- Choosing a storage location for gas cylinders

- Separate tank room

- Requirements for a cabinet for storing gas cylinders

- Safety

- What determines the consumption of carbon dioxide

- Connecting the cylinder to consumption devices

- How to convert a heating boiler to liquefied gas

- LPG boiler nozzles

- What is the consumption of liquefied gas at the boiler

- Which gas is more profitable to heat - natural or liquefied

- 4 How gas cylinders are stored and transported

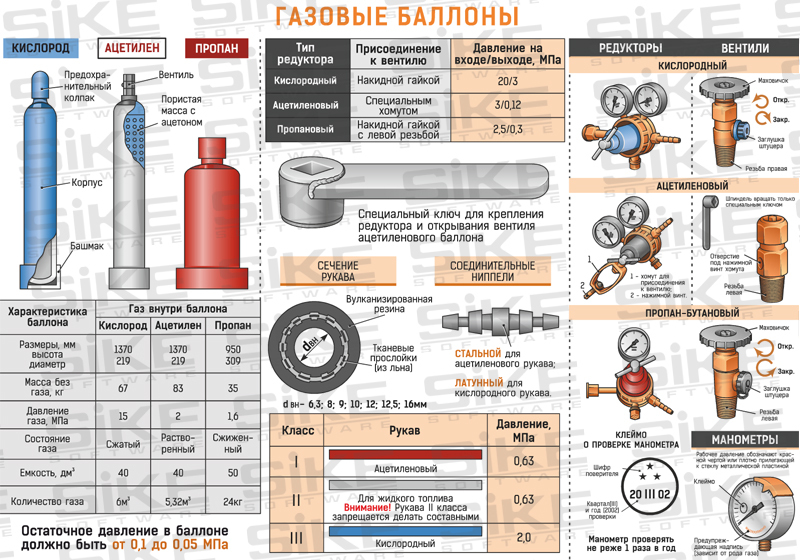

- Conditions for cutting metal with gas

- Heating a private house with gas cylinders: the consumption of the necessary fuel

- Can consumption be reduced?

- — high-quality gas for welding

- Choosing a boiler for cylinder heating

- 1 How a gas cylinder works - basic details

- Features of use

- CO2 tank features

- We will select the power of the boiler and see where you can save on gas heating in cylinders.

