- Compressor stations

- Sequence and installation rules

- Types of systems

- What determines the choice of communications

- Features of choosing the type of gas pipeline

- Which way to choose: underground or above ground?

- Trench for gas pipeline

- Laying gas pipelines indoors

- When the gasification project is ready

- Selecting a contractor and concluding a contract

- Commissioning of the gas pipeline

- Starting and setting up the system

- Underground highways

- Technology of laying underground highways

- Laying a gas pipe underground: technology, GOST, video

- Advice on laying

- Distinctive features of the product

- Rules for the placement of sewerage wells

- Stages of transit laying of the gas pipeline

- Polymer gas lines

- Features of plastic structures

- Pipe restrictions

Compressor stations

Compressor stations are needed to maintain the pressure level and transport the required volume of gas through the pipeline. There, the gas undergoes purification from foreign substances, dehumidification, pressurization and cooling. After processing, the gas under a certain pressure returns to the gas pipeline.

Compressor stations, along with gas distribution stations and points, are included in the complex of surface structures of the main gas pipeline.

Compressor units are transported to the construction site in the form of blocks completely ready for assembly. They are built at a distance of about 125 kilometers from each other.

The compressor complex includes:

Compressor station of main gas pipelines

Compressor station of main gas pipelines

- the station itself

- repair and maintenance and service and maintenance units;

- the area where the dust collectors are located;

- cooling tower;

- water container;

- oil economy;

- gas-cooled devices, etc.

A residential settlement is usually erected next to the compression plant.

Such stations are considered a separate type of man-made impact on the natural environment. Studies have shown that the concentration of nitrogen oxide in the air on the territory of compressor installations exceeds the maximum allowable level.

They are also a powerful source of noise. Scientists have found that prolonged exposure to noise from the compressor station causes disturbances in the human body, and, as a result, causes various diseases and can lead to disability. In addition, noise forces animals and birds to move to new habitats, which leads to their overcrowding and a decrease in the productivity of hunting grounds.

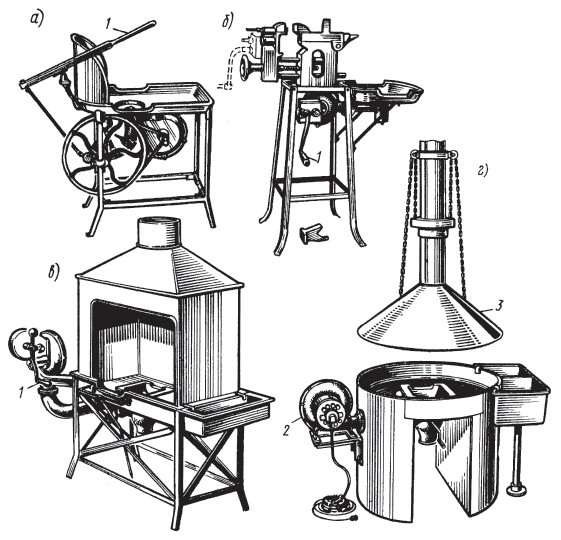

Safety system installation unit

Safety system installation unit

Sequence and installation rules

Installation work should be carried out according to the following rules:

- When laying underground gas pipes, the optimal depth is 1.25 - 2 m.

- At the site where the pipe enters the house, the depth should be reduced to 0.75 - 1.25 m.

- Liquefied gas can be transported at a depth below the freezing depth of the soil.

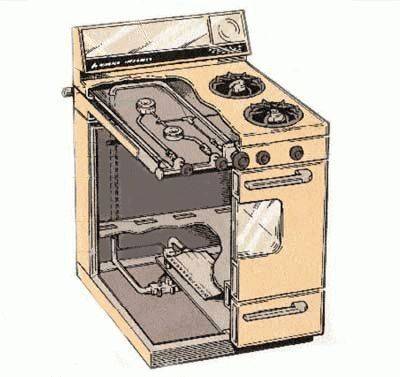

- When installing a gas boiler, it should be noted that one piece of equipment must have a room area of 7.5 m2.

- For the installation of boilers and columns with a capacity of less than 60 kW, rooms of at least 2.4 m will be required.

An autonomous source of gas in the backyard is carried out in accordance with specific safety standards. This will guarantee the normal functioning of the stove, column and boiler. An underground tank should be located no closer than 15 m from the well, 7 m from outbuildings, and 10 m from the house. The most popular types of such tanks are tanks with a volume of 2.7 - 6.4 m3.

Rules for laying underground gas pipelines:

- What pipes are used for the gas pipeline in this case? With a positive result of the study of soil for corrosion, it is better to refrain from laying underground communications. The exception is situations when high-voltage lines pass nearby: in this case, the pipes are laid underground using additional insulation.

- If a polyethylene pipeline is laid, high-strength products (PE-80, PE-100) are used for this. PE-80 pipes are able to withstand operating pressures up to 0.6 MPa: if this figure is higher, it is better to use PE-100 products or steel pipes for a high-pressure gas pipeline. The depth of penetration into the ground is at least one meter.

- Communications with a working pressure above 0.6 MPa are allowed to be equipped with reinforced polyethylene pipes. The requirements for the depth of the bookmark here are also from one meter.

- In areas where arable work or abundant irrigation will be carried out, the depth of laying the gas pipeline is increased to 1.2 m.

