of the unit depends on the type of tank. But there is a simple pattern: the lower the submersible pump is located, the easier it will be to work with it.

Among the main advantages of submersible devices, it is worth highlighting:

- high power and productivity in comparison with surface units;

- the possibility of draining deep reservoirs of several tens of meters;

- quiet running - the units immersed in the tank during operation practically do not produce noise.

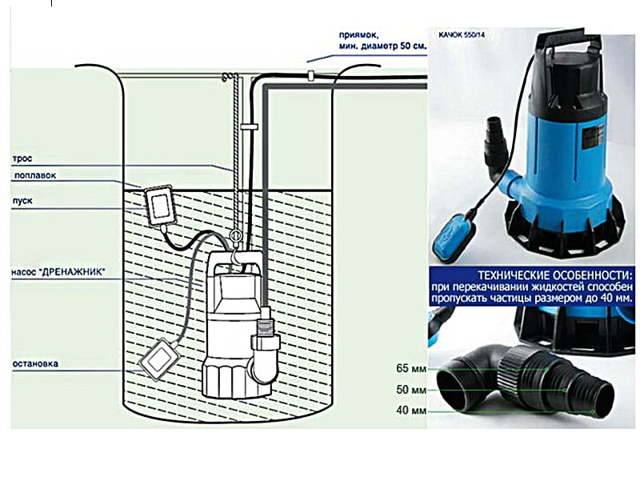

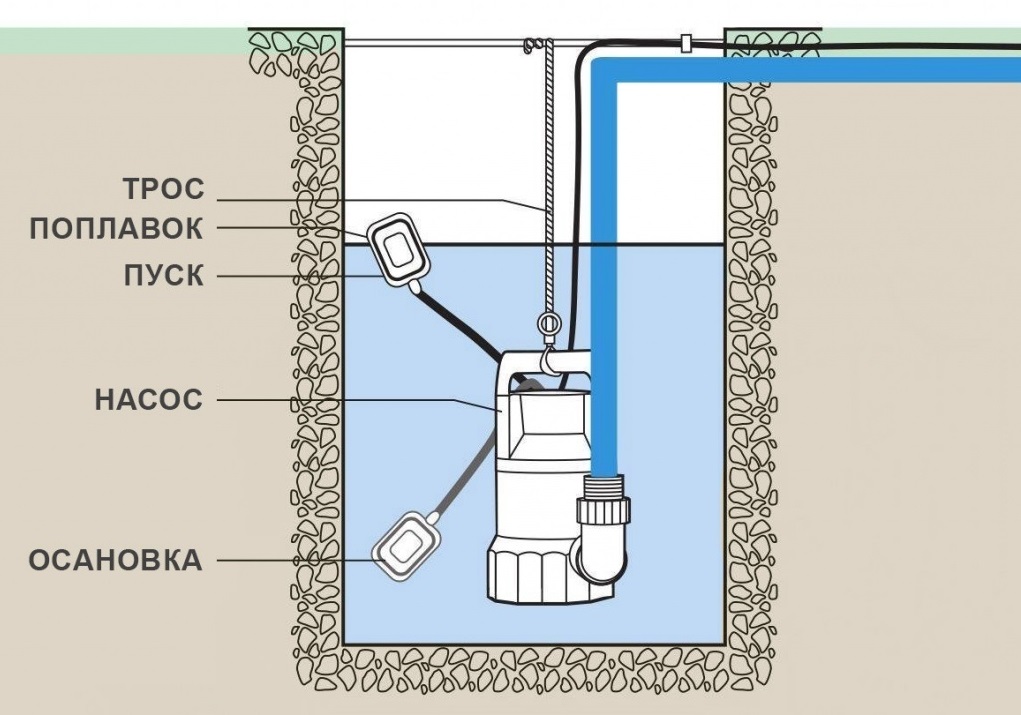

A feature of installations of this type is that they work automatically. Equipping the device with a float mechanism or a plastic bubble ensures uninterrupted operation of the pump in automatic mode.It turns off the pump motor when the set water level is reached.

The presence of a float switch is especially important when it is necessary to pump out liquid from slowly filled tanks.

The constant operation of the device under water requires reliable isolation of the automation and sealing of the electric motors of the device. Therefore, in the manufacture of submersible units, only corrosion-resistant materials are used that are able to withstand mechanical damage.