- Burner parameters

- Features of heating with liquefied gas

Choosing a storage location for gas cylinders

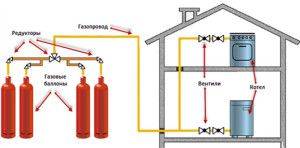

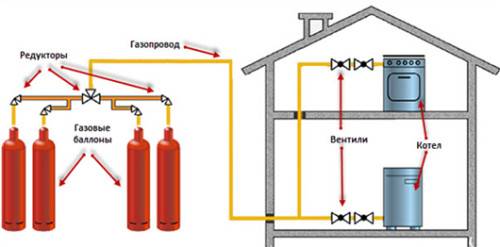

Cylinder connection diagram

Cylinder connection diagram

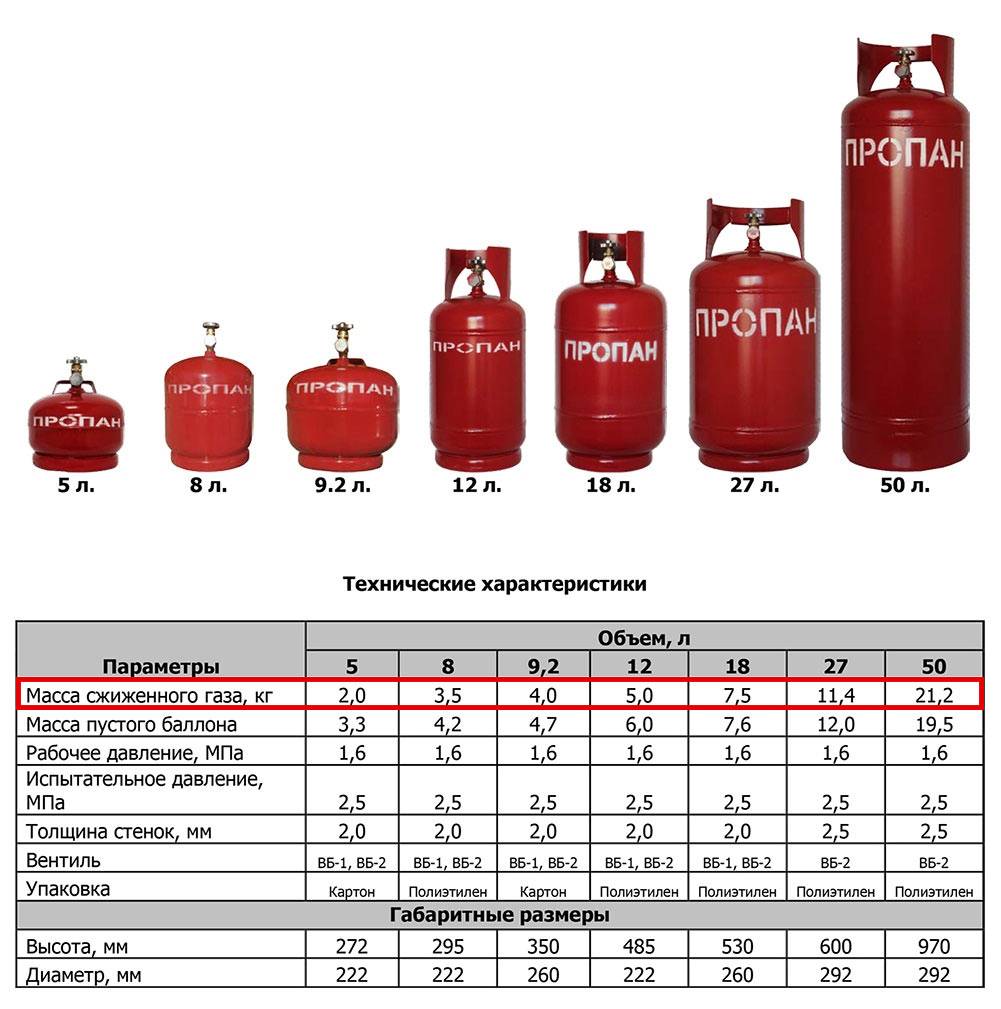

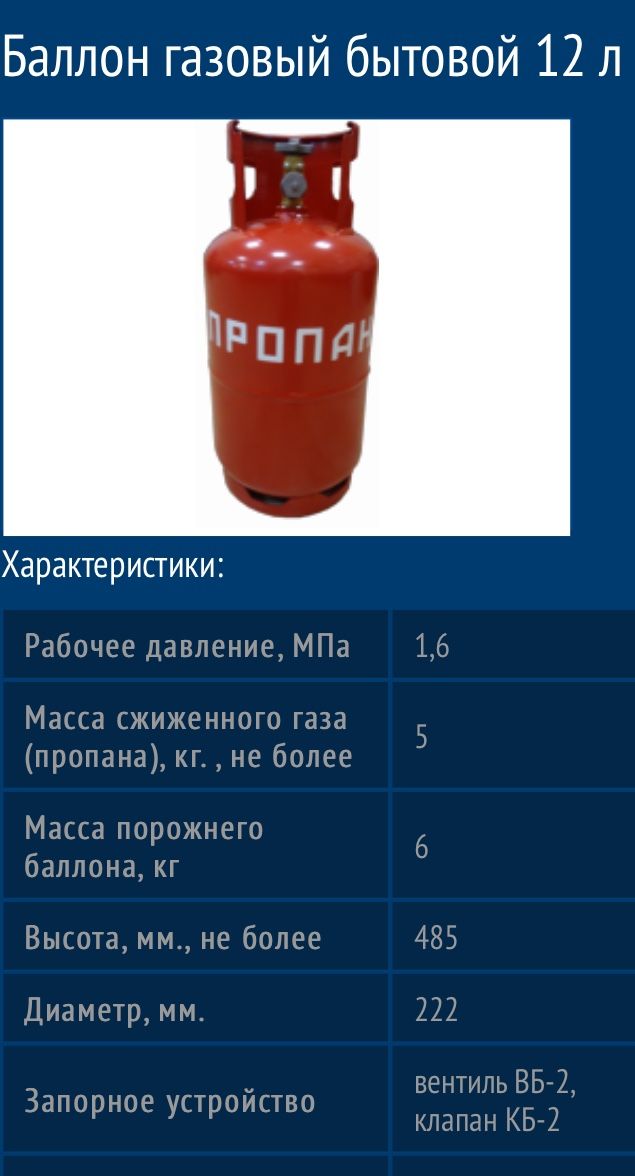

Before deciding on the method of storing gas cylinders, it is necessary to choose their capacity correctly. Currently, containers with a capacity of 5, 12, 27 and 50 liters can be used.If the heating of a private house with bottled gas is regular, it is best to purchase containers with a maximum volume of 50 liters.

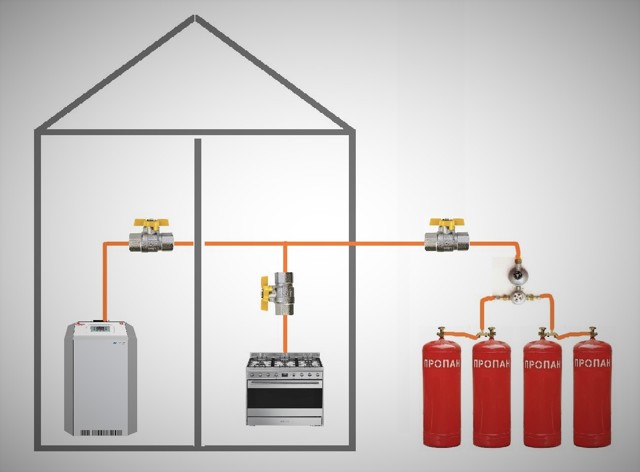

To supply gas, a pipeline is made from the place where the cylinders are stored to the boiler. You can use several containers at once by setting per gas reducer. It should include two manometers. One of them is necessary to verify the pressure readings inside the cylinder, and the second shows this value at the outlet. The shut-off valve regulates the intensity of the fuel supply.