If you adhere to all the above requirements and rules, the arrangement of an underground gas pipeline can be done with your own hands.

Types of systems

I classify highways intended for the supply of "blue fuel" according to several criteria:

- type of gas (SUG, natural);

- the number of pressure control stages (single or multi-stage);

- structures (dead-end, ring, mixed).

Mostly natural gas is supplied to settlements for use by owners of houses and apartments. LPG (liquefied) is rarely transported by highways. In most cases, it is pumped into cylinders. LPG is supplied through pipes only if there is a reservoir plant or a regasification station in the settlement.

In cities and large towns, a multi-stage distribution gas pipeline is usually laid. The assembly of a single-stage low pressure is very expensive. Therefore, it is advisable to mount such systems only in small villages. When assembling multistage gas pipelines, regulatory points are installed between branches of different pressure.

What determines the choice of communications

A special commission is responsible for the project of the new gas pipeline, which determines the route of the pipeline, the method of its construction, and the points for the construction of the GDS.

When choosing a laying method, the following criteria are taken into account:

- population of the territory where it is planned to stretch the gas pipeline;

- the presence on the territory of already extended underground utilities;

- type of soil, type and condition of coatings;

- characteristics of the consumer - industrial or household;

- the possibilities of various kinds of resources - natural, technical, material, human.

An underground laying is considered preferable, which reduces the risk of accidental damage to pipes and provides a stable temperature regime.It is this type that is practiced more often if it is necessary to supply gas to residential areas or detached buildings.

At industrial enterprises, highways are carried out above ground - on specially installed supports, along the walls. Open laying is also observed inside the buildings.

In rare cases, gas pipes are allowed to be masked under a concrete floor - in laboratories, places of public catering or public services. For safety reasons, the gas pipeline is placed in anti-corrosion insulation, poured with cement mortar, and placed in reliable cases at the exit points to ensure stability.

Features of choosing the type of gas pipeline

Before the construction of the highway, you should decide on the best option that is suitable for specific conditions, and familiarize yourself with the rules for laying it. Since all this affects financial costs, efficiency and labor costs.

Since, first of all, the gas pipeline must be reliable, when choosing an option, it is necessary to take into account such points as:

- corrosive activity of soils;

- building density;

- the presence of stray currents;

- terrain features;

- type of road surface, if the gas pipeline will cross it;

- entrance width;

- the presence of water barriers and many others.

In addition, it is necessary to determine the type of gas that will be supplied. And also its quantity - volumes should be enough to meet the needs of all consumers.

To avoid associated risks, as well as unnecessary financial expenses, the laying of any gas pipeline should begin with special calculations, the result of which will be the creation of a project

Consideration should also be given to the security of supply.In view of this, it should be remembered that a ring gas pipeline is preferable to a dead-end or mixed one. For example, if gas is supplied to the so-called non-switchable consumer, then the specified option should be chosen.

All of the above points cannot be ignored - each of them is indicated in the documents regulating issues related to the laying of gas pipelines. Among which are SP 62.13330.2011 and others.

Also, we must not forget that the construction and modernization of any gas pipelines must be carried out in accordance with gas supply schemes. Which are developed at various levels - from federal to regional.

Therefore, before starting the design, the owner of the building, the premises must:

- obtain a permit for gasification in the city, district architectural and design department;

- apply in writing to the local gorgaz (raygaz) in order to obtain the so-called technical assignment, which is a set of information necessary for the creation of a gas pipeline.

And only after that it is allowed to start designing. Which ends with the agreement in Gorgaz (Reigaz).

Only after that it will be possible to start laying the gas pipeline. Which, by readiness, should provide consumers with fuel in the required quantity and be safe.

We described the subtleties of laying a gas pipeline to a private house in the next publication.

The place of laying the gas pipeline must be fenced off and marked with special signs. Moreover, this rule is relevant for all cases. This is done to ensure safety.

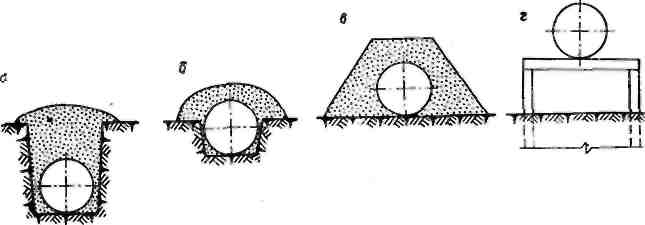

Which way to choose: underground or above ground?

The choice of laying method depends on the specific case, namely: on the characteristics of the soil, climatic conditions, built-up area, etc. Therefore, it is impossible to give an unambiguous answer to this question.

Consider the main tips for choosing the method of laying gas pipelines:

- if the soil at the site has a high corrosion coefficient, then it is recommended to carry out the gas pipeline by the above-ground method.

- if there is a high-voltage power line near the site where the installation work will take place, the pipes are laid underground.

- if the gas pipeline is supposed to be laid on the territory of neighboring sections, then it should be done in an open way (aerial).

- in addition, if the gas pipeline is to be laid through the auto canvas, it is advisable to choose a combined pipe installation option. The combined option includes: underground laying under the roadbed and aboveground along the territory of the site. Thus, an optimal solution to the problem is obtained.

In most cases, an underground method of laying pipes is used to protect the pipeline from the effects of various negative factors.