The material of manufacture for key parts, depending on the purpose and perceived loads, can be:

- polymers and engineering plastics;

- electrical, alloyed and carbon alloys and steels.

In expensive models, seals made of ceramic cuffs or with an oil lock are used to seal the electric motor of the device.

The only disadvantage of submersible devices is that for maintenance and drain pump repair, it has to be removed from the tank to the surface. And due to the tightness of the case, they are quite problematic to maintain and repair.

Product classification

There are two main types:

- Submersible;

- Surface.

The first are installed in the pool, sump. There are no specialized pipes (hoses). Water is pumped into a specially prepared tank. Moisture goes through the small hole of the drain pump. For this, products are equipped with specialized filters that are capable of passing only fractions of a certain size.

Surface products have a significant difference. Installation is carried out next to the pits, as well as wells. Water goes through special hoses.Models with liquid level control available. They are equipped with a special float. There are products without a switch, they work exclusively stationary.

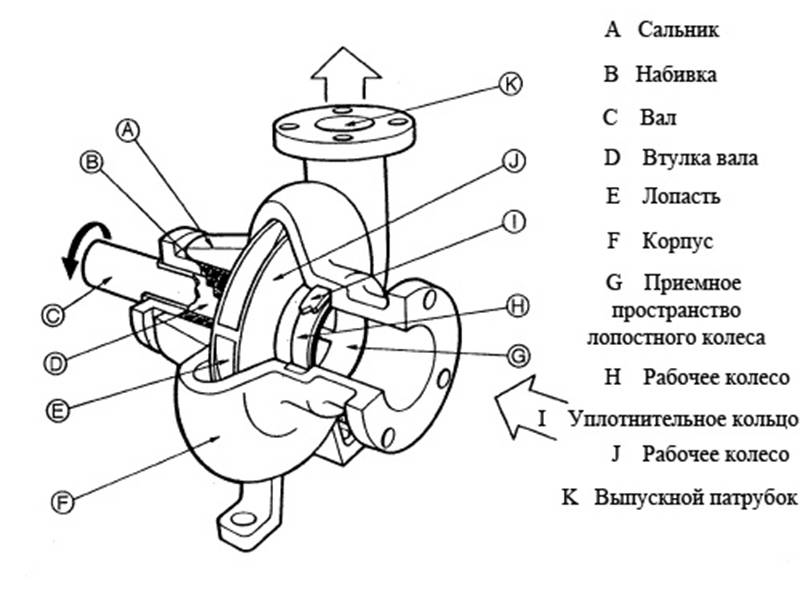

The principle of operation of the drainage pump

The drain pump works on a very simple principle. Immediately after connecting the unit to the mains, the engine starts, which drives the shaft with blades. Water under high pressure enters the device through the suction pipe, after which the blades act on it. The latter push the liquid through the pump assembly into the discharge pipe. From there, the water is pushed out into the outlet pipe.

The drain pump works on a very simple principle. Immediately after connecting the unit to the mains, the engine starts, which drives the shaft with blades. Water under high pressure enters the device through the suction pipe, after which the blades act on it. The latter push the liquid through the pump assembly into the discharge pipe. From there, the water is pushed out into the outlet pipe.

For more efficient operation of the pump, the water must contain a minimum of solid particles. It is possible to use the unit for sewage in a private house only if the diameter of the fractions in the composition of the water does not exceed 1.2 cm.

The immersion depth of the drainage device is also of great importance. In practice, the shallower the depth, the better, because in extreme cases it will be easier to pull out the equipment and fix the problem in a timely manner.

Drain pump selection criteria

Considering how choose a drain pump it is important to pay attention to some important parameters that are responsible for the compliance of the functionality of this equipment with the declared requirements of the system.

Characteristics of the pumped medium

Before proceeding with the selection of the necessary model for pumping water, you need to understand what kind of liquid medium is to be pumped. Ideally, there should be no gravel, sand or dirt. In practice, they are used in flooded rooms, reservoirs and reservoirs. The accompanying documentation for each model describes the allowable solids values.

According to this indicator, they are divided into varieties:

- pumping water with fragments up to 5 mm;

- transportation of medium contaminated liquid with possible fractions up to 25 mm;

- for more polluted environments with possible fragments up to 38 mm.