Reducer for cylinders

Reducer for cylinders

The place of choice for their storage directly depends on how many cylinders are needed for the heating boiler. The estimated number of containers depends on the following indicators:

- The total area of the house;

- Heat loss in the building;

- Minimum temperature in winter.

An important point is the place where the gas heating boiler will be installed on bottled gas. The length of the supply line should be kept to a minimum in order to reduce the possibility of depressurization and optimize gas consumption.

Separate tank room

Storage of gas cylinders in the house

Storage of gas cylinders in the house

The best way to store gas cylinders for heating is to prepare a separate room. The arrangement rules and requirements for it are described in detail in SNiP 2.04.08-87. Therefore, before installing heating using gas cylinders, it is necessary to familiarize yourself with this document.

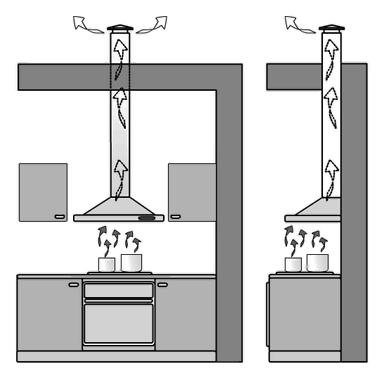

The best option if the storage room will be located in the immediate vicinity of the boiler installation site. In this way, the supply line can be made as short as possible. It is also necessary to ensure the following conditions for storing containers for heating a private house from gas cylinders with your own hands:

- Flammable or lubricating materials must not be stored in the room;

- It is forbidden to use any heating devices - convectors, heaters. The exception is pipes and radiators for water heating;

- Providing forced ventilation. The average air exchange rate is 12 m³ / hour per 1 m² of the room;

- Each cylinder must be placed on a pallet. This is necessary to maintain stability in case of possible fluctuations in capacity during the release of gas.

To ensure safety, the room must be closed. The supply of fuel for heating a private house with bottled gas occurs using a highway. If flexible hoses are used for this, it is necessary to avoid bending them during installation.

Requirements for a cabinet for storing gas cylinders

Storage of cylinders in cabinets

Storage of cylinders in cabinets

An alternative to the above method is the use of special metal cabinets. This is true for heating the cottage with gas cylinders with low fuel consumption.

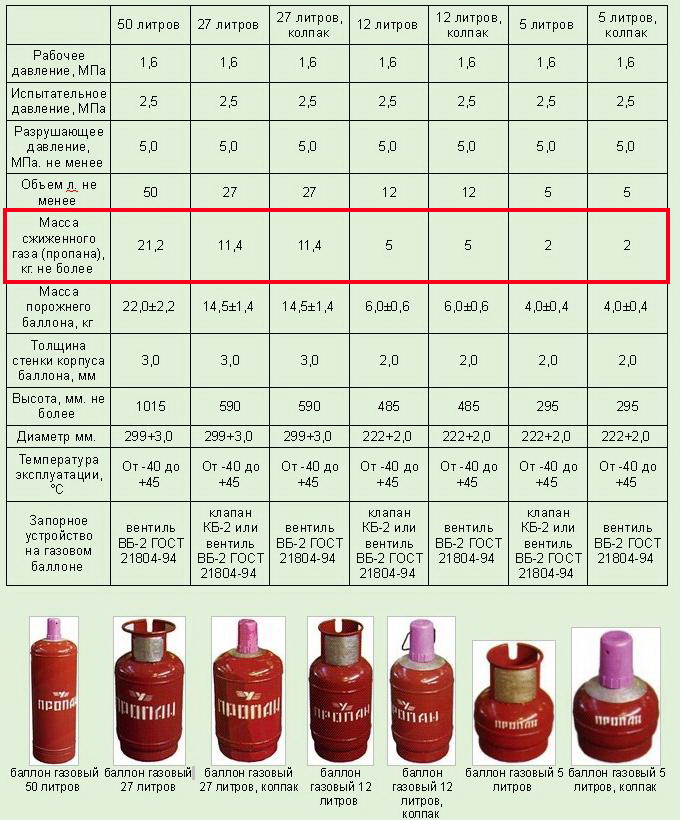

It is recommended to purchase a ready-made design, as it will take into account the requirements of GOST 15860-84. They are as follows:

- Airing. To do this, the cabinet design must have ventilation holes;

- Elimination of the possibility of sunlight hitting gas cylinders. This can lead to an increase in temperature on their surface;

- All elements of individual heating from gas cylinders must be made of non-combustible materials. The same applies to storage cabinets;

- The presence of warning signs and inscriptions.