Depending on which of the methods of installation of gas pipeline communications will be carried out, pipes from various materials are used. There are two types of gas pipes according to the material of manufacture:

- steel;

- polyethylene (PE);

Steel pipes are versatile - they can be used for any laying (aboveground and underground), but modern polyethylene products are used for underground installation of gas pipelines. This is due to the fact that polyethylene has poor resistance to ultraviolet radiation.Under the influence of ultraviolet rays, polyethylene loses its properties and is destroyed

However, it has a number of useful advantages that are worth paying attention to.

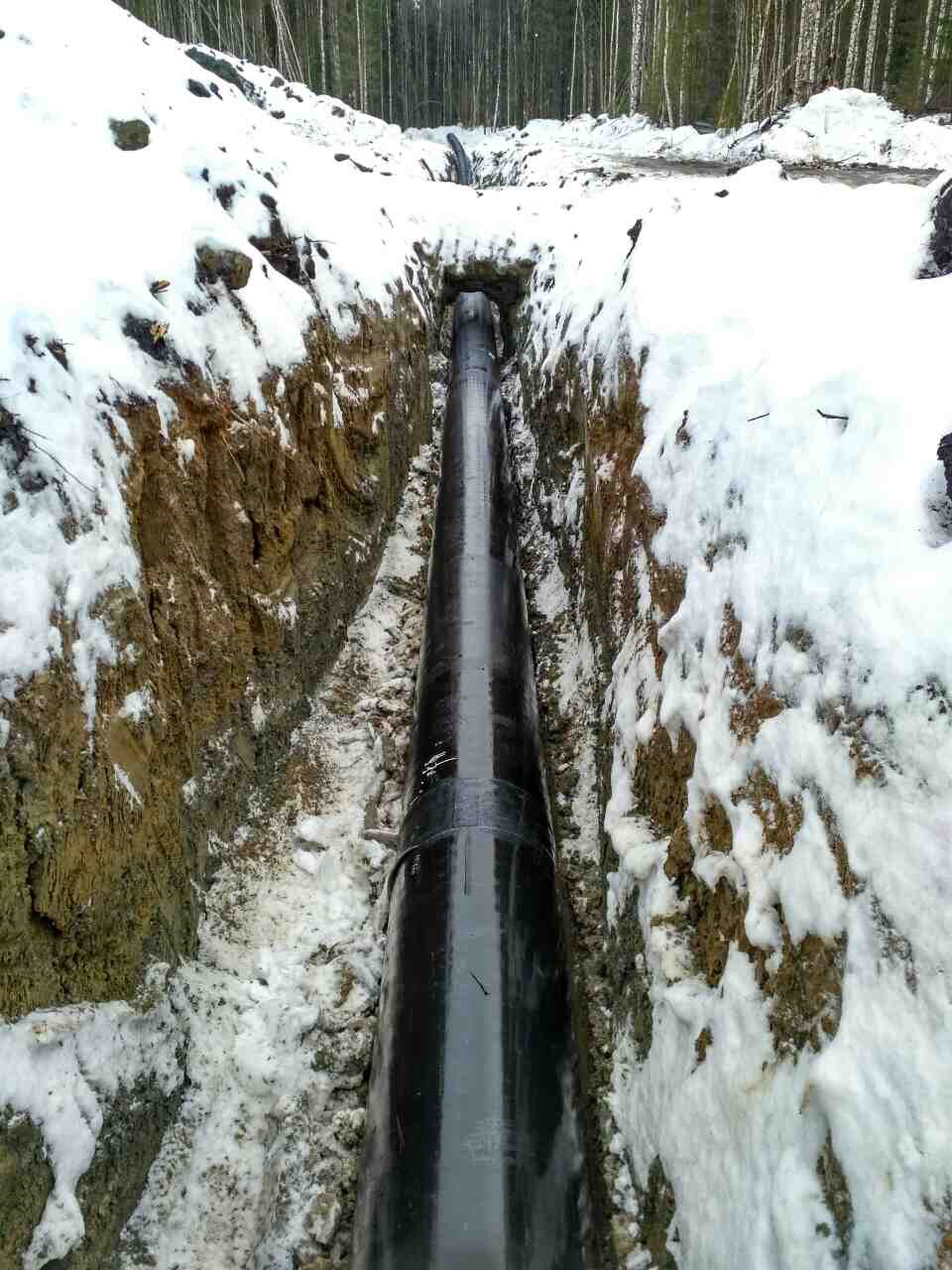

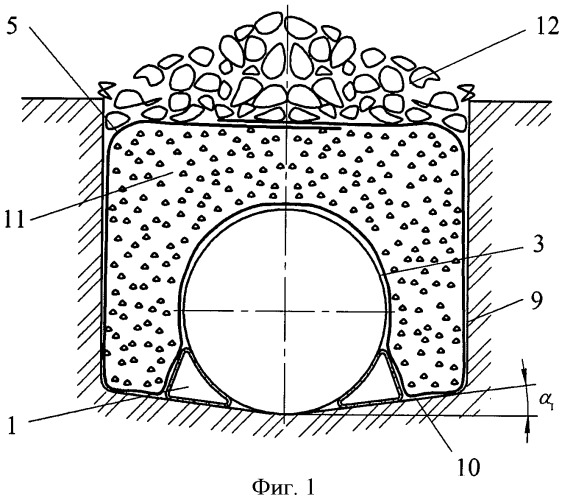

Trench for gas pipeline

The depth of laying (laying) of a low-pressure gas pipeline is determined by the regulatory document “SNiP 42-01-2002. Gas distribution systems” and is described in paragraph 5.2 as follows:

Laying of low-pressure gas pipelines should be carried out at a depth of at least 0.8 m to the top of the gas pipeline or case. In places where the movement of vehicles and agricultural machines is not provided, the depth of laying low-pressure steel gas pipelines can be at least 0.6 m.