In addition, it is important to take into account the temperature of the transported substance and its chemical composition. Indeed, for operation with aggressive components, it will be necessary to select drainage pumps with special technical abilities.

Materials used in manufacturing

The materials used determine the degree of reliability of the entire structure. Housing units for pumping water can be made of metal or durable plastic:

- Metal products are characterized by increased strength, provide more opportunities for the use of repair operations to restore functionality. This allows you to extend their service life.

- Durable plastic keeps the overall cost of equipment down, which is considered attractive to the average person.

No less important is the type of material for the production of working parts of drainage pumps for dirty water, namely the blades of a rotating element. They are made of stainless alloys and polymers with unique capabilities.

It is considered the best, high-quality polymer, it is able to be used under heavy loads. However, these items are not repairable. Stainless steel is much cheaper, it wears faster.

Type of circuit breaker

Basically, drainage pumps are equipped with automatic switches that can turn on the mechanism when the liquid reaches the required level.

They may look like:

- electronic special device, which is an expensive node;

- devices using a float, considered a cheaper alternative.

All of them work to stop the flow of water, turning off the electric motor, thereby protecting it from overheating.

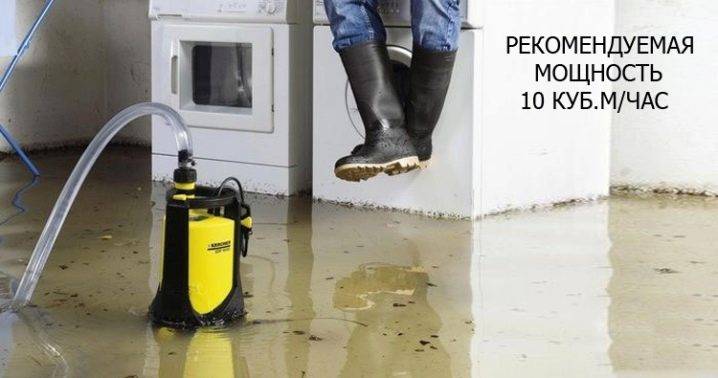

Drain pump performance

This concept denotes the volume of a substance transported during a fixed time period:

- to meet the needs of everyday life, an indicator of approximately 10 m³ / h is enough;

- for professional use, more powerful devices are selected with an indicator of more than 100 m³ / h.

This is an important indicator, it is indicated in the attached documents.

The pressure of the device for pumping water

Average drainage pumps give out a jet of 5-50 meters:

- this indicator depends on the type of pumping equipment used, it indicates the permissible lifting height and the distance of its movement on a horizontal surface;

- this is an important performance characteristic indicated in the accompanying documentation;

- as a rule, it is calculated in a ratio of 1:10;

- if the lifting height is specified as 6 meters, then the horizontal withdrawal distance is equal to 60 m.

Naturally, this characteristic will be influenced by the diameter of the hose for transporting the liquid. For a domestic appliance, a lifting height of several meters exceeding the depth of the storage tank will be quite enough. It is always necessary to calculate this indicator with a margin.

Outlet diameter

To increase the efficiency of the device, you need to choose the right hose diameter:

- when transporting water, you will need a diameter in the range of 0.5-1.5 inches;

- if a contaminated liquid medium is to be pumped, a pipe with a diameter of at least 8 inches will be required;

- in addition, there are pipes for connecting in a horizontal or vertical plane.