How long does a gas cylinder for heating with a capacity of 50 liters last? It all depends on the nominal consumption of the boiler. But, despite this, only two cylinders can be stored in one cabinet. The optimal dimensions of the structure in this case will be 2000 * 1000 * 570.Before installing the cabinet, you need to make a separate foundation. Its dimensions should exceed the dimensions of the structure by 15-20 cm.

Do-it-yourself installation rules for heating a private house from gas cylinders are also observed:

- The minimum distance from doors and windows should be 5 m;

- The wall to which the cabinet will adjoin is made of non-combustible materials.

Be sure to make special ventilation gaps on the surface of the foundation. Experts recommend grounding the structure to remove possible static stress.

Safety

It is better to entrust the implementation of metal cutting using a gas installation to an experienced specialist, since if handled carelessly, the consequences can be quite sad.

Safety precautions require the following conditions:

Gas burner device

Gas burner device

- good ventilation in the room where the work will be carried out;

- at a distance of 5 meters there should not be cylinders with gas and other combustible substances;

- work must be carried out in a protective mask or special glasses, as well as in fireproof clothing;

- it is necessary to direct the flame in the opposite direction from the gas source;

- hoses during the operation of the device must not be bent, stepped on, clamped with your feet;

- if a break is taken, then the flame at the burner should be completely extinguished and the gas valves of the cylinders should be tightened.

Compliance with these simple conditions will ensure safe and efficient metal cutting work with a gas machine.

What determines the consumption of carbon dioxide

As with other shielding gases, in order to determine how long carbon dioxide cylinders last, it is necessary to know the thickness of the metal being processed, the diameter of the wire and the current strength.These are the main parameters that affect gas consumption.

Below are the average CO2 consumption values, depending on the wire diameter and current:

- 0.8-1.0 mm (60-160 A) - 8-9 l / min;

- 1.2 mm (100-250 A) - 9-12 l / min;

- 1.4 mm (120-320 A) - 12-15 l / min;

- 1.6 mm (240-380 A) - 15-18 l / min;

- 2.0 mm (280-450 A) - 18-20 l / min.

Consumption depends on wire diameter, current strength and speed

External factors have a great influence on consumption rates. Outdoors, more shielding gas will be required to ensure normal welding conditions, especially if working in windy conditions. Therefore, in a closed room, one cylinder is enough for a longer period.

An equally important role is played by the quality of the mixture and its suitability for working with a particular metal. Read more about this in the article: welding mixture or carbon dioxide - choosing a shielding gas for welding.

Connecting the cylinder to consumption devices

Connecting gas cylinders to consumption devices

The device must be connected via a reducer. Inside a conventional gas cylinder, the pressure is not constant and depends on the ambient temperature. It can vary from 4 to 6 atm. The reducer is able to lower and equalize the pressure to the optimum operating level of the cooker.

A hose is connected to the reducer, and a plate is connected to it. The place of fixation is fixed with clamps, after which it is necessary to check the tightness of the connection with soap suds. Any foam will do. The fixation points must be covered with soapy water: if bubbles form on the surface, then the connection is leaky.

We eliminate the leak: tighten the nut even more at the junction of the fitting with the gearbox.If a leak is found in the sleeve area, then tighten the clamps. After adjustment, it is necessary to check again with soap suds to finally make sure that there is no leakage. Such a check is carried out whenever a gas cylinder is connected - this is the golden rule of safe use.

Correct connection of gas cylinders on the street, figure 1

Correct connection of polymer-composite gas cylinders, figure 2

IMPORTANT! You should not act like some especially “experienced” gas masters: in no case do not check the tightness with lit paper. This results in small flames at the leaks.

This is strictly prohibited by safety regulations. In addition, such flames are very small and in daylight can go unnoticed and lead to sad consequences.

How to convert a heating boiler to liquefied gas

The main difference between natural gas and liquefied gas is that the former is supplied and burned at a higher pressure. Automation of conventional equipment is configured for indicators equal to 6-12 atm. When the indicators decrease, a pressure sensor is activated that turns off the burner.

The operation of a heating boiler on a propane-butane mixture requires a change in configuration and parameters:

- It is necessary to change the flow rate of the gas-air mixture.

- You will need to install a set of jets for liquefied gas.

- Adjust automation to other operating parameters.

Modern single-circuit and double-circuit heating boilers are designed to operate on liquefied and main gas.Re-equipment requires replacement of nozzles and switching the boiler to another mode.

The technical conditions for the use of liquefied gas in individual boilers that are not designed for this type of fuel differ significantly. In addition to replacing jets, a complex reconfiguration of automation and control valves will be required.