When crossing or passing the gas pipeline communication under roads and other places of movement of vehicles, the laying depth must be at least 1.5 meters, to the top point of the gas pipeline, or its case.

Accordingly, the depth of the trench for the gas pipeline is calculated according to the following formula: the diameter of the gas pipeline + the thickness of the case + 0.8 meters, and when crossing the road - the diameter of the gas pipeline + the thickness of the case + 1.5 meters.

When a low-pressure gas pipeline crosses a railway, the laying depth of the gas pipeline from the bottom of the rail or the top of the road surface, and if there is an embankment, from its bottom to the top of the case, must meet safety requirements, but be at least:

in the production of works in an open way - 1.0 m;

when performing work by punching or directional drilling and shield penetration - 1.5 m;

in the production of work by the puncture method - 2.5 m.

When crossing other communications with a low-pressure gas pipeline - water pipelines, high-voltage cables, sewerage and other gas pipelines, it will be necessary to go deeper below these communications in the place where they pass, by at least 0.5 meters, or you can go above them if they lie at a depth of at least 1.7 meters.

The depth of laying low-pressure gas pipelines in soils of varying degrees of heaving, as well as in bulk soils, should be taken up to the top of the pipe - at least 0.9 of the standard freezing depth, but not less than 1.0 m.

With uniform heaving of soils, the depth of laying the gas pipeline to the top of the pipe should be:

not less than 0.7 of the standard freezing depth, but not less than 0.9 m for medium heaving soils;

not less than 0.8 of the standard freezing depth, but not less than 1.0 m for heavily and excessively heaving soils.

Laying gas pipelines indoors

In this case, certain safety standards must also be observed. Transit laying of the gas pipeline inside the buildings along the outer surfaces of the walls at a height of at least 1.5 meters from the floor is being carried out. Sometimes pipes are pulled in channels covered with shields. At the same time, according to the regulations, the latter should be easily removable. Gas pipelines are laid through walls or ceilings in metal sleeves insulated with non-combustible material.

According to the regulations, it is forbidden to pull pipes:

- on door and window frames;

- transoms;

- platbands.

Wooden walls before installing gas equipment next to them must be insulated with asbestos-cement sheets. All joints of the internal gas pipeline are connected by a welded method. Detachable is allowed to make only connections in the places of installation of stop valves.

For the assembly of internal systems, steel pipes are usually used. But sometimes copper is also used for this purpose. It is not allowed to use such highways only for LPG transportation.

The connection of the internal transit gas pipeline to the external one and its assembly must be carried out according to the standards only by specialists of a licensed company. After the installation of the system, it is tested and accepted with the signing of the relevant document.

When the gasification project is ready

A prerequisite for the transition from the design stage to construction and installation work is the coordination of the project with the technical department of the gas service. This procedure is usually completed within 2 weeks.

Selecting a contractor and concluding a contract

After approval, the project must be accompanied by:

- estimate for the performance of the work provided for by the project;

- agreement on technical supervision;

- an act on the inspection of smoke ventilation channels, drawn up and signed by a representative of the VDPO service.

When the entire list of necessary documents is in hand, you can proceed to the arrangement. As a rule, any design organization has a license for construction and installation work. If such a license is not available, you will have to take care of finding a contractor.

Since it is the installation organization that will be responsible for the construction and commissioning of the gas pipeline, it is desirable:

- check the license for gasification;

- see other permits;

- make sure that employees have the appropriate permissions.

Before concluding a contract, it is necessary to agree and approve the terms of installation, which should be fixed in the contract.

When performing installation, fire extinguishing equipment designed for fires of class "C" (burning gases) must be at hand

In the agreement for the performance of work, in addition to other obligations, the following conditions must be fixed:

- the employees of the organization working at the facility have a protective screen that protects the walls from heating, and all the necessary fire extinguishing equipment;

- issuance of executive technical documents to the customer immediately after the execution of calculations for the work provided for in the project;

- the obligation of the contractor to complete the installation within the agreed time, in accordance with the established standards and the required level of quality;

- the obligation of the contractor to timely draw up all the prescribed executive and technical documentation.

The contractor must provide the customer with the specified documents after the installation work has been completed, before the visit by the commission for the acceptance and delivery of the object.

Commissioning of the gas pipeline

The delivery of the finished gas pipeline is carried out in the presence of a commission, which includes representatives of the contractor, the gas service and the customer himself. During the acceptance process, it is necessary to check the availability of all equipment provided for by the project, the correctness of its installation and connection.

The commission accepts works from 2 weeks to a month. If no deficiencies are identified, the representative of the gas service issues a receipt for payment, which the customer pays, and transfers a copy of the document to the contractor.