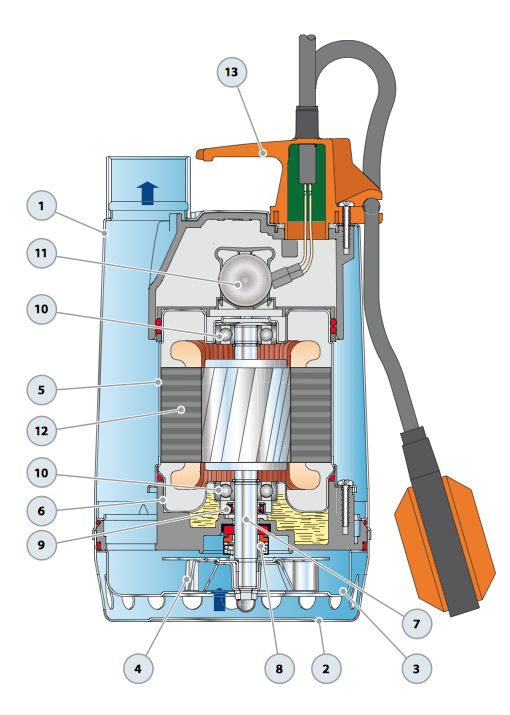

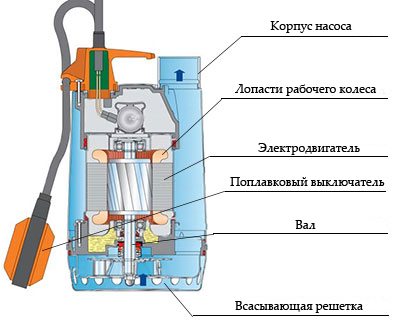

Basic structural elements

In a simplified form, the design of the device in question consists of:

- Electric motor. Pumping water requires energy, which is converted into mechanical energy by means of an electric motor. The electric motor is the main structural element, classified by power and design features. There are models on sale that have an electric motor power rating in the range from 1 to 20 kW and above.

- Shaft with impeller. The most widely used models are centrifugal-vortex type. A similar pump model has a wheel with an impeller as a moving element. At the same time, we note that the wheel itself can be located directly on the motor shaft or in a special chamber. With a remote location of the wheel with an impeller, an intermediate element is also included in the design.

- A pump assembly with a suction pipe. In order for groundwater to be able to enter the pumping system, the pump is connected to a pipe that descends into a flooded area or reservoir.

- Often, a grinder is installed at the inlet, which allows you to increase the protection of the device from the effects of large impurities. The wheel impeller is made of soft and light material, which makes it less resistant to large impurities.If there are a lot of large particles in the water, and they will not be crushed, then the impeller can be deformed; with a large number of revolutions, even an insignificant deviation from the normal shape will cause increased wear of the entire mechanism.

- Frame. In order to significantly extend the life of the pump, its main elements should be protected from environmental influences. In its manufacture, plastic or stainless steel, as well as cast iron, can be used. It should be borne in mind that plastic is more resistant to environmental influences and has a relatively small weight. All models with an increased mobility indicator are made of plastic, but it should be borne in mind that this material has low strength.

- Float type switch. Idling can cause increased wear on the structure. That is why a float switch is installed, which can automatically turn off the device depending on the water level.

In addition, the design of the pump may have additional elements, it all depends on the specific purpose of the device.

Which to choose?

The selection of drainage pumps is based on operating conditions

To purchase equipment that meets all requirements, you should pay attention to several indicators

Although drainers perform well, their operation can be difficult if there are solid particles in the pumped liquid. Given this quality, we can conclude that the pump is ideal for pumping fluid from flooded premises.

When calculating the required power, you need to use the following formulas: the required power of one meter of depth is identical to ten meters in the horizontal plane. For example, to pump out liquid from a pit, the depth of which is 50 meters, you should prepare a hose 50 meters long. It should be borne in mind that the pumping speed will be small, since there is a length of the outlet running along the soil. If, with correct calculations, there is still a small pressure, you will need to add a length of three meters

Efficiency indicators directly depend on the power level, so you should pay attention to this factor

Choosing the right model depends on several factors.

First of all, you should pay attention to the installation location. Experts advise installing a hand pump without a float in a small recess (about 0.5 meters)

This step eliminates the leakage of liquid to the surface. If automatic equipment is used, the floor will always remain dry, as automation is considered the most reliable system. If the installation site has a length and width of more than 50 cm, any float pump can be used. If complete draining of the tank is required, the use of surface products without a float is allowed.

The service life of drainage pumps depends on the material from which the parts are made. The body part can be plastic or metal. The first models are distinguished by a lower cost, but plastic does not have a sufficient level of resistance to mechanical stress.Therefore, the plastic case can be deformed and cracked. Experts recommend purchasing products with a metal case, as they have sufficient strength and can be repaired. Pumps made of stainless steel and cast iron have the longest service life.