It is difficult to correctly adjust the gas supply to the boiler when switching to liquefied gas, set the minimum pressure limit and perform other work on your own, without special skills. According to current regulations, all work must be performed exclusively by licensed specialists.

In the technical documentation of heating equipment, the minimum pressure at which the burner continues to work is indicated. The lower this indicator, the more propane-butane mixture it will be possible to use from a filled fuel tank. Usually, 15-30% of the total volume remains in the container.

LPG boiler nozzles

In the section on how to transfer the heating boiler to the consumption of a gas boiler on liquefied gas, it was mentioned that it is necessary to replace jets or nozzles. Refurbishment is required for several reasons:

-

The difference between nozzles for liquefied and main gas lies in the different diameters of the outlet. As a rule, jets for propane-butane mixture are narrower.

- After installing a set of nozzles to transfer the heating boiler from natural gas to liquefied gas, the pressure in the system slightly increases.

- The reduced diameter of the jet leads to a decrease in the flow rate of the gas-air propane-butane mixture. For normal operation of a 10 kW unit, it is required that the pressure is no more than 0.86 kg / h.

Nozzles or jets are sold in sets.Some manufacturers, in the basic configuration, make all the fittings necessary for conversion. In other cases, the kit will have to be purchased separately.

What is the consumption of liquefied gas at the boiler

The volume of consumption of liquefied gas in gas heating boilers is indicated in the technical documentation provided by the manufacturer. For all models, it is different and depends on several factors:

- Performance.

- Burner type.

- Equipment setup.

The technical characteristics of the consumption of liquefied gas are also affected by how the selected model is adapted for this type of fuel. On average, for a 10-15 kW unit, it will take 2 per week and per month, 9 cylinders.

Which gas is more profitable to heat - natural or liquefied

The comparative consumption of natural and liquefied gas during the operation of a heating boiler shows that it is more profitable to heat a house when the boiler equipment is connected to the mains. It is worth heating with a propane-butane mixture only in the following cases:

- Changes in the design and reconfiguration of the boiler when using liquefied gas are temporary. It may take about six months from the start of registration and ordering a project for the installation of heating equipment connected to the main gas pipeline. During this period, it is not economically feasible to heat the room with electric or solid fuel heating equipment specially purchased for this purpose. The cost of converting a conventional boiler to liquefied gas ranges from 500-1000 rubles.

- Connecting a gas tank - in this case, the cost of using the mixture is more profitable than heating with wood, electricity or diesel fuel.The only condition is that the pressure of liquefied gas, adjust the operation of the automation, should be reported by a qualified specialist. Incorrect settings lead to an increase in flow, approximately 15%.

The economic component, operational safety, the possibility of switching back to natural gas - all these factors make it expedient to use boilers running on liquefied gas.

4 How gas cylinders are stored and transported

When operating 50-liter containers with pure propane or propane-butane mixture, it is customary to adhere to the following rules:

- Cylinders stand only in a vertical position, leaning on a shoe.

- Tanks with liquefied gas are exclusively on the street, in an iron box.

- The box for cylinders necessarily has a perforation that provides ventilation.

- The distance from the container to the door and window of the first floor cannot be less than 50 cm.

- The distance from the place of storage of containers to the well or cesspool should not be less than 300 cm.

- Cylinders should be placed on the north side, since the maximum operating temperature cannot be higher than 40-45 degrees Celsius. And in direct sunlight, the metal heats up more.

- Between the cylinder and the gas consuming device there must be a reducer that equalizes the pressure in the gas pipeline.

Moreover, this set of rules applies to both one cylinder and a whole group of containers, combined with the help of a gas distribution manifold.

Conditions for cutting metal with gas

Gas cutting of metal will be effective only when the ignition temperature of the metal is lower than the melting point.Such proportions are observed in low-carbon alloys, they melt at 1500 °C, and the ignition process occurs at 1300 °C.

For the high-quality operation of the installation, it is necessary to ensure a constant gas supply, since oxygen needs a constant amount of heat, which is maintained mainly (by 70%) due to the combustion of the metal and only 30% is provided by the gas flame. If it is stopped, the metal will stop producing heat and oxygen will not be able to perform the functions assigned to it.

Cutter work, metal cutting training

The maximum temperature of handheld gas cutters reaches 1300 ° C, which is sufficient for processing most types of metal, however, there are those that begin to melt at especially high temperatures, for example, aluminum oxide - 2050 ° C (this is almost three times higher than the melting point of pure aluminum), steel with chromium content - 2000 °C, nickel - 1985 °C.

If the metal is not sufficiently heated and the melting process is not started, oxygen will not be able to displace refractory oxides. The reverse of this situation, when the metal has a low melting point, under the influence of a burning gas, it can simply melt, so this cutting method cannot be used for cast iron.