After acceptance of the finished gas pipeline, the system meter must be sealed in the presence of the customer

The contractor transfers all technical documentation to the gas service, where it is stored for the entire period of operation.According to the results of the commission's work, the gas service must seal the meter within 3 weeks, after which the system is considered ready for gas supply.

The agreement with Gorgaz regulates the maintenance of the system, for which this service will be responsible. It is the basis for the gas supply.

In addition to the conclusion of the contract, you will need to undergo a safety briefing. It is carried out at the company's office or at the place of residence by a specialist with the appropriate clearance. In any case, after the briefing, the customer must confirm the completed briefing with a signature in the logbook.

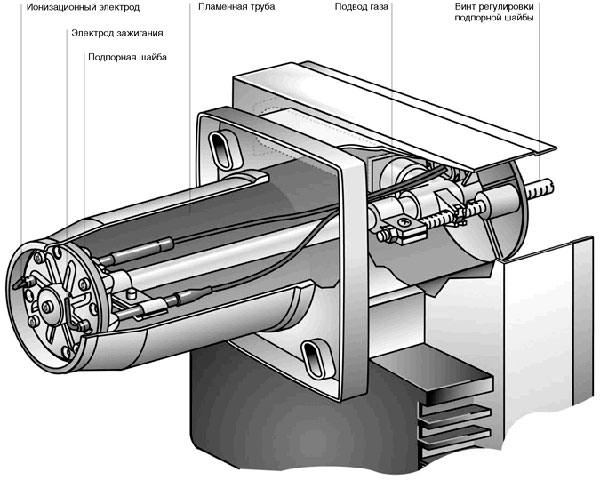

Starting and setting up the system

The tie-in is carried out by the relevant service, the procedure is paid, it is carried out within a predetermined timeframe, when all the equipment has been accepted and recognized as functional.

Tapping into the main pipe under pressure must be carried out by specialists using the appropriate equipment

After that, a test run is carried out, checking the instrumentation and the meter for leaks. The final debugging of the equipment and the launch is carried out by the equipment supplier organization with which there is a service agreement:

- the system is starting up;

- it is adjusted to the optimal mode of operation;

- the representative of the company is obliged to explain all the nuances of the operation of the equipment, the rules for its operation.

In cases where malfunctions and other problems are noticed, the launch is suspended until they are eliminated.

If everything is in order and the launch was successful, a bilateral act is signed confirming the completion of the work.