Equipment blades can be made of stainless steel or special technical polymers. The latter option is considered optimal, since special impurities are present in the polymers, due to which the parts become resistant to aggressive influences. But such parts cannot be repaired.

Most modern models are equipped with automation, which starts the mechanism when a certain liquid level is reached. There are the following devices:

- Electronic built-in. They are complex and expensive components that operate on the basis of an electronic control unit.

- Float. These are simple and reliable elements.

Automated switches of both types do not allow the operation of the device "dry", therefore, provide smooth operation.

Performance refers to the amount of liquid in cubic meters that the pump pumps in 60 minutes. The efficiency is indicated in the technical data sheet for the pump. To determine the required performance for the job, you will need to divide the volume of the pumped tank by the expected period of work.

The pressure depends on the type of pump and is 5-50 m. Consider the distance over which the liquid is drained and the height of the pumped water. All characteristics are prescribed in the technical data sheet and are indicated in a ratio of 1: 10.

If the technical documentation indicates that the pump is capable of lifting water to a height of five meters, then the transfer of fluid can be carried out to a length equal to 50 meters. These are average figures that do not take into account other characteristics (for example, hose diameter).

To ensure maximum efficiency of the pump, you will need to choose the right size of the nozzles. For pumping water fit models with a small diameter of 0.5-1.5 inches. For contact with contaminated liquid, choose a diameter of 8 inches or more.

On sale there are branch pipes in vertical or horizontal execution

You should also pay attention to the diameter of the hose, which must match the nozzle. Portable and lightweight products suitable for domestic use

They are characterized by mobility and ease of use.