Heating a private house with gas cylinders: the consumption of the necessary fuel

As practice shows and consumer reviews testify, for a house of 100 m², gas is needed approximately 3 to 2 cylinders per week, provided that the capacity is 50 liters. From this calculation, you can determine how much fuel you need to heat a country house. For example, for a house of 200 m², the amount of gas will increase to 4 containers per week. If your house has an area of about 50 m2, then 1 cylinder will be enough for you.

It is possible to accurately calculate the fuel consumption of a bottled gas boiler using the attached technical documentation, which is mandatory included in the kit by the responsible manufacturer.

Can consumption be reduced?

As noted above, during the workflow, external factors are of great importance. Therefore, it is desirable to minimize their negative impact. To do this, it is enough to build a closed room, protected from wind and drafts. Do not forget about the safety of the welder, providing the room with good ventilation.

In a closed room, a filled cylinder will last for a longer amount of time

A special reduction in consumption usually does not lead to the desired result, since, in this case, the protective functions are reduced and the quality of the welds becomes worse. To reduce consumption, you can use a multi-component gas mixture, such as Mixpro 3212, which, in addition, will provide a significant increase in welding quality. However, the price of such a mixture will be higher than that of conventional carbon dioxide. Therefore, the final choice must be made based on technical requirements and budget.

— high-quality gas for welding

If you are really interested in how long carbon dioxide cylinders last, and you do not want to pay for air, then you need to contact only trusted and reliable suppliers. A lot of useful information on this issue can be found in the article: carbon dioxide: where to refuel is not an idle question.

is engaged not only in filling cylinders with technical gases from the best Russian suppliers, but is itself a manufacturer of them. Therefore, there is no doubt about the quality of the charged gas mixture, since all processes are carried out in accordance with established standards, rules and regulations. For other technical gases, you will find articles in the corresponding section of the blog.

Choosing a boiler for cylinder heating

LPG boilers

Currently, manufacturers do not produce narrow-profile heating boilers for bottled (liquefied) gas. However, equipment designed for natural gas cannot be used without prior modification.

Before purchasing the boiler, you must make sure that the package includes a kit for adapting equipment for propane. The set includes nozzles with a wider nozzle and a kit for attaching them to the burner. The reinstallation procedure can be performed independently only if it is provided for by the design.

There are several types of gas-fired heating boilers for bottled gas, which differ in operational and technical indicators:

- Burner type - open or closed. It is best to purchase heat supply boilers on a gas bottle with a closed burner. For their operation, air is taken from the street using a coaxial pipe;

- Mounting - wall or floor. Most models up to 24 kW are wall mounted;

- The number of contours. To supply heat to the dacha with gas cylinders, you can purchase an inexpensive single-circuit boiler. If permanent residence is planned in the house, it is recommended to buy a two-circuit model with hot water supply.

You can pre-calculate the flow rate for heat supply with gas cylinders by reading the technical data sheet of the equipment. However, often manufacturers give the maximum flow at the maximum power of the equipment. The lower the intensity of the burner, the less fuel will be consumed.

The best performance indicators are gas-fired heating boilers on bottled (liquefied) gas with a cast-iron heat exchanger. It will last much longer than steel.

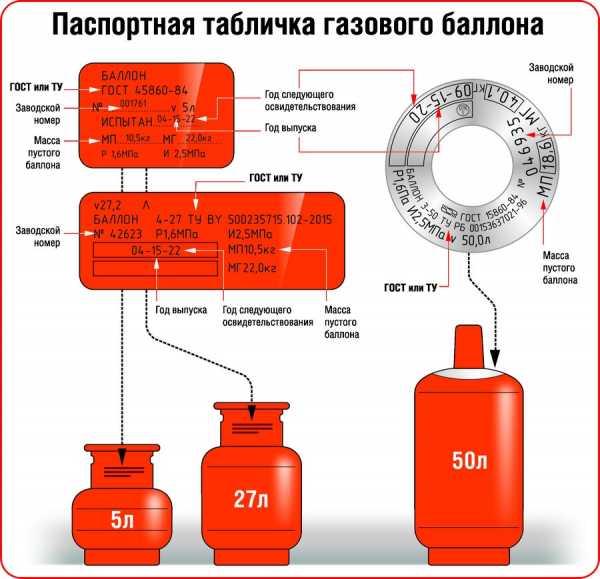

1 How a gas cylinder works - basic details

Any cylinder is assembled on the basis of a flask welded from sheet metal, the top and bottom of which are decorated with stamped cup-shaped lids. Moreover, an annular apron-stand (support shoe) is welded to the lower part, and a special shut-off assembly is screwed into the upper part of the flask (neck ring) - a valve for a gas cylinder. The main cylinder (shell) and both bowls are made of steel sheet with a thickness of at least 2 mm. Moreover, the cup-shaped shape of the bottom and lid is explained by the physical properties of the gas, which, being in a closed container, presses on every square millimeter of its internal area with the same force. Therefore, the welds that connect the shell and bowls must meet the highest quality criteria.