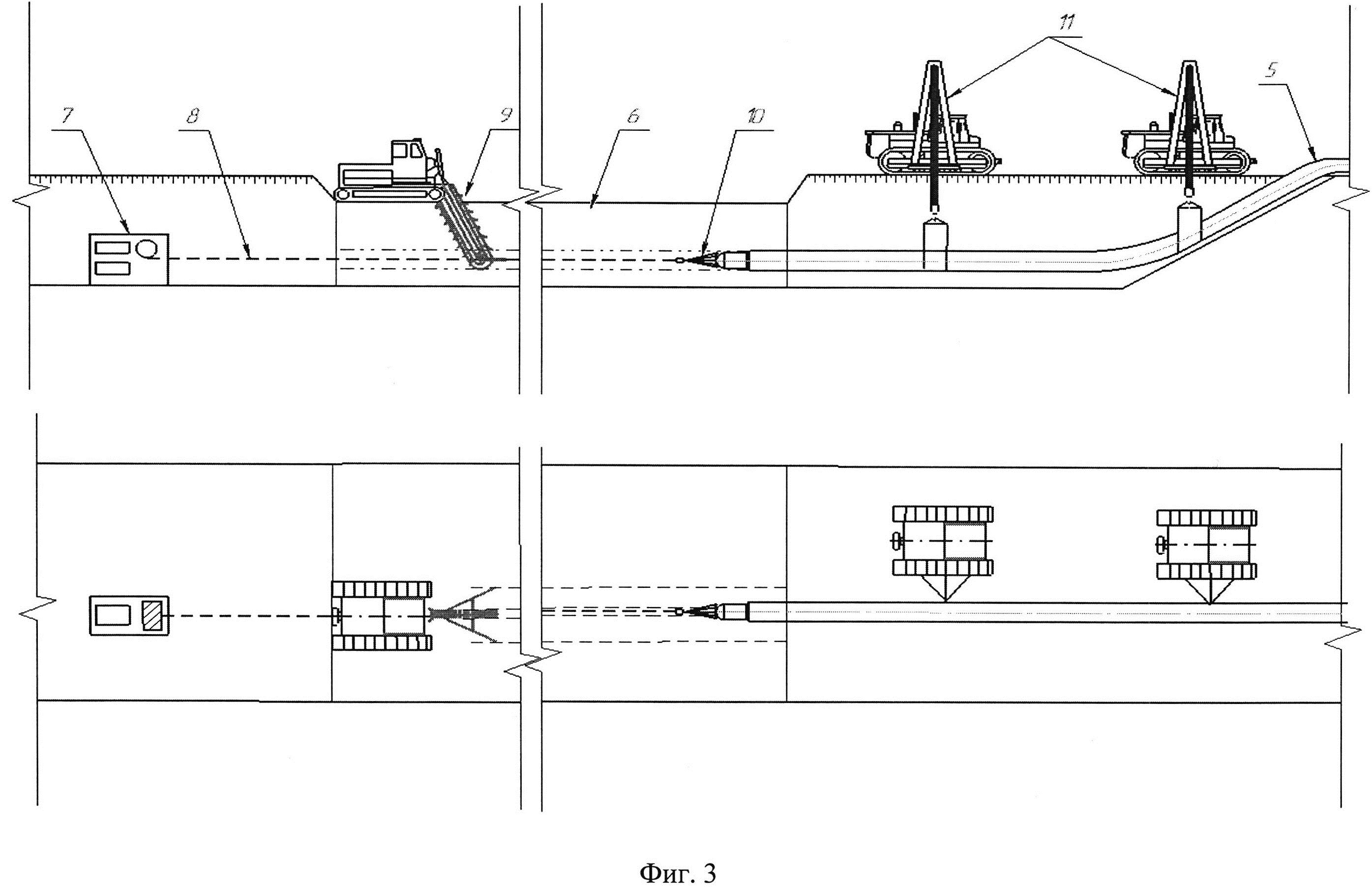

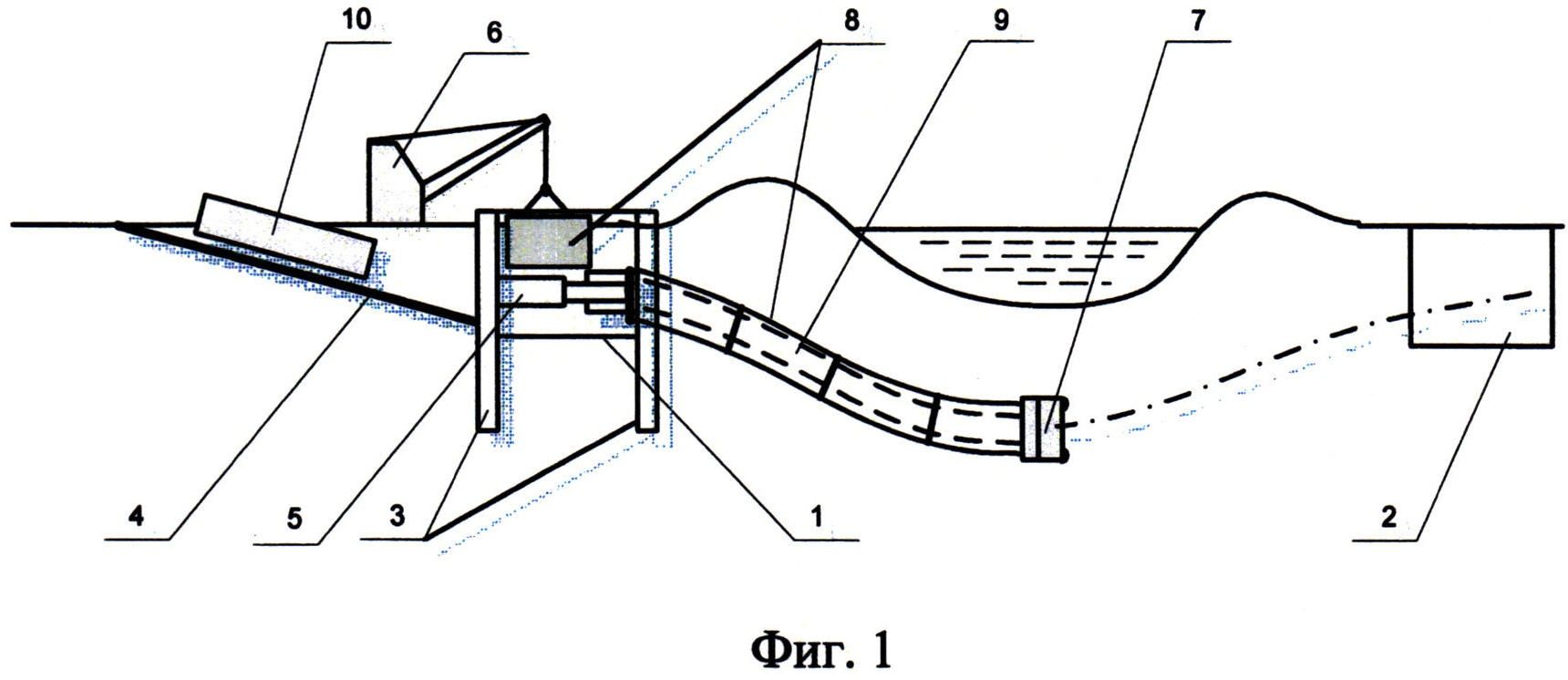

Underground highways

Once the permit is received, the pipeline construction process begins. It can be carried out in two ways - underground and aboveground.The first option requires special trenches for laying pipes. They may pass:

- in normal soil;

- in a swampy area;

- in the rock.

Different specialists are responsible for laying the pipeline. Some do it on linear sections, others - in areas where roads and railways pass, as well as in places where there are water obstacles.

The elements of the gas pipeline are interconnected by welding. To do this, they are first cleaned, cemented and leveled relative to each other, leaving the gap necessary for welding.

Then, with the help of a pipelayer, they are hung into the installation position. Due to the presence of soft slings, the risk of damage to the outer insulation applied to the pipe during manufacture is eliminated.