Drainage in the basement

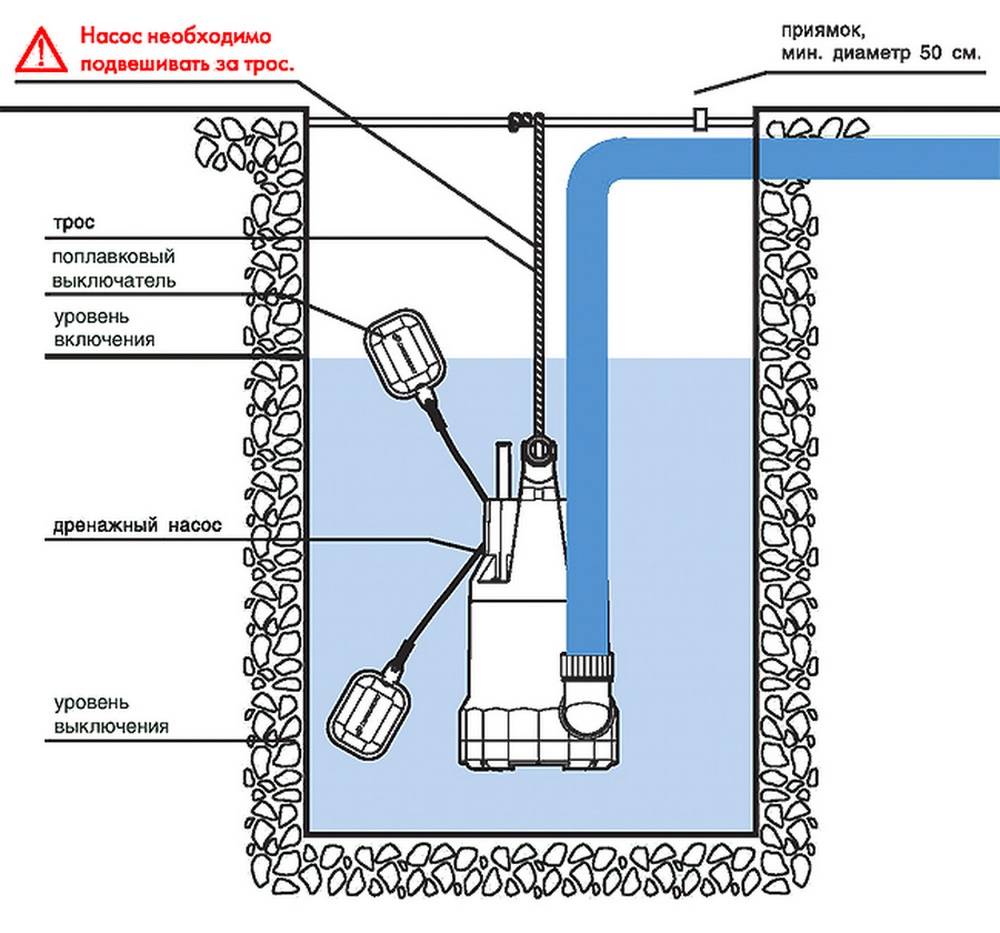

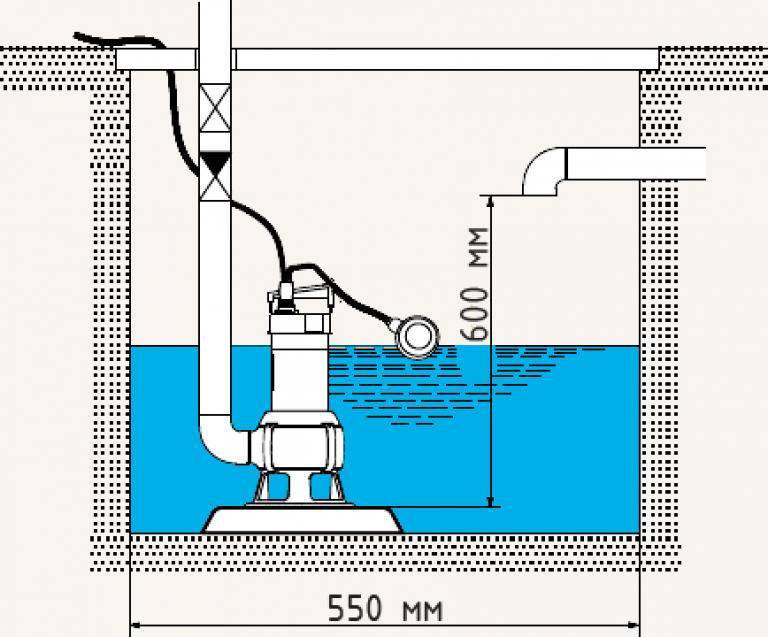

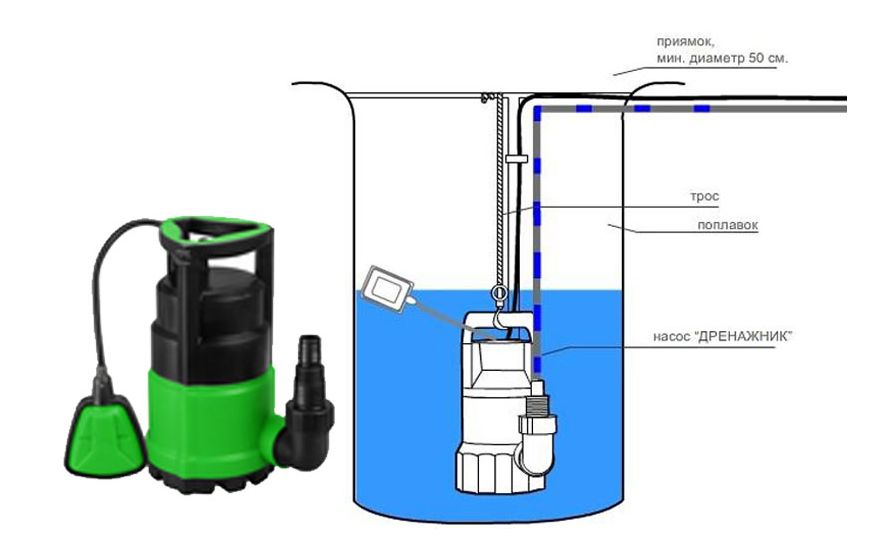

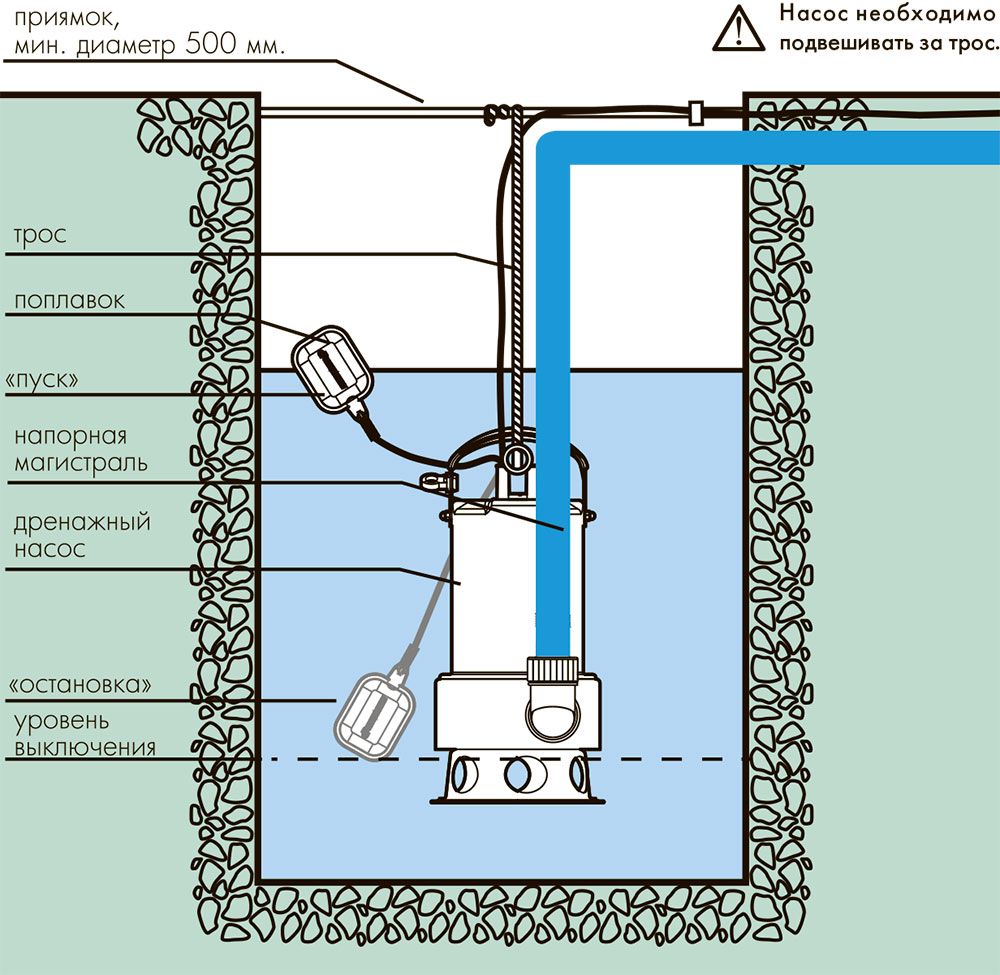

One of the possible solutions to the issue of protection from water in the basement is a drainage device or a slope with a pit for installing a drainage pump. It is preferable to carry out work at the lowest possible level of groundwater

For basements with earthen floors, a drainage system is recommended - a network of drainage pipes located around the perimeter of the room. For its device, it will be necessary to dig a trench (depth of about 0.5 m) along the perimeter of the basement. The bottom of the trench is carefully tamped and covered with crushed stone or gravel to a height of 15-20 cm. We lay drainage pipes on top of the layer (perforated pipes, preferably with a geotextile coating). Pipes are laid with a slope towards a pit or drainage well. Slope - approximately 3 mm per linear meter of length.

We fill the laid pipes with crushed stone or gravel to the floor level.A prefabricated pit or well is installed at a low point. A well is made of monolithic reinforced concrete or ready-made wells made of PVC pipes are used. We install a drainage pump in the well, which is controlled by a float.

In the event that wooden floors are arranged in the basement on top of the earthen floor, they should first be removed.

In addition to the drainage device, it is possible to waterproof the bottom of the basement.

We carry out waterproofing as follows: For a pit device, it is easiest to use a pipe D = 0.5 m, which allows you to install a drainage pump with

The bottom of the pipe must be closed, for example with concrete, with a layer of 5 - 10 mm with a rammer. The pipe is installed in the prepared pit, after installing the pipe, the space around is filled with crushed stone. The top of the pipe should be at floor level. For safety, we close the pipe with a grate, finished or welded from reinforcement. To pit a pit in an existing concrete floor, the concrete will have to be broken in the right place, a pit dug and a pit made of concrete with low water permeability.