The cylinder valve must work for a long time and withstand high pressure

The bottle valve is subject to special requirements. It must withstand enormous pressure and work for a very long time. Therefore, the lower side of its body is designed as a conical threaded fitting, and on top there is a threaded rod flywheel that locks the seat. Moreover, the locking mechanism of some valves is able to withstand pressure up to 190 atmospheres, while maintaining performance.The side outlet in the valve body is optimized for the connection of the nut of a reinforced or bellows hose. However, in most cases, a reducer is screwed onto the outlet, equalizing the pressure to an acceptable level. And in the case of transportation, the outlet in the gas valve is closed with a special threaded plug.

In addition, in some cylinders, a steel collar is equipped around the valve, which protects the shut-off assembly from mechanical damage. And in the place where the valve is inserted, a special washer made of soft metal (aluminum) is mounted, on which the dates of the last technical inspection of the entire structure are stamped with the help of stamping. In the event of a technical inspection delay, filling the cylinder to the maximum pressure level is strictly prohibited. Moreover, any user can detect the fact of a deferred check. To do this, you need to read the symbols on the washer under the neck ring. There, in addition to the time of the last inspection, there is also the date of the next one. If today's date is greater than this date, it is better not to use the balloon.

Features of use

Many owners of private houses are interested in how long one cylinder lasts and what performance the system has on such fuel. Another problem is the need to reduce gas consumption.

Important! All boilers using main gas for heating can also be operated on liquefied fuel. To do this, you only need to change the burner

The main indicator when choosing a suitable heating boiler is the minimum gas pressure at which the device is able to continue to work. The smaller this value, the better.

One gas cylinder holds 35-42 liters of gas. In liquid form, this is 22 kg. The cost of filling one liter is 12-16 rubles.Based on these calculations, filling one cylinder costs about 470-630 rubles. A gas boiler with a capacity of 12-15 kW consumes from 1.2 to 1.7 kg of gas per hour. At the same time, it generates 1 kW of energy. This is enough to heat 120-140 m² of area.

With the constant operation of the boiler at the limit values, gas is consumed in the amount of 33.6 kg of gas per day. When recalculated for cylinders, this is 1.5. It costs from 870 to 950 rubles. These heating costs are quite high. However, when correct setting of heating equipment and home insulation, the boiler consumes much less. In this case, it maintains a comfortable temperature.

In an insulated building with an area of 120 to 140 m², which does not have drafts and heat leaks through the windows, the boiler consumes from 10 to 12 kg of gas per day. This is when calculating the temperature outside to -23 degrees, and in the house - + 23. With this consumption, one cylinder of 50 liters is enough for two days. 3-4 bottles are spent per week. Weekly home heating costs 1.7-2.2 thousand rubles.

You can reduce costs by equipping the boiler with automation. At night, the temperature will decrease, which will reduce the amount of gas consumed by the boiler. With its daily decrease to 15 degrees at night, the daily consumption is reduced by 25-40%. One balloon in this case can be stretched for 3-4 days. A week of gas heating will cost 900-1300 rubles. Monthly costs will be reduced to 5-7 thousand rubles.

Advice! When heating a dwelling with liquefied gas, it is worth combining cylinders into groups of 6-10.

With the correct setting of the boiler with a programmer and a regular decrease in temperature, it is possible to reduce the consumption of bottled gas to 8-10 bottles per month.

CO2 tank features

The cylinder for carbon dioxide must be completely painted black, and also have the inscription "CARBON DIOXIDE" made of yellow enamel. It should be noted that the weight of the container is set without taking into account such details as a valve, rings, caps, shoes. In addition to the coloring and inscription, the tank must contain passport information about it.

The application of these data is carried out by the impact method.

It is important to know that information is applied in the upper part of the cylinder, and its location is completely cleaned to a metallic sheen and has a highlighting yellow line 20-25 mm wide. Here is a list of the information that a passport must contain:

- date of manufacture of the container and year of subsequent inspection;

- what is the pressure of carbon dioxide in the cylinder (indicated in MPa (kgf / cm 2);

- (indicated in liters);

- the weight of the empty container (indicated in kilograms);

- the serial number of the tank and the brand of the company that made it;

- the brand of the company that carried out the technical examination;

- the last stamp from the technical control department of the company that manufactured the tank.

We will select the power of the boiler and see where you can save on gas heating in cylinders.

There is a simple calculation of the heat output of the boiler.

Here is an example: my house has a total area of S = 200m²:

| or like this: 200m²x10 100 = 20 + 20 x 20 100 = 24KW; |

I bought a CT - 26 TCX (26 kW) - this is an order of magnitude higher, but you never know what in the future, let there be a reserve.

But there is a more complicated way - this is a boiler power calculator based on the calculation of the replacement of heat losses at home.