Separate sections of gas pipelines often have to be built in tunnels (for example, under canals). In such cases, special mechanized complexes are used, equipped with jacks and other necessary equipment. Qualified operators are responsible for their management.

For laying gas pipelines underground, polyethylene pipes are best suited. They are characterized by low weight, resistance to corrosion, ease of installation.

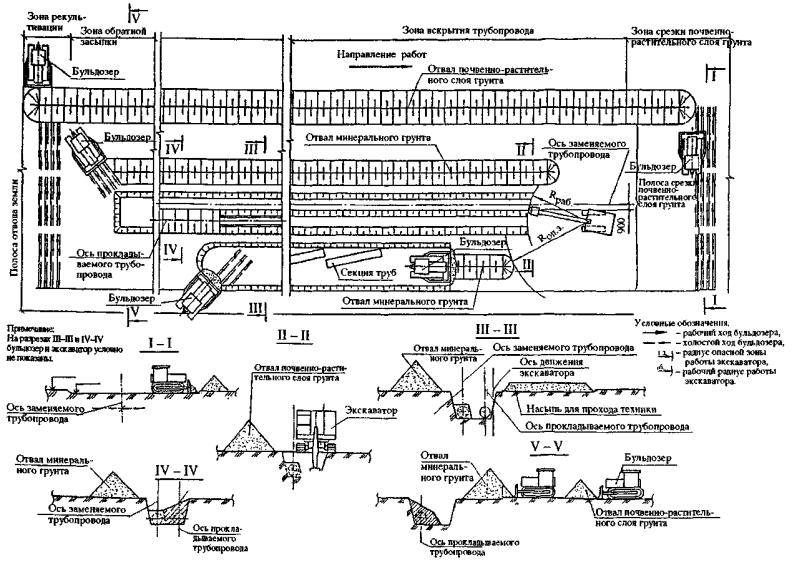

Technology of laying underground highways

Such systems are assembled as follows:

- the marking of the construction strip and the geodetic breakdown of the horizontal and vertical angles of rotation are carried out;

- earthworks are carried out by a single-bucket excavator with a backhoe;

- manual completion of the trench is carried out;

- the bottom of the trench is leveled;

- pipes are delivered to the site immediately before laying;

- pipes are inspected to detect defects;

- lashes are laid in a trench;

- welding and connecting works are carried out;

- gas pipeline tests are being carried out;

- trench backfilling work in progress.

It is not allowed to prepare a trench for laying a gas pipeline in advance by standards. There should not be any stones and debris at its bottom. Pipes are welded in a whip outside the trench. This eliminates the possibility of future leaks. When lowering the lashes, they should not be allowed to hit the bottom and walls.

It is allowed by the regulations to assemble gas pipelines in the winter season. However, in this case, the trench is supposed to be dug up to unfrozen soil. In rocky areas, pipes are laid on a sand cushion. The thickness of the latter should be approximately 200 mm. This eliminates the risk of damage to pipes due to contact with stones.

Laying a gas pipe underground: technology, GOST, video

For laying an underground gas pipeline, it is necessary to provide that the roadway is blocked, and the company that installs the gas pipeline underground, using road projects, draws a terrain plan for the location of the equipment and indicates in the drawing the exact geometry of the objects that are adjacent to the buildings. This will ensure that traffic signs are properly positioned to restrict access to the highway or land where the underground gas system is planned to be laid.

Such an arrangement of prohibition signs must be agreed with the territorial authority of the road inspectorate, which, in turn, if a positive decision is made, must issue an authorization order for the installation of highways underground.

laying a gas pipe in a section above the ground

Advice on laying

So, when performing installation work, the following is taken into account

one.It is necessary to lay the gas system at a depth level, the indicator of which is at least 80 cm to the top of the structure (box). In areas where the passage of agricultural combines and equipment is not provided, a depth of at least 60 cm is allowed for the implementation of underground structures.

2. For terrain that is unstable to erosion and landslides, the depth level where the installation of the gas pipeline will take place must be at least the boundaries of the area where destructive processes are possible, and not less than 50 cm below the level of the sliding mirror.

3. In areas where highways and communication systems intersect underground for various purposes, highways that transmit a heat source, channelless systems, as well as in areas where the gas pipeline passes through the walls of wells, the structure must be placed in a box or case. If it intersects with heating networks, then installation in a metal box (steel) is needed.

4. If there are structures with different pressure indicators in a populated area, the duct should be installed at the level of engineering networks, which are located underground and which, in turn, are below the level of the gas pipeline. The ends of the box should be led out on both sides of the outer walls of the communication systems, taking into account the gap, which should not be less than 2 meters. If there is an intersection with the well, the gap must be kept at 2 cm. Using waterproofing, it is necessary to put plugs on the ends of the box.

5.At the top point of the slope (with the exception of the area where the walls of the well cross) on one side of the box, it is necessary to build a control tube, which will be located under the protective device.

6. It is not prohibited to lay an operating cable (eg, electrical protective wire, communication cable) in places between the system structures and the duct, which is intended for servicing distribution networks.

laying a gas pipe around the site with your own hands

Distinctive features of the product

In construction work, building elements and pipes made of polyethylene are used, which have a reserve index of such a property as strength, not less than 2. Such elements are installed, their pressure index is up to 0.3 MPa, in populated areas (cities, villages) and its circumference.