Whatever calculation you use, it is better to choose a boiler 10% more powerful for your home

This is also for the power reserve for the “development” of the house, and you can always lower the heating temperature, which will reduce the deposition of scale in the boiler, and this is already a plus.

Now it is important to choose the number of radiators sufficient for the selected boiler and a comfortable temperature in the house.

And finally, let's see where you can save on gas heating in cylinders.

Consider gas heating in numbers. For Ukrainian latitudes, the power norm for heating a room with a volume of 1m³ is 41W/h

From this figure we will dance, and along the way we will find out how much and what is in the balloon

For Ukrainian latitudes, the power rate for heating a room with a volume of 1m³ is 41W/hour. We will dance from this figure, and along the way we will find out how much and what is in the balloon.

In a 50l cylinder - 21kg of liquid propane-butane. For a simplified idea of the mass of gas in a cylinder, we can assume that this is equal to 42 liters of liquid gas at a pressure of 1.6 MPa. From it it turns out, if you're lucky - 9.9 m³ of gas.

If we assume that burning 1 liter of liquid gas, we get 11000kcal, then in a 50l cylinder (42l) they cool - 462000kcal

If we assume that in 1 kcal \u003d 1.163 watt hour, then the balloon will come out - 537306 watt hour

How long will one bottle last?

For 1 m³ house, the norm is 41 watts. So we take everything that is in our cylinder in watts and divide by this rate - 537306 watt hour: 41 watt = 13105hours

So the room is 5 x 3 x 3 (ceiling) = 45m³ can be heated with gas from a cylinder during: 13105h/24h/45m³=12 days!

I don't like the result.It turned out that if we just burn gas, then we will last a little more than 12 days and the whole house is 45m³!

Let me remind you that these theoretical clevernesses have nothing to do with reality. I have a question - speaking of gas heating, what do you mean: just burn gas directly from a cylinder, heat it with a gas stove, converter or boiler? How do you see it in practice? After all, every heater has its own set (declared by the manufacturer) gas consumption, also theoretical.

Let's recalculate how much gas is needed to heat my house (600m³) with a double-circuit boiler Colvi Thermon KT-26TSH

My double-circuit boiler has 26.5 kW of power. Passport data on natural gas consumption: 1.5 ÷ 3.25m³/hour

If we take according to the minimum gas consumption declared by the manufacturer, it turns out:

In a 50l bottle - 9.9m³ of gas, divided by 1.5 (minimum flow) = 6.6 hours!

I can't help but quote: "... it's the same as heating the stove with banknotes."

During the writing of the article, 1.5m³ gas!

Burner parameters

Gas burners for a cartridge with a collet connection represent a separate class of tools. They are used in conditions of high fire safety where serious construction equipment is involved, and the risk of damage to the apparatus is minimized.

The main parameters are the temperature and the shape of the flame. In the simplest devices, the combustion temperature is close to the minimum - 700−1000°C. Air comes in naturally and is always in short supply. More expensive products have a special shape of the air supply channels, which increases the air flow, and the flame temperature rises to 1200 ° C.

The flame of an even higher temperature is in ejector burners, in which air enters the hearth due to rarefaction, and the flow force is in direct proportion to the working gas pressure. Due to this, the temperature can be increased to 1500−1600°C and relatively smoothly regulate it with the length of the flame only by turning the tap. The apparatus may have several sources of combustion. Such a tool does not perform delicate work, but successfully warms up large areas.

The threshold temperature of the burners is 2000–2400°C, and it is achieved by concentrating the injected air into the combustion chamber, as well as using propadiene methylacetylene gas (MAPP). A high-temperature cone is formed in the flame, whose power and temperature can be compared with oxy-fuel welding.

In addition, any type of product can be equipped with a flexible or swivel tube, piezo ignition and a highly sensitive control valve. There is a wide range of devices in terms of power and gas consumption.

Features of heating with liquefied gas

The choice of heating units that run on liquefied gas is simply huge today. Here you can find products from both domestic manufacturers and goods from various world brands.

In order for a propane heater to work properly, it must be connected correctly and the nozzles replaced. This equipment has performed quite well. It is willingly installed by the owners of a country cottage, who do not have the opportunity to connect to a common gas main or independent heating. This type of heating is very practical in operation, has a low coefficient of emission of harmful substances, is compact, and the efficiency is quite high.Propane-butane gas is a great alternative to the usual natural gas.

When buying a boiler, consider the following:

- Type of heater. Apparatus for heating on liquefied gas can be single-circuit and double-circuit. The first option is suitable exclusively for heating, while the second type, in addition to heating, also provides hot water supply.

- efficiency. In fact, all units that operate on liquefied gas have high efficiency rates that reach 90-94%.

- Power. This indicator is one of the most important parameters characterizing the type of heating equipment. It is necessary that the unit you have chosen can easily provide hot water and heating to all rooms in the house.