It is necessary to lay products using polyethylene connecting nodes and gas ones with a margin of at least 2.6. When laying systems whose pressure drop is in the range of 0.306 MPa in a populated area, it is necessary to use connecting nodes and pipes that have a reserve strength index of at least 3.2.

laying a gas pipe underground a private house

Rules for the placement of sewerage wells

Wells

wastewater systems are an important part of the network, enabling

maintenance, cleaning, technology for moving the flow. They are installed at a given

distance apart

The density of the containers depends on the diameter

channel. For example, for a 150 mm line between inspection tanks there should be

35 m. For pipes of 200 and up to 450 mm, the distance between the wells increases to 50

m.These norms are determined by the specifics of the work and the parameters of the equipment, which

cleans channels. You can not break them, because because of this will disappear

ability to restore the network.

How

should be a distance from

gas pipeline to the sewer, the norms do not directly indicate. Main

requirements relate to gaps between foundations, site boundaries, drinking

wells or wells, reservoirs, etc. It is believed that threats to

There is no gas pipeline from the sewer side. However, both for the sewerage network and

and for gas communications, sanitary and protective standards apply. They are not

meet technical requirements, which often becomes a source of controversy and

disagreements.

So, for gas pipelines

the security zone is 2 m around the pipe. Sewerage security zone

is 5 m around the pipeline or well. Therefore, the distance from the gas pipeline to

sewerage according to SanPiN standards should be at least 7 m. This can be

provide for the construction of large buildings, but in private construction, perform

such a requirement is not possible. Plot sizes, proximity to other objects and others

factors that interfere with compliance.

It should be taken into account that the security zone of communications increases significantly if there are reservoirs, drinking wells and other water bodies nearby. Therefore, the location of pipelines is the subject of constant controversy. They are allowed, guided by the conditions of the location of the building, the size of the site and other factors. At the same time, the formal right to complain about violations in the laying of networks in the SES services remains, although they do not try too hard to use it.

Stages of transit laying of the gas pipeline

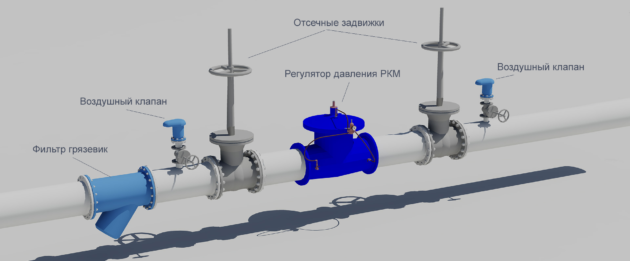

Gas control systems are installed throughout the pipeline

Gas control systems are installed throughout the pipeline

When there are buildings on the path of the gas pipeline, an engineering decision is made on the transit laying through the facade or a high strip foundation, depending on the structure of the building.

The procedure consists of the following steps:

- Training. Calculations are carried out, project documentation is drawn up. The wall is cleaned of the exterior finish, a hole of the desired diameter is made in it.

- Mounting. A sleeve is inserted into the hole made. The definition of the horizontal is made and the near and subsequent supports are installed at its level. The pipe is passed through the building and out of it in a similar way. When entering a gas pipeline into a building, the requirements of SNiP are observed at each phase of the laying.

- Control and acceptance of work. Commission check of the tightness of the system, completeness and correctness of installation of instruments and equipment. Measurements are also taken relative to the normalized distances from heating, electrical devices and water supply systems.

The changes made are reflected in the technical passport of the house.

Polymer gas lines

For above-ground gasification options, it is recommended to use pipes made of low-alloy steel alloys that are resistant to external influences.

Features of plastic structures

Underground laying allows the use of polypropylene pipes, which saves on installation costs and provides a number of other advantages.

The advantages are due, first of all, to the properties of the material:

- high corrosion resistance, which positively affects not only the cost of installation, but also reduces operating costs;

- ease of processing - the material is well cut, weldable, which simplifies installation;

- ideally even internal cavity provides good throughput properties, the features of the material make it possible to avoid their reduction during use;

- lack of sensitivity to electric currents, which ensures high safety, eliminates the need for additional protection.

In addition to these advantages, such pipes have a high level of flexibility, which allows them to be used in horizontal drilling.

Polypropylene pipes are gradually replacing metal counterparts due to their high reliability and durability.

To this should be added a small mass, which is several times lower than the steel counterpart. An important advantage is the service life of about 50 years. All this time the system works without loss of the set characteristics.

Pipe restrictions

Despite the high resistance to external influences, such pipes can not always be used. There are a number of restrictions under which their installation is not allowed.

These include:

- climatic conditions under which the temperature drops below 45 ° C, which leads to freezing of the soil and the walls of the outlet;

- the use of liquefied hydrocarbon options;

- high seismic activity with a magnitude of more than 7 points, when there is no possibility for ultrasonic control of the integrity of seam joints.

In addition, polypropylene materials cannot be used to create all types of above-ground communications, including bypass sections through natural or man-made barriers.

Highways and branches from them, passing over the road or other obstacles, must be made only of metal

Their laying through tunnels, collectors, channels is excluded.To enter the system into the house and wiring it, only steel analogues are used.

Additional recommendations for choosing pipes for laying a gas pipeline are given in the article - Gas pipes: a comparative overview of all types of gas pipes + how to choose the